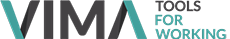

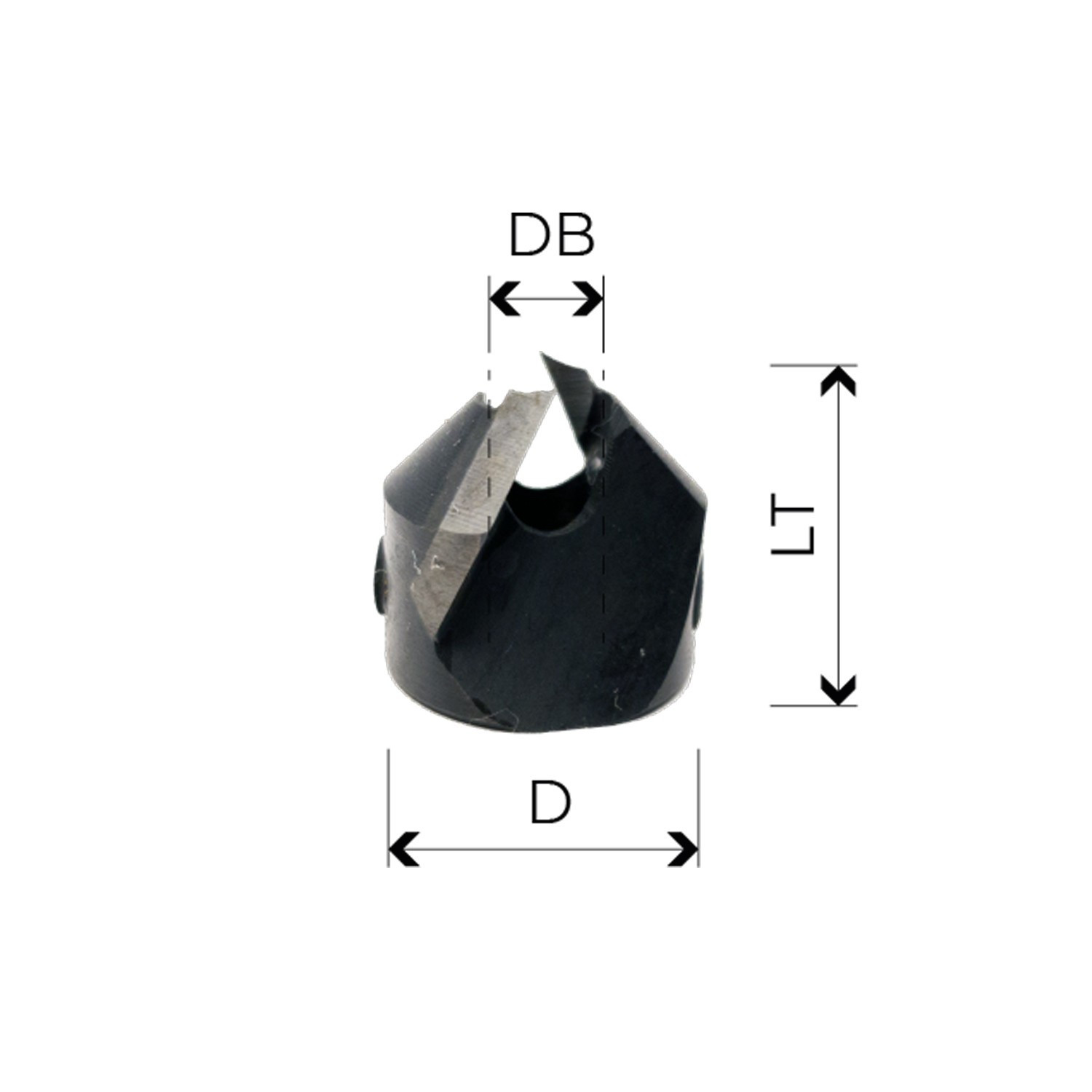

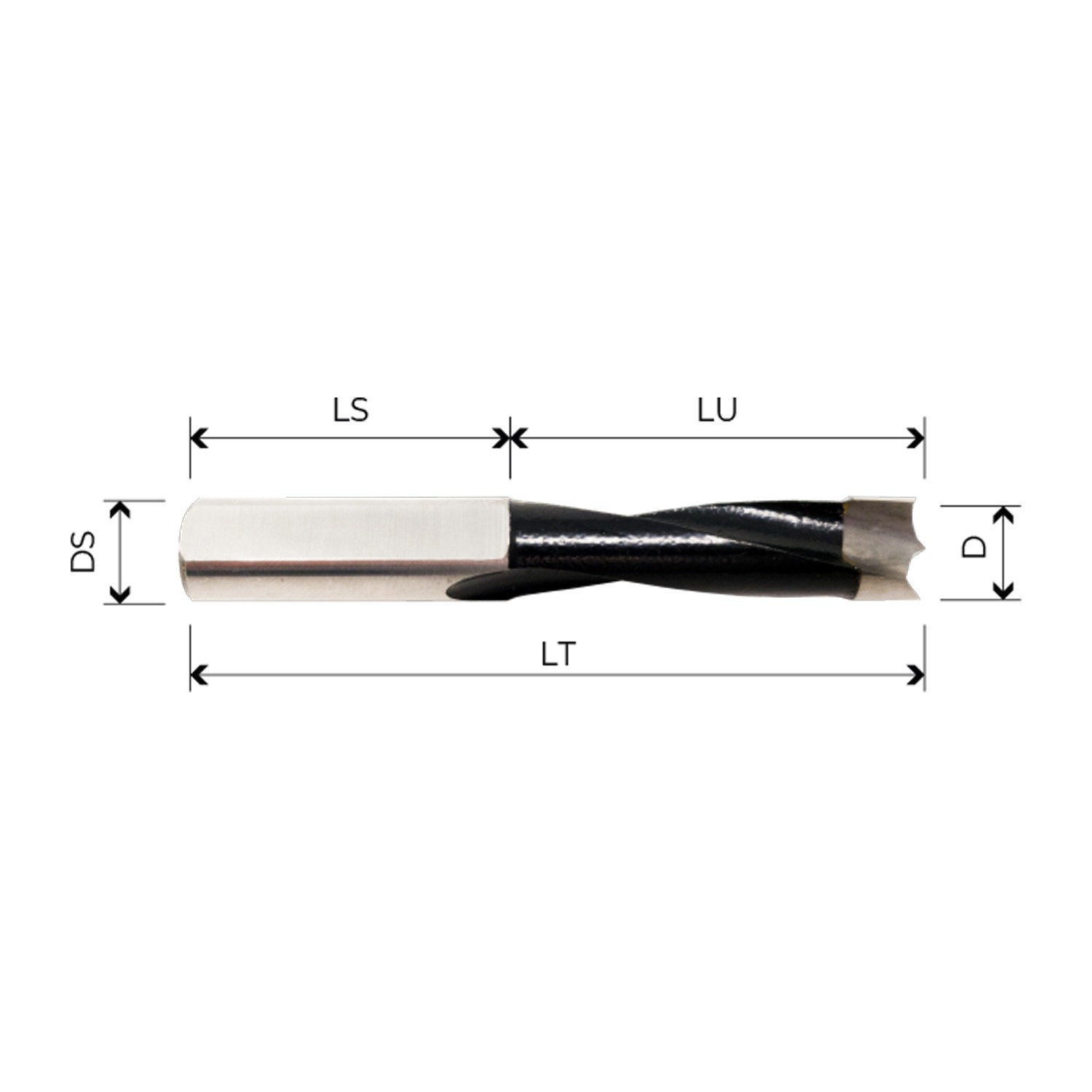

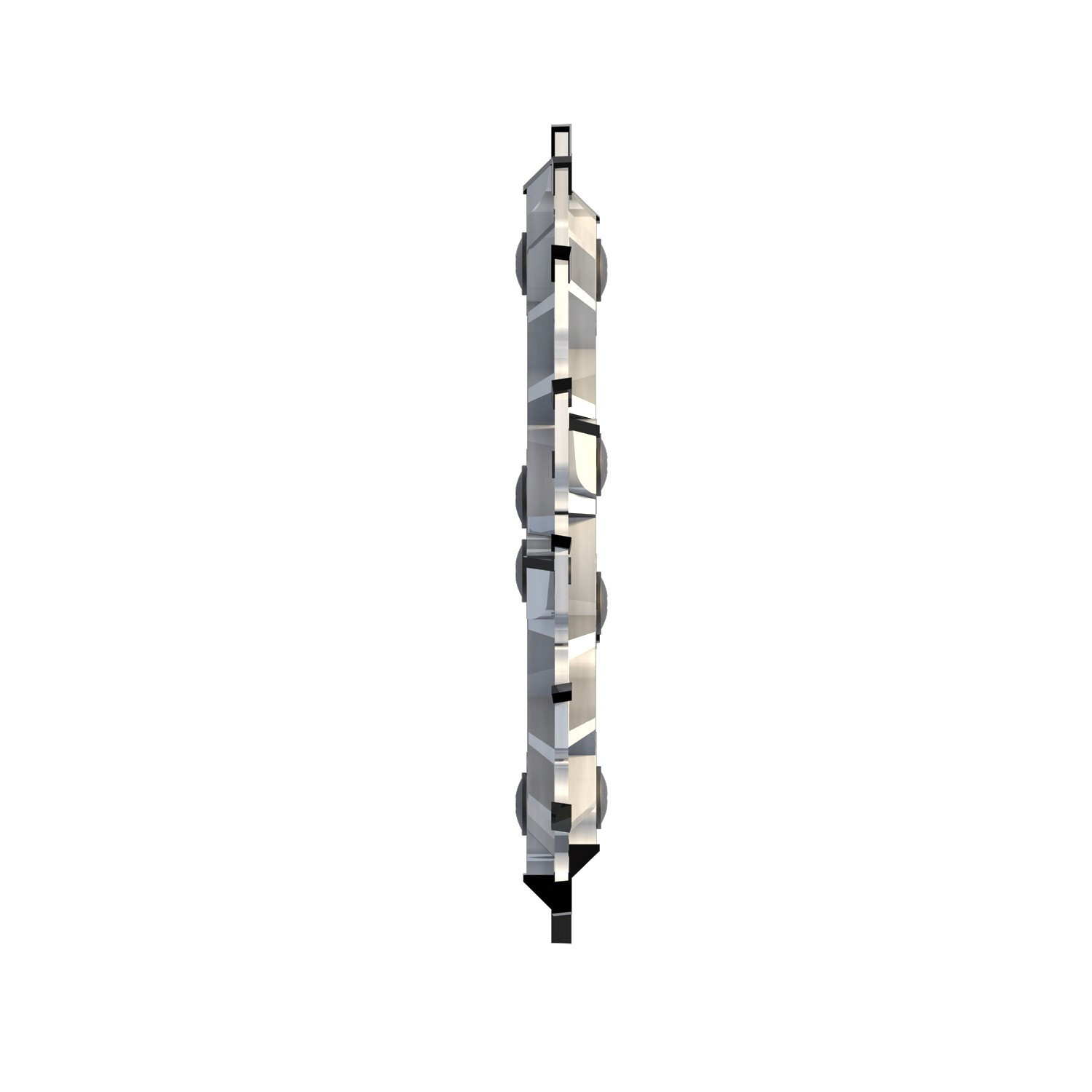

Super-strLENGTH steel, Spiral portion coated with orange or black P.T.F.E.. HW head with precision balanced centre point, 2 HW precision ground cutting edges (Z2), 2 negatively ground spurs (V2), 2 spiral flutes. Parallel shank with driving flat and LENGTH adjusting screw.

Super-strLENGTH steel, Spiral portion coated with orange or black P.T.F.E.. HW head with precision balanced centre point, 2 HW precision ground cutting edges (Z2), 2 negatively ground spurs (V2), 2 spiral flutes. Parallel shank with driving flat and LENGTH adjusting screw.

Super-strLENGTH steel, Spiral portion coated with orange or black P.T.F.E.. HW head with precision balanced centre point, 2 HW precision ground cutting edges (Z2), 2 negatively ground spurs (V2), 2 spiral flutes. Parallel shank with driving flat and LENGTH adjusting screw.

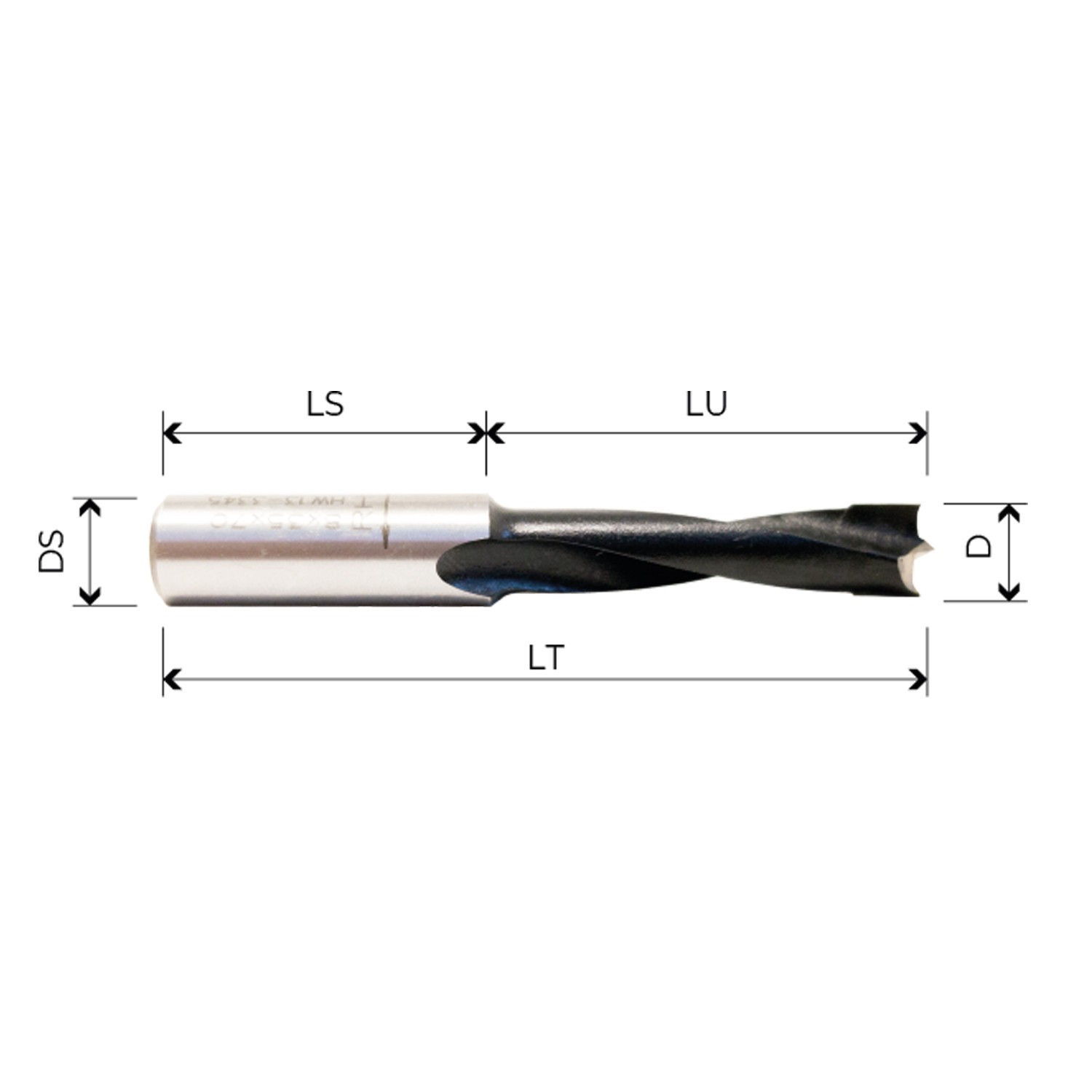

Super-strLENGTH steel, cutter portion coated with black or orange P.T.F.E.. HW head with precision balanced centre point, 2 HW precision ground cutting edges (Z2), 2 negatively ground spurs (V2), 4 spiral flutes. Parallel shank with driving flat and LENGTH adjusting screw.

Super-strLENGTH steel, cutter portion coated with black or orange P.T.F.E.. HW head with precision balanced centre point, 2 HW precision ground cutting edges (Z2), 2 negatively ground spurs (V2), 4 spiral flutes. Parallel shank with driving flat and LENGTH adjusting screw.

Super-strLENGTH steel, cutter portion coated with black or orange P.T.F.E.. HW head with precision balanced centre point, 2 HW precision ground cutting edges (Z2), 2 negatively ground spurs (V2), 4 spiral flutes. Parallel shank with driving flat and LENGTH adjusting screw.

Super-strLENGTH steel, cutter portion coated with black or orange P.T.F.E.. HW head with precision balanced centre point, 2 HW precision ground cutting edges (Z2), 2 negatively ground spurs (V2), 4 spiral flutes. Parallel shank with driving flat and LENGTH adjusting screw.

Super-strLENGTH steel, cutter portion coated with black or orange P.T.F.E.. HW head with precision balanced centre point, 2 HW precision ground cutting edges (Z2), 2 negatively ground spurs (V2), 4 spiral flutes. Parallel shank with driving flat and LENGTH adjusting screw.

Super-strLENGTH steel, cutter portion coated with black or orange P.T.F.E.. HW head with precision balanced centre point, 2 HW precision ground cutting edges (Z2), 2 negatively ground spurs (V2), 4 spiral flutes. Parallel shank with driving flat and LENGTH adjusting screw.

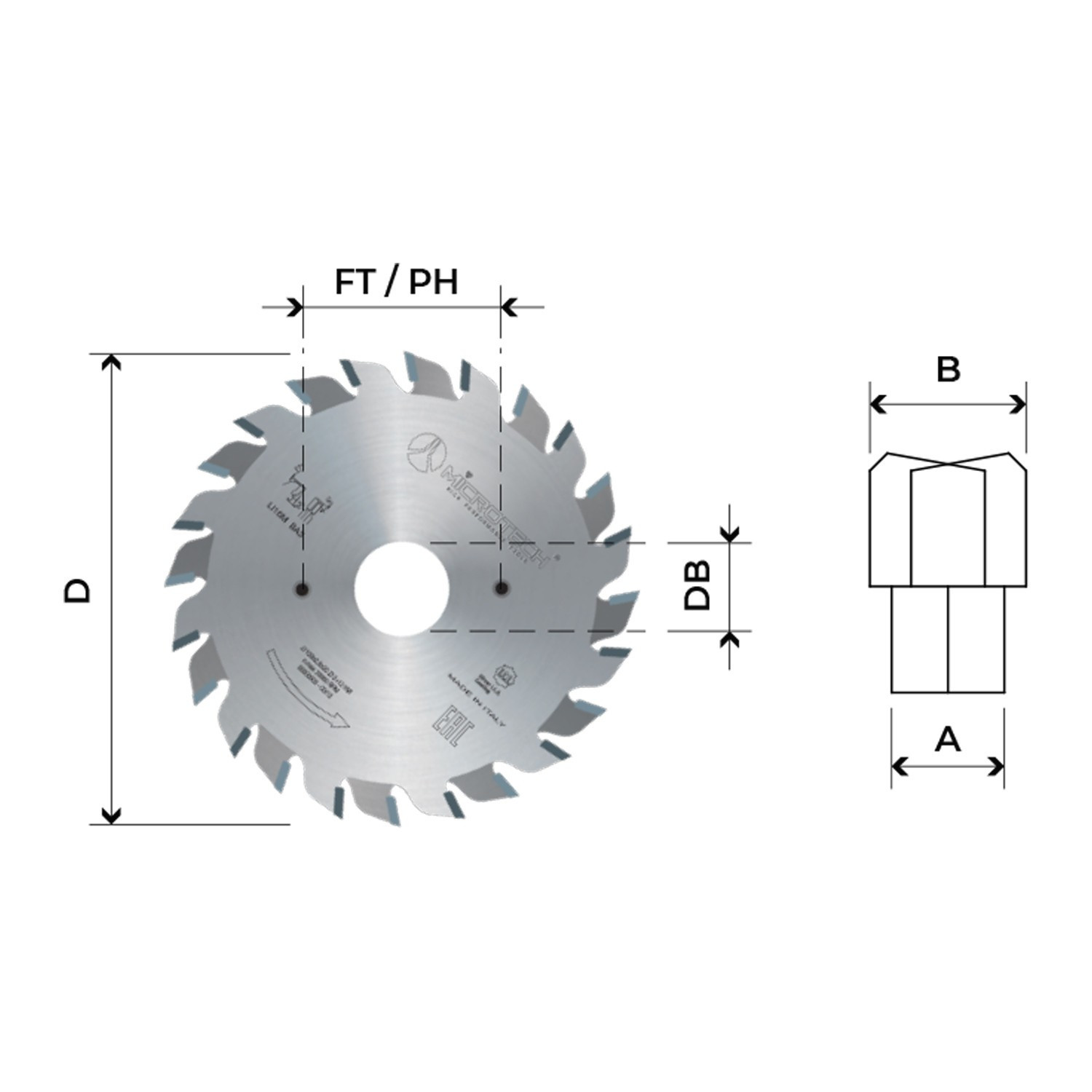

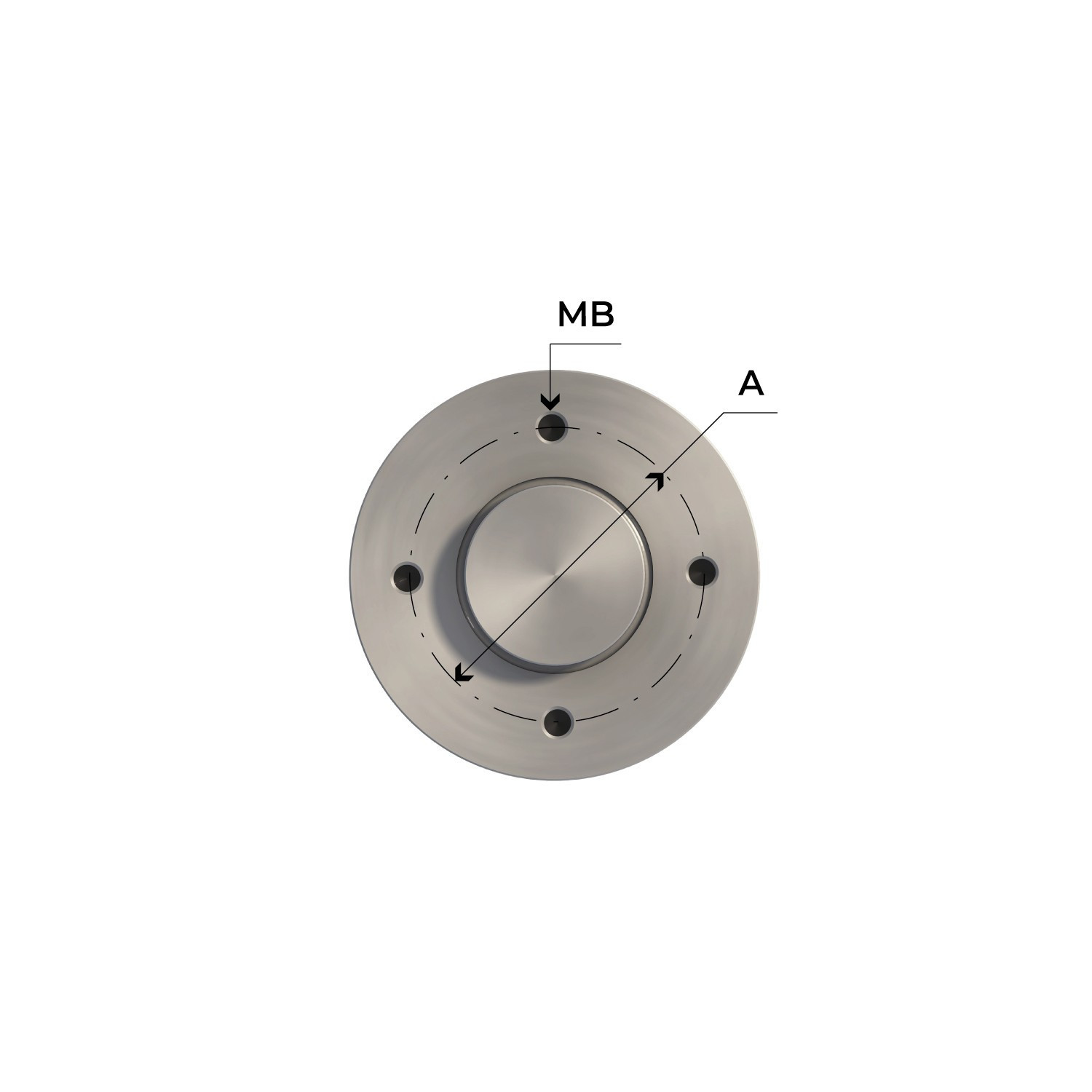

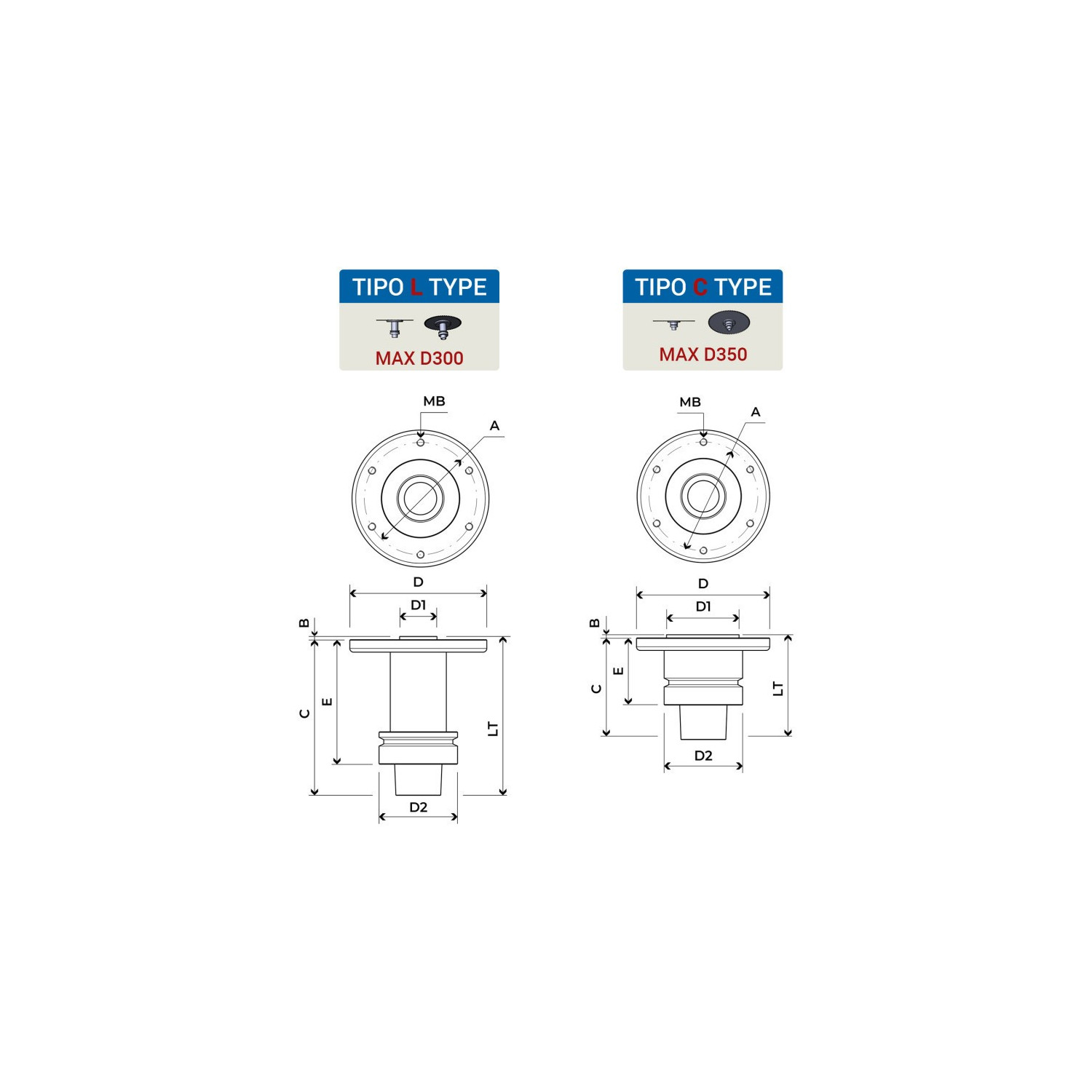

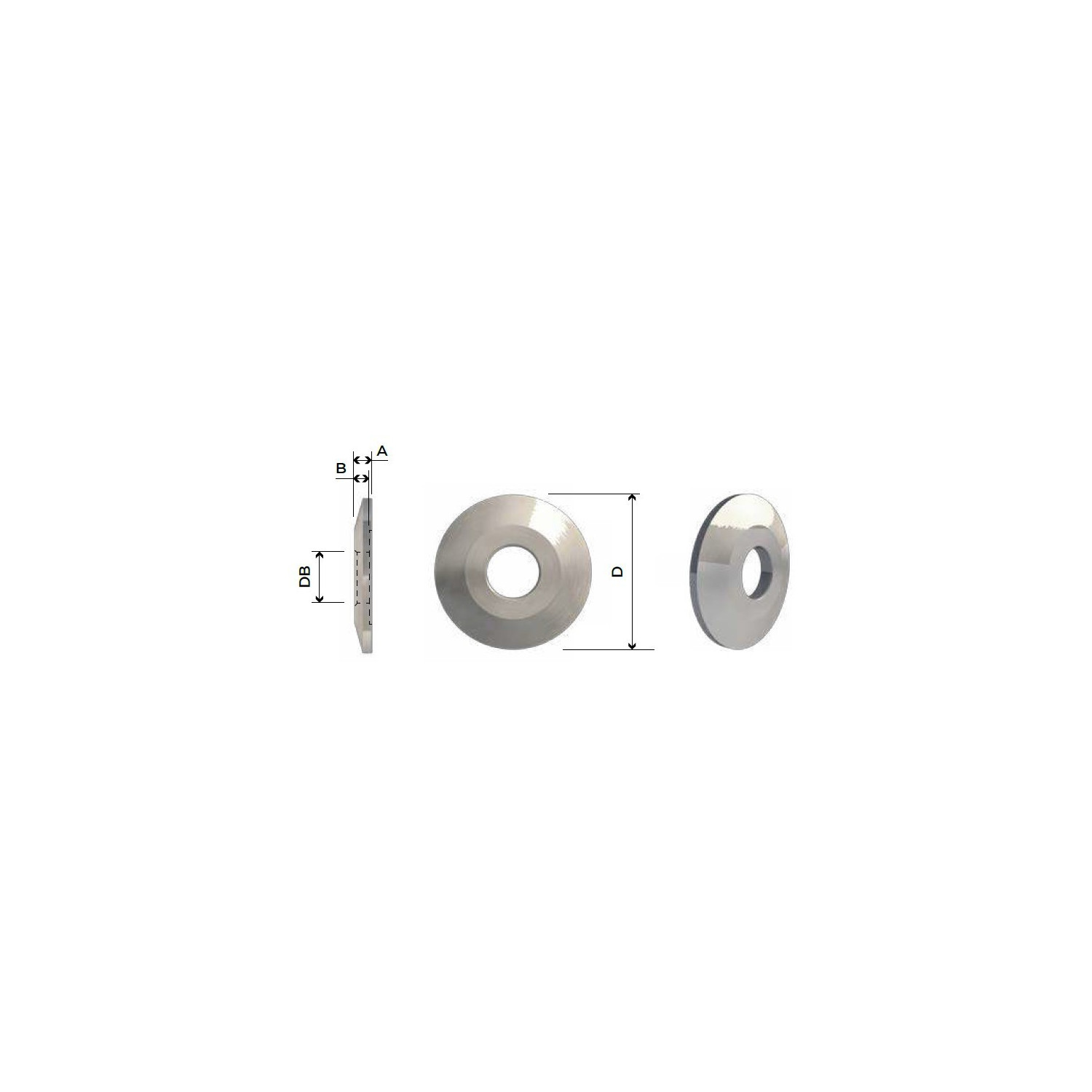

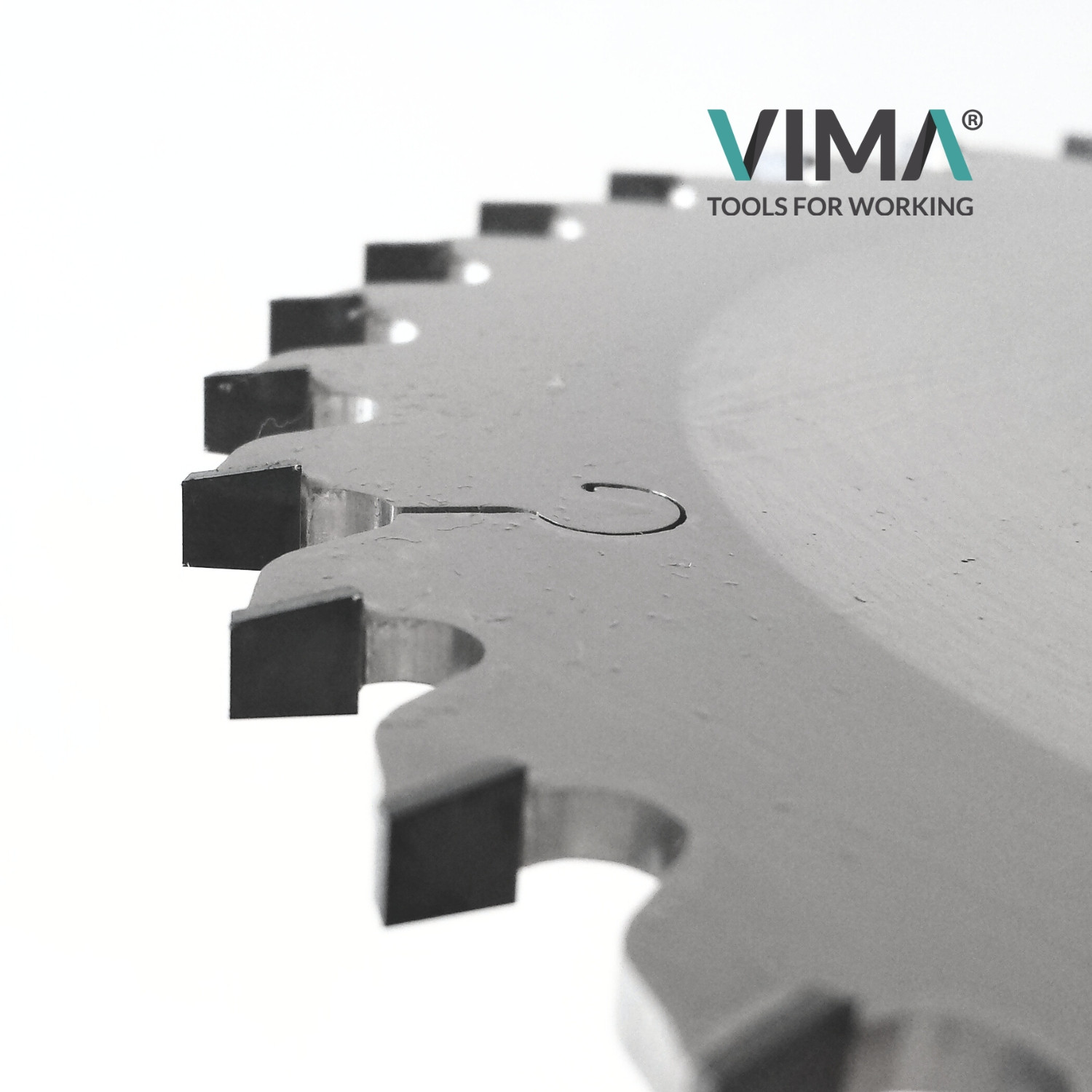

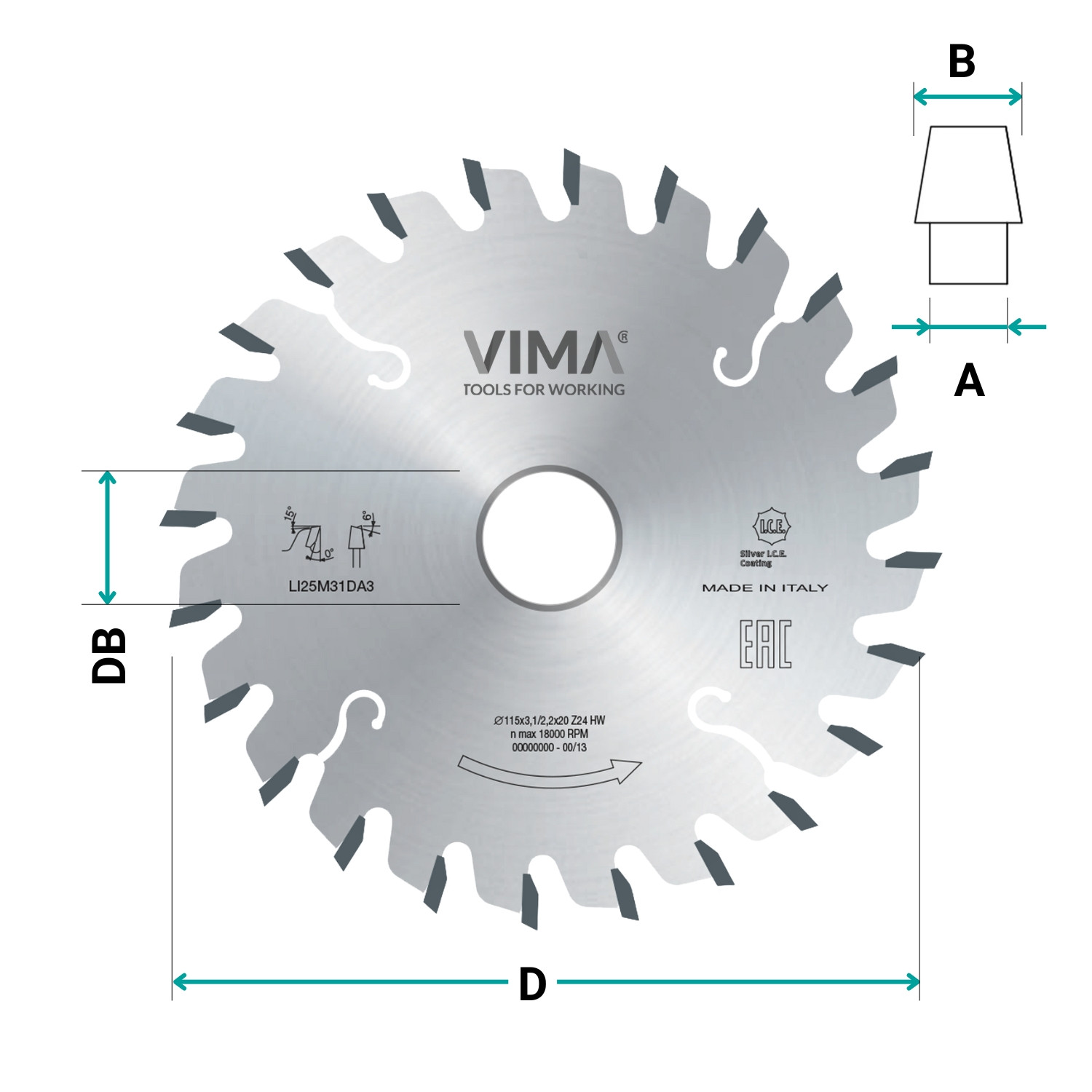

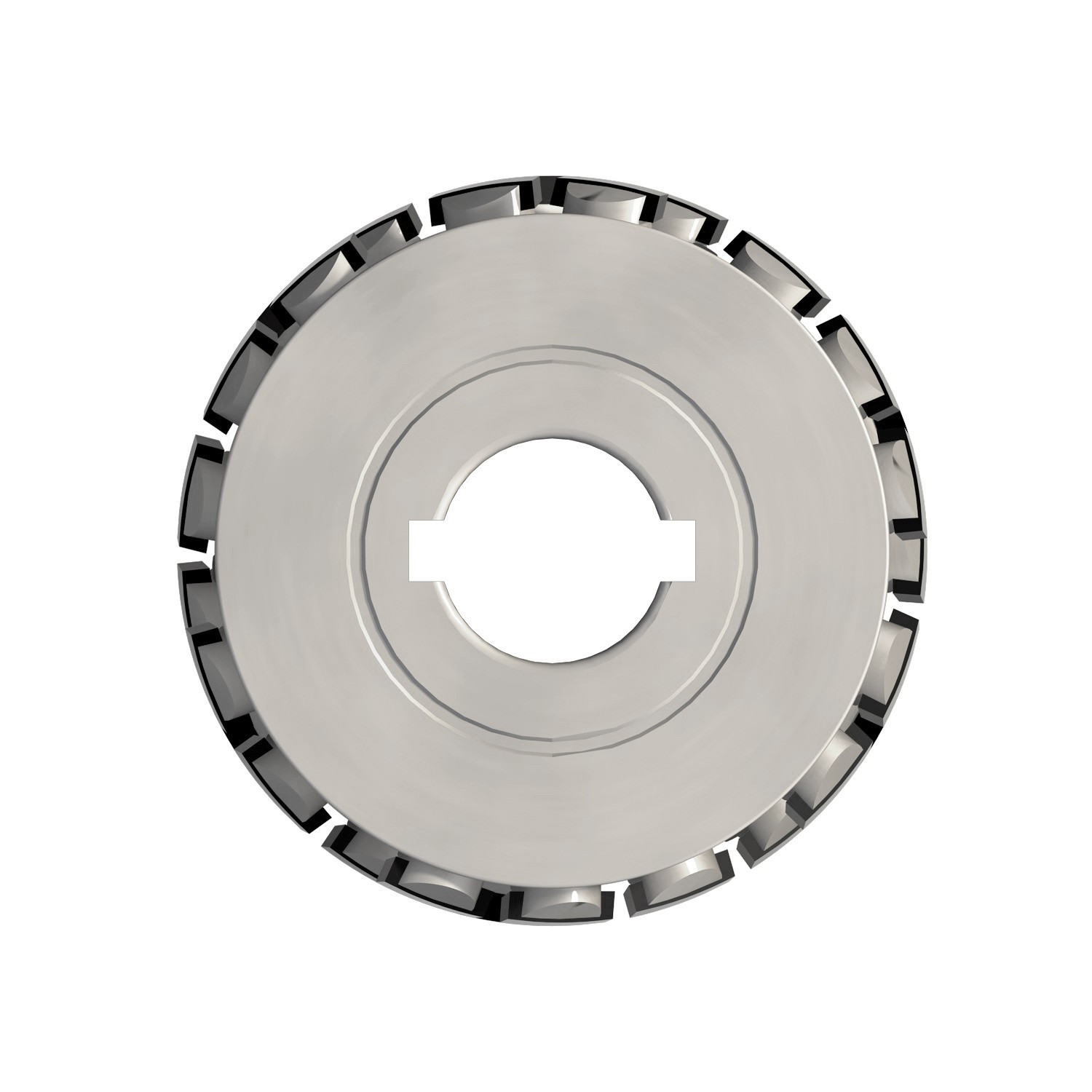

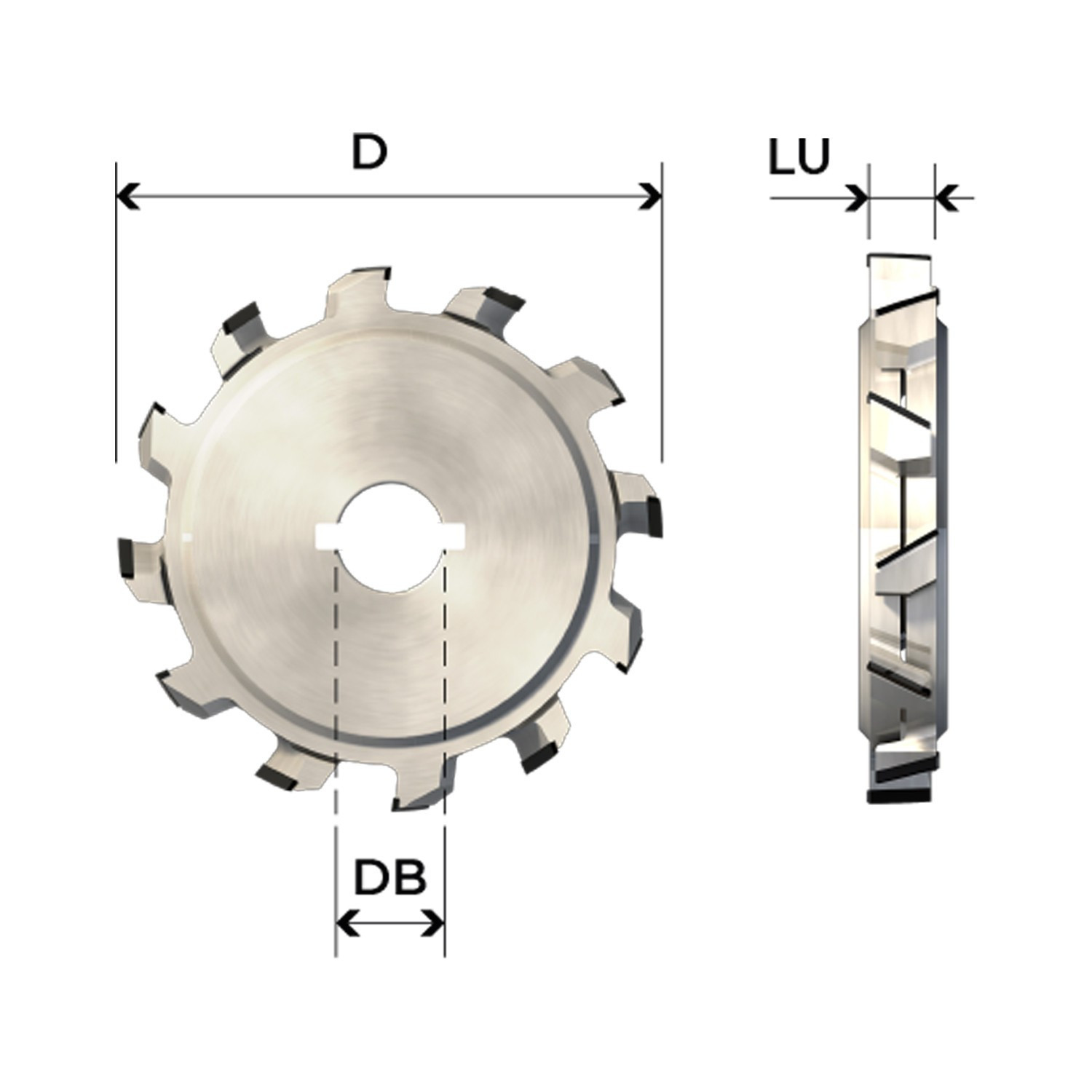

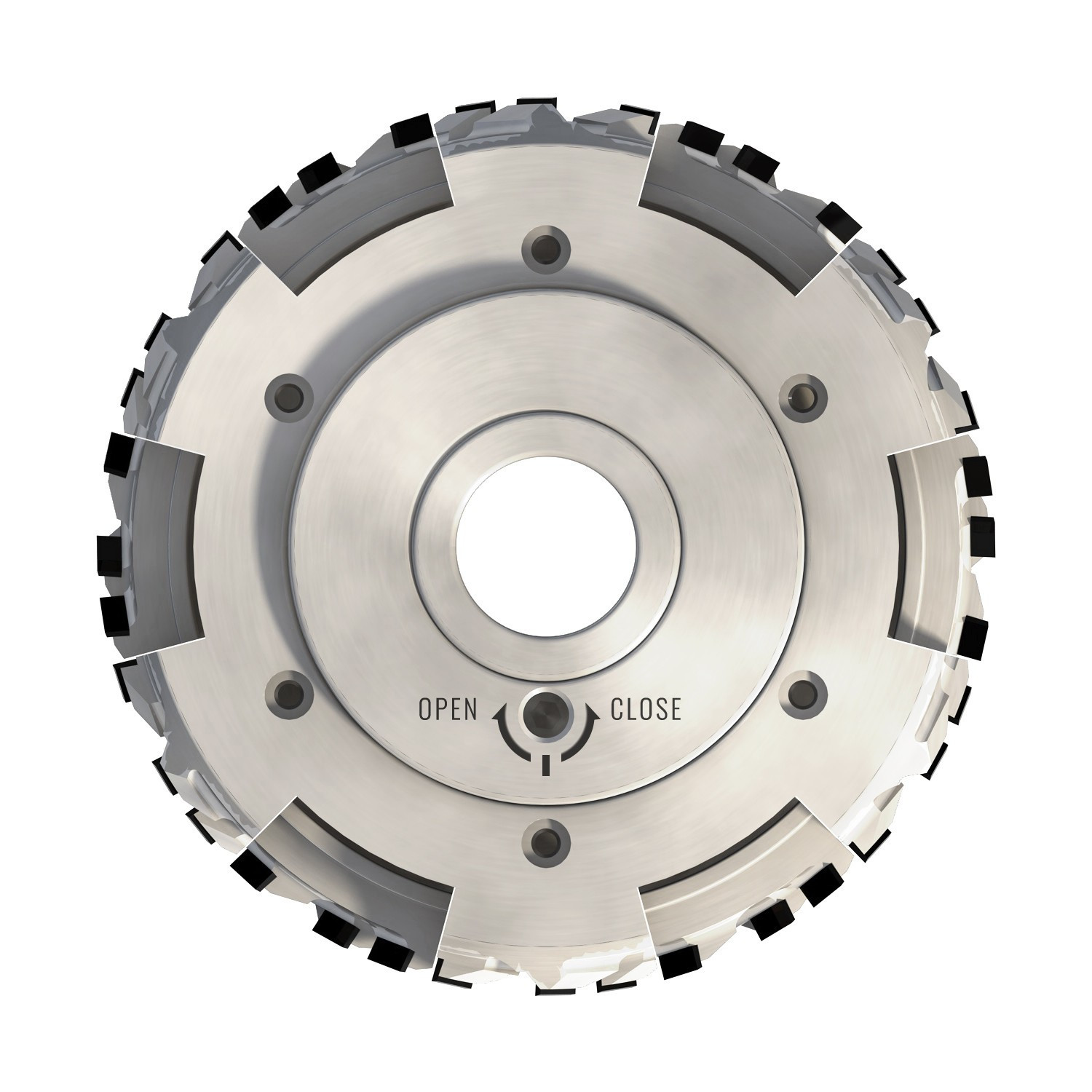

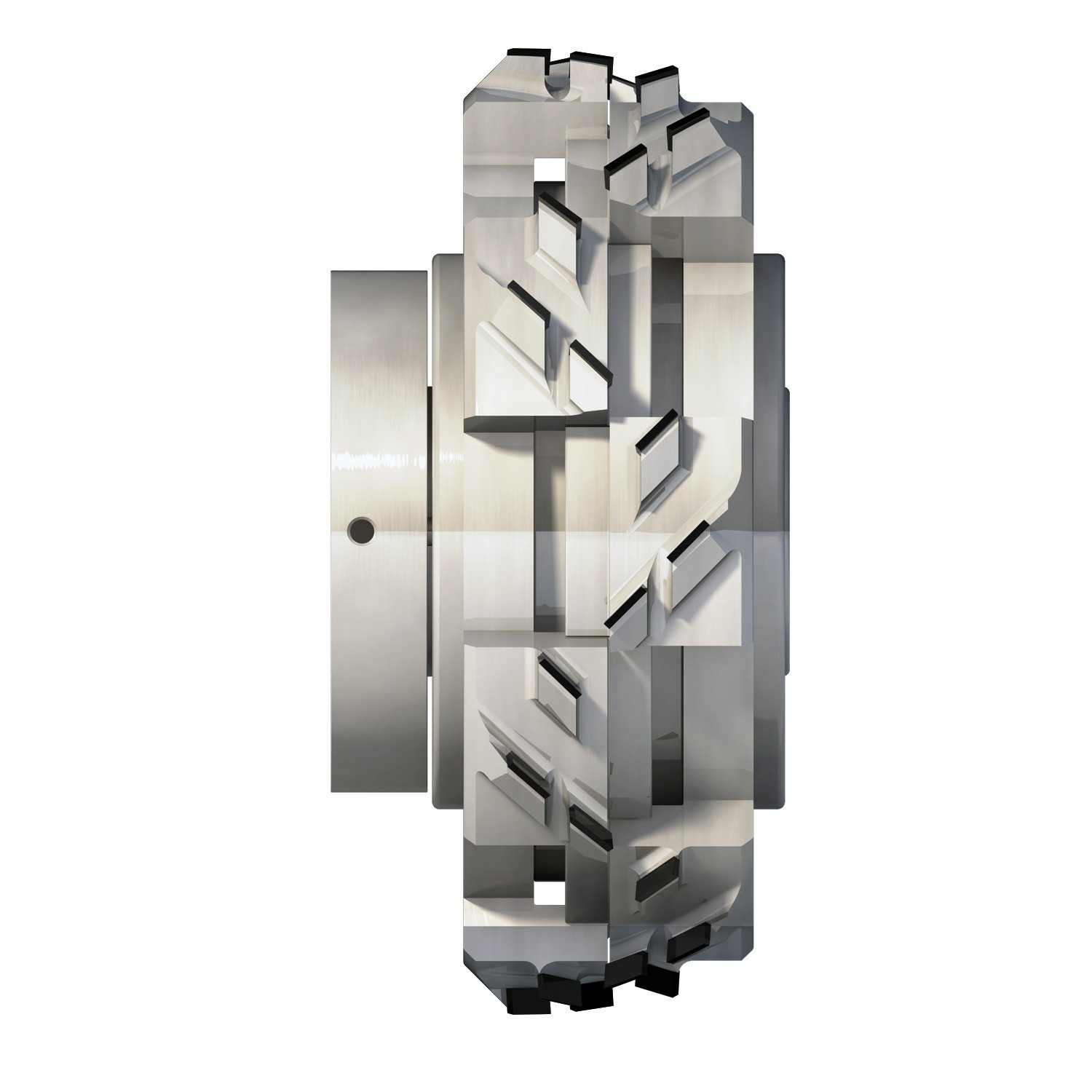

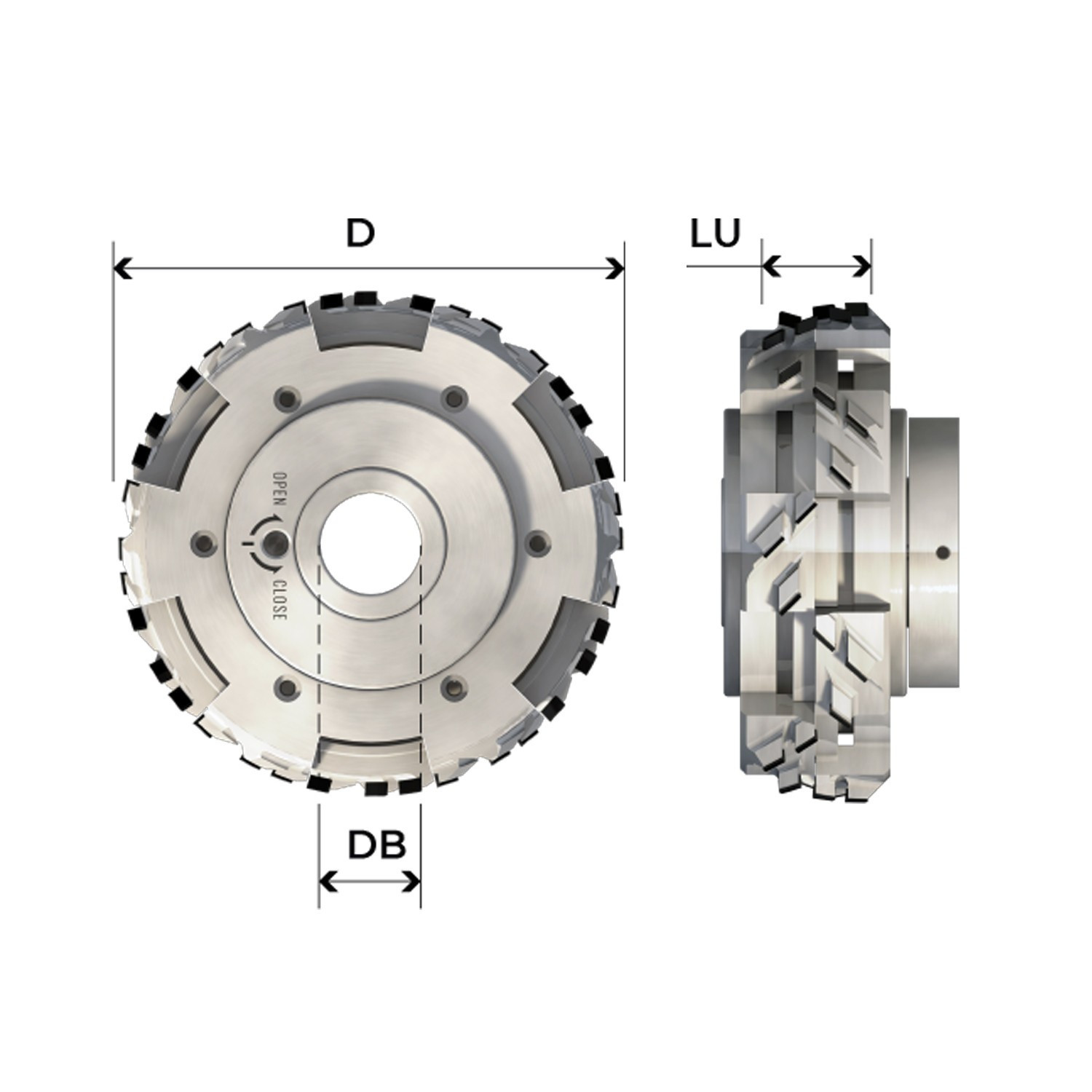

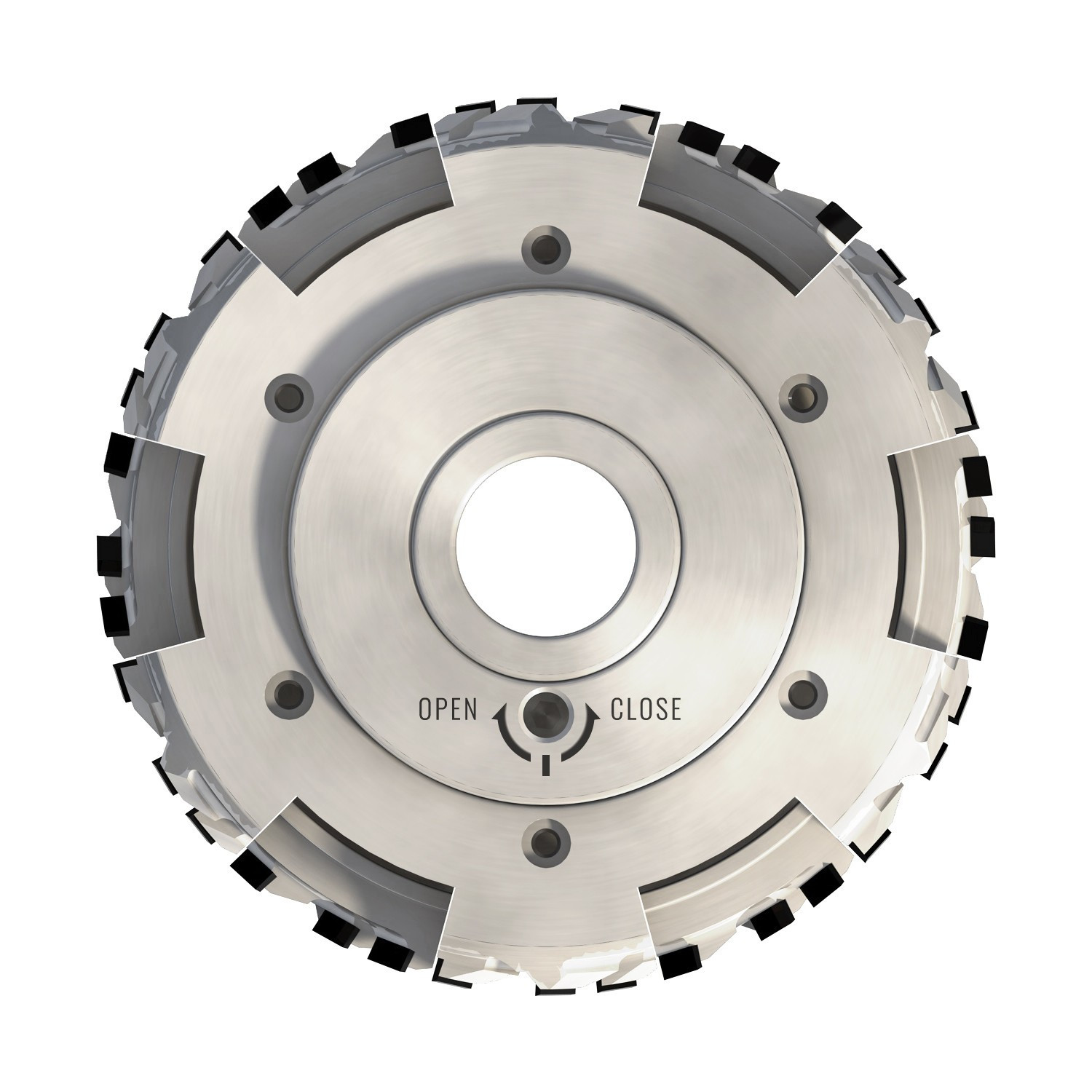

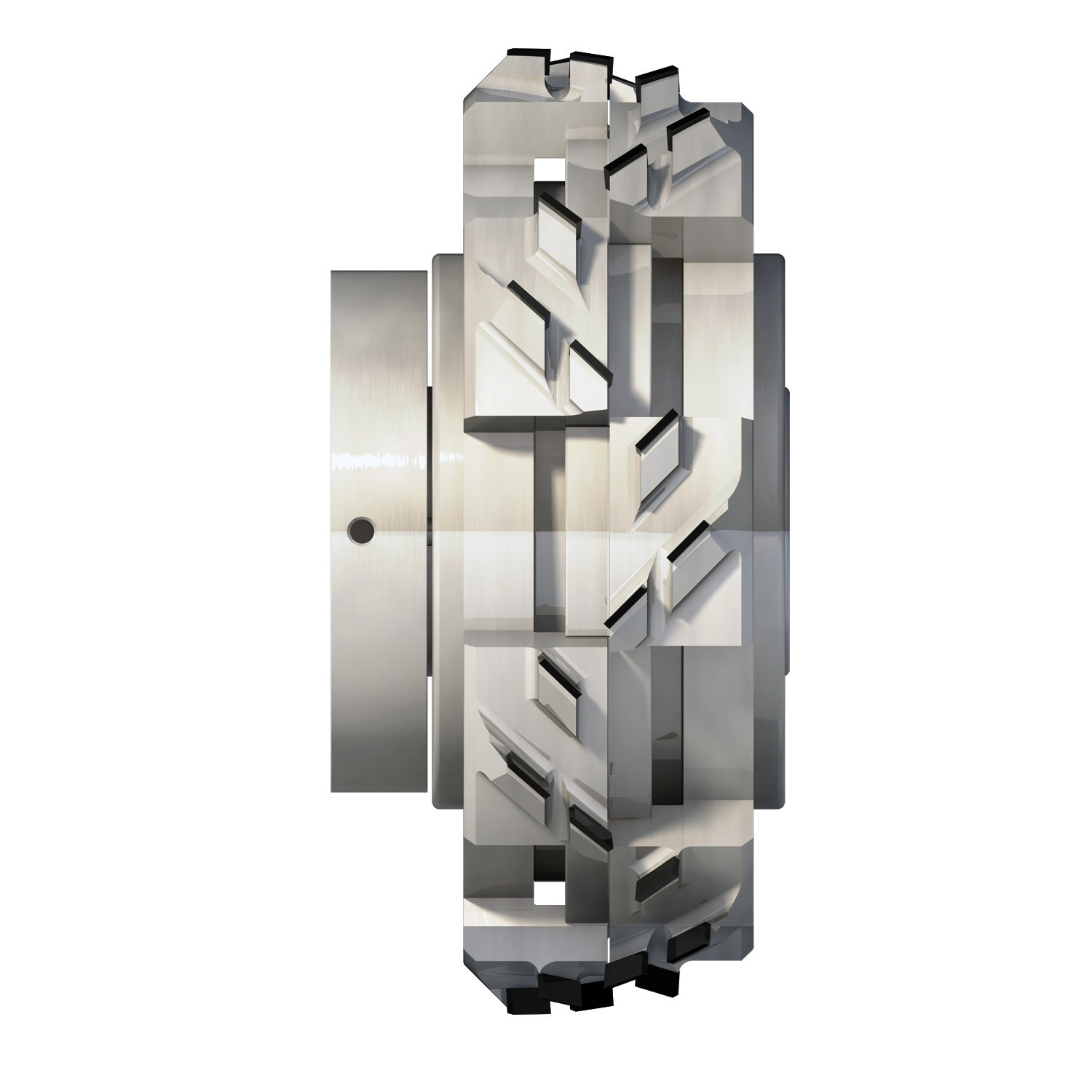

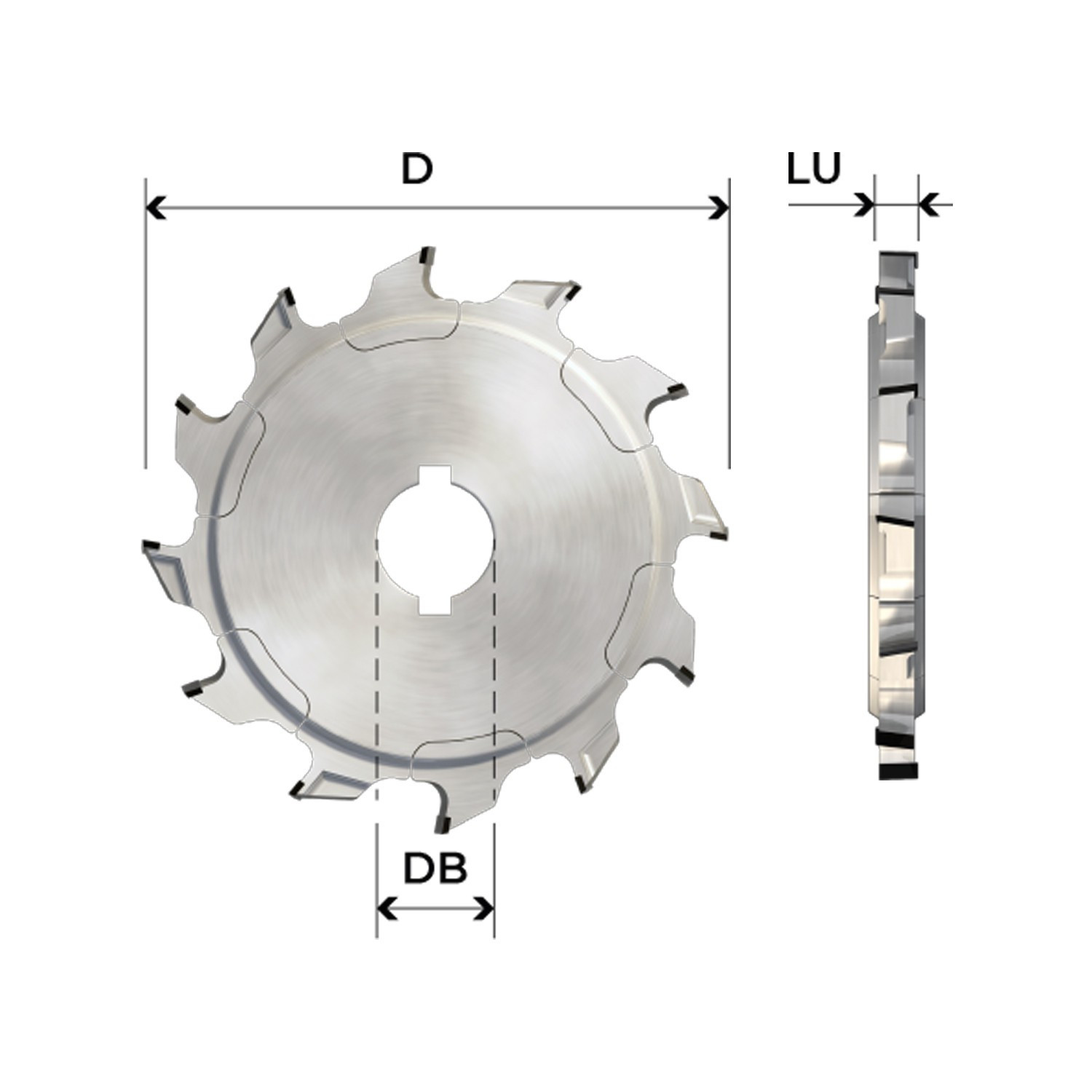

Adjustable HW scoring blade engineered for precise and chip-free scoring on laminated panels and wood-based materials.

• WZ geometry for clean scoring

• Low-noise body for reduced vibration

• Ideal for manual and mechanical panel saws

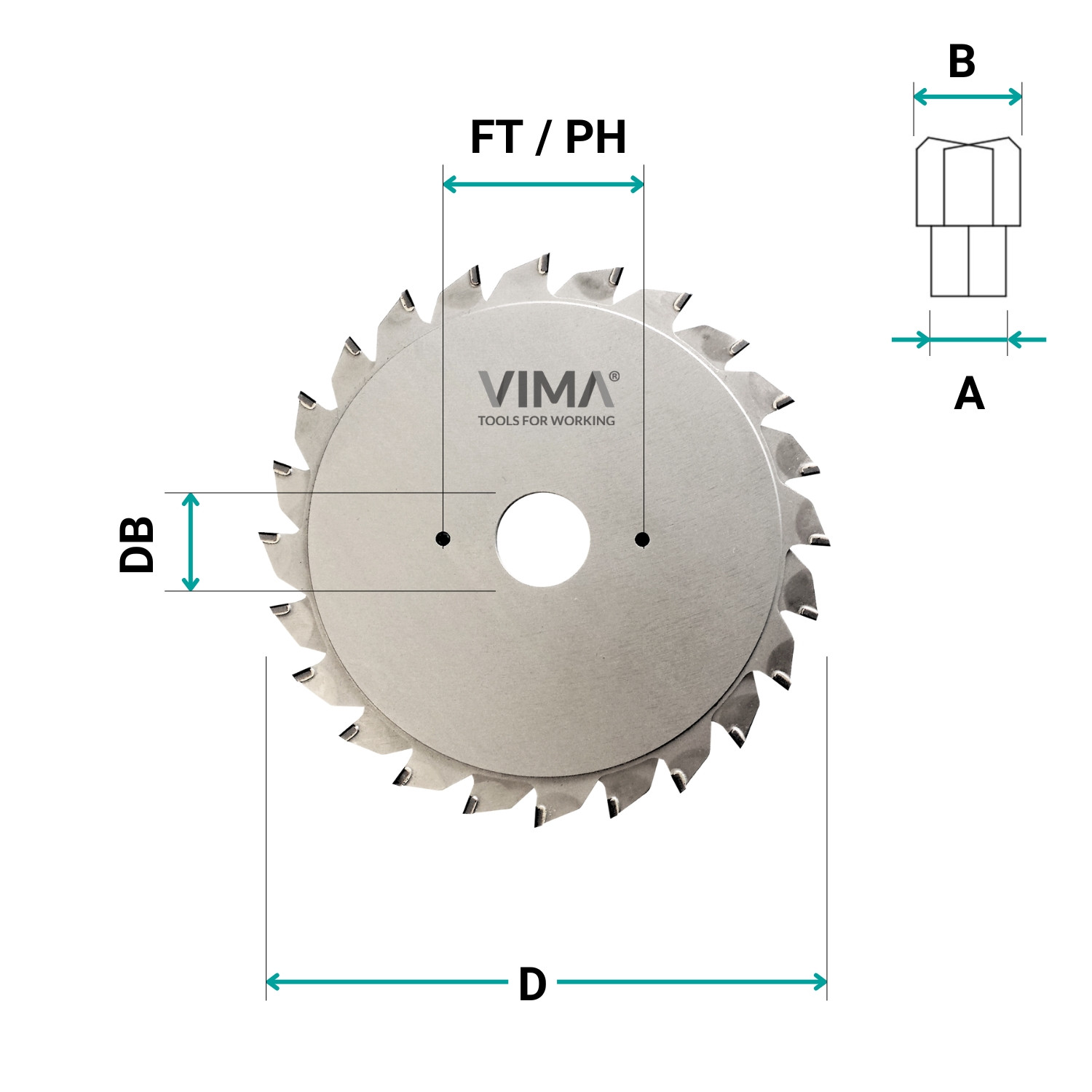

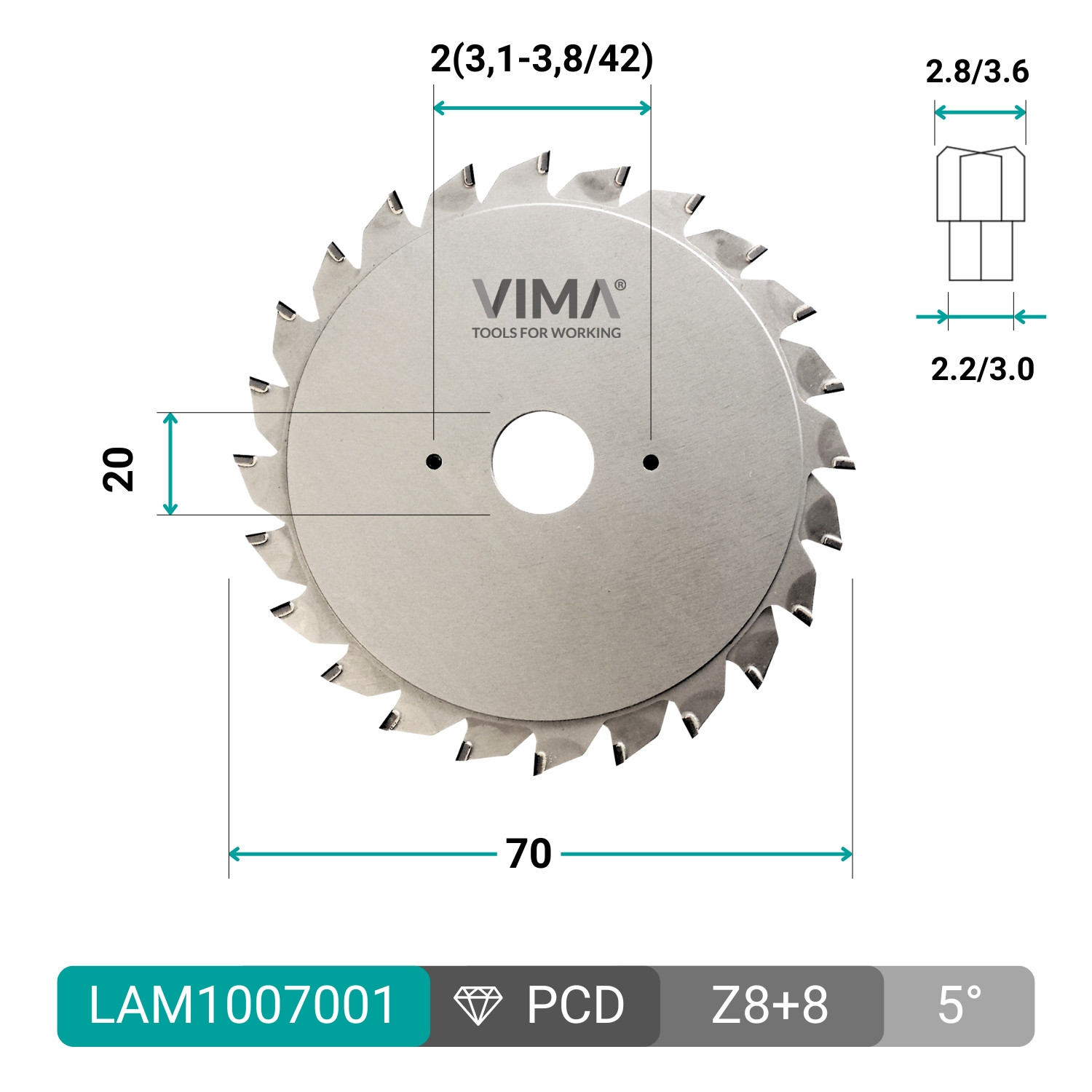

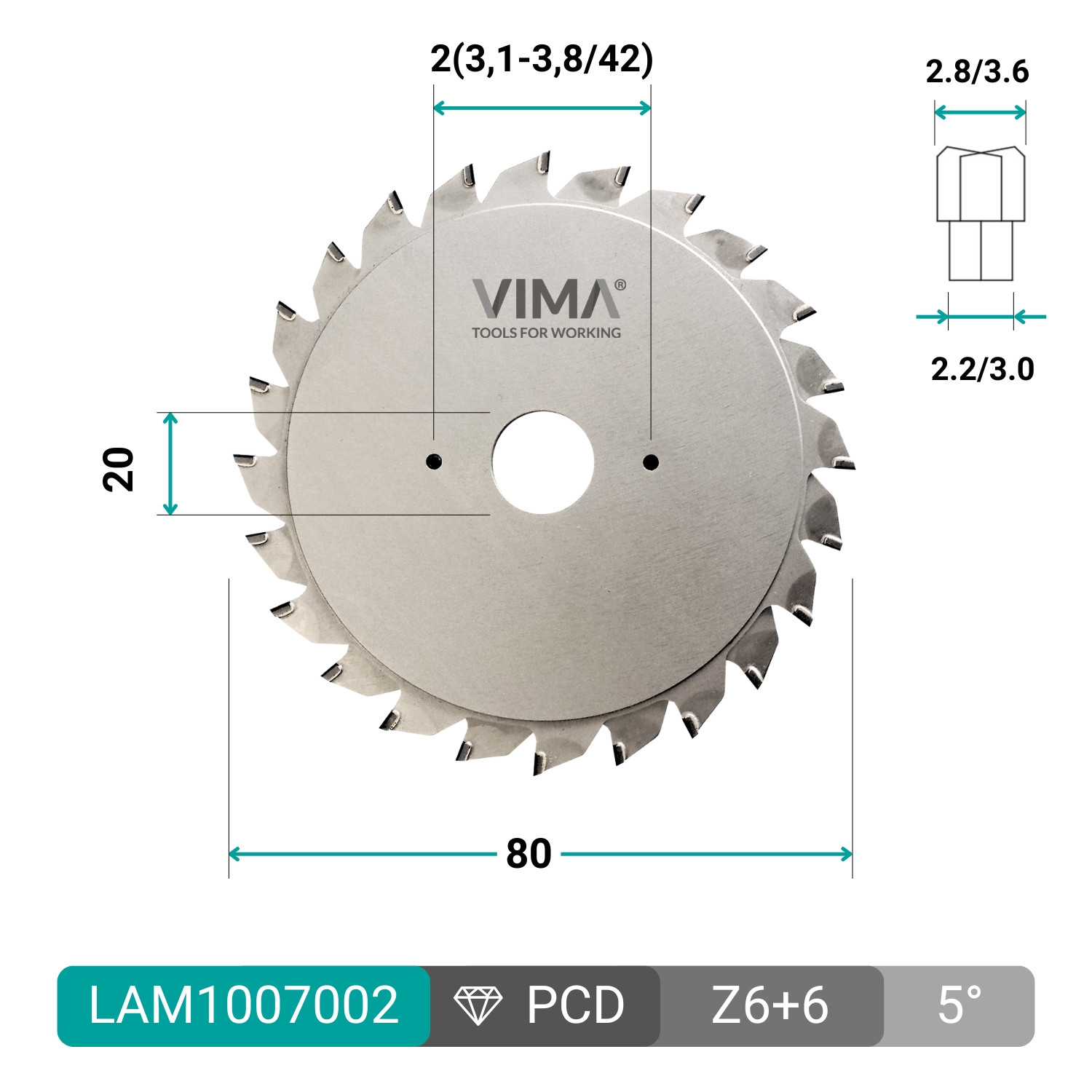

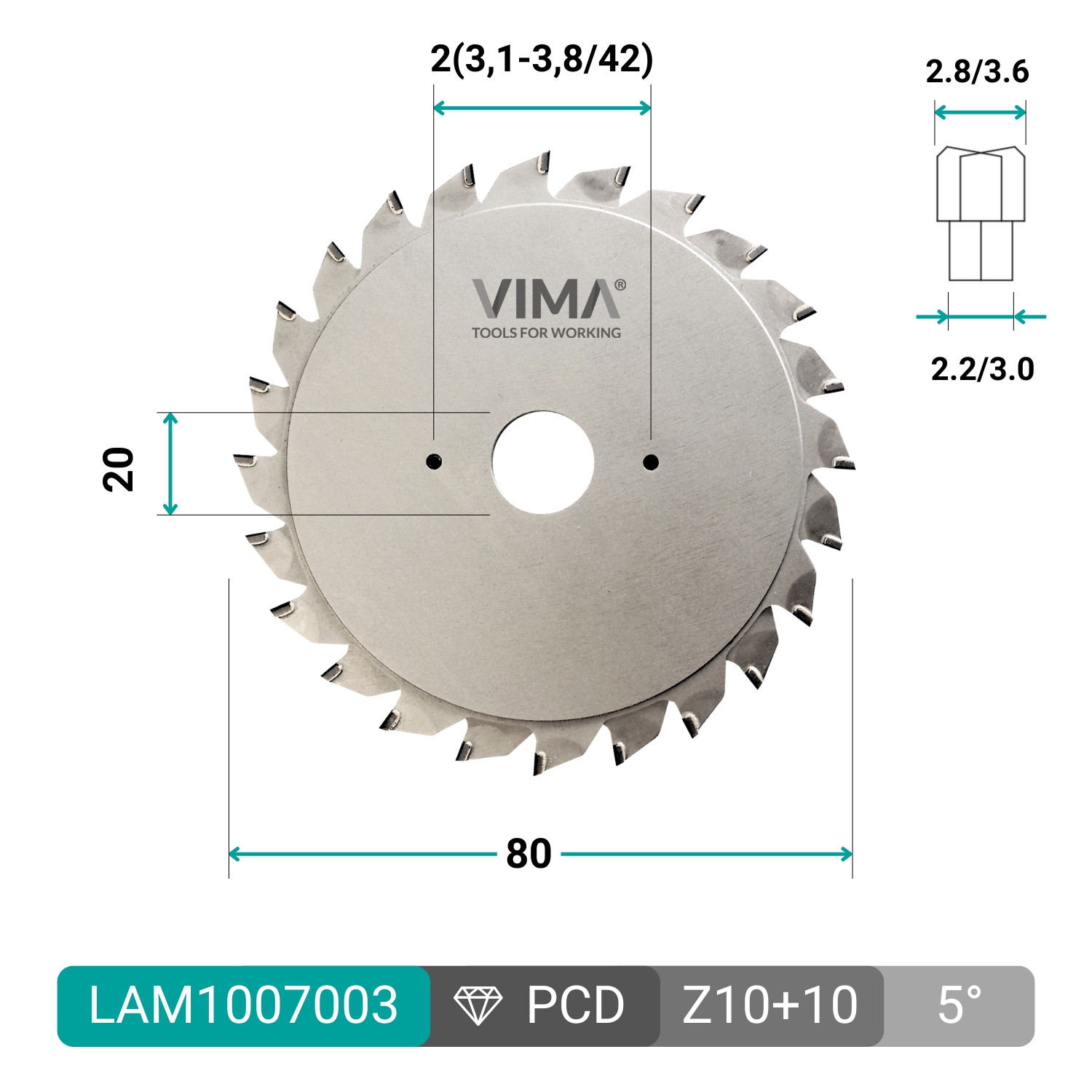

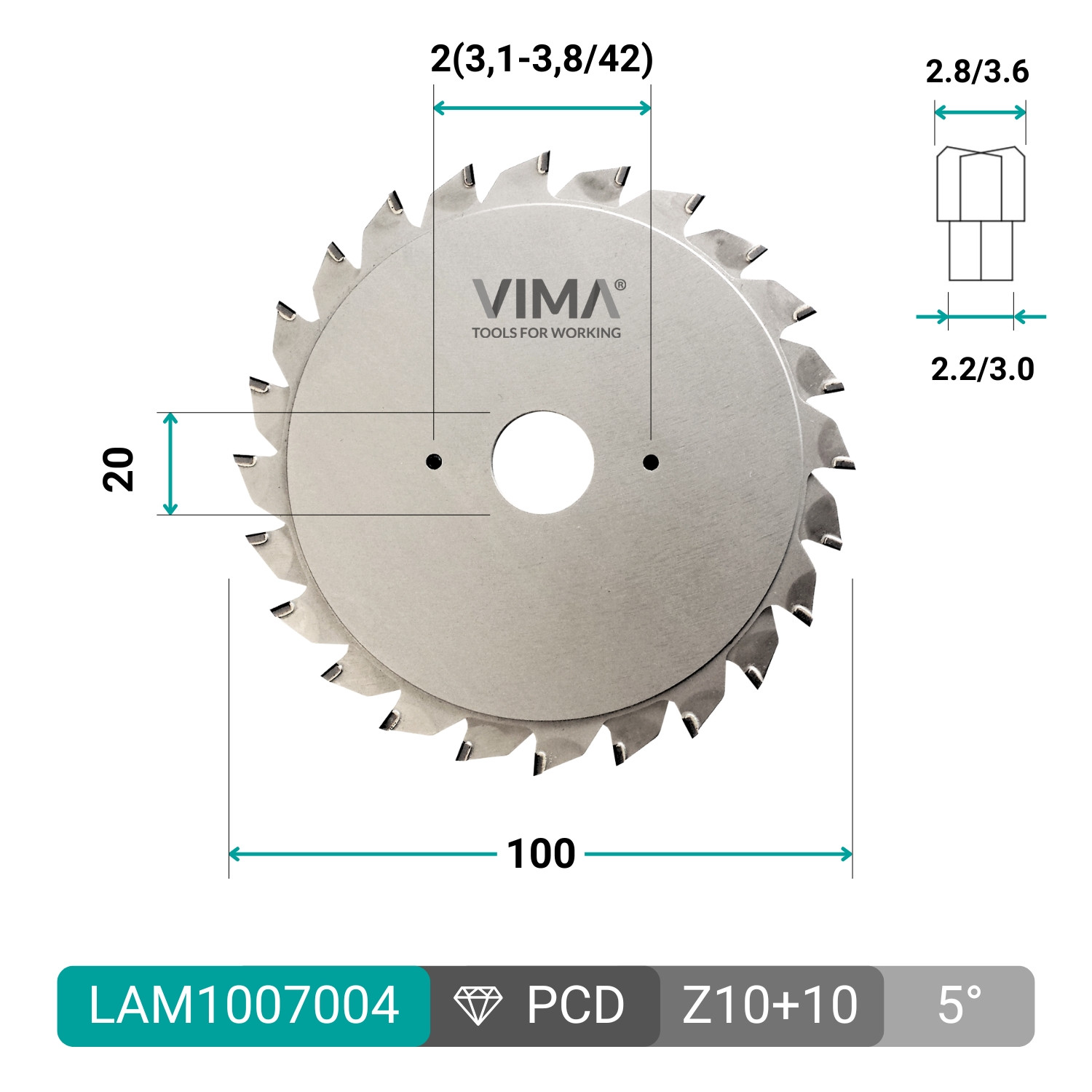

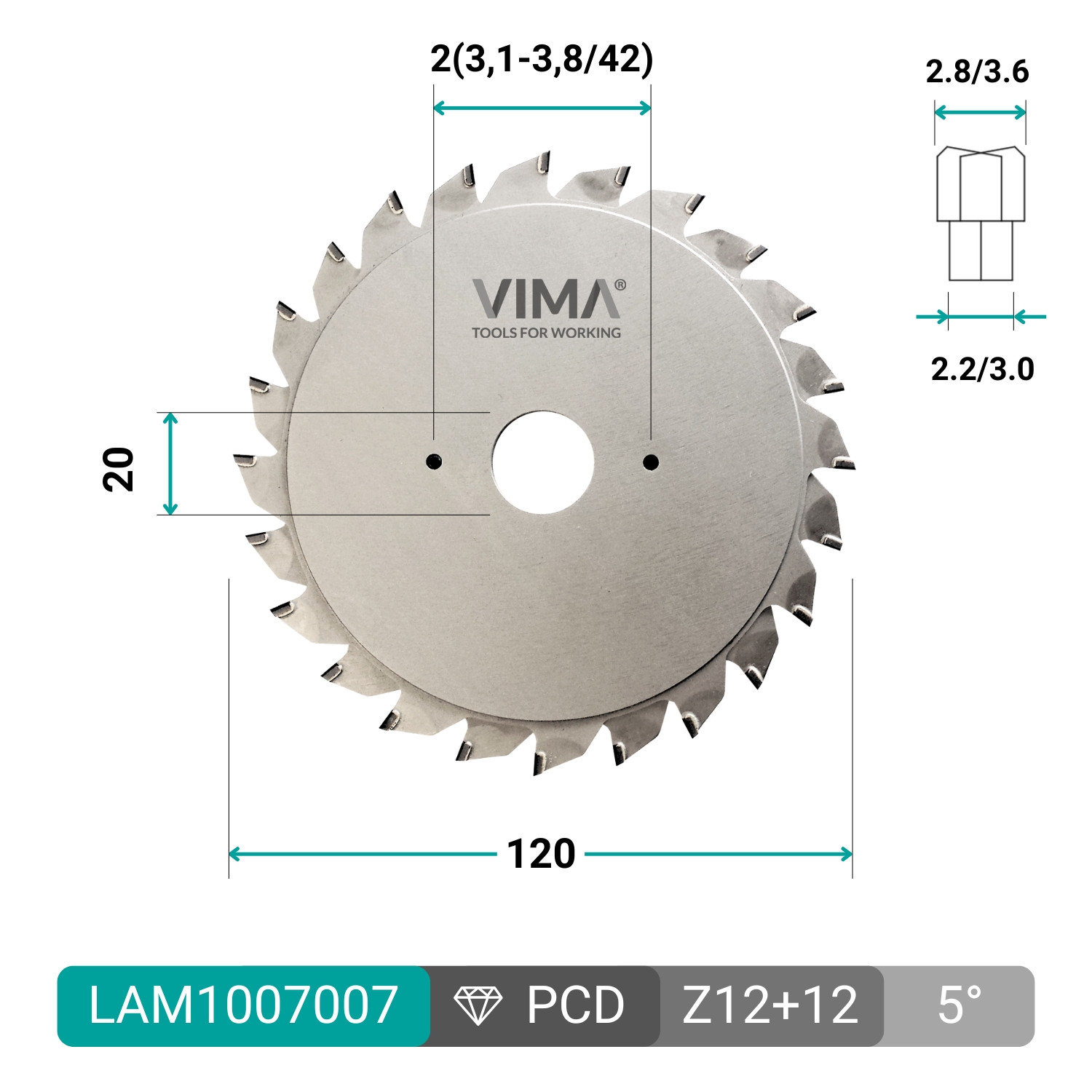

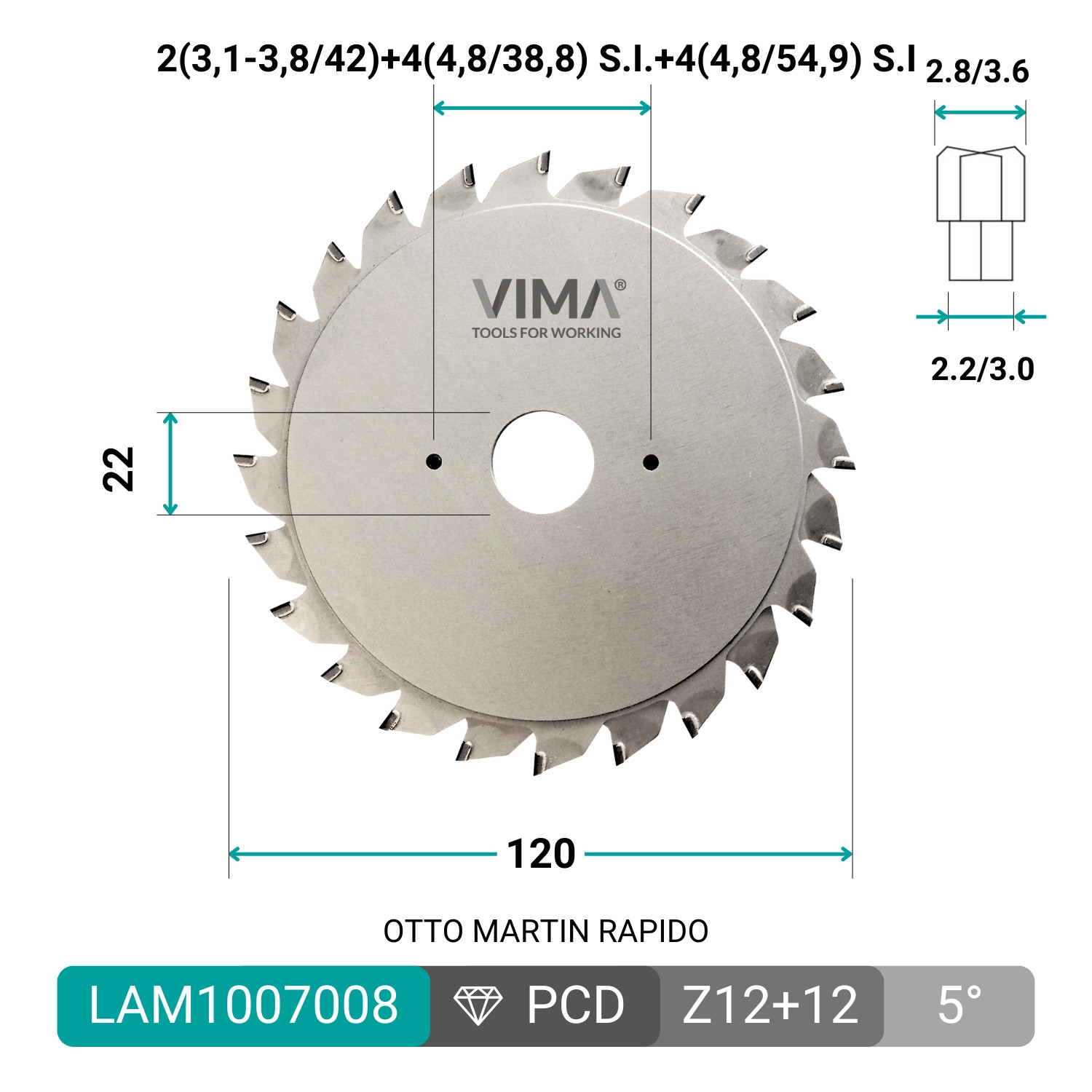

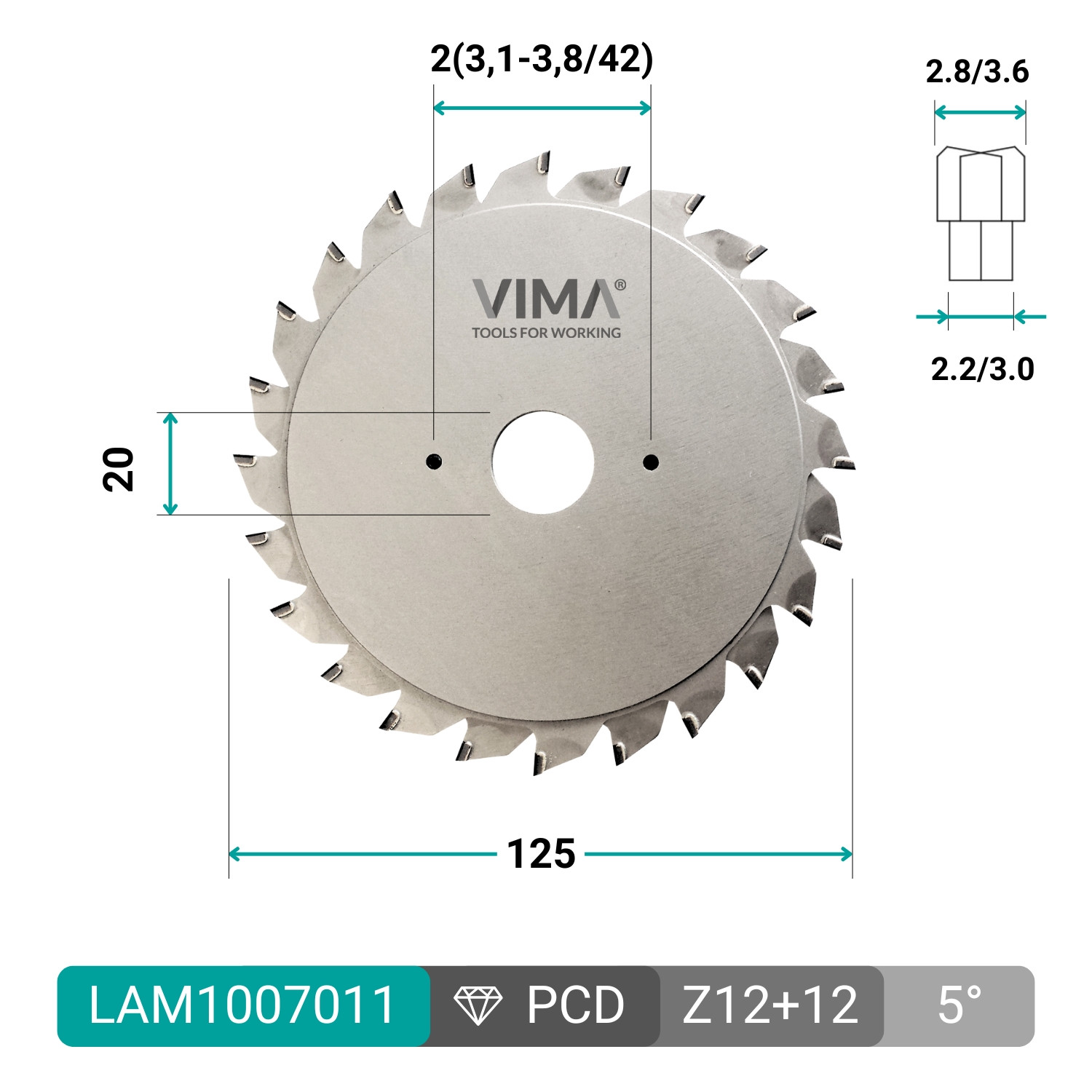

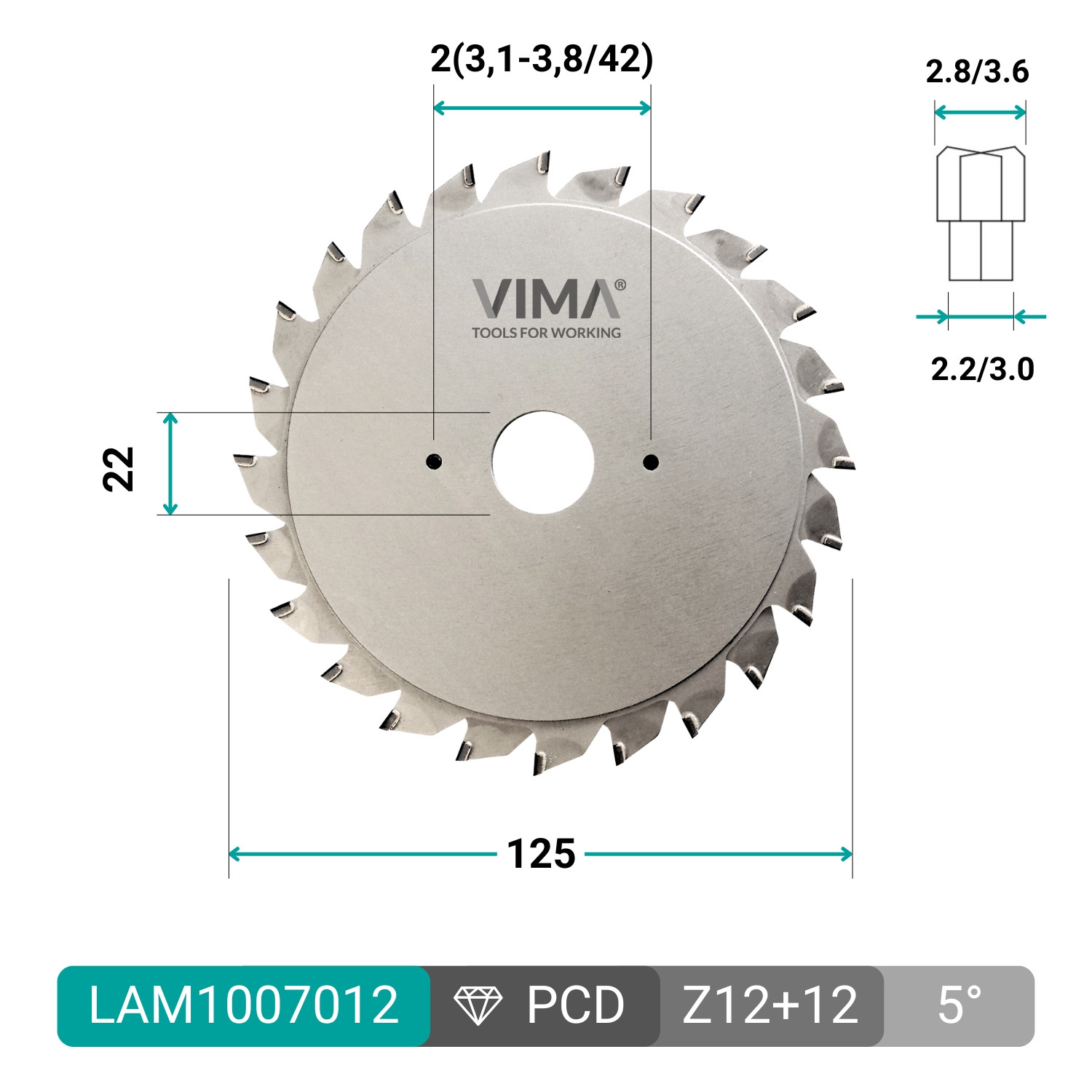

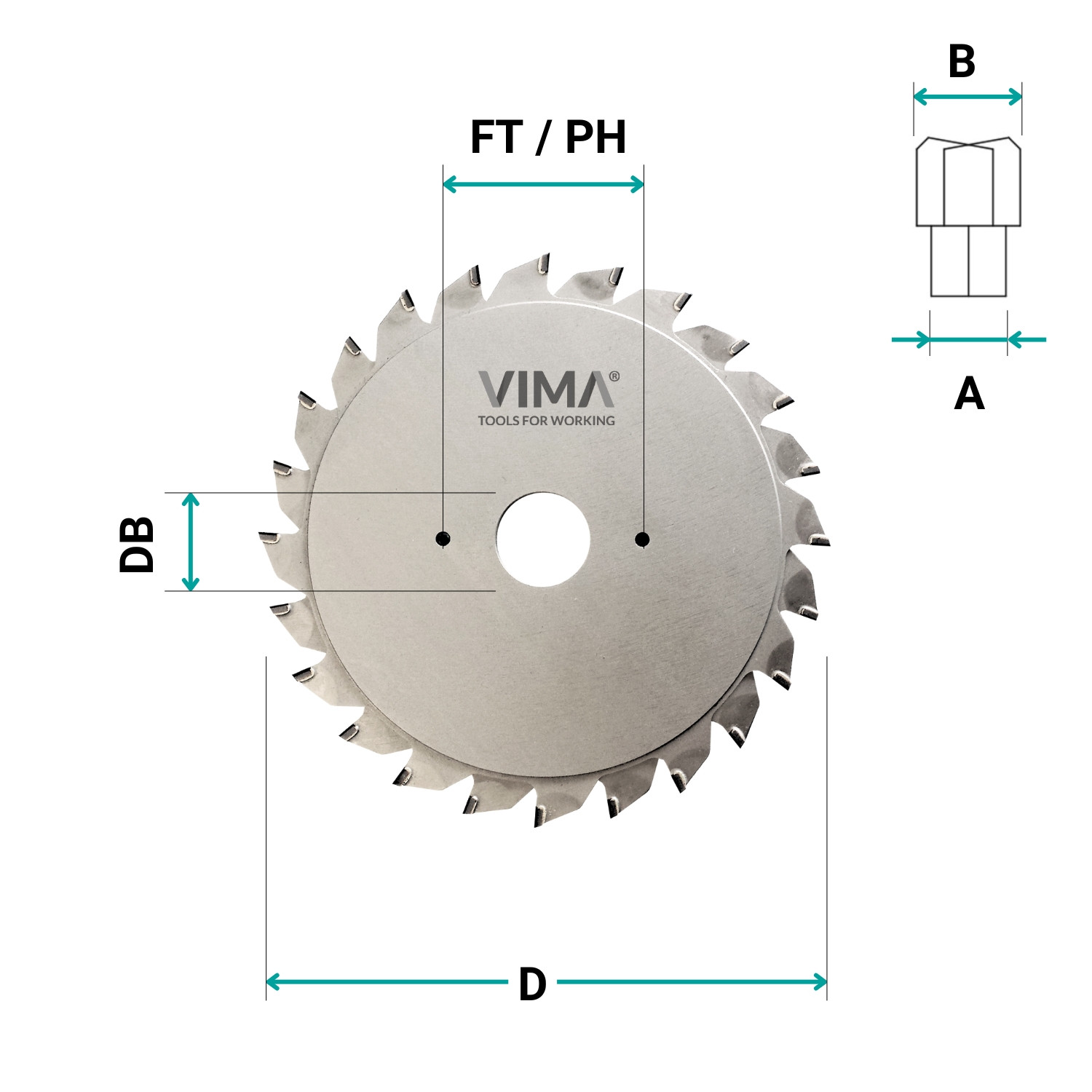

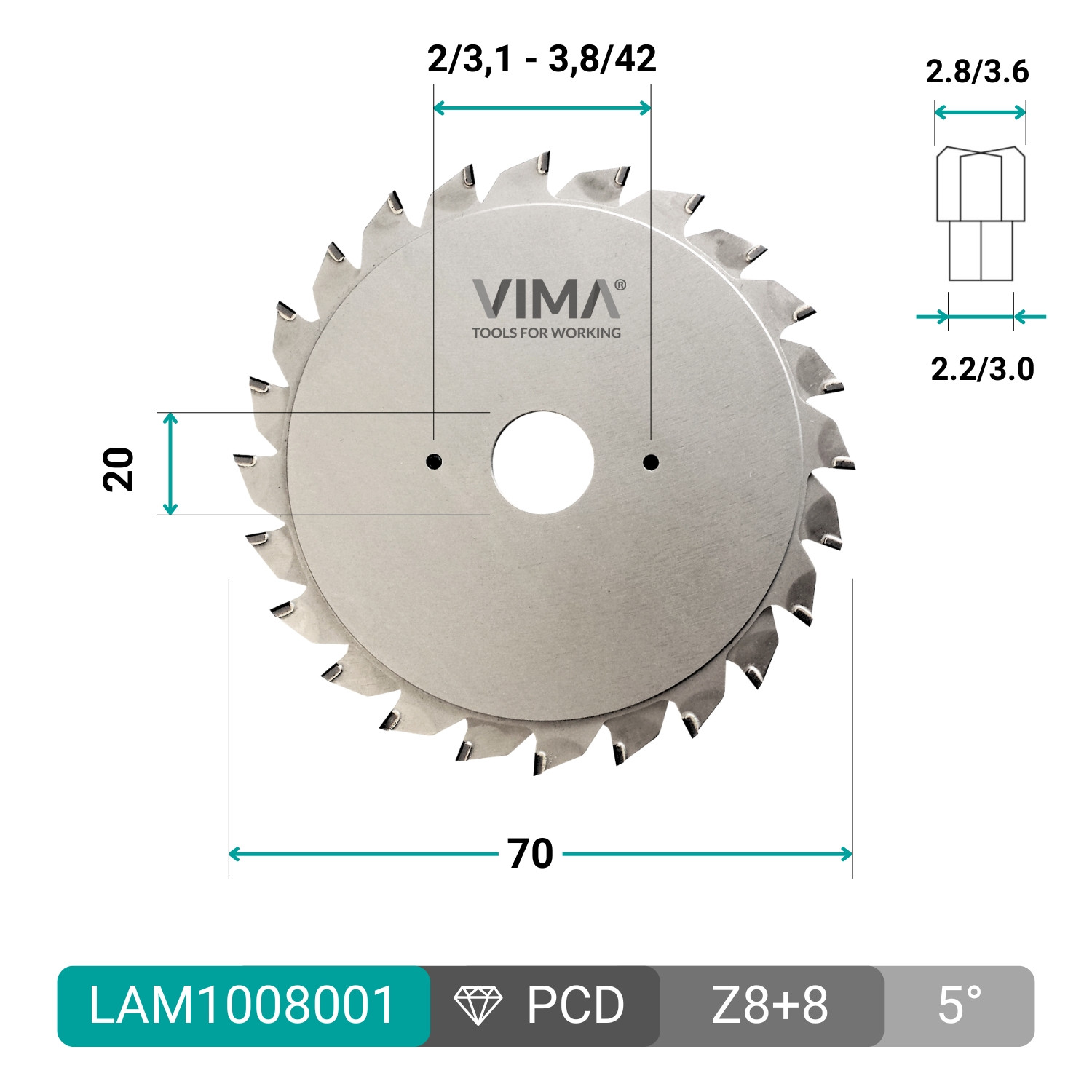

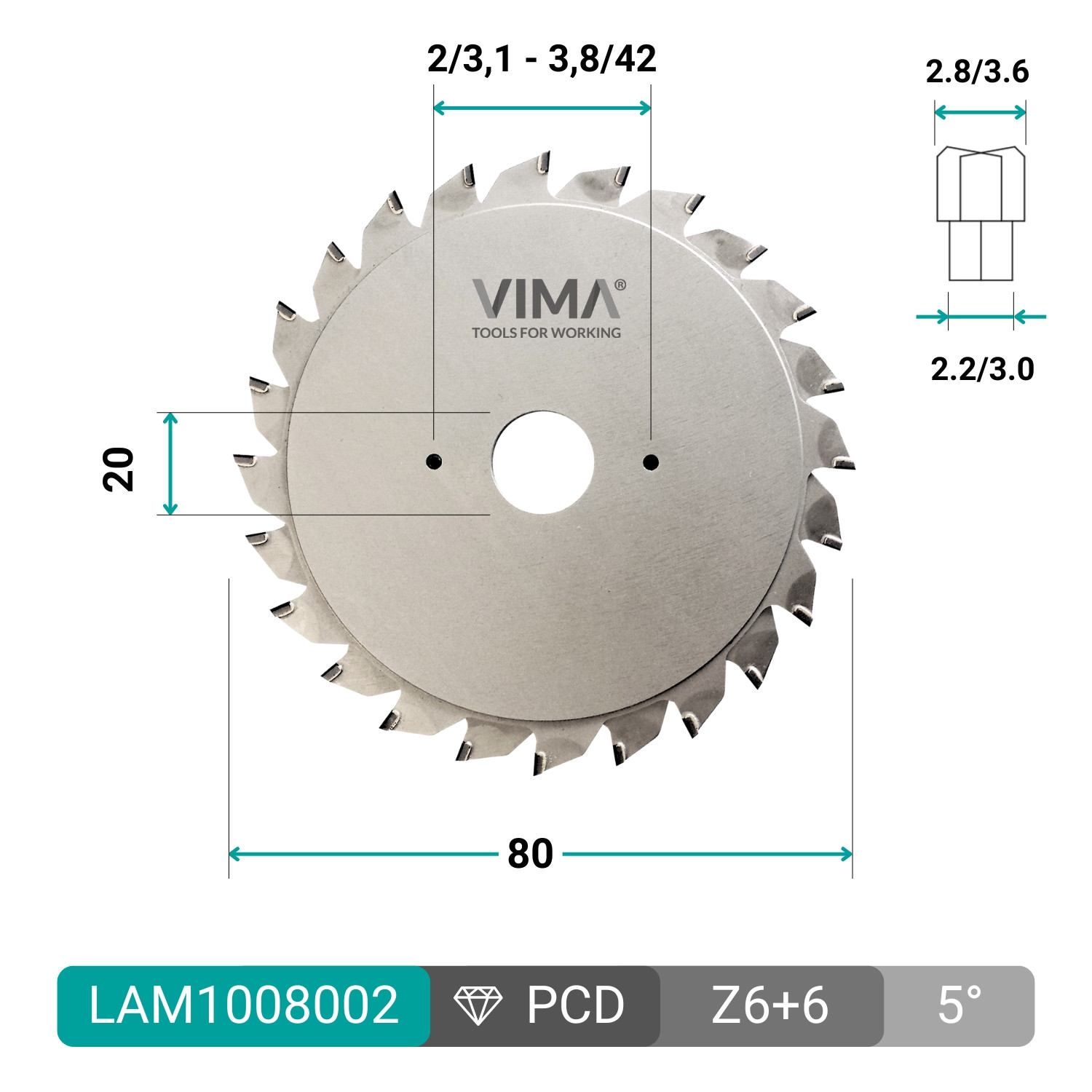

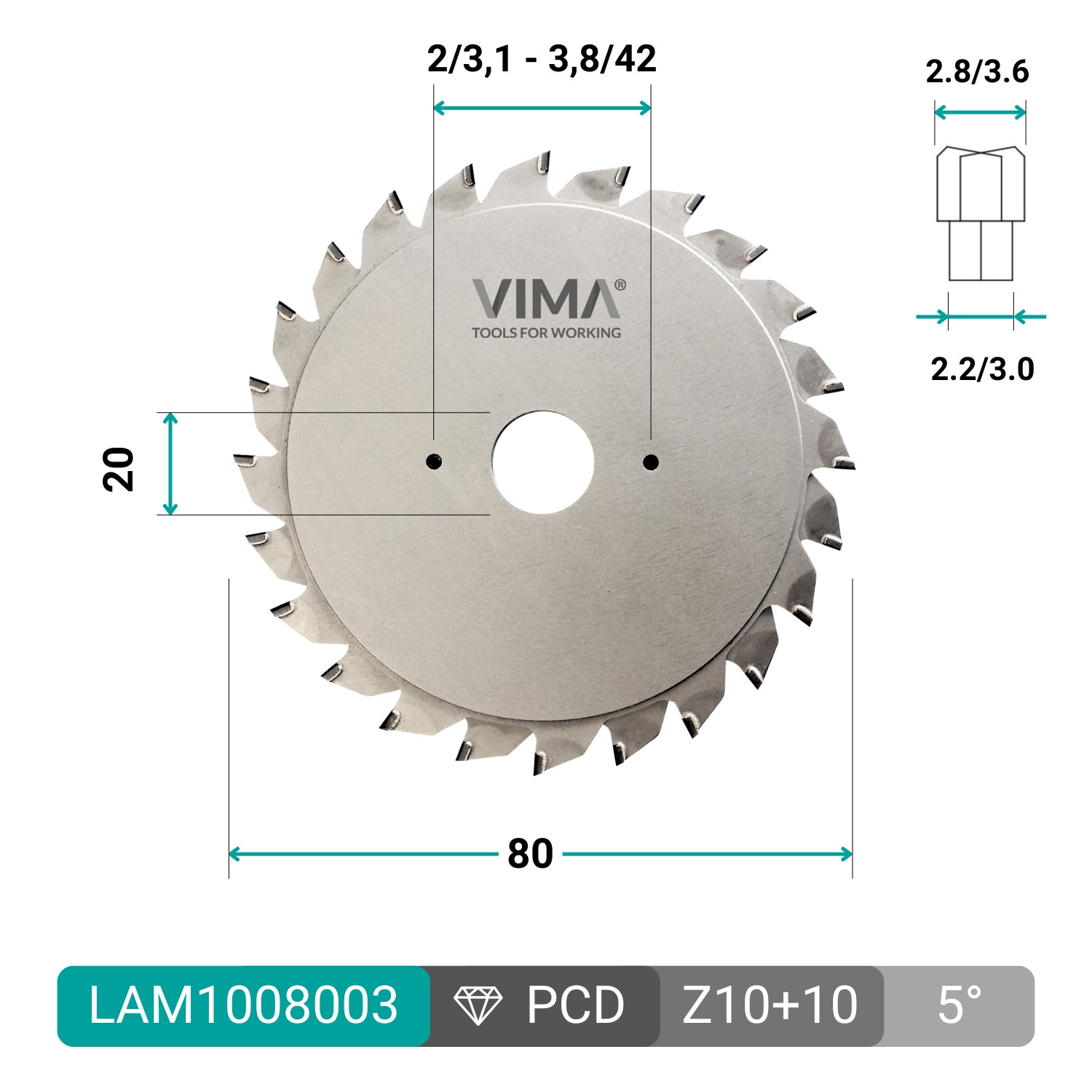

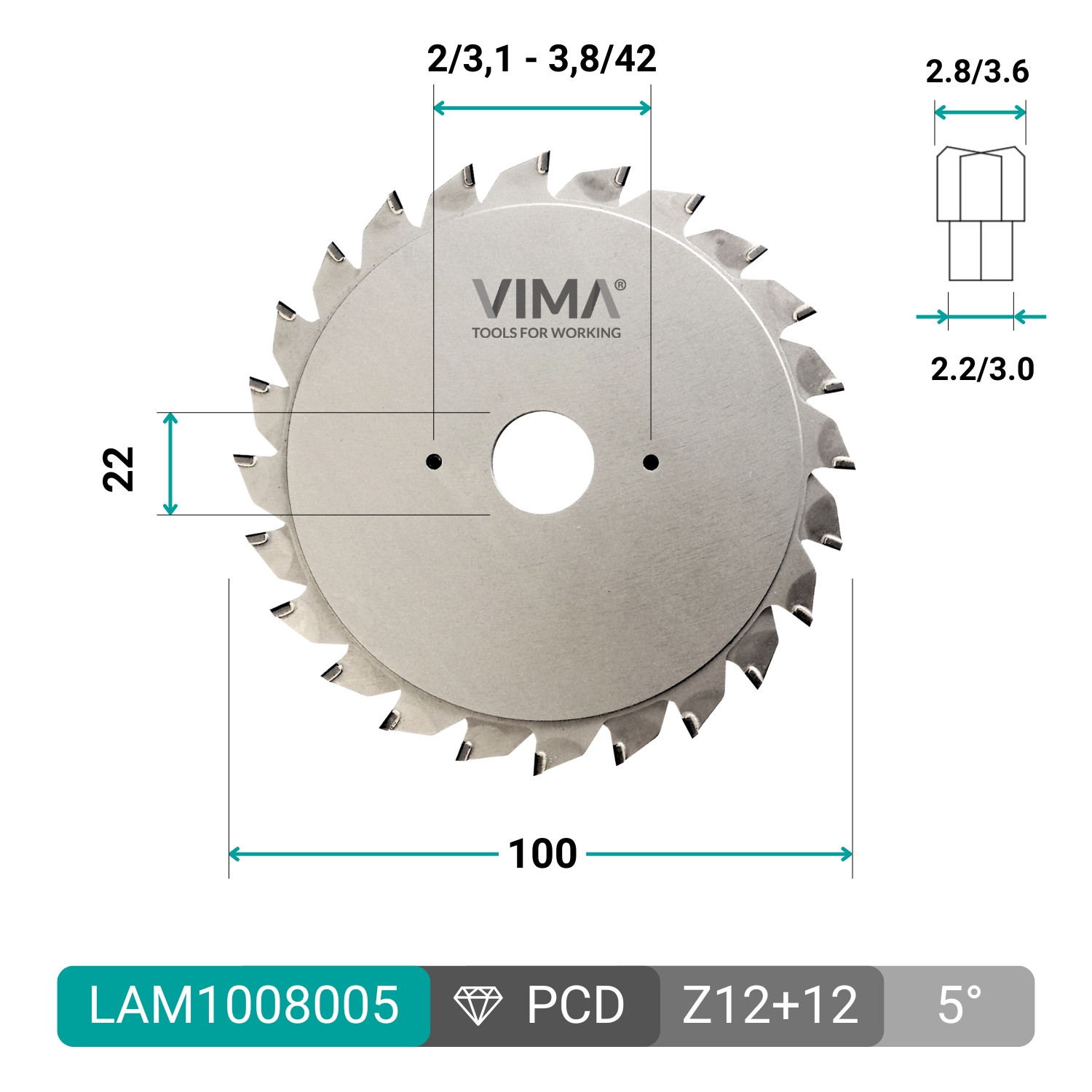

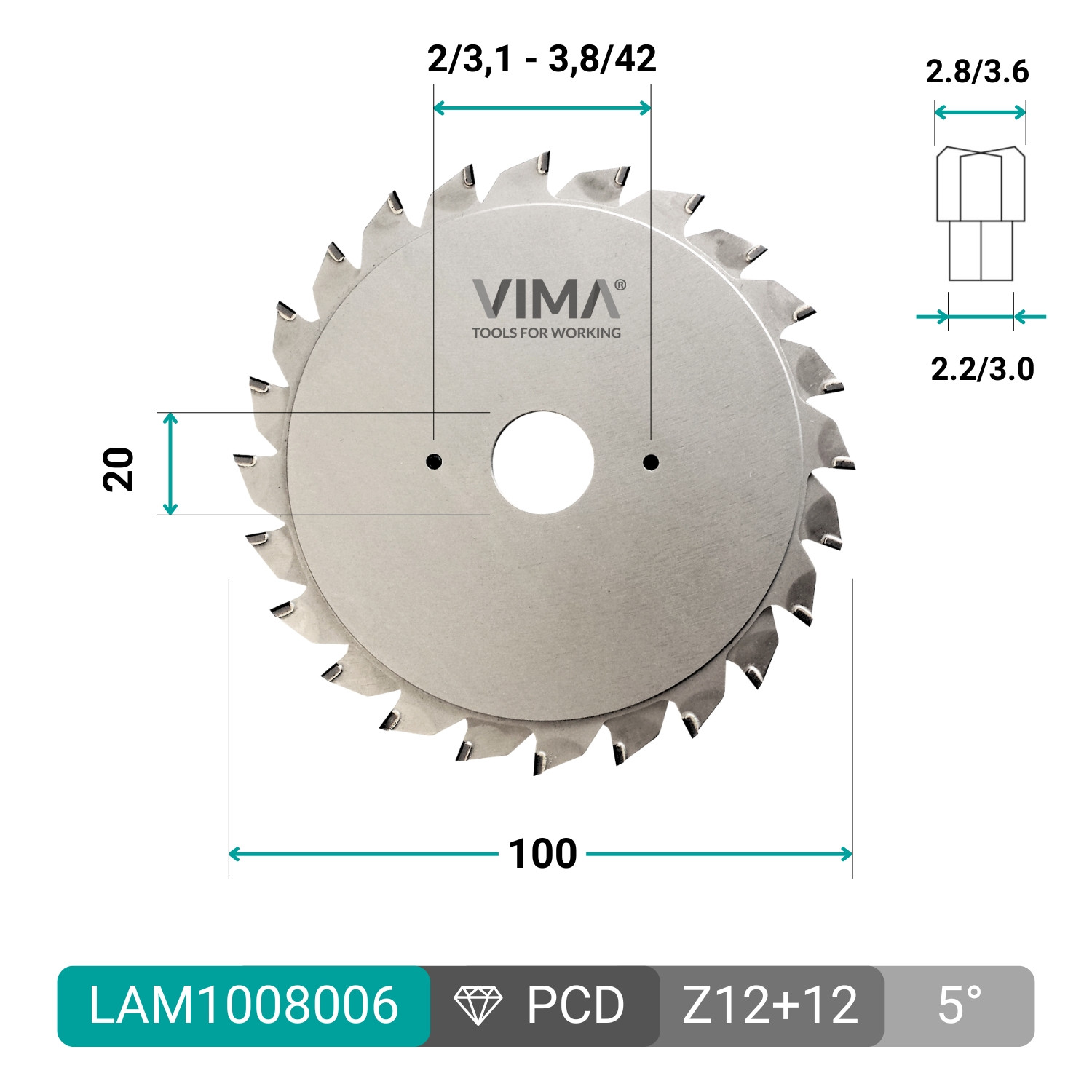

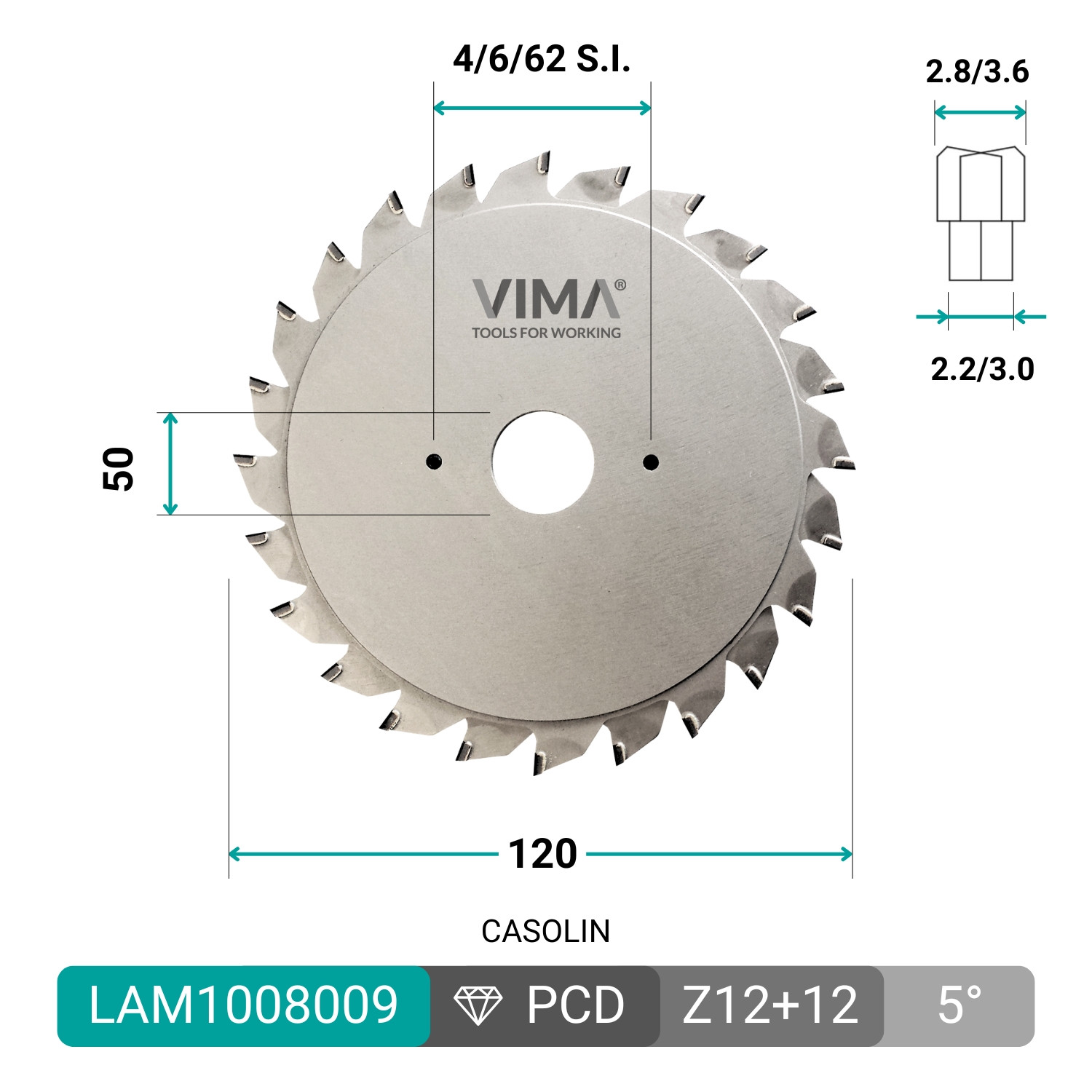

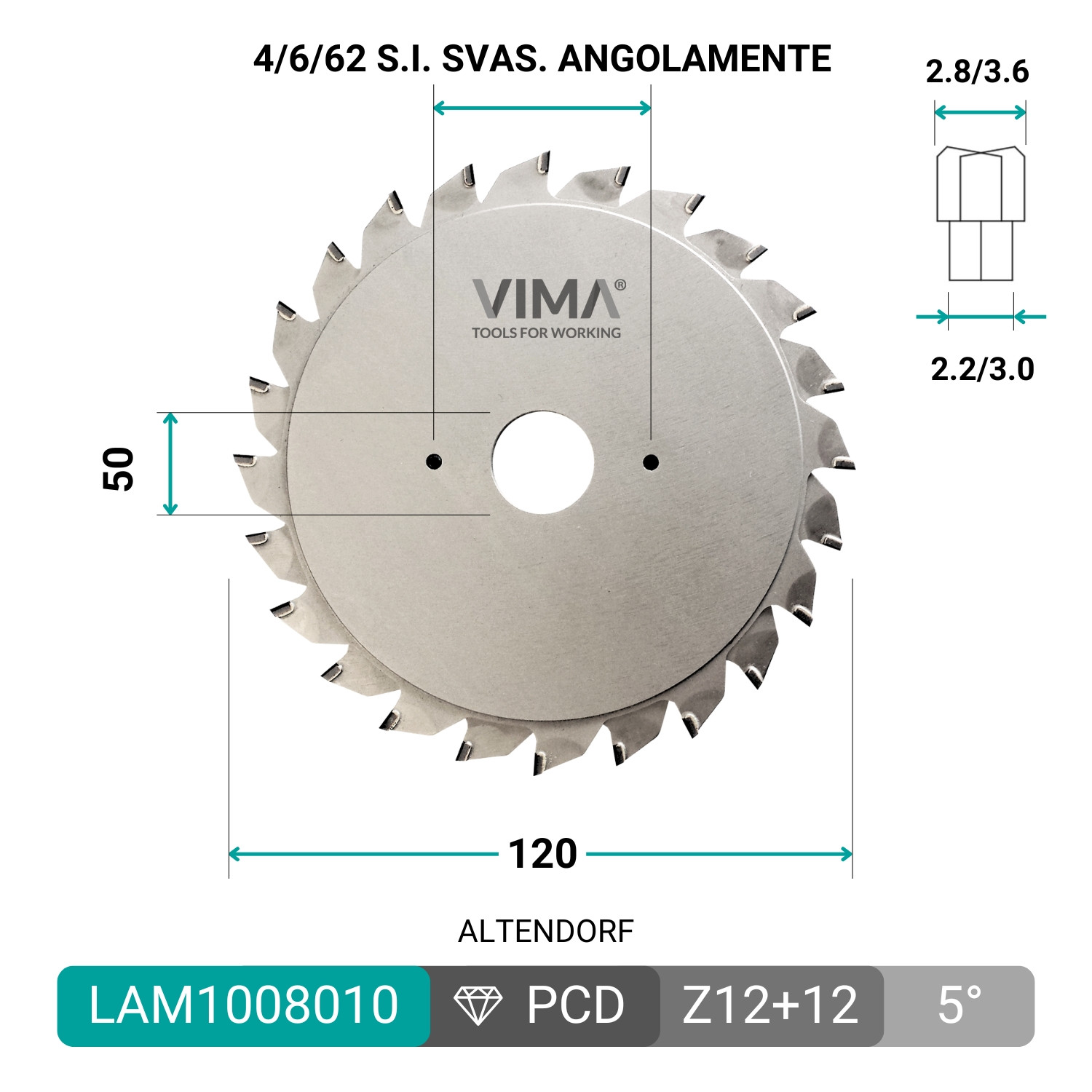

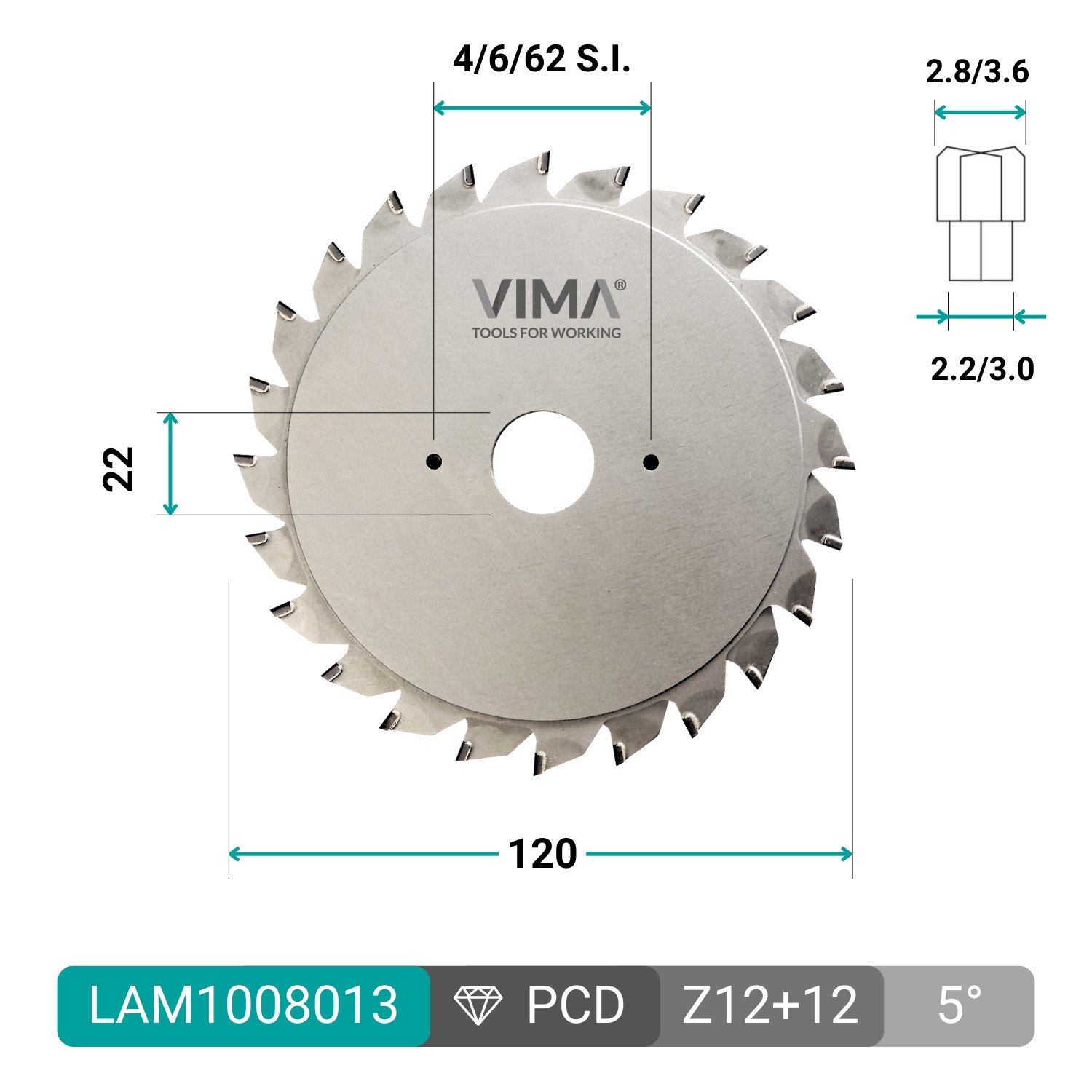

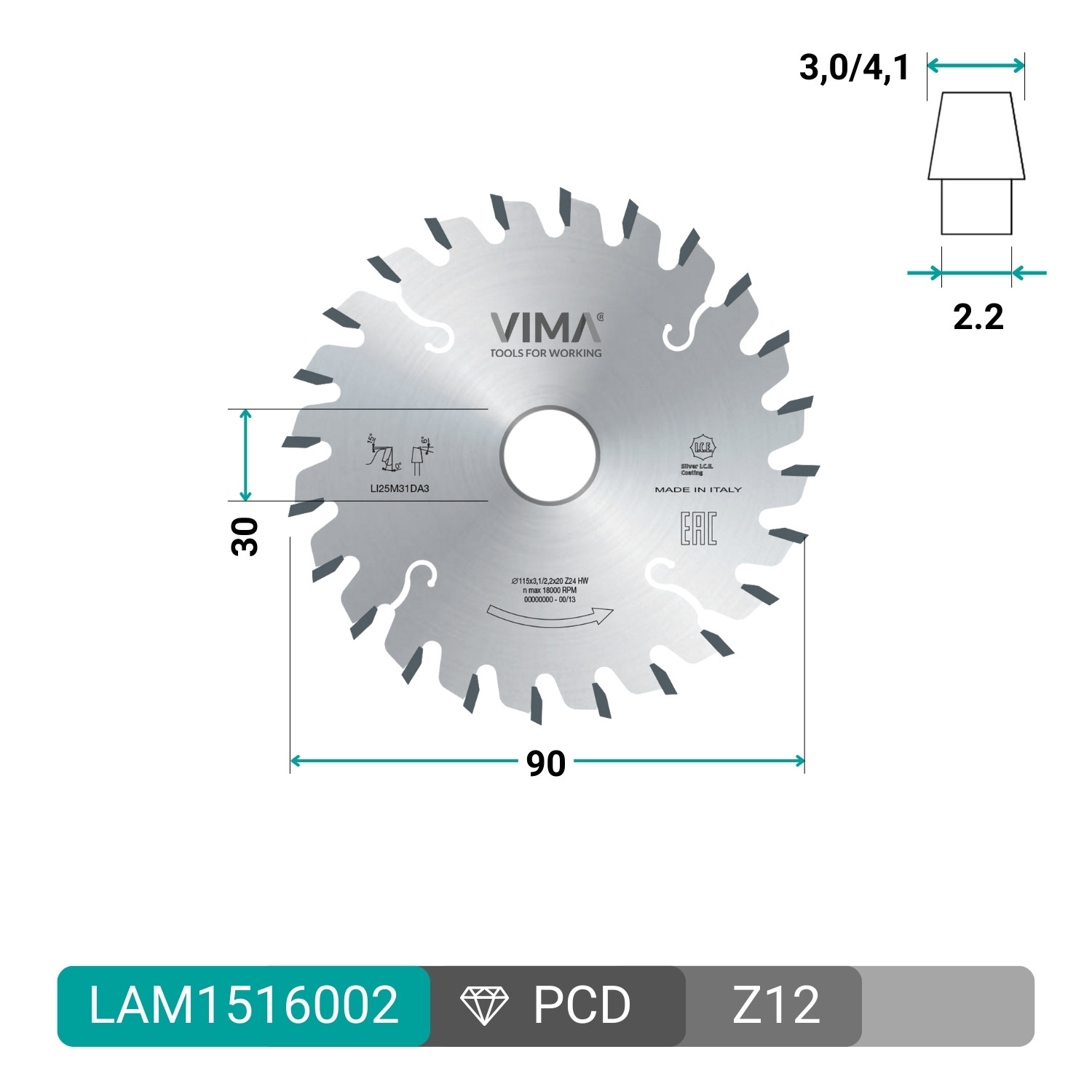

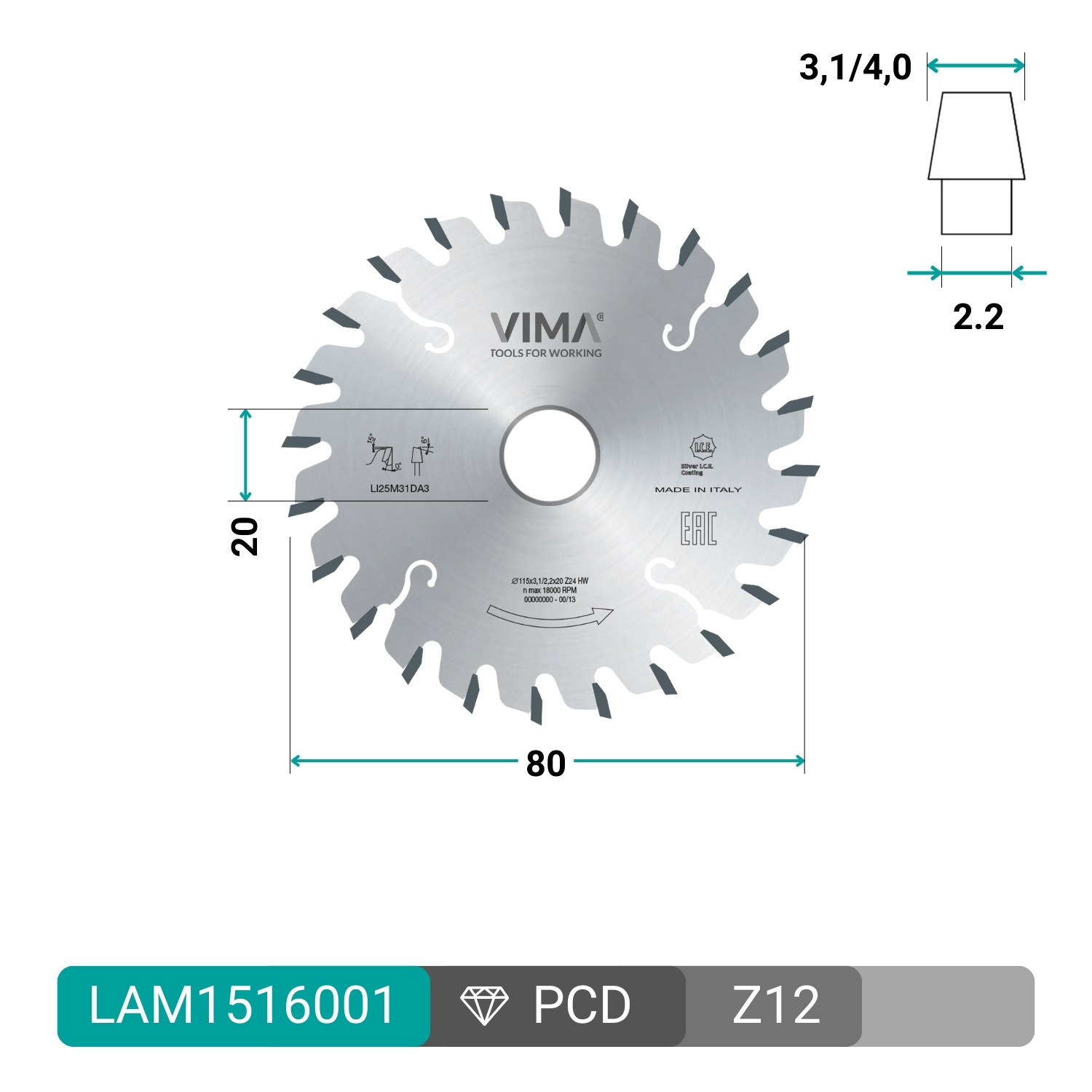

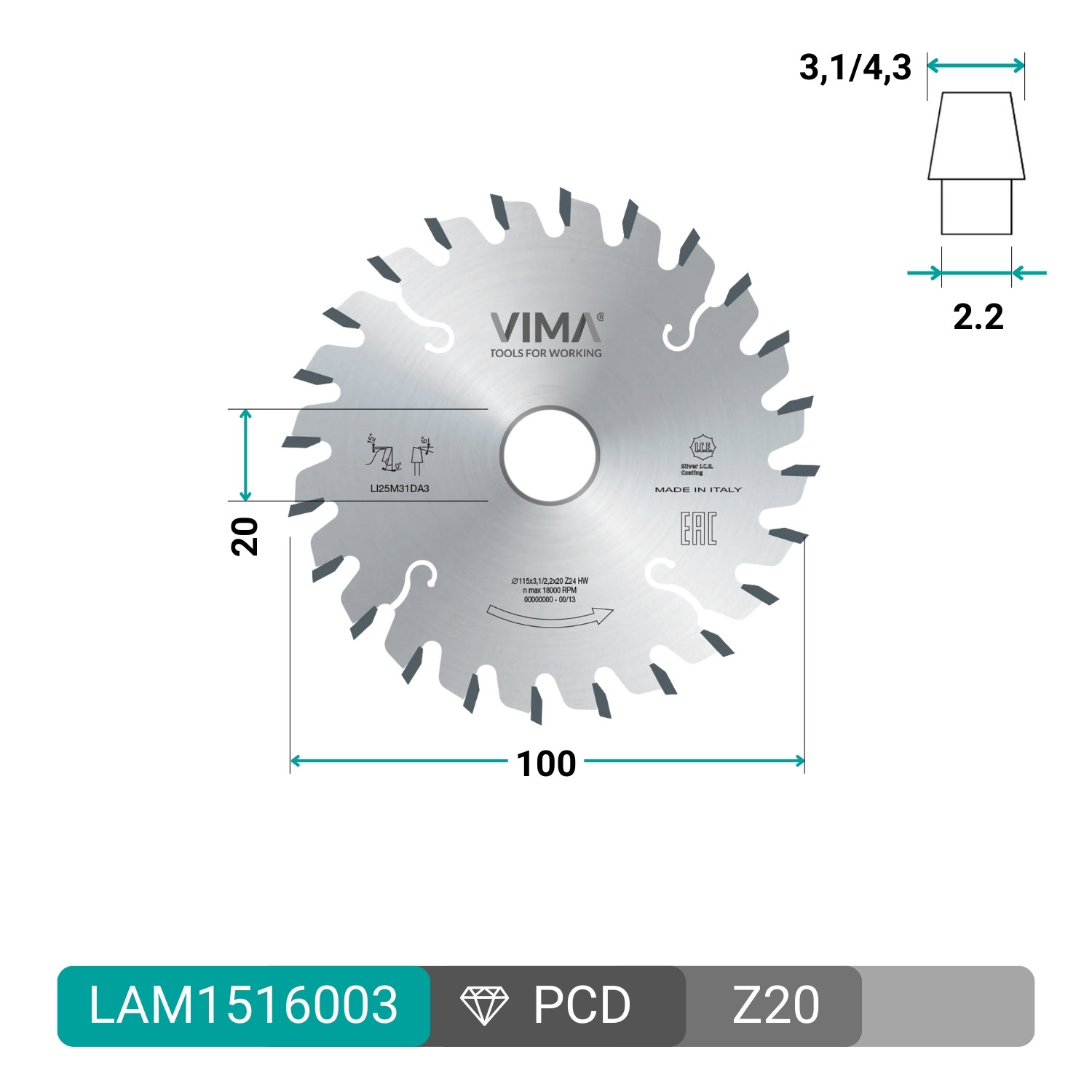

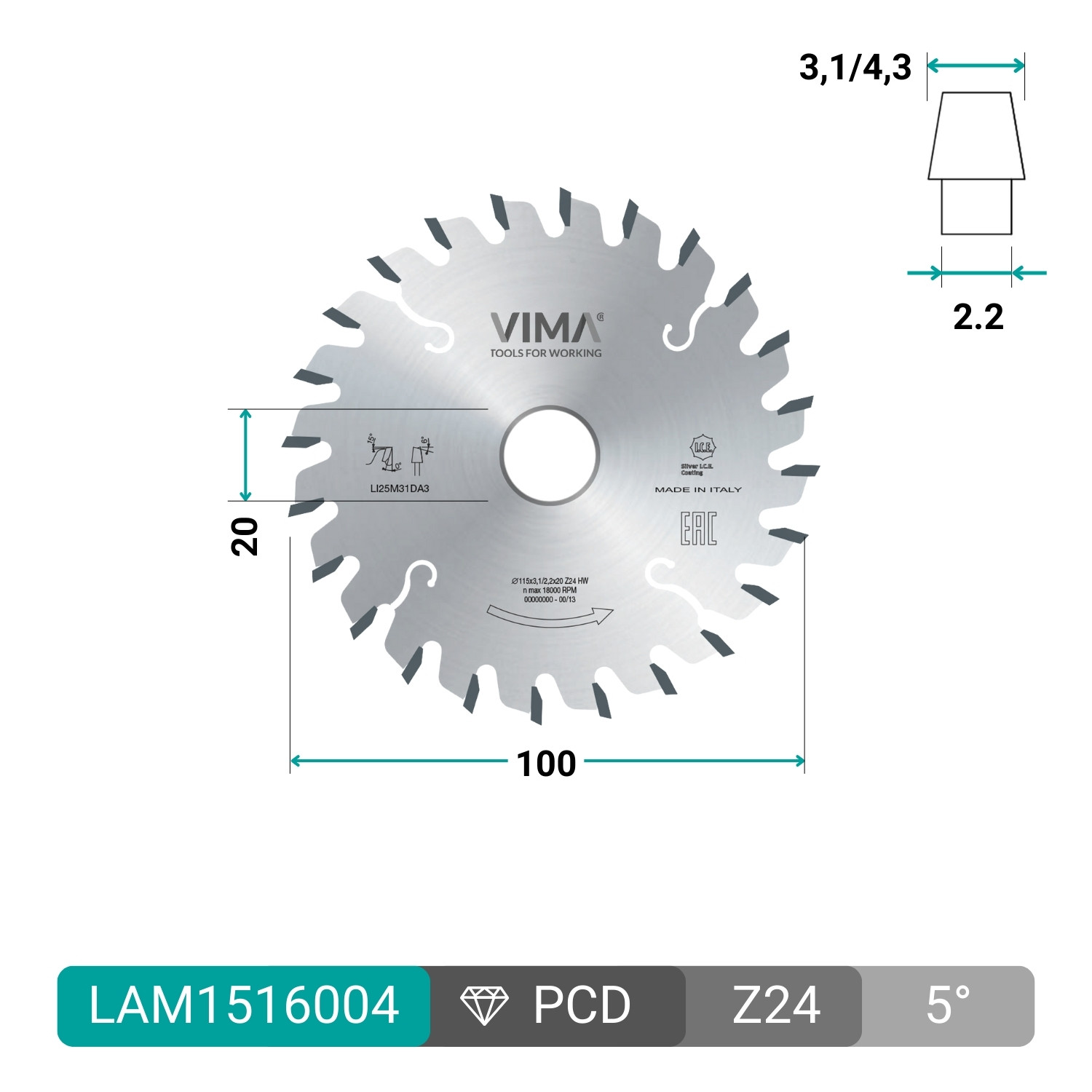

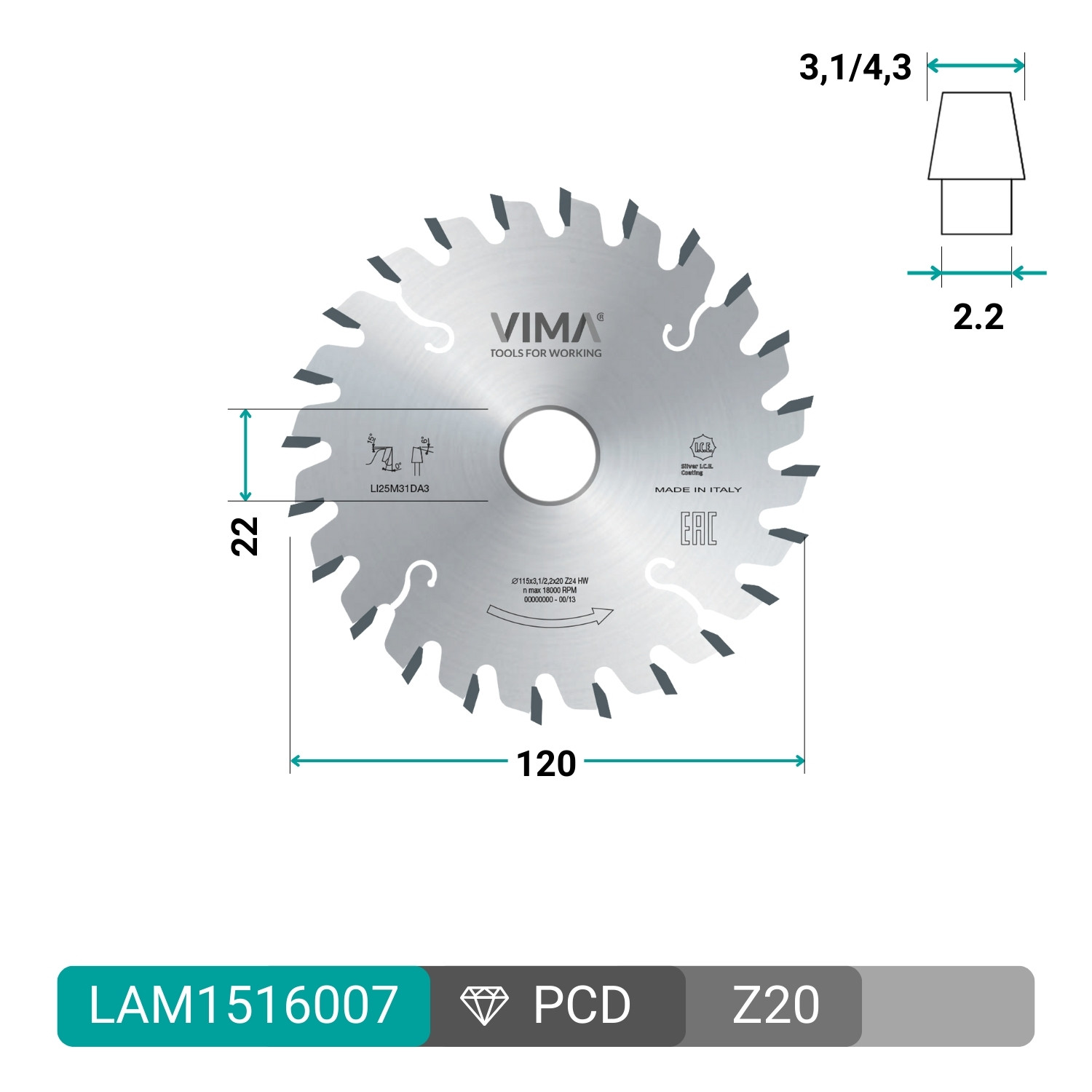

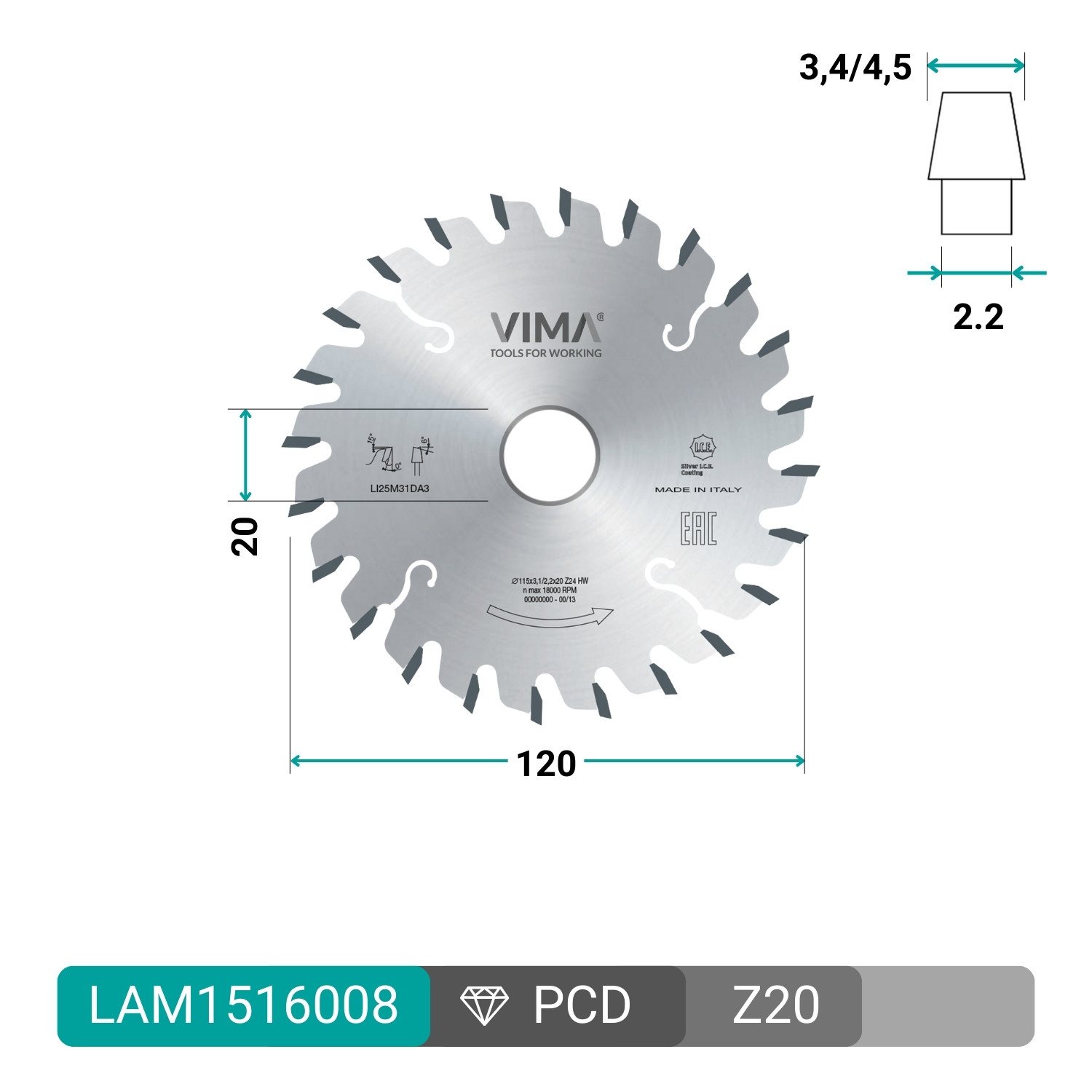

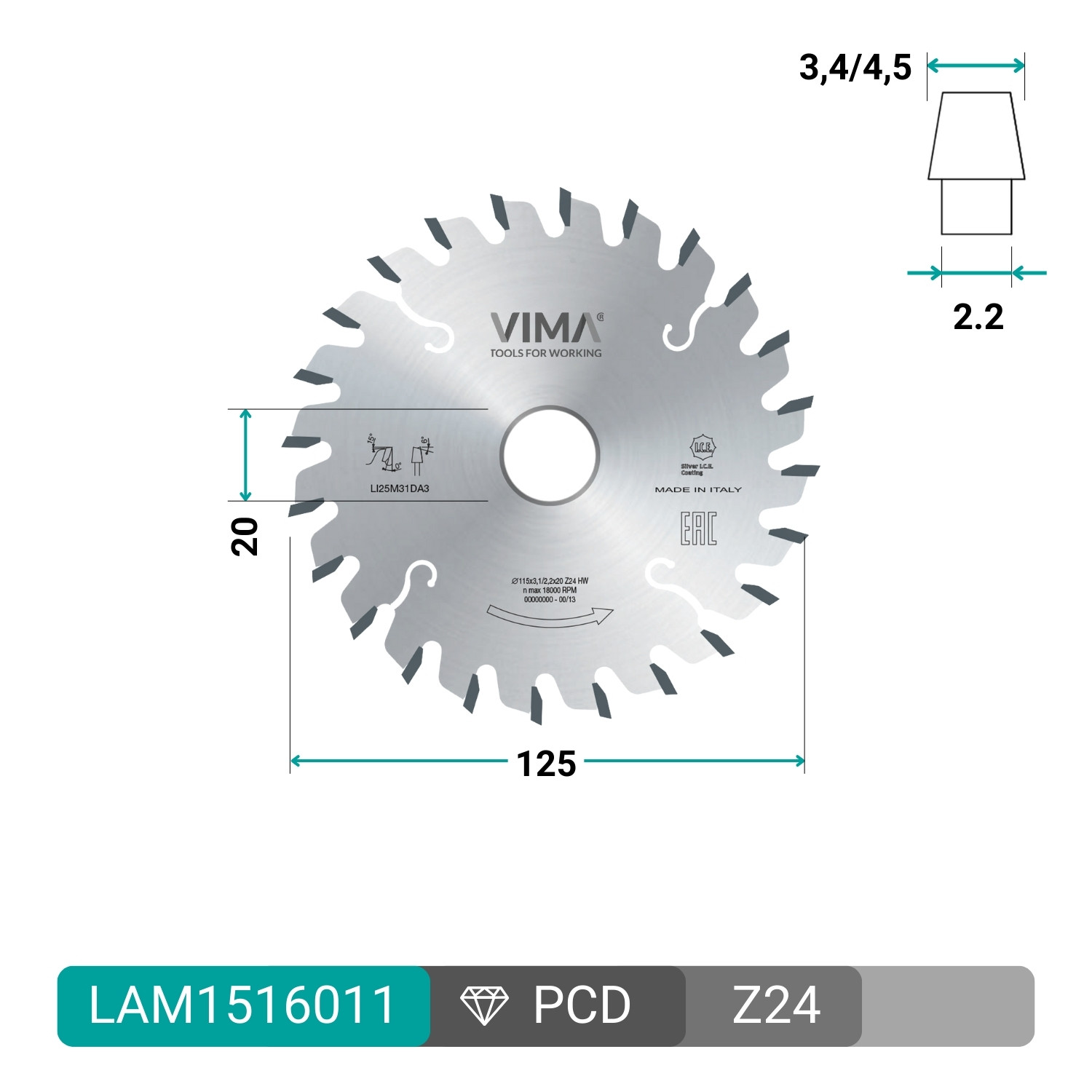

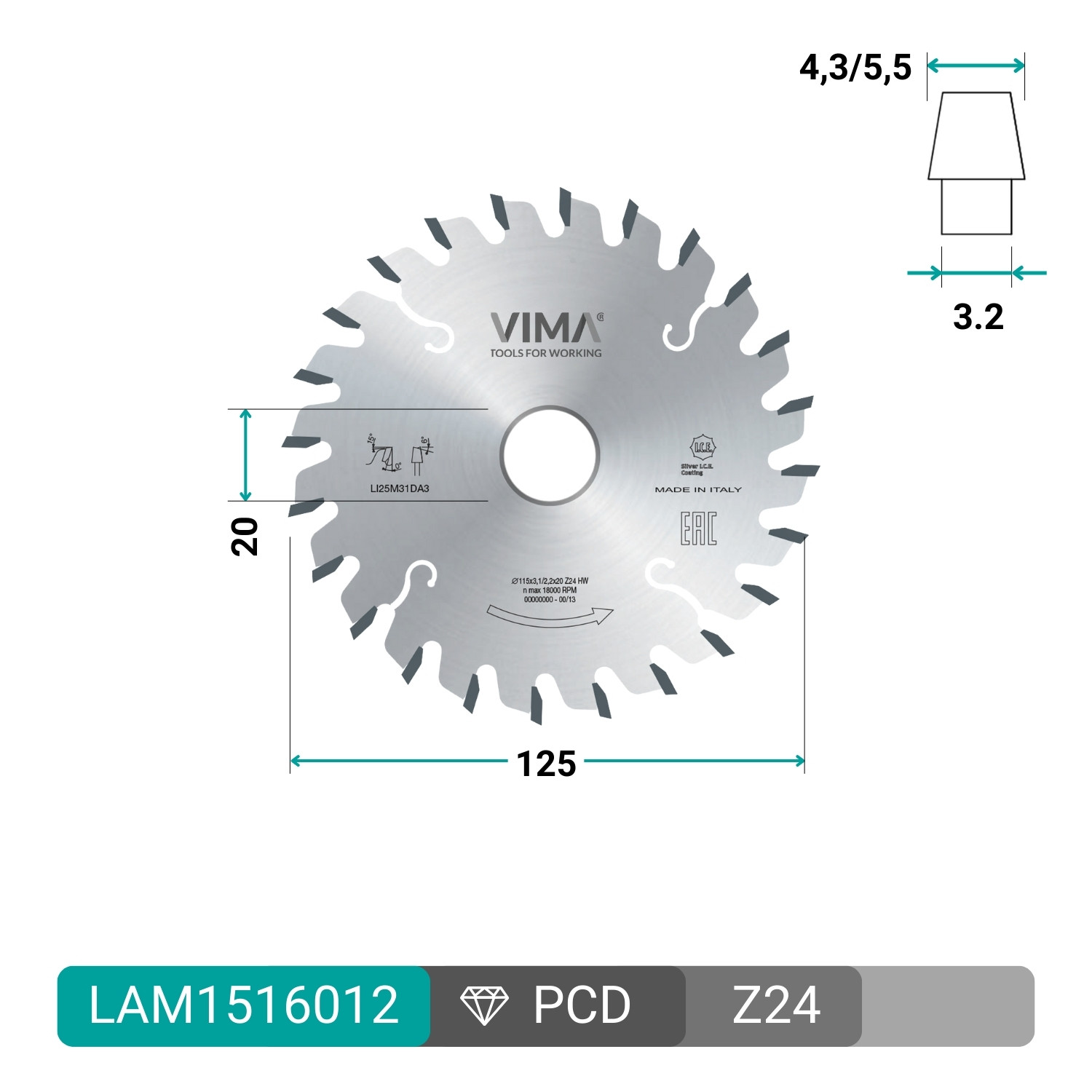

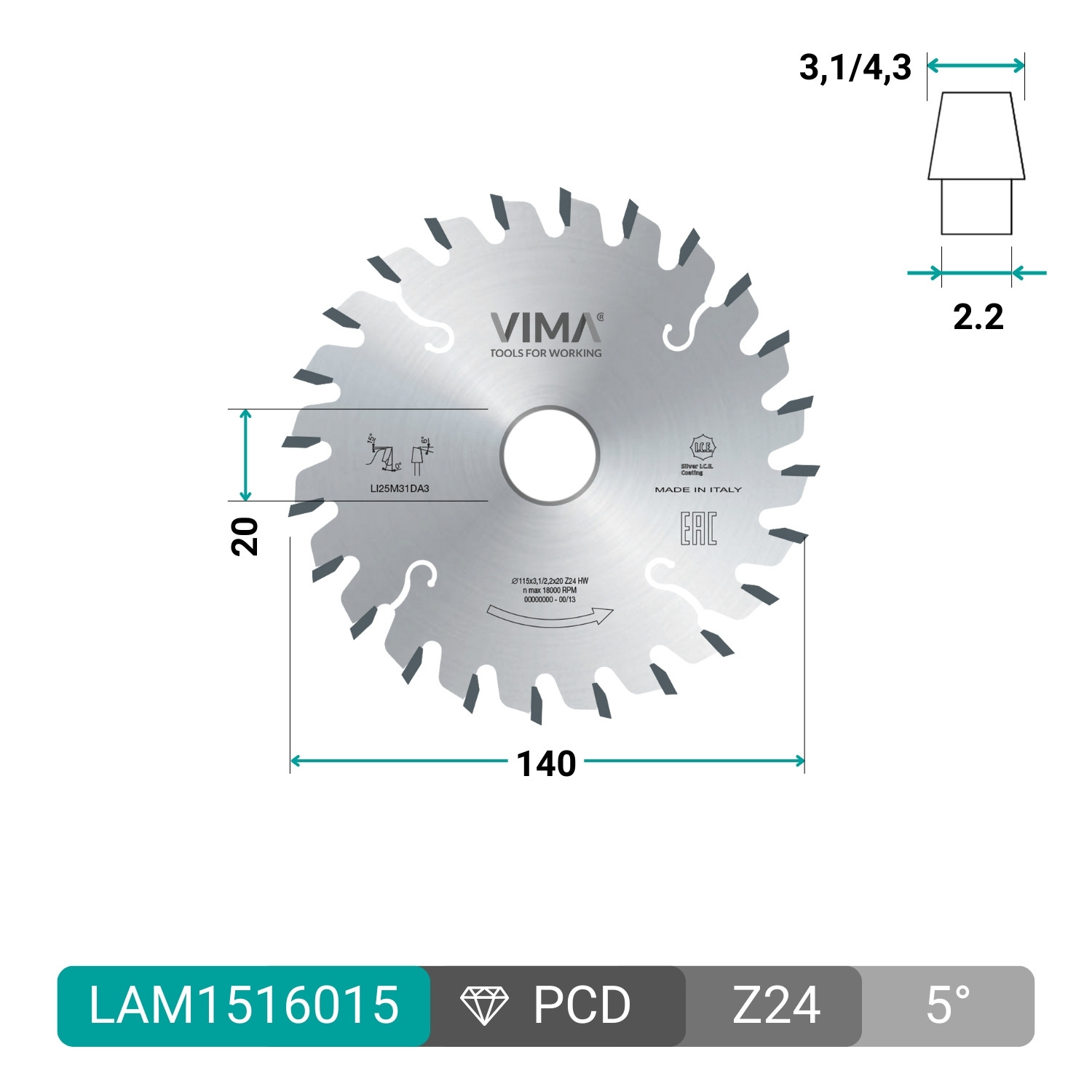

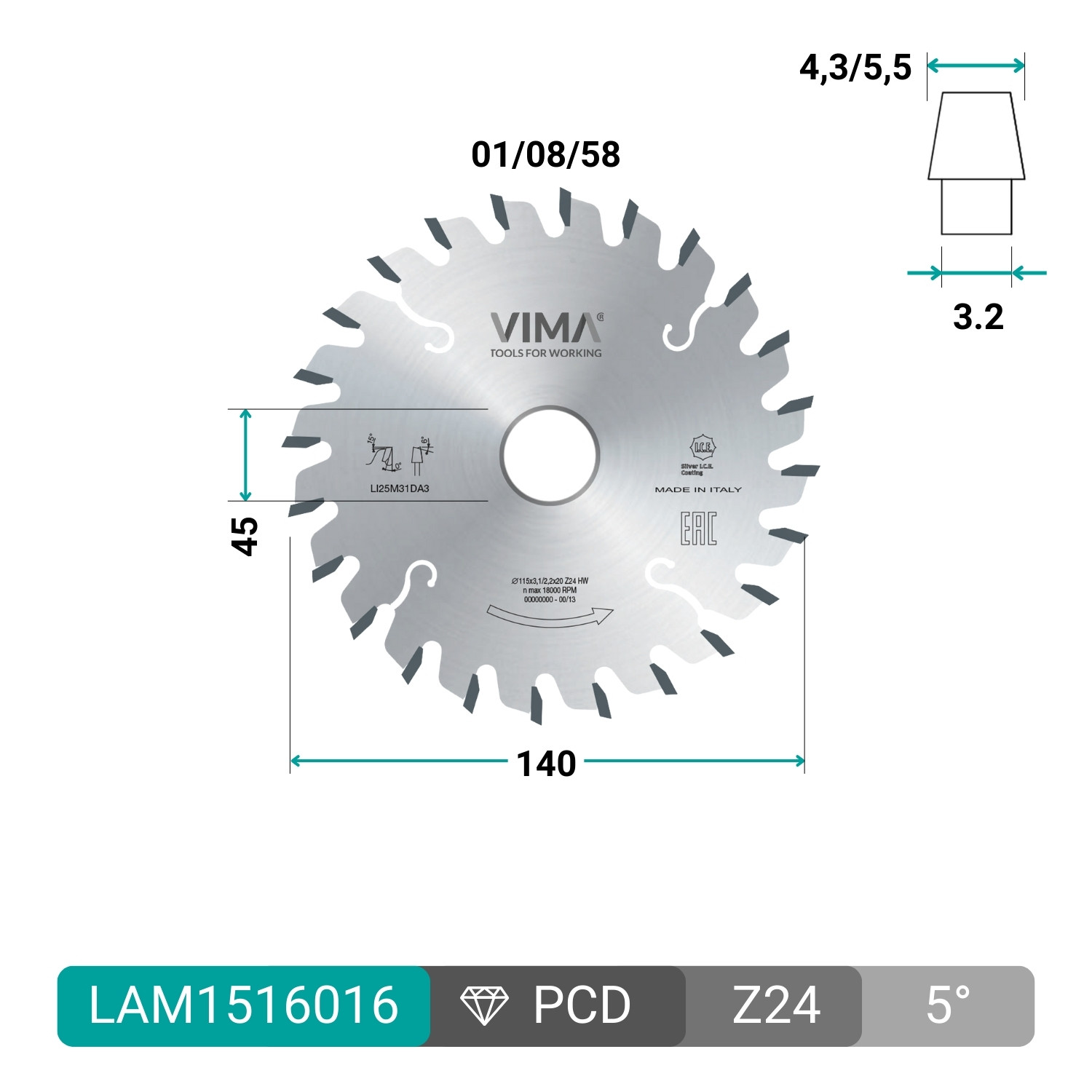

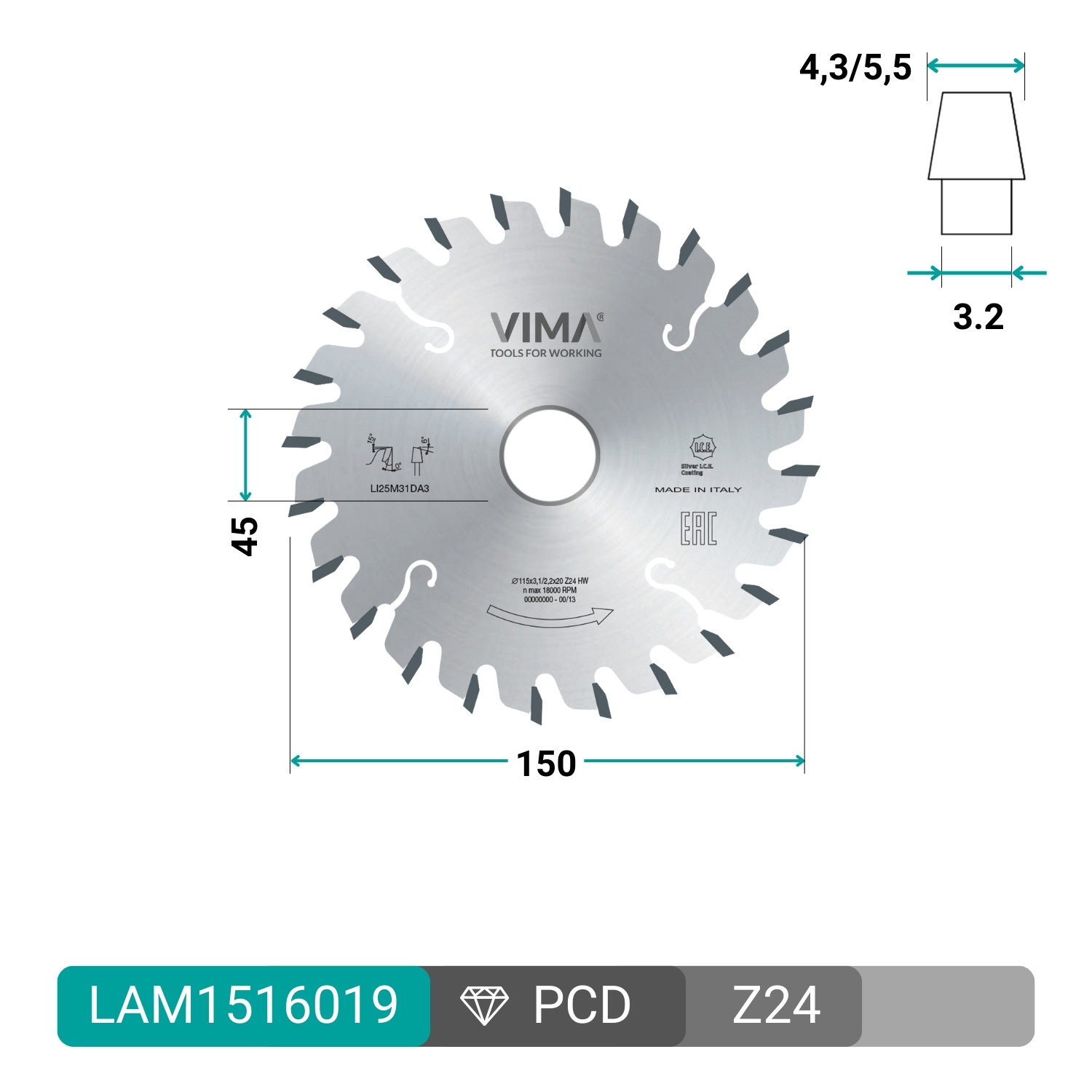

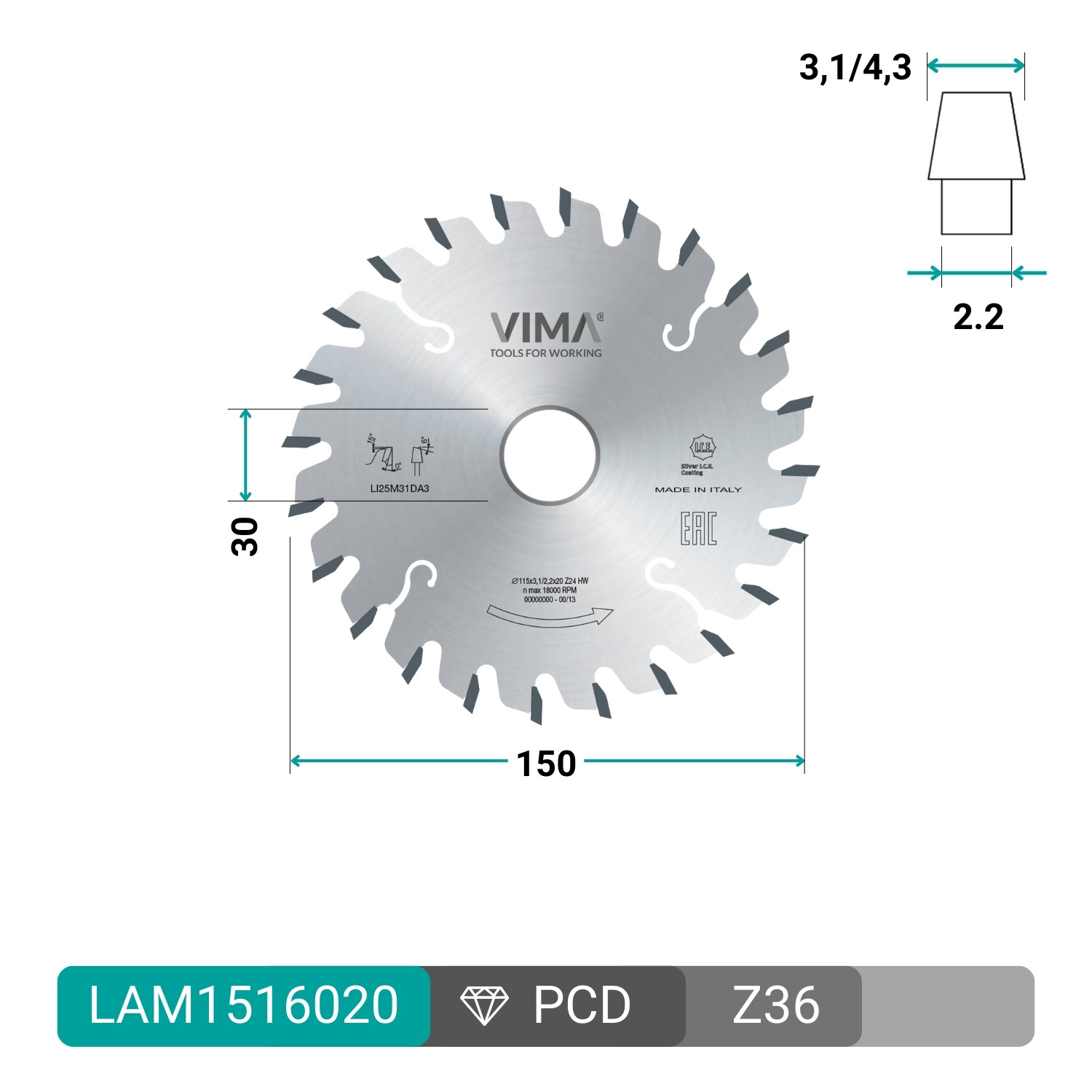

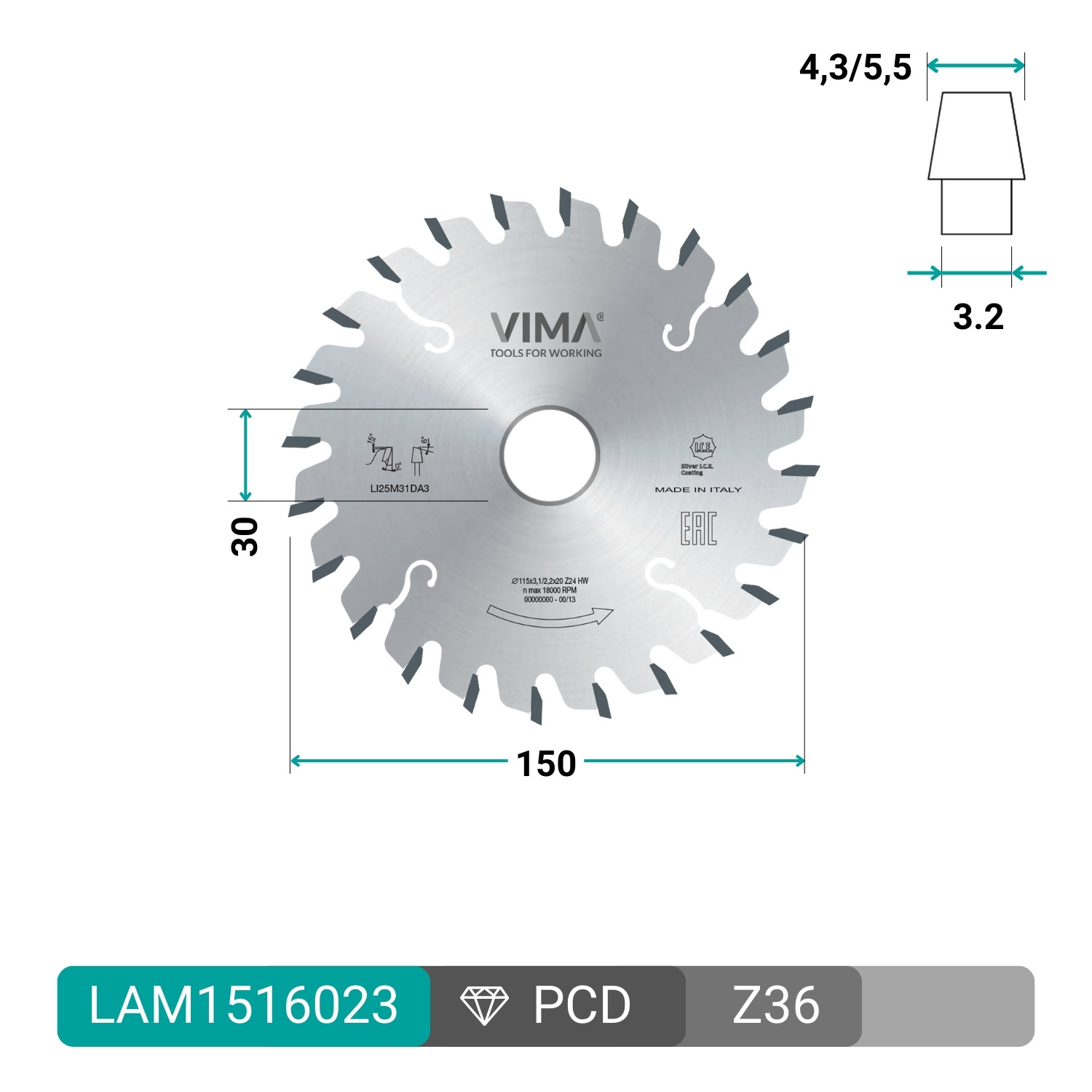

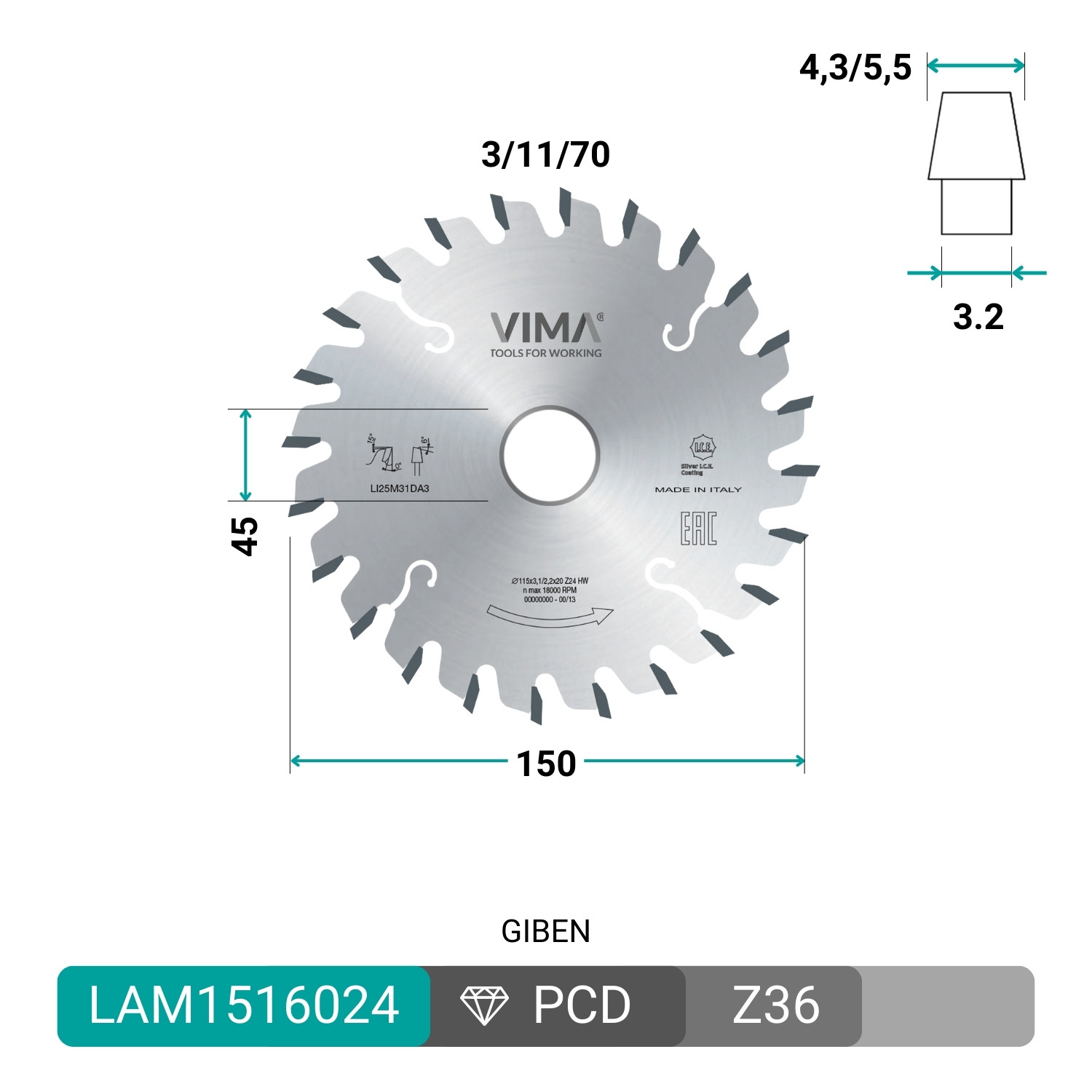

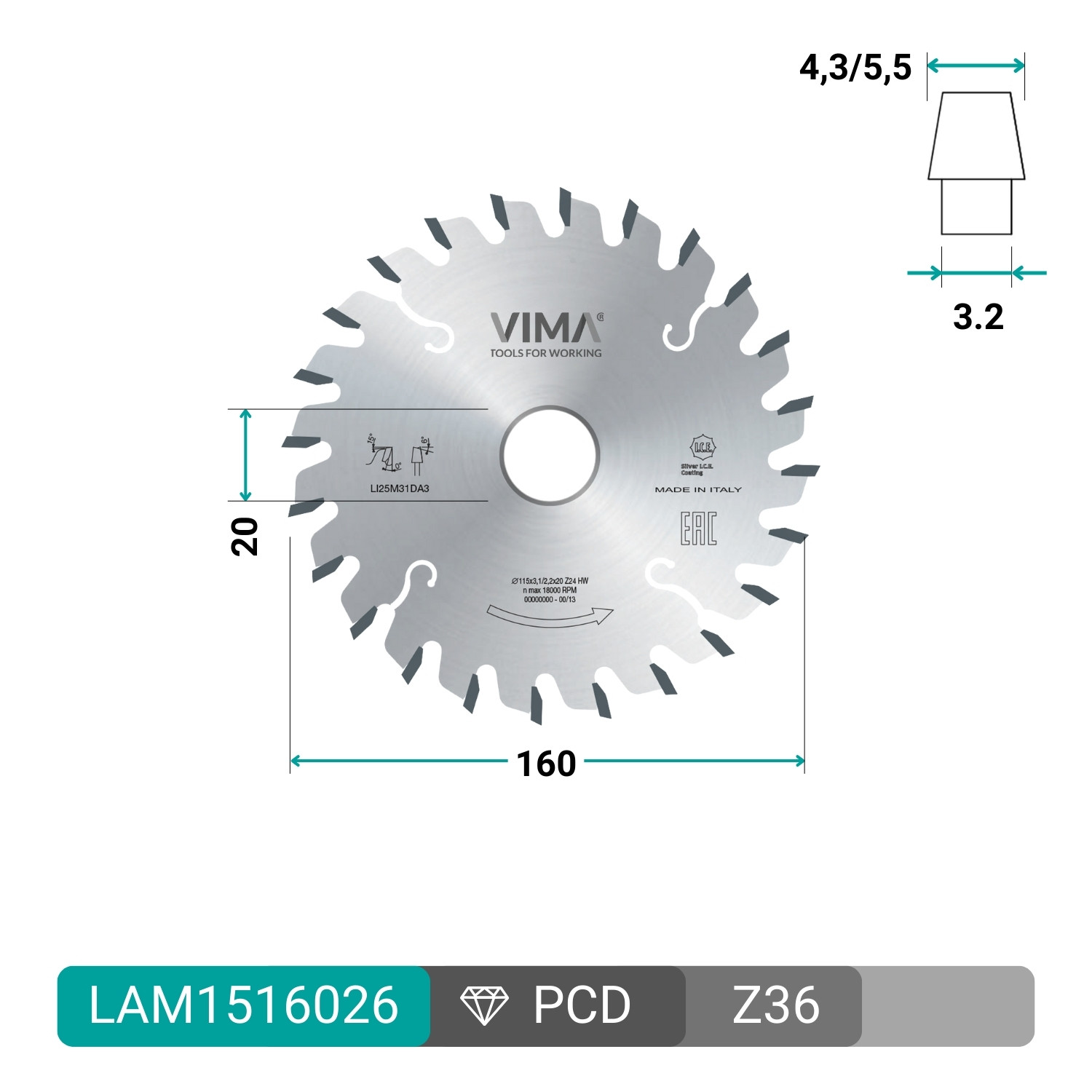

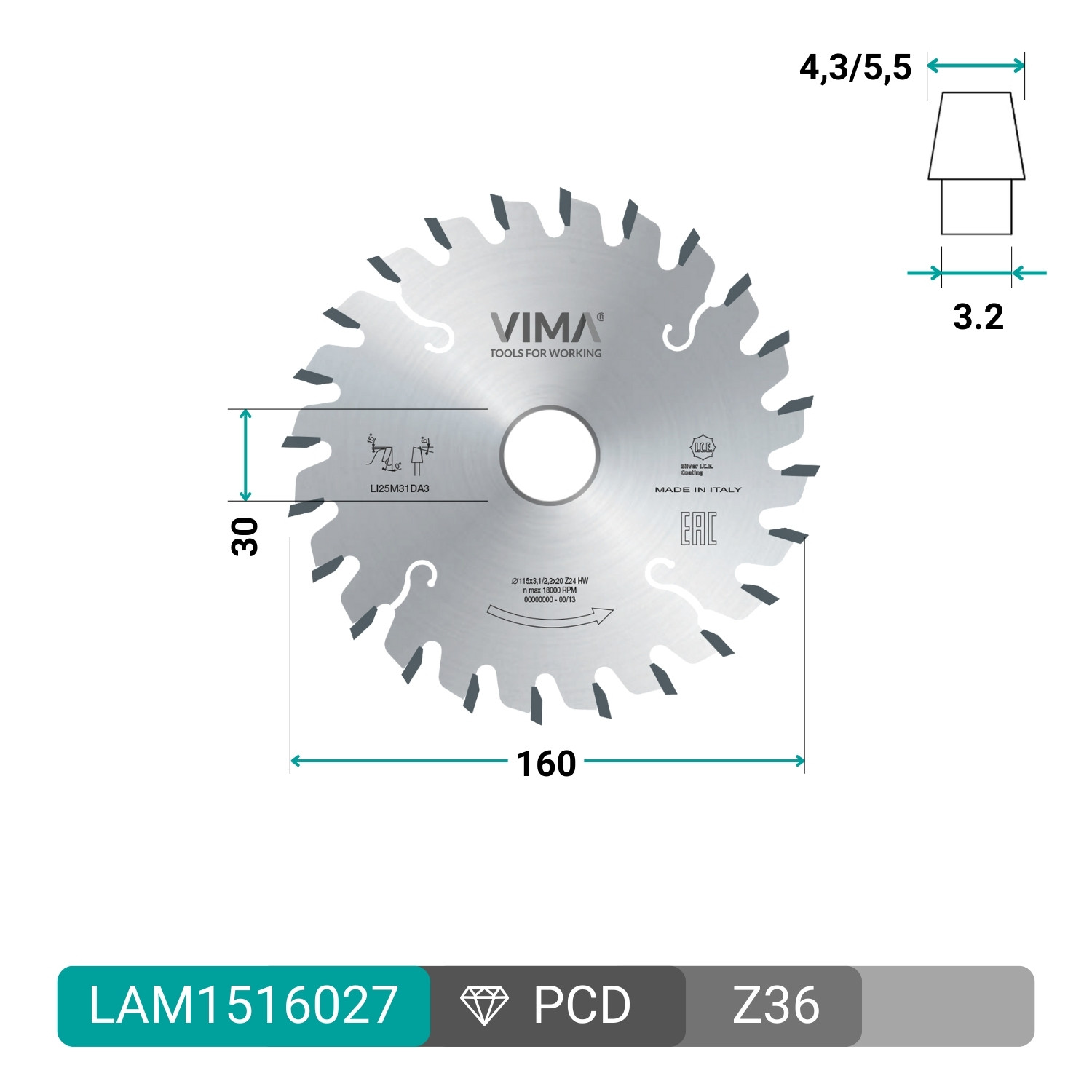

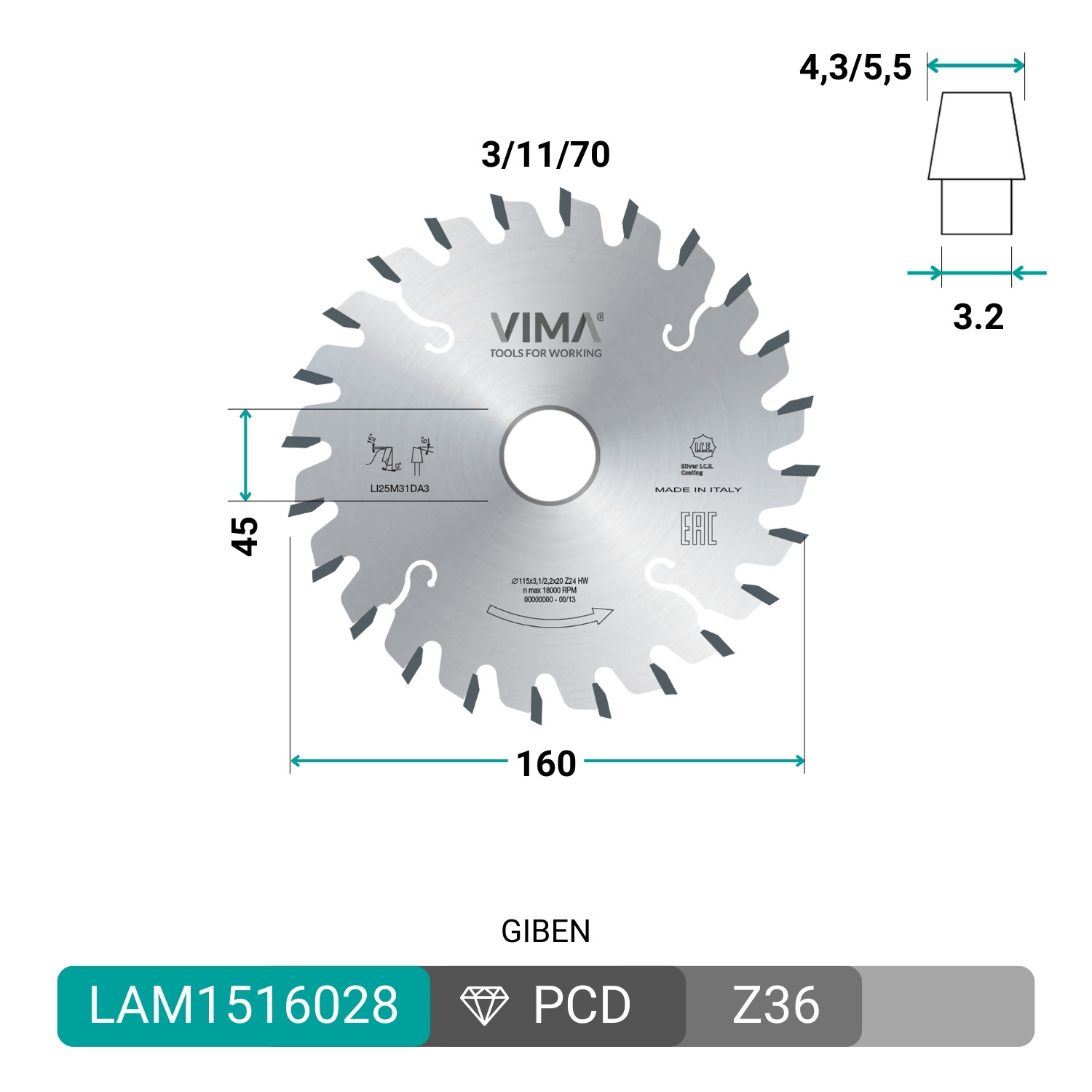

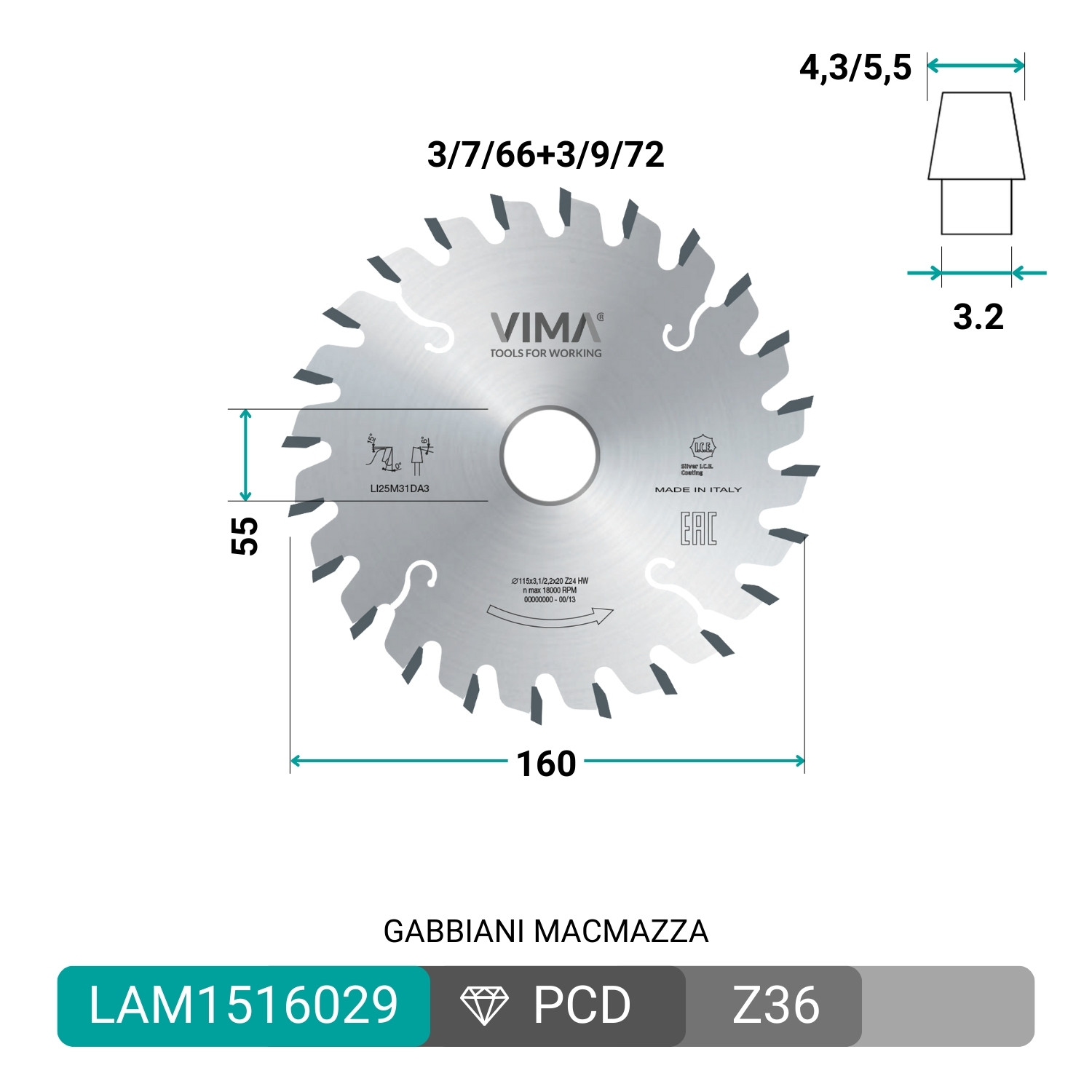

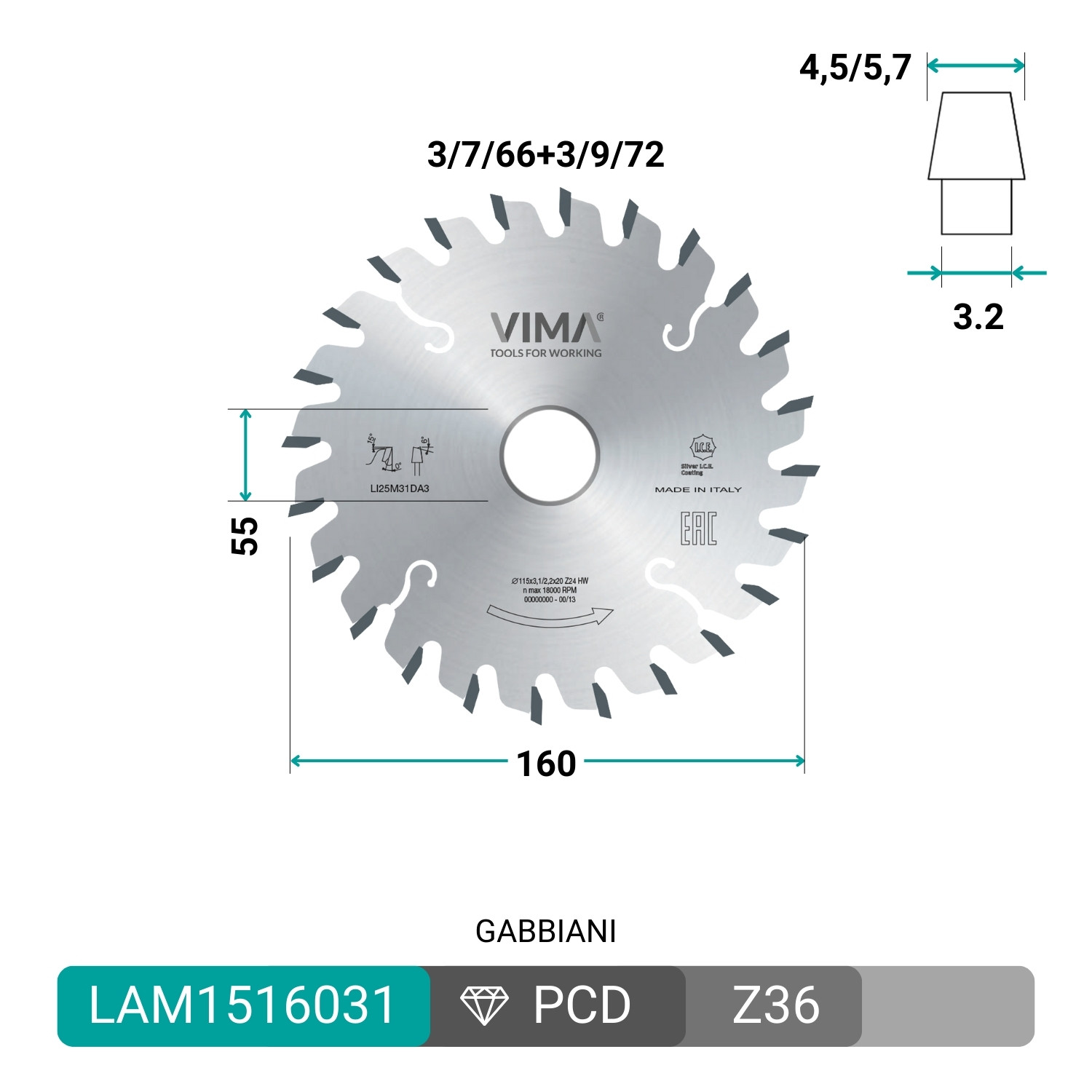

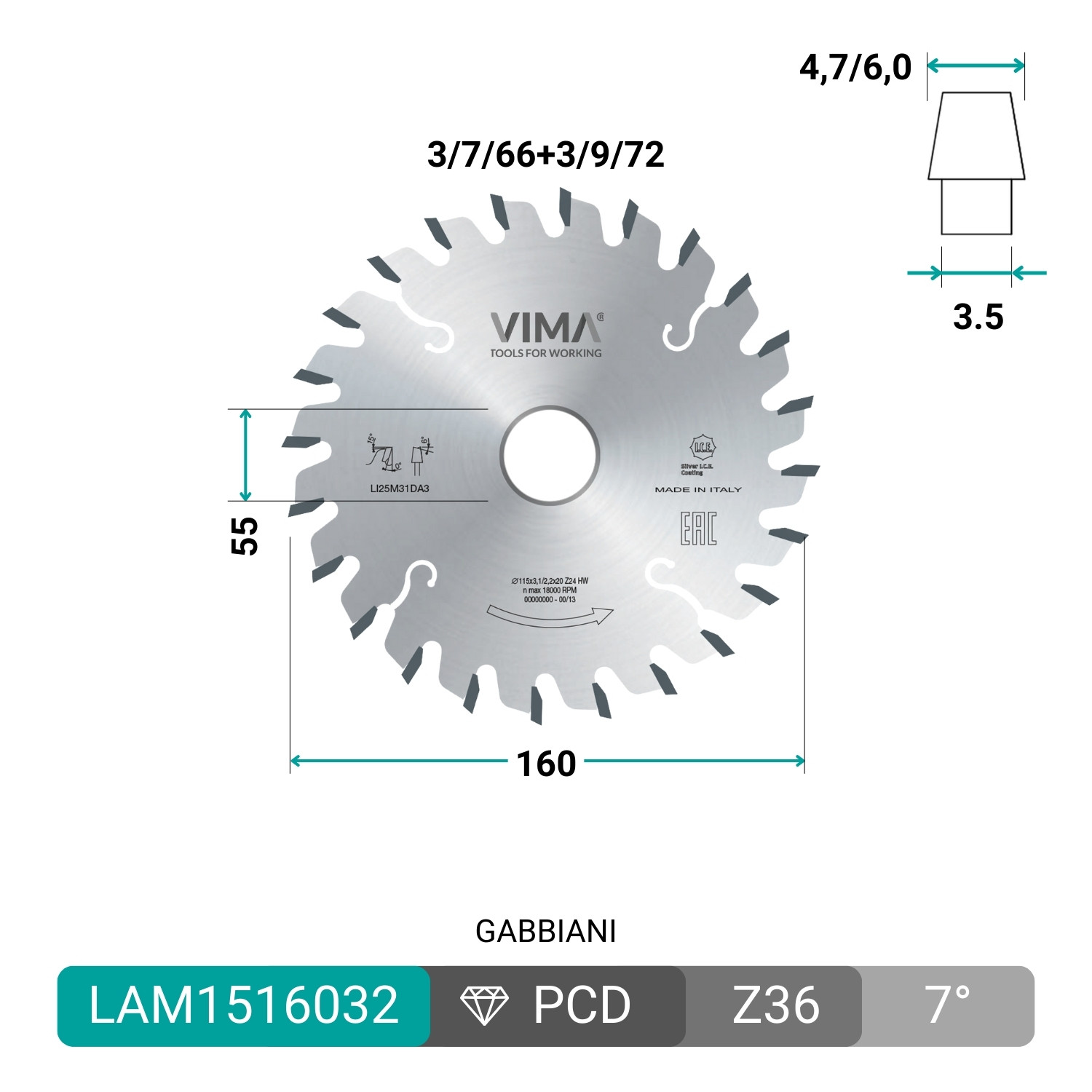

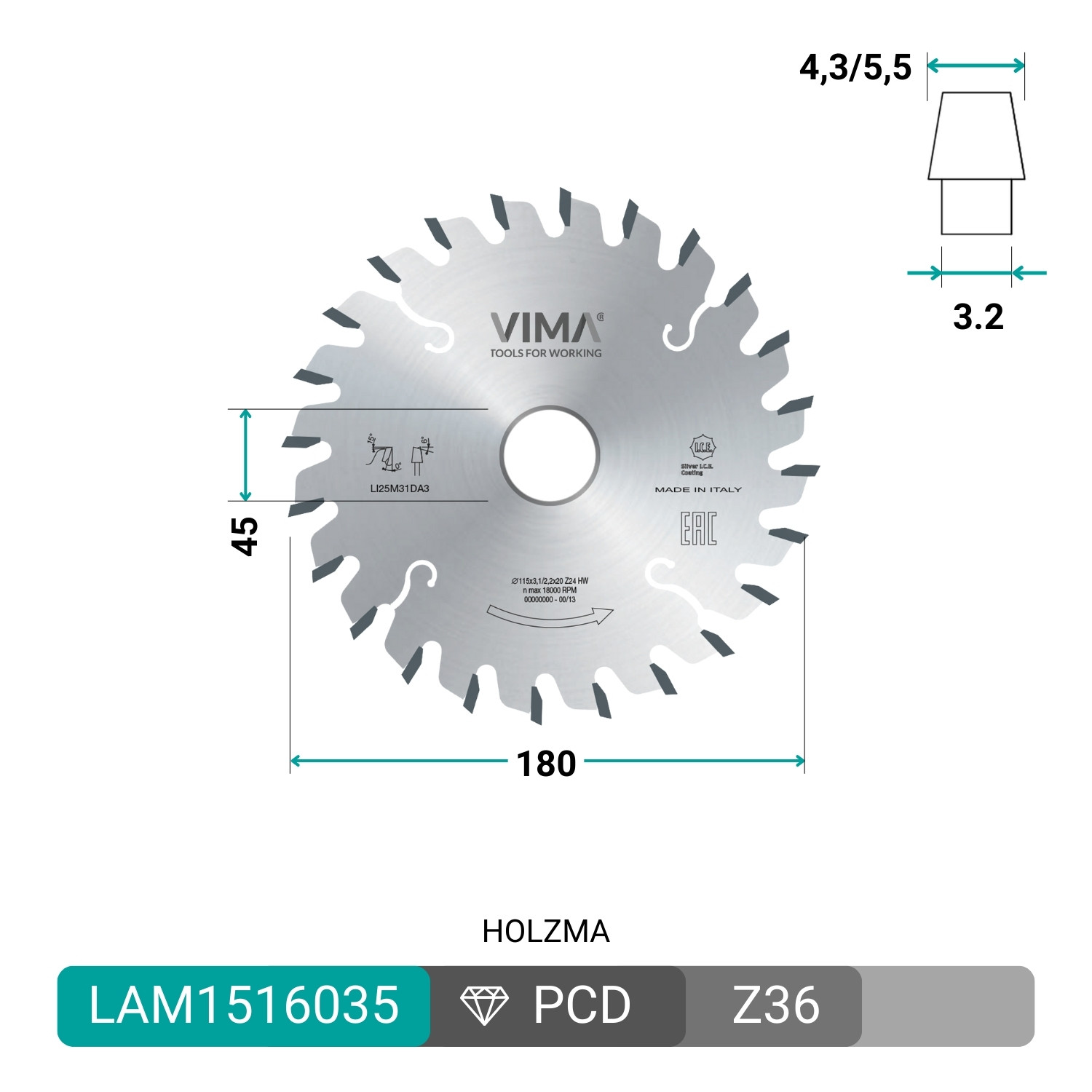

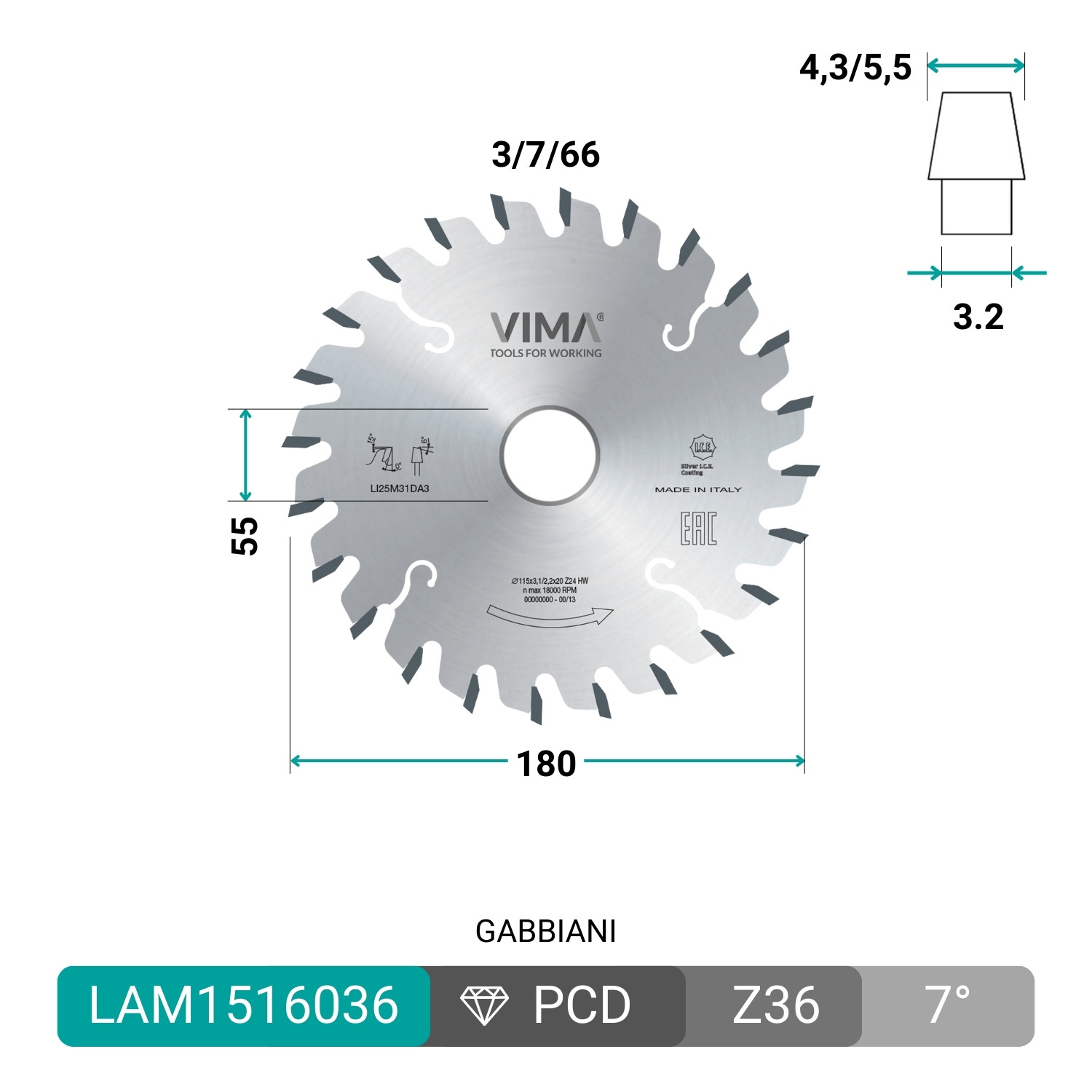

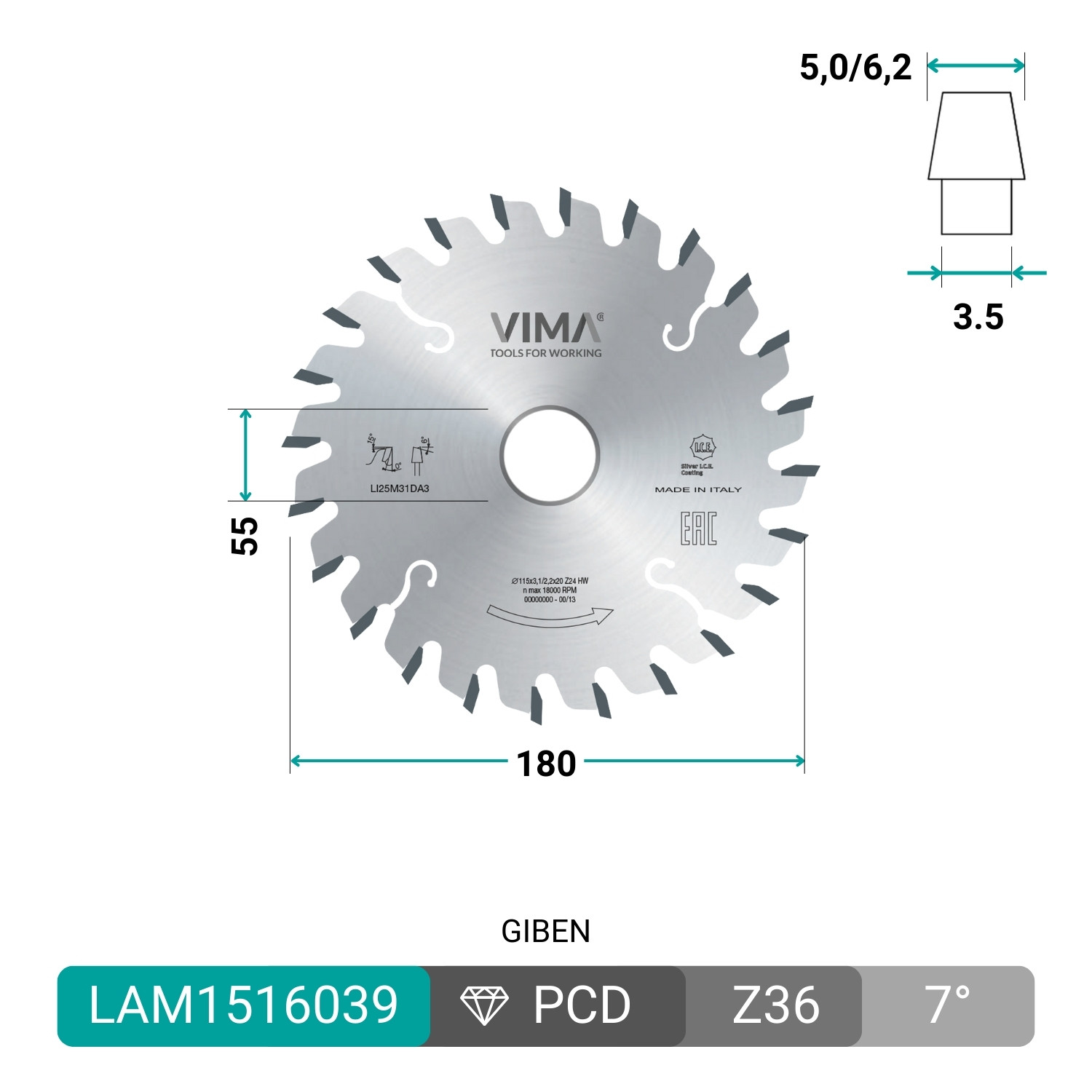

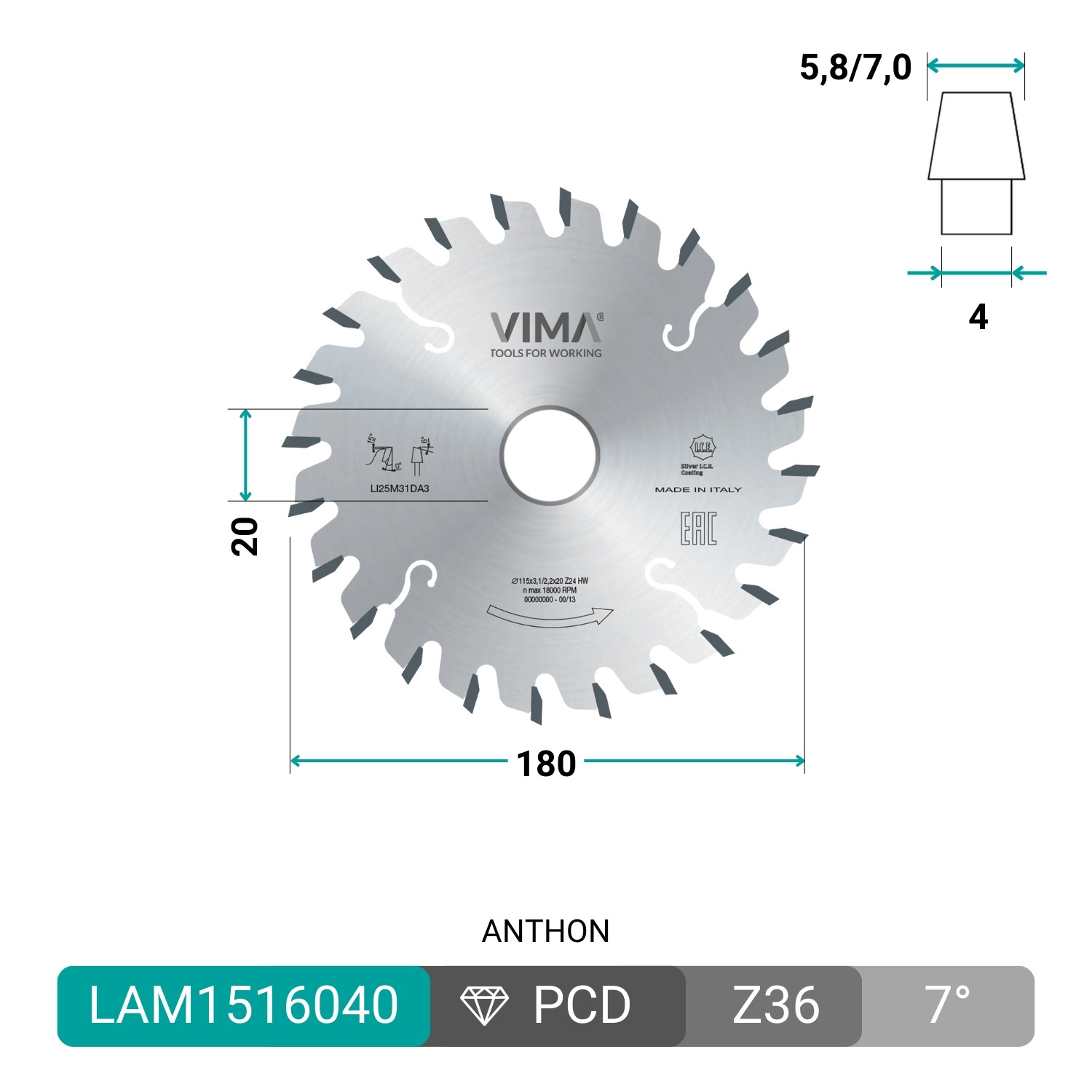

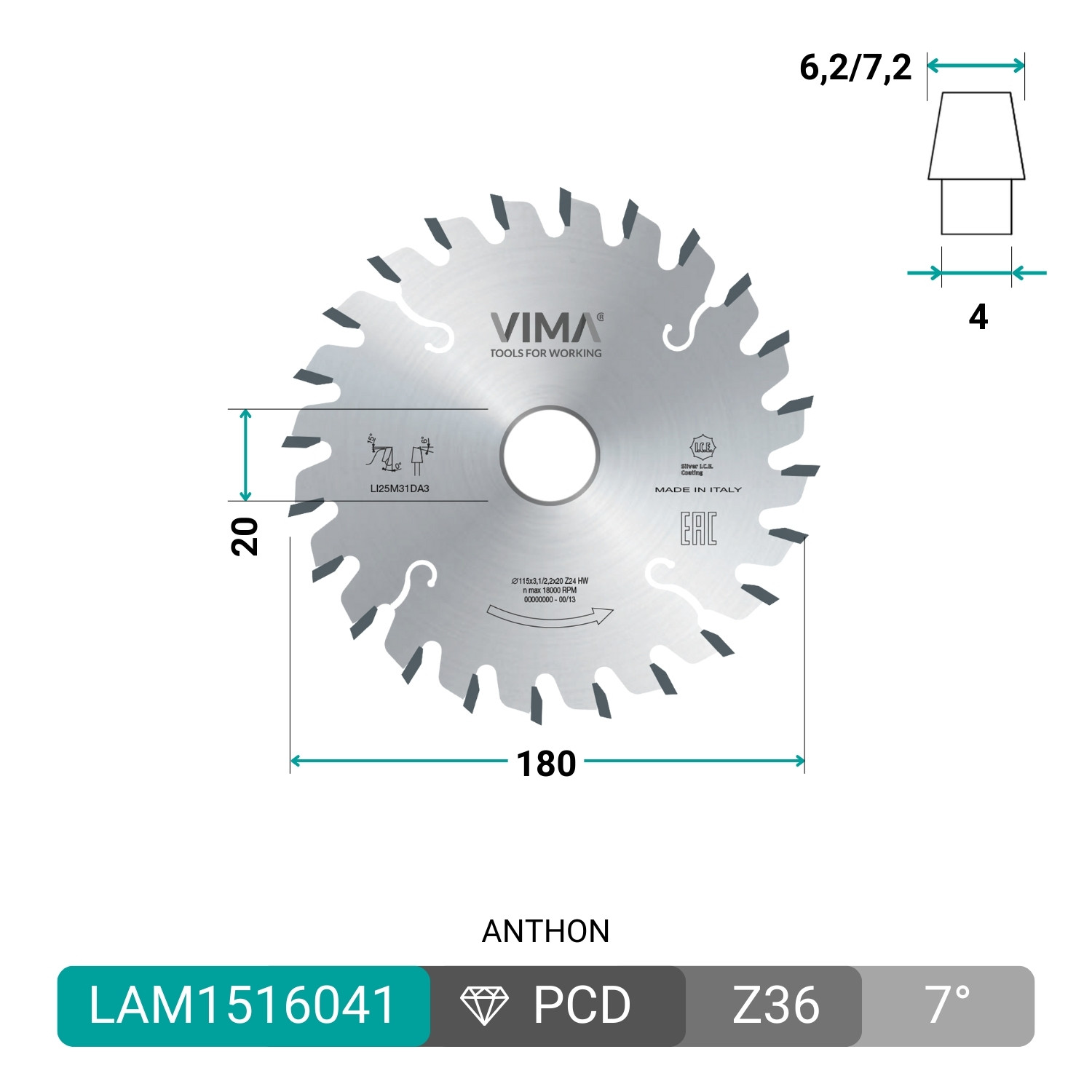

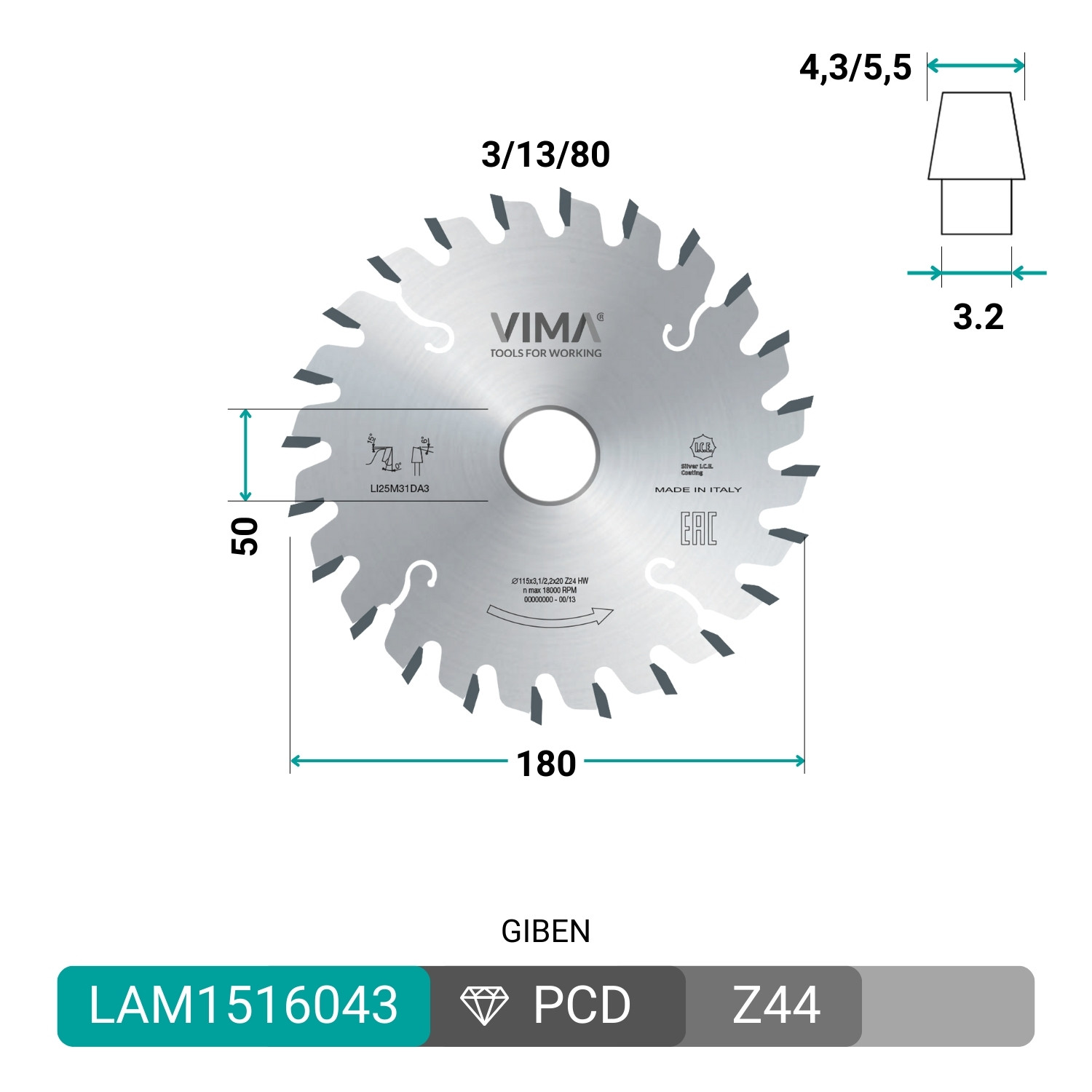

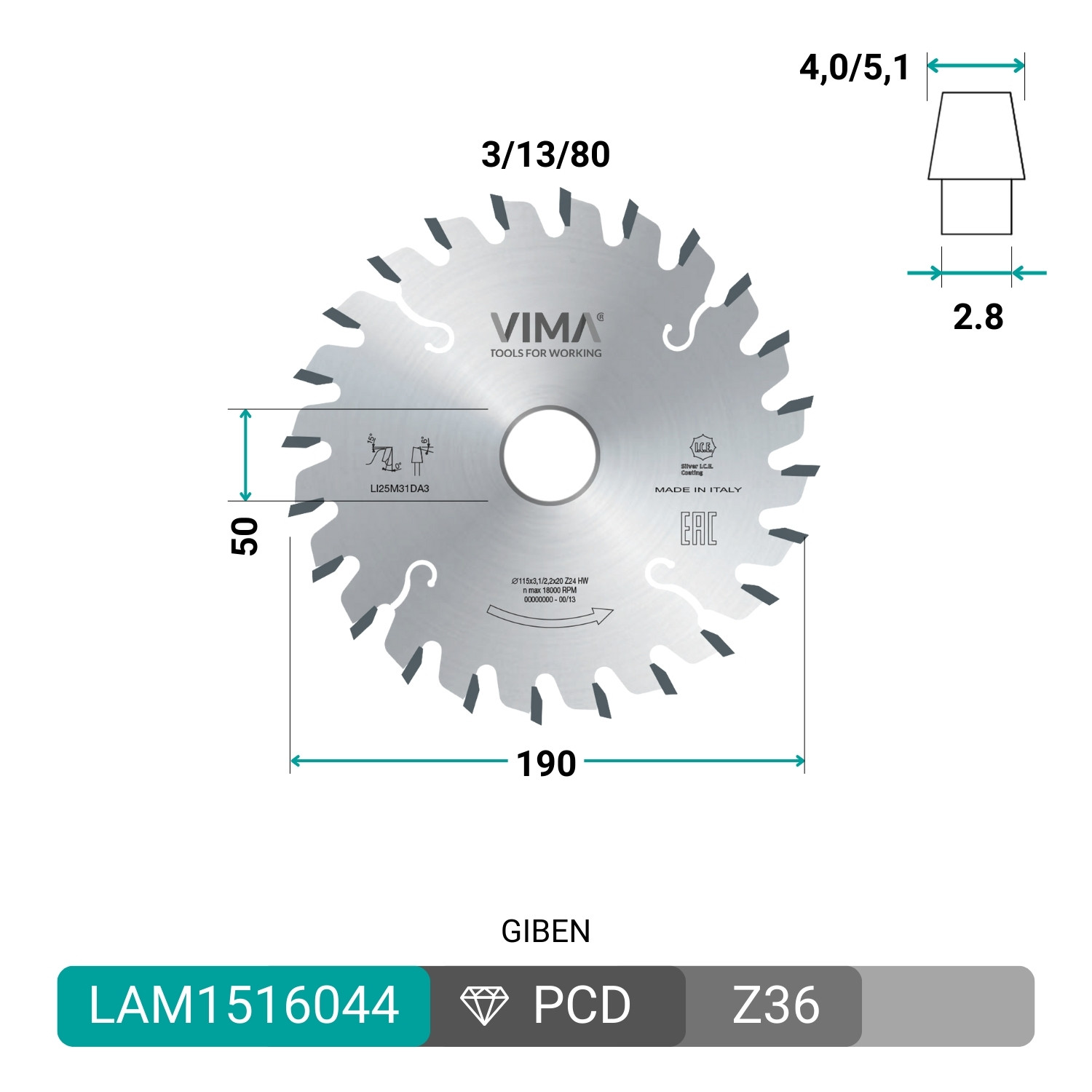

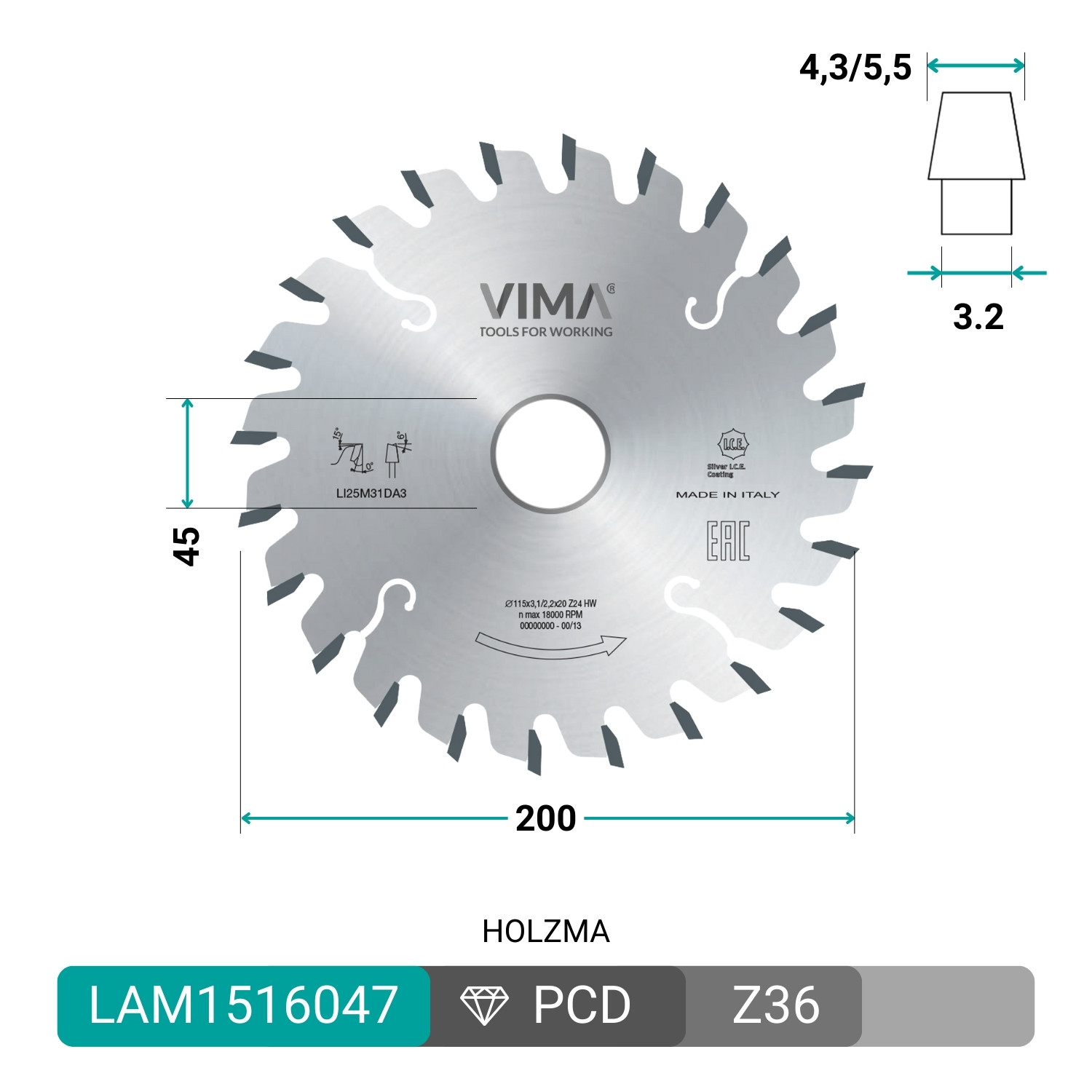

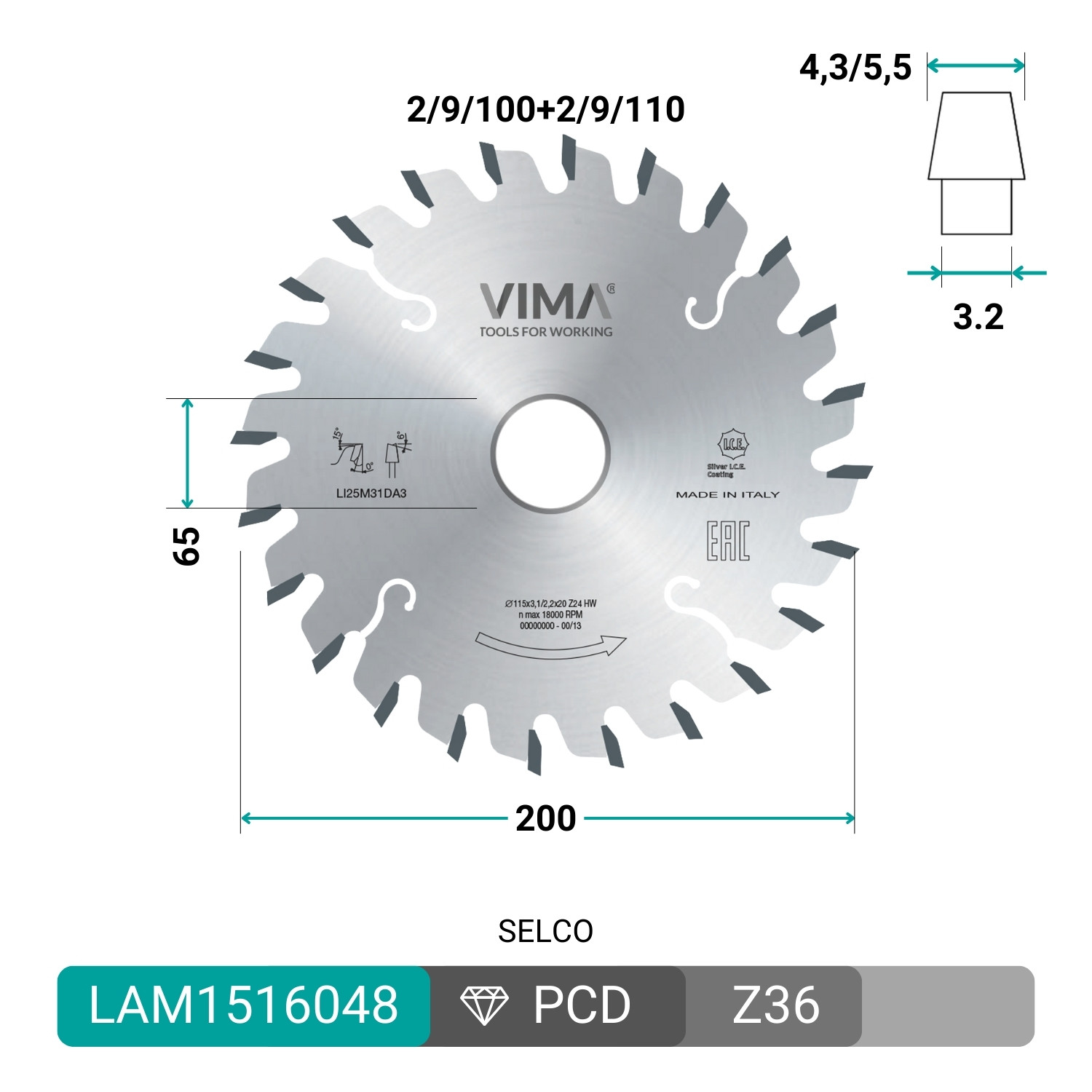

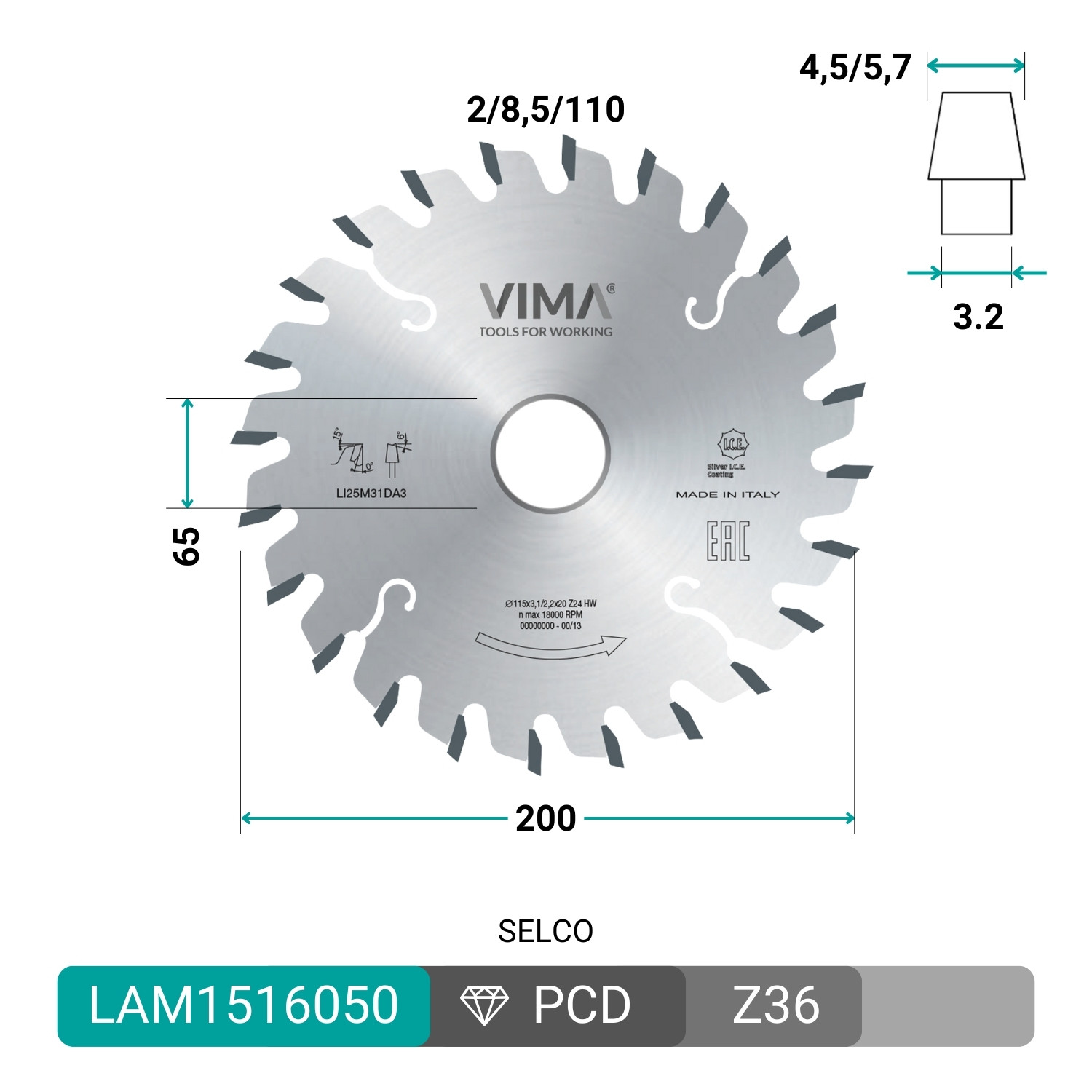

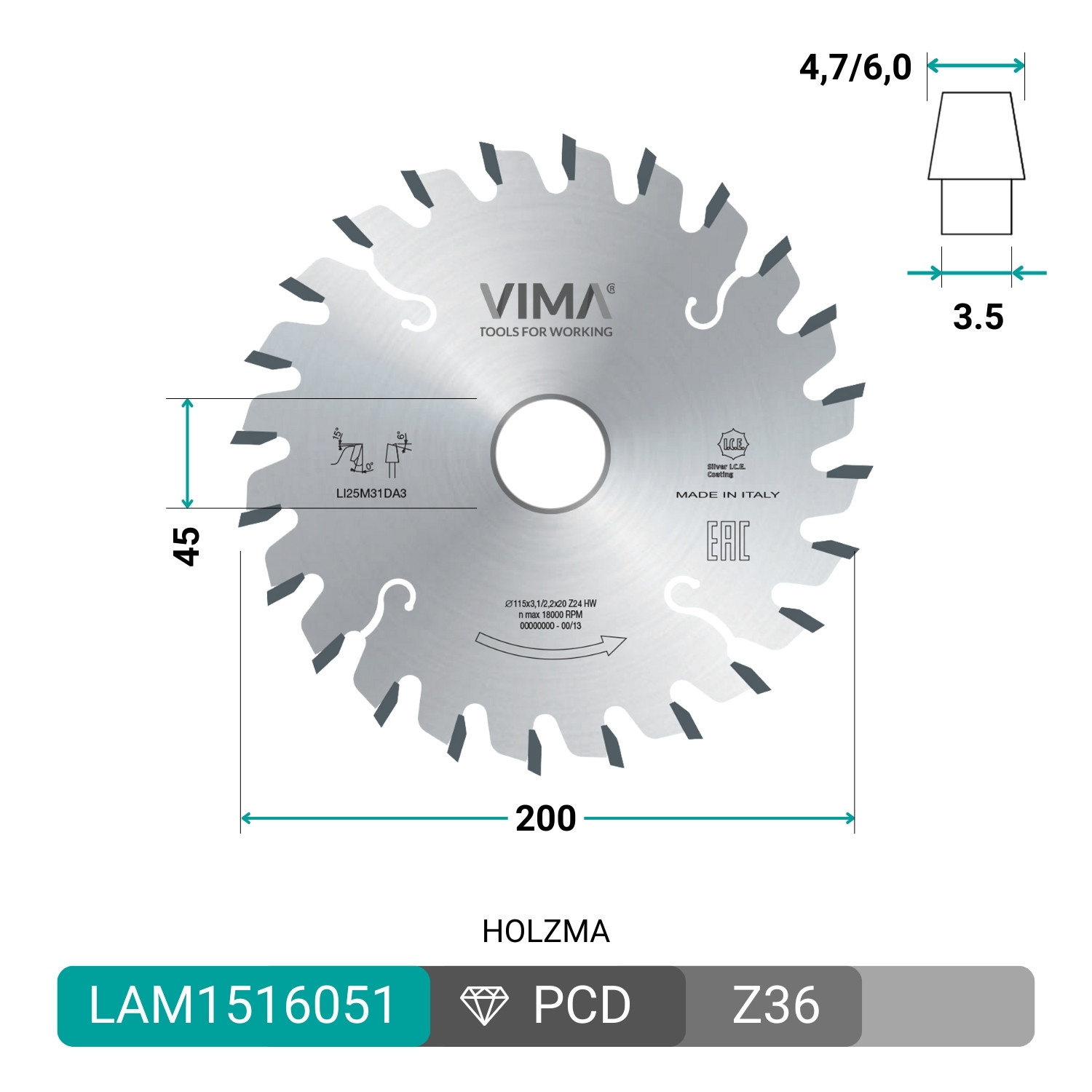

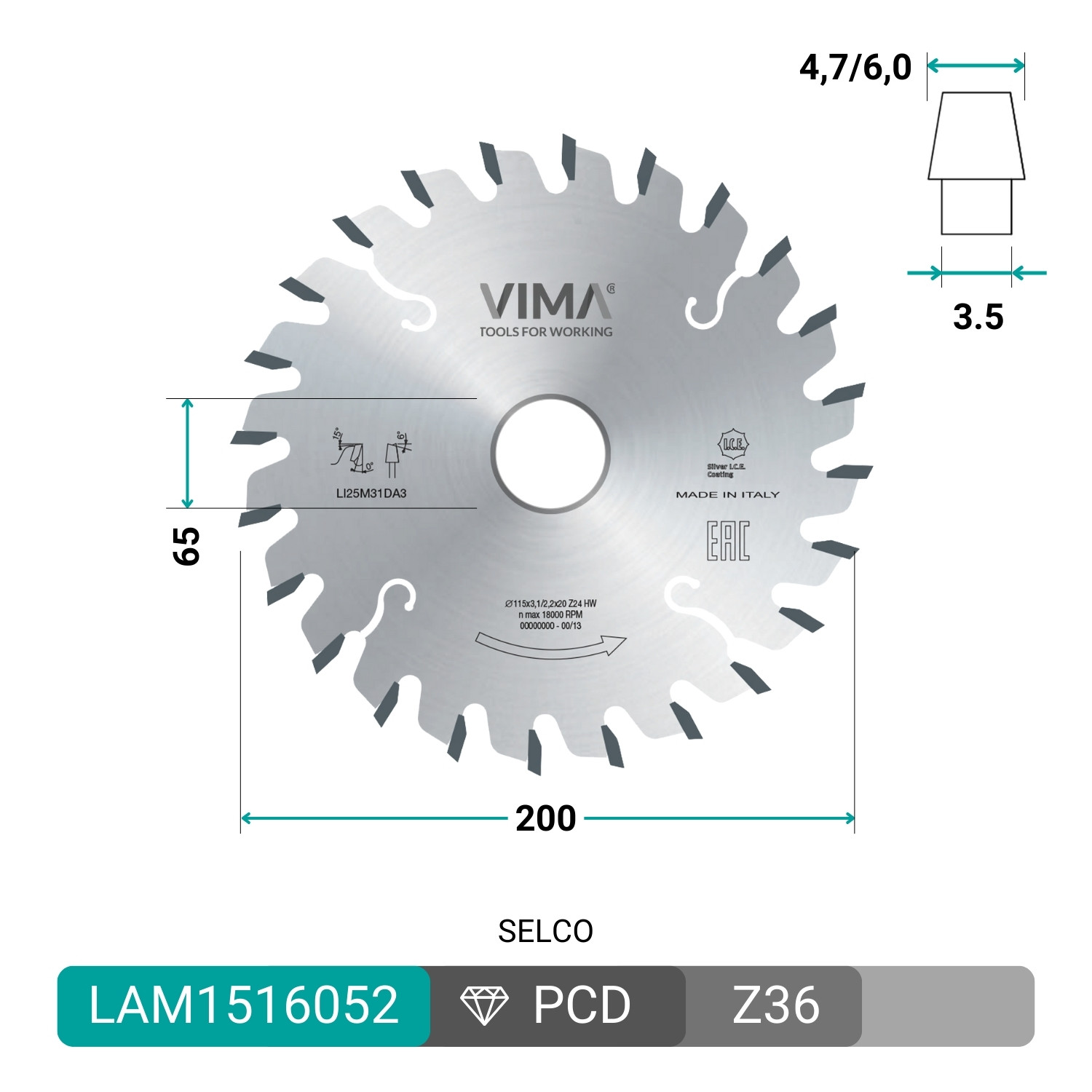

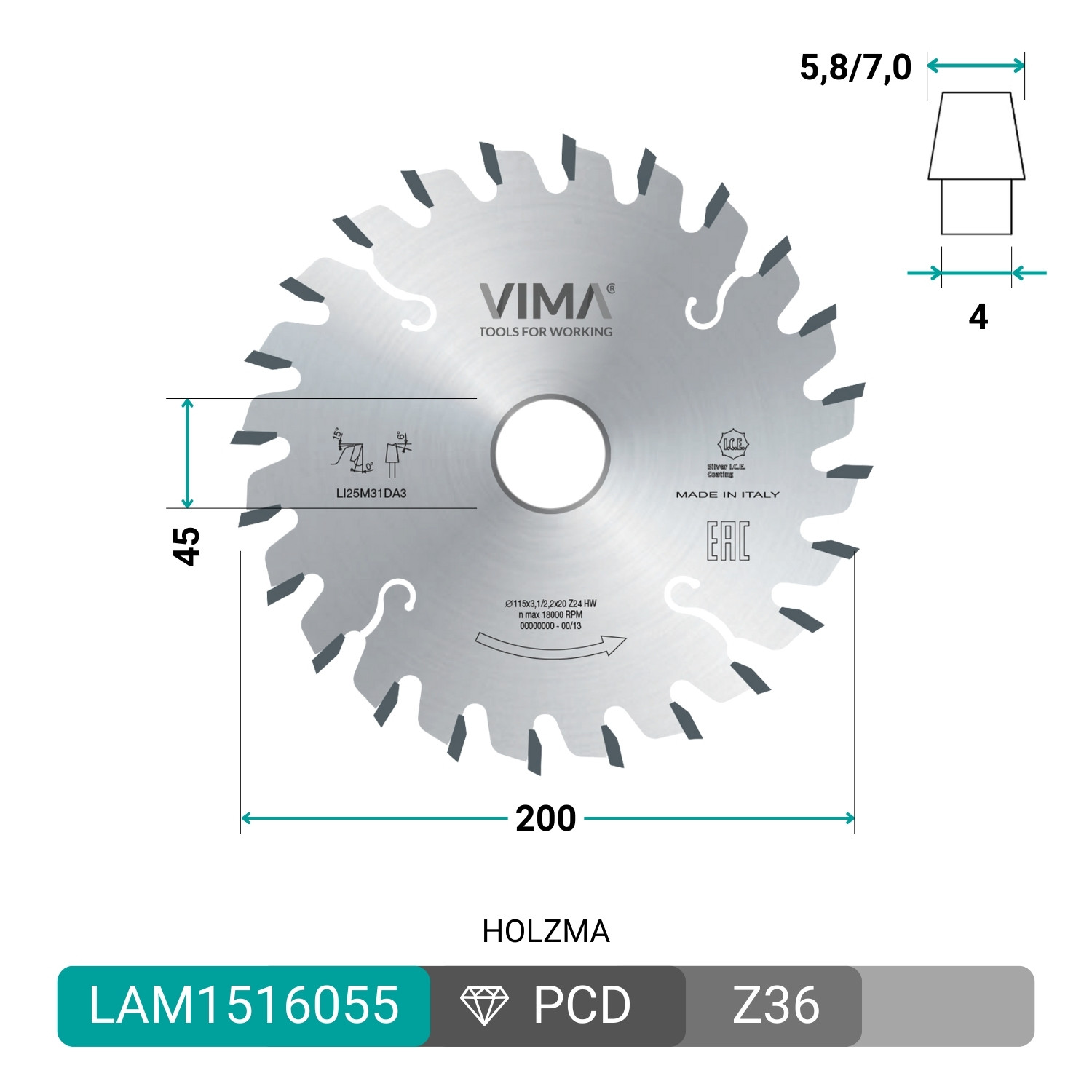

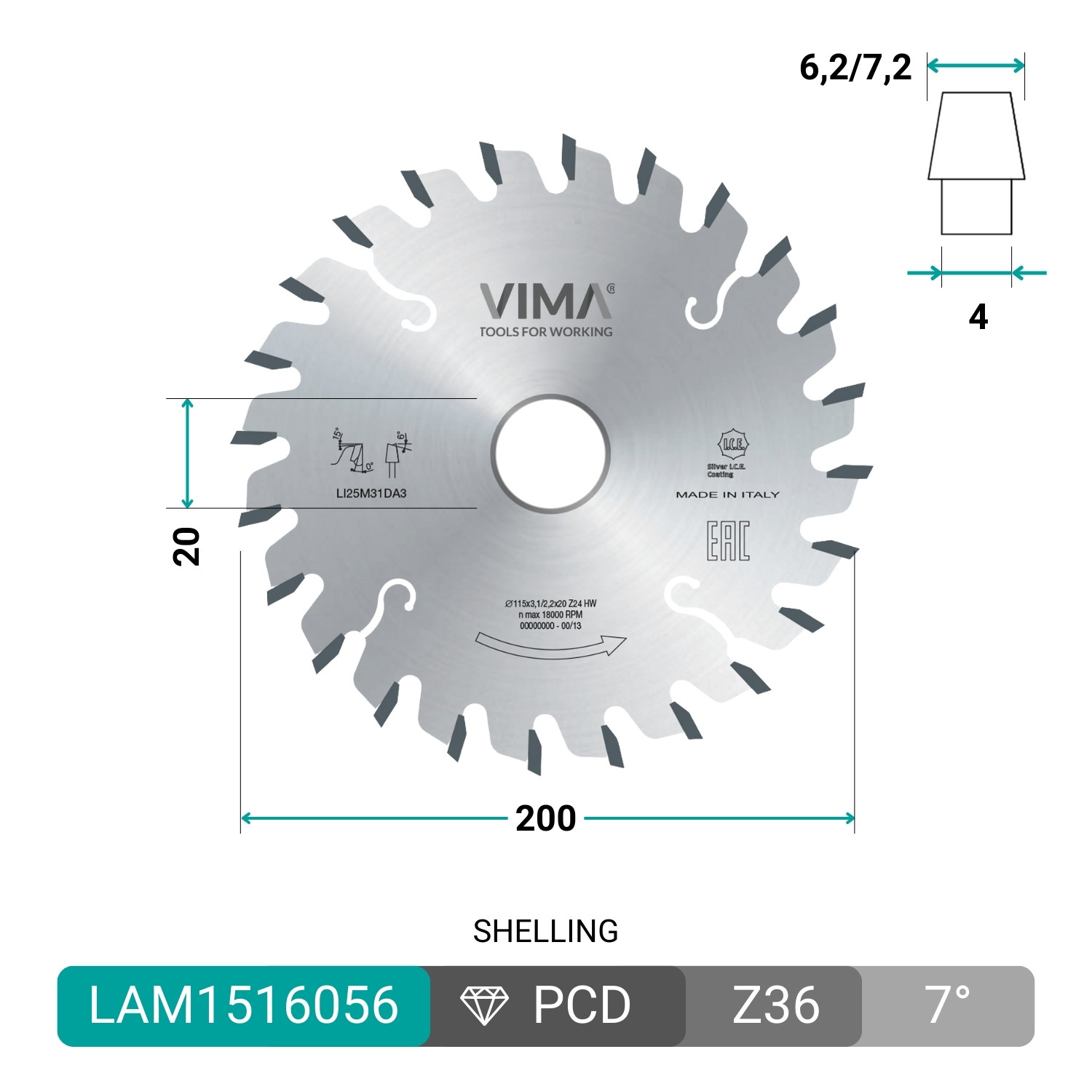

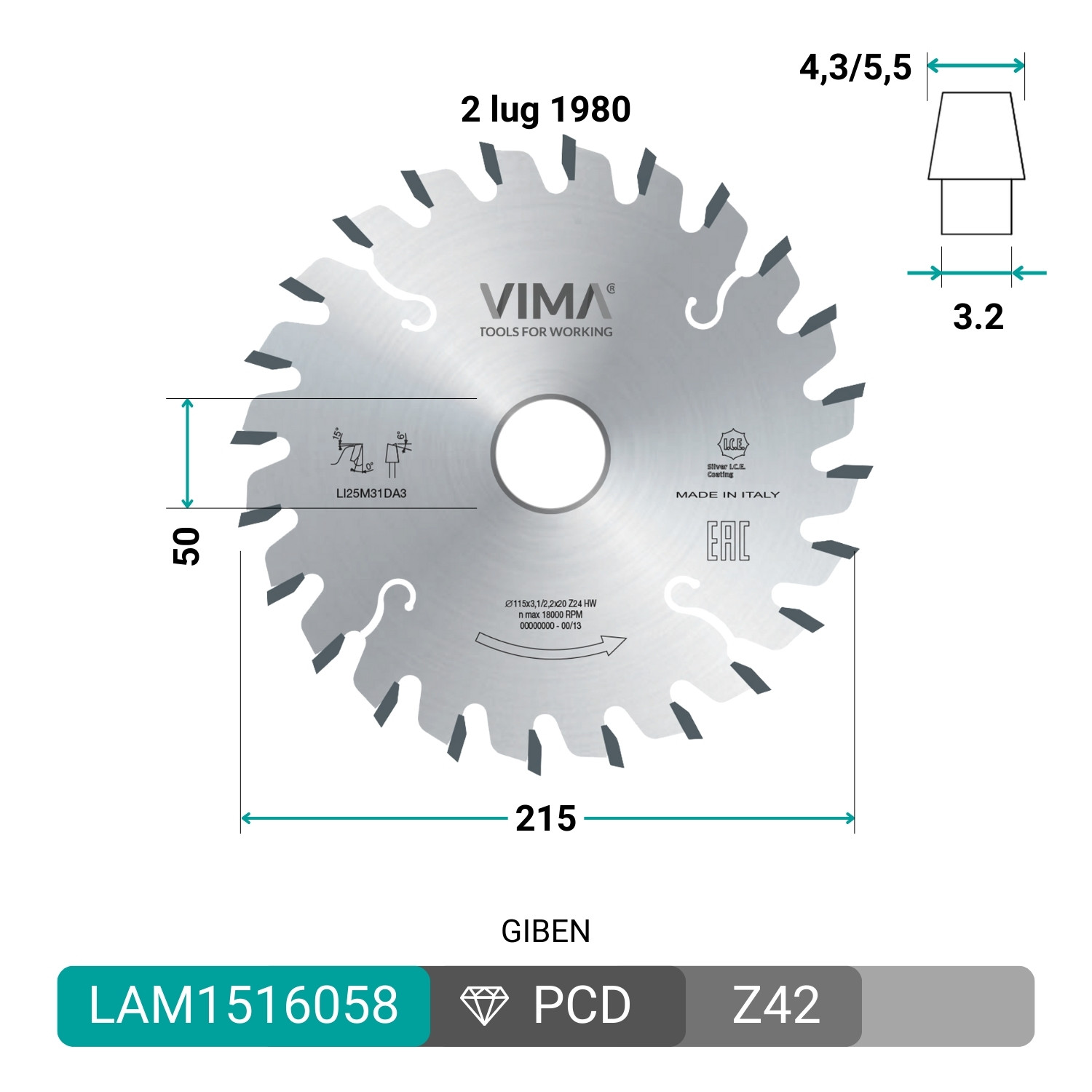

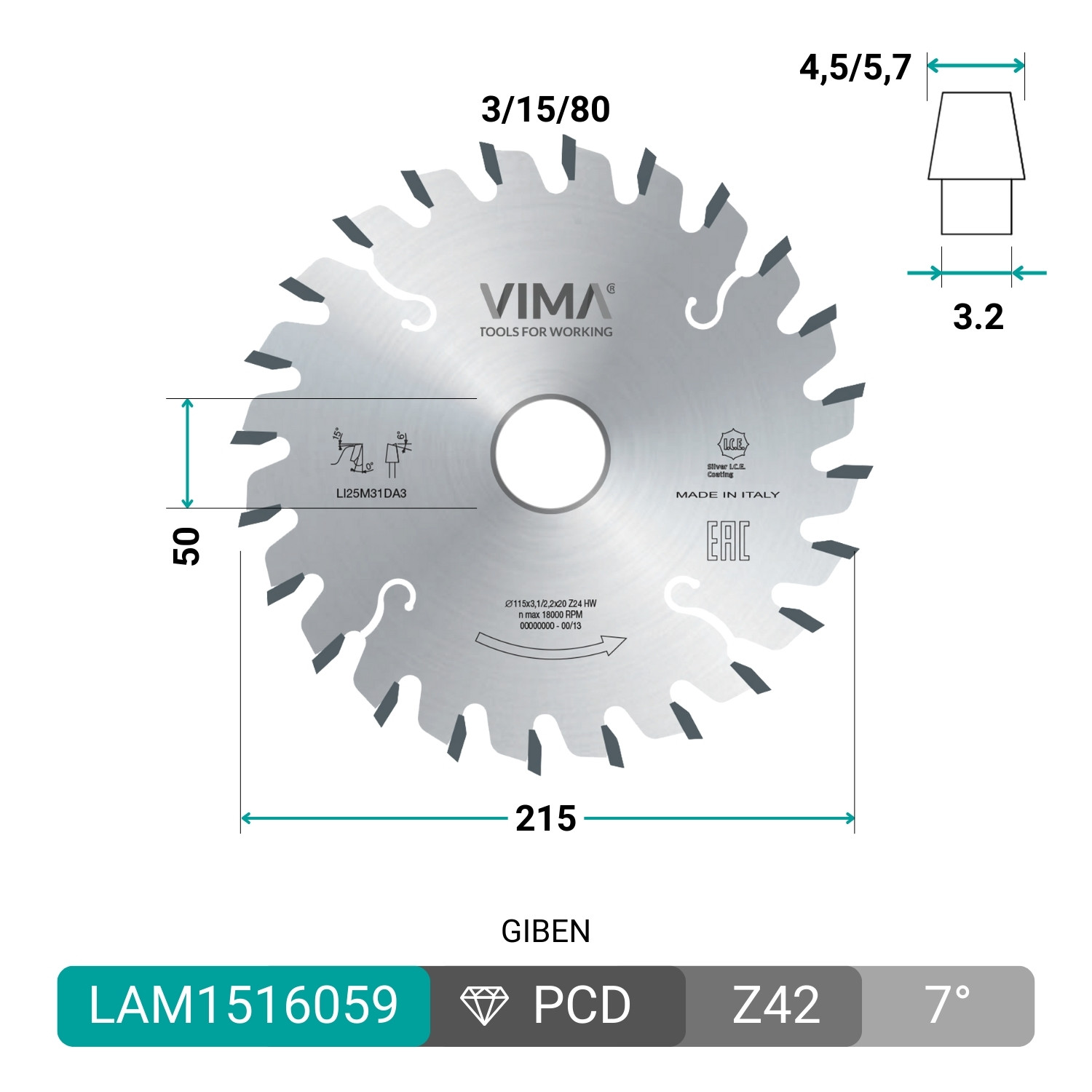

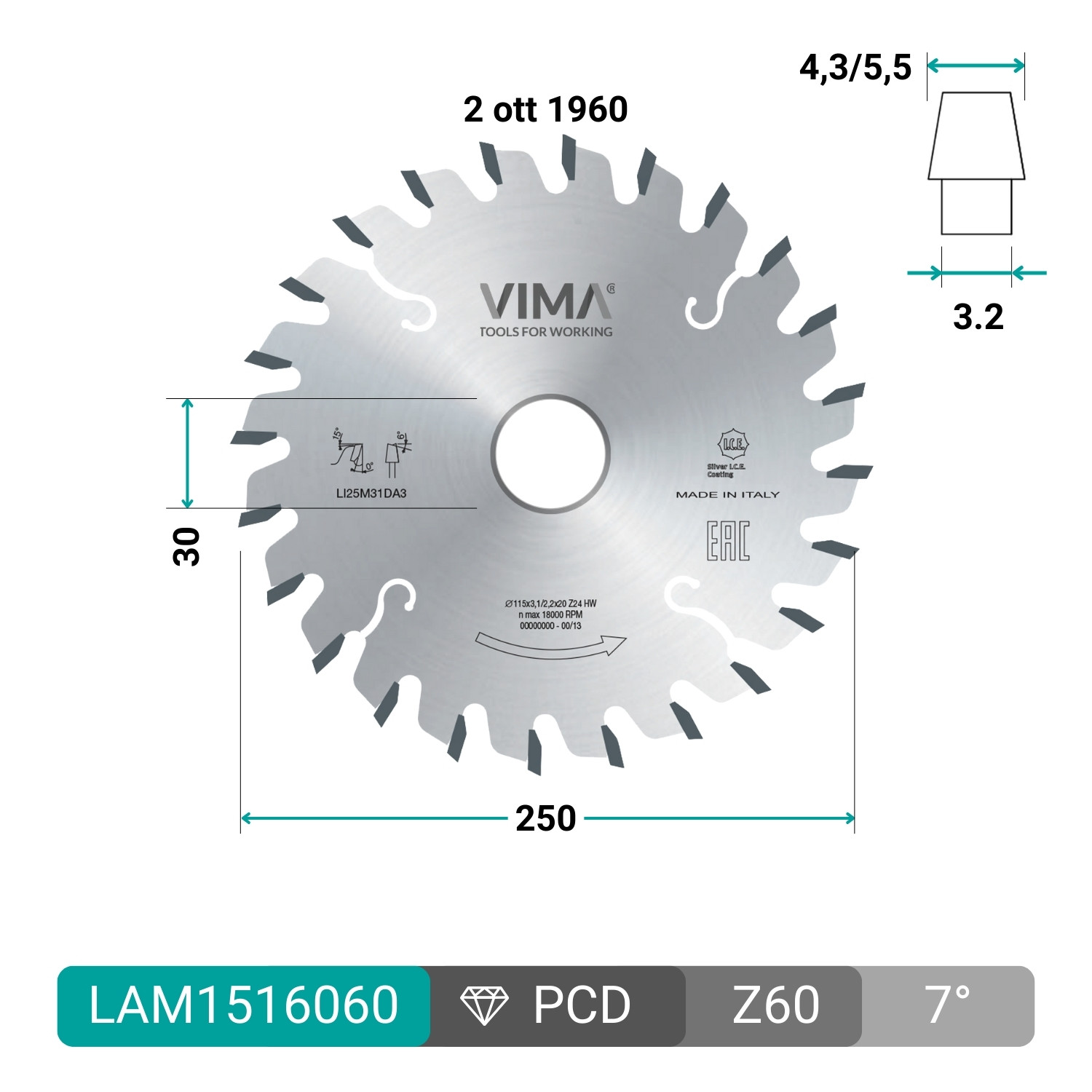

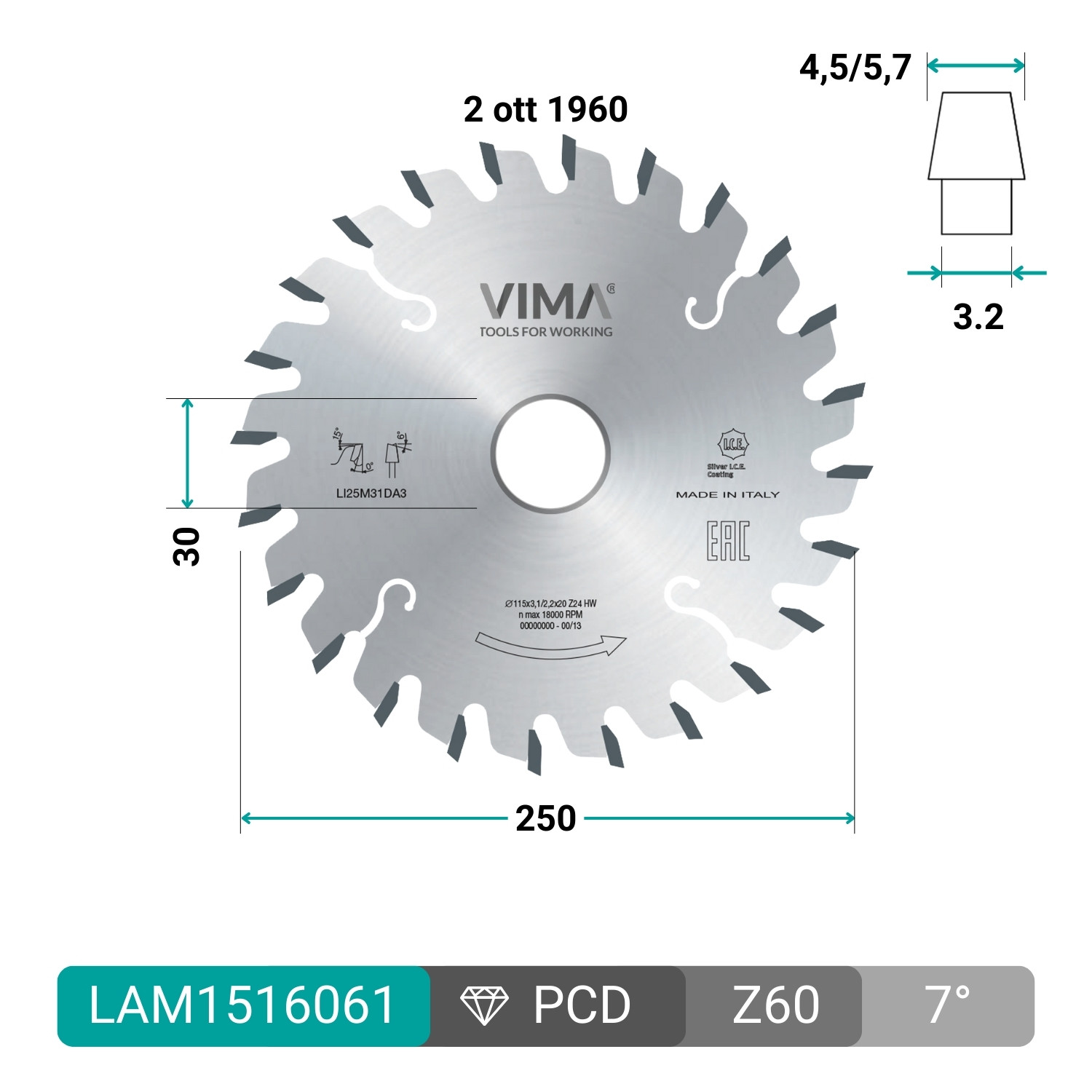

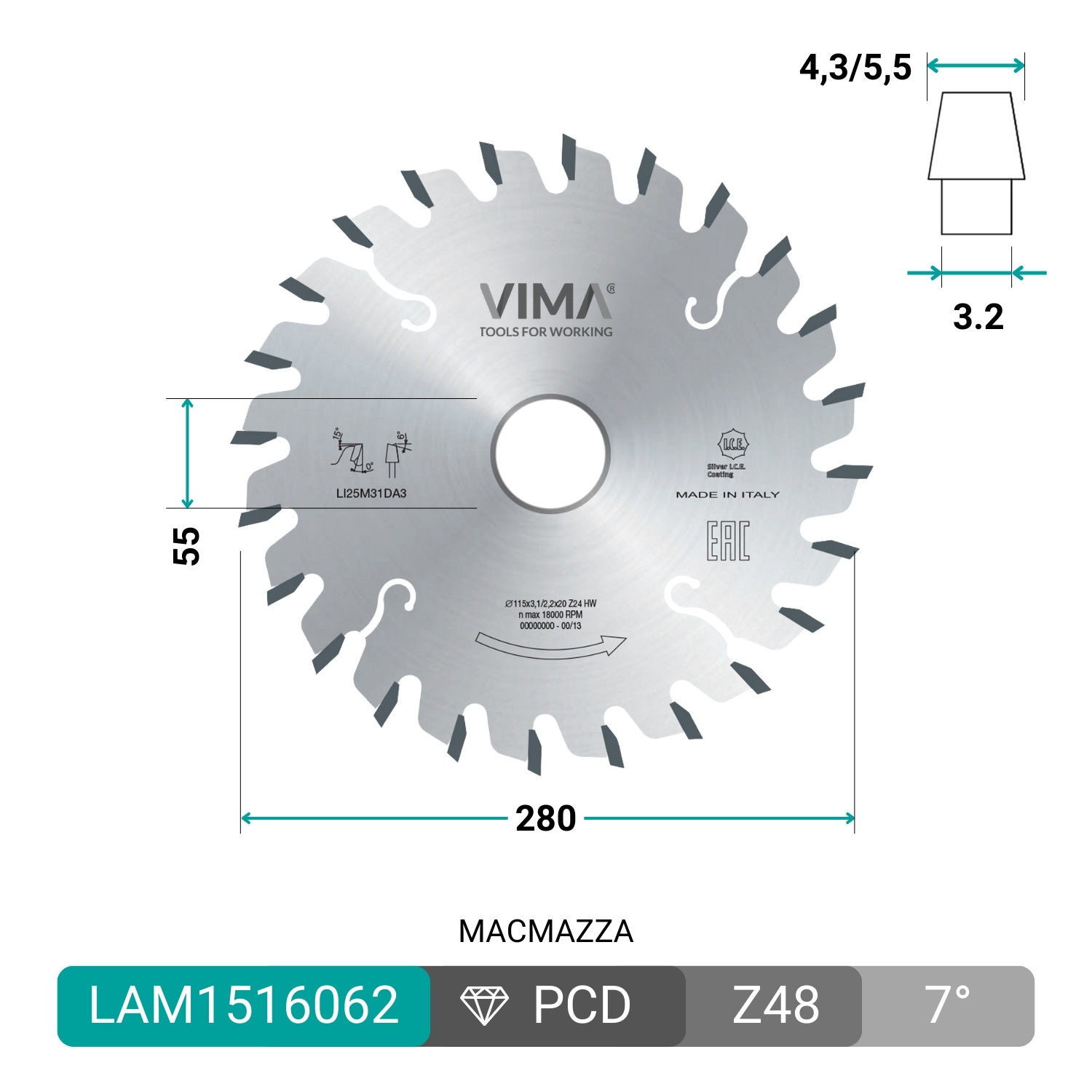

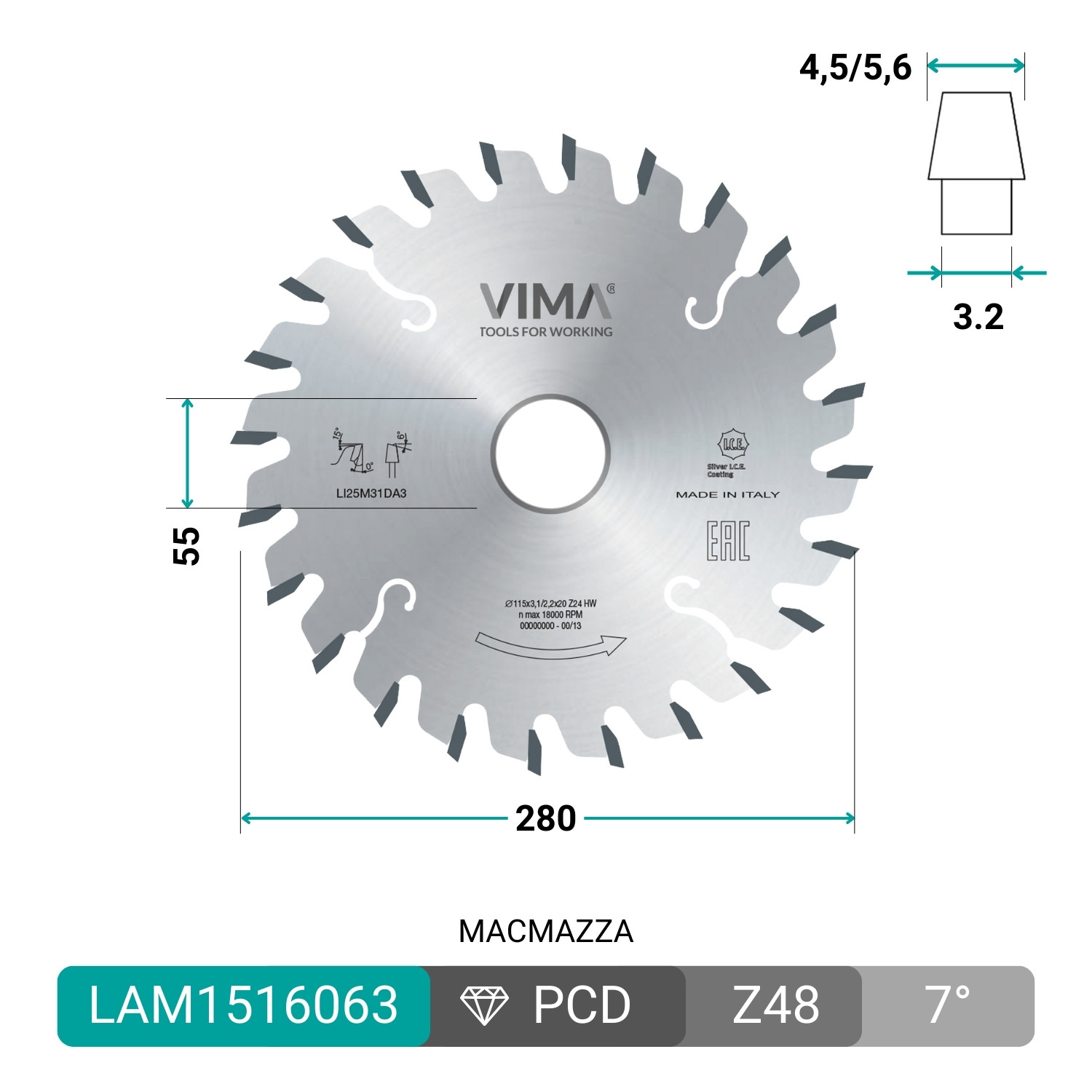

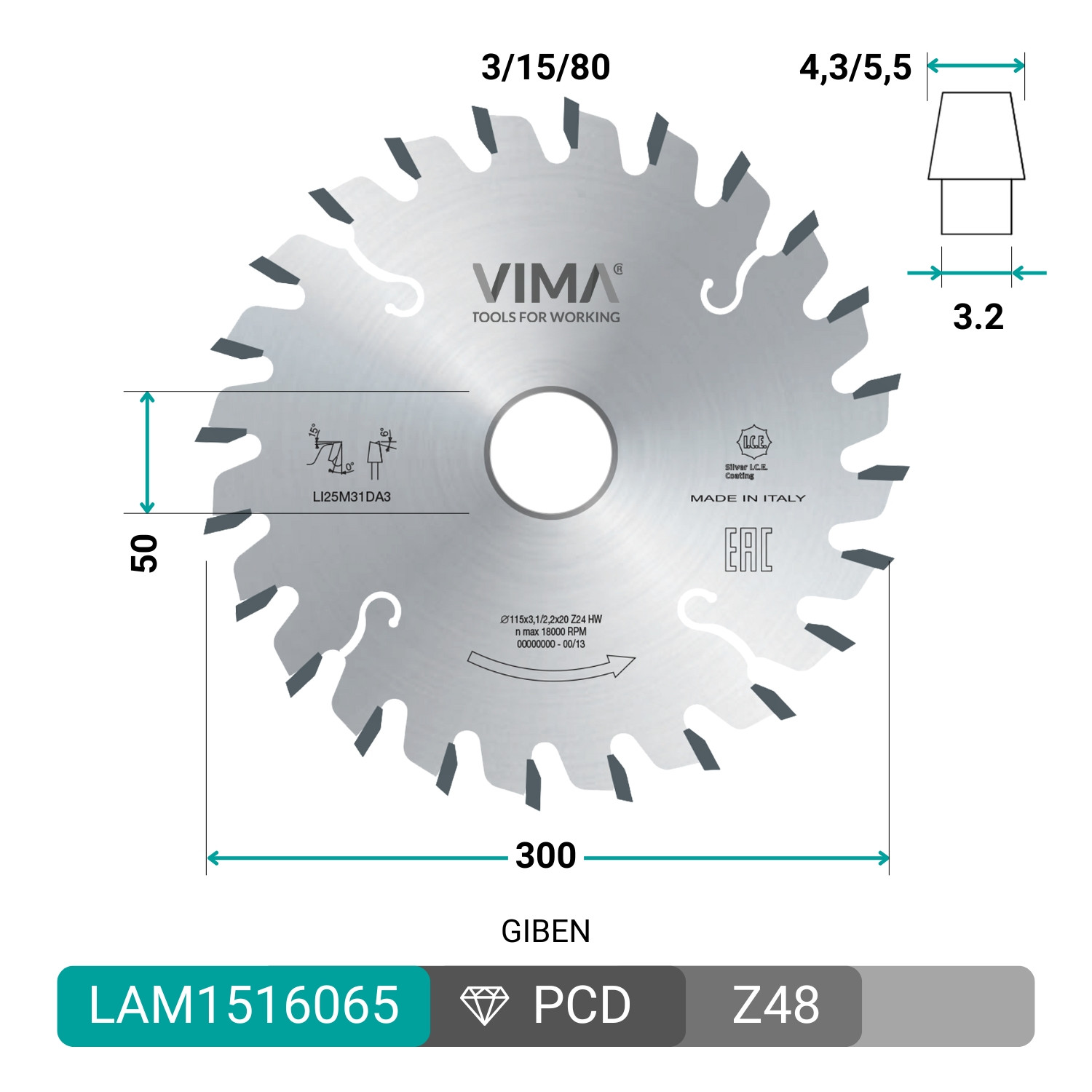

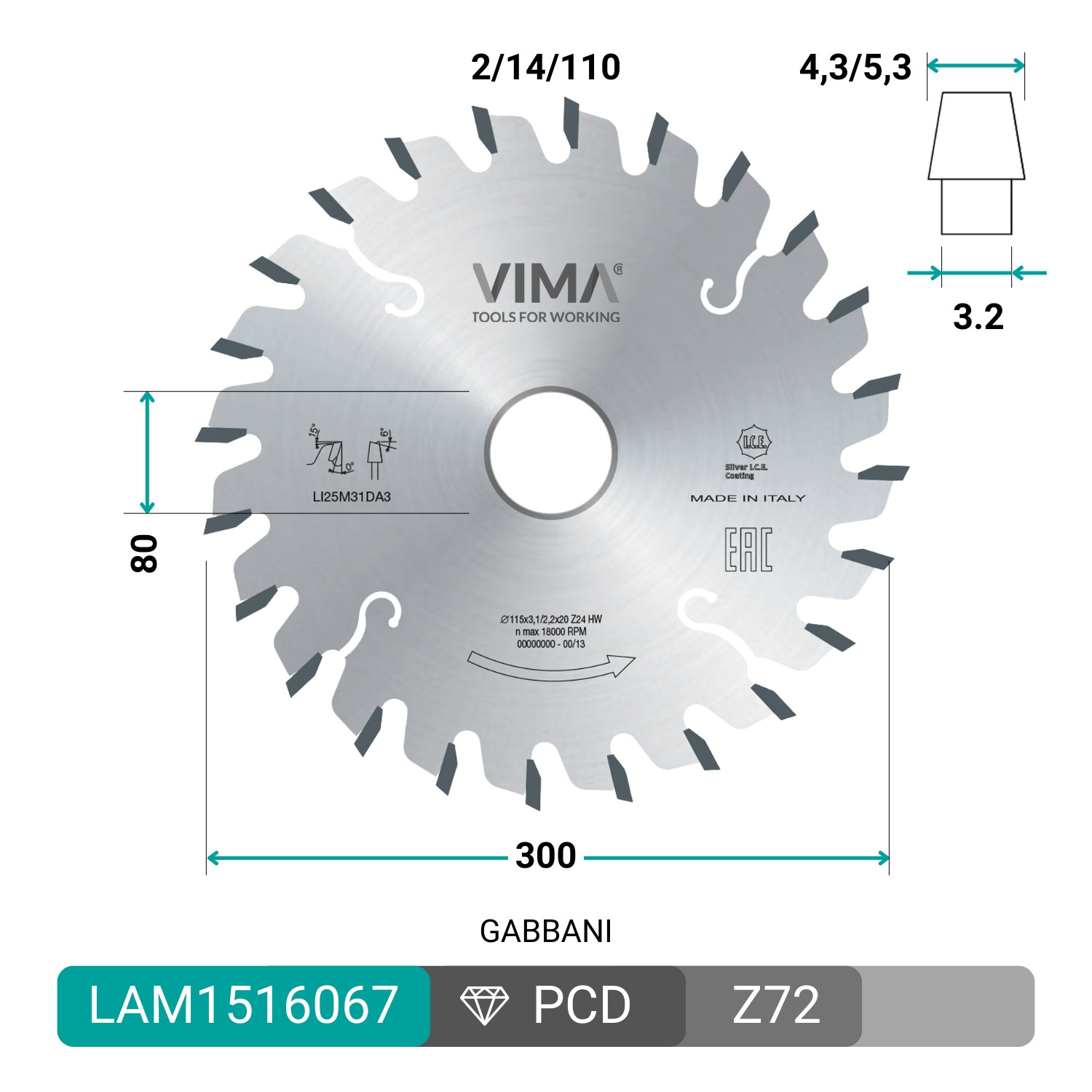

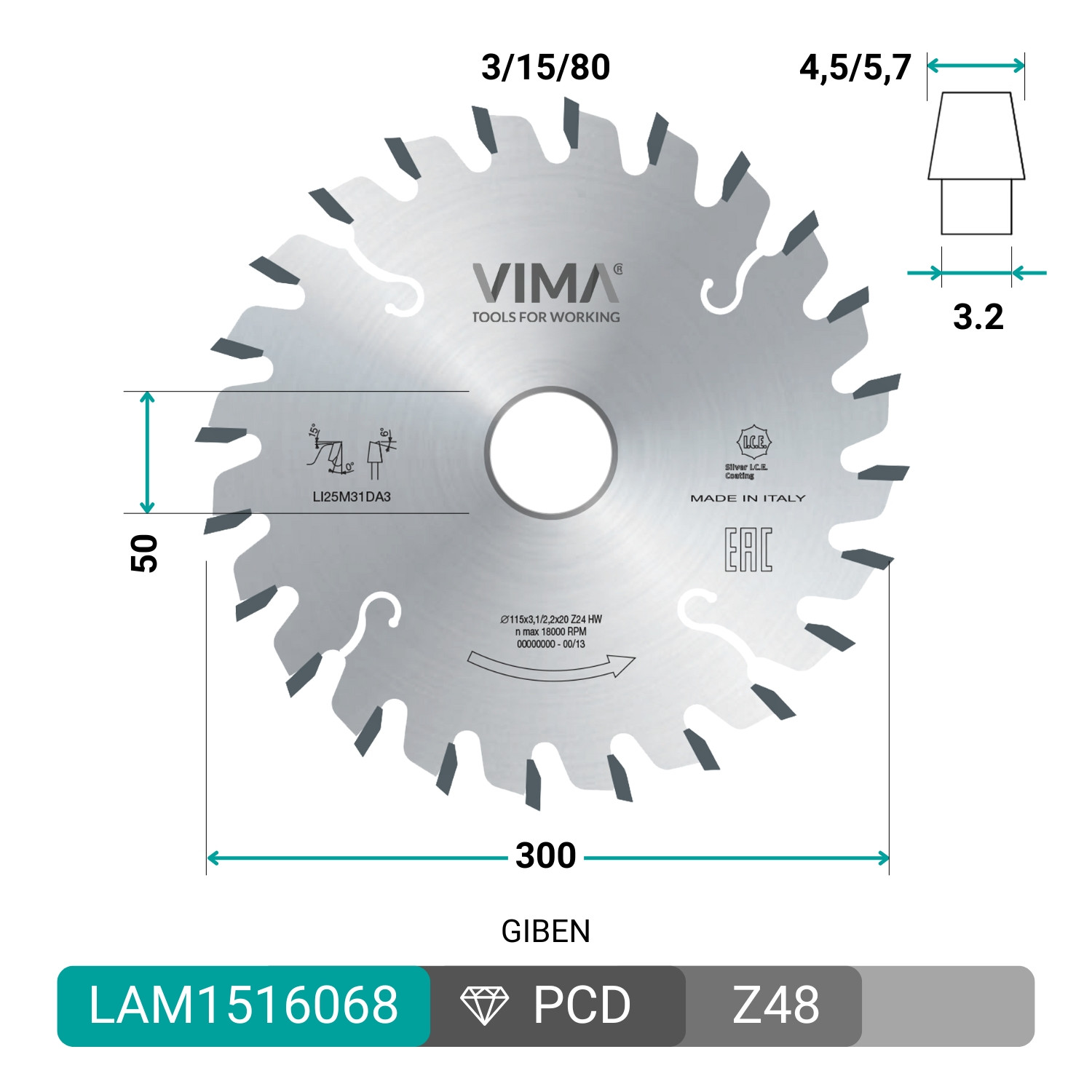

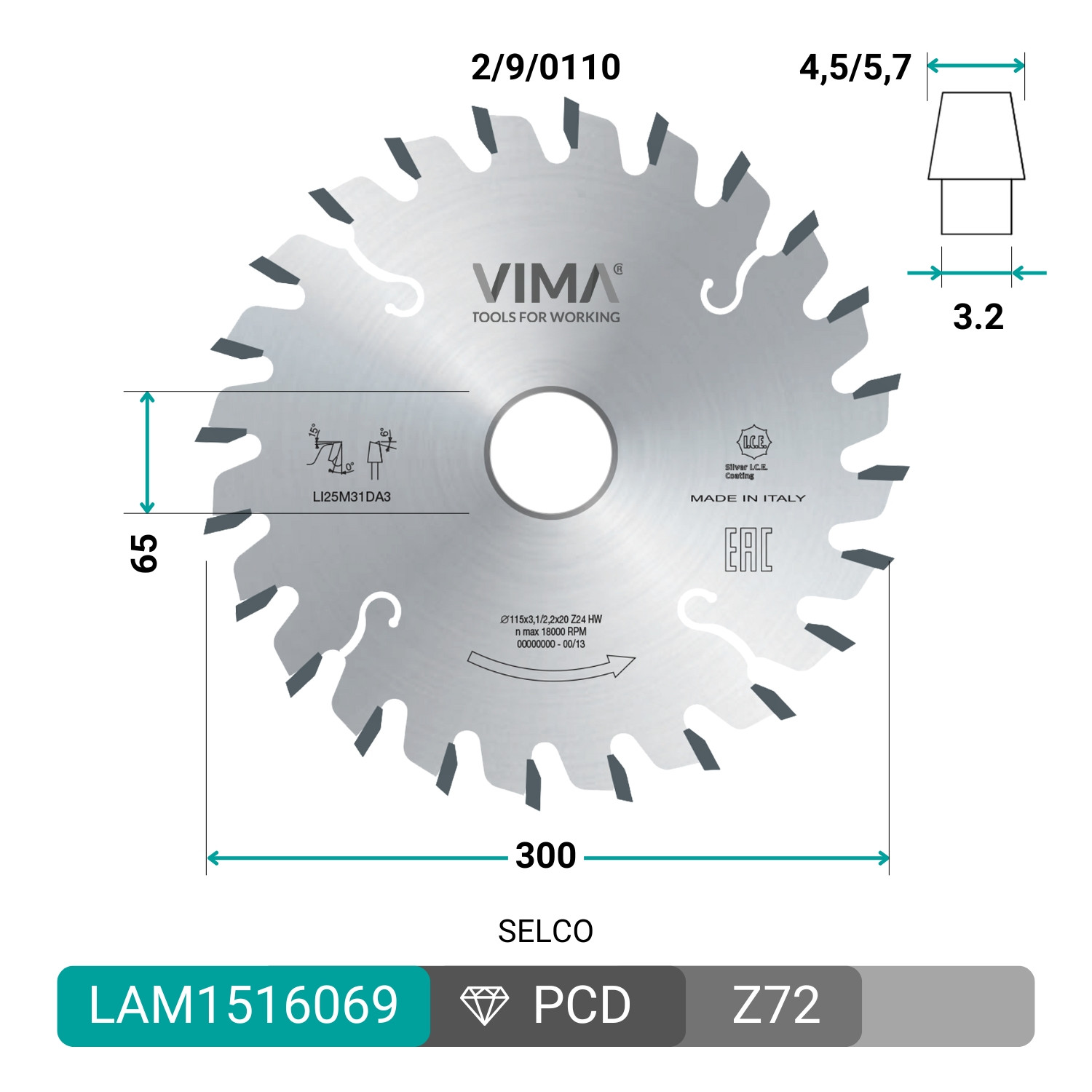

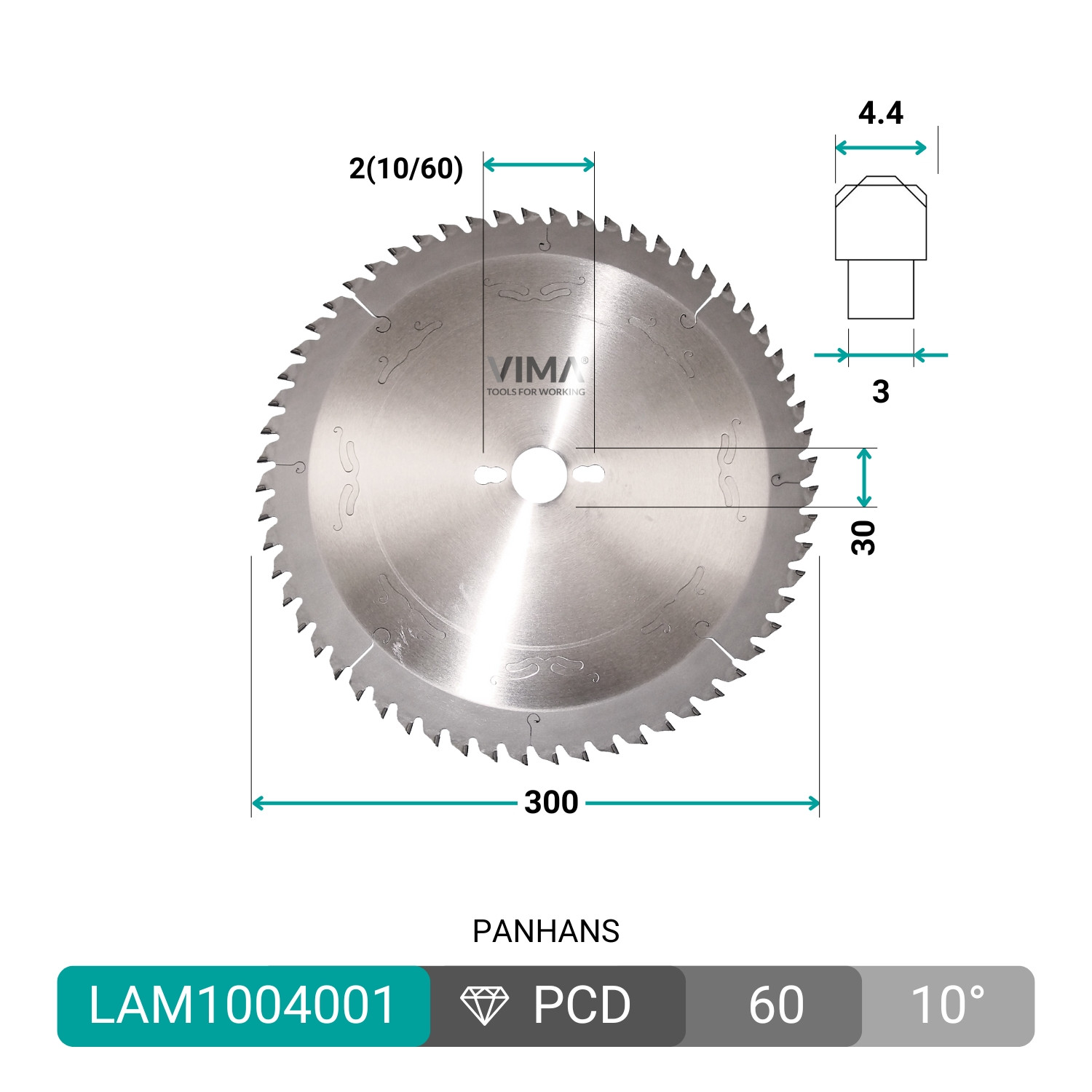

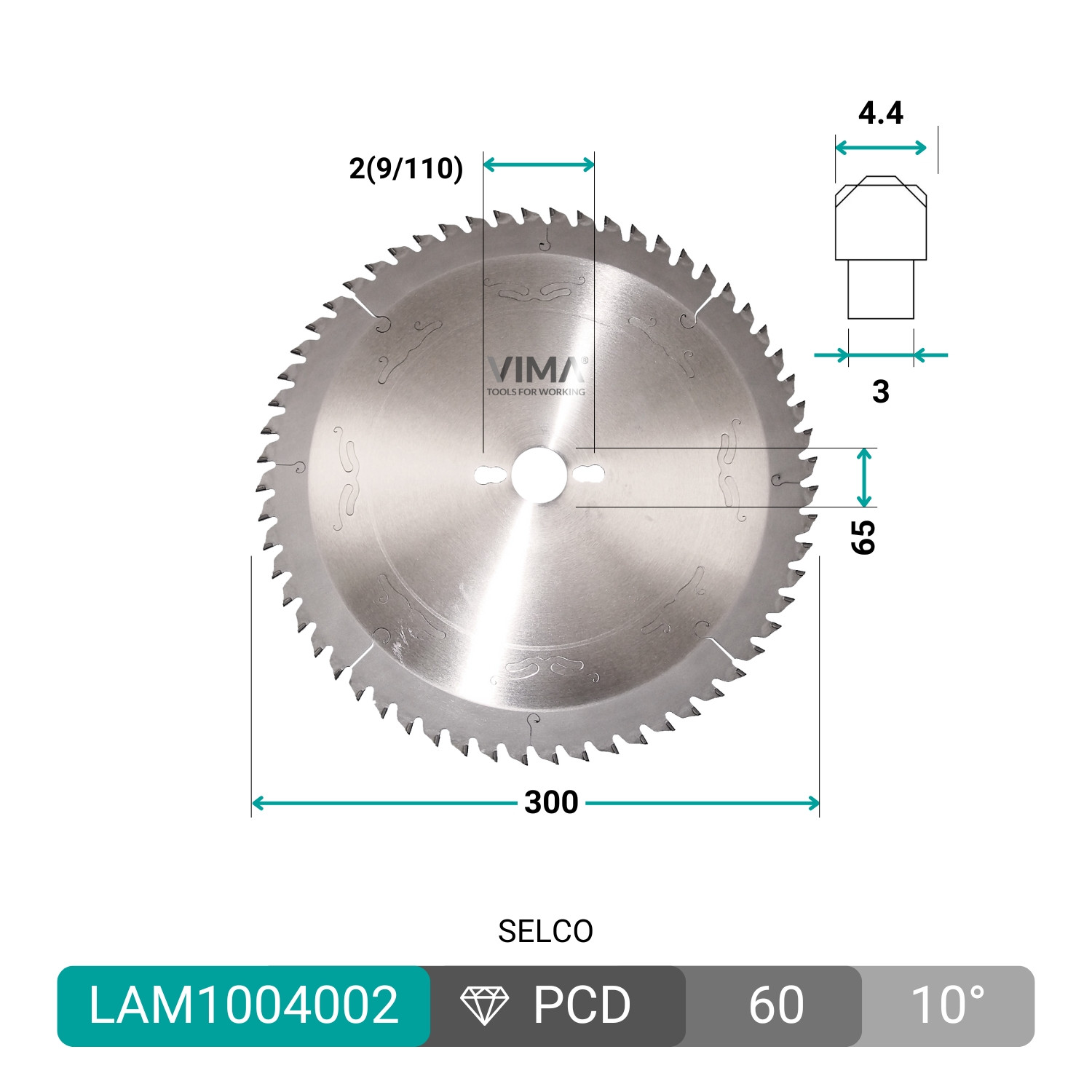

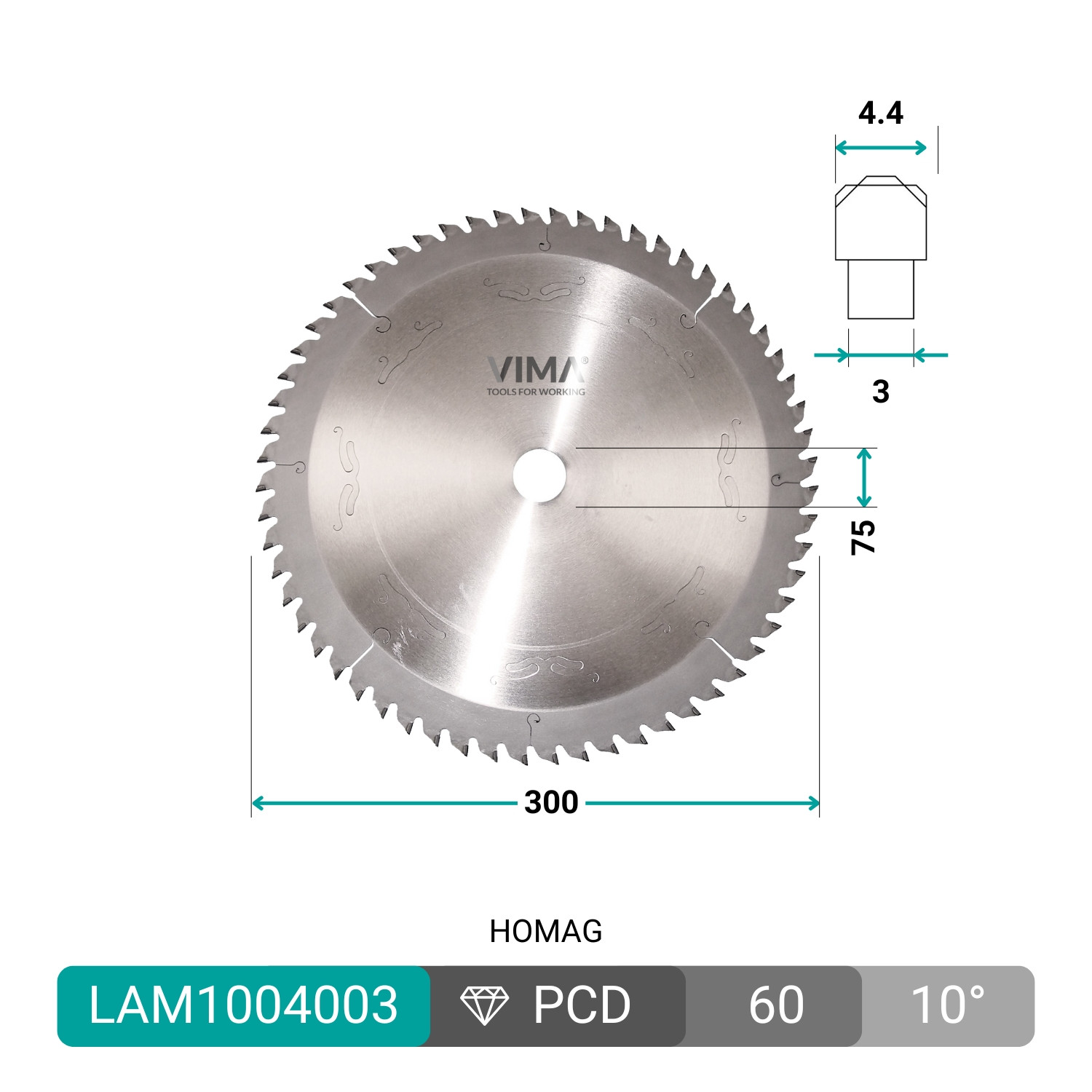

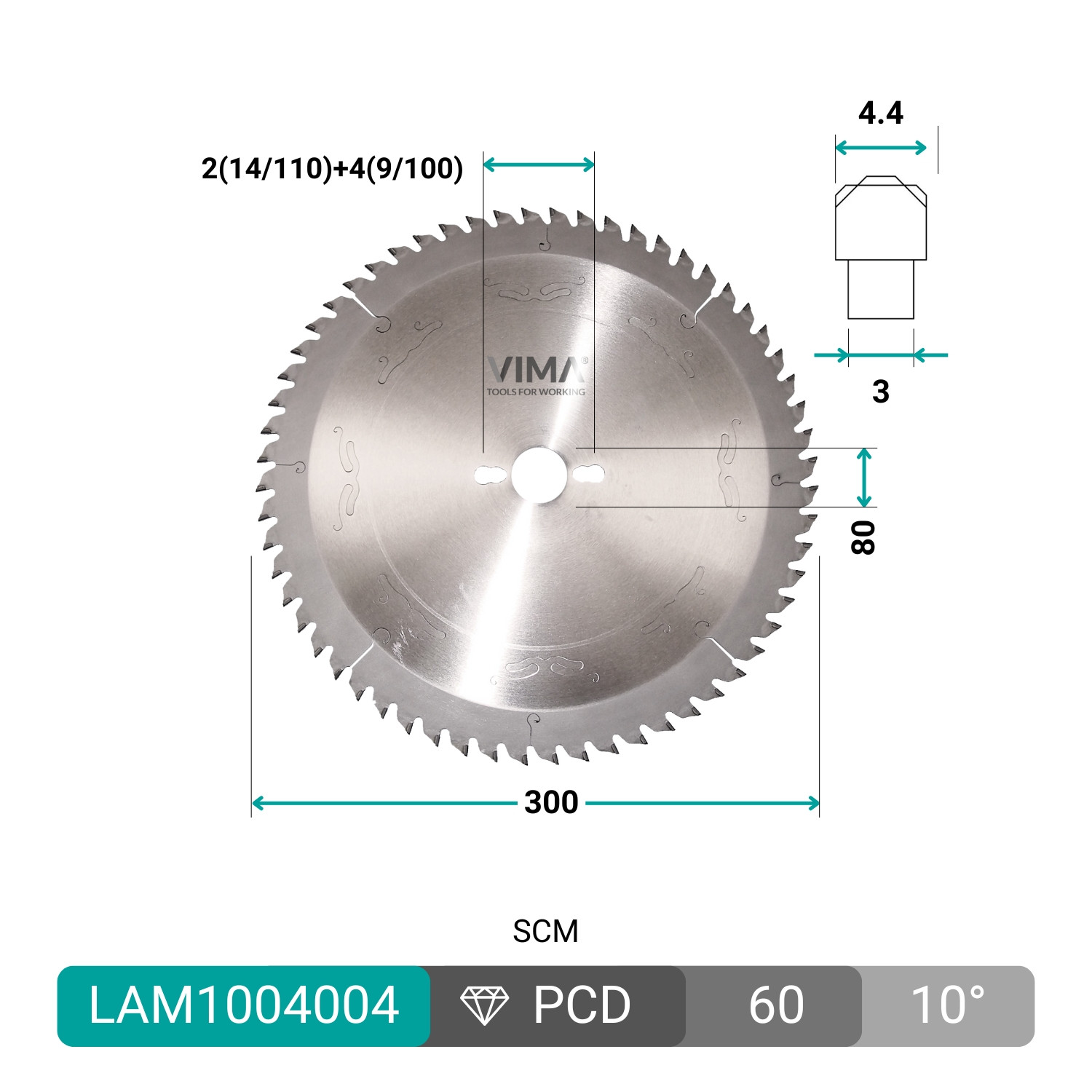

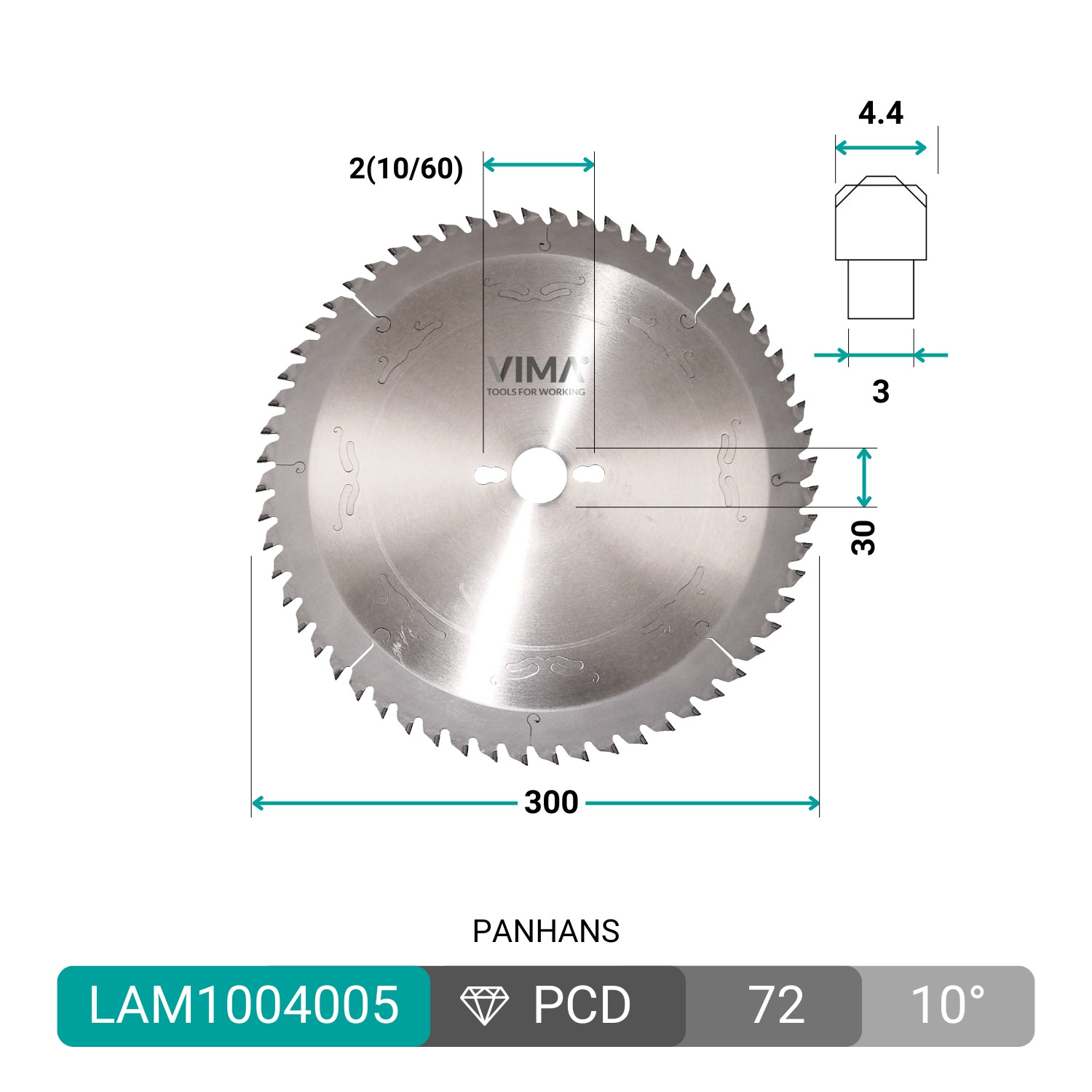

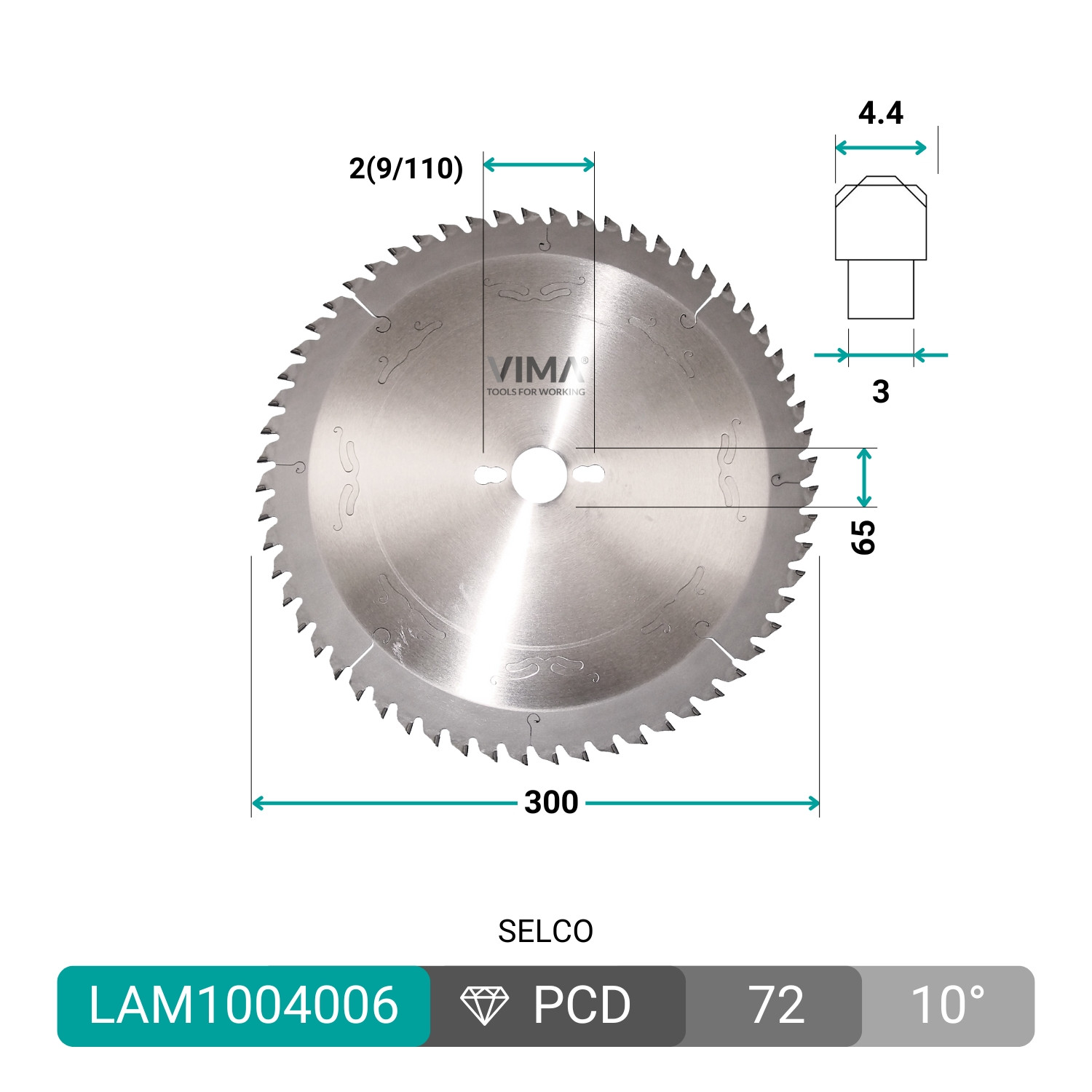

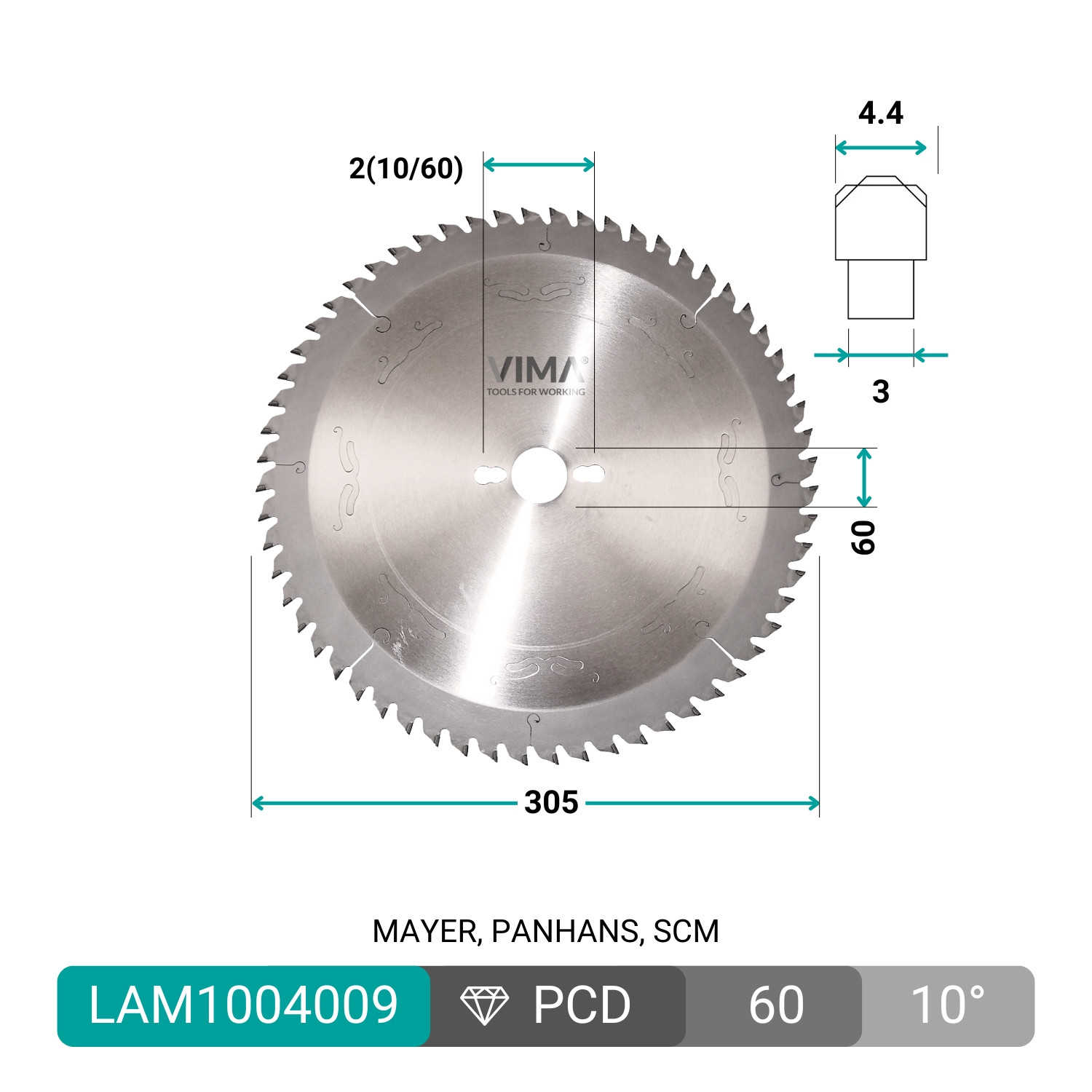

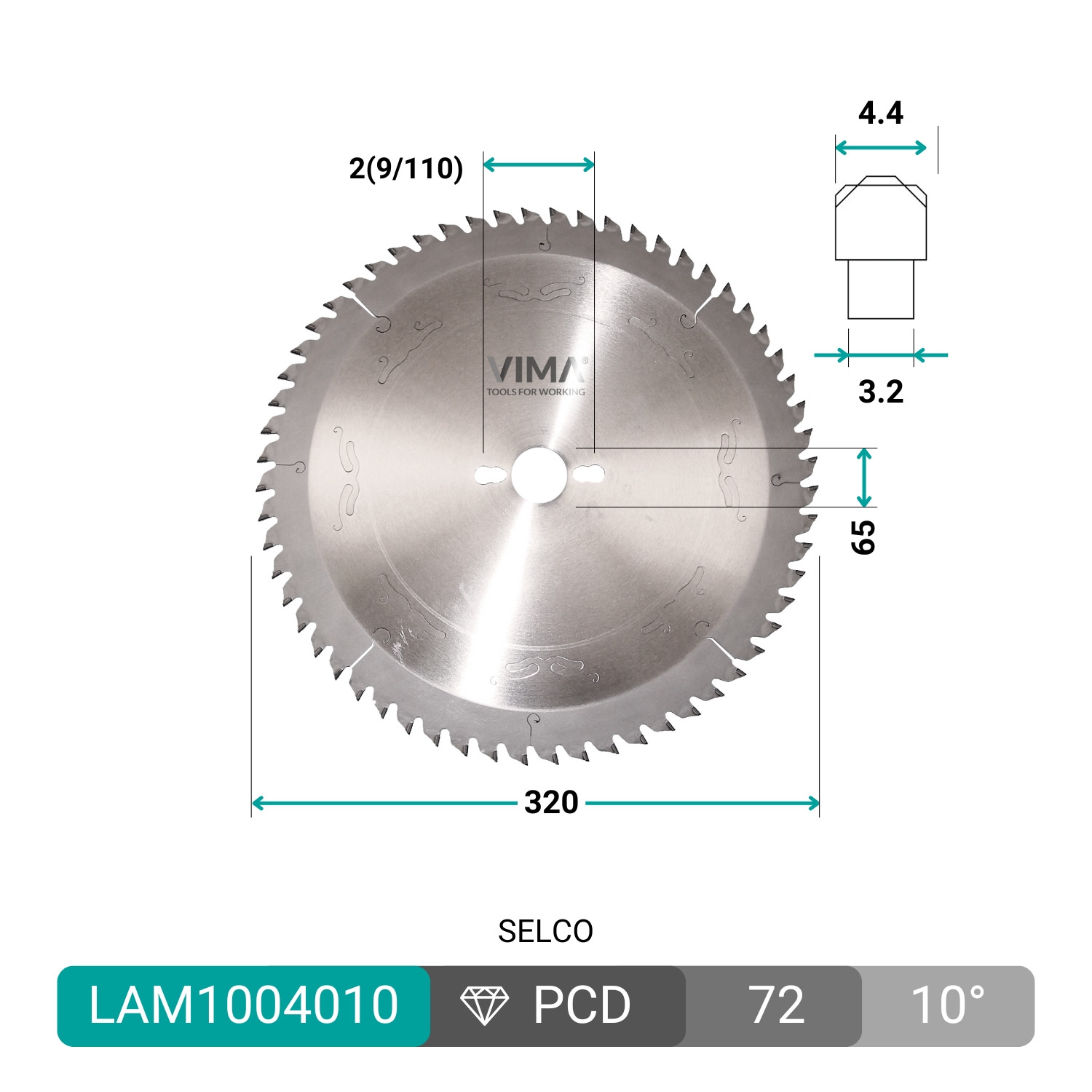

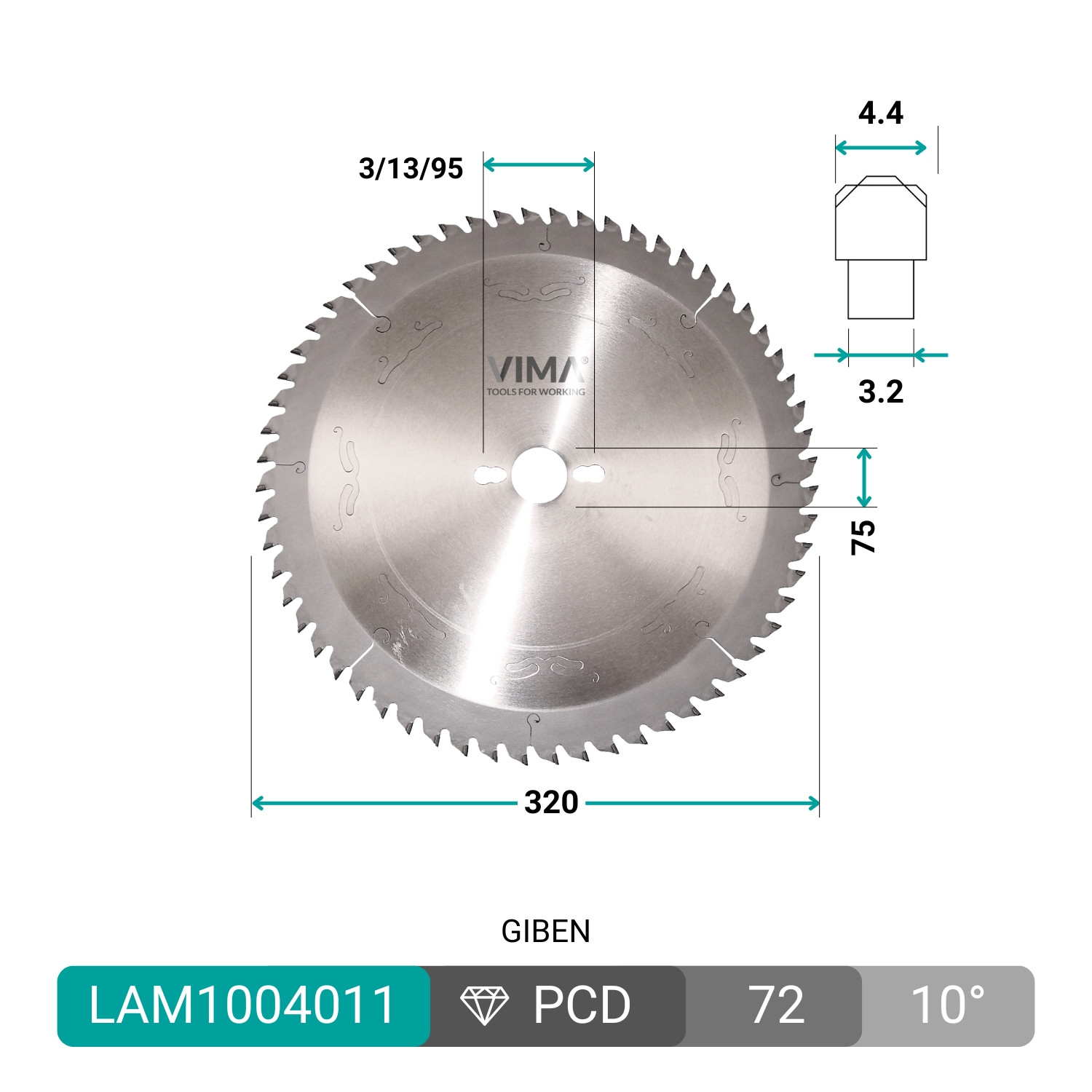

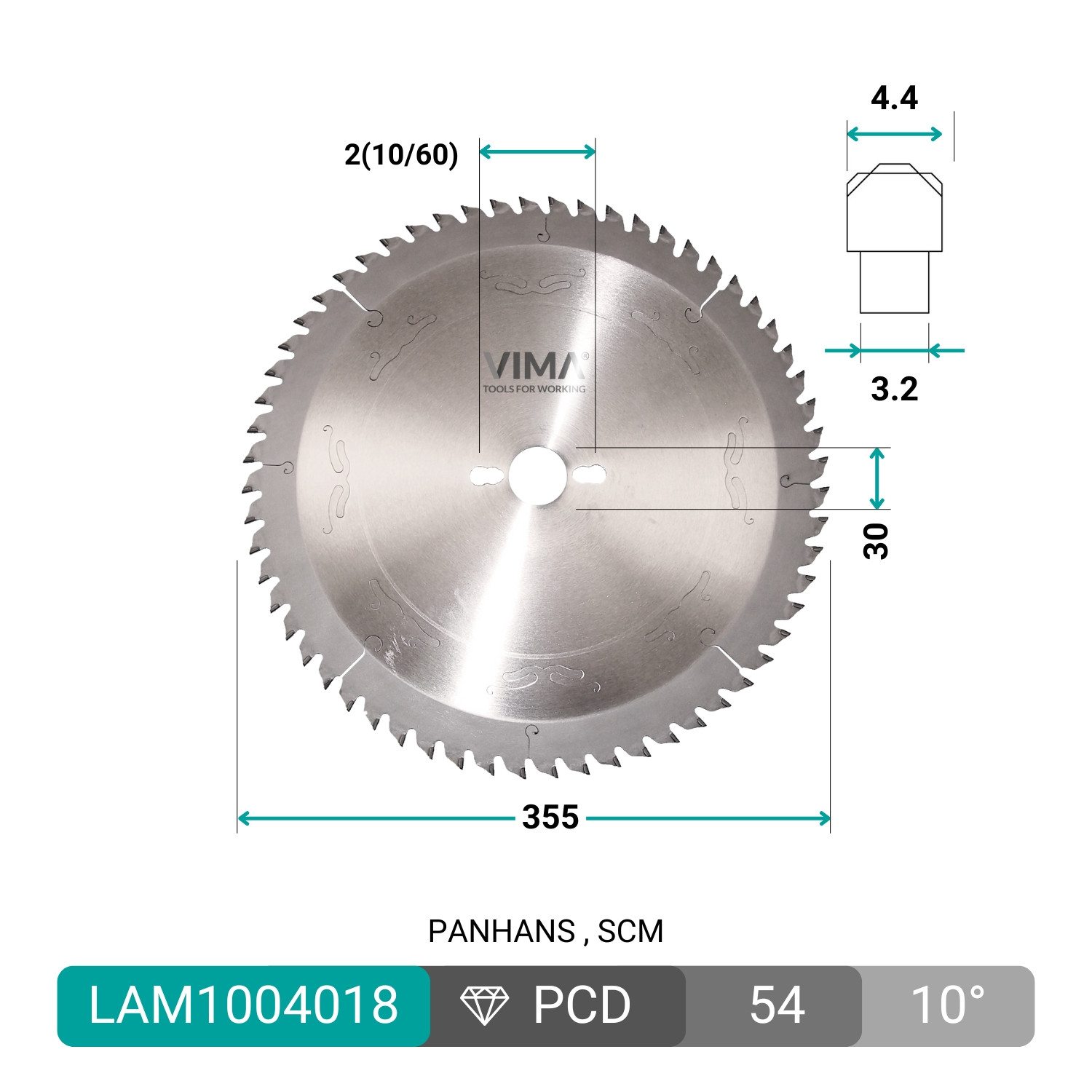

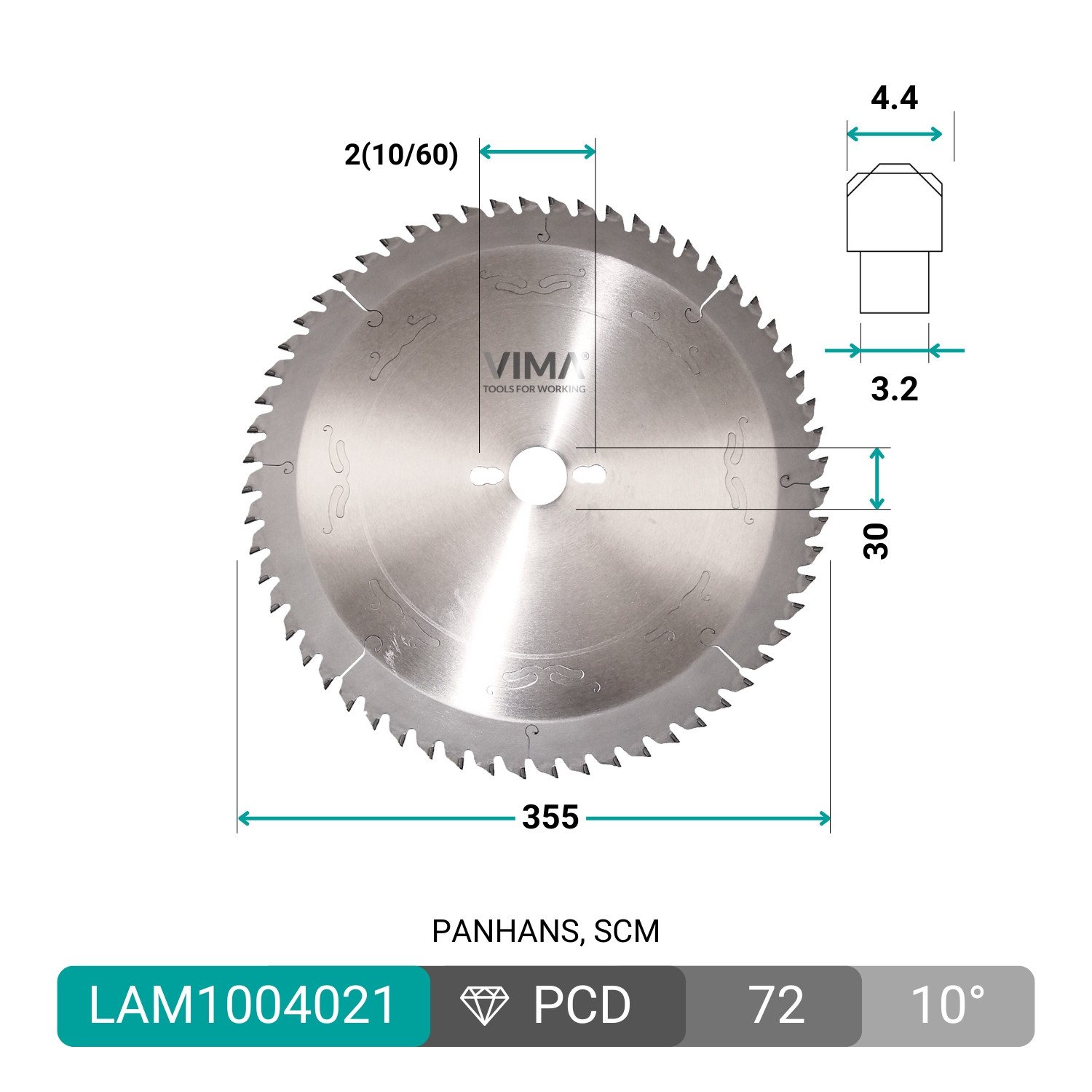

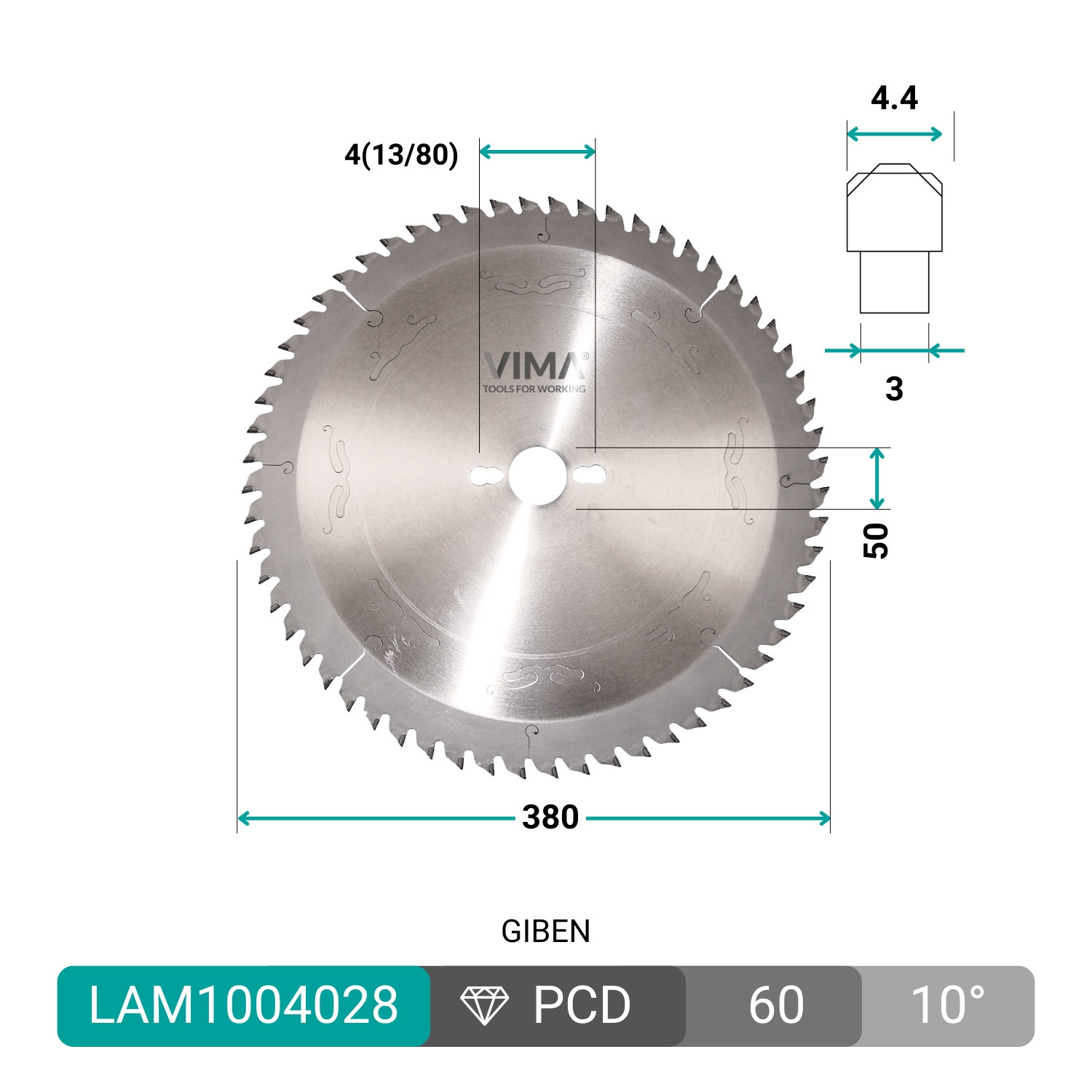

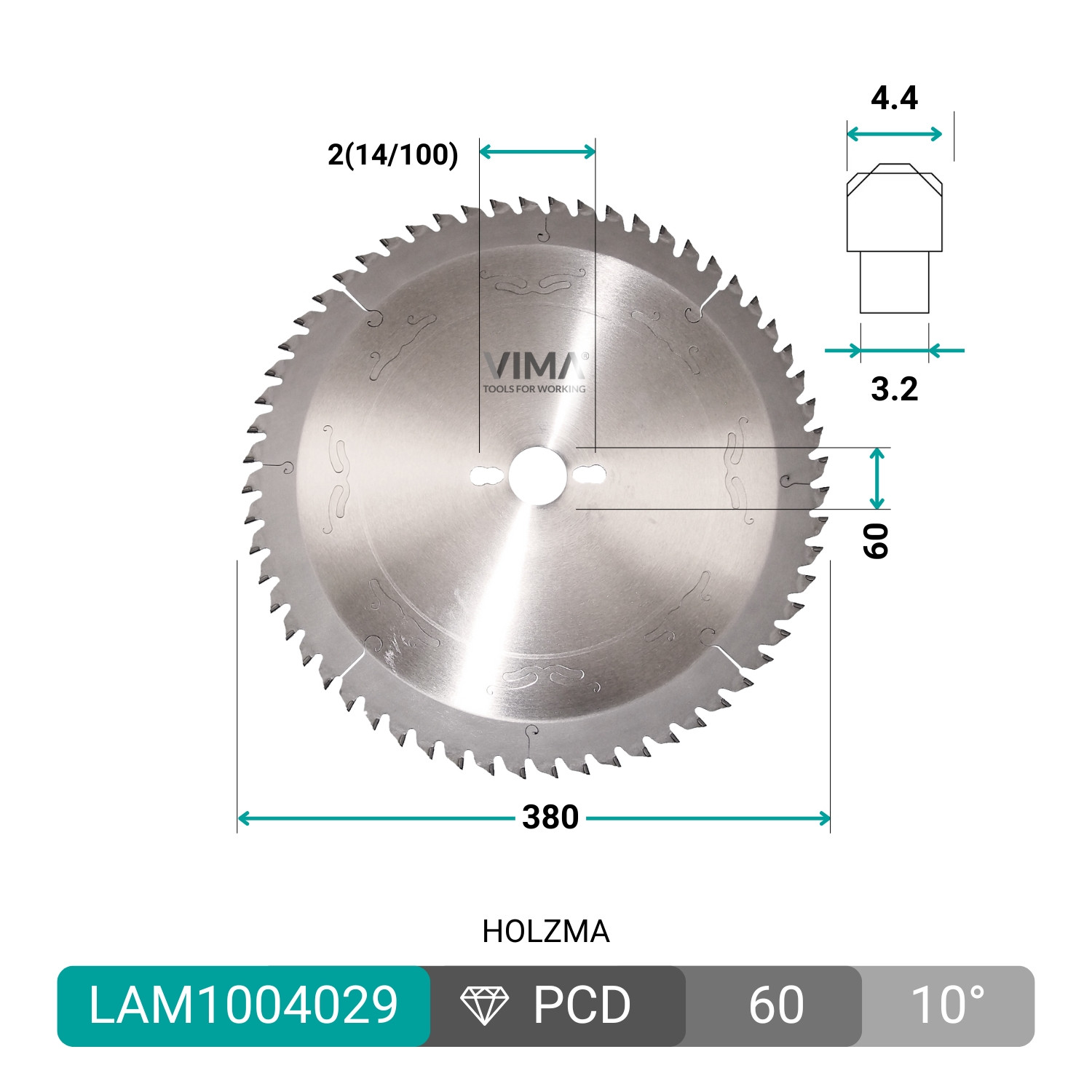

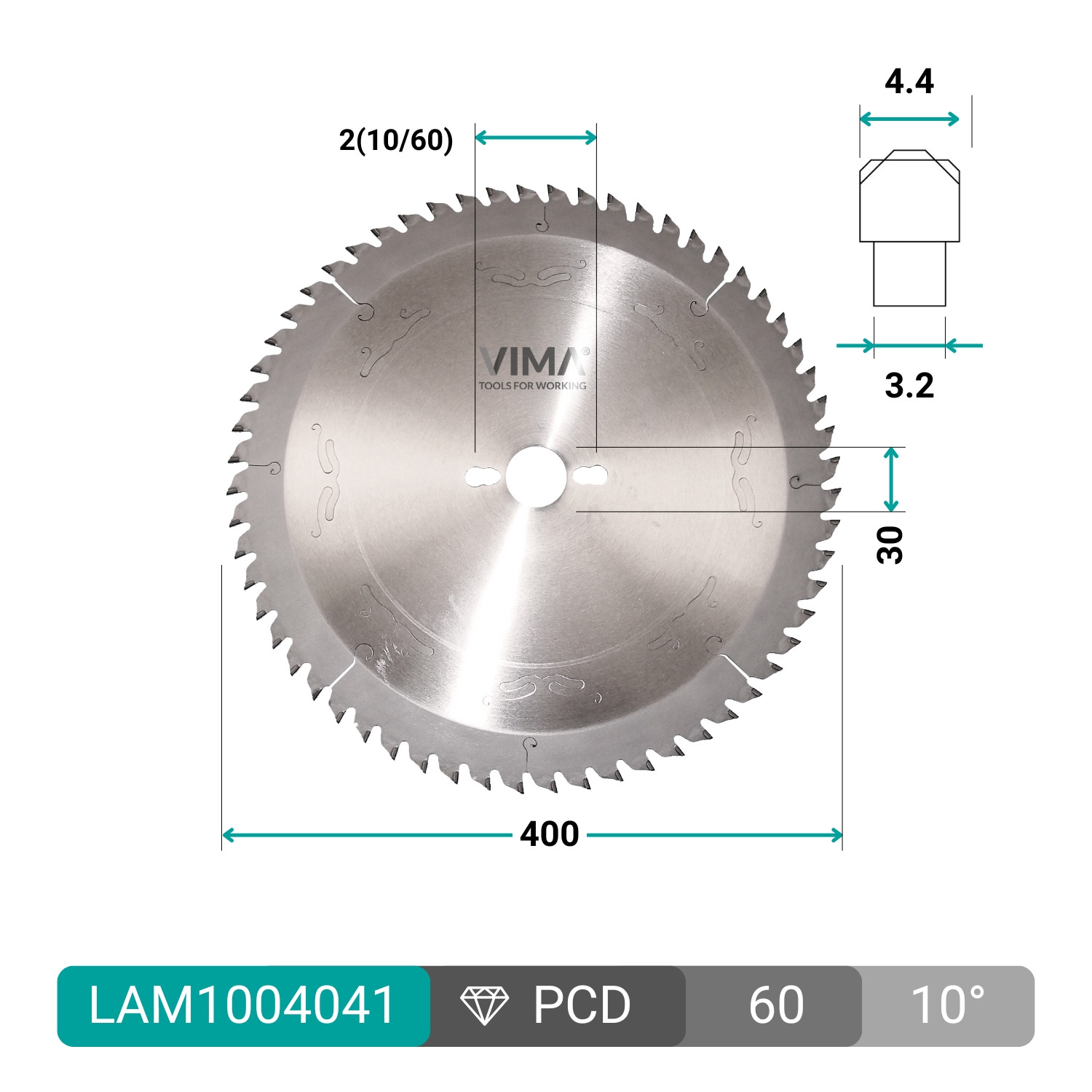

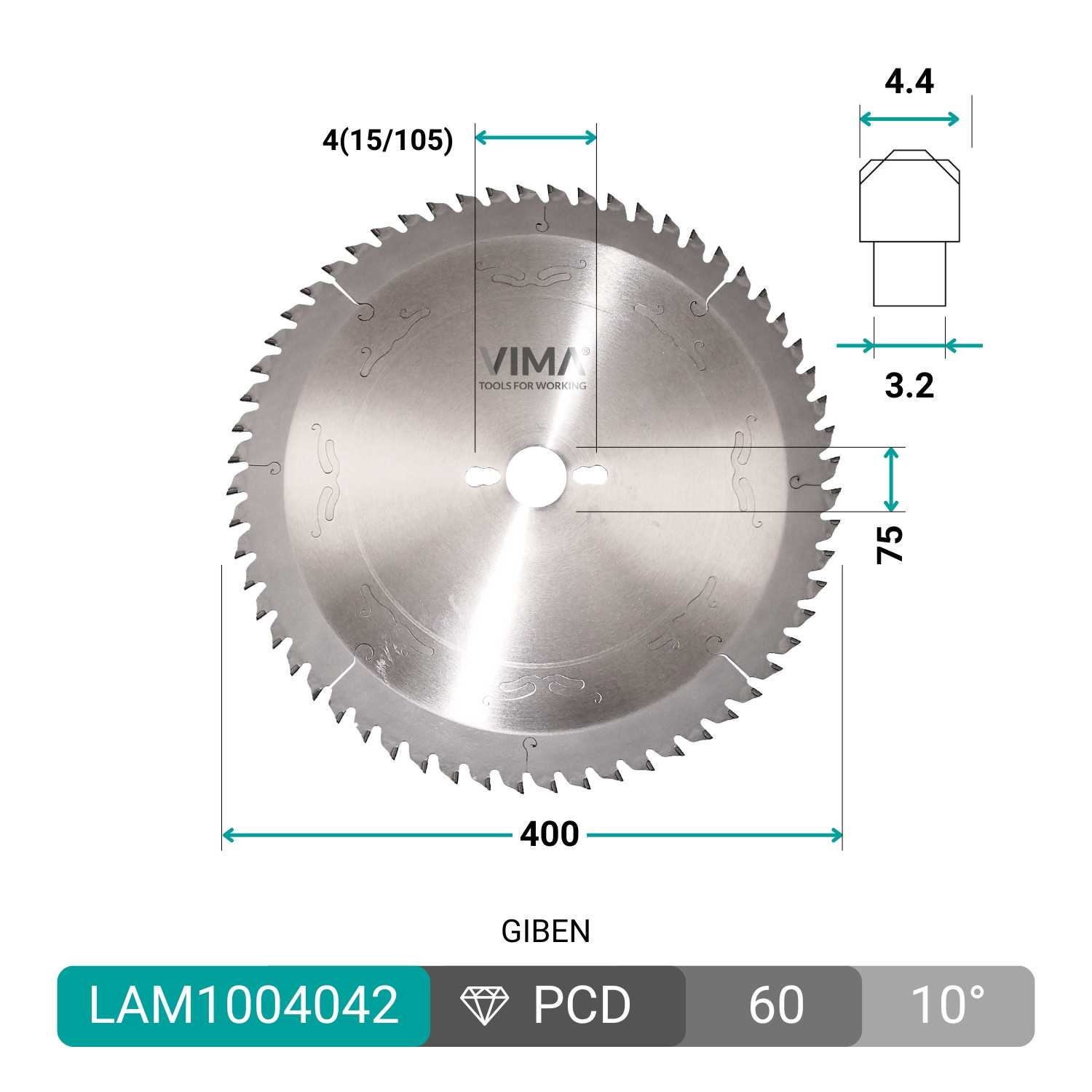

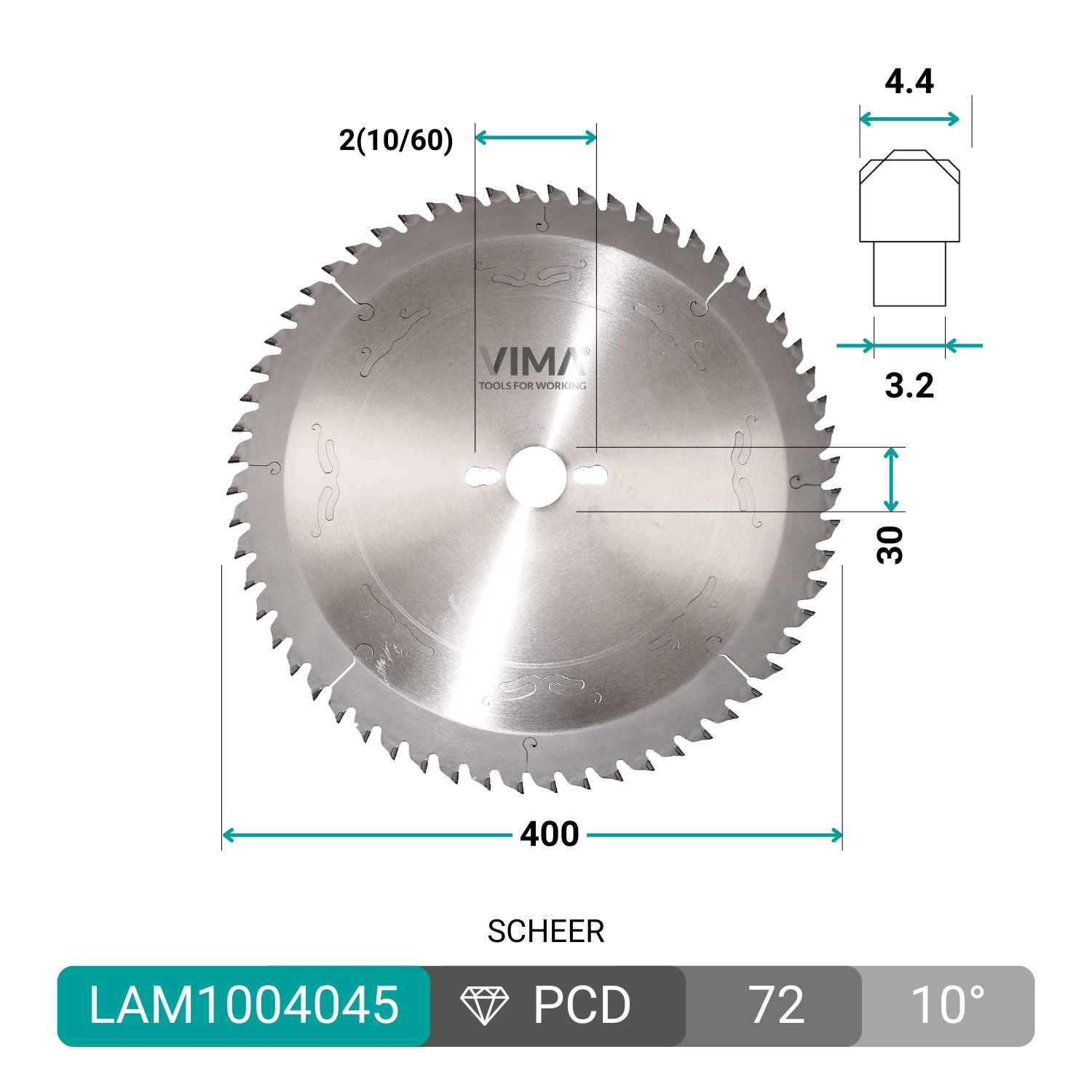

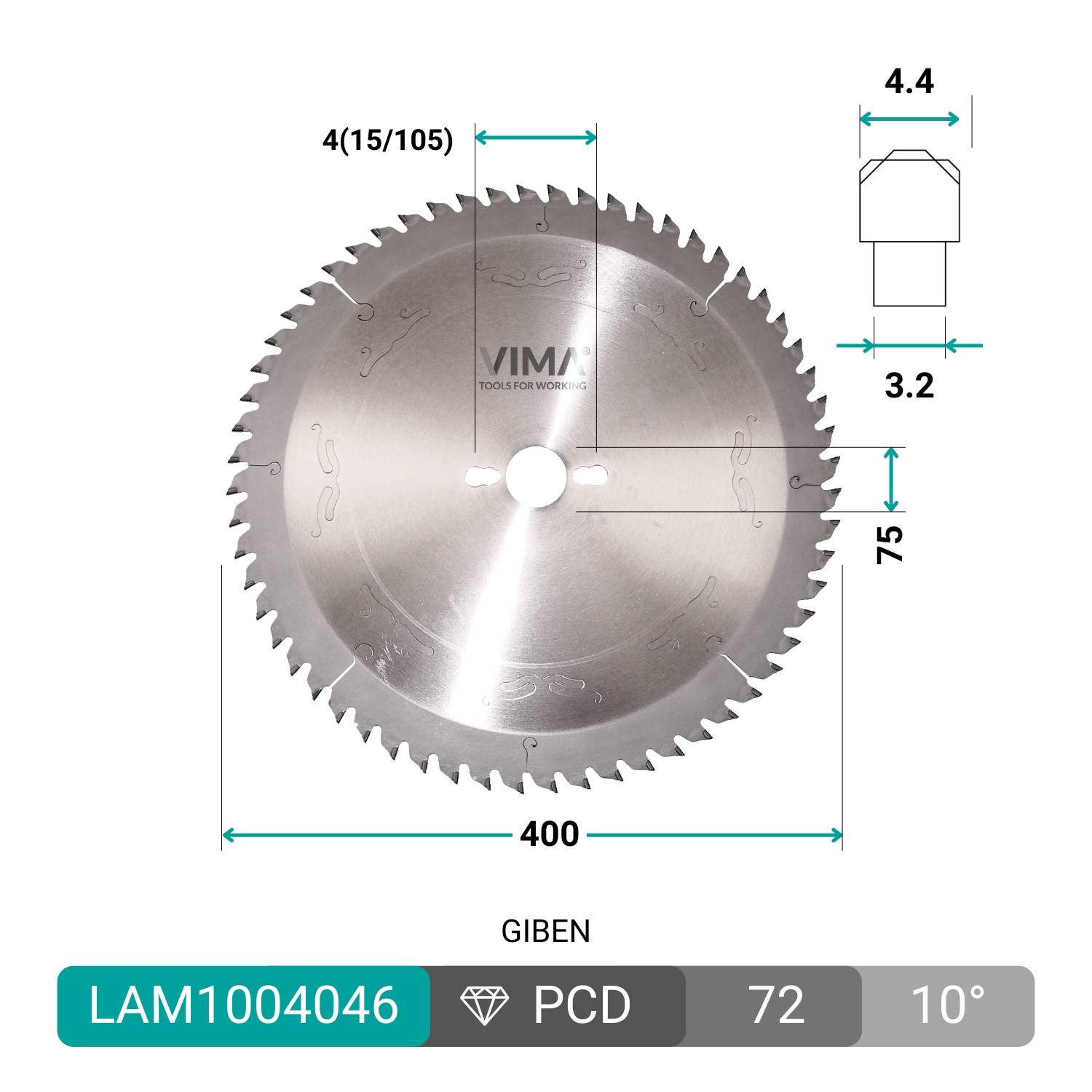

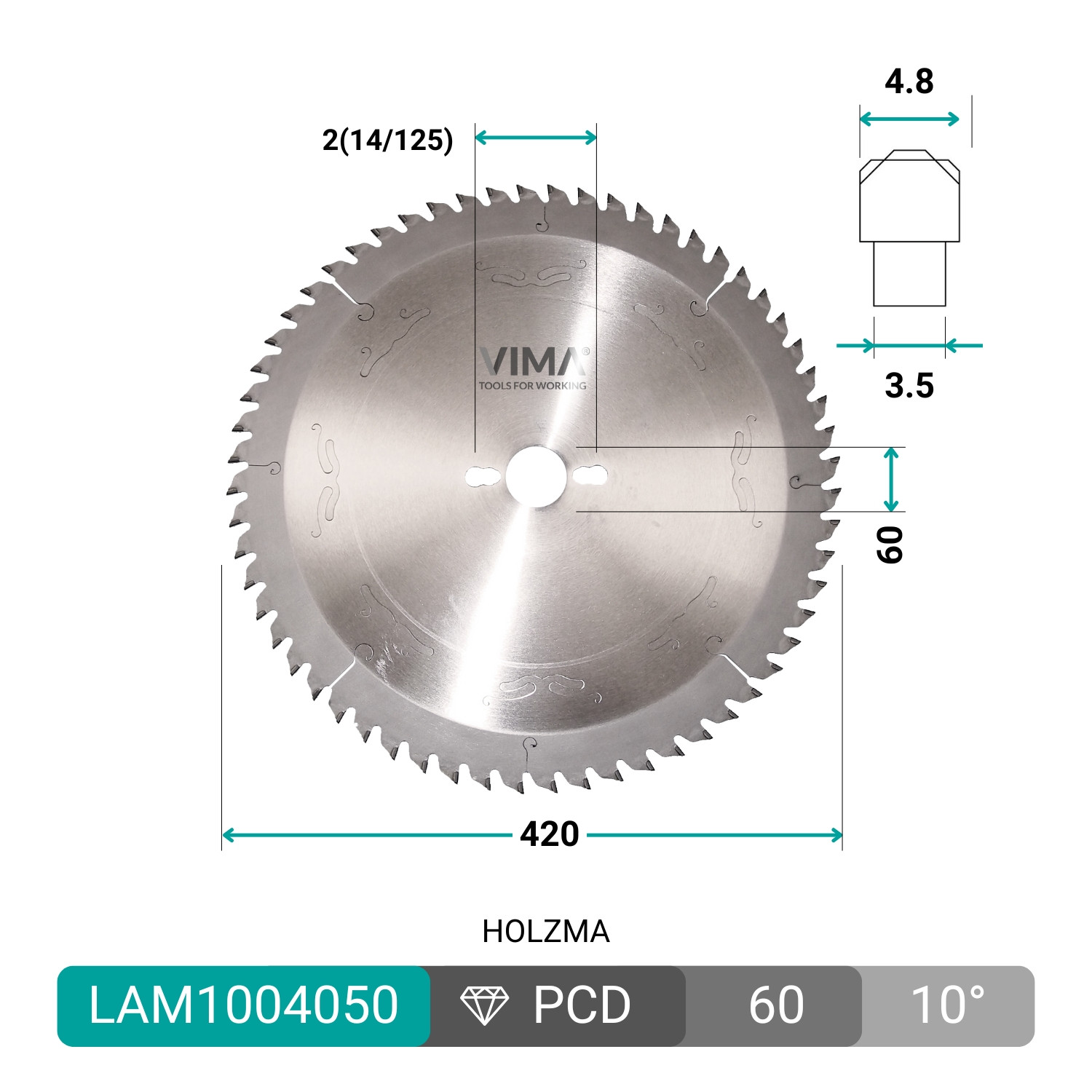

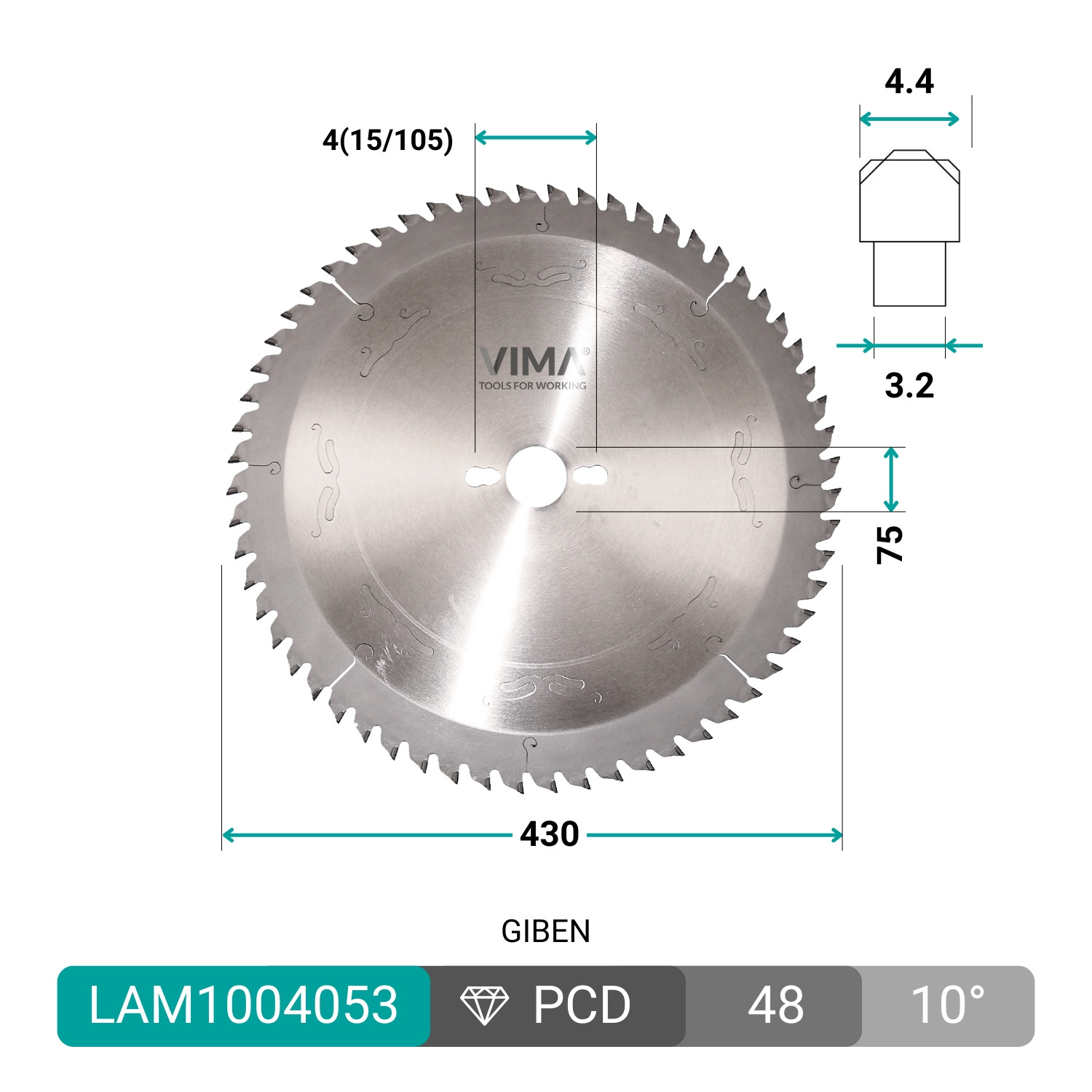

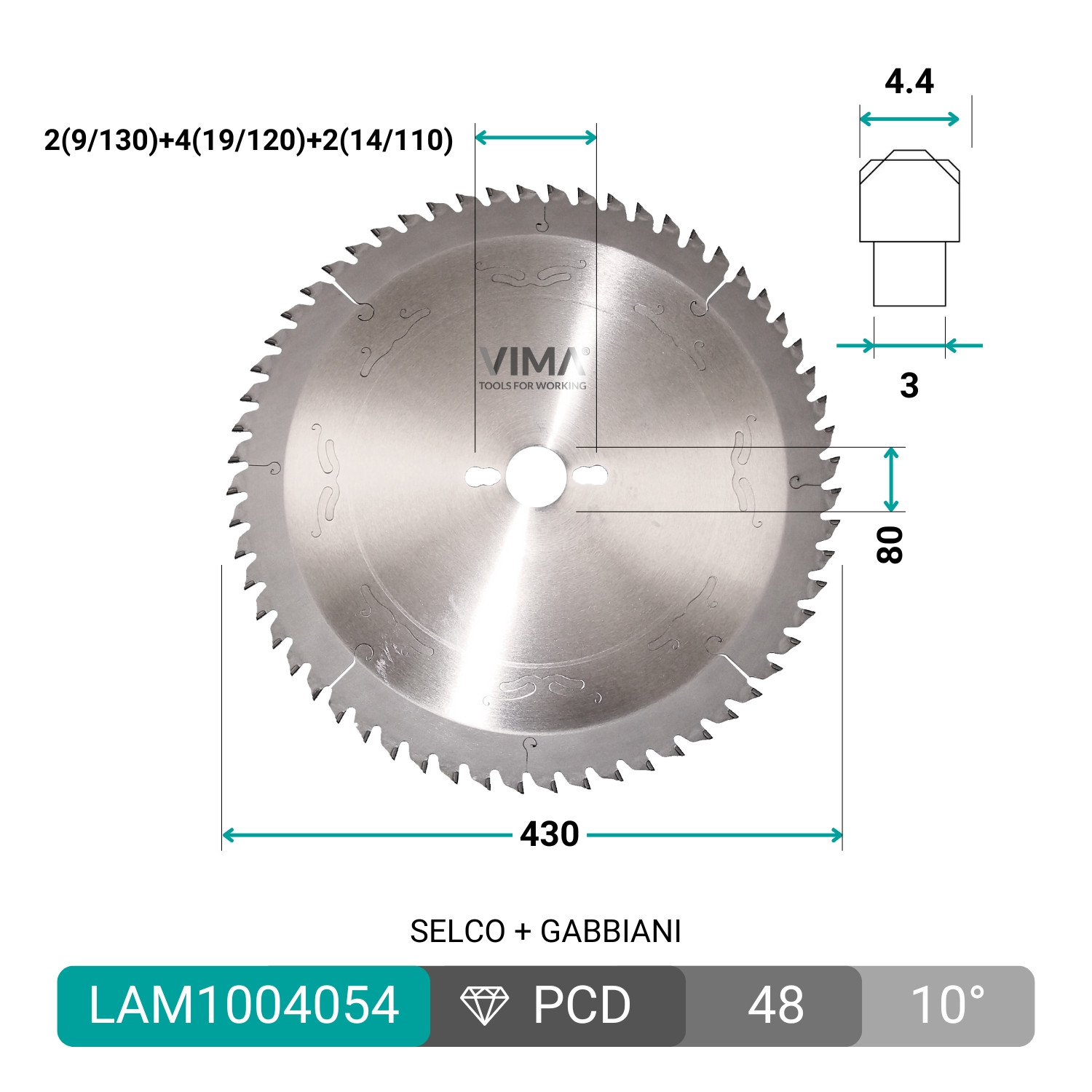

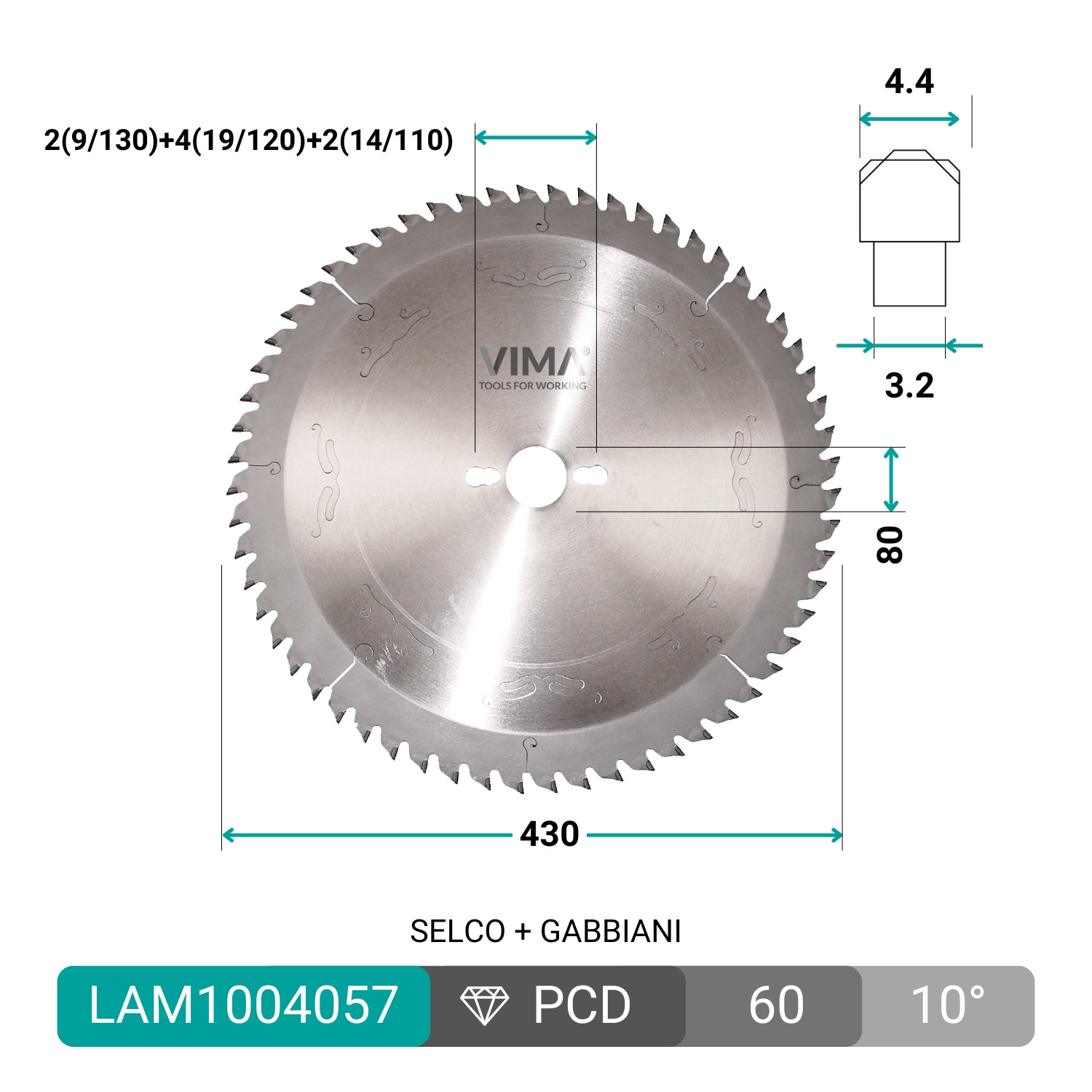

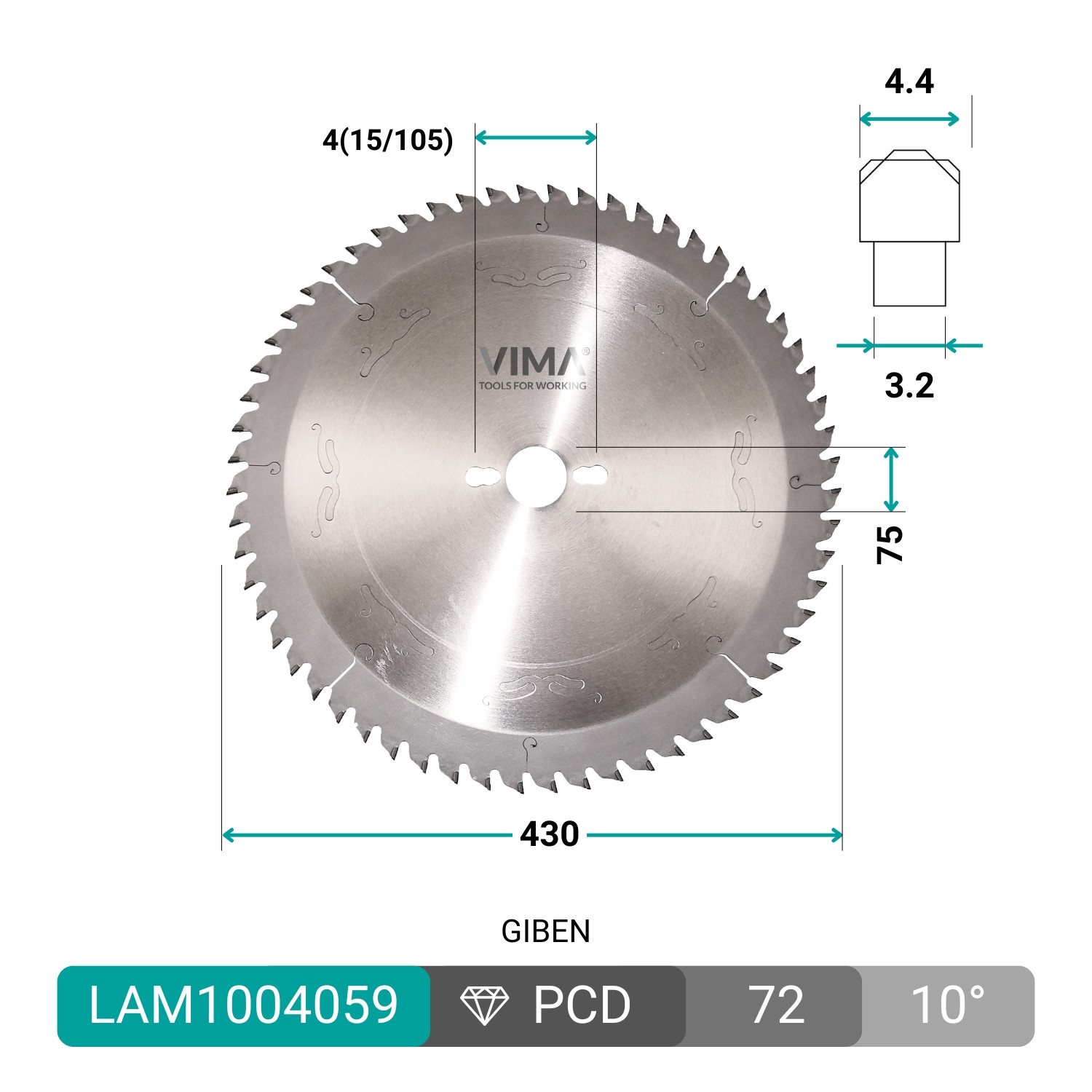

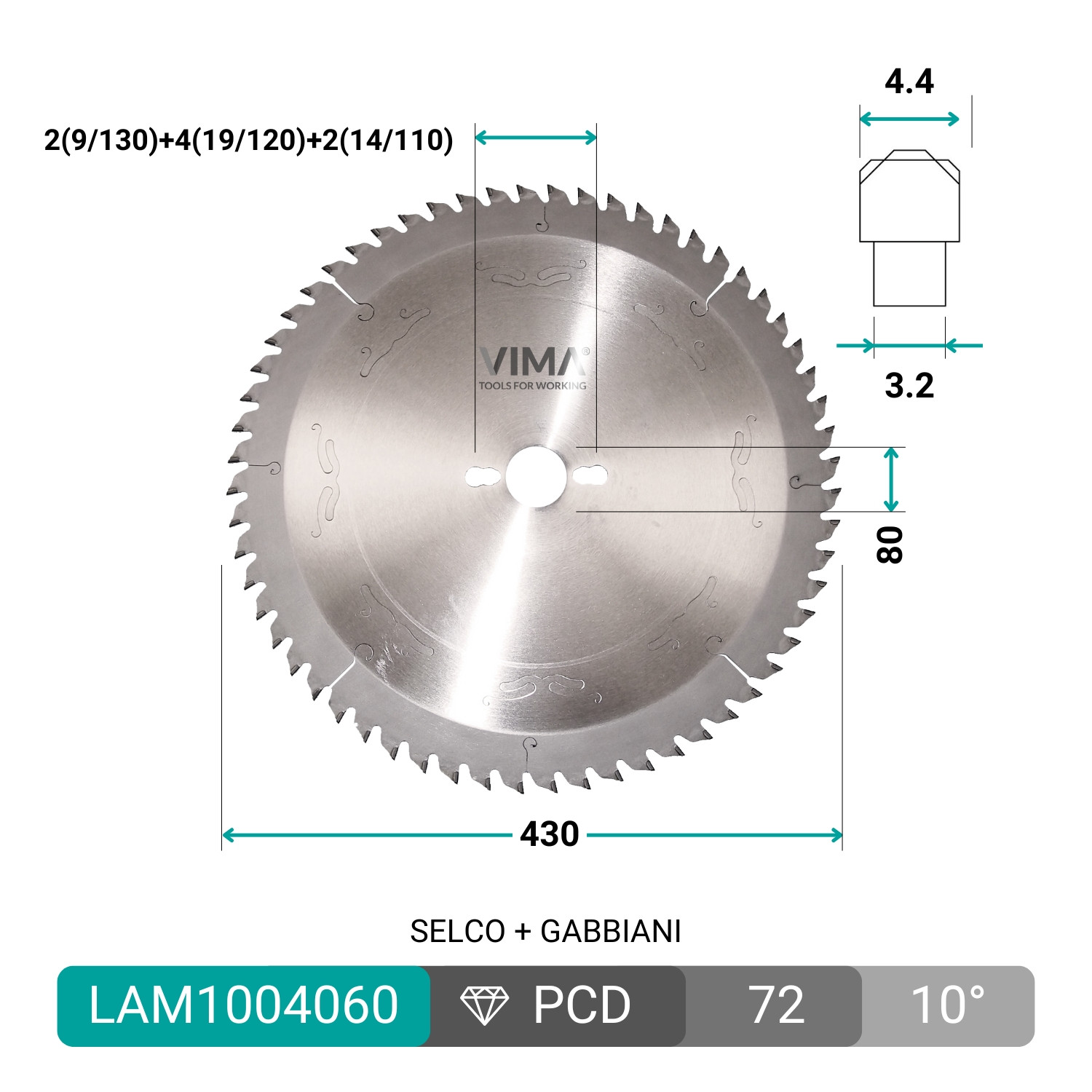

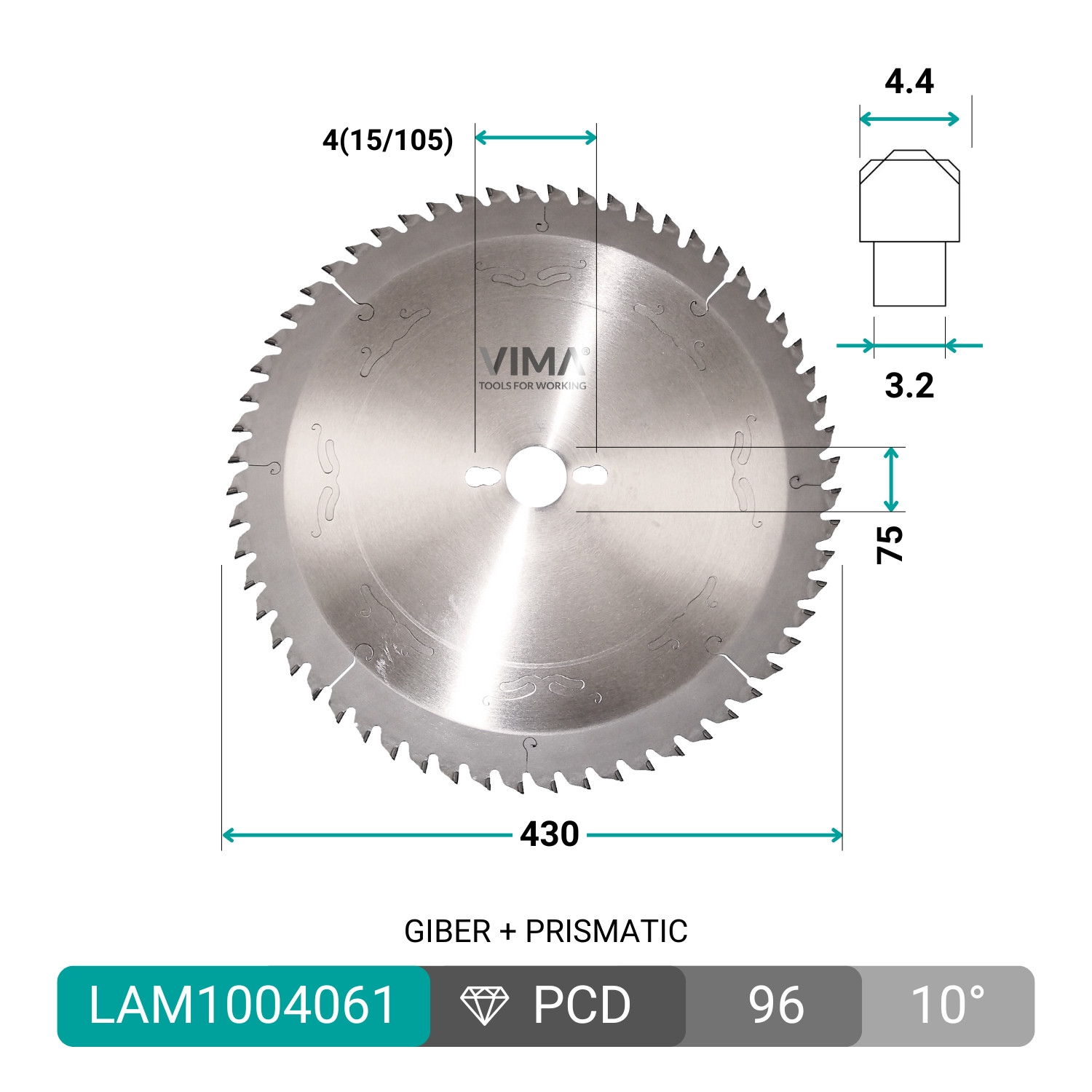

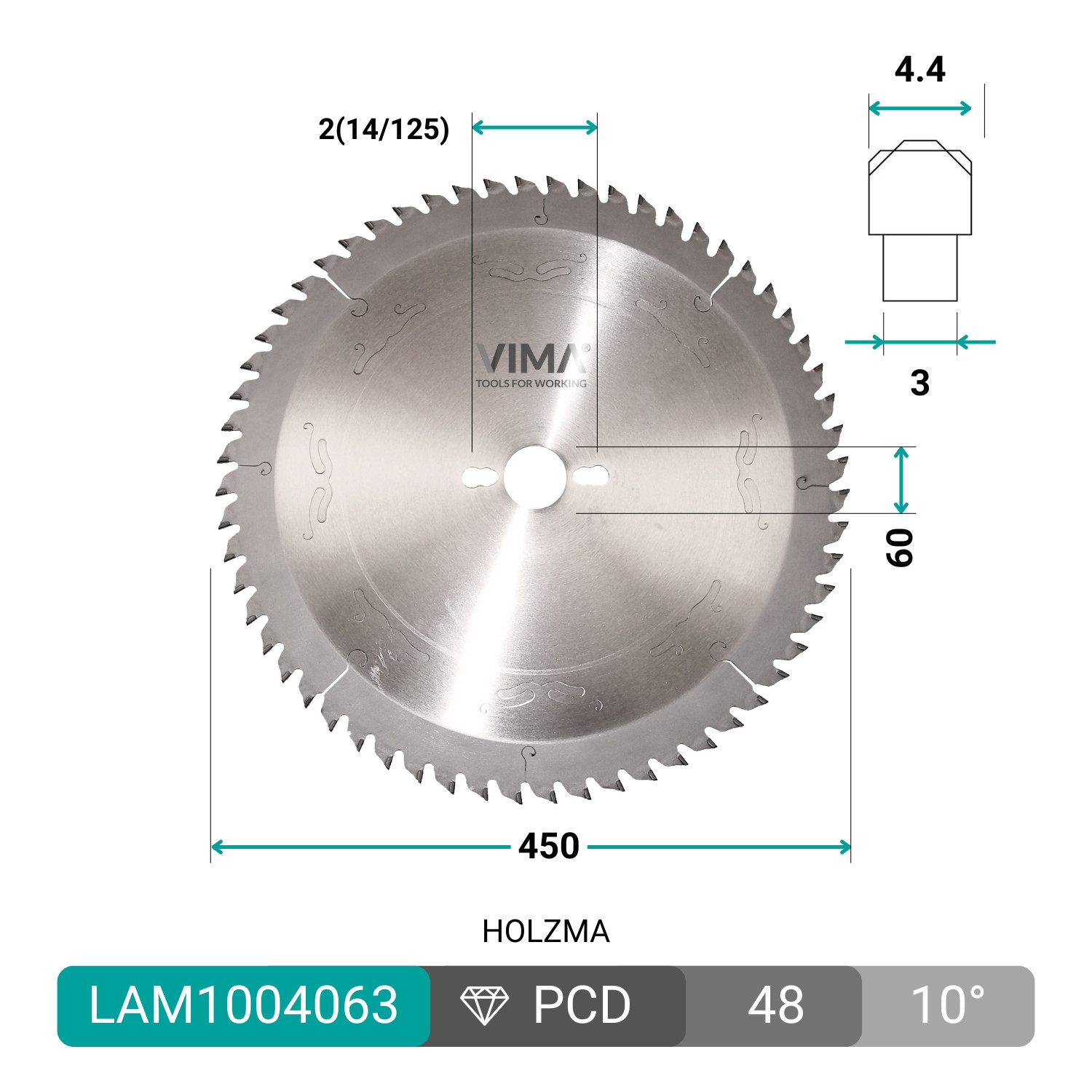

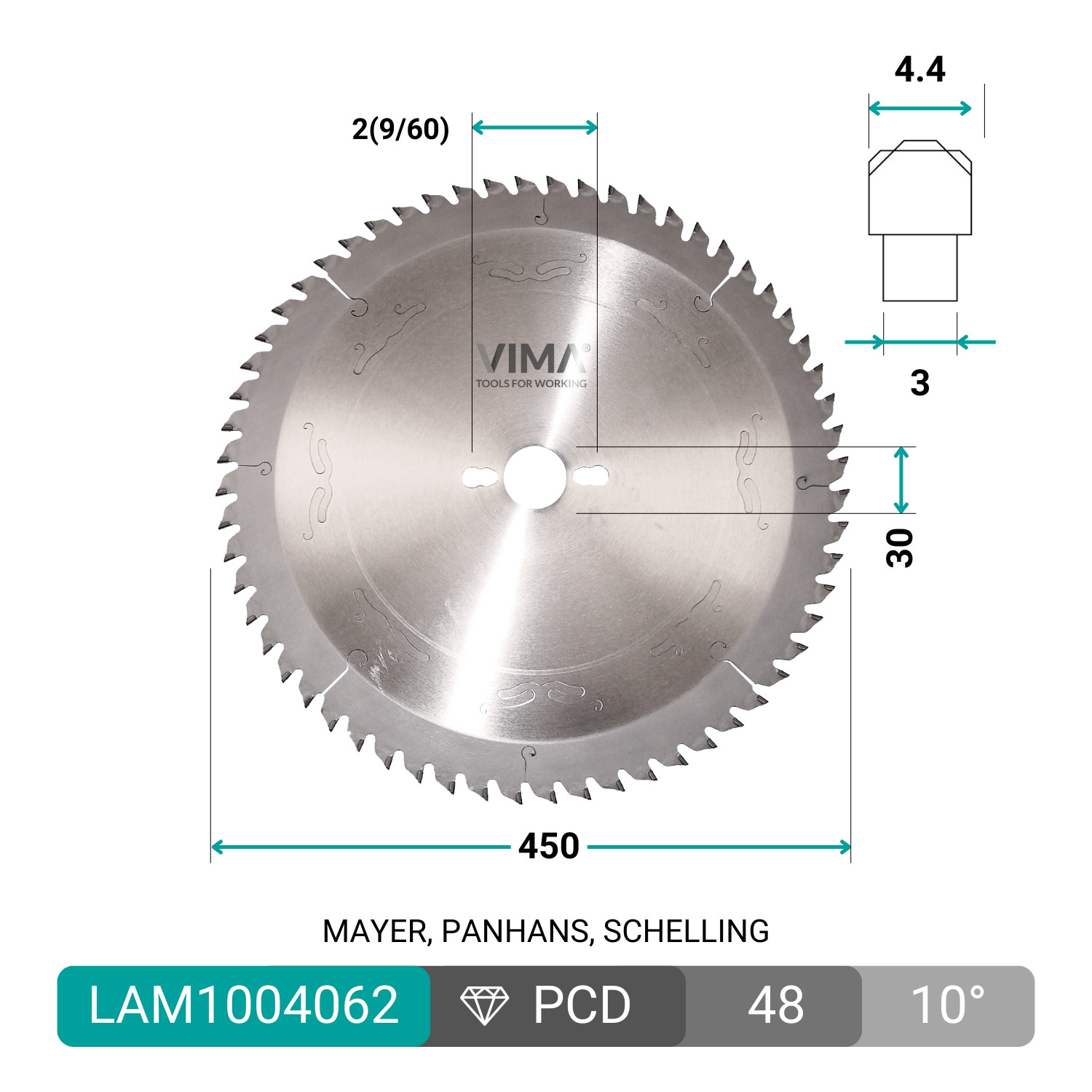

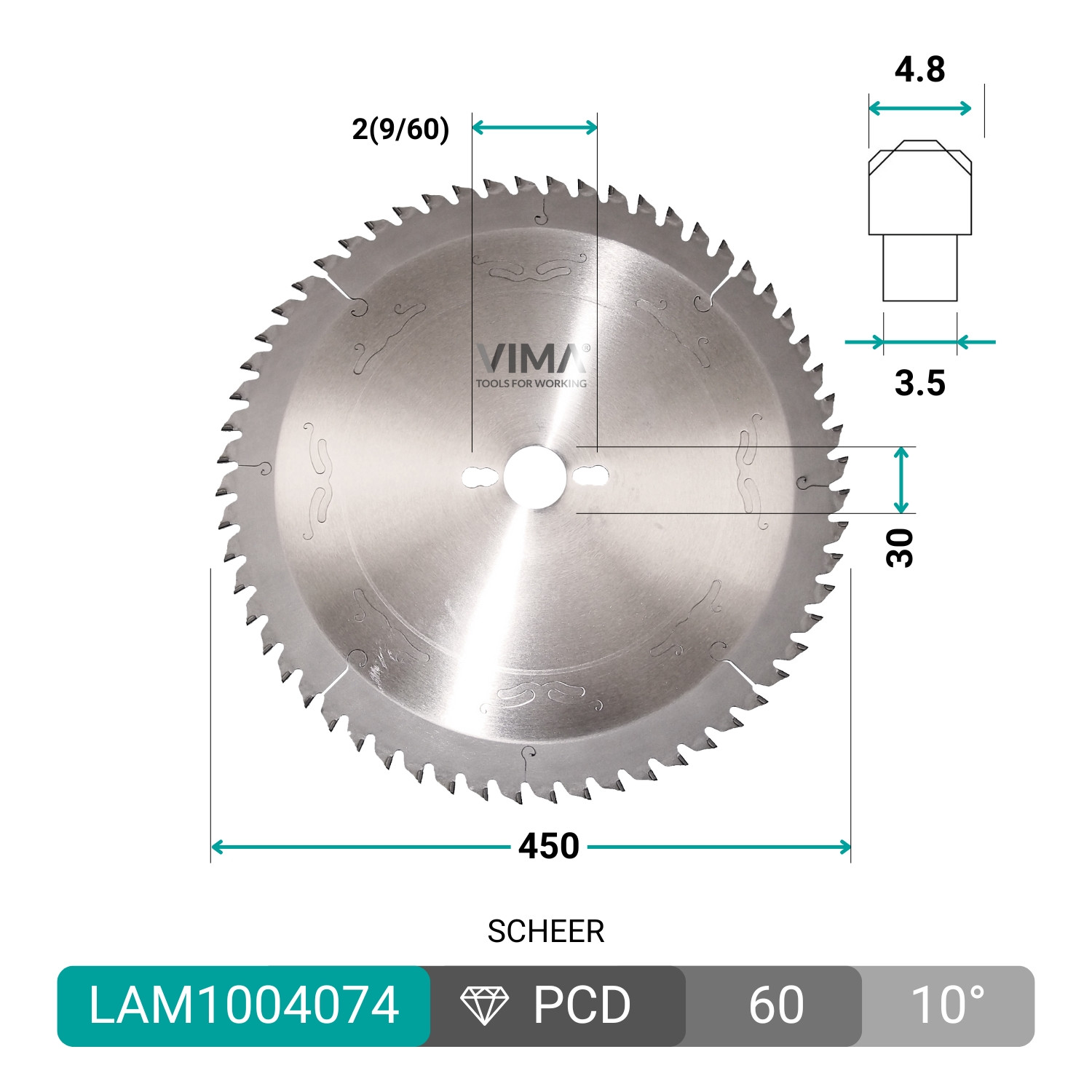

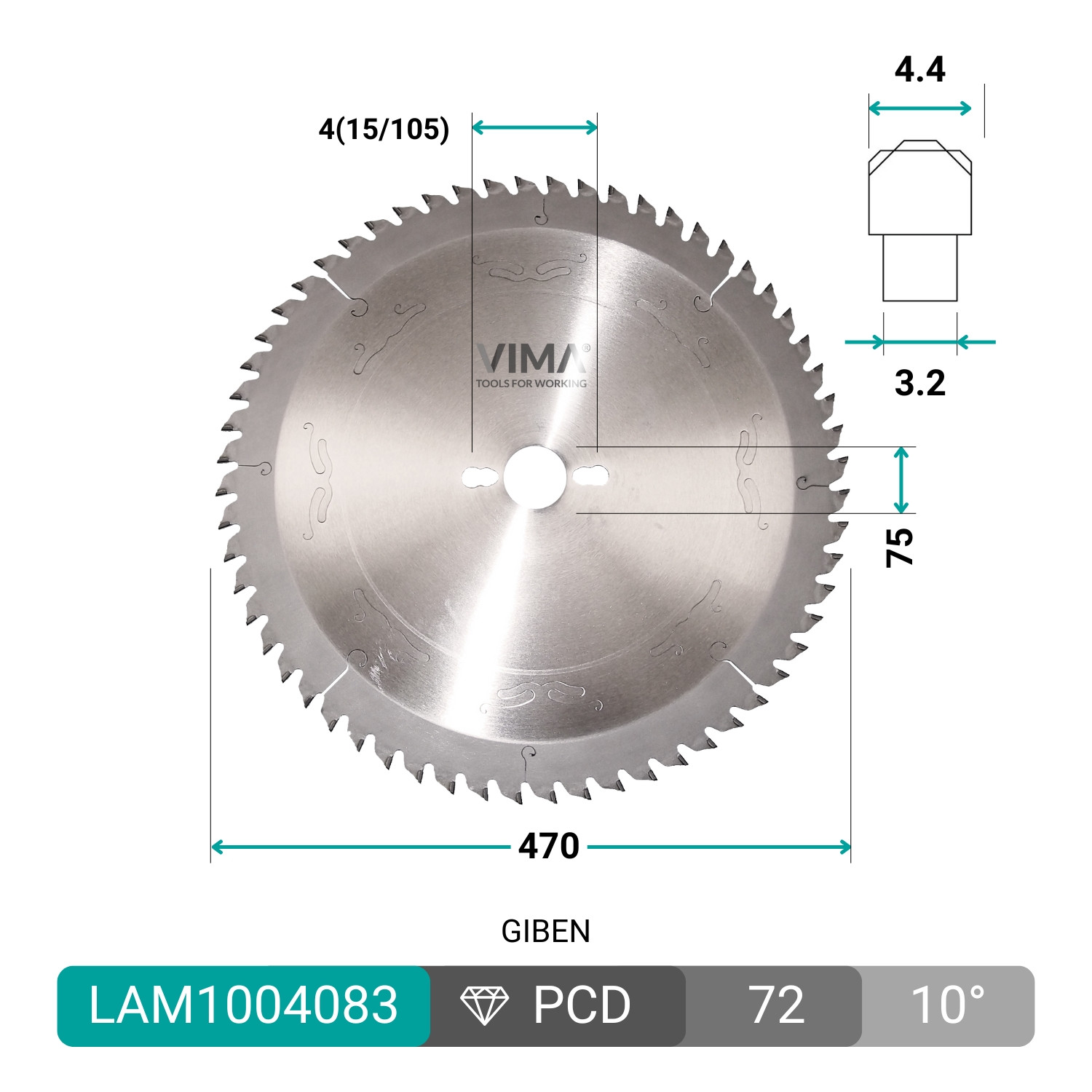

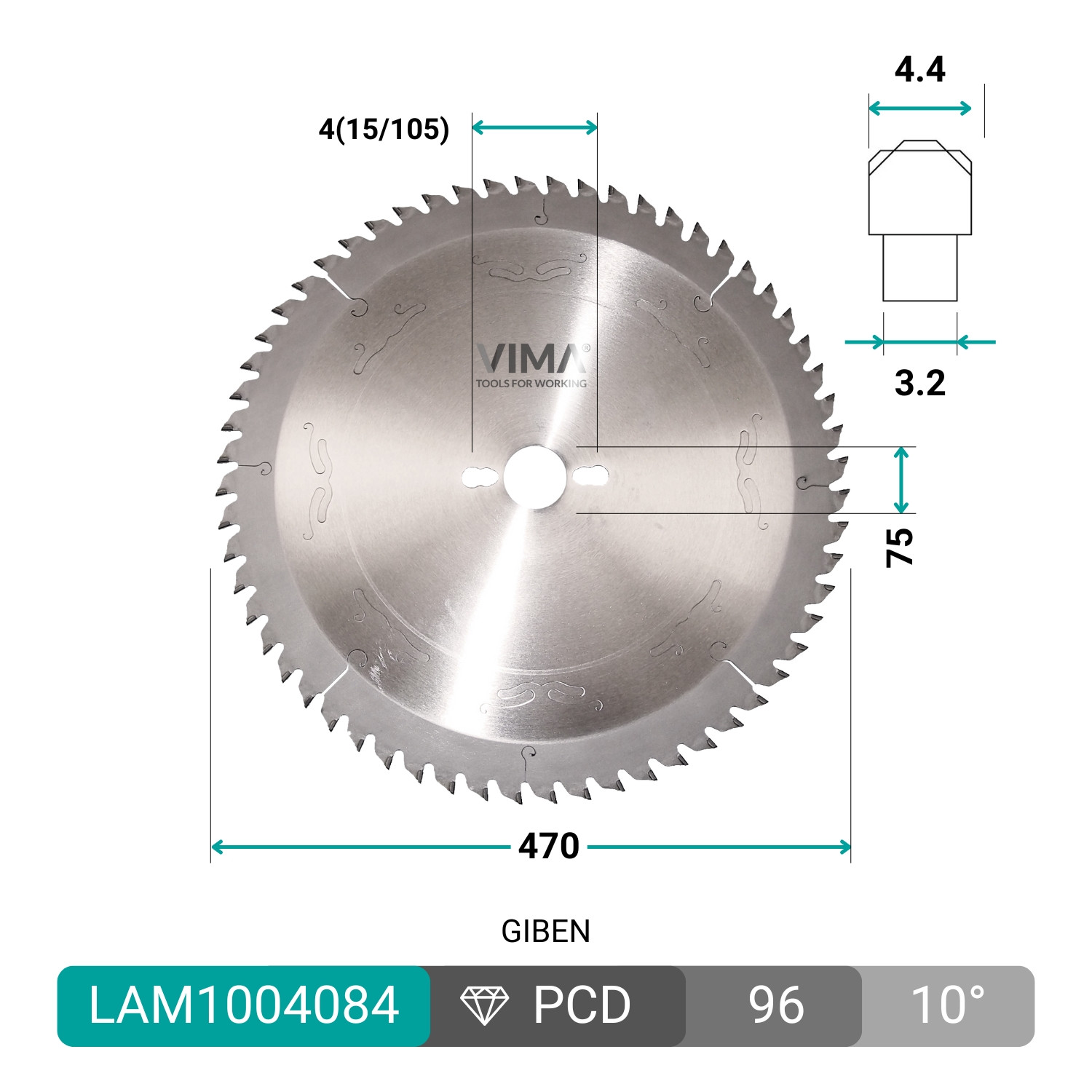

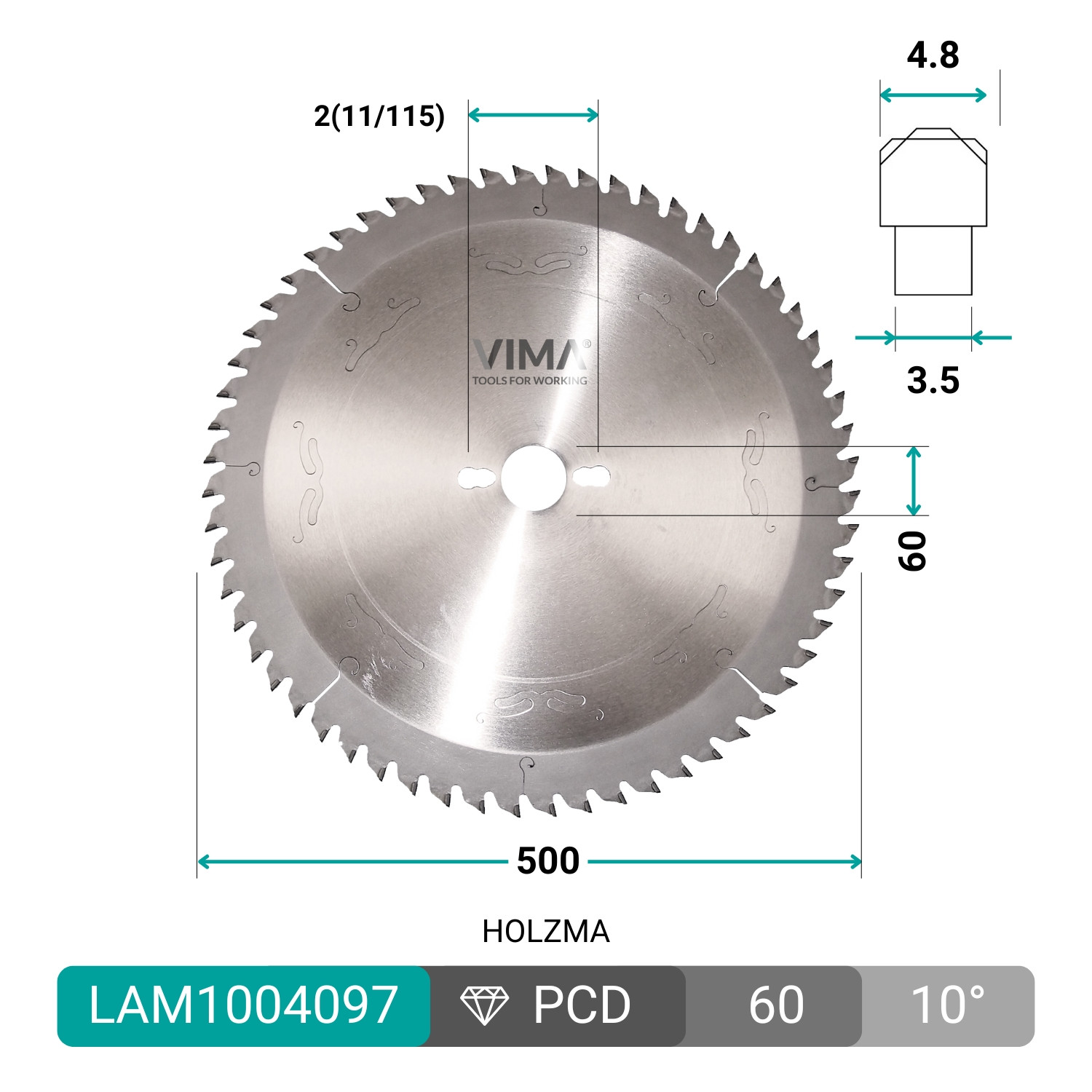

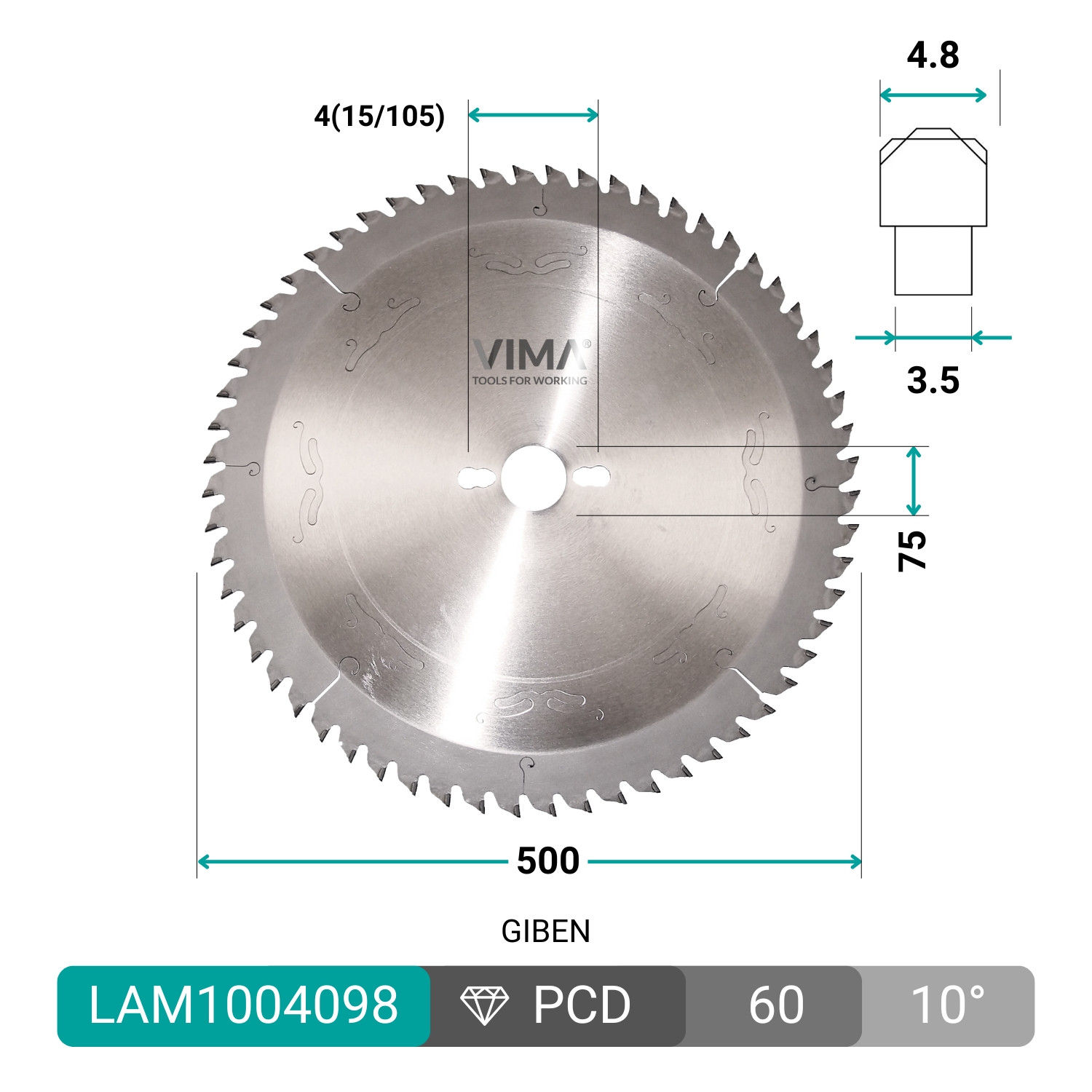

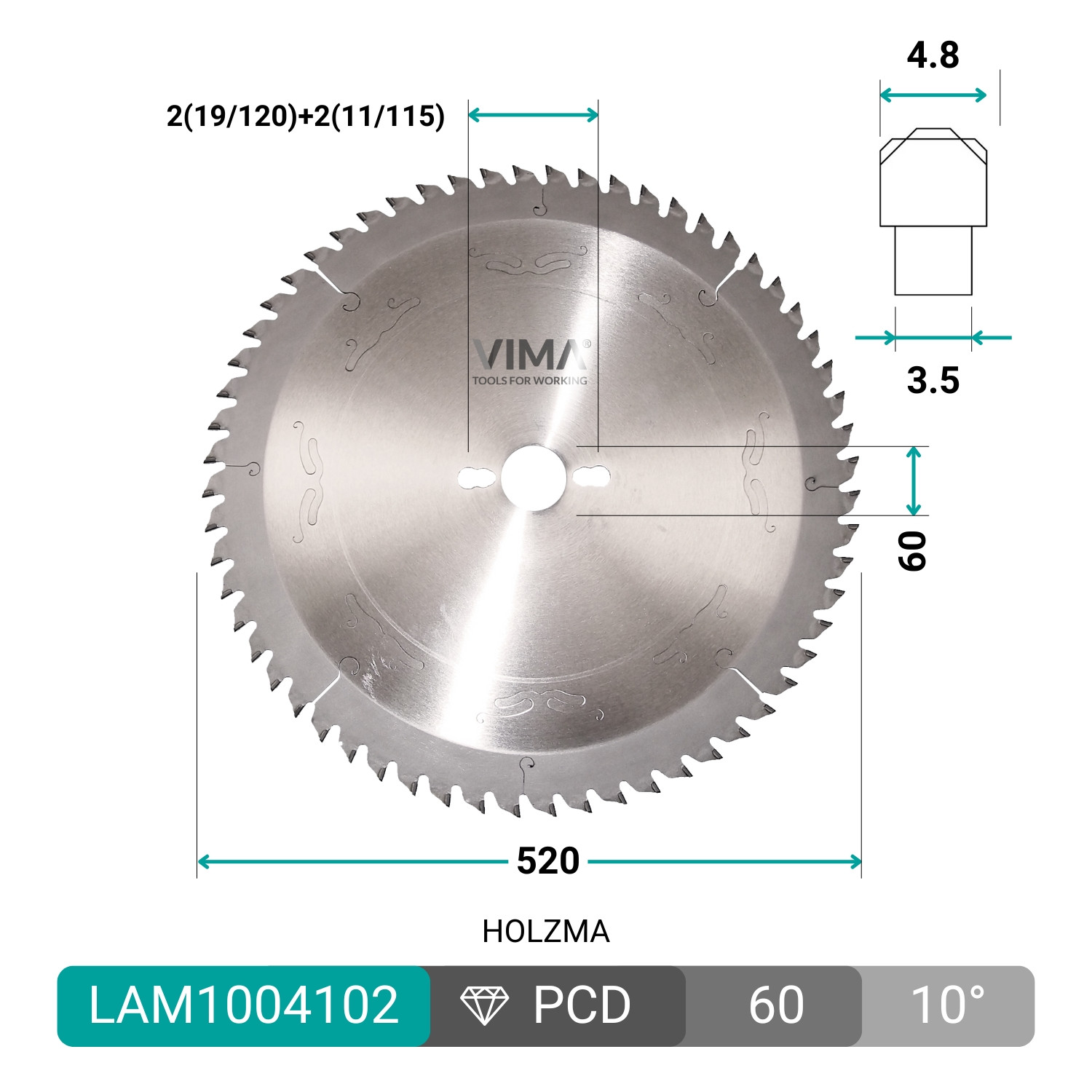

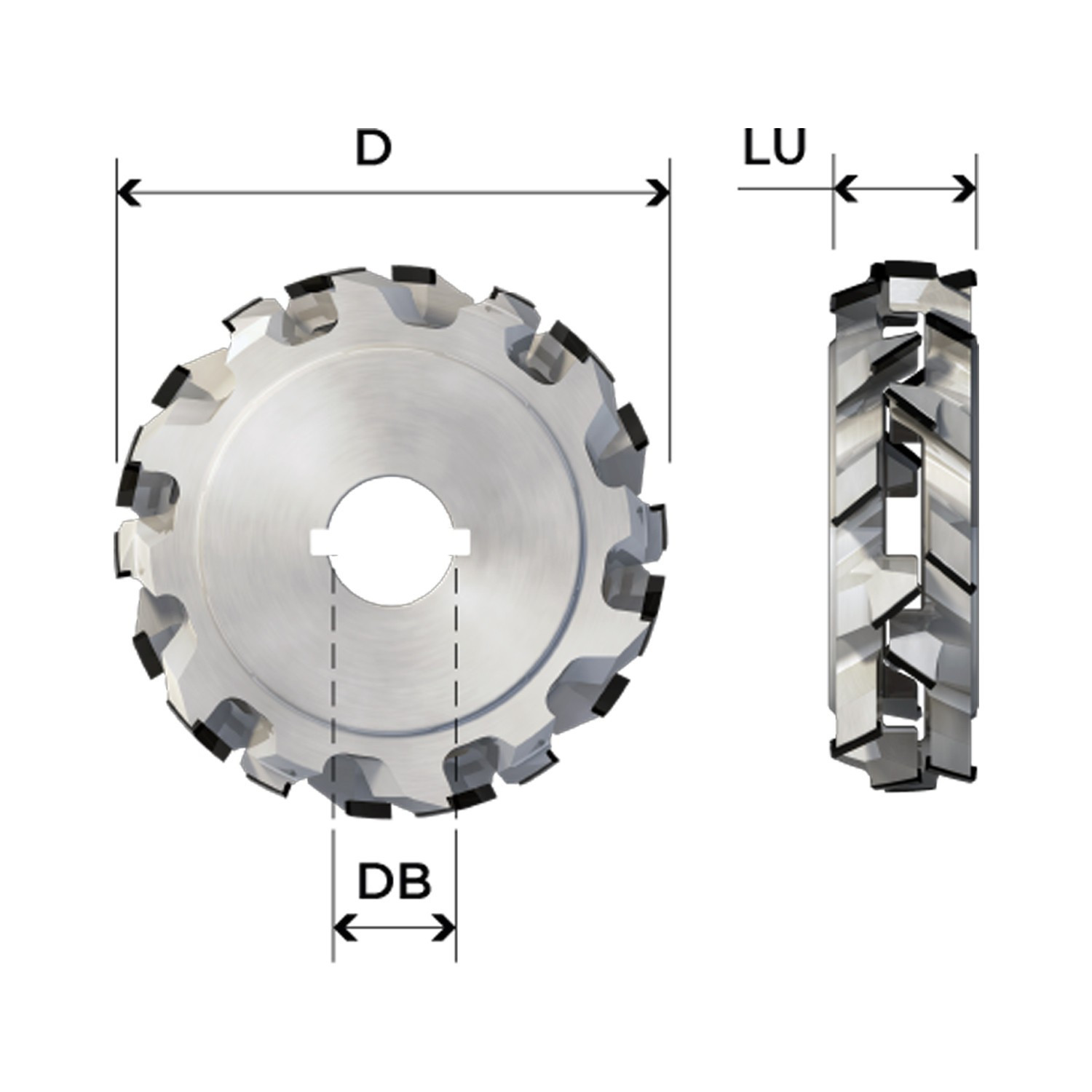

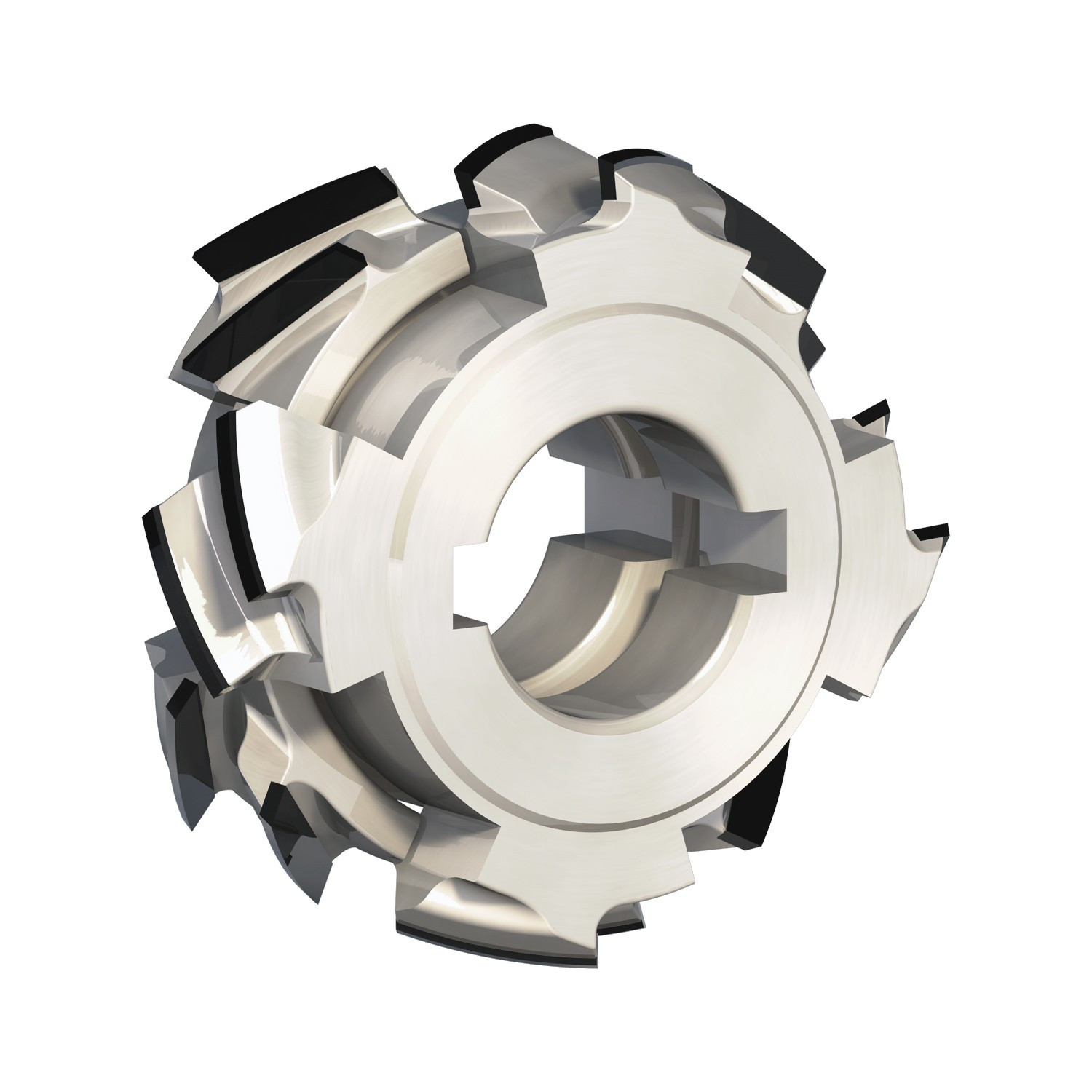

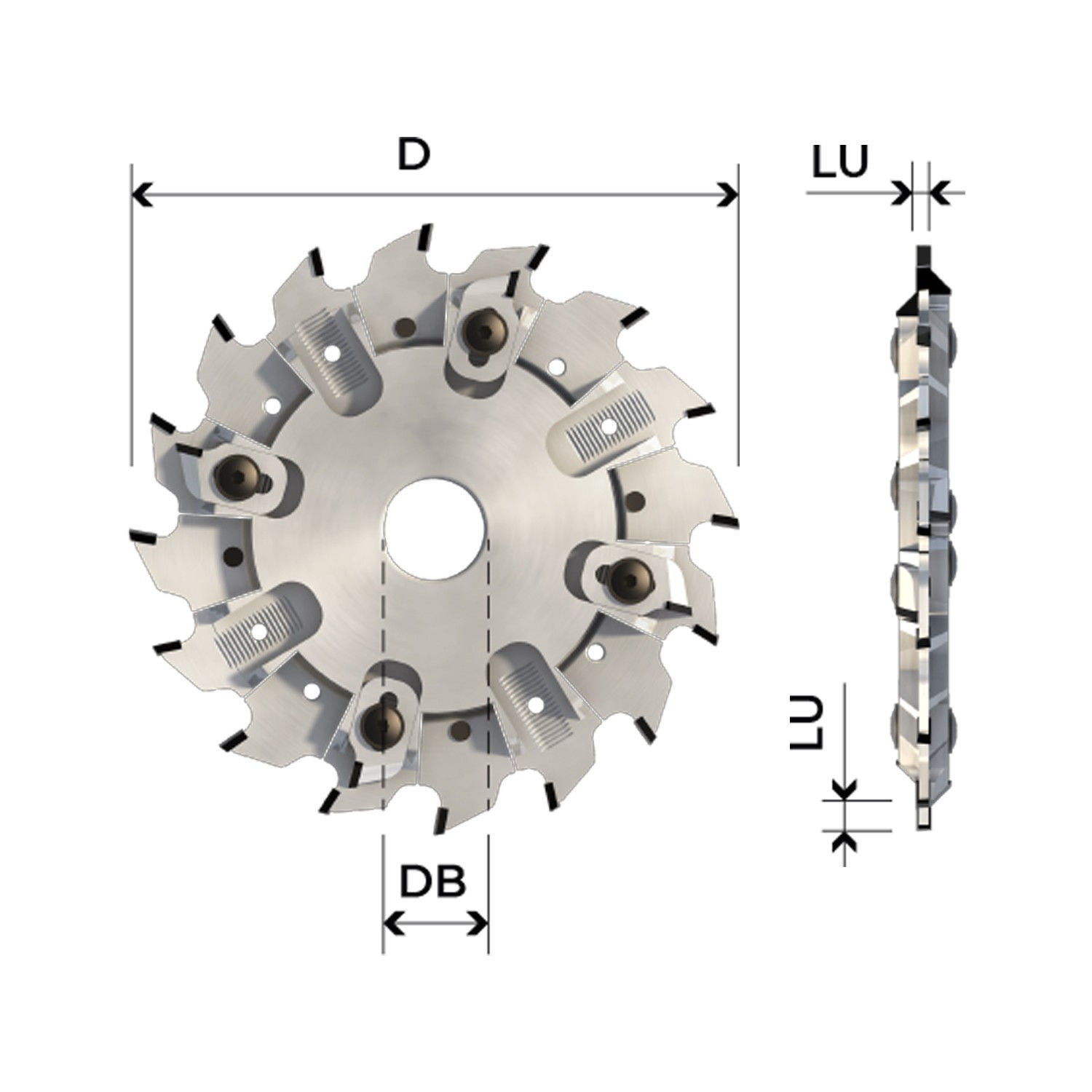

Adjustable PCD scoring blade designed for clean and accurate scoring on laminated panels. The PCD construction ensures superior wear resistance, while the adjustable width allows perfect alignment with the main saw blade. Suitable for professional horizontal panel saws.

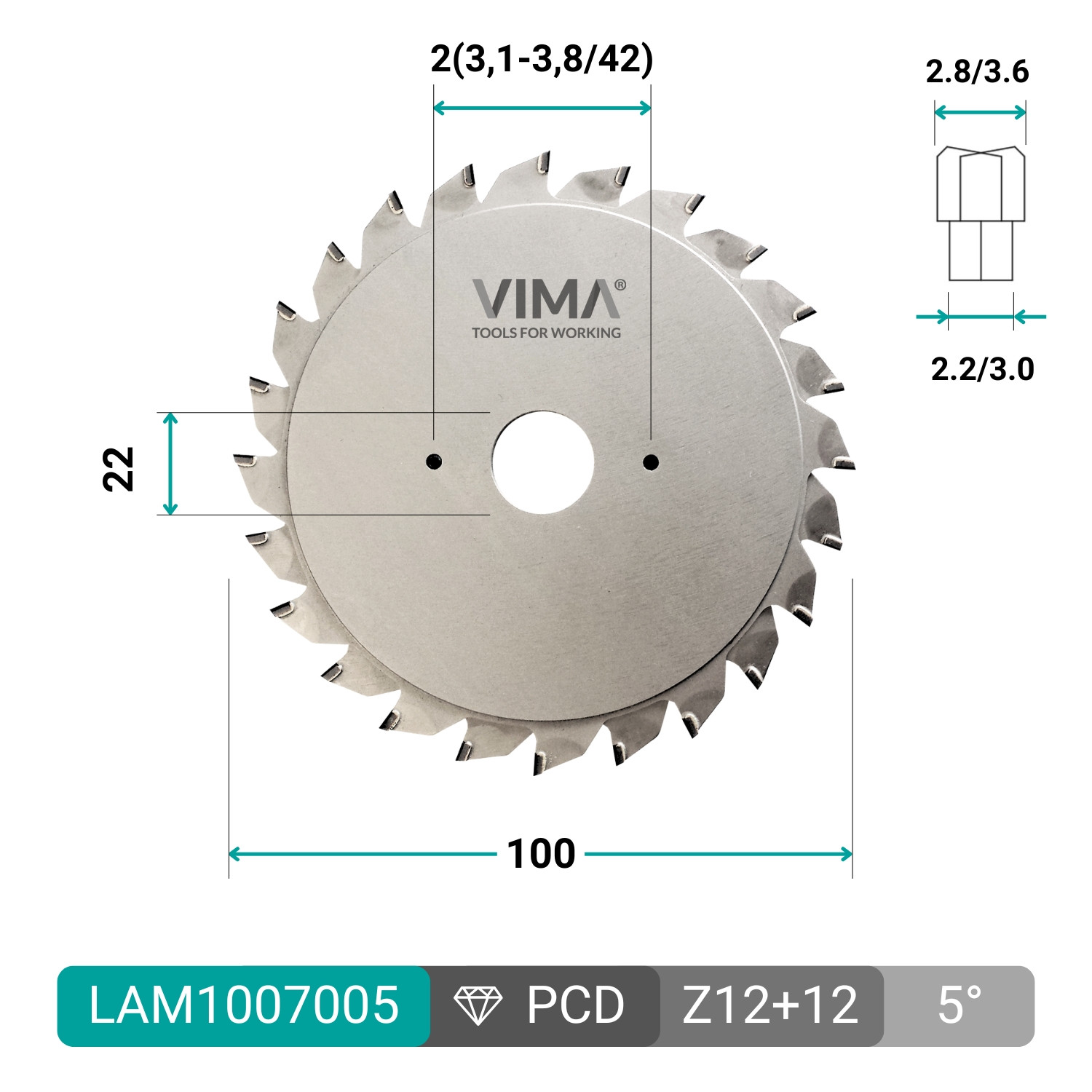

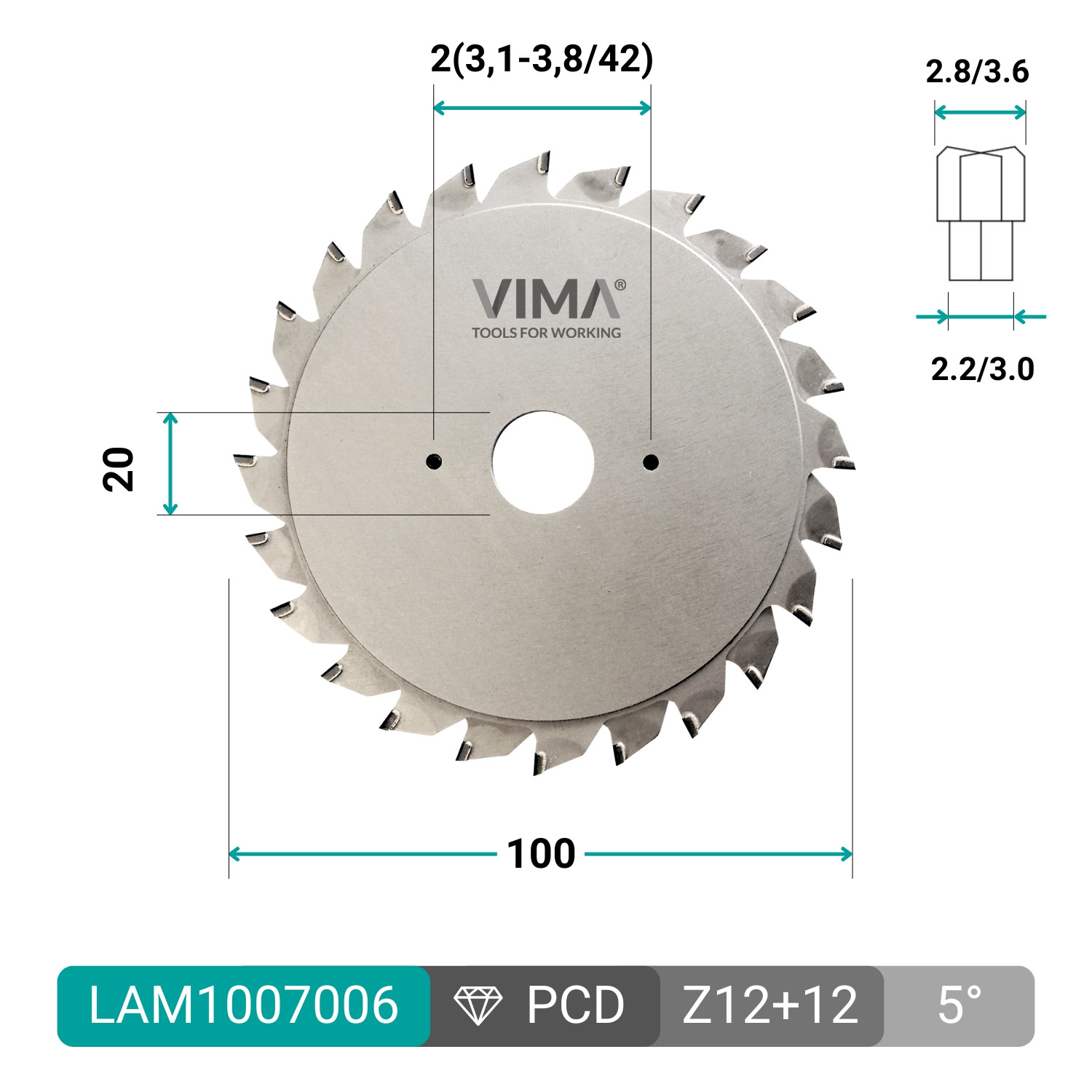

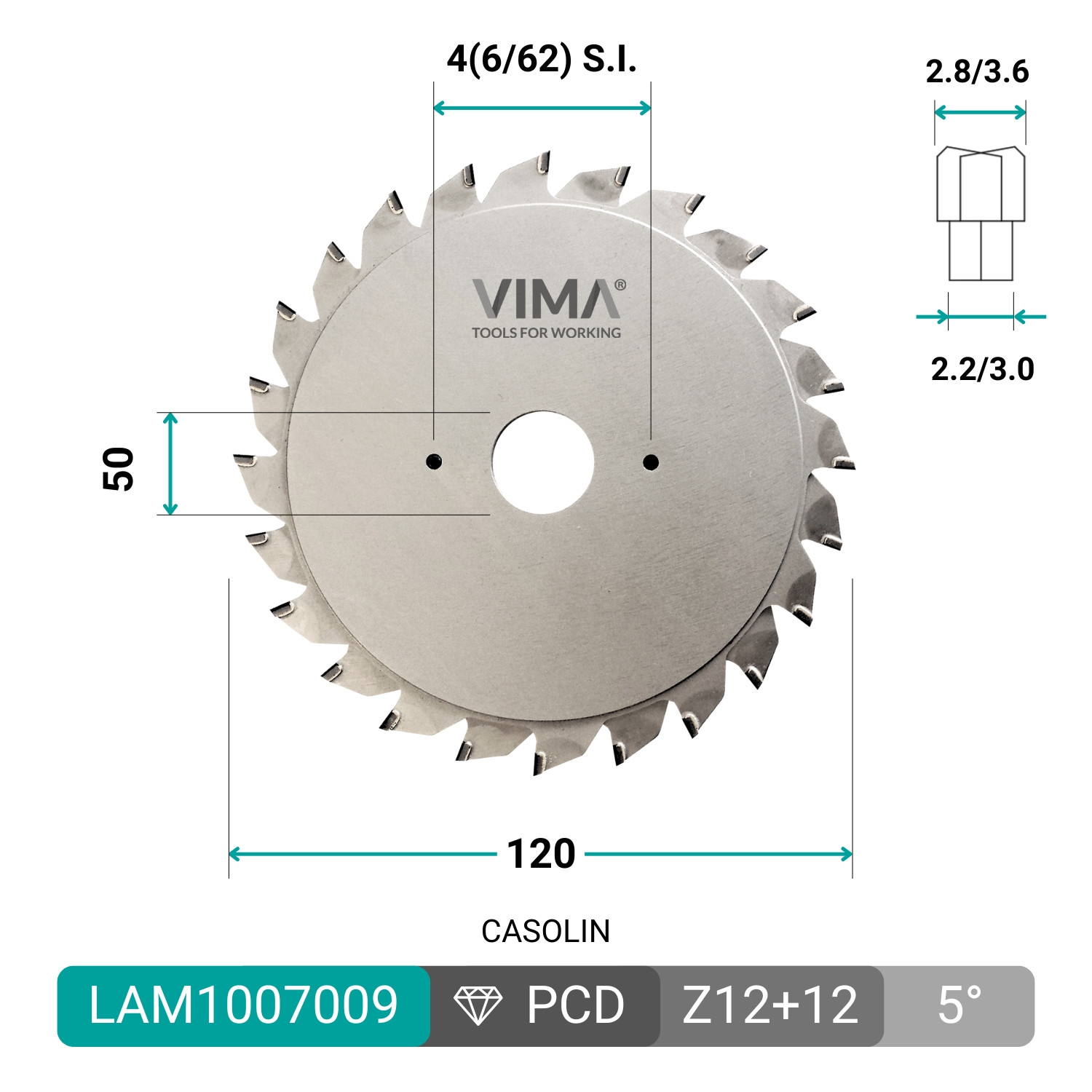

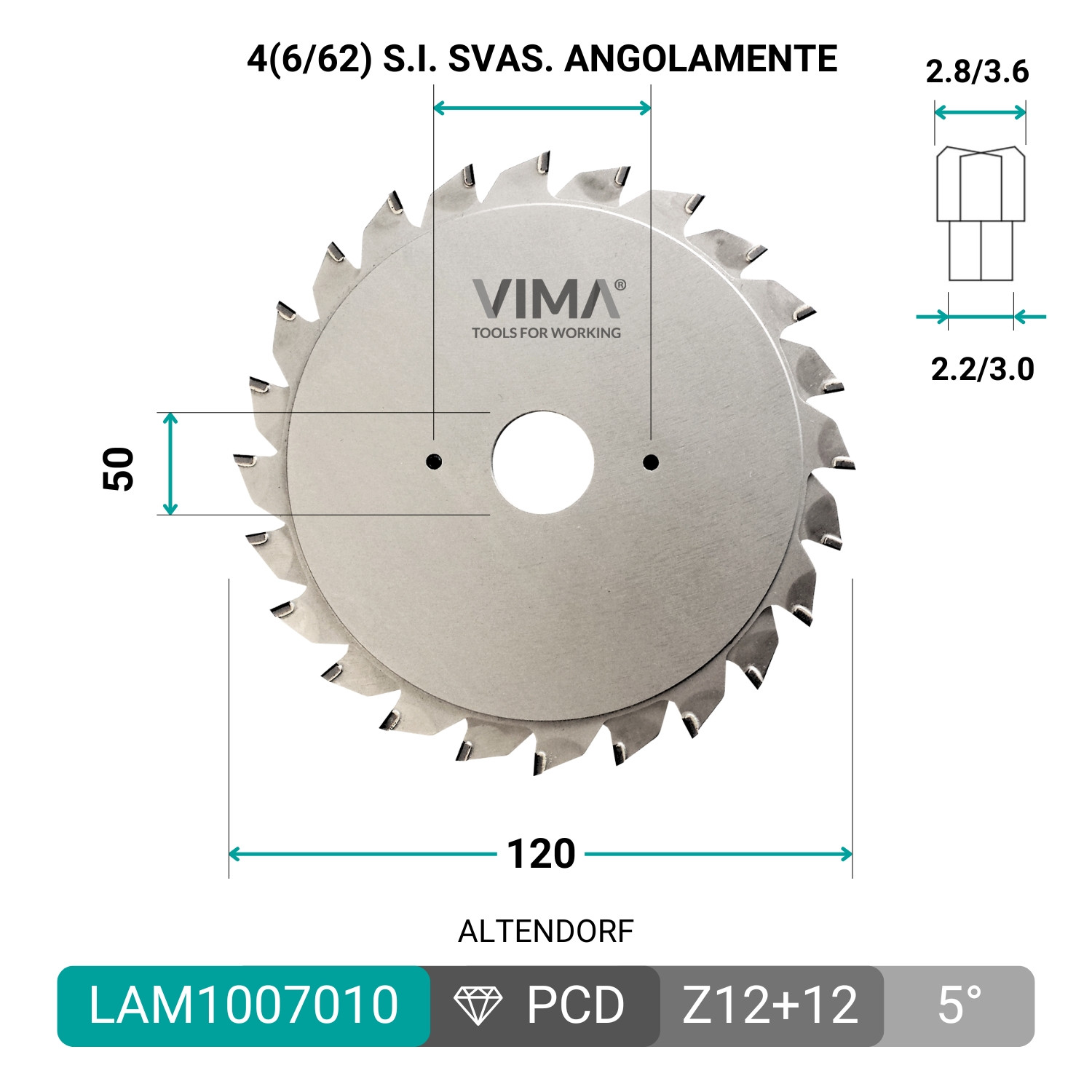

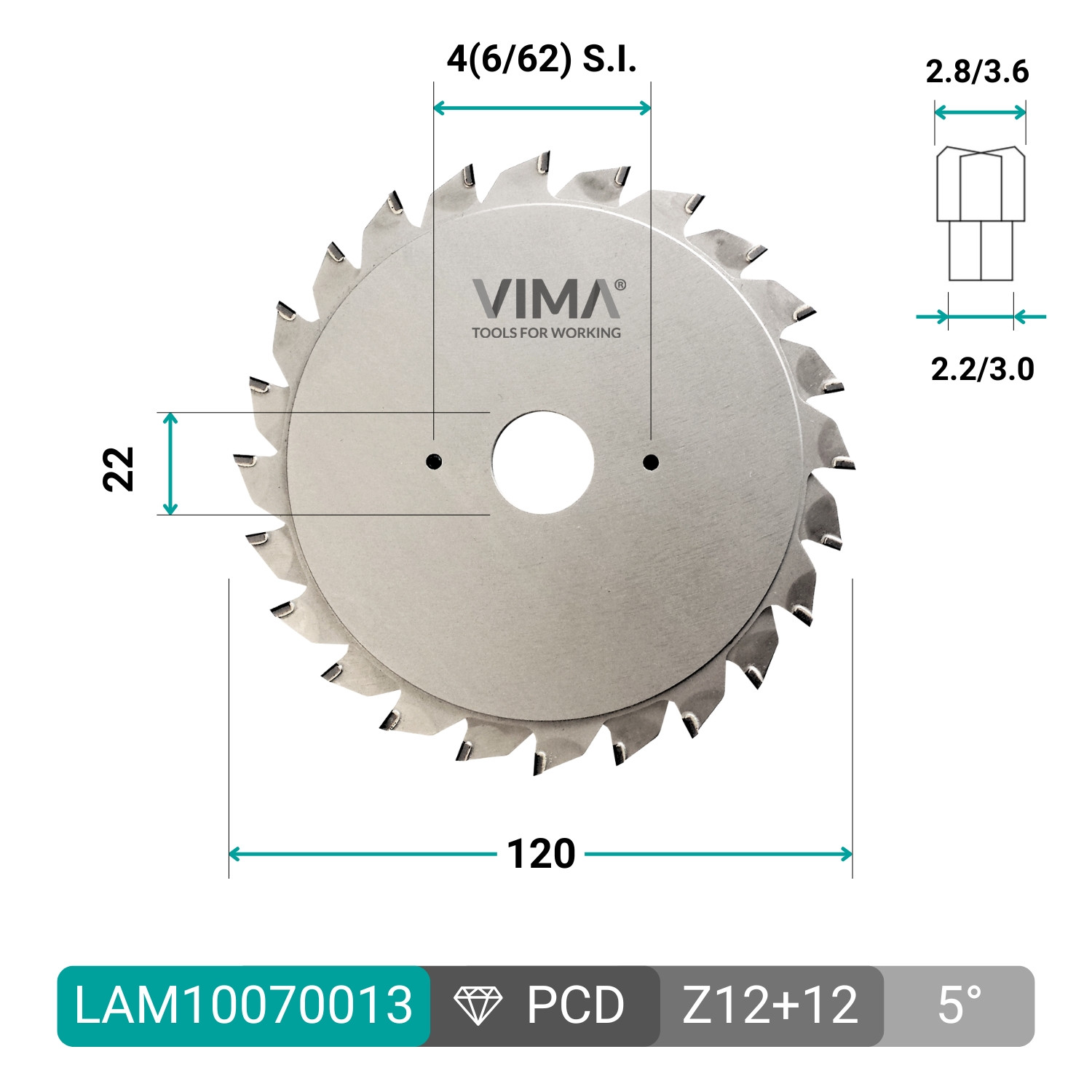

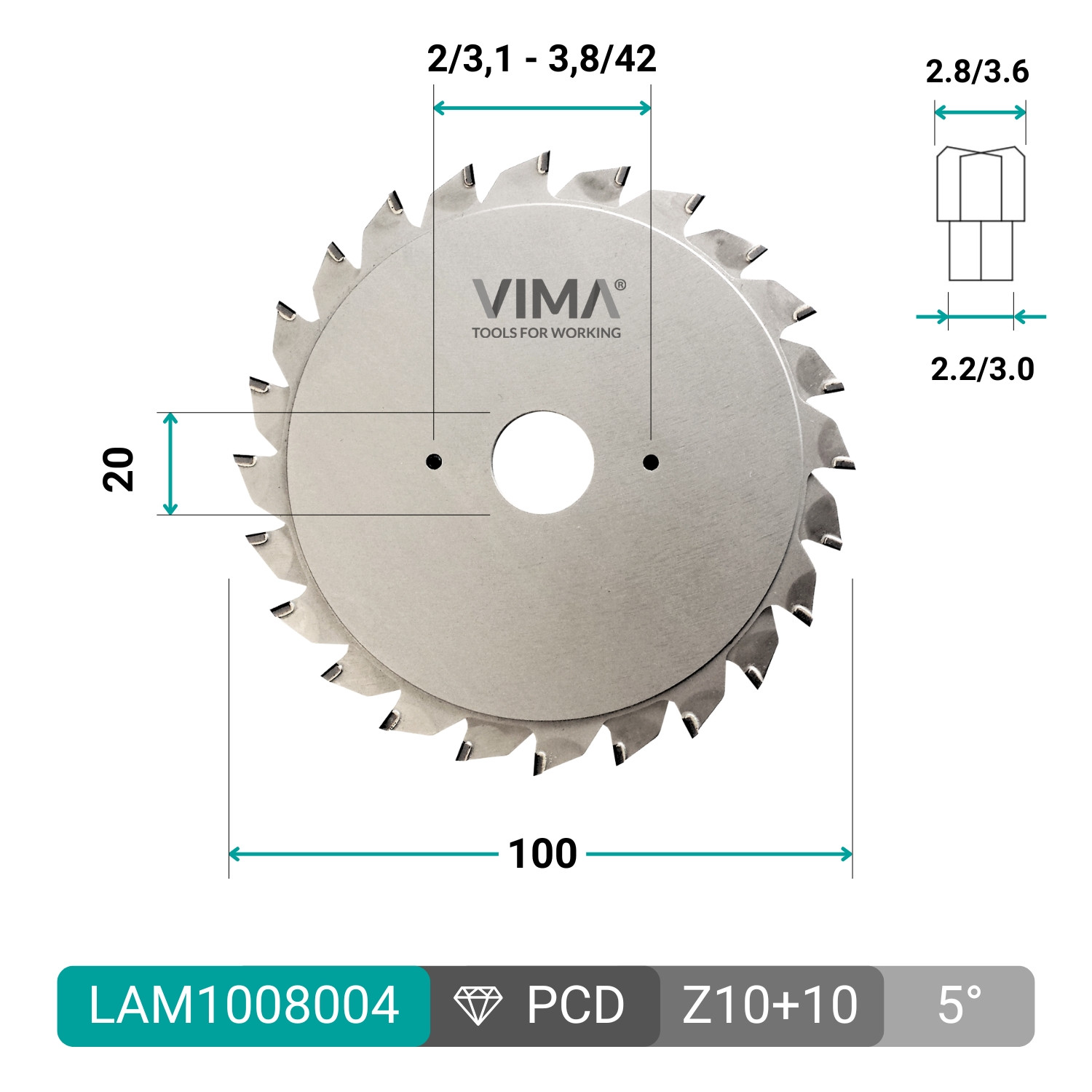

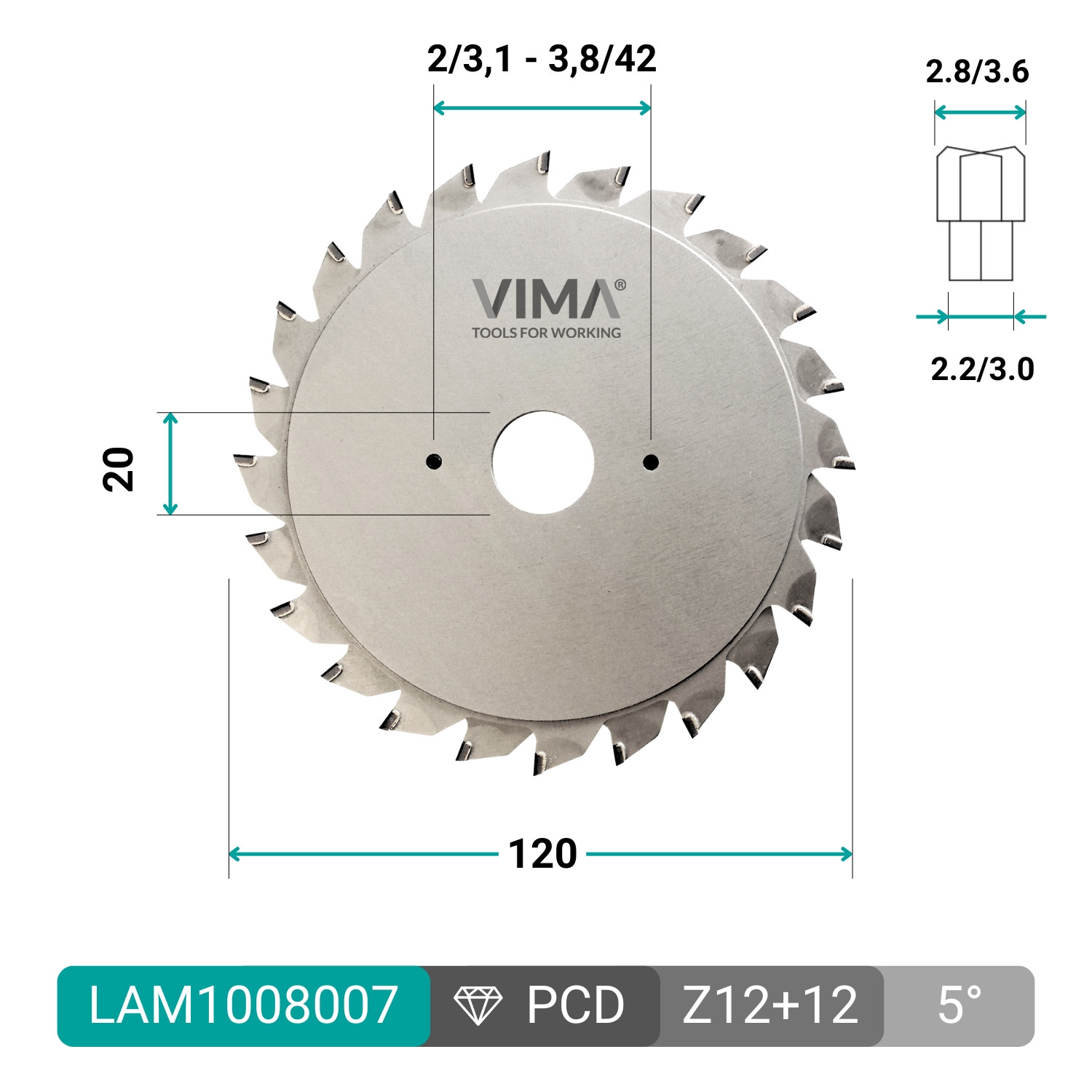

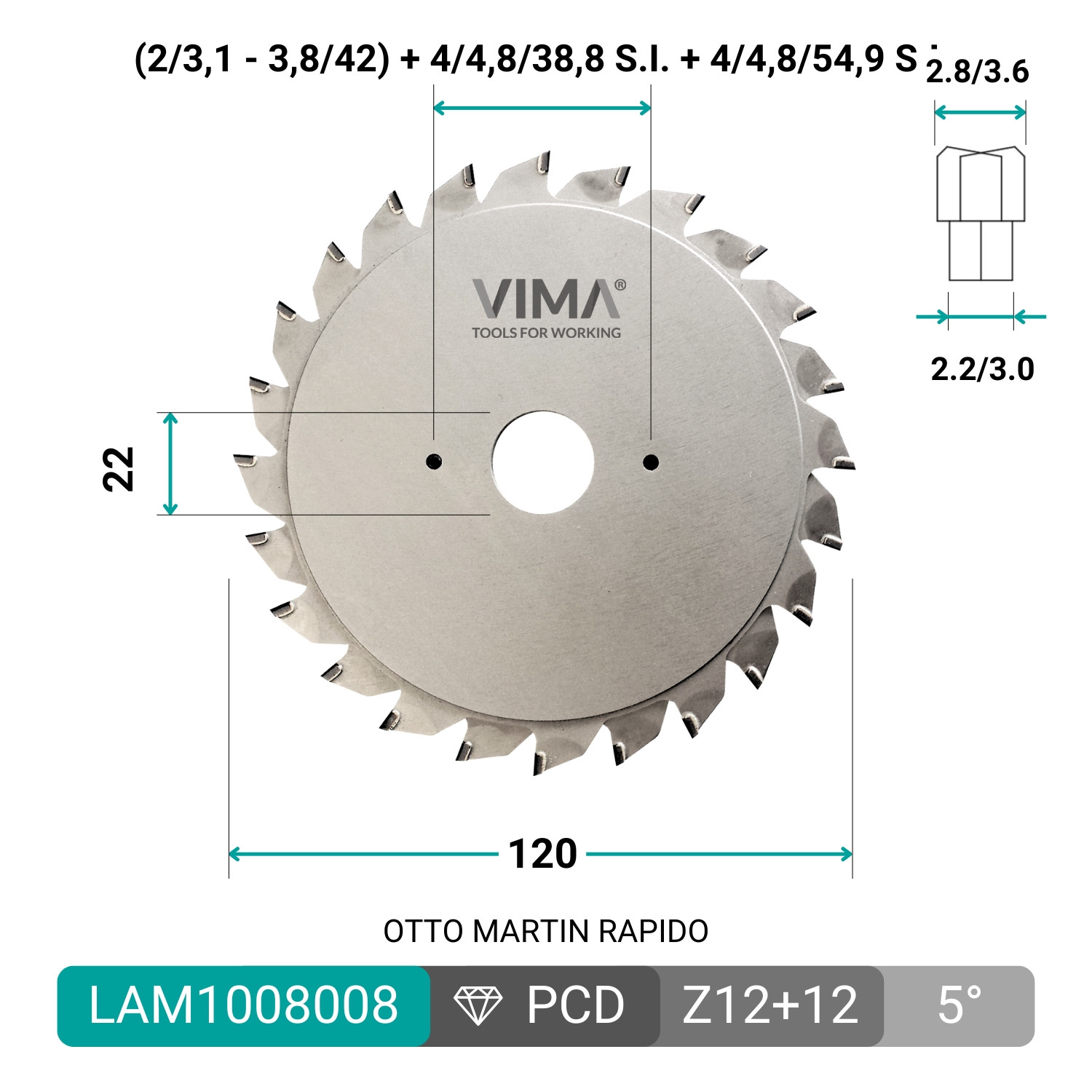

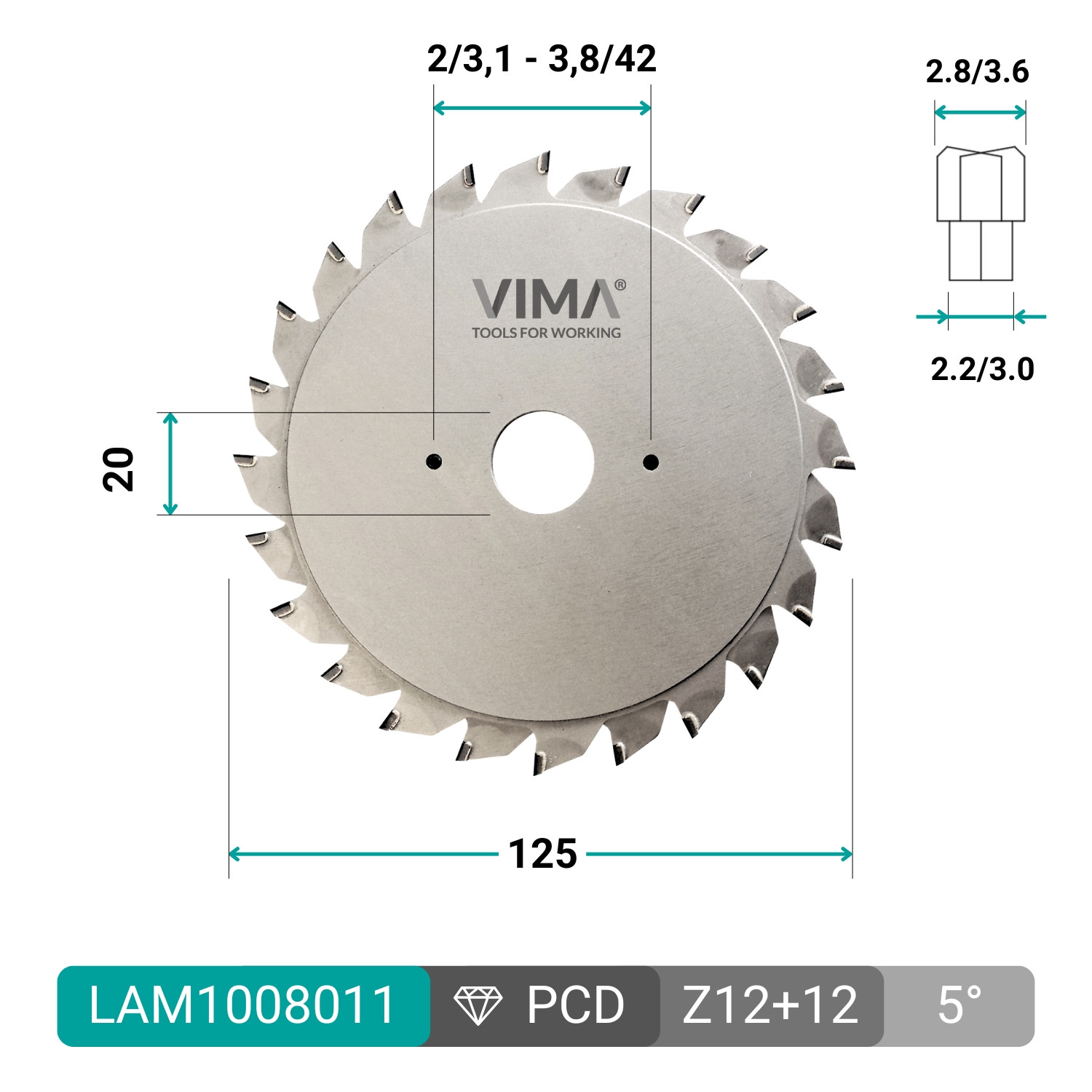

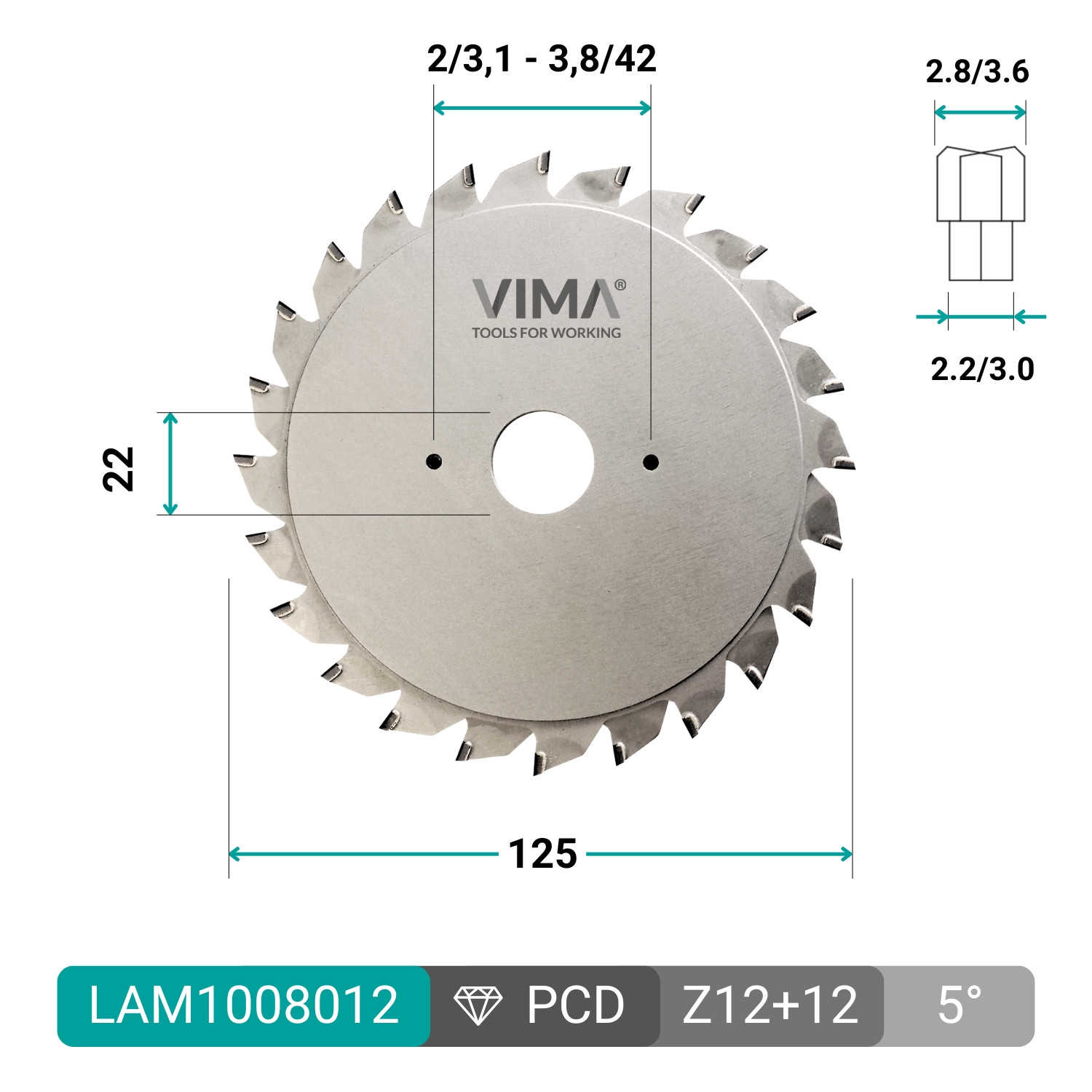

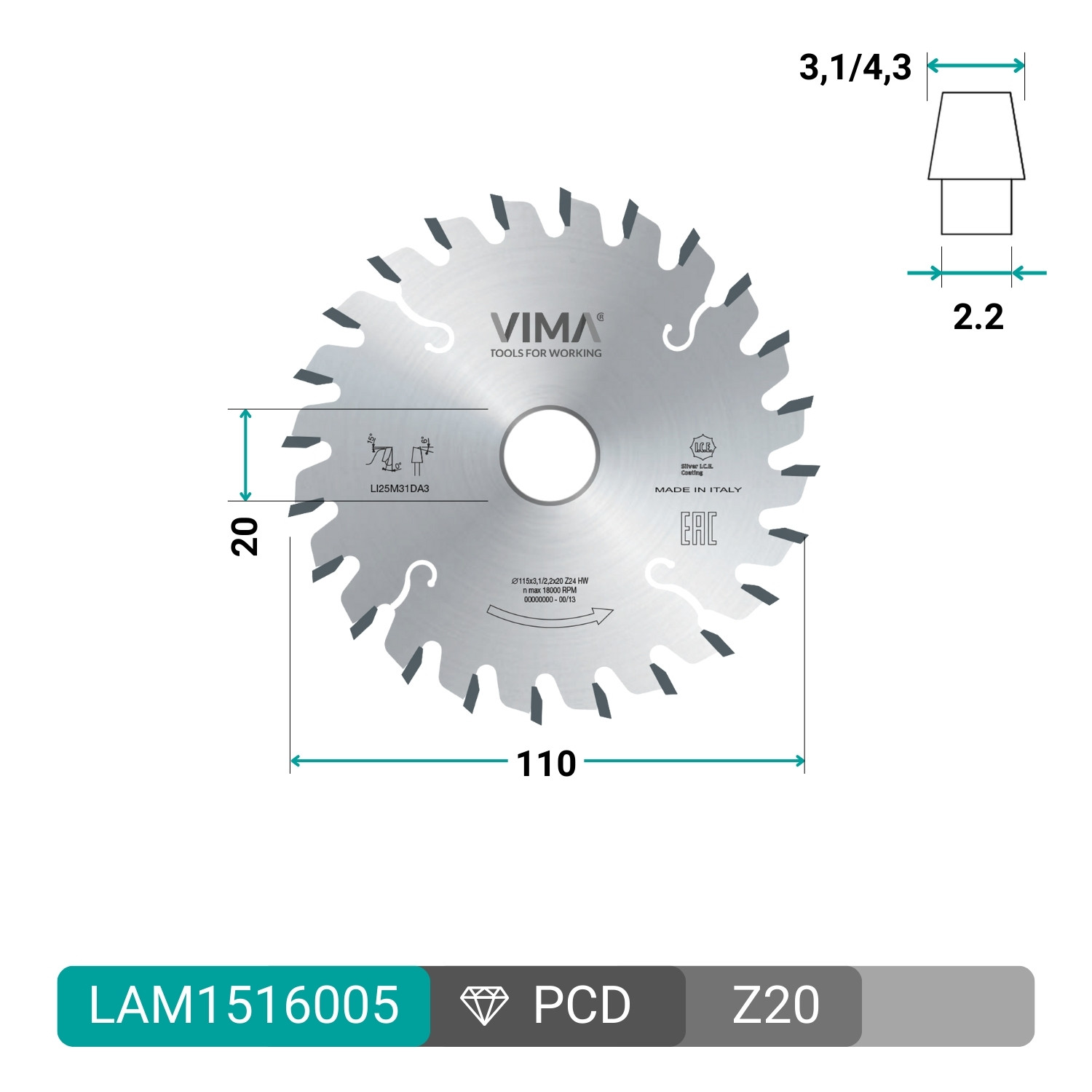

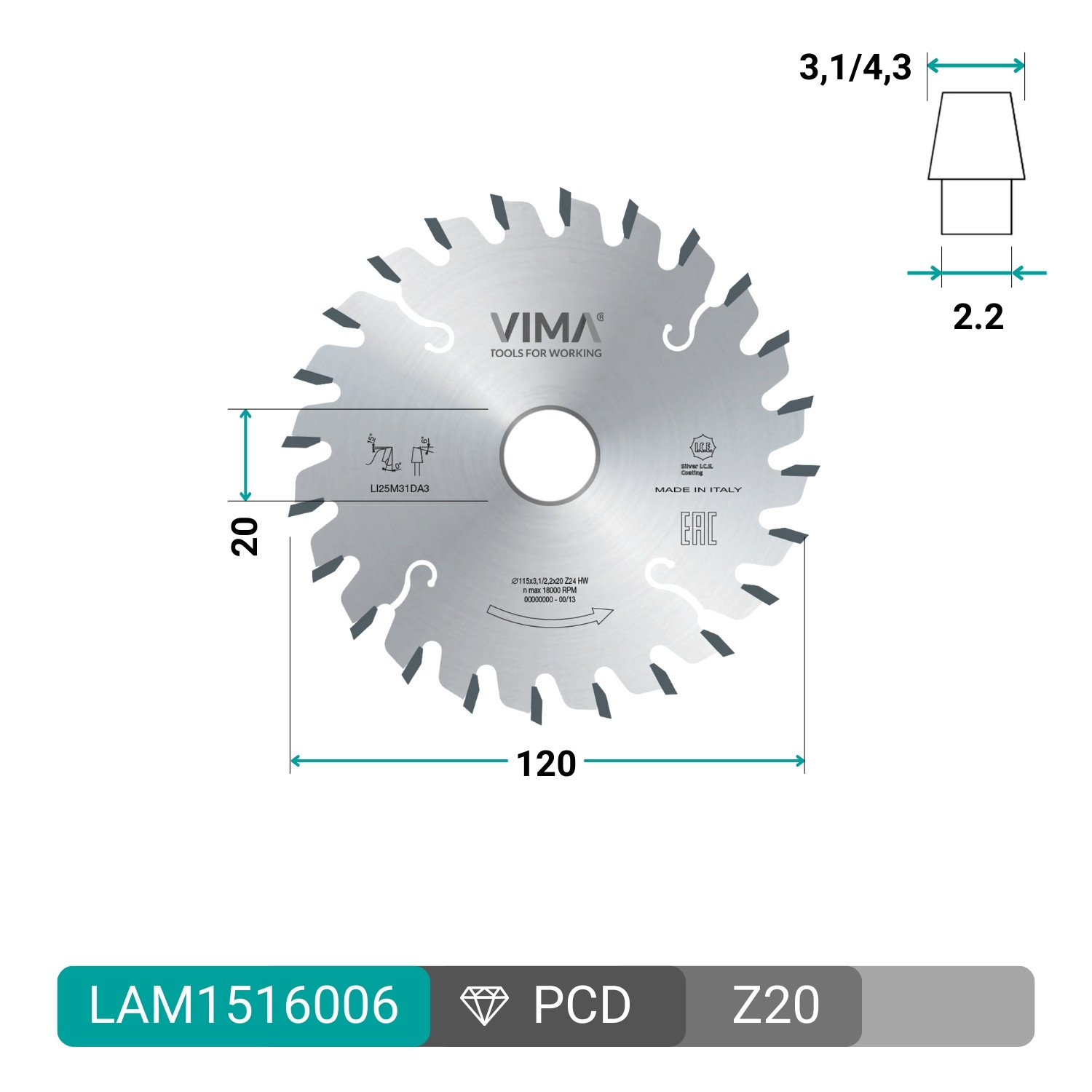

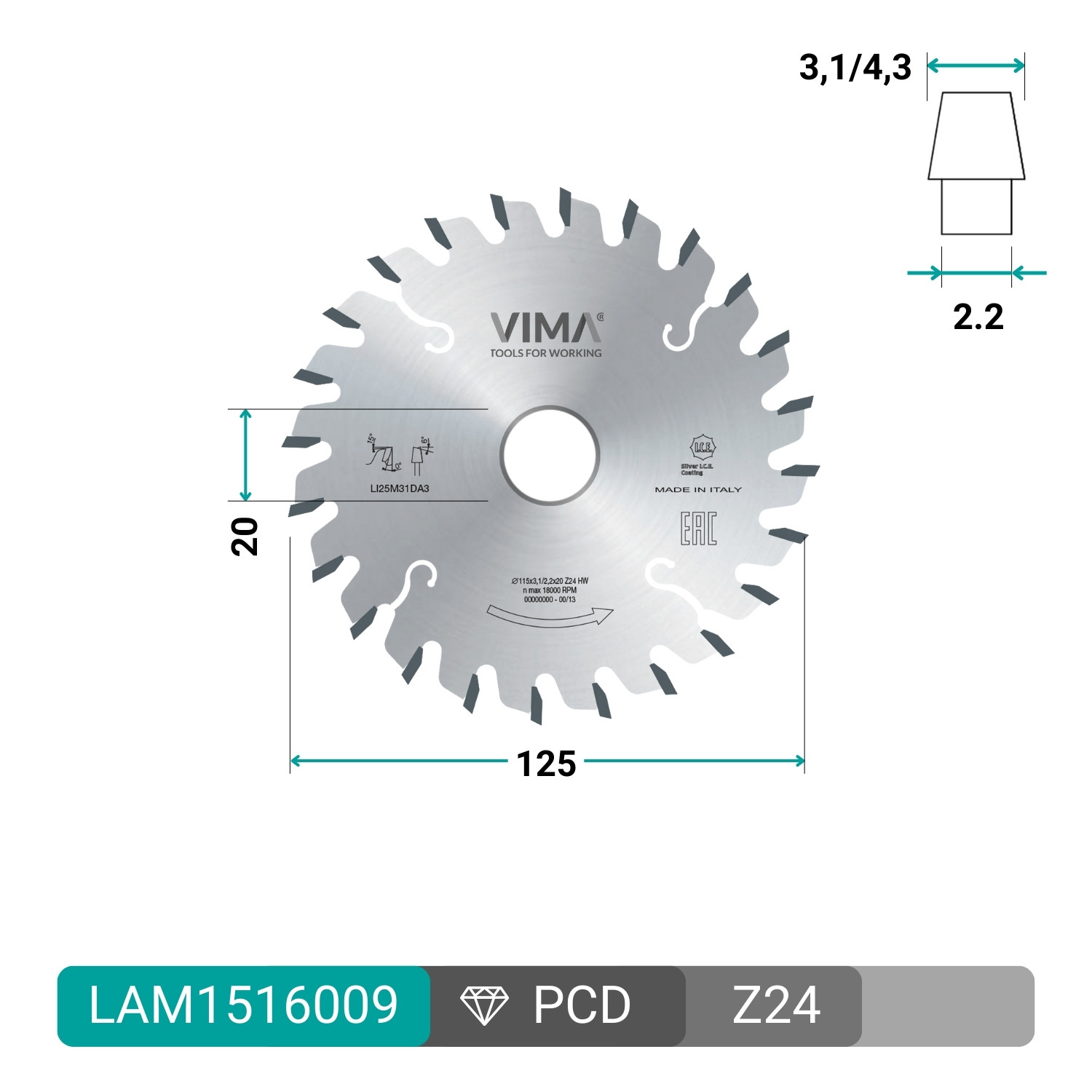

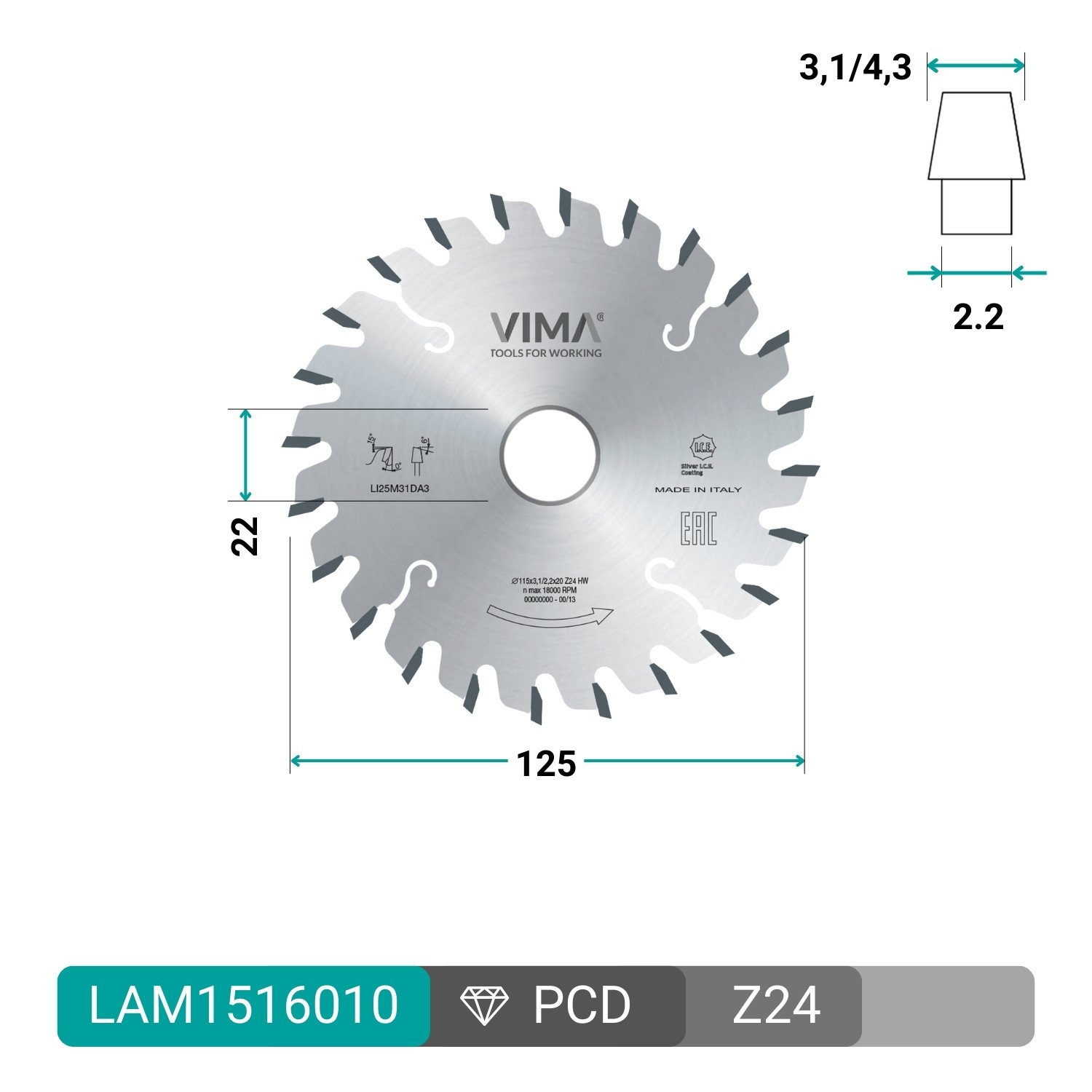

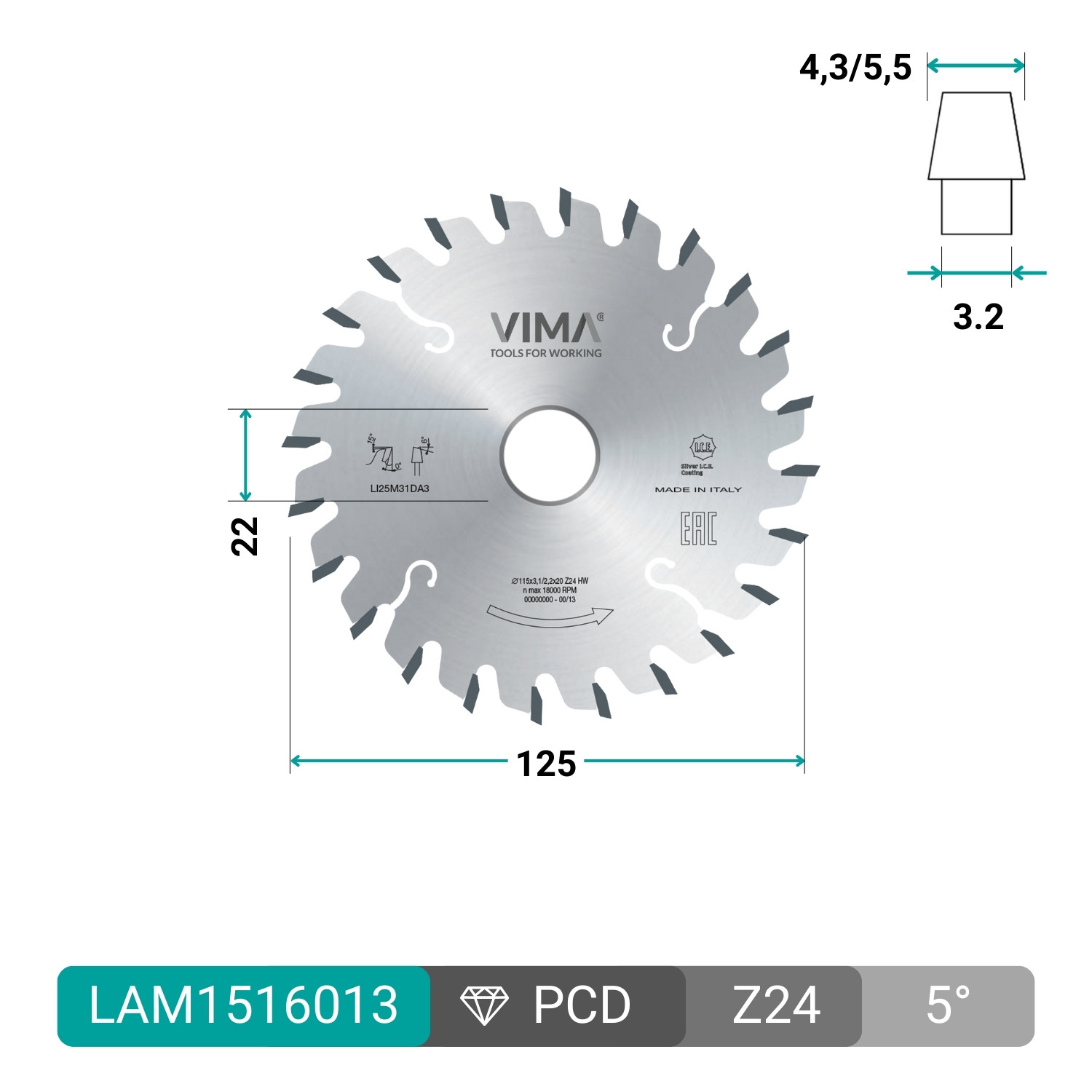

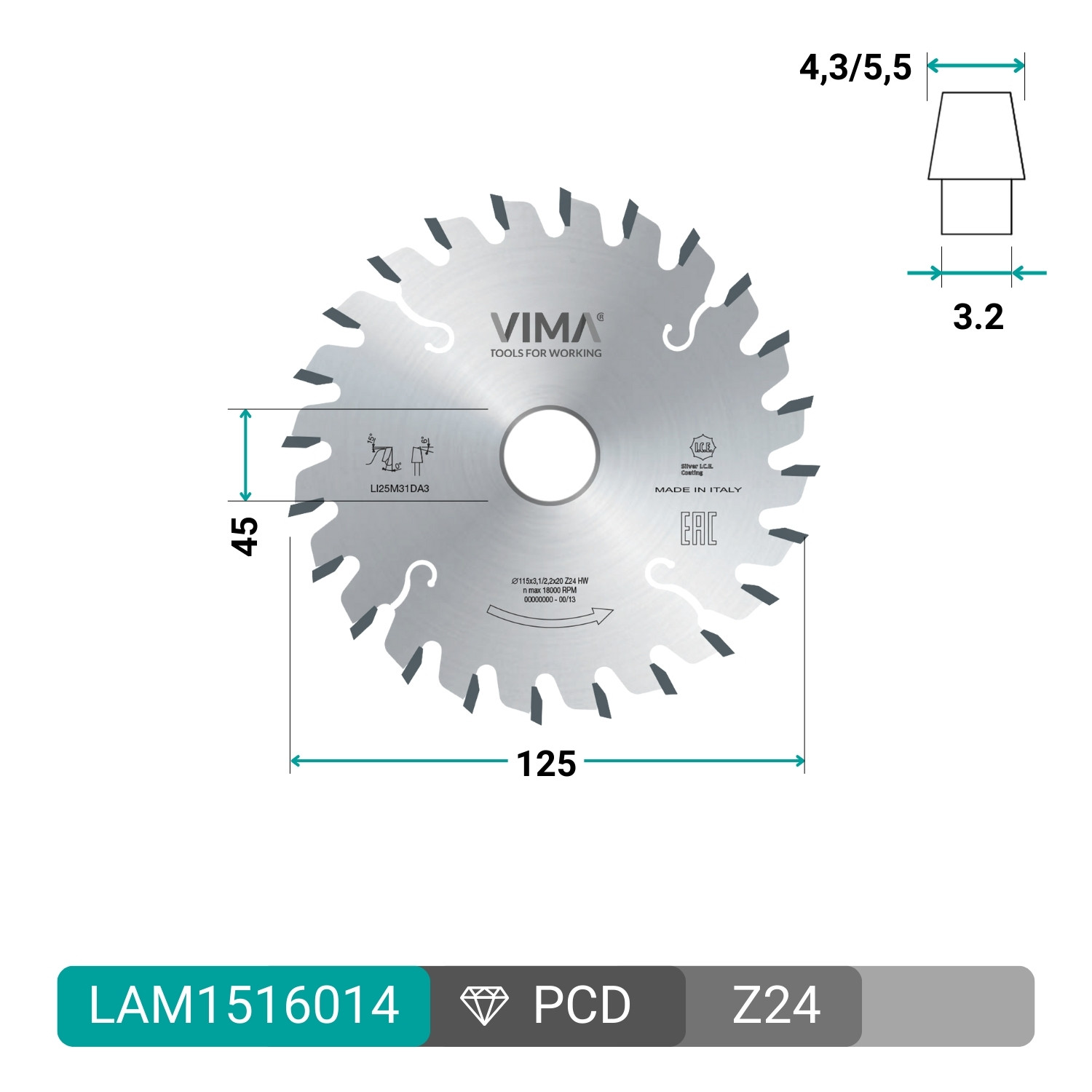

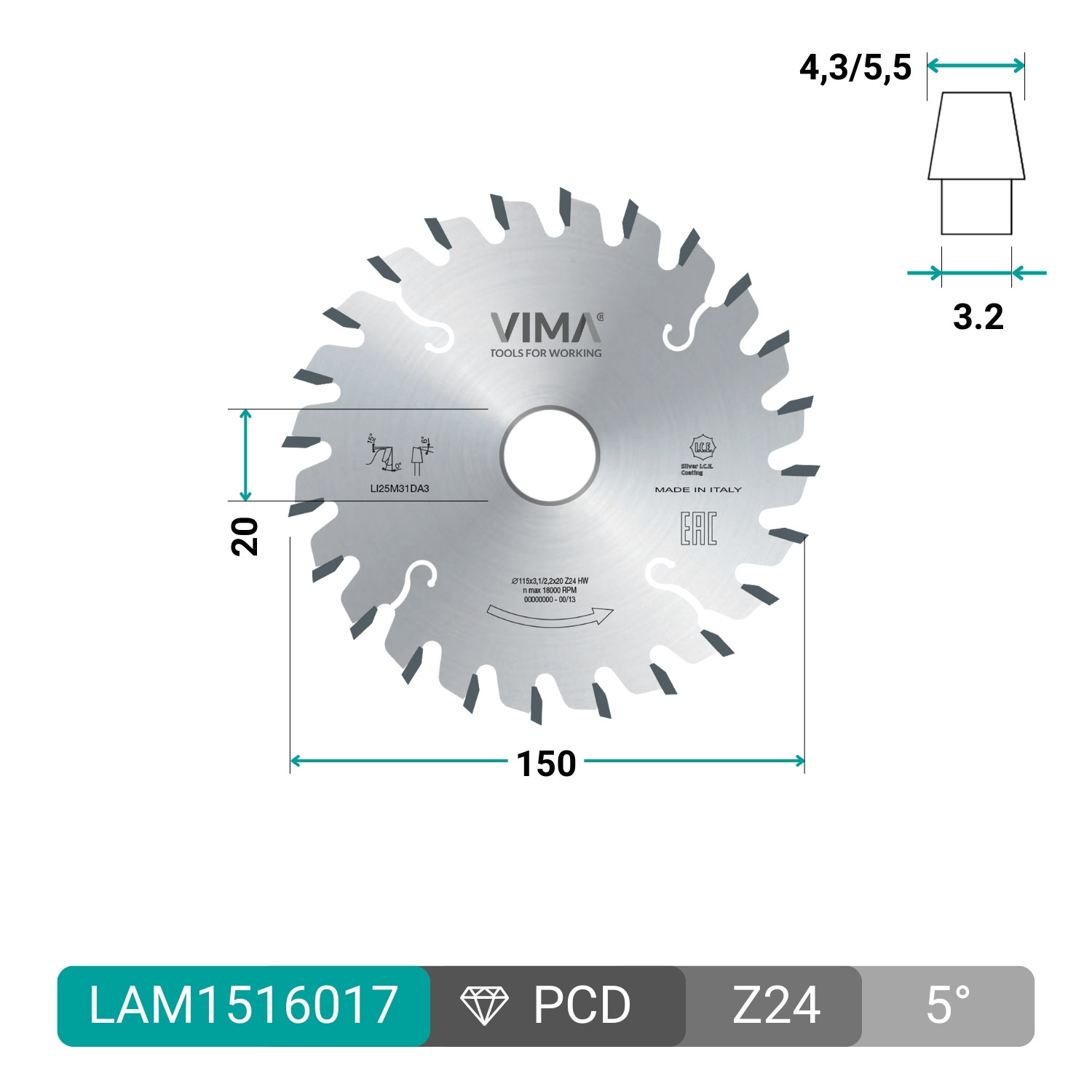

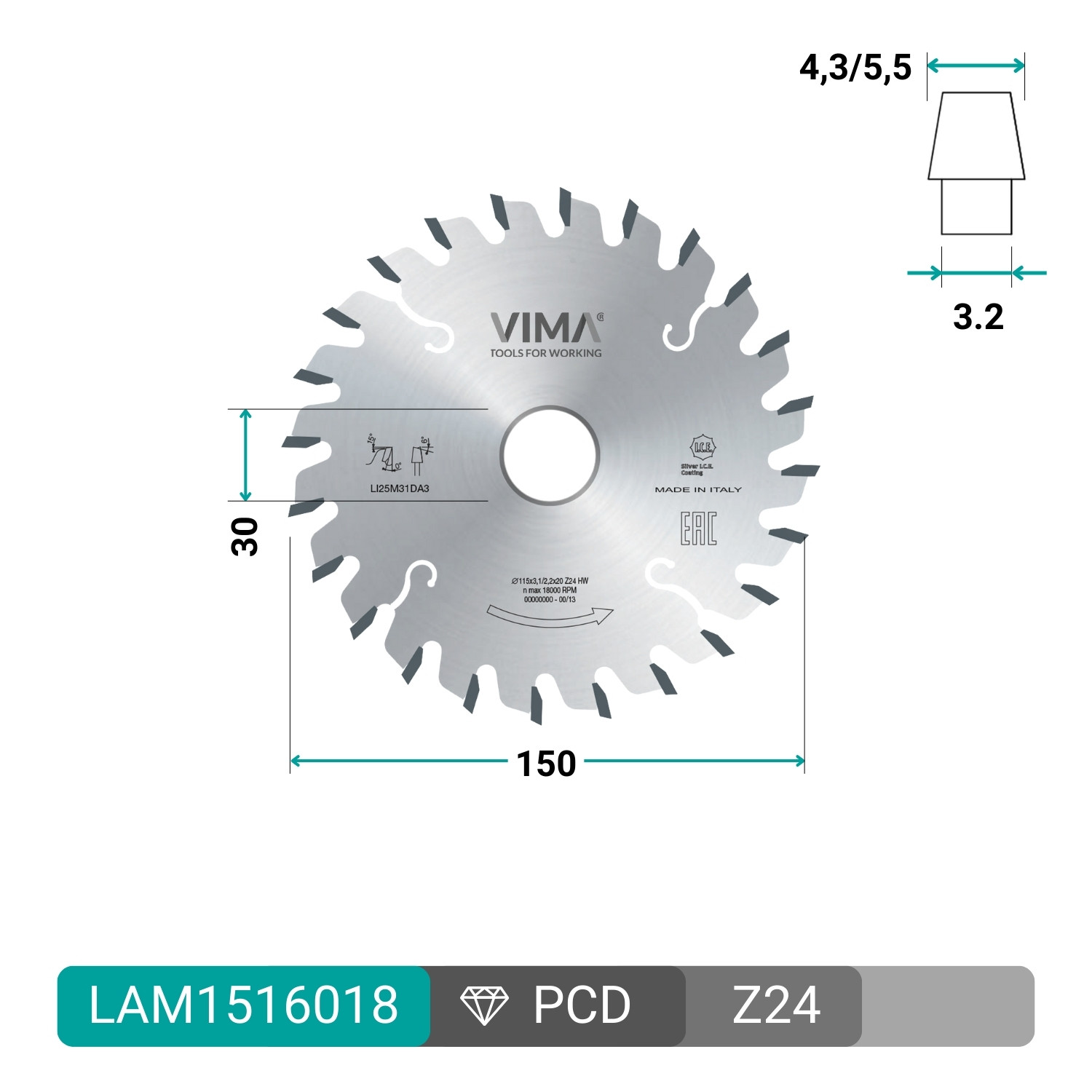

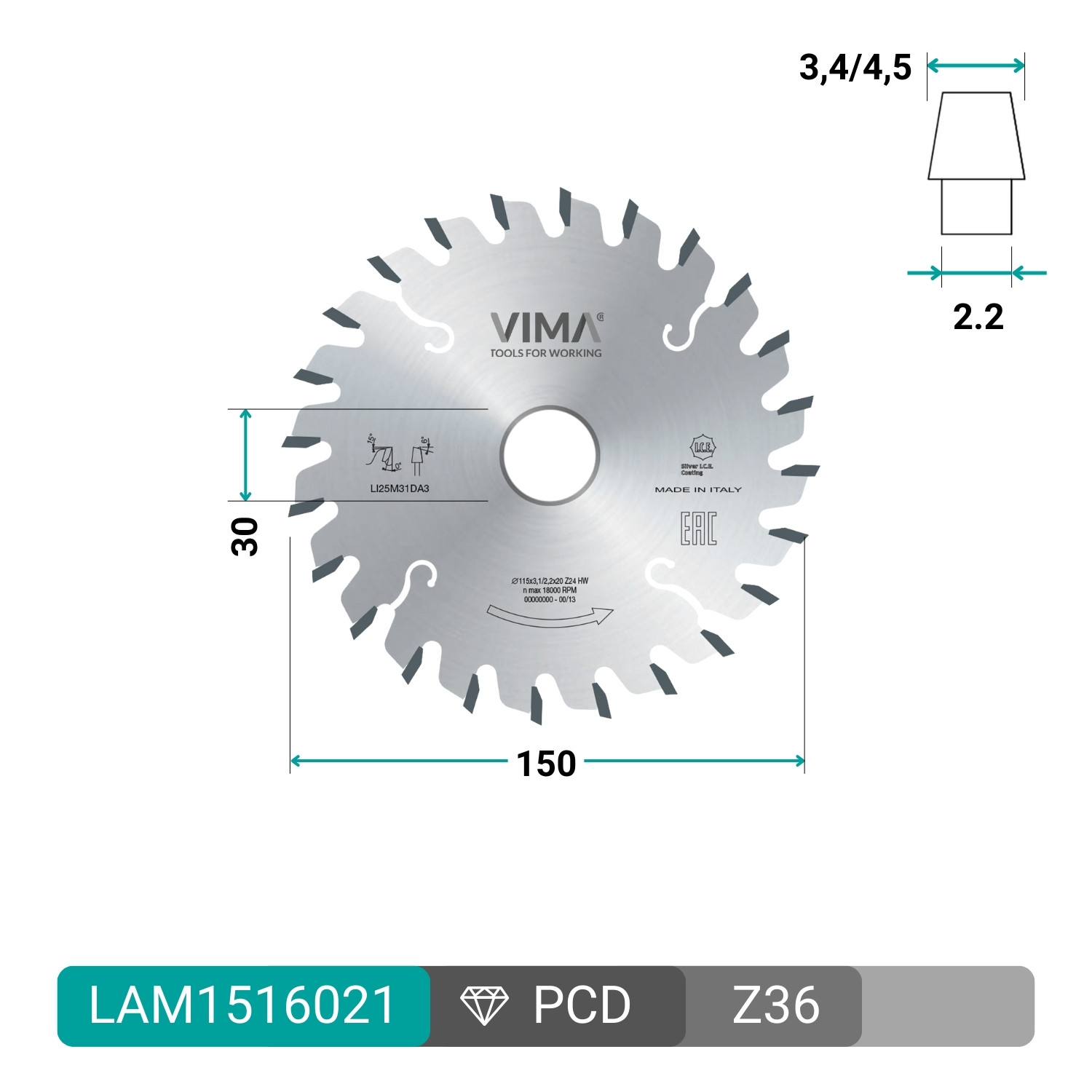

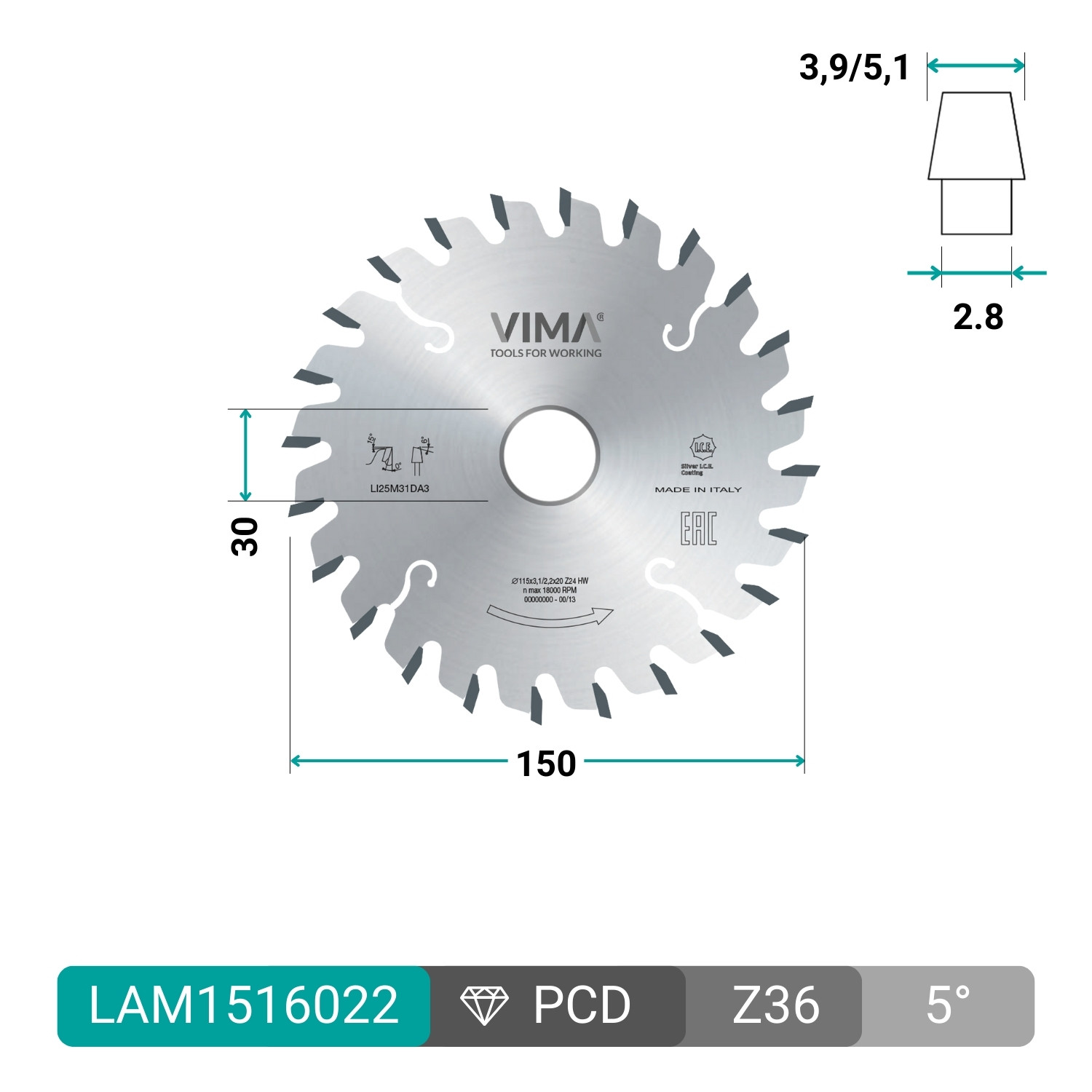

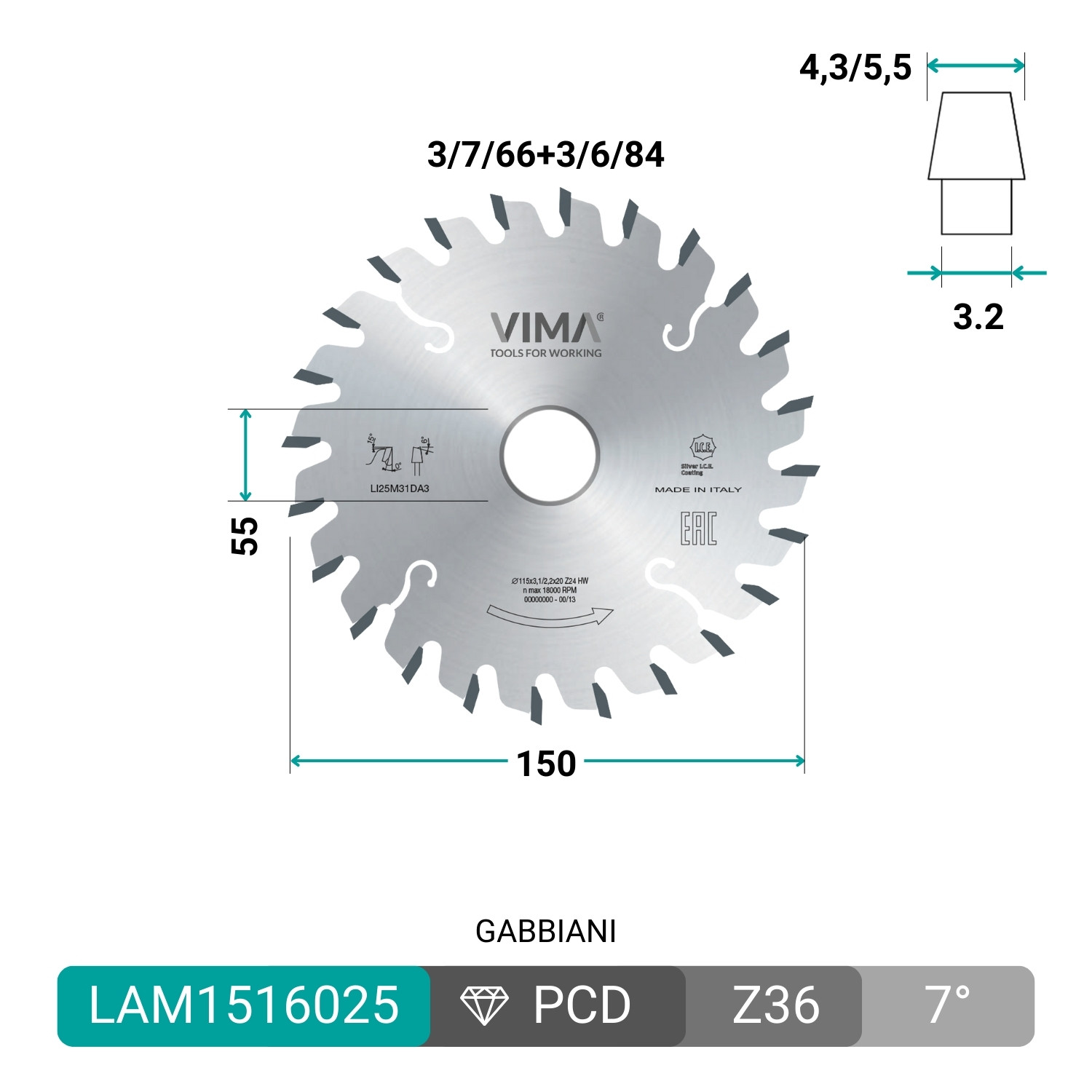

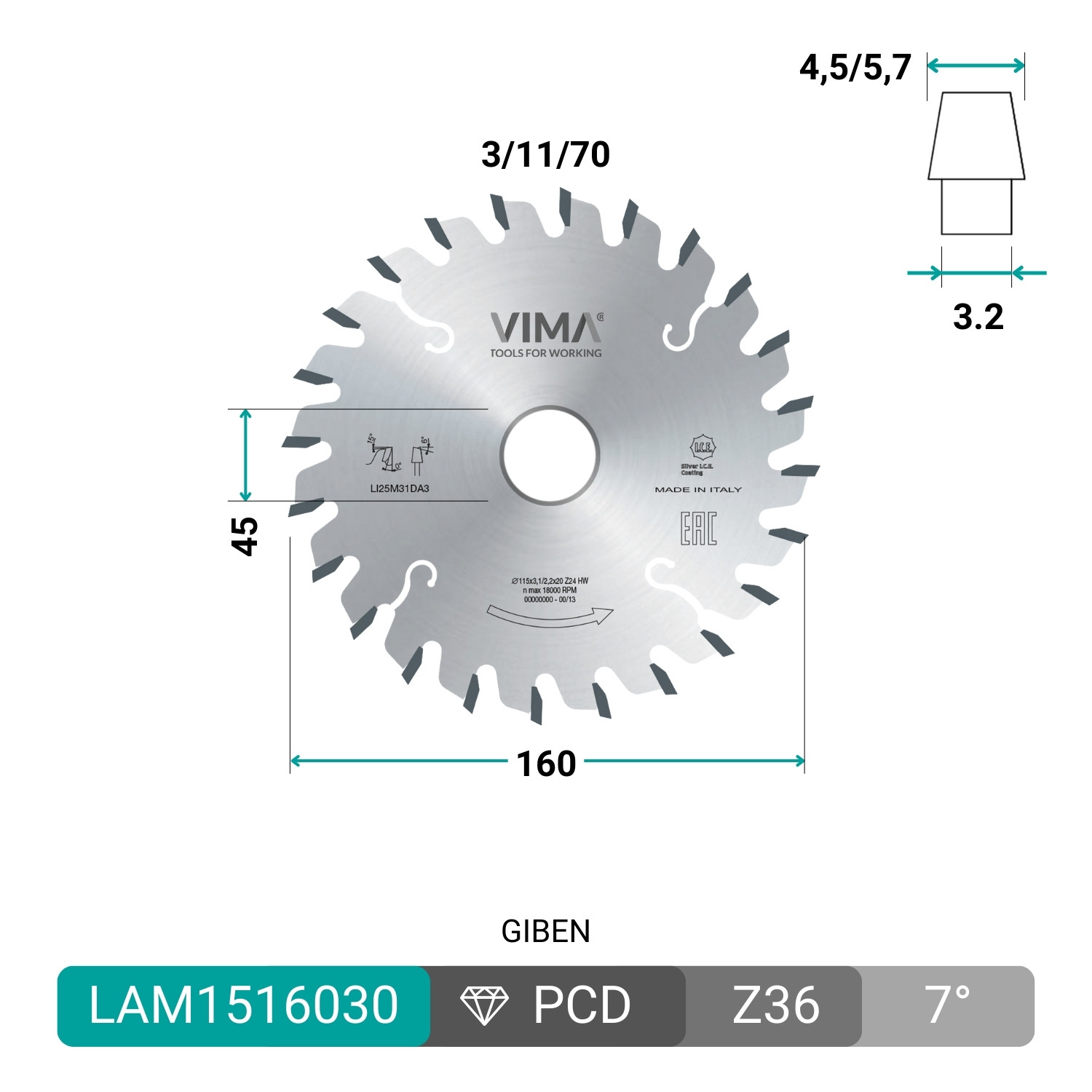

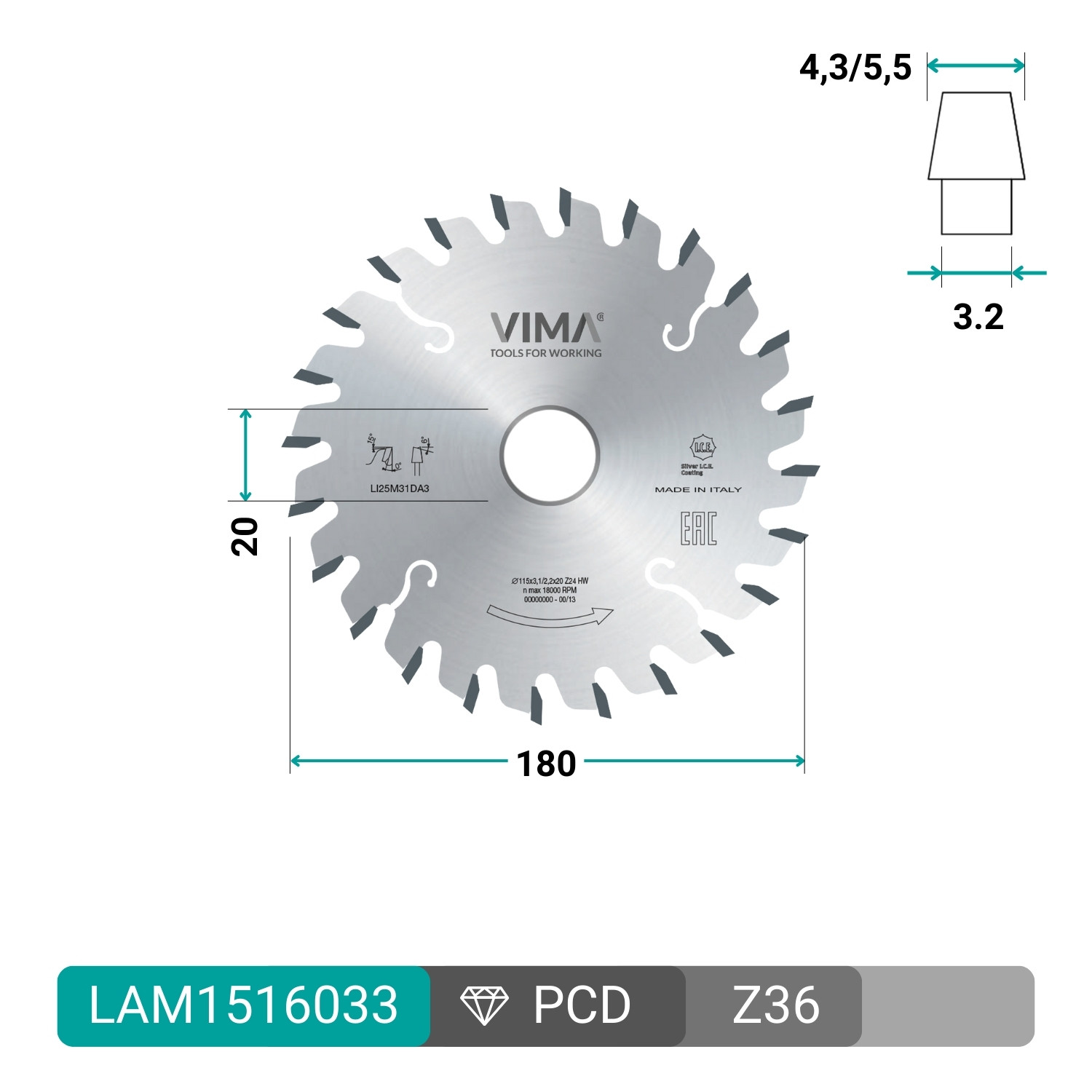

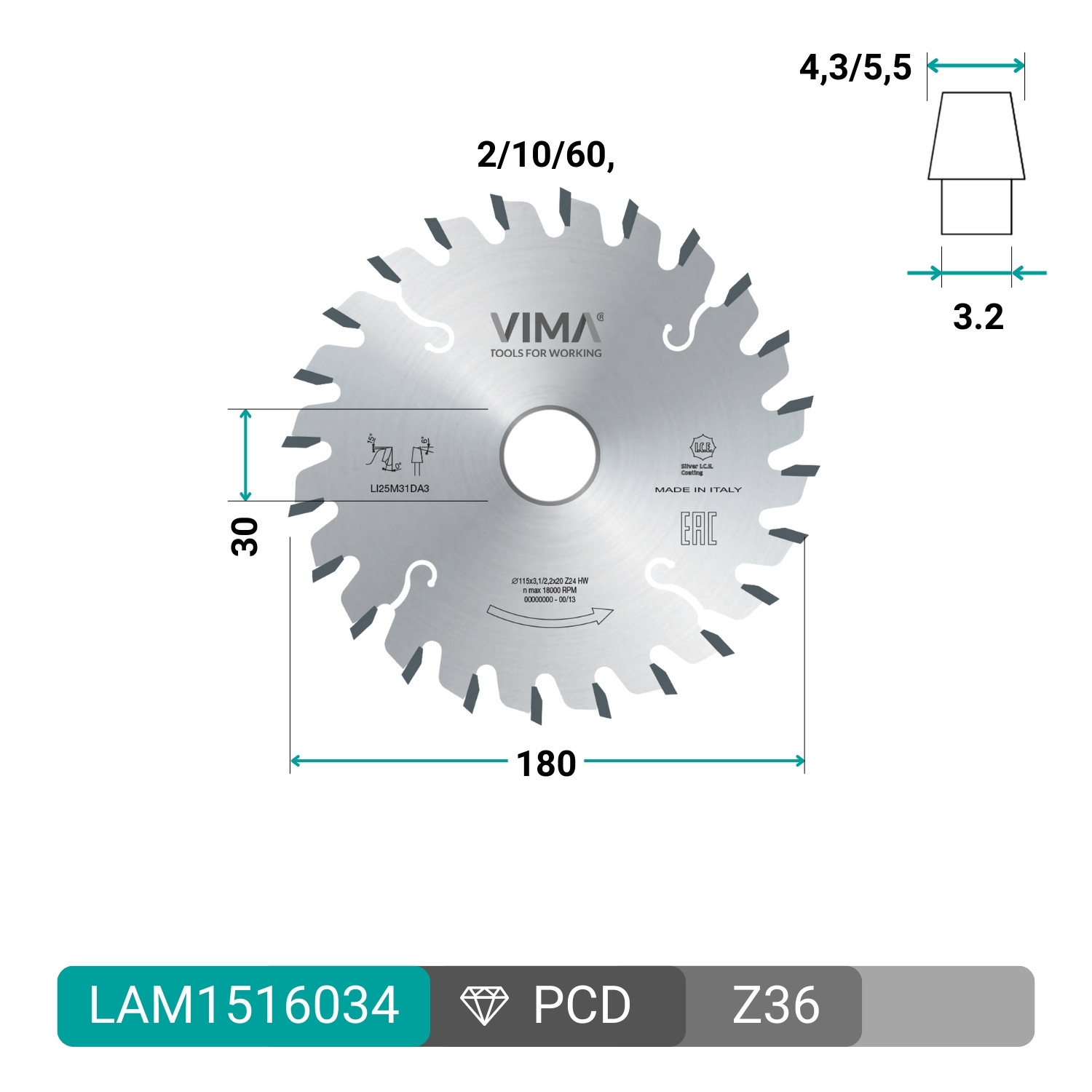

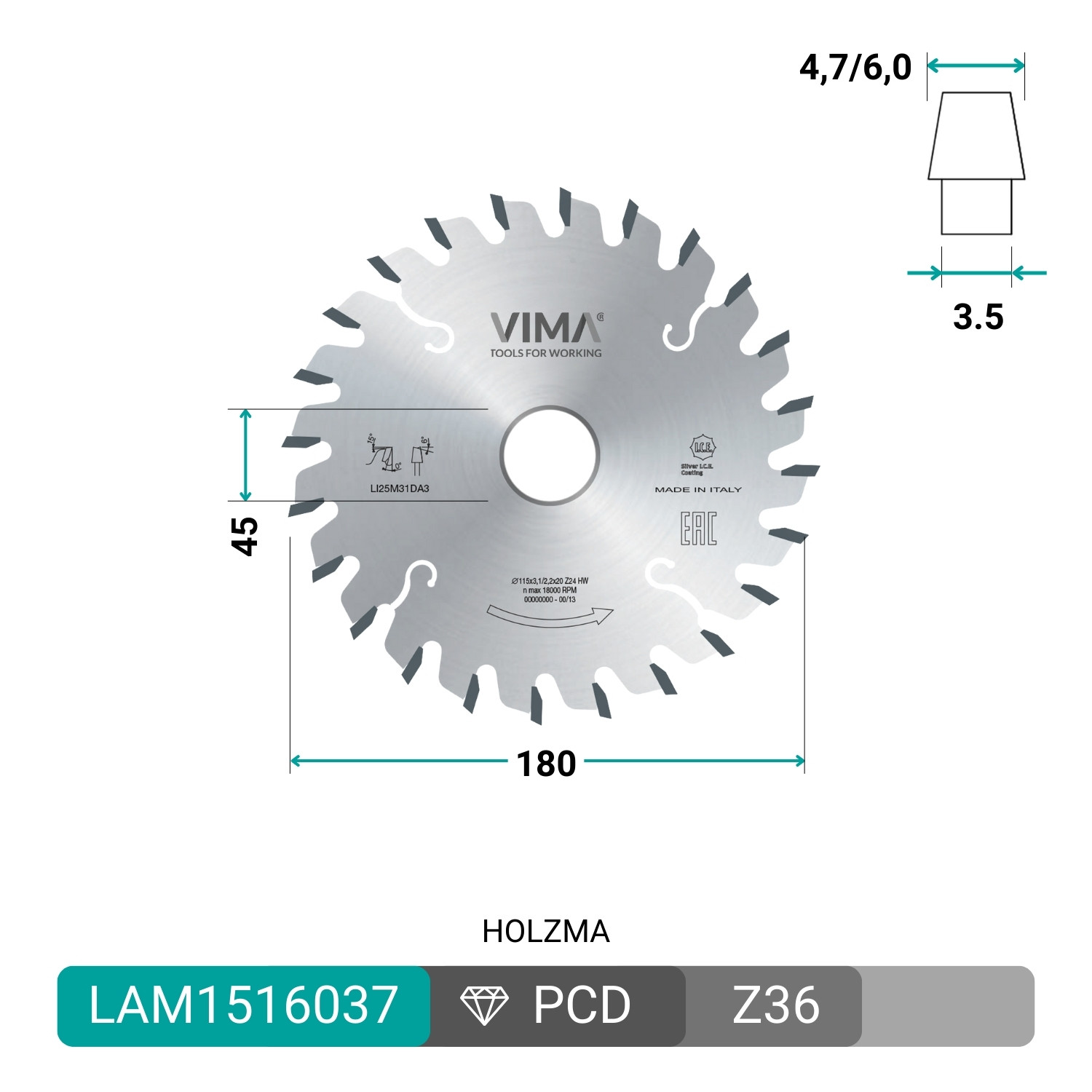

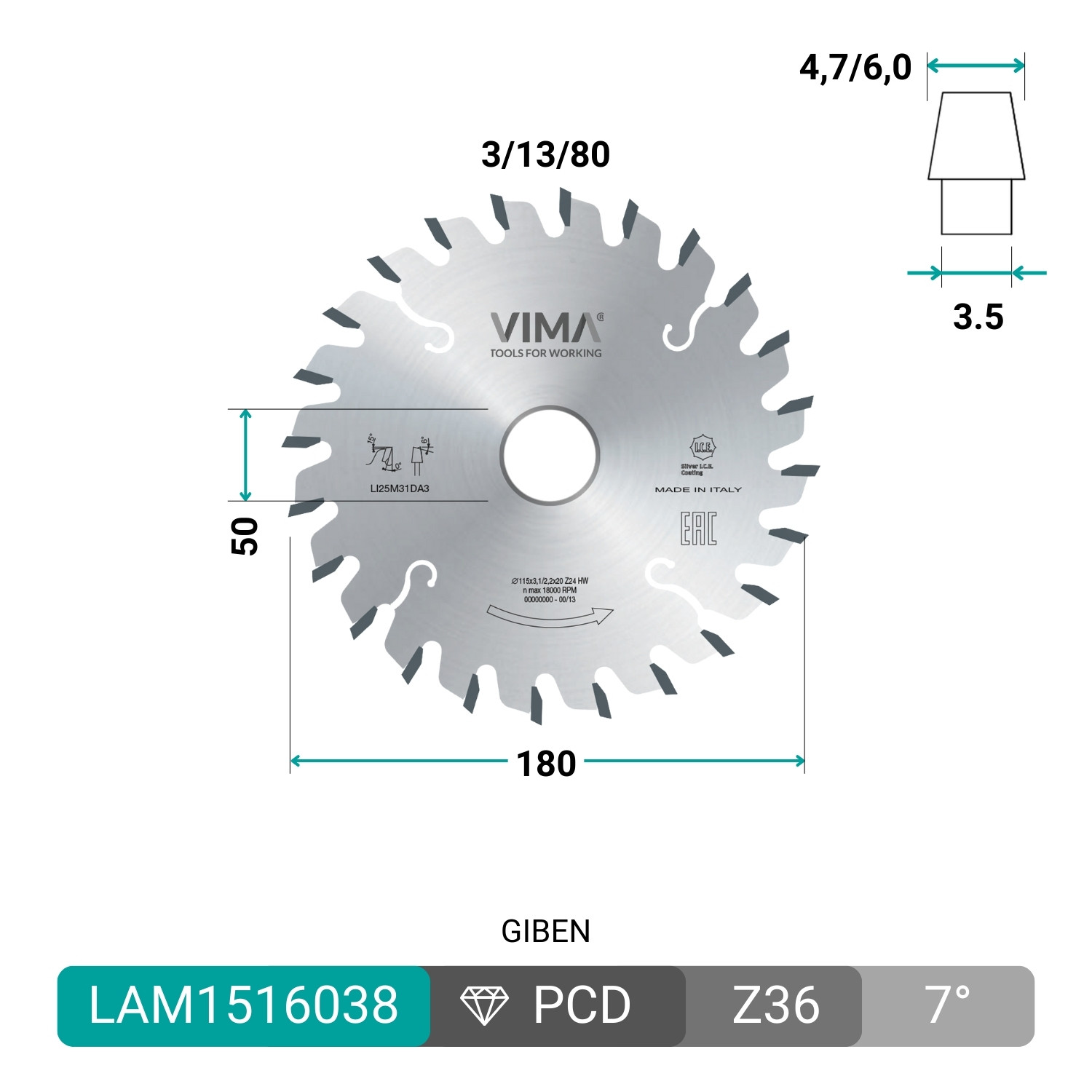

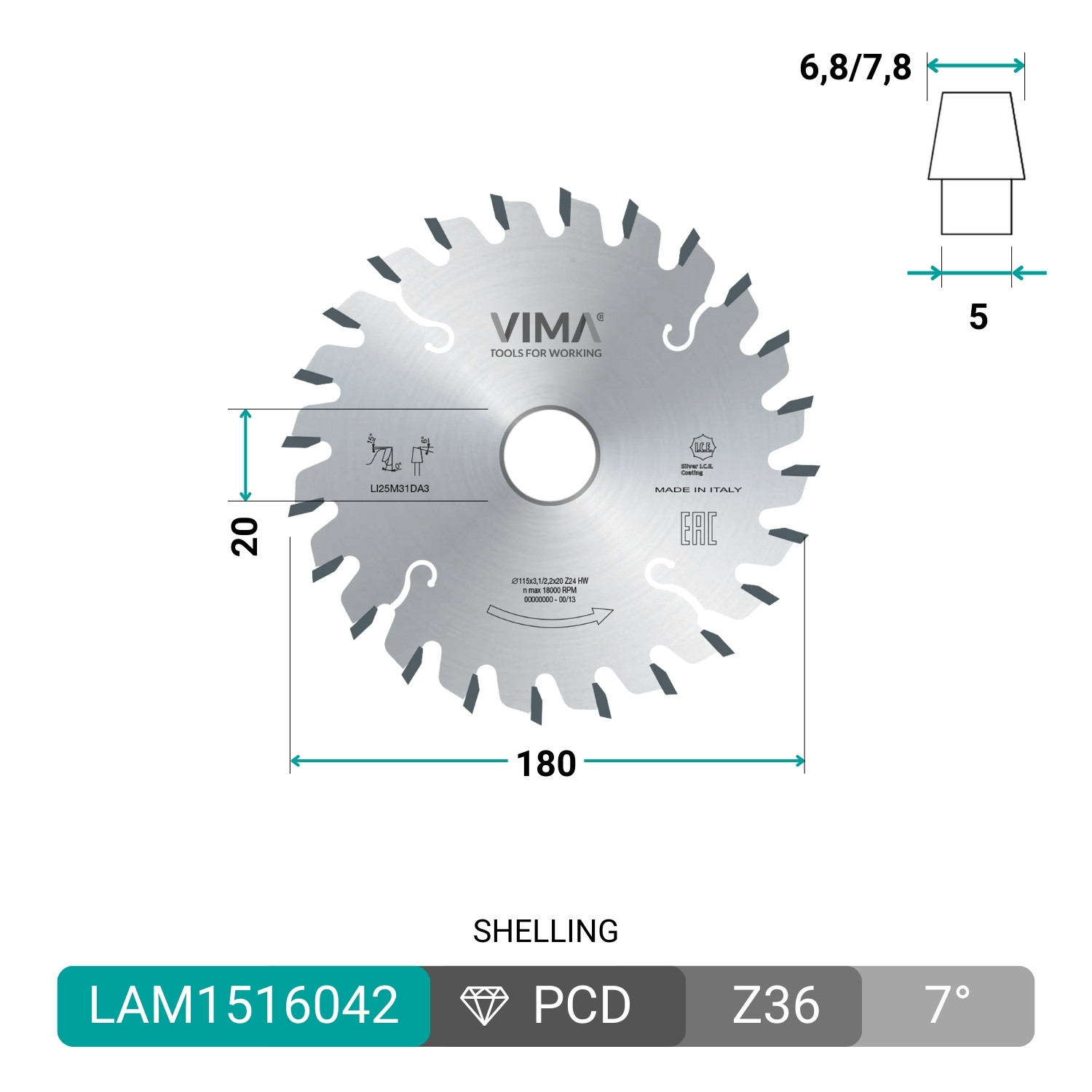

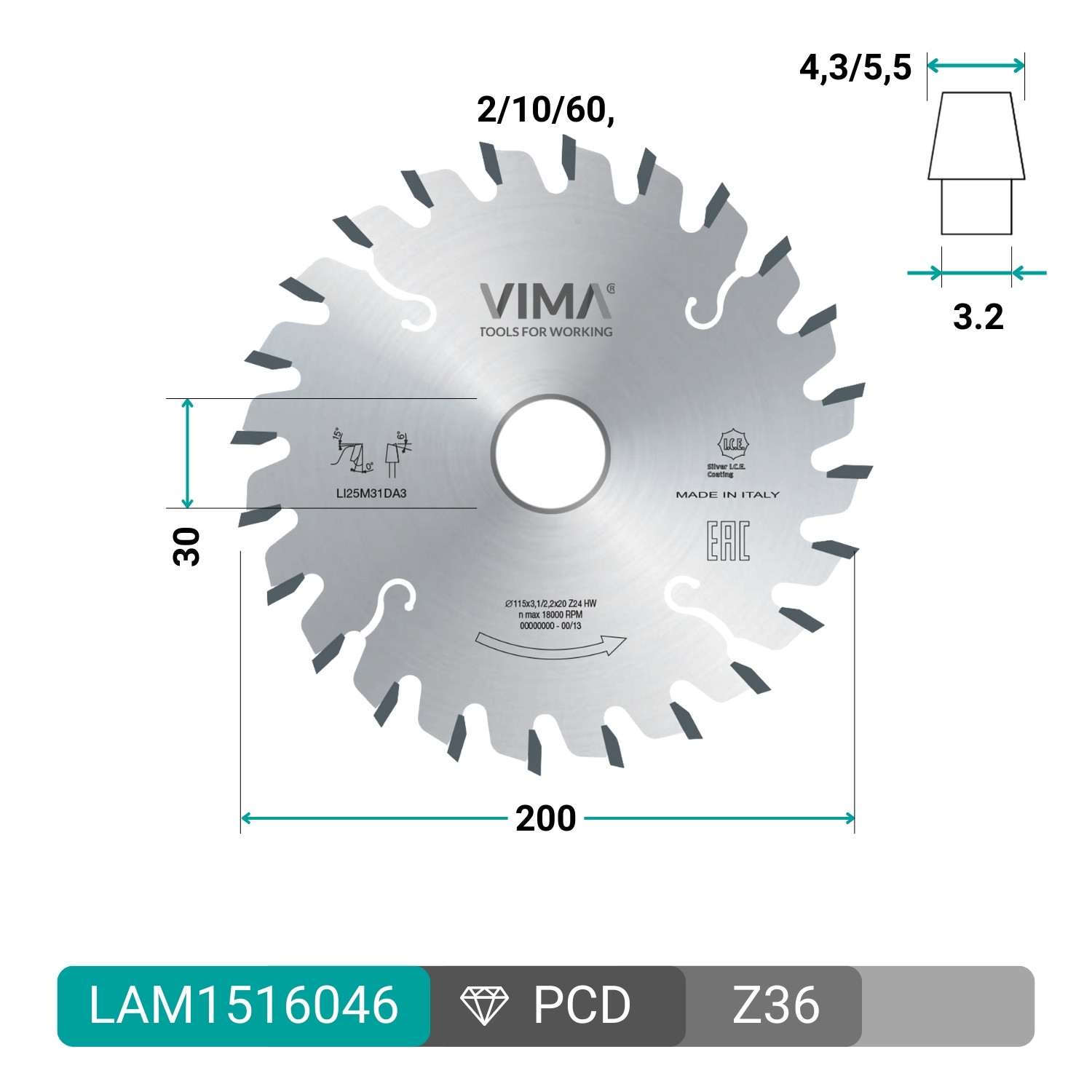

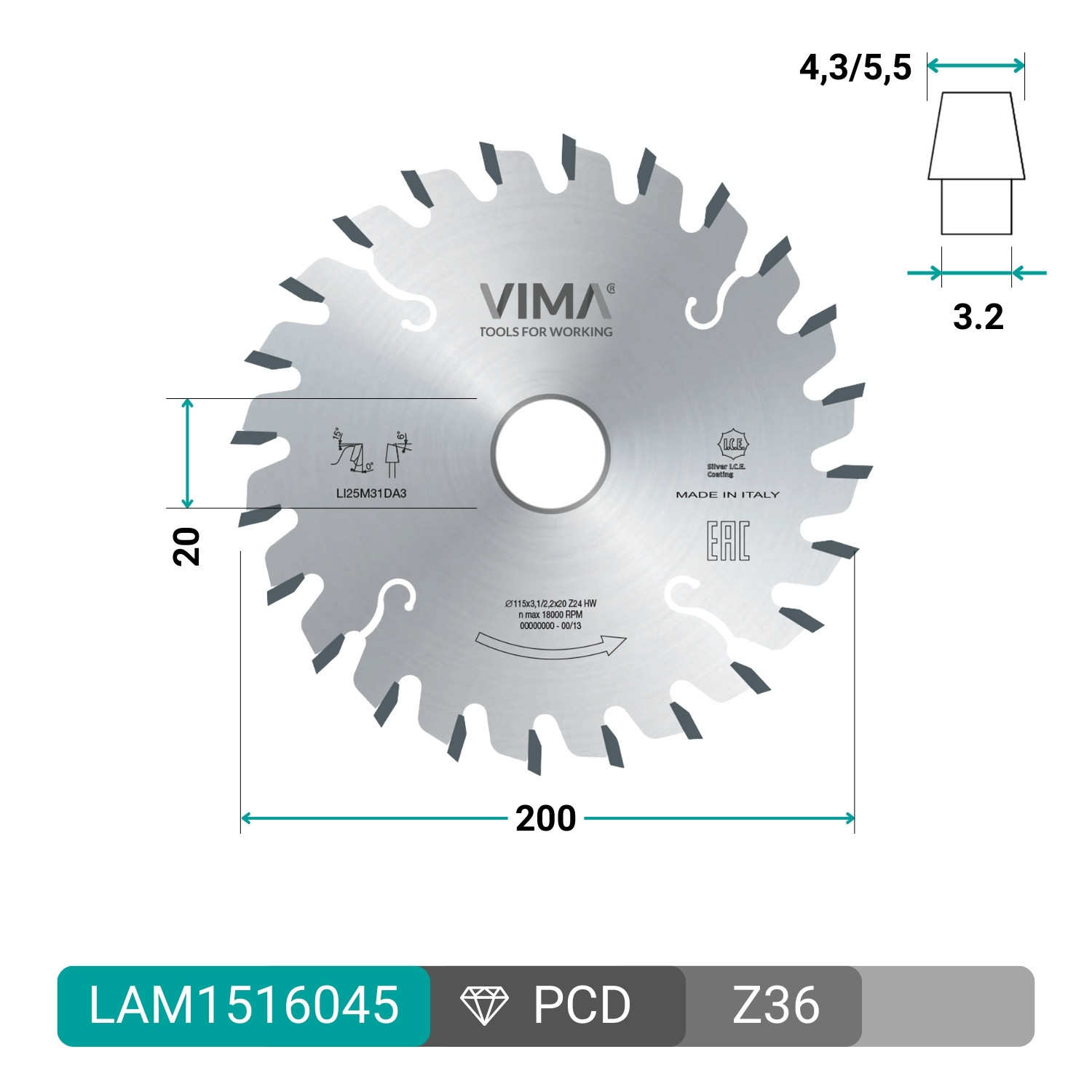

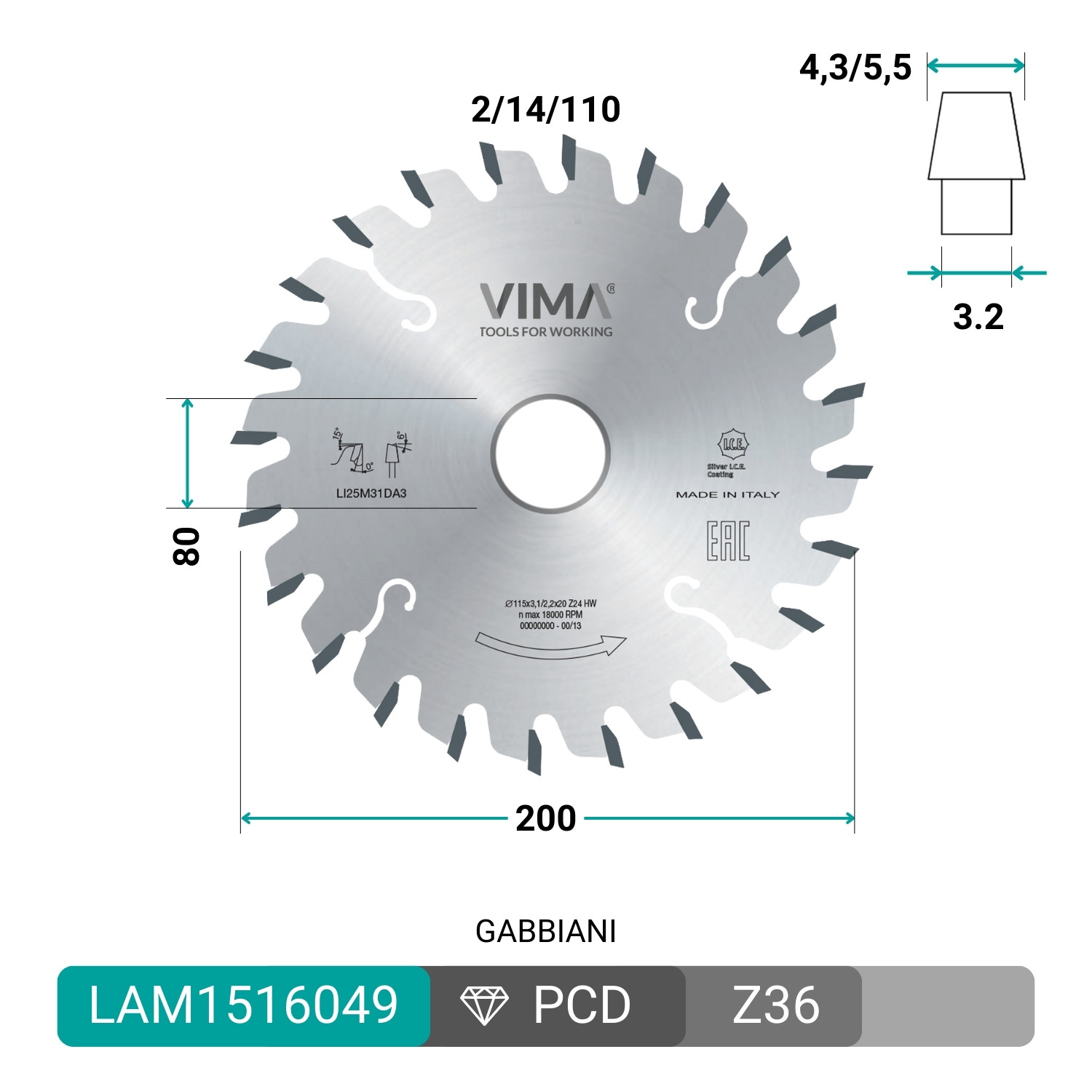

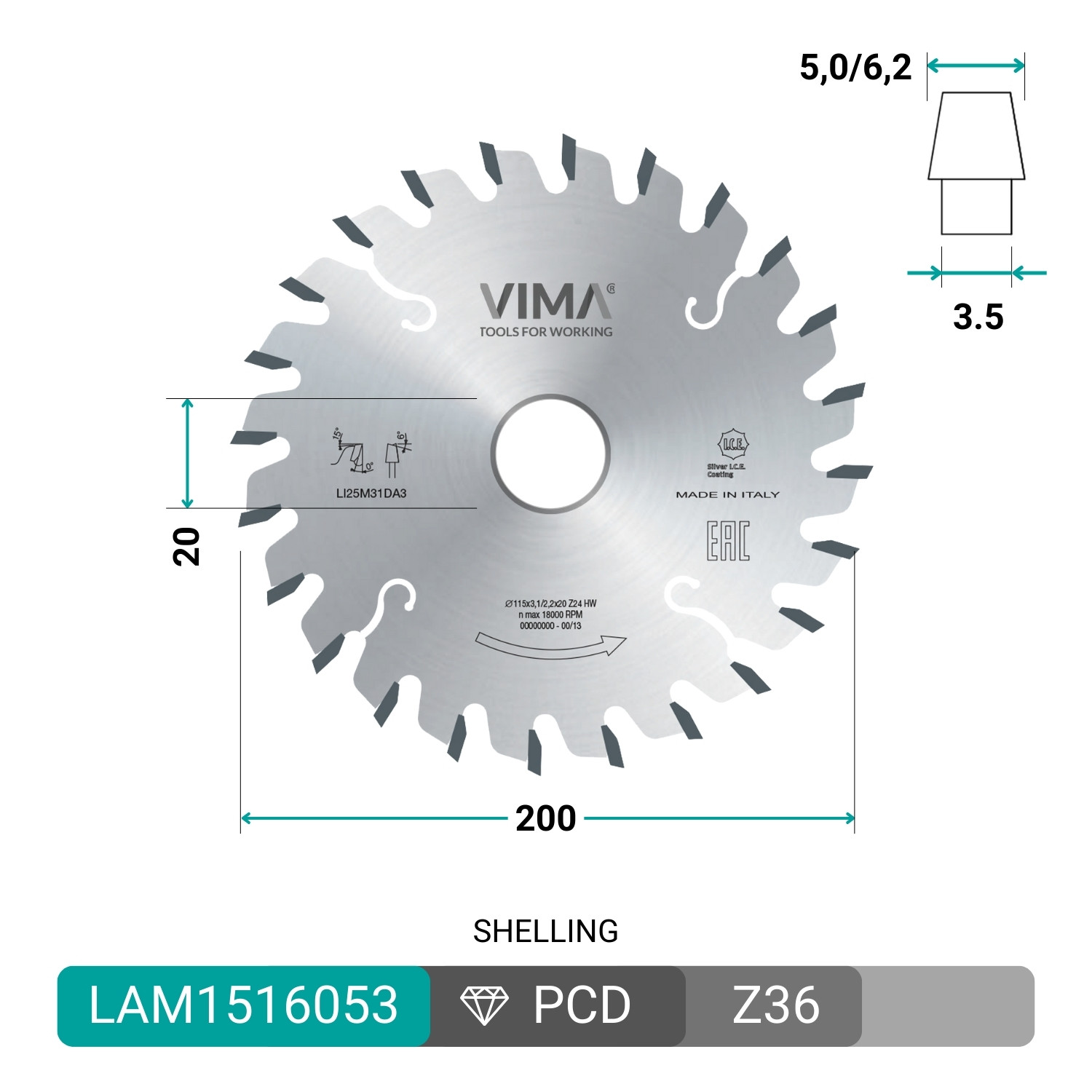

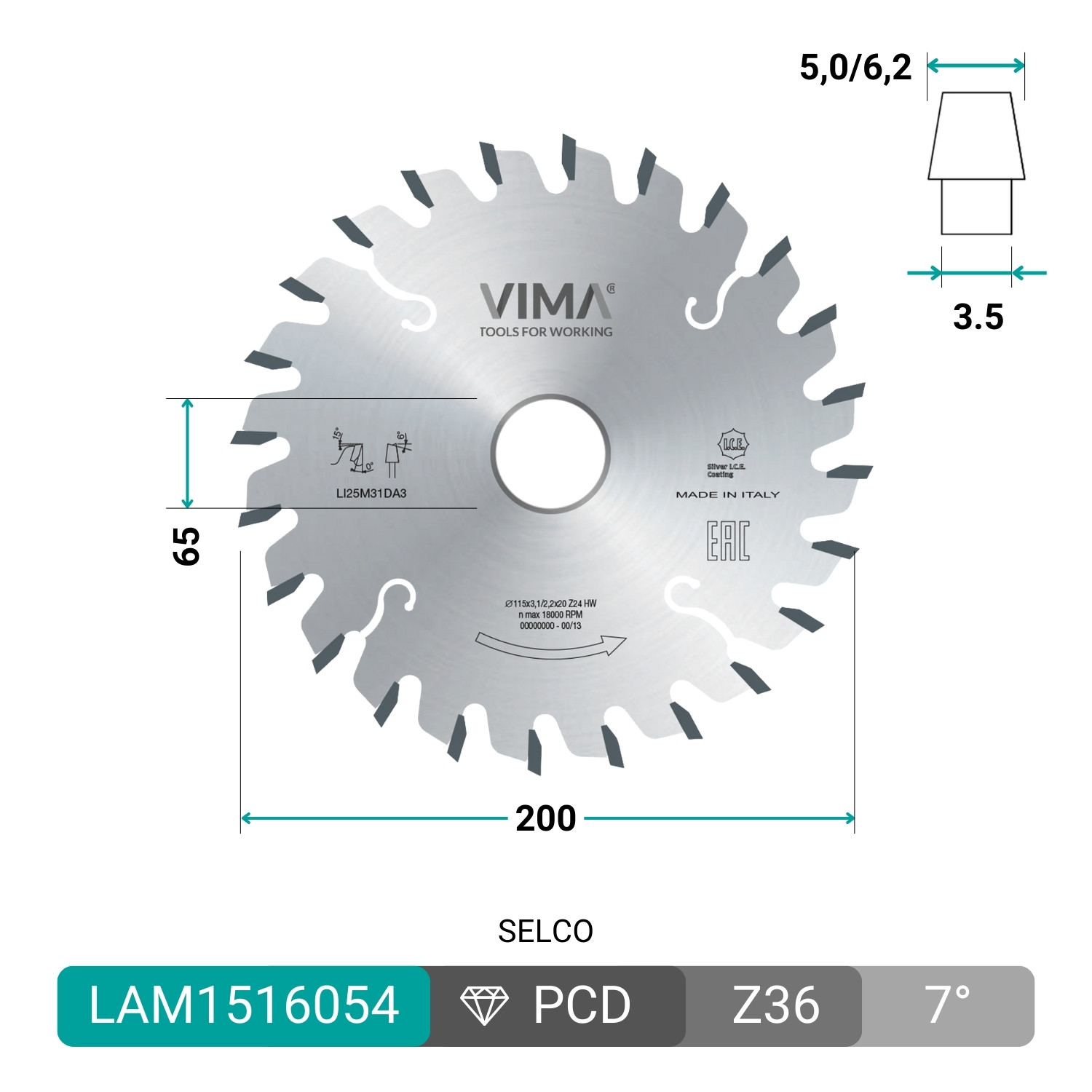

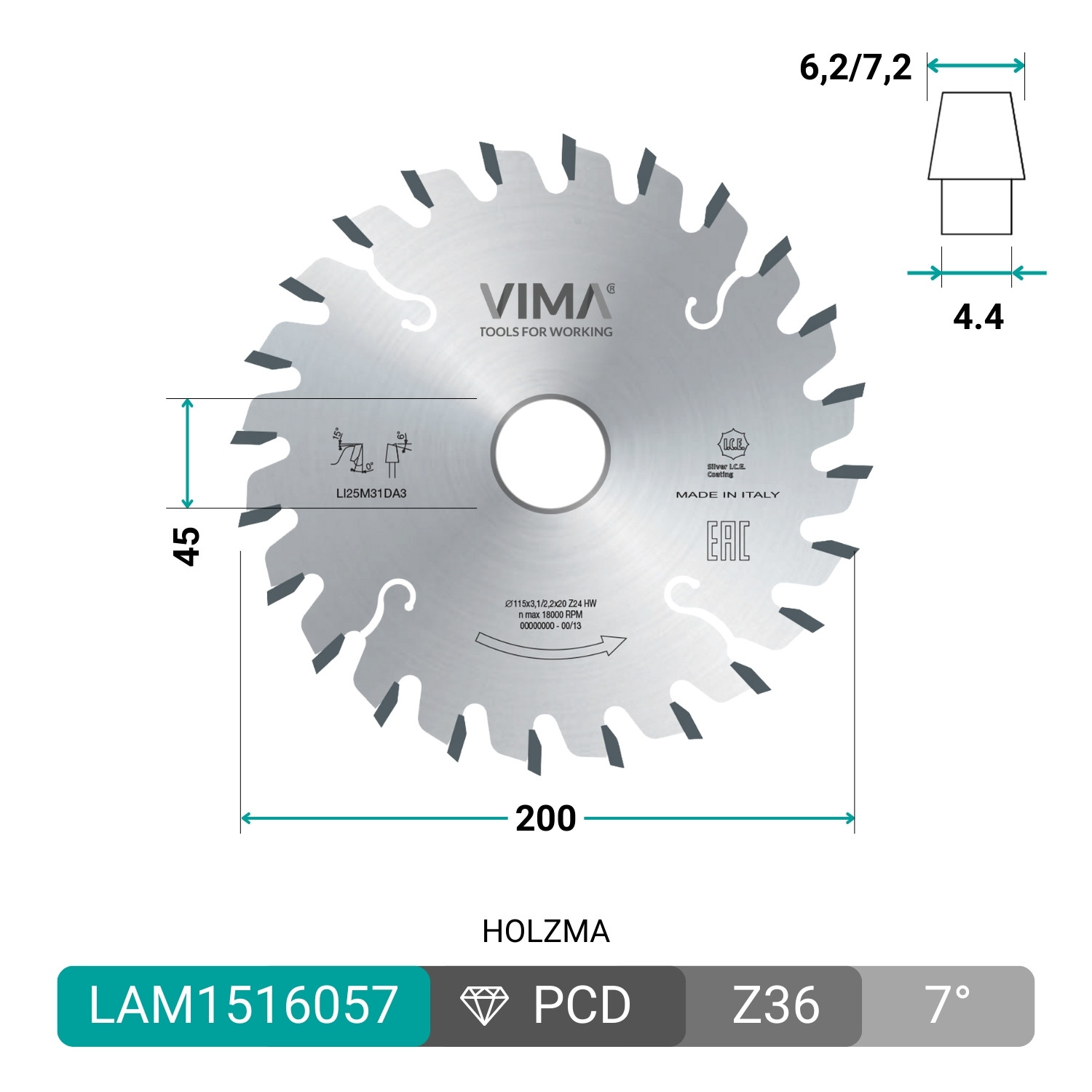

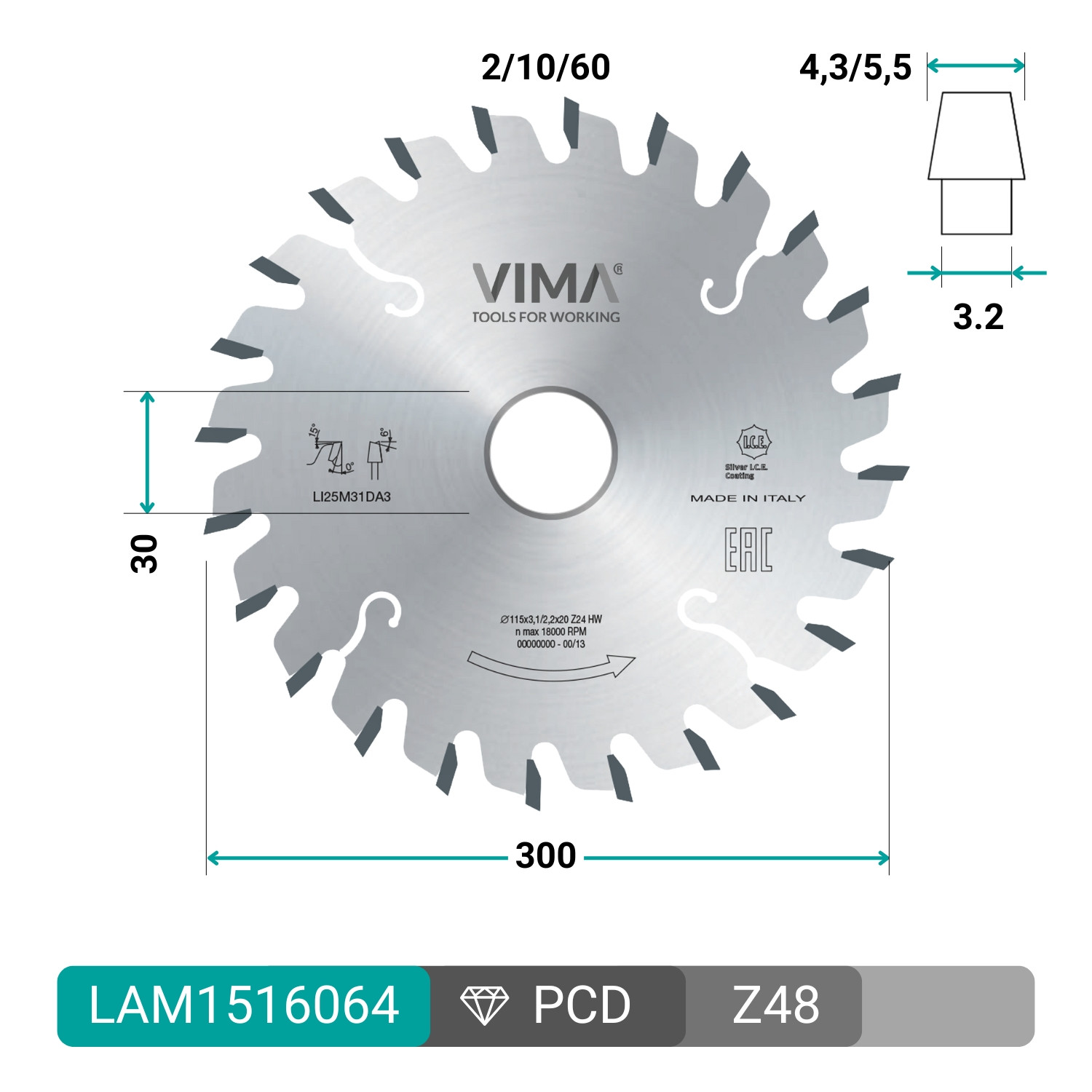

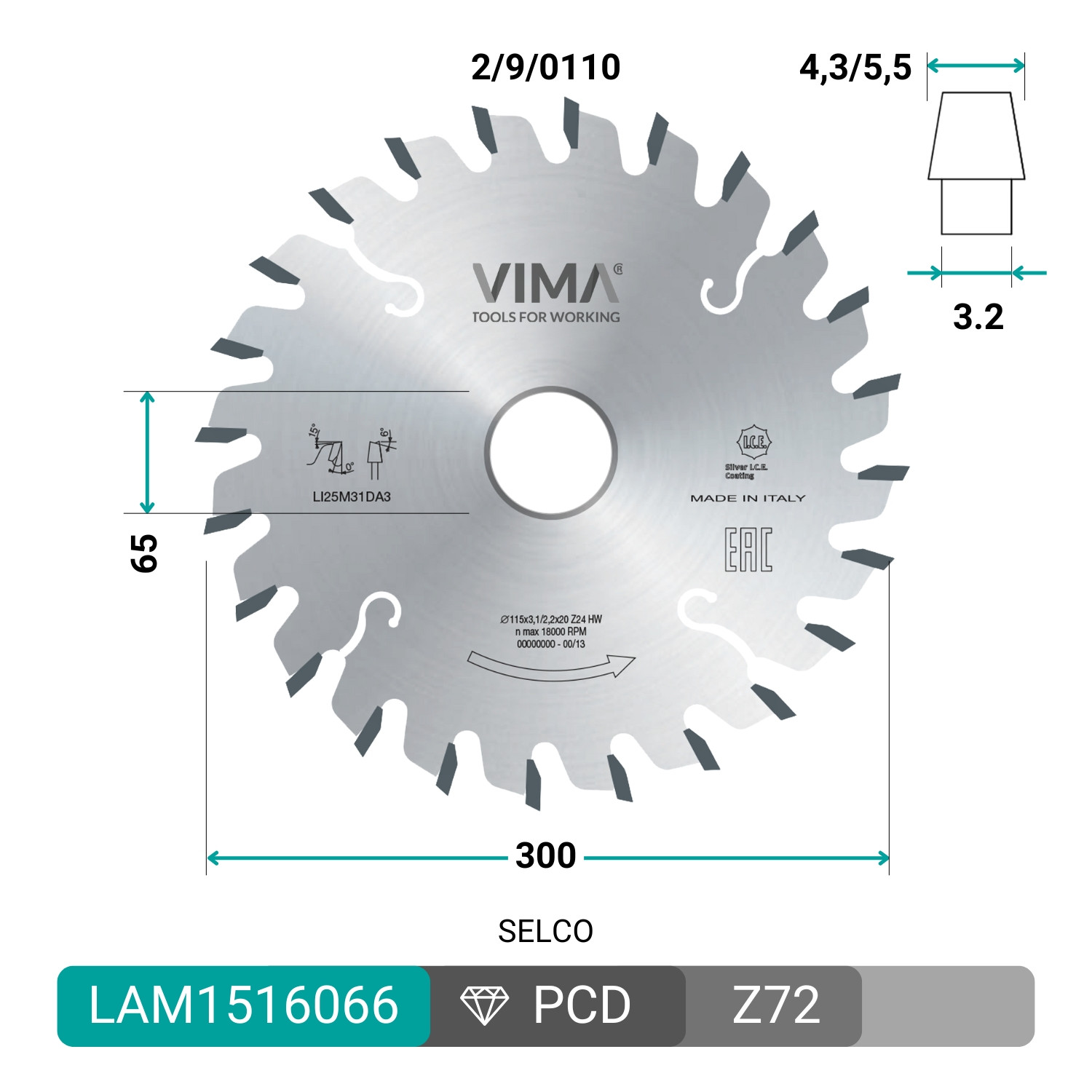

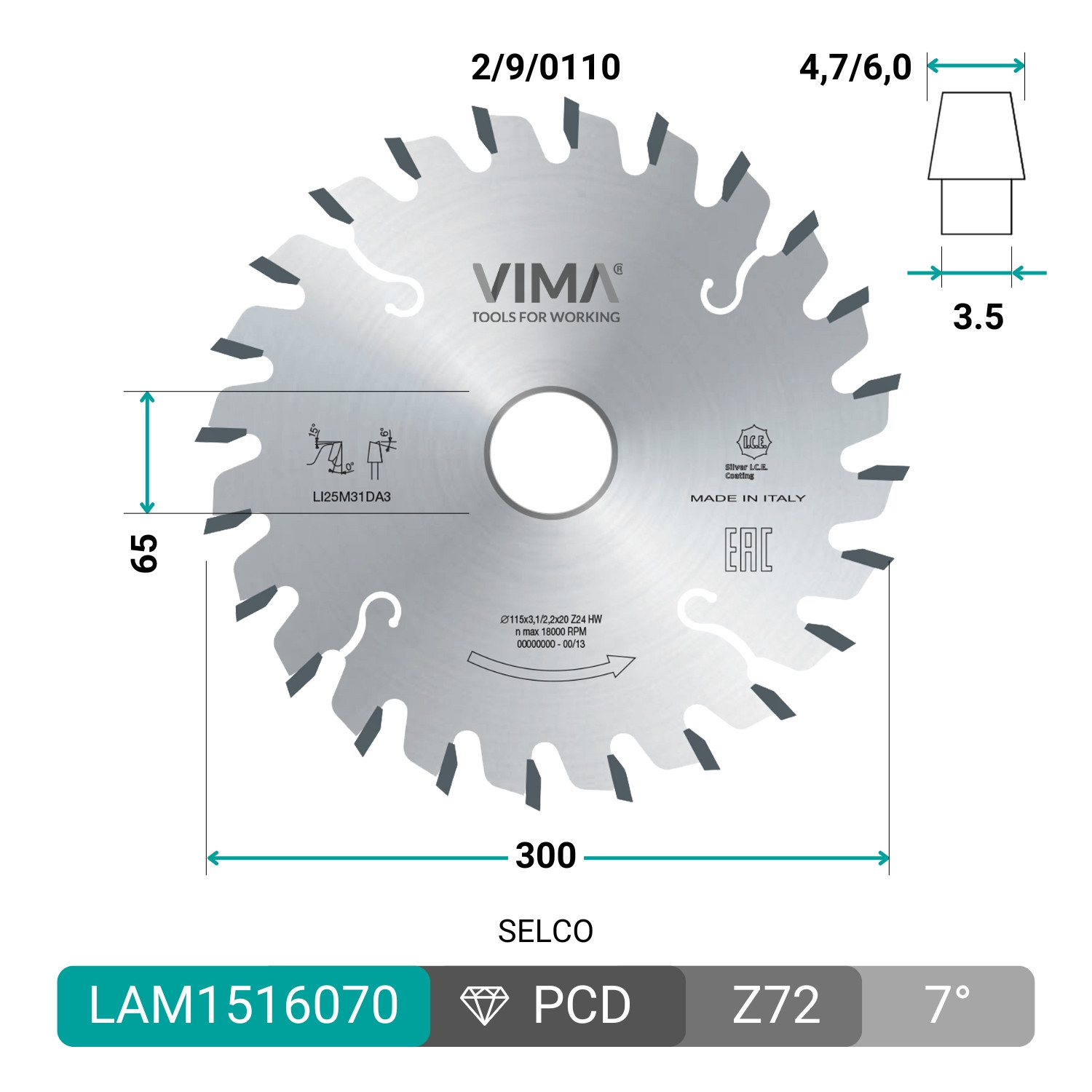

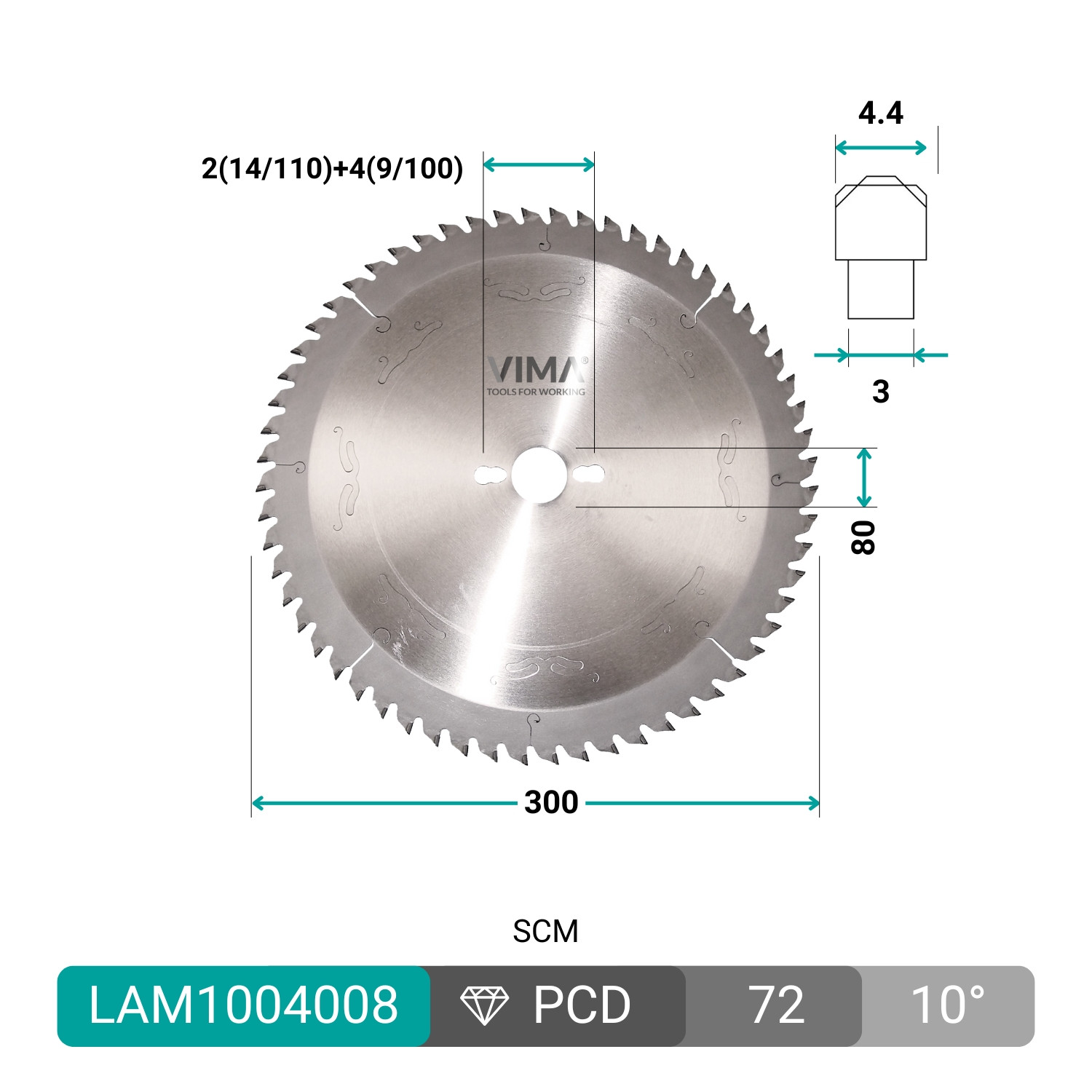

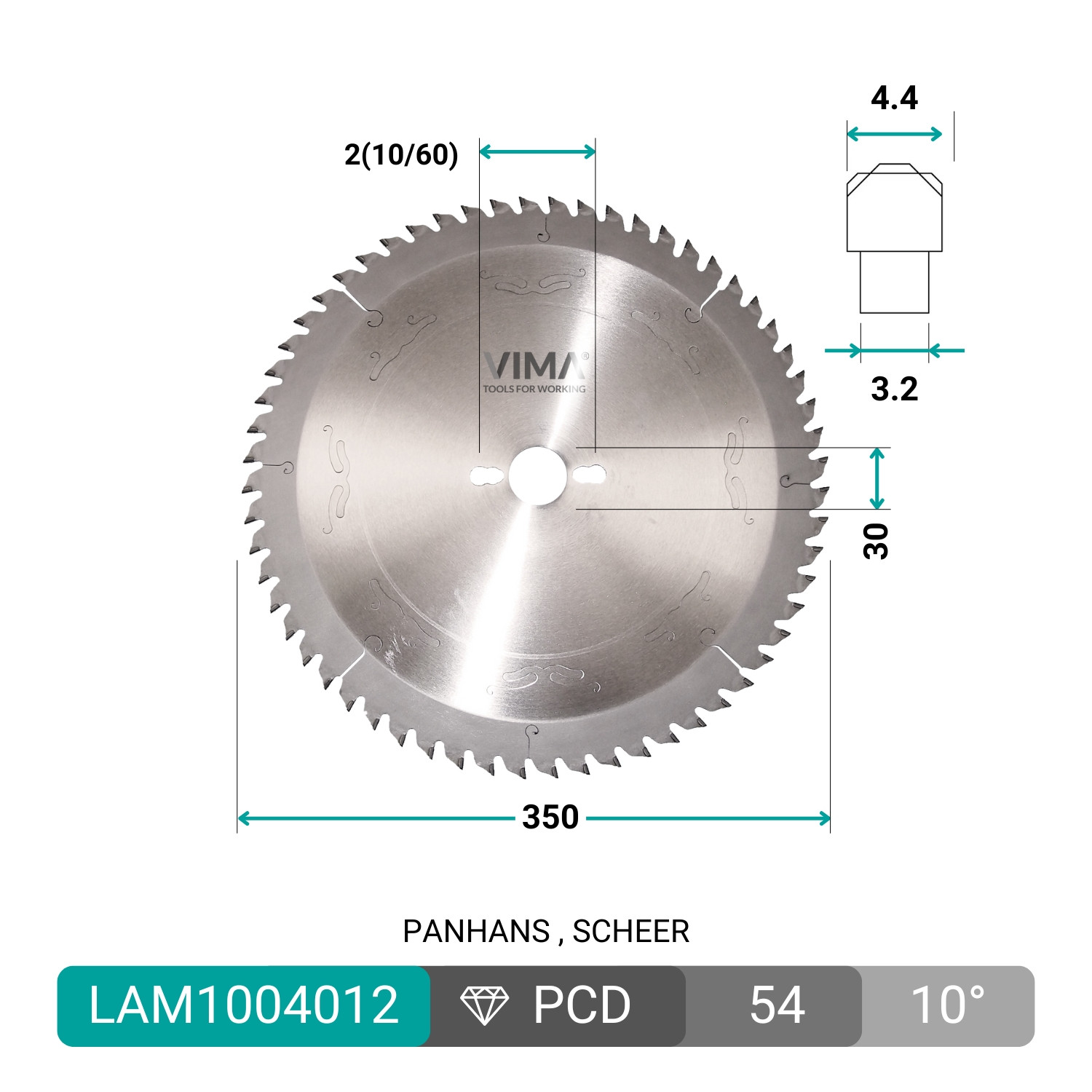

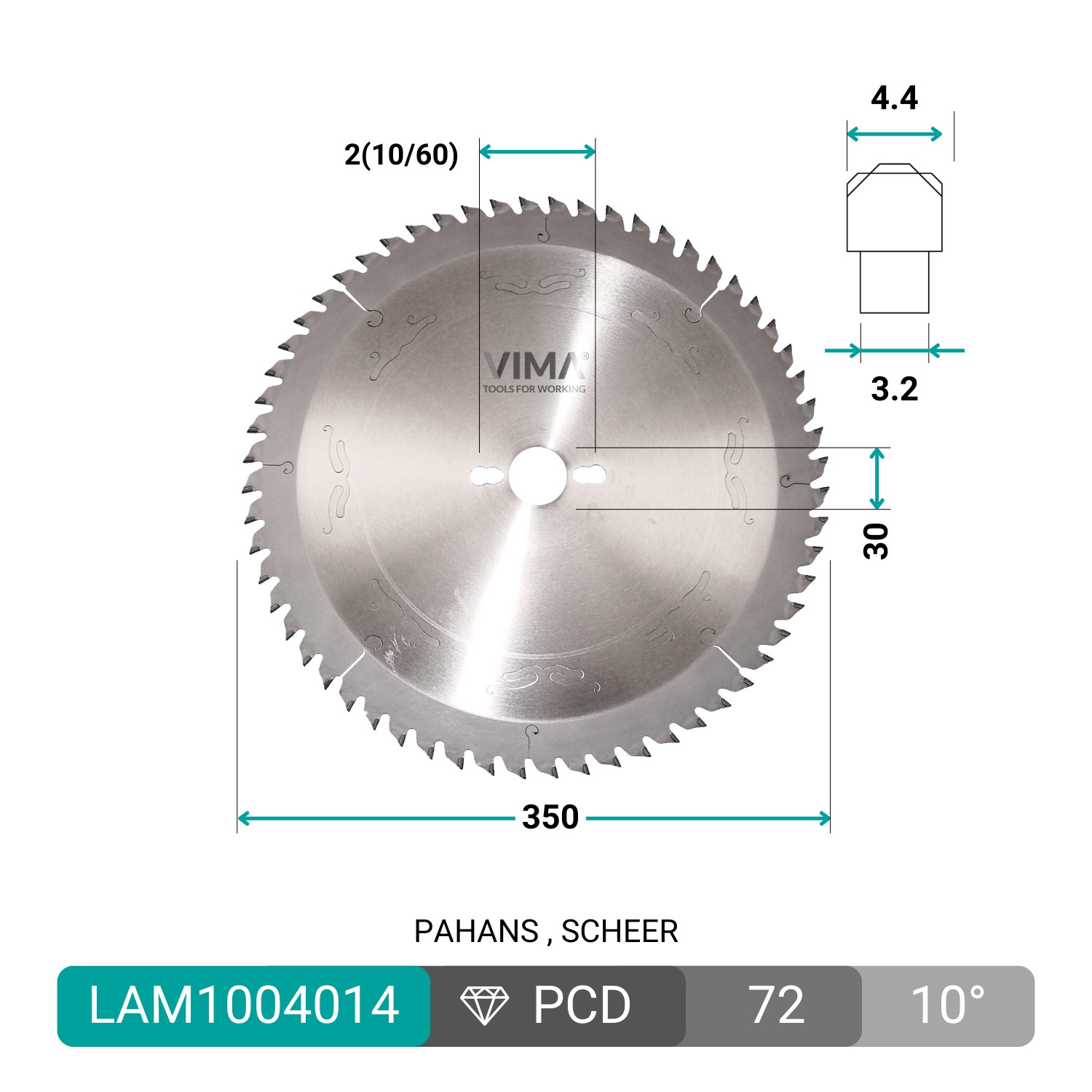

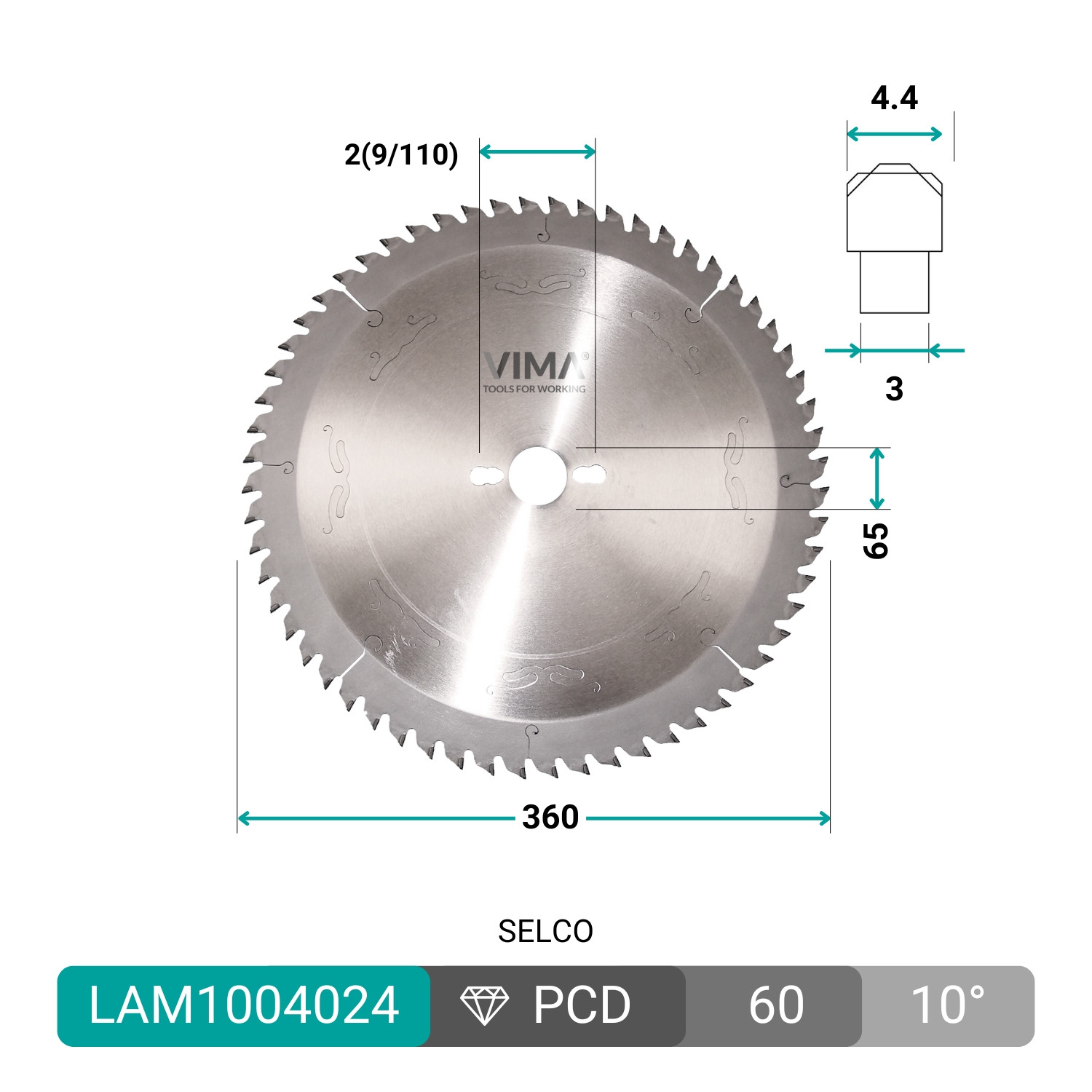

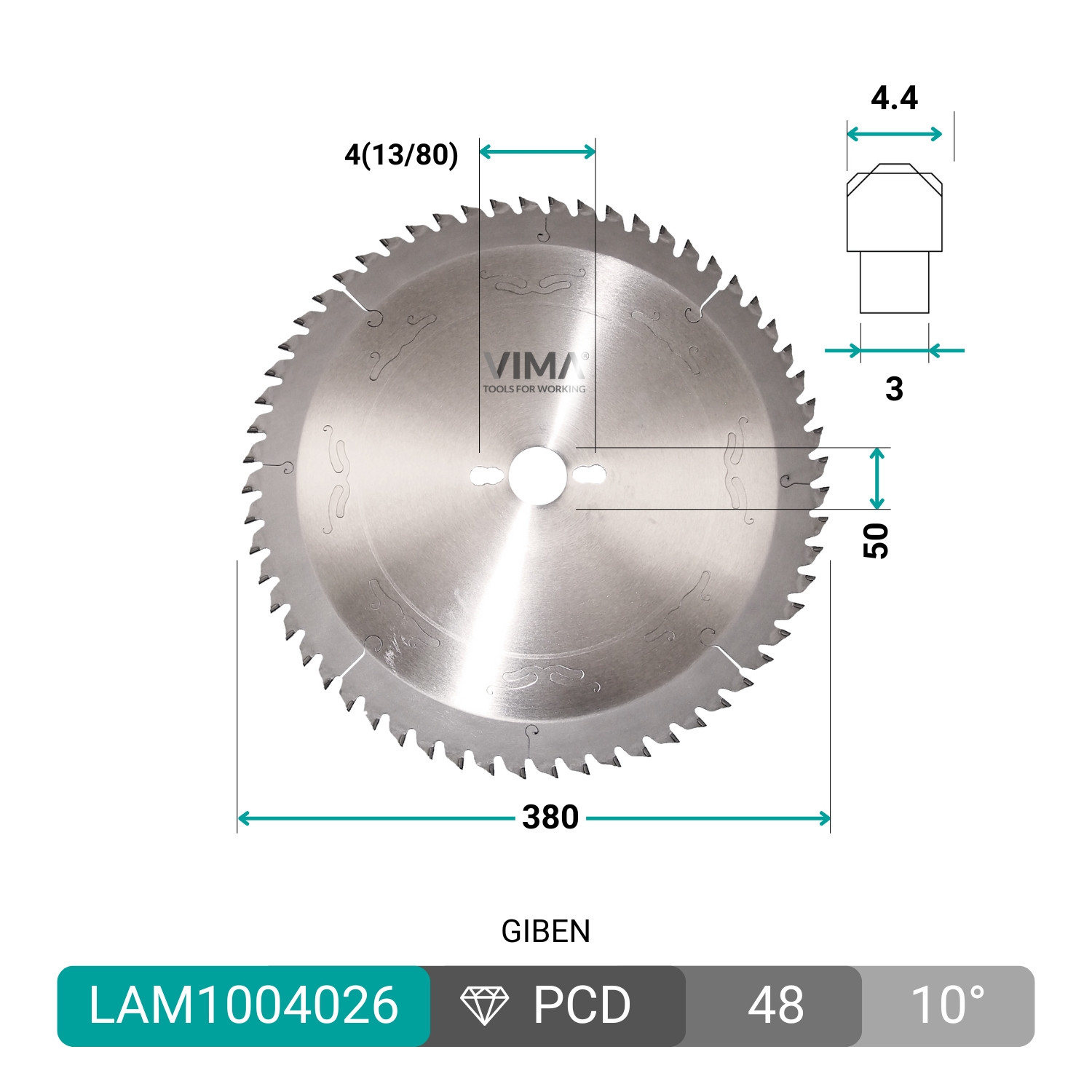

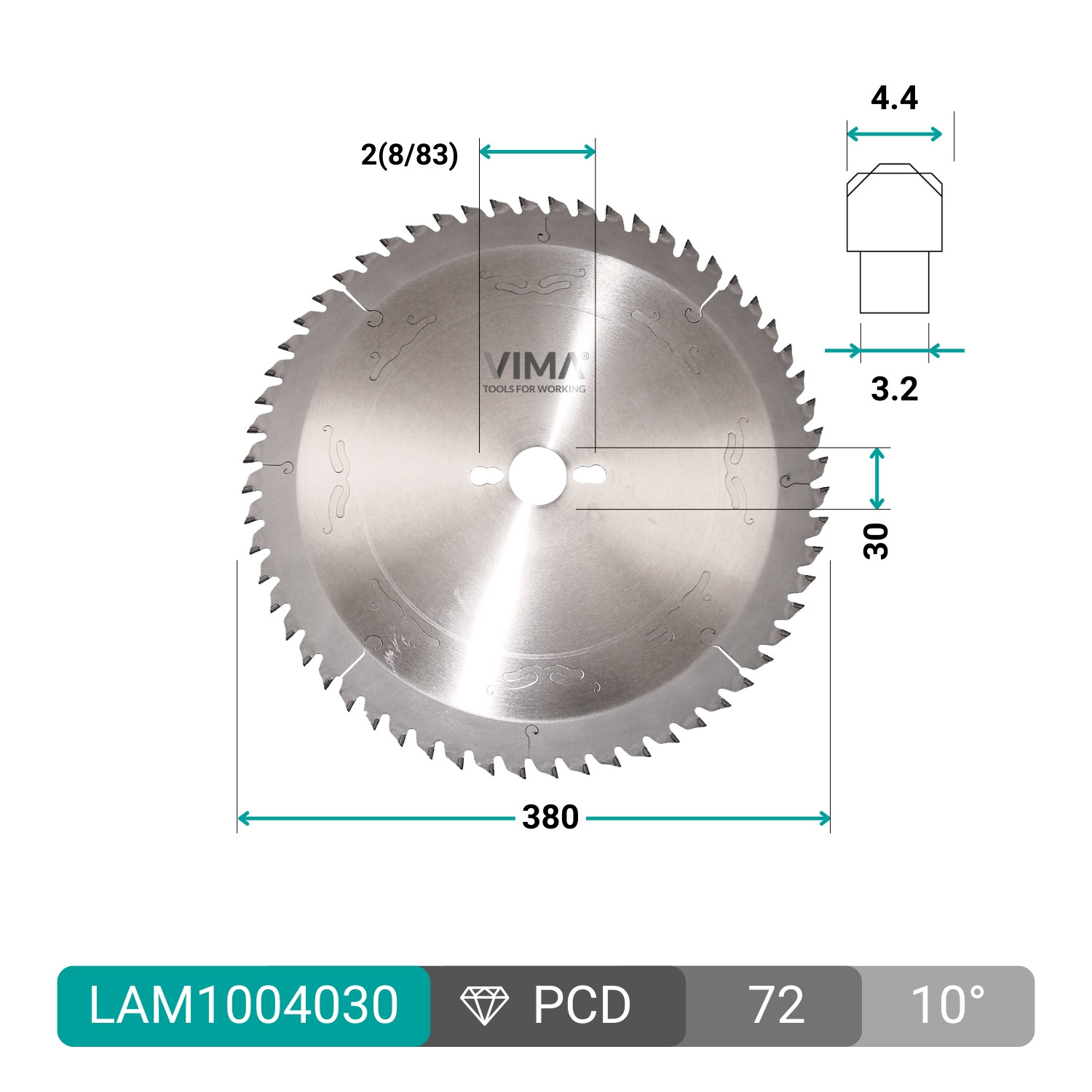

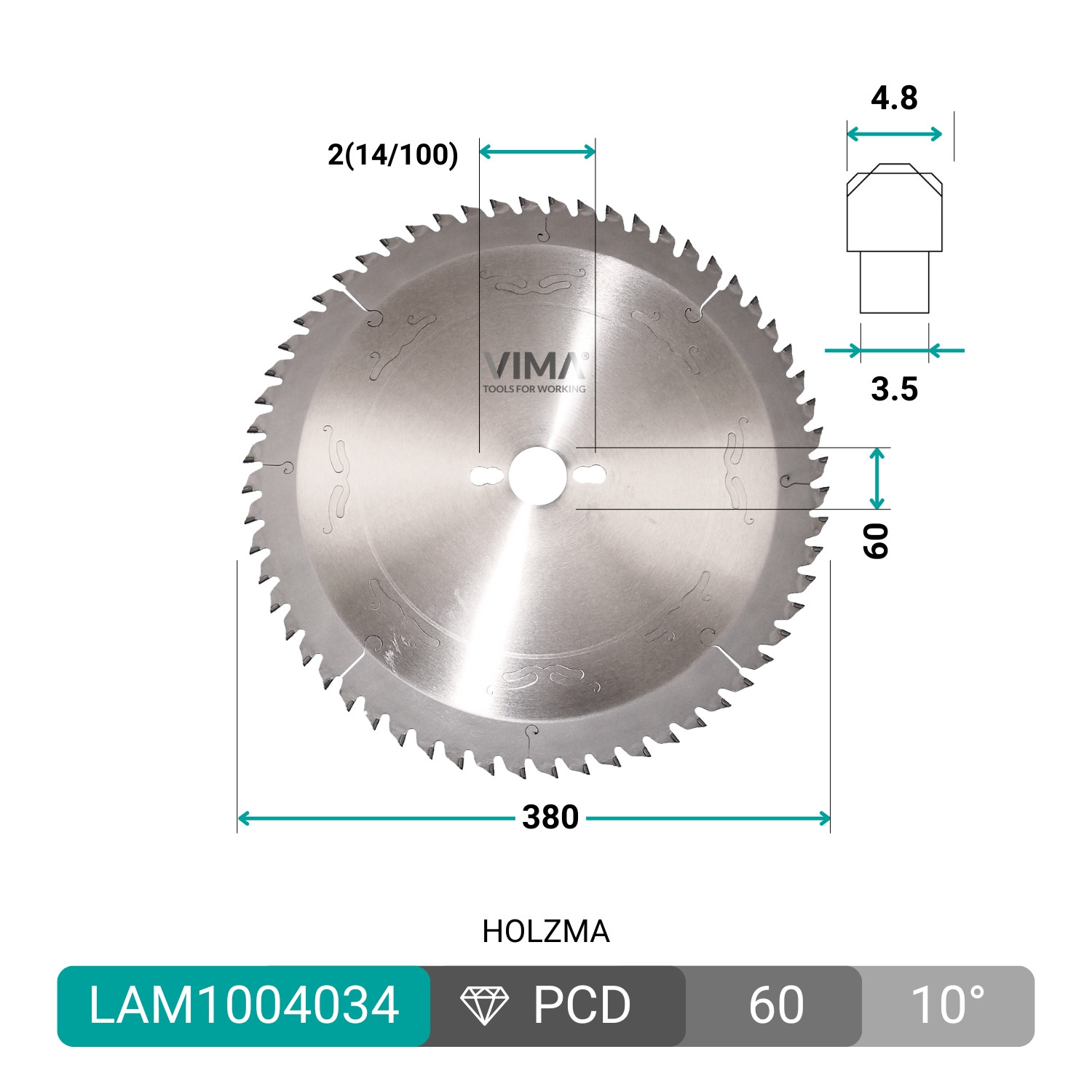

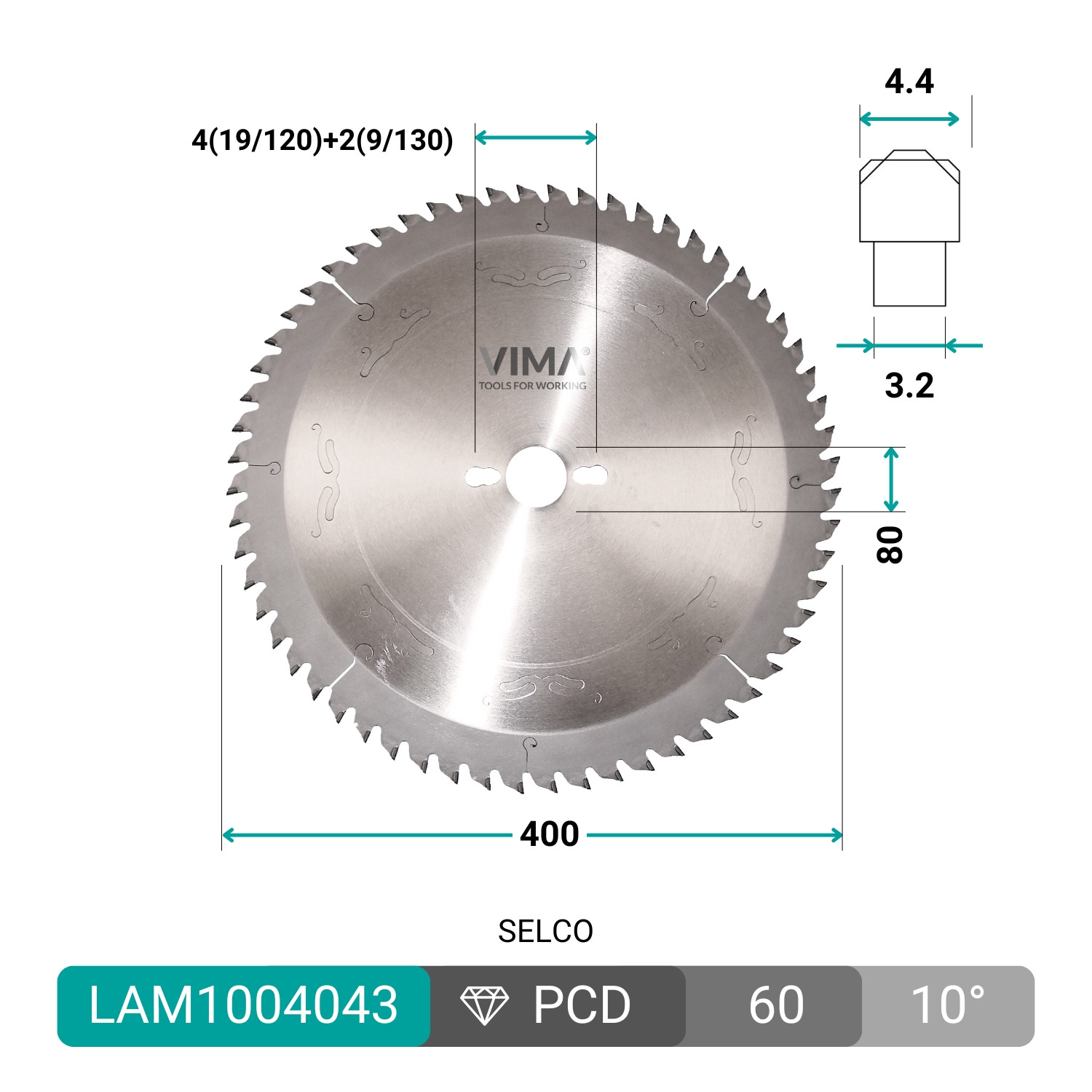

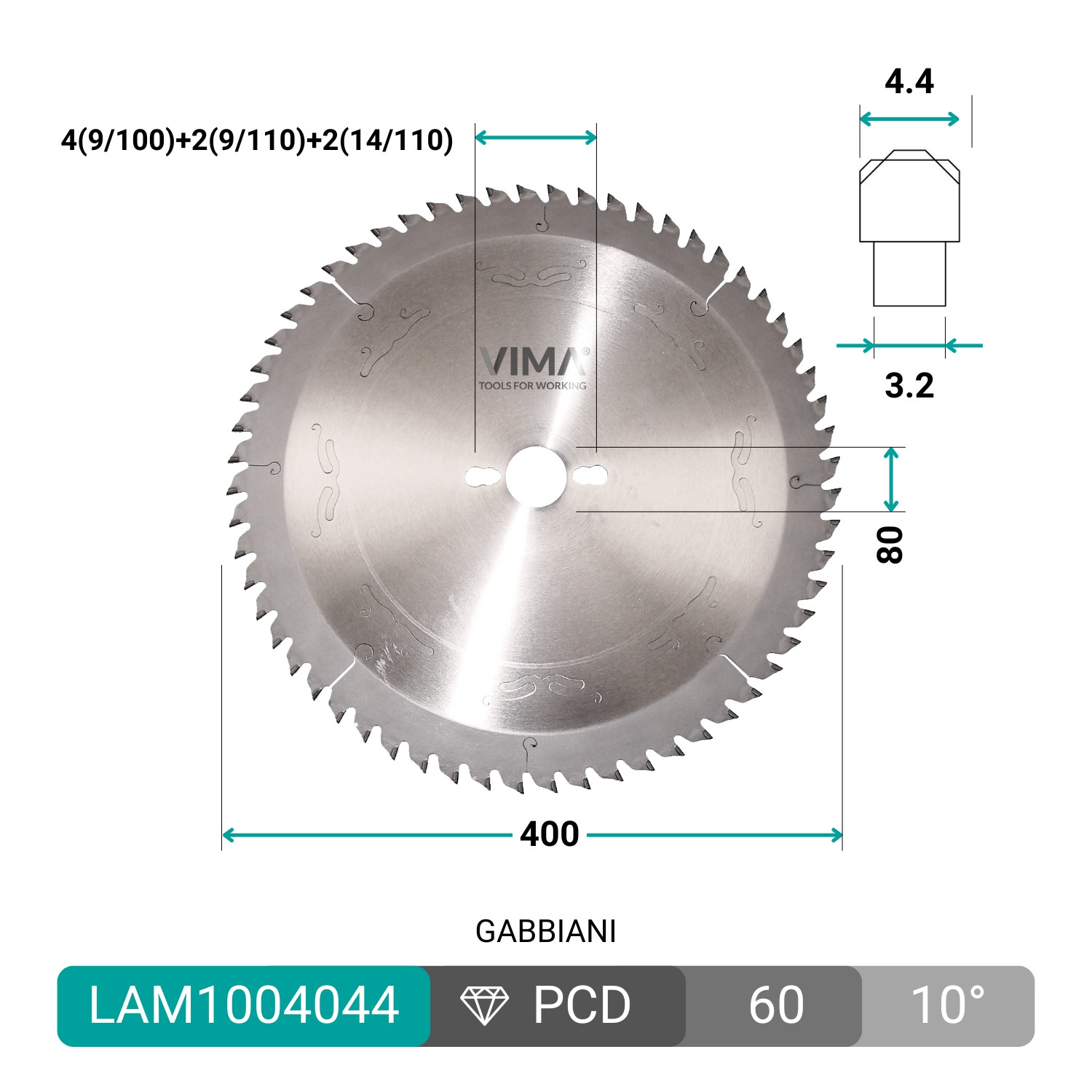

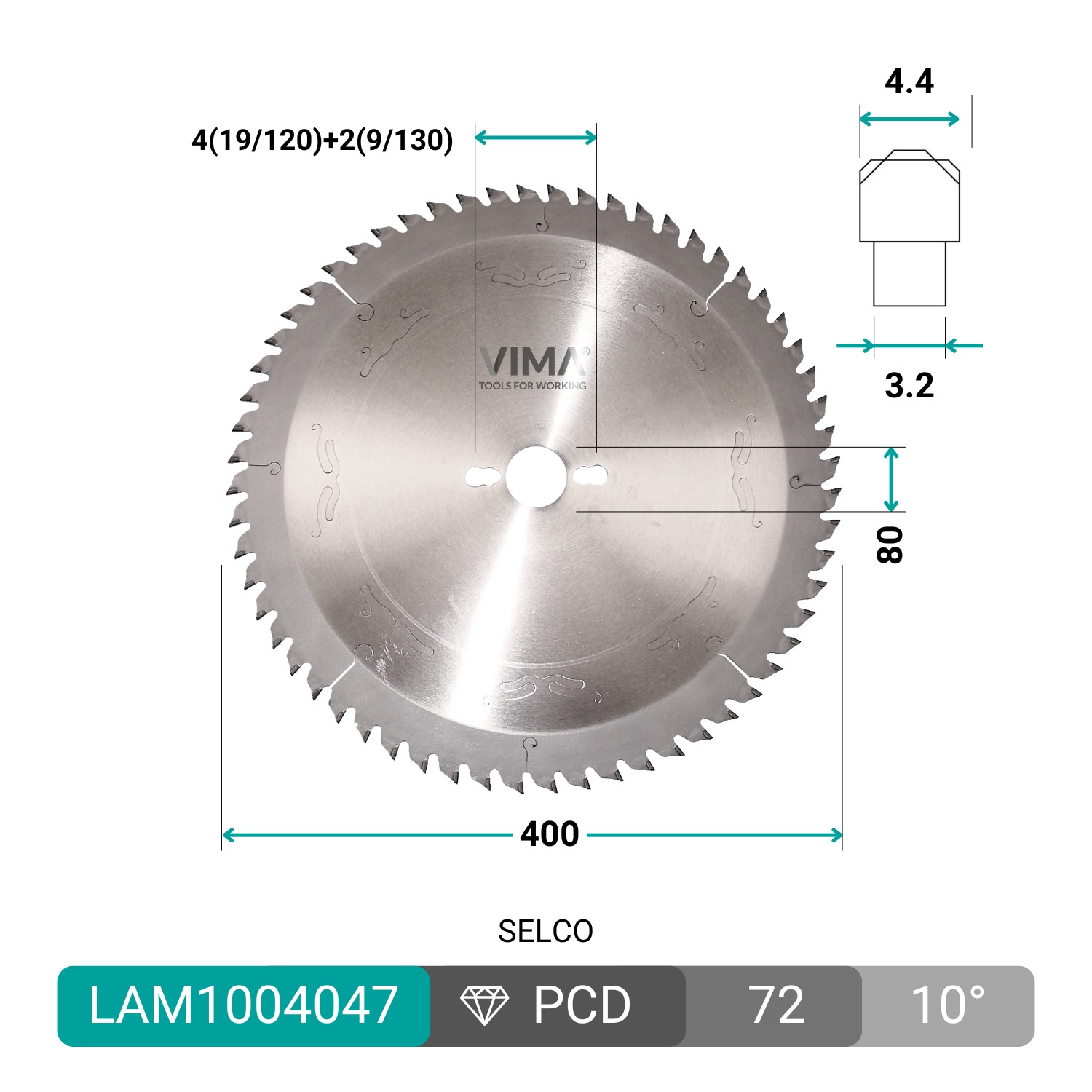

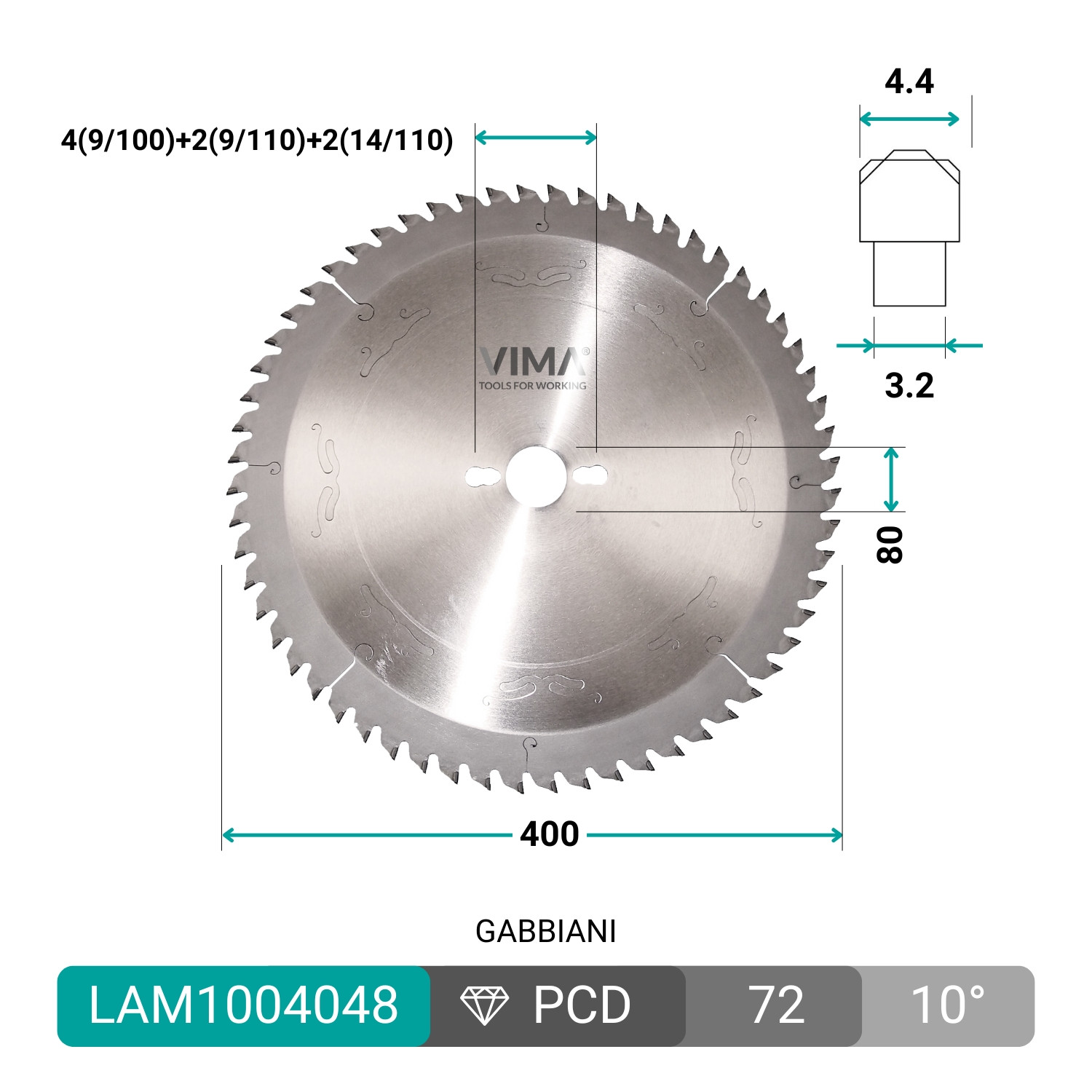

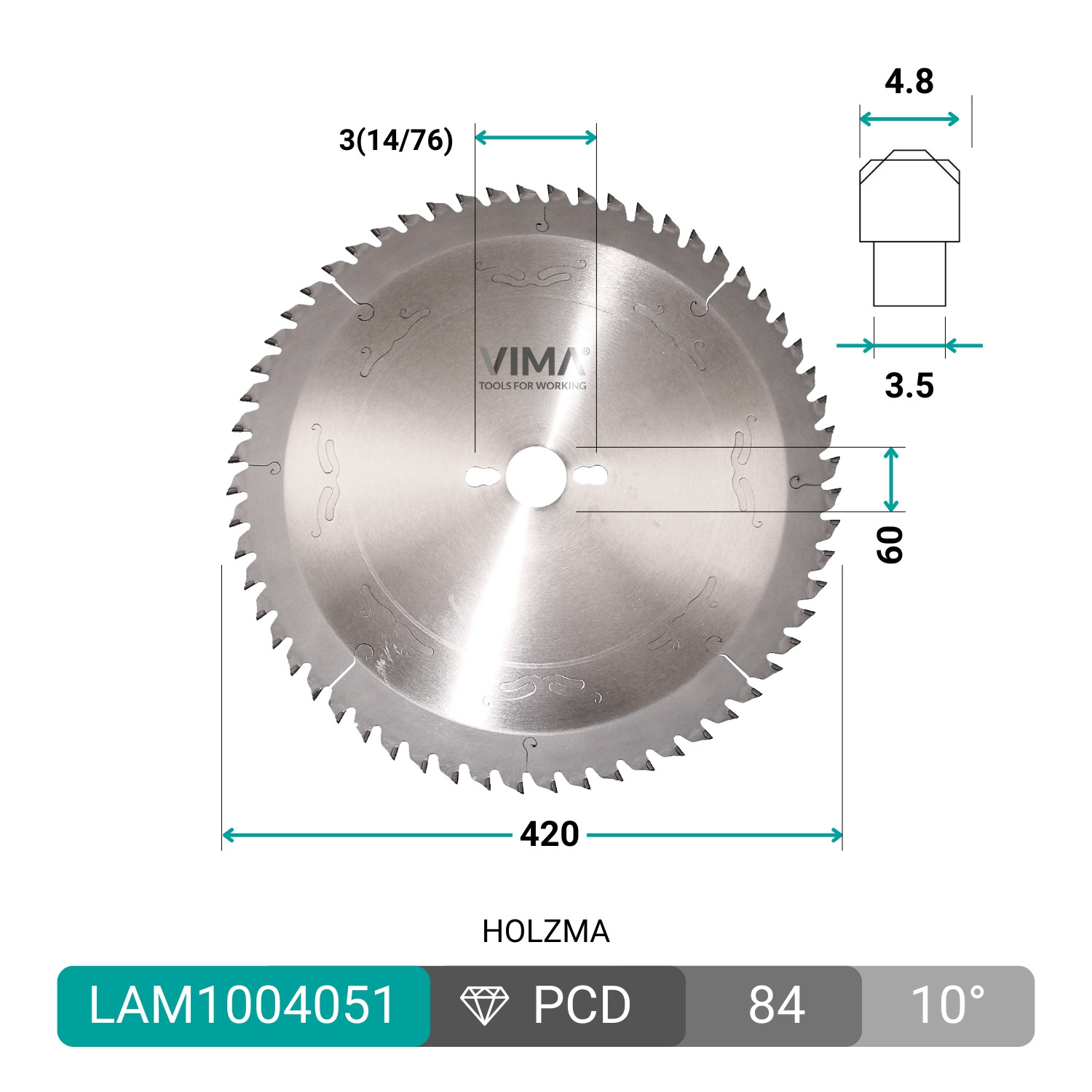

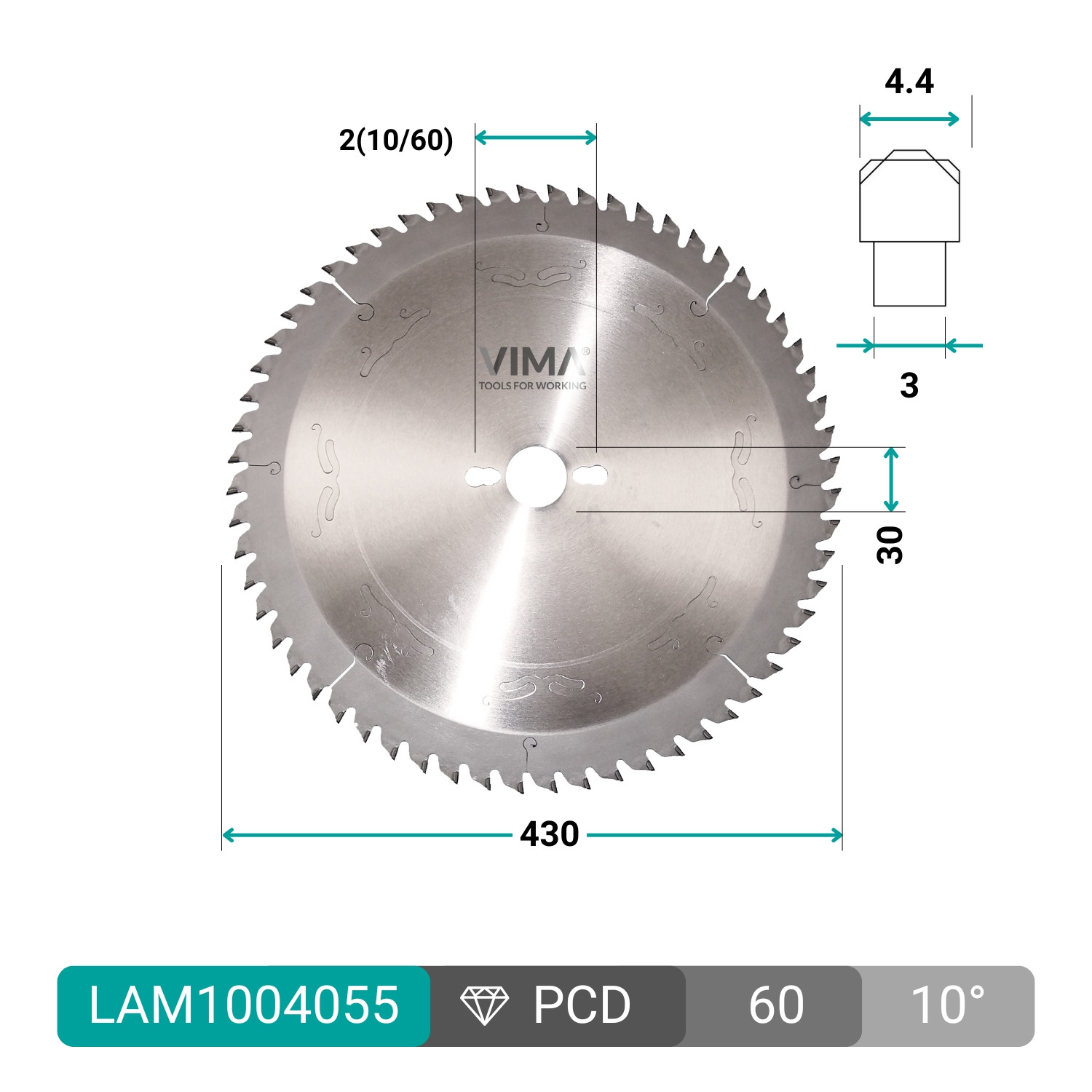

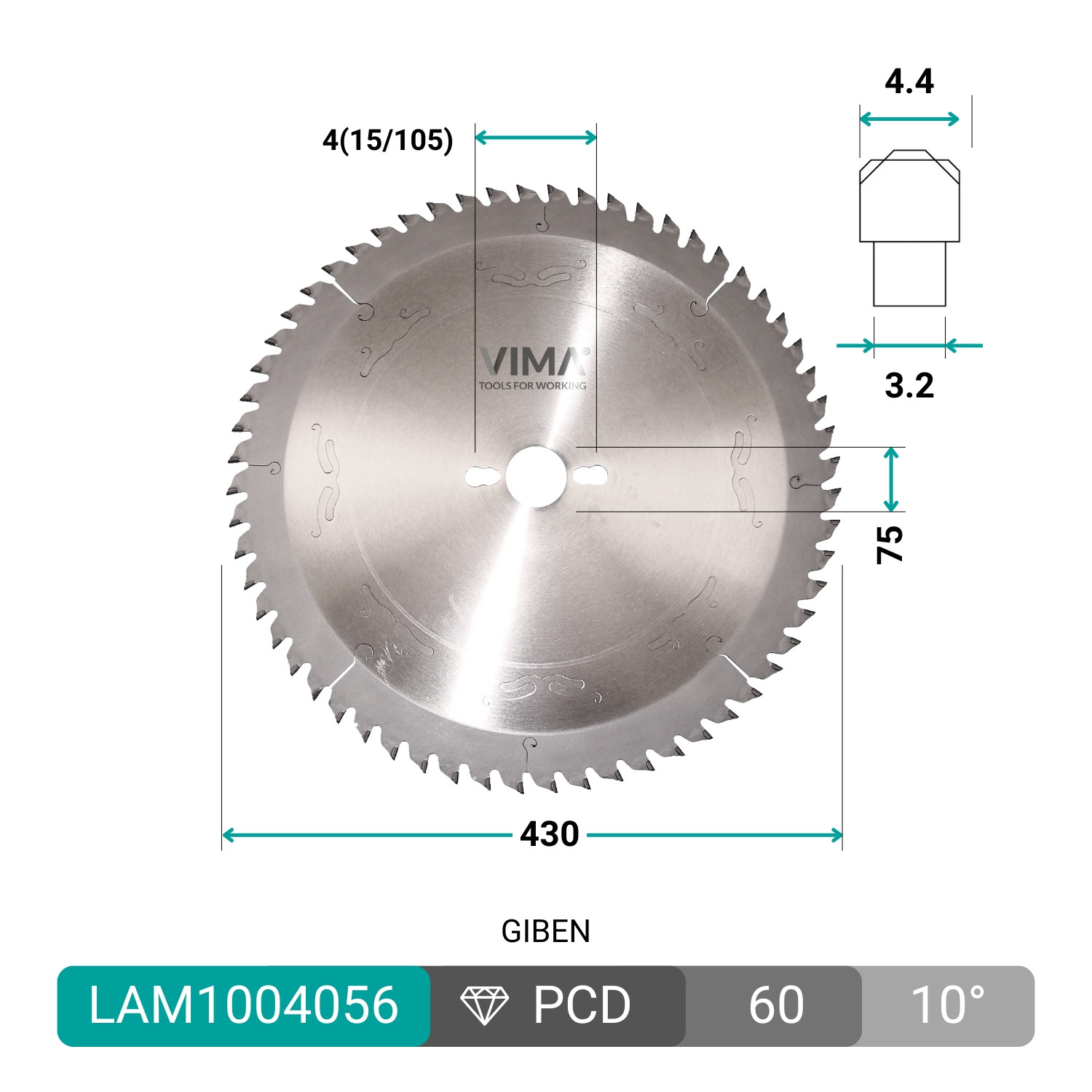

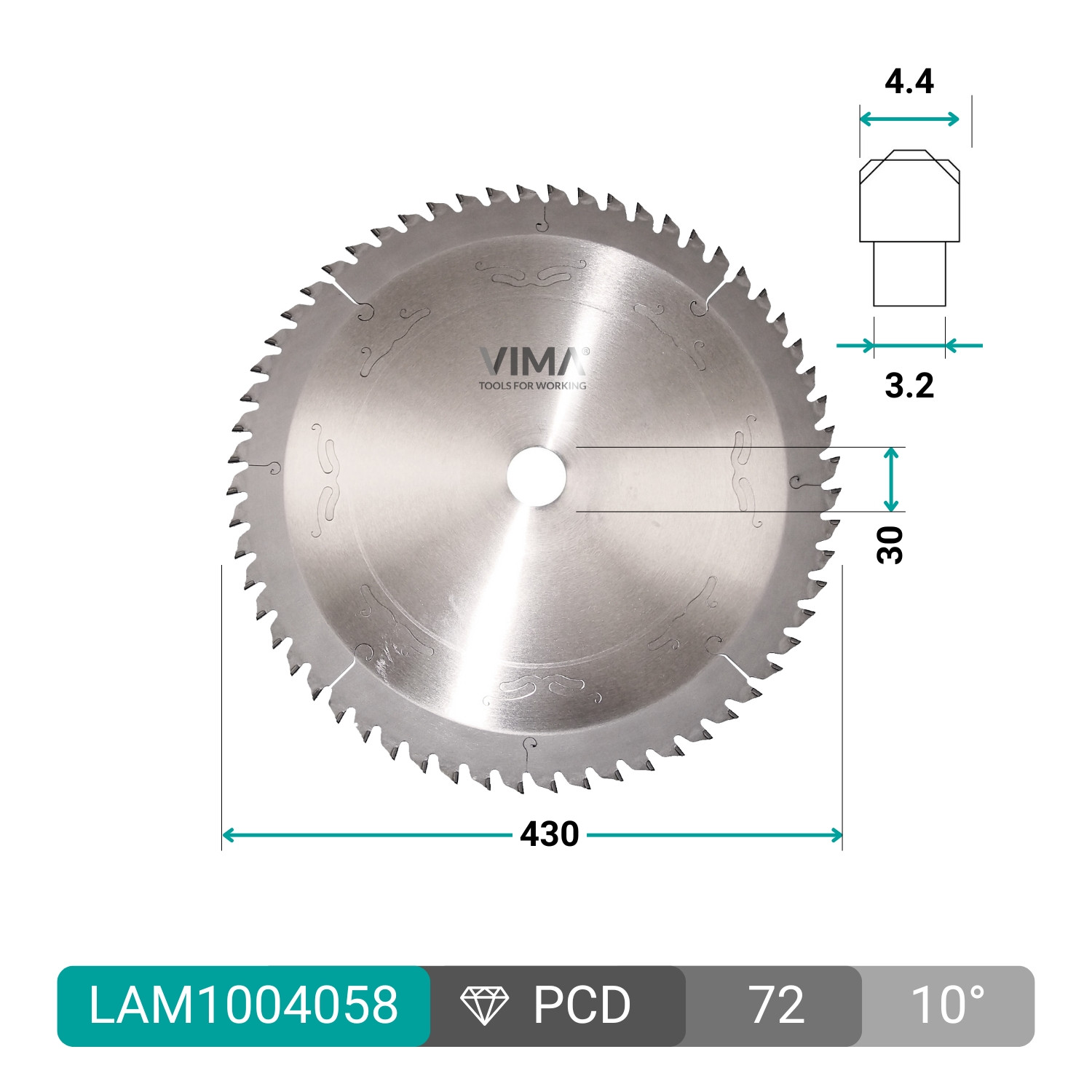

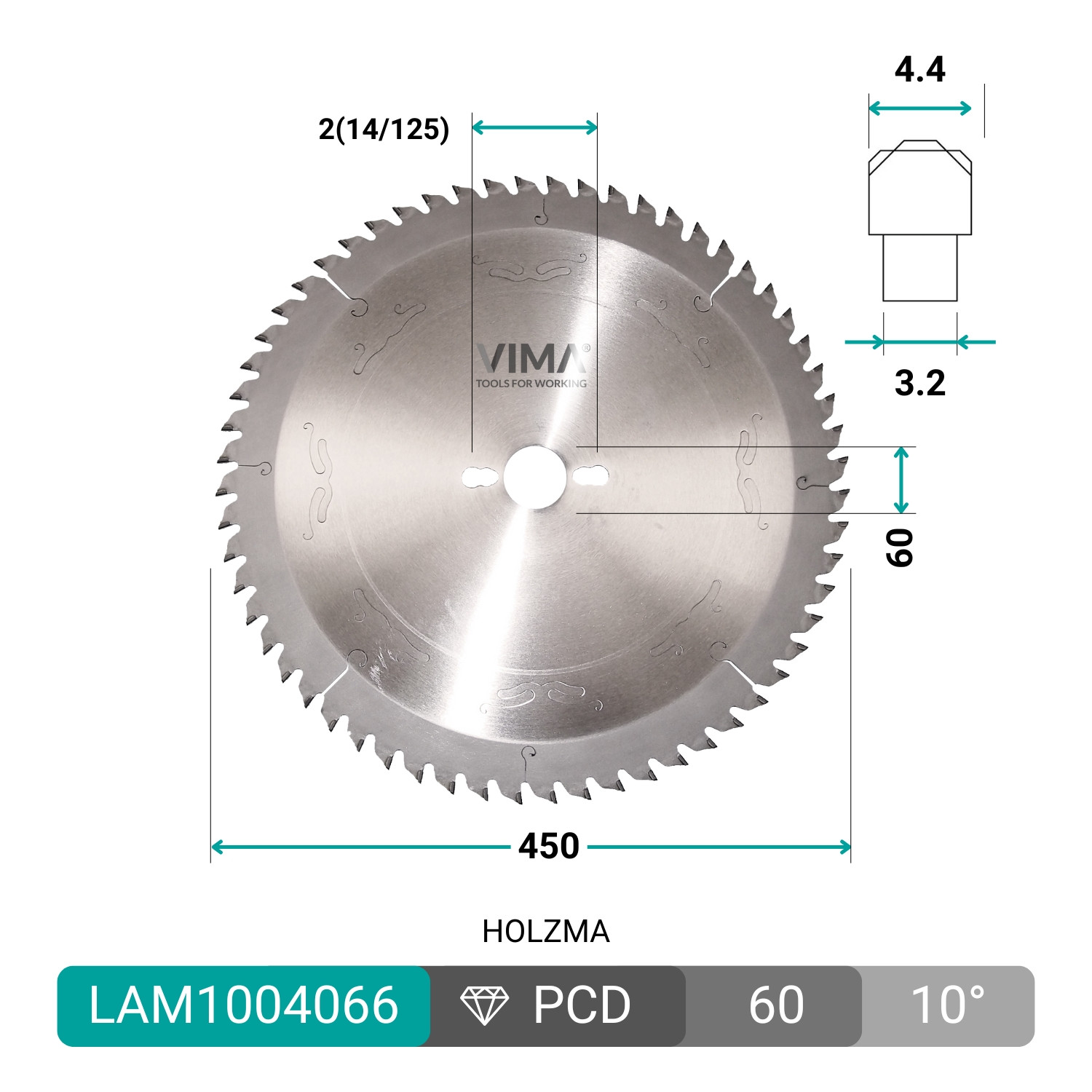

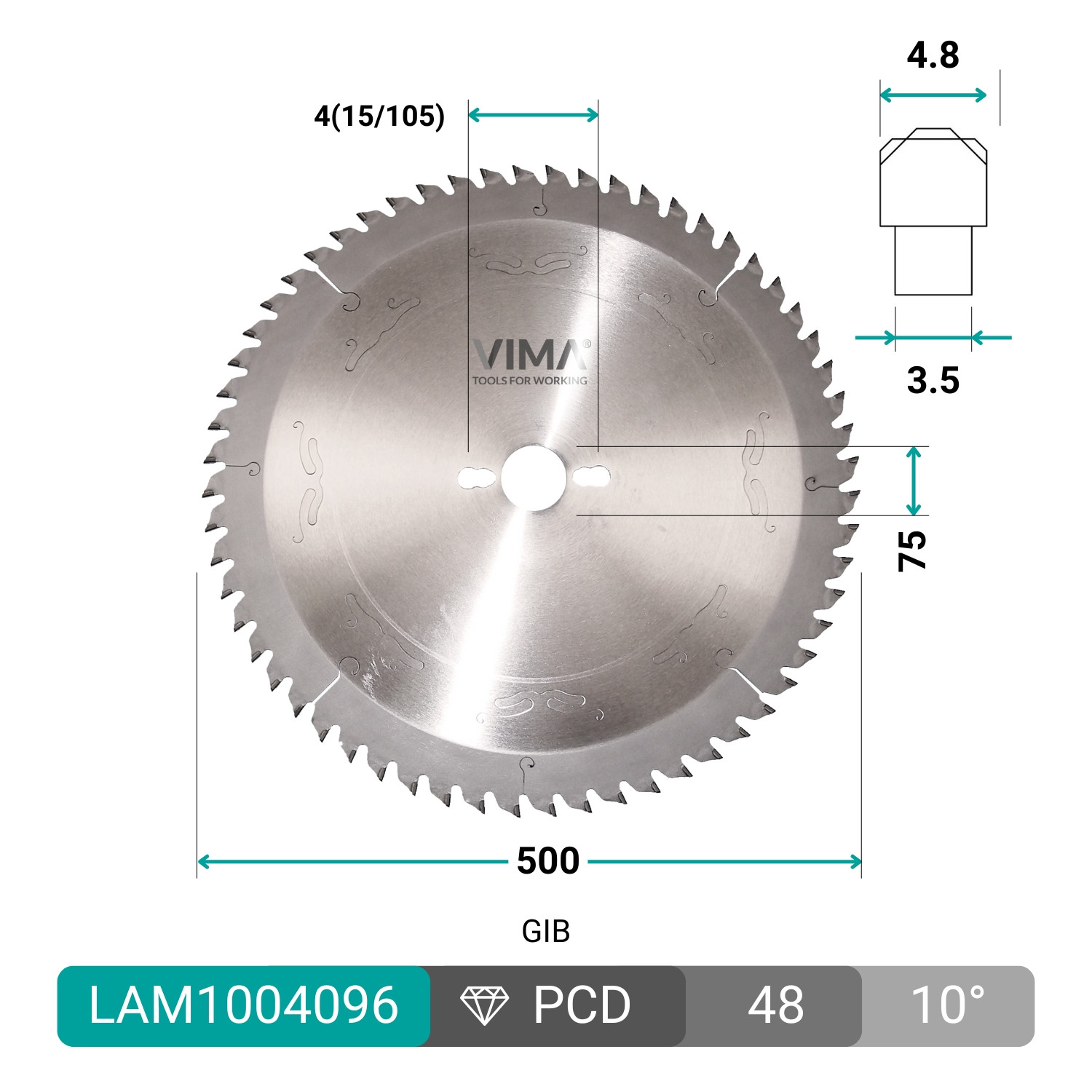

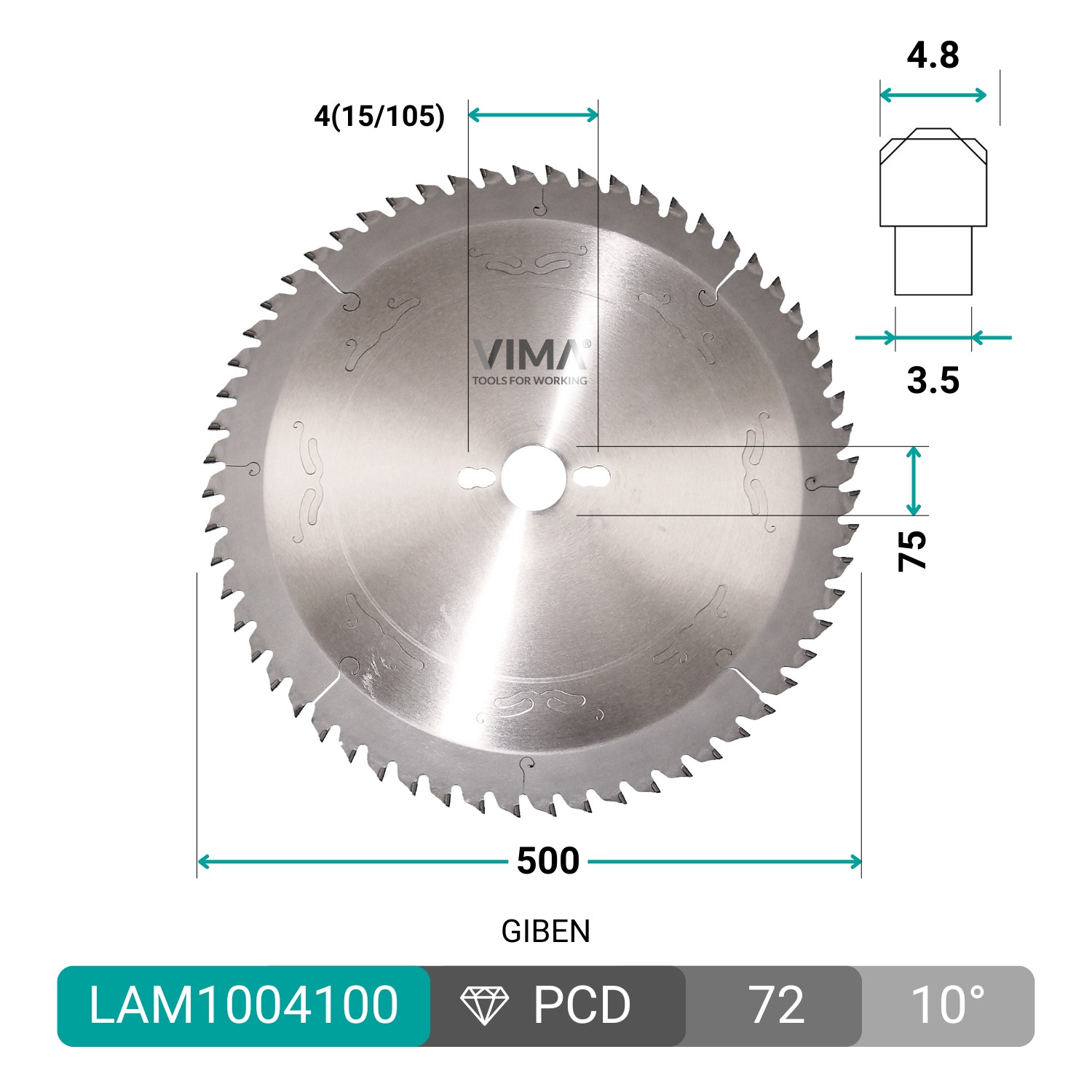

Adjustable PCD scoring blade designed for accurate, chip-free scoring on laminated panels. The 6 mm PCD height ensures exceptional durability, while the adjustable width allows perfect alignment with the main blade. Ideal for professional horizontal panel saws.

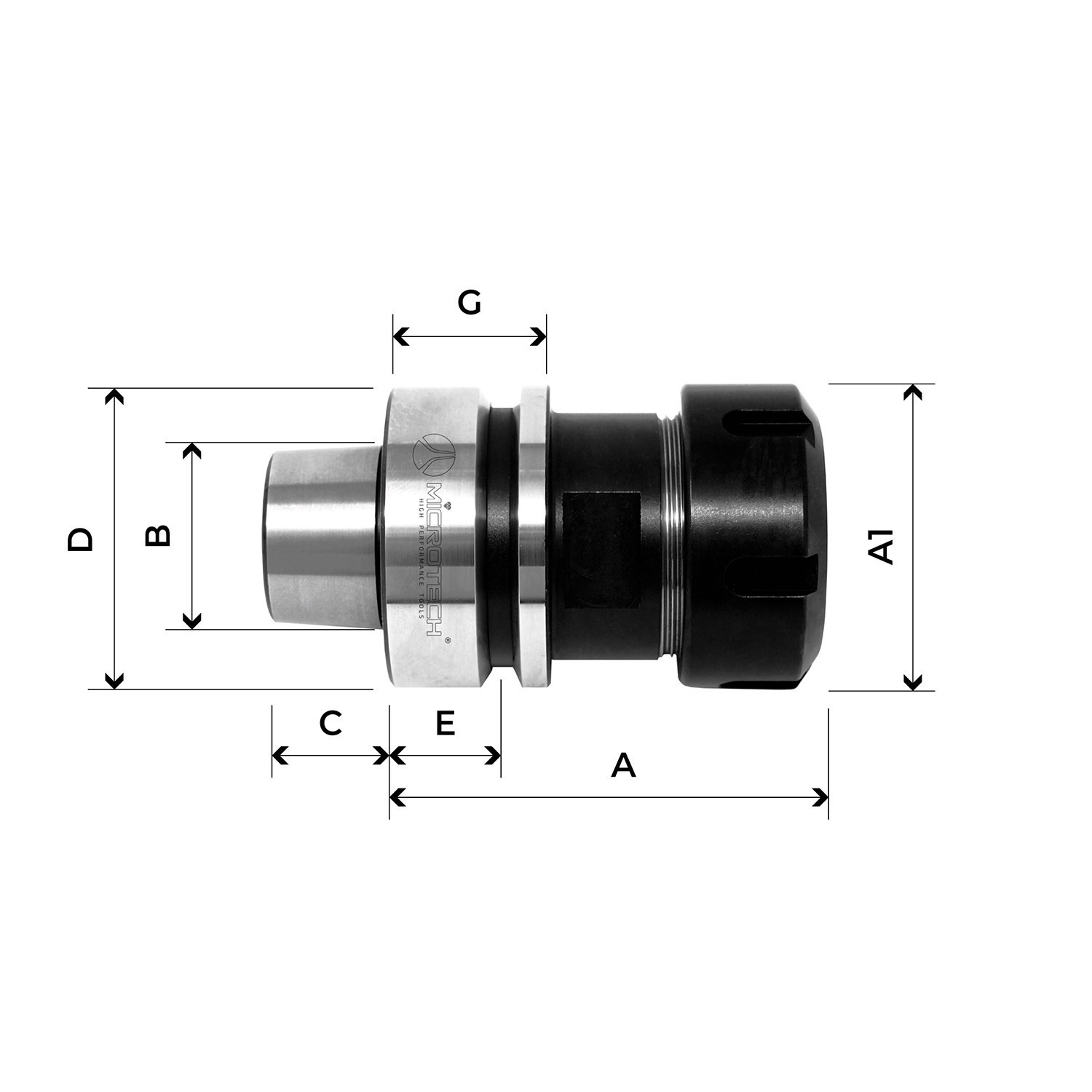

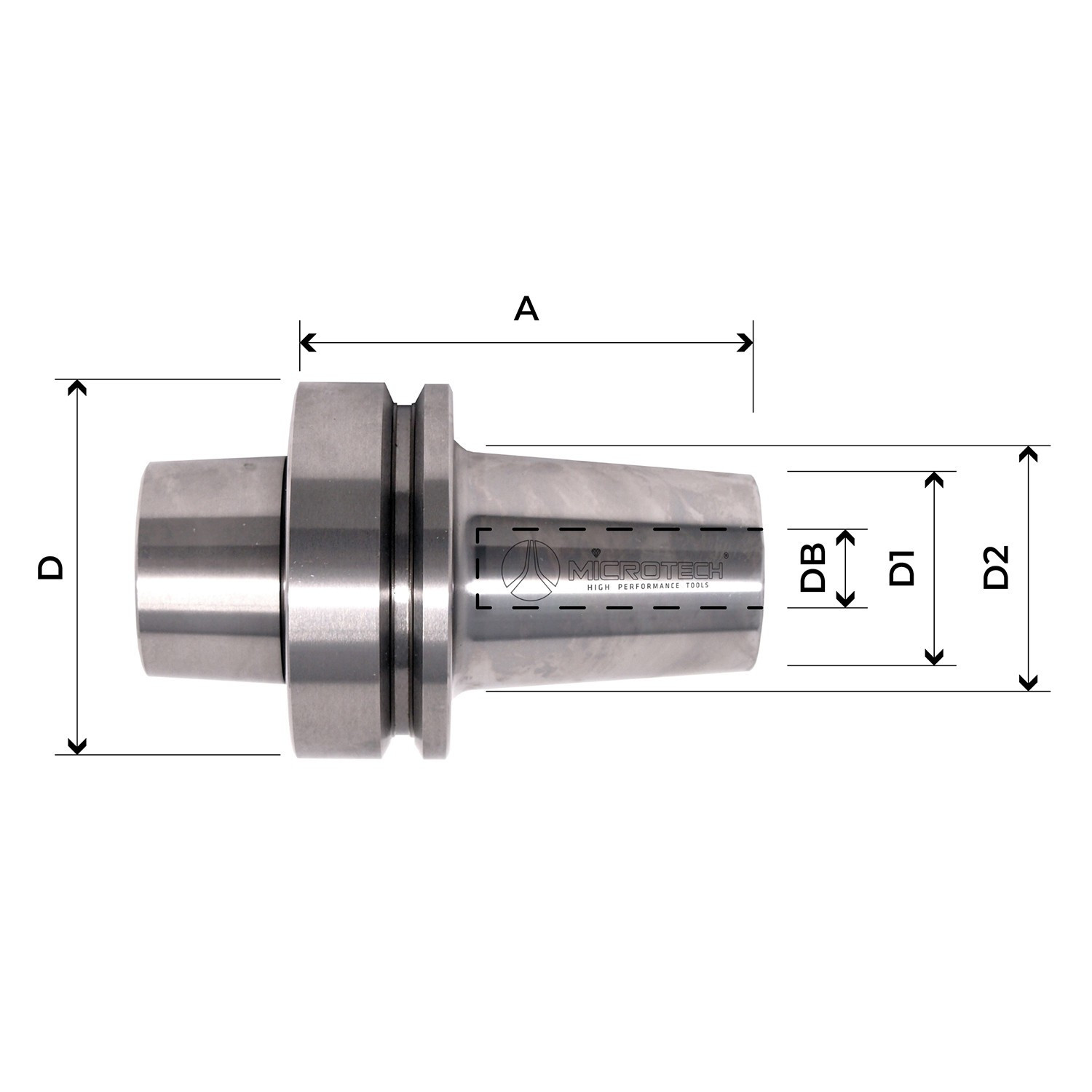

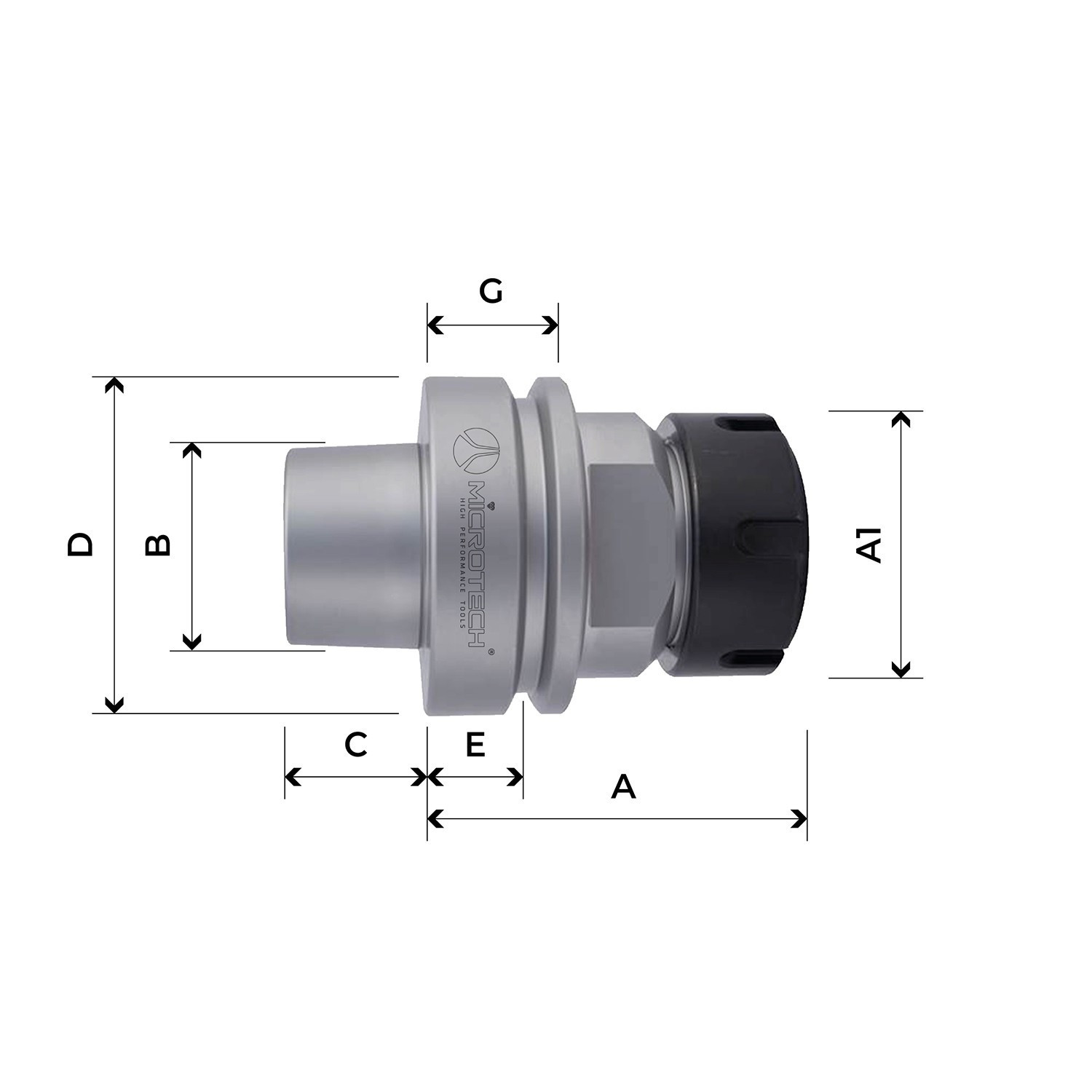

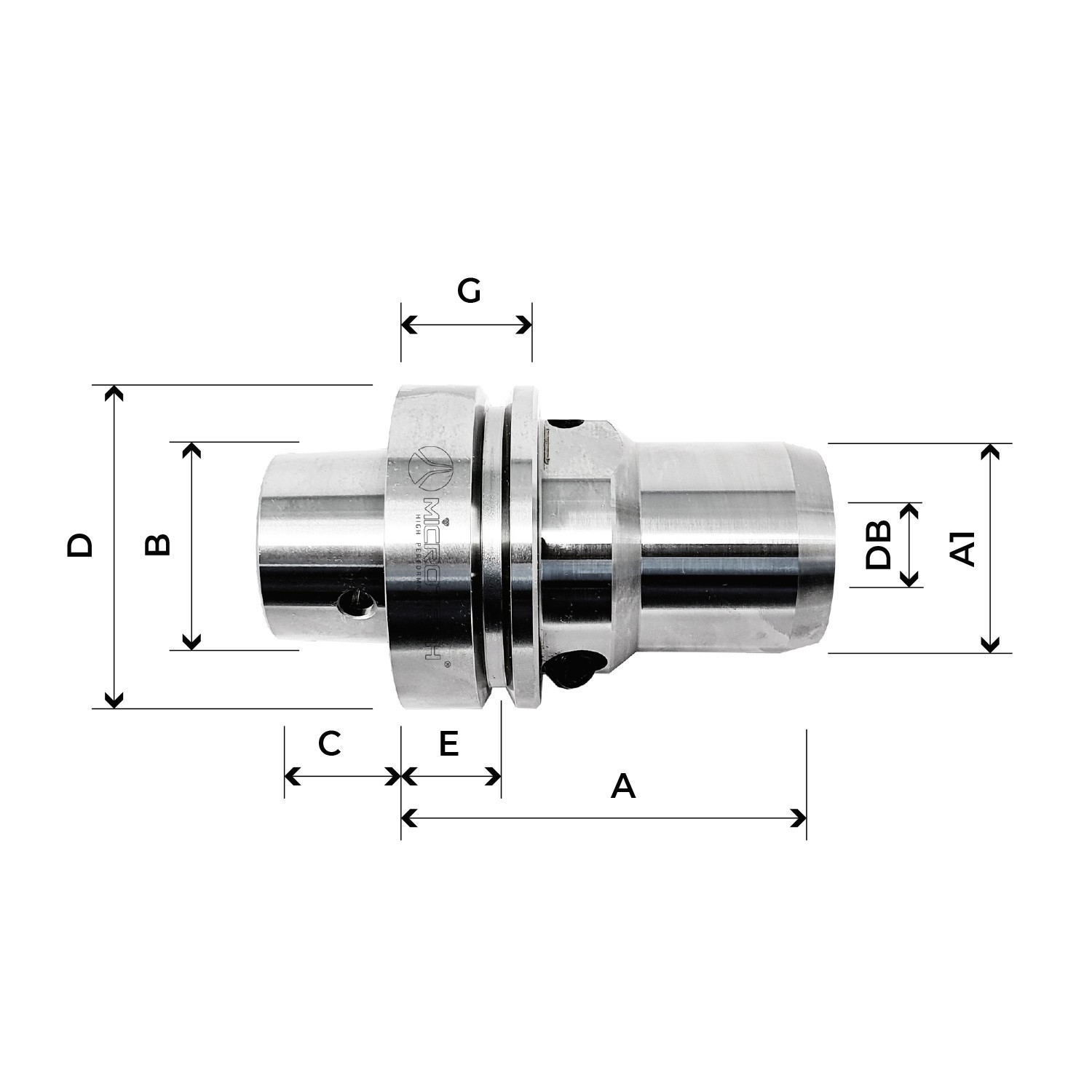

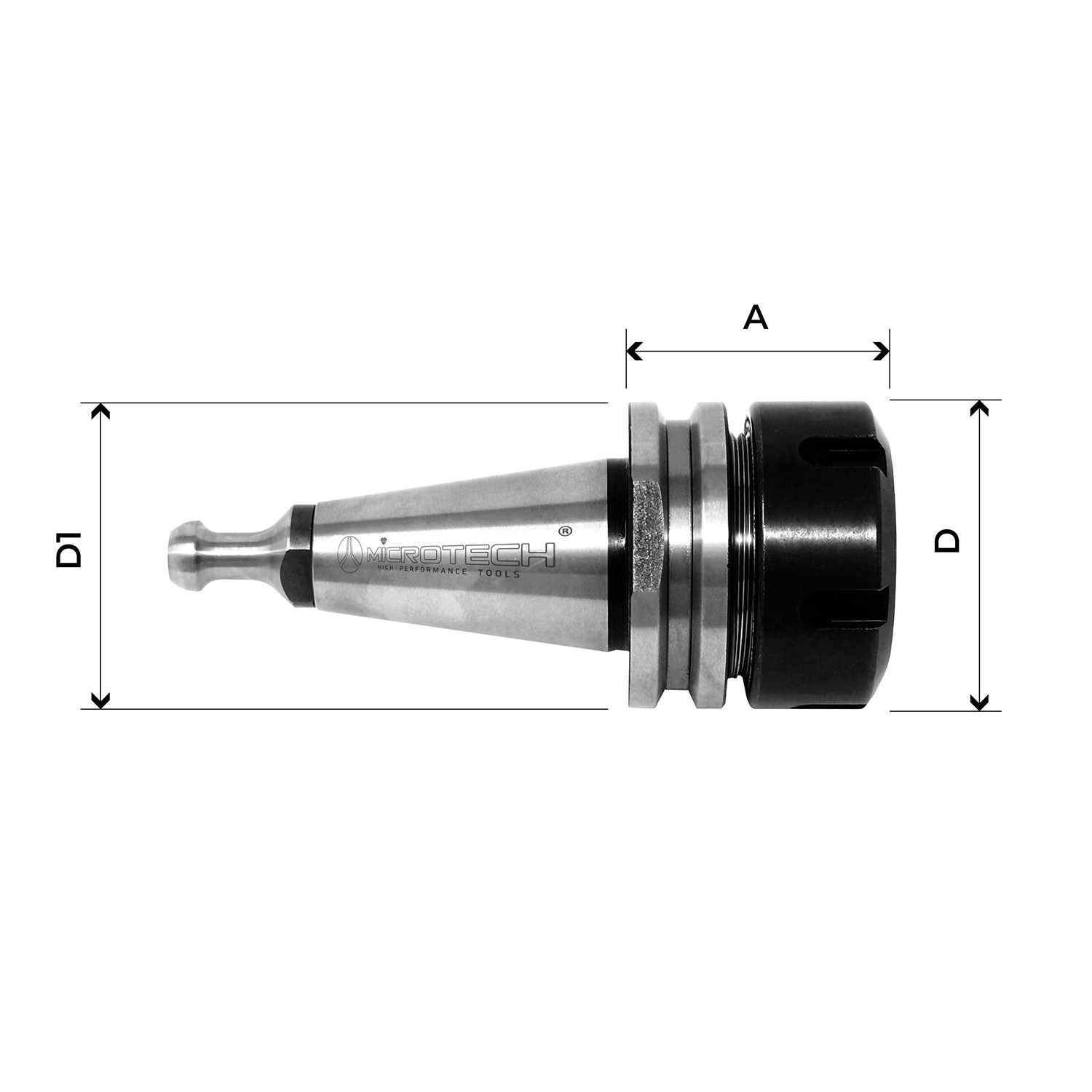

Tool holder HSK50F with tollerance between the tool holder and tool house 0,003 mm.

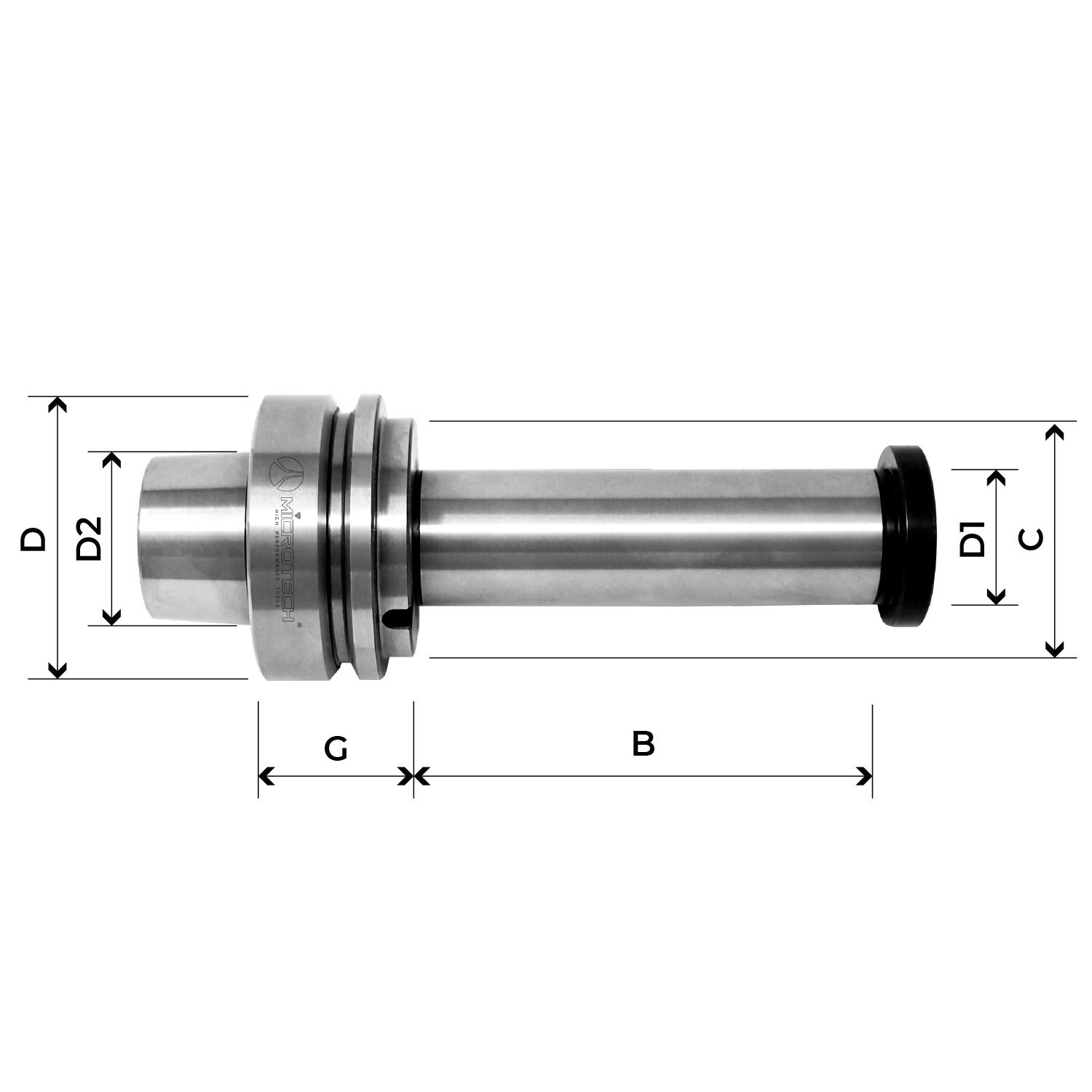

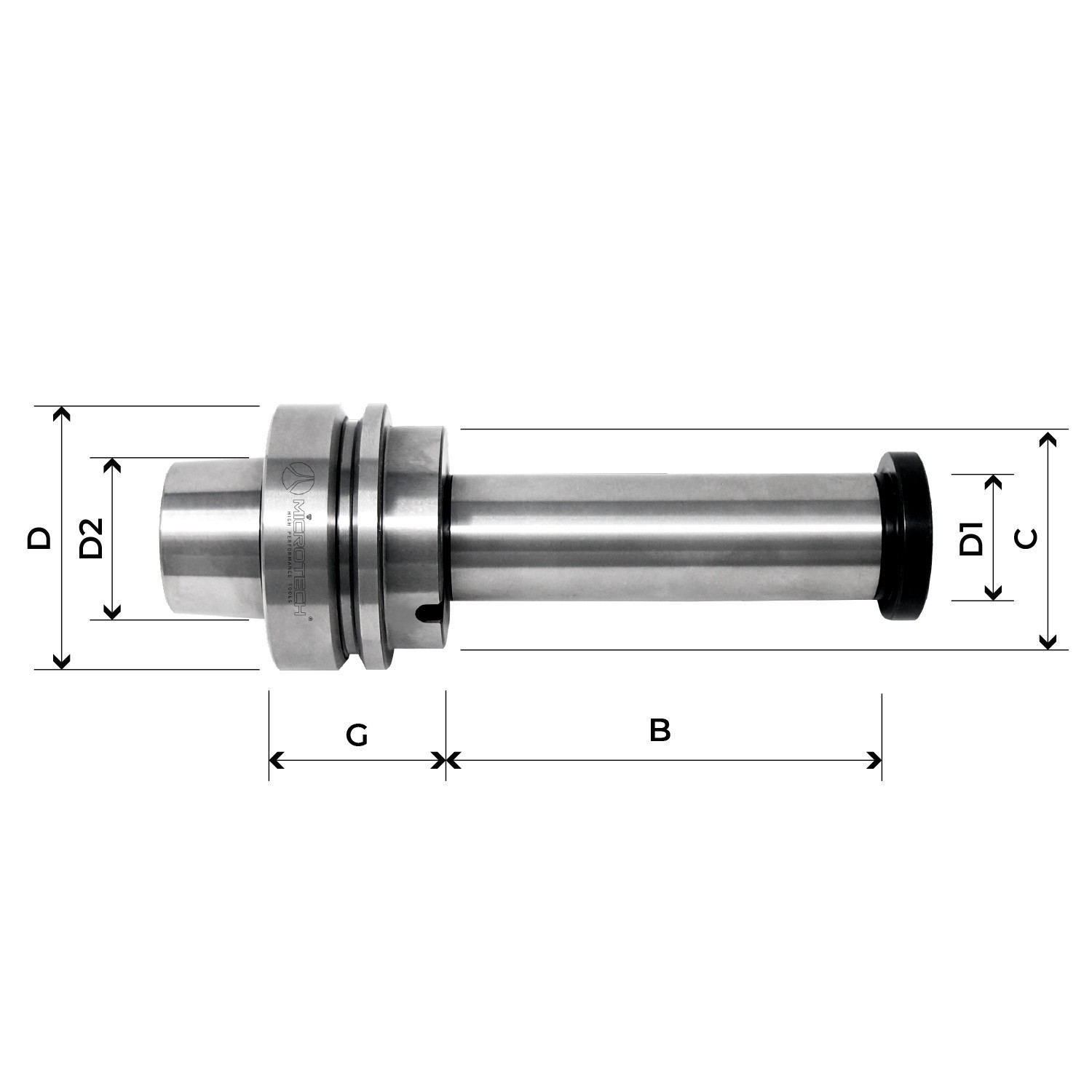

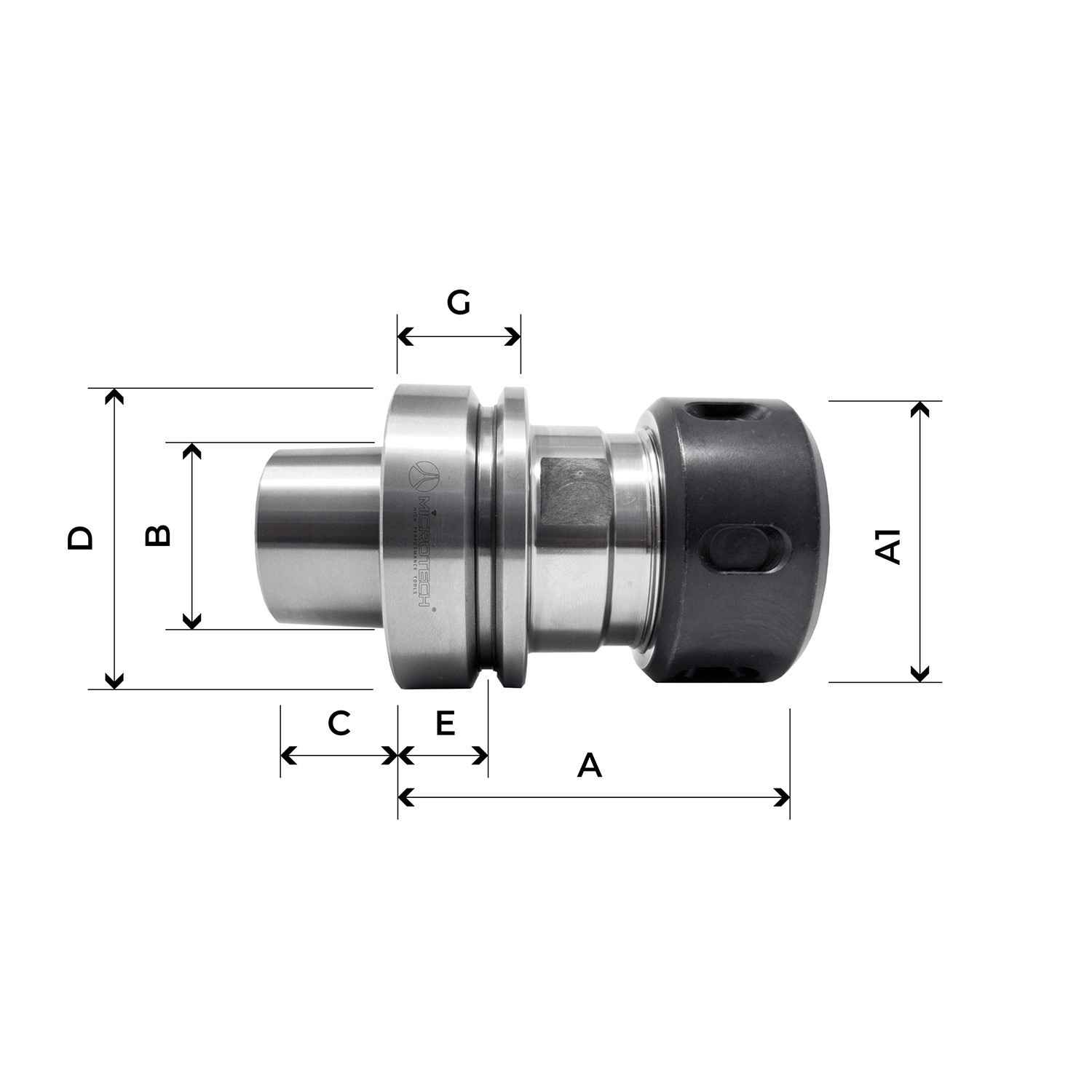

Tool Holder HSK63F of various heights with arbor different size.

Tool Holder HSK63F of various heights with arbor different size.

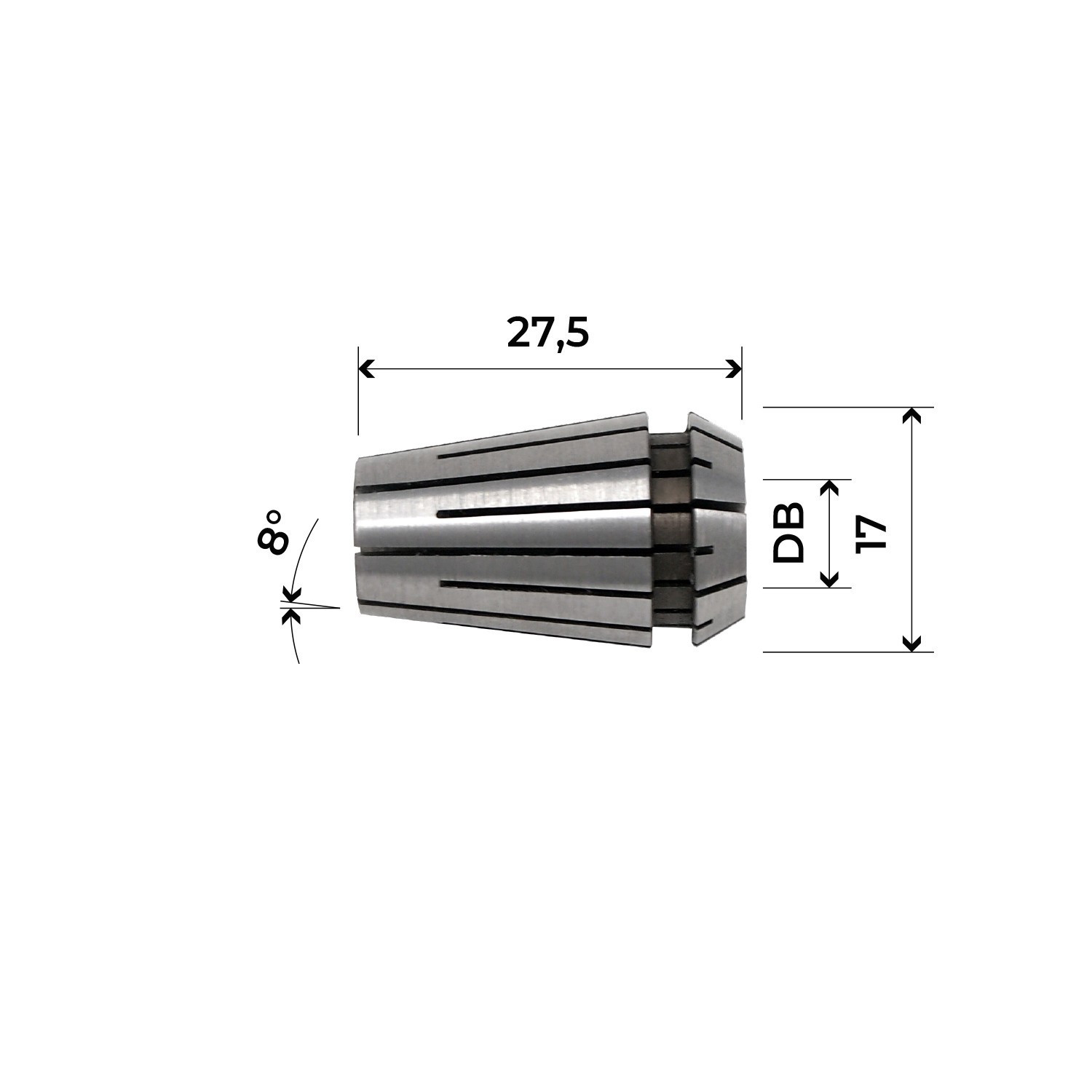

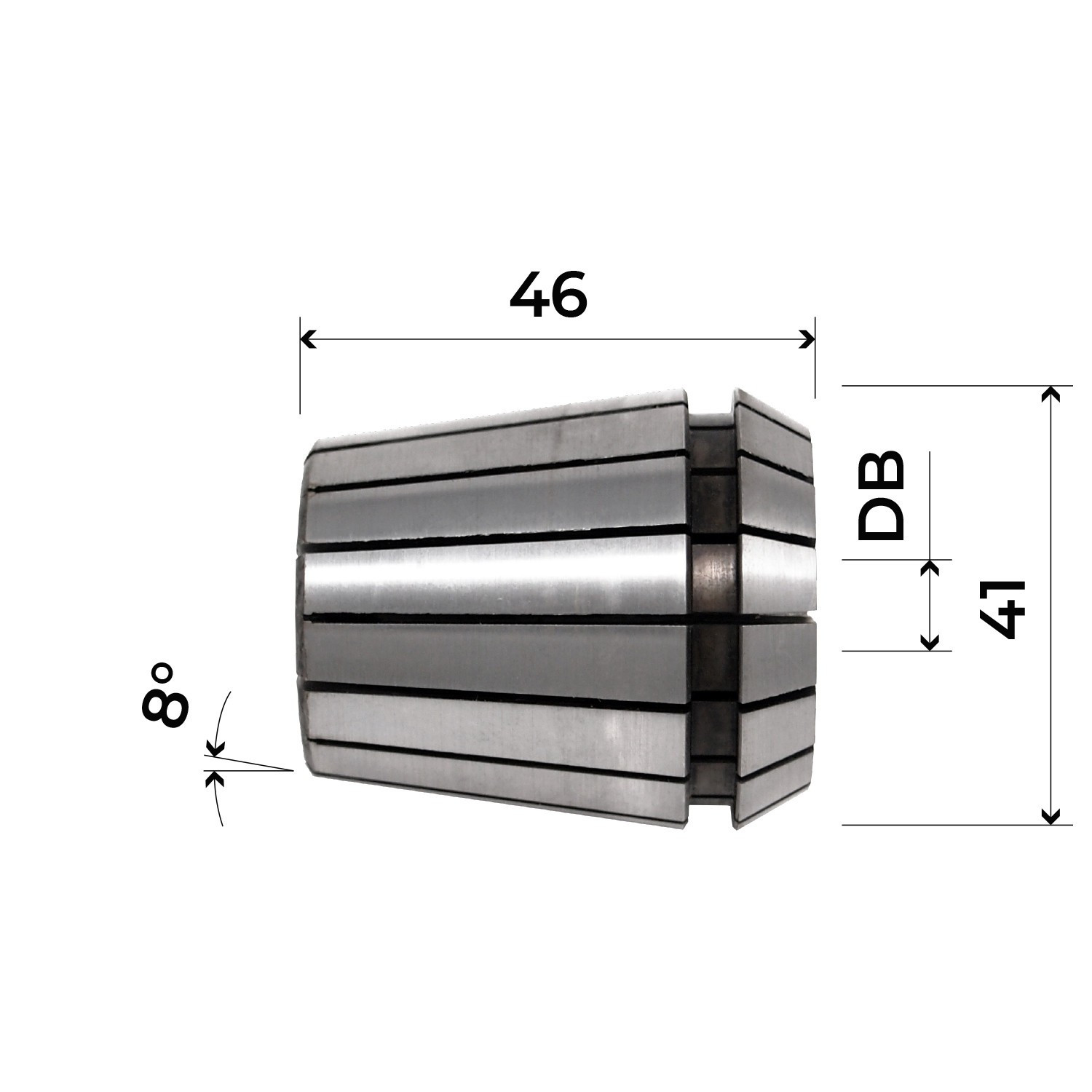

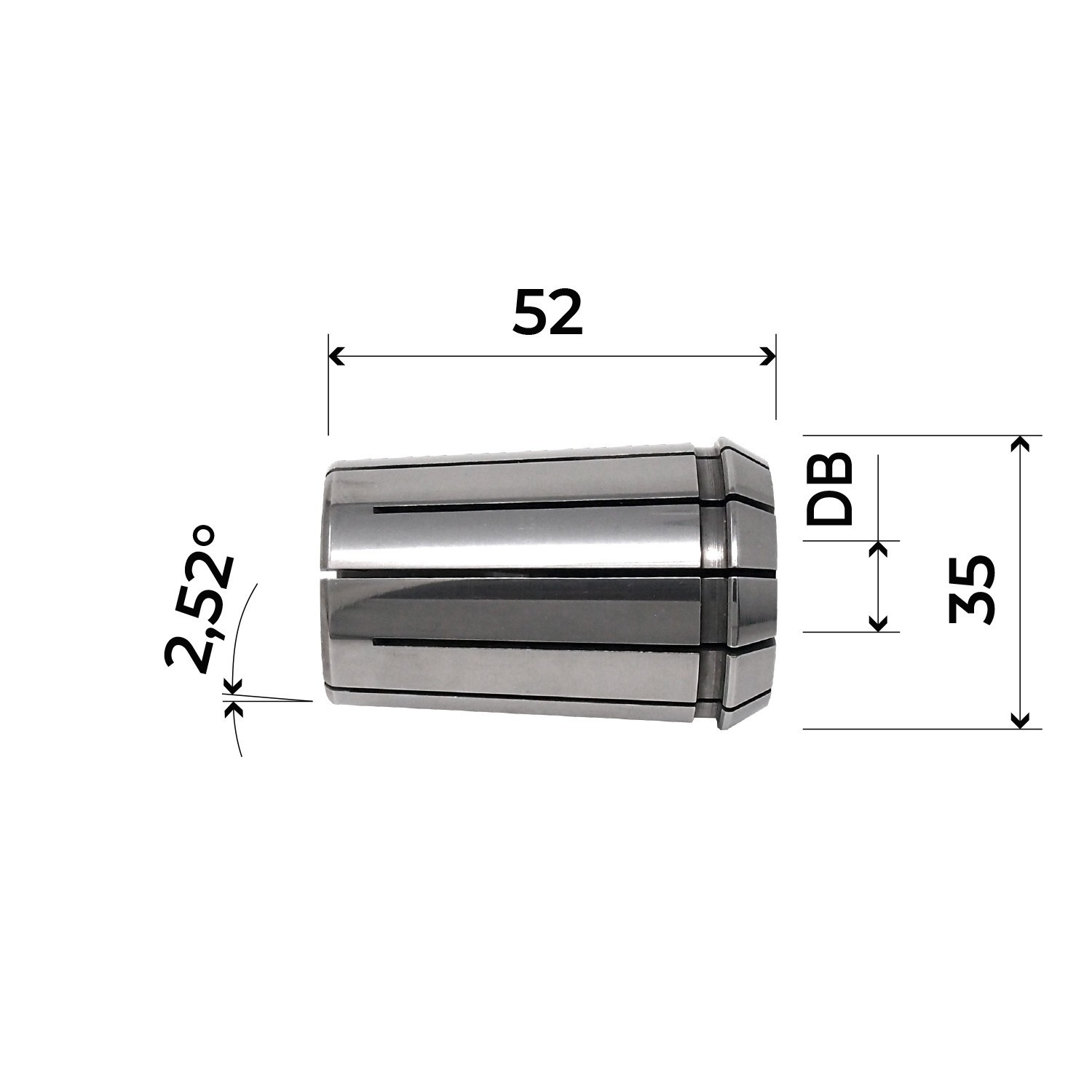

Replaceable standard ”ER16” collets (from 2 mm to 10 mm). Suitable for most conical chucks.

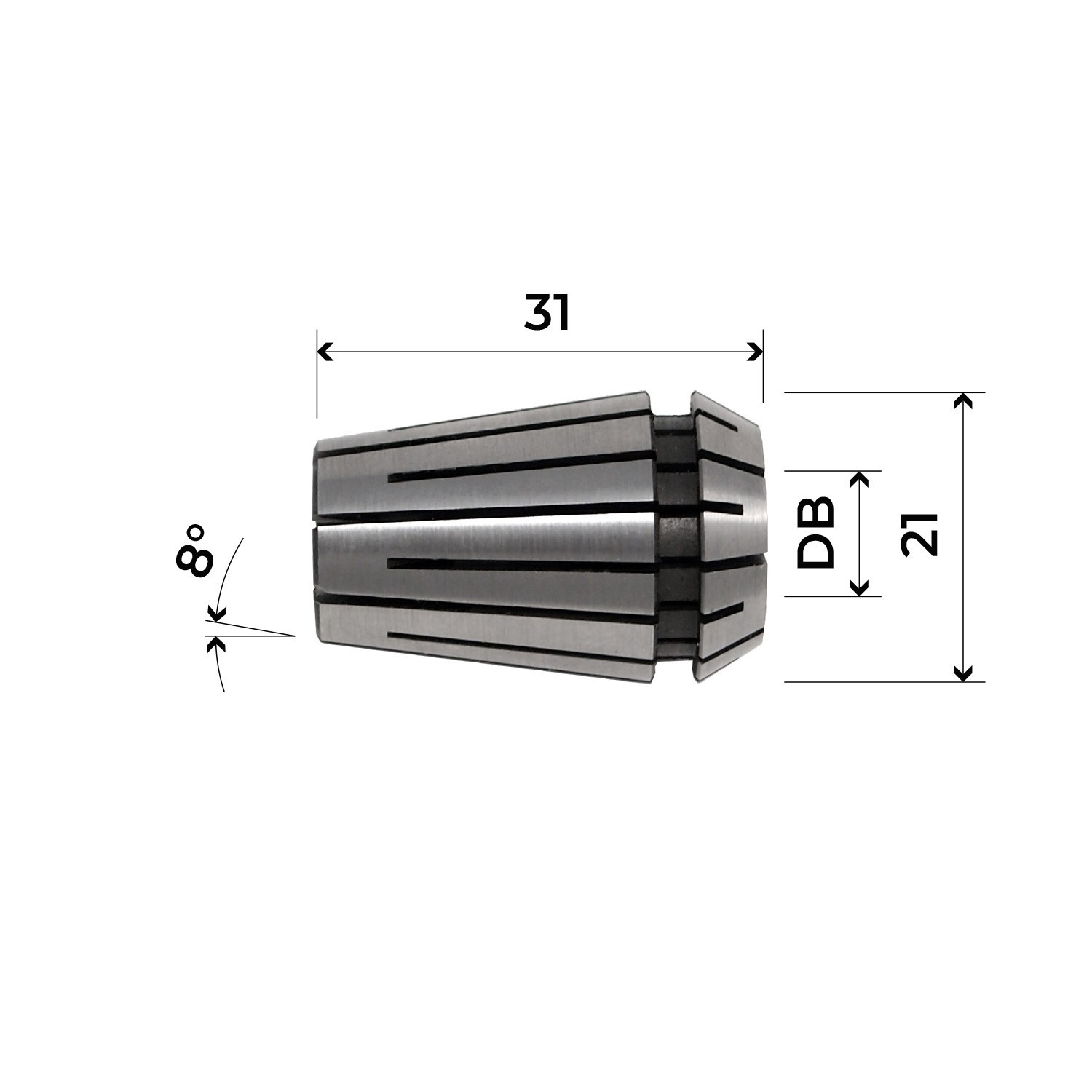

Replaceable standard ”ER20” collets (from 2 mm to 13 mm). Suitable for most conical chucks.

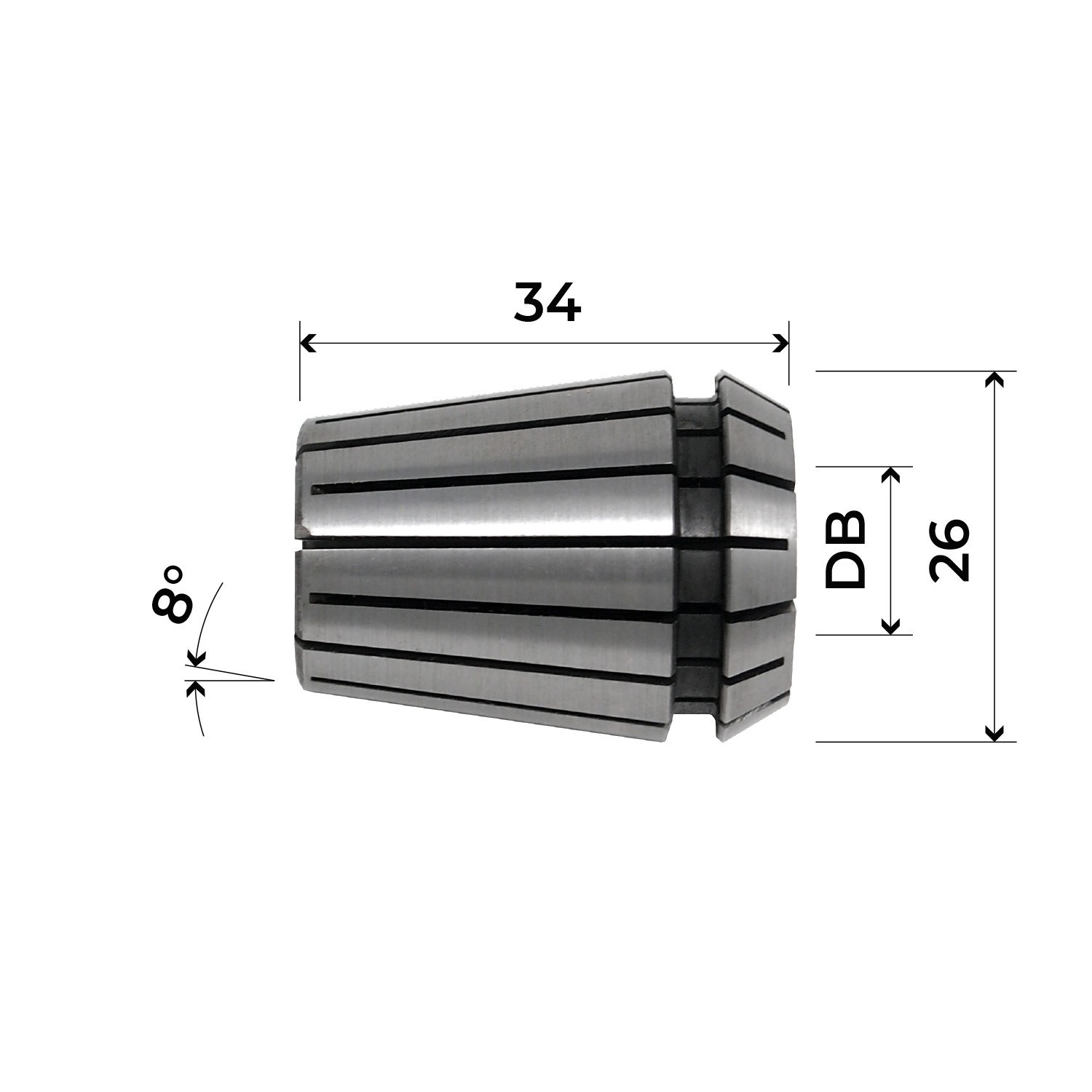

Replaceable standard ”ER25” collets (from 3 mm to 20 mm). Suitable for most conical chucks.

Replaceable standard ”ER32” collets (from 3 mm to 20 mm). Suitable for most conical chucks.

Replaceable high precision standard ”ER32” collets (from 3 mm to 20 mm). Suitable for most conical chucks.

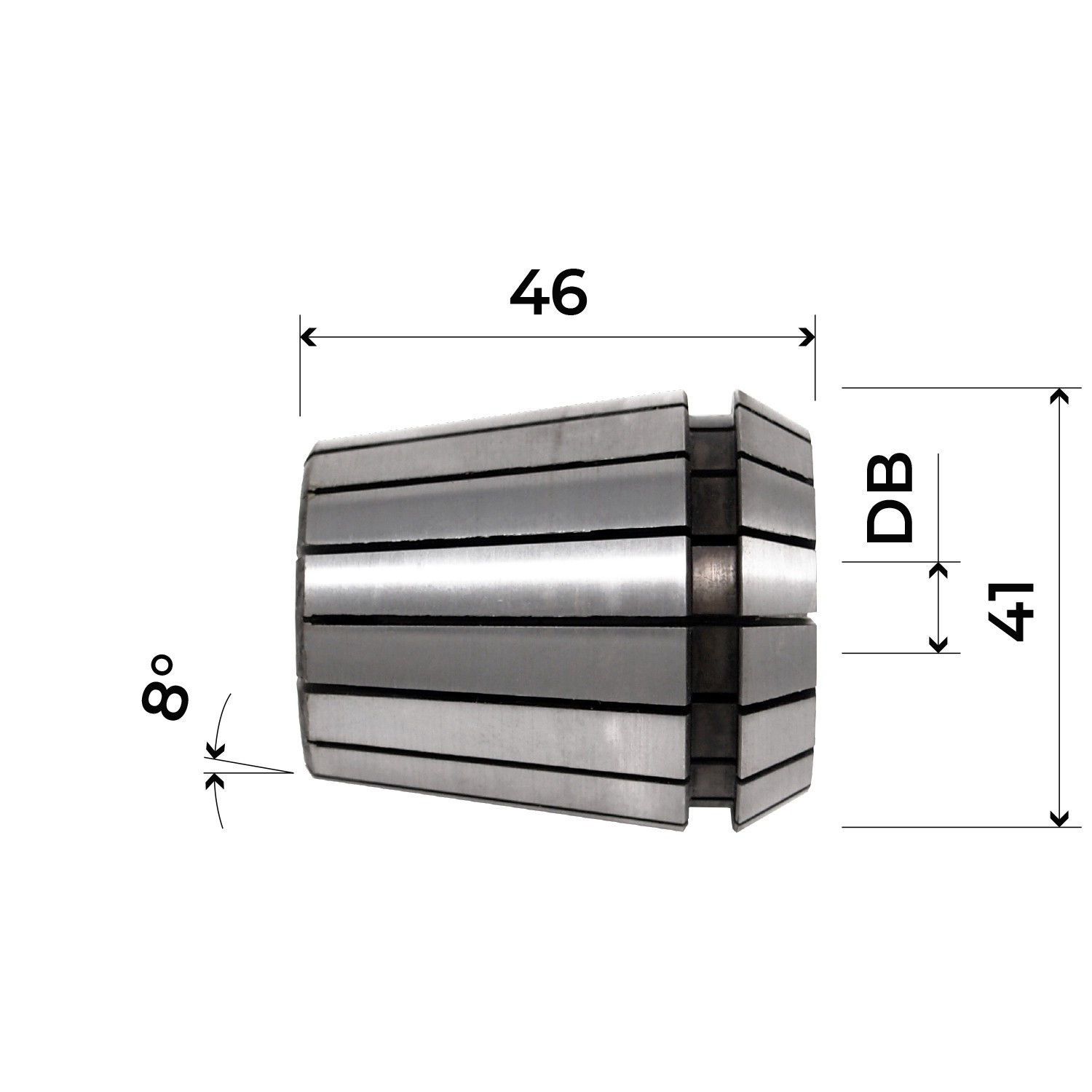

Replaceable standard ”ER40” collets (from 3 mm to 25 mm). Suitable for most conical chucks.

Replaceable high precision standard ”ER40” collets (from 3 mm to 25 mm). Suitable for most conical chucks.

Replaceable standard ”EOC25” collets (from 3 mm to 20 mm). Suitable for most conical chucks.

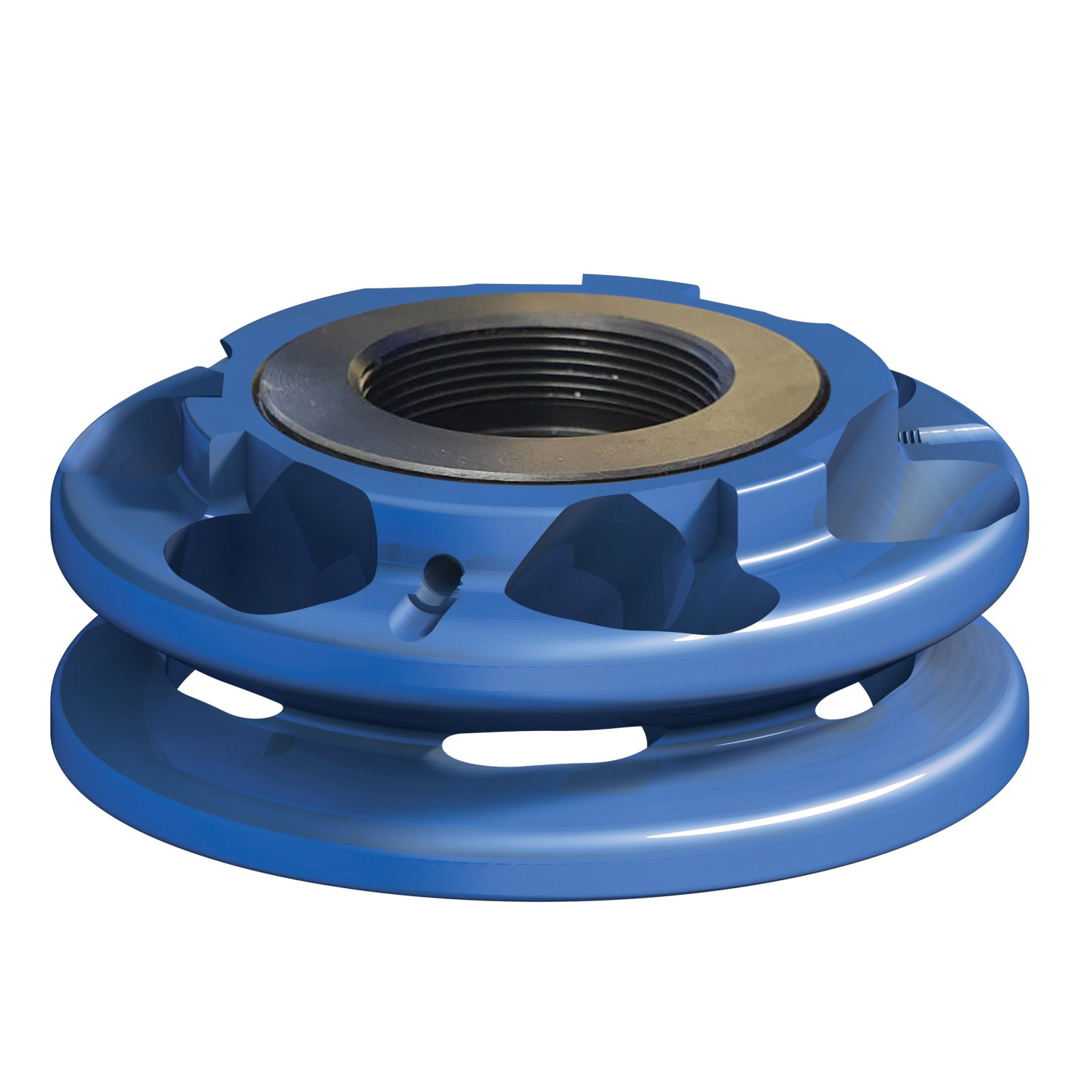

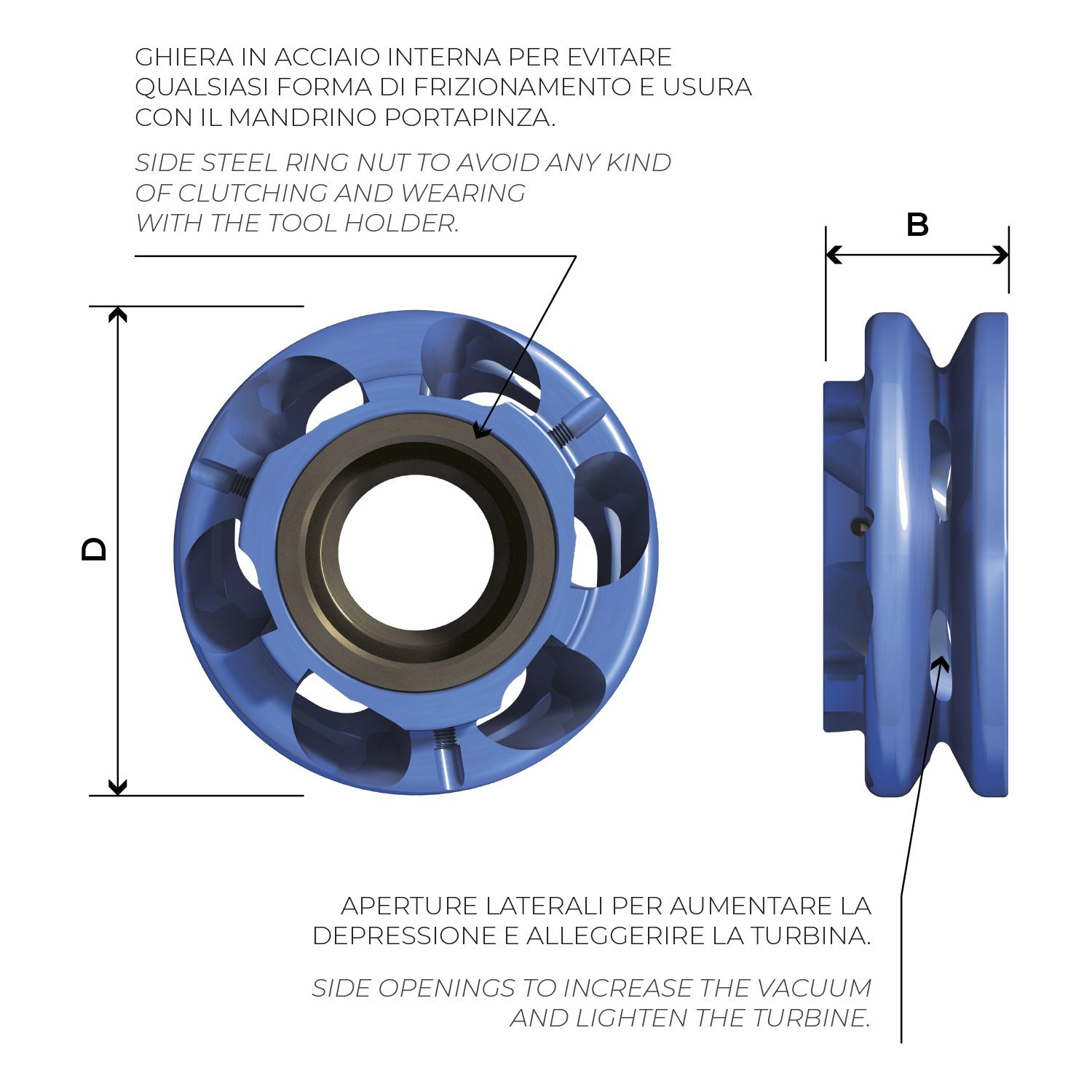

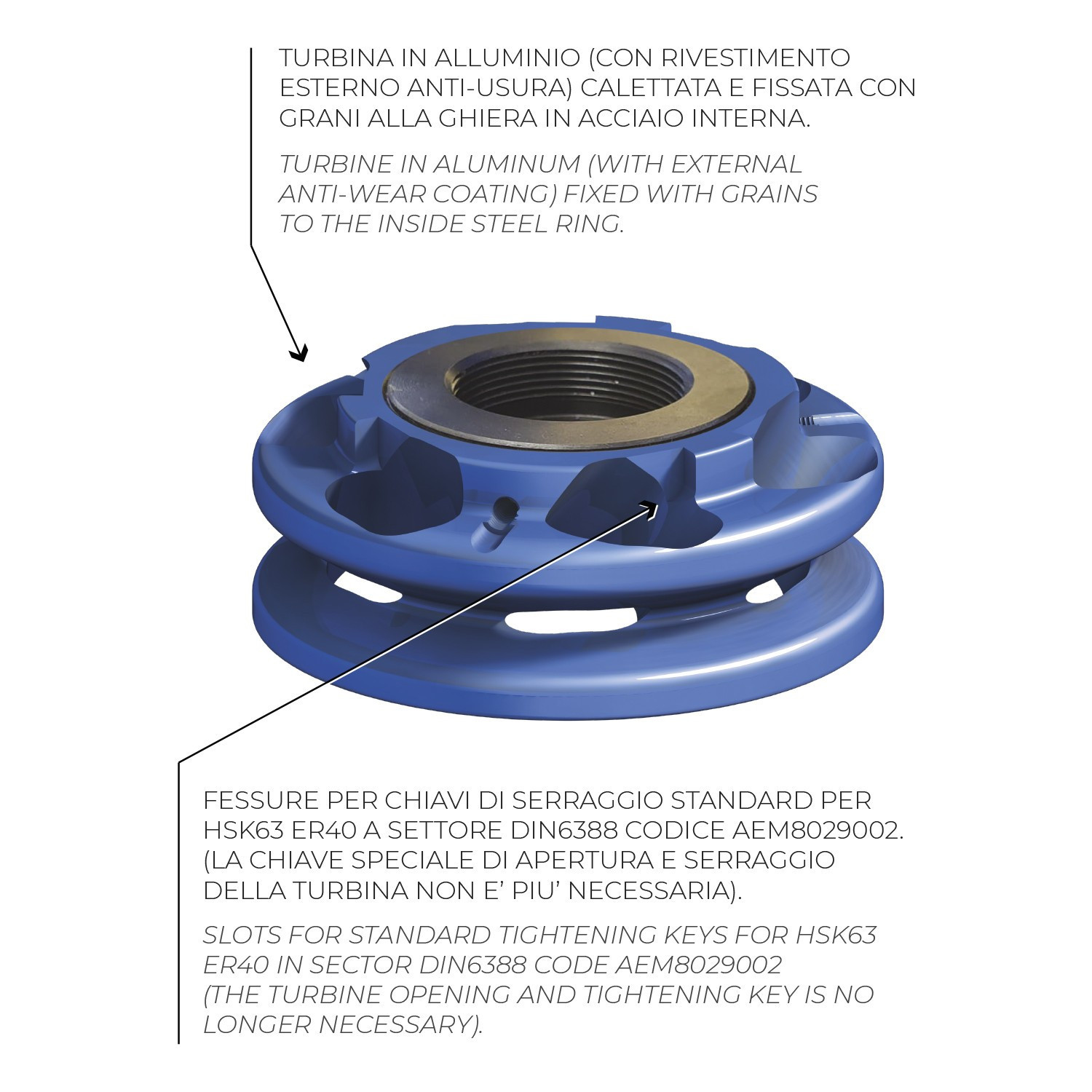

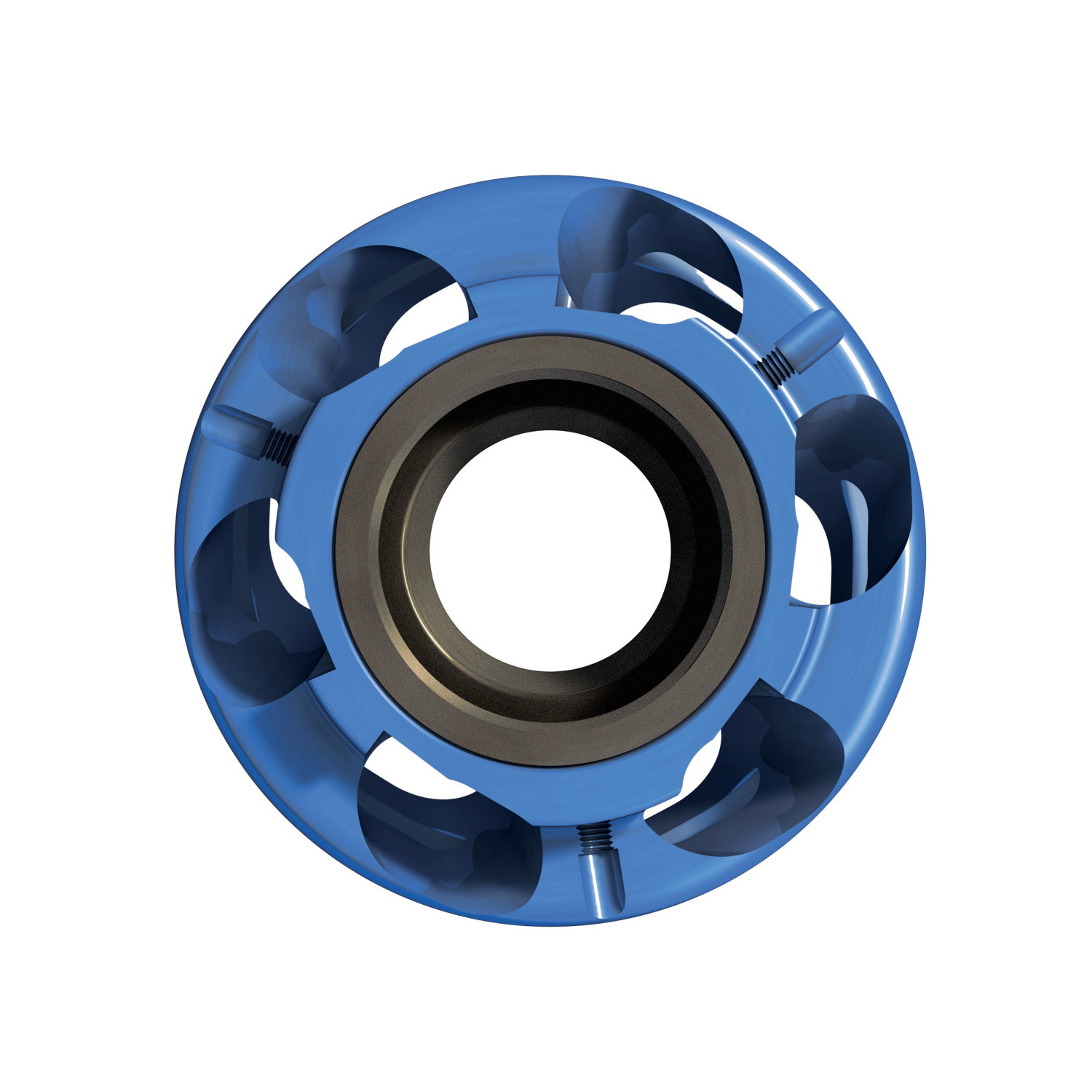

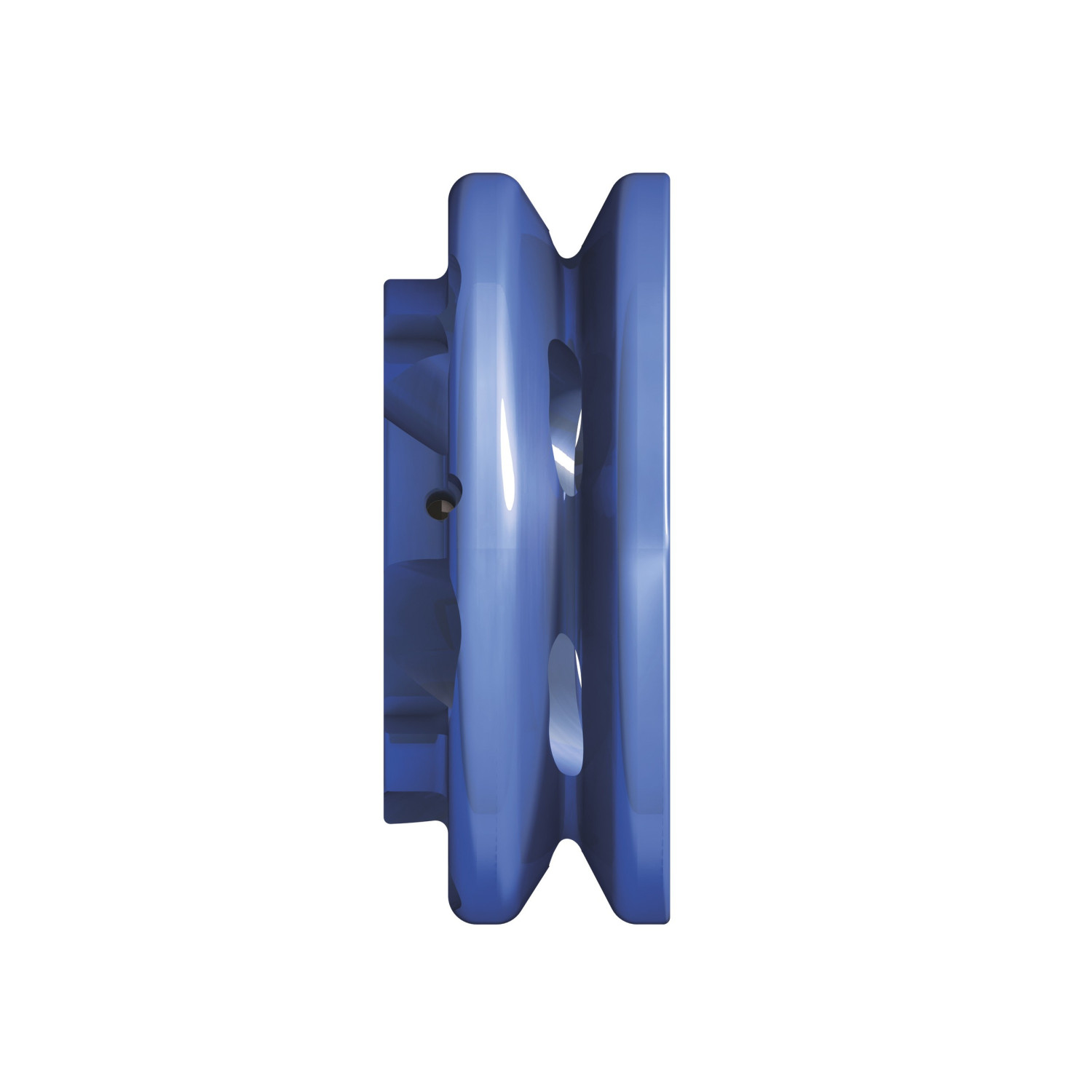

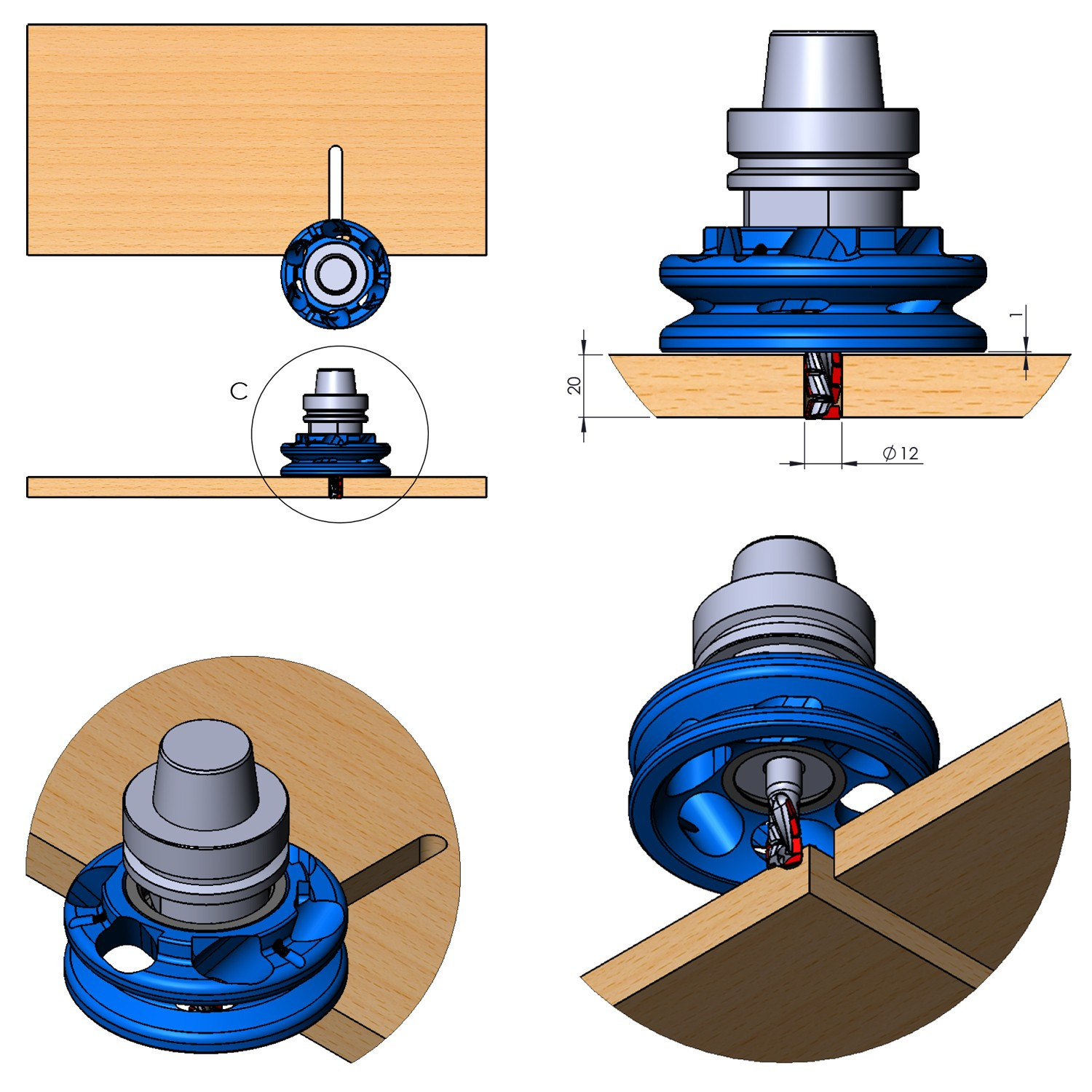

Collet nut with chip extraction turbine applicable on tools holders HSKER32 HSKER40 EOC25 (DIN6388) and HYDRO ETP. The turbine replaces the standard collet nut or is externally applied to the HYDRO ETP spindle.

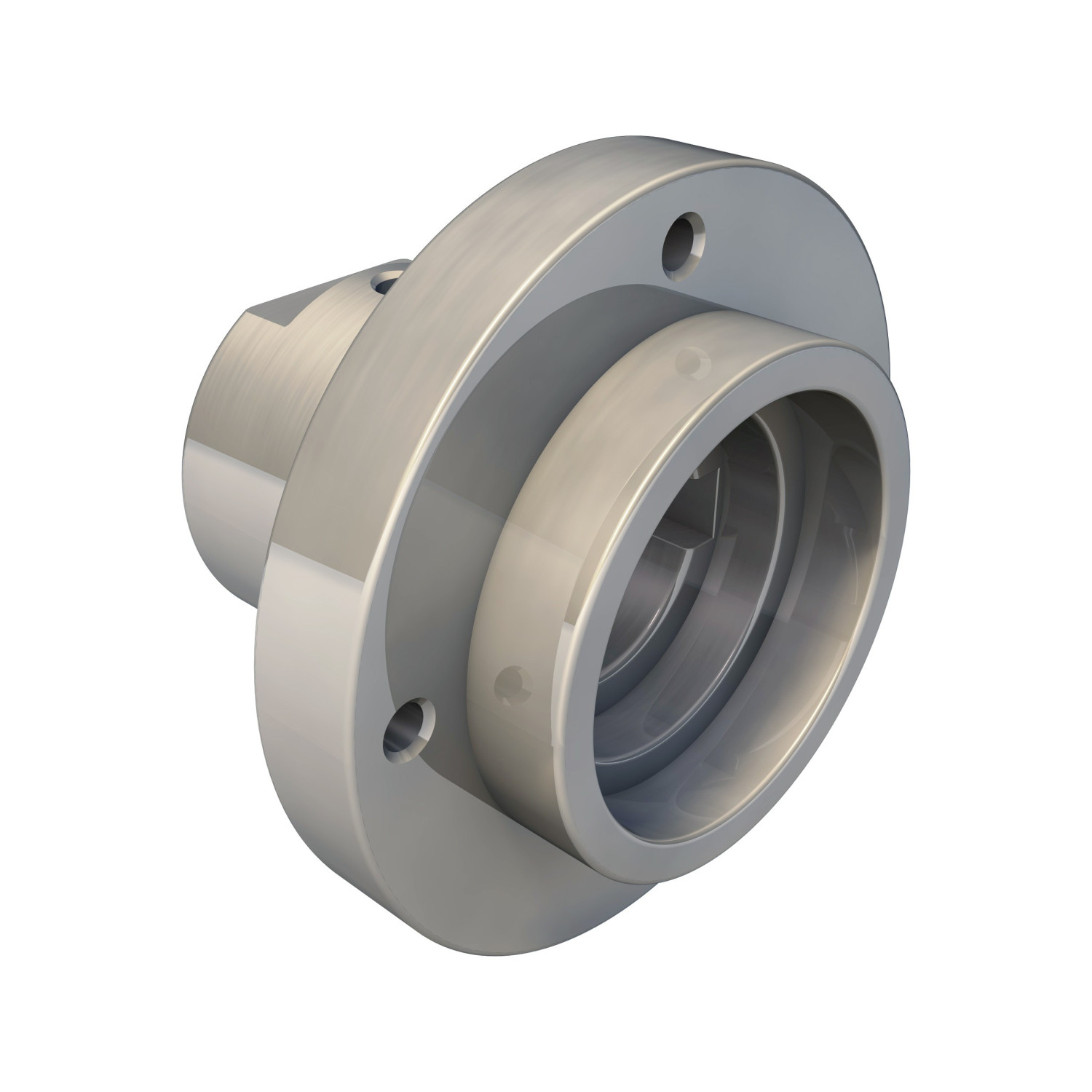

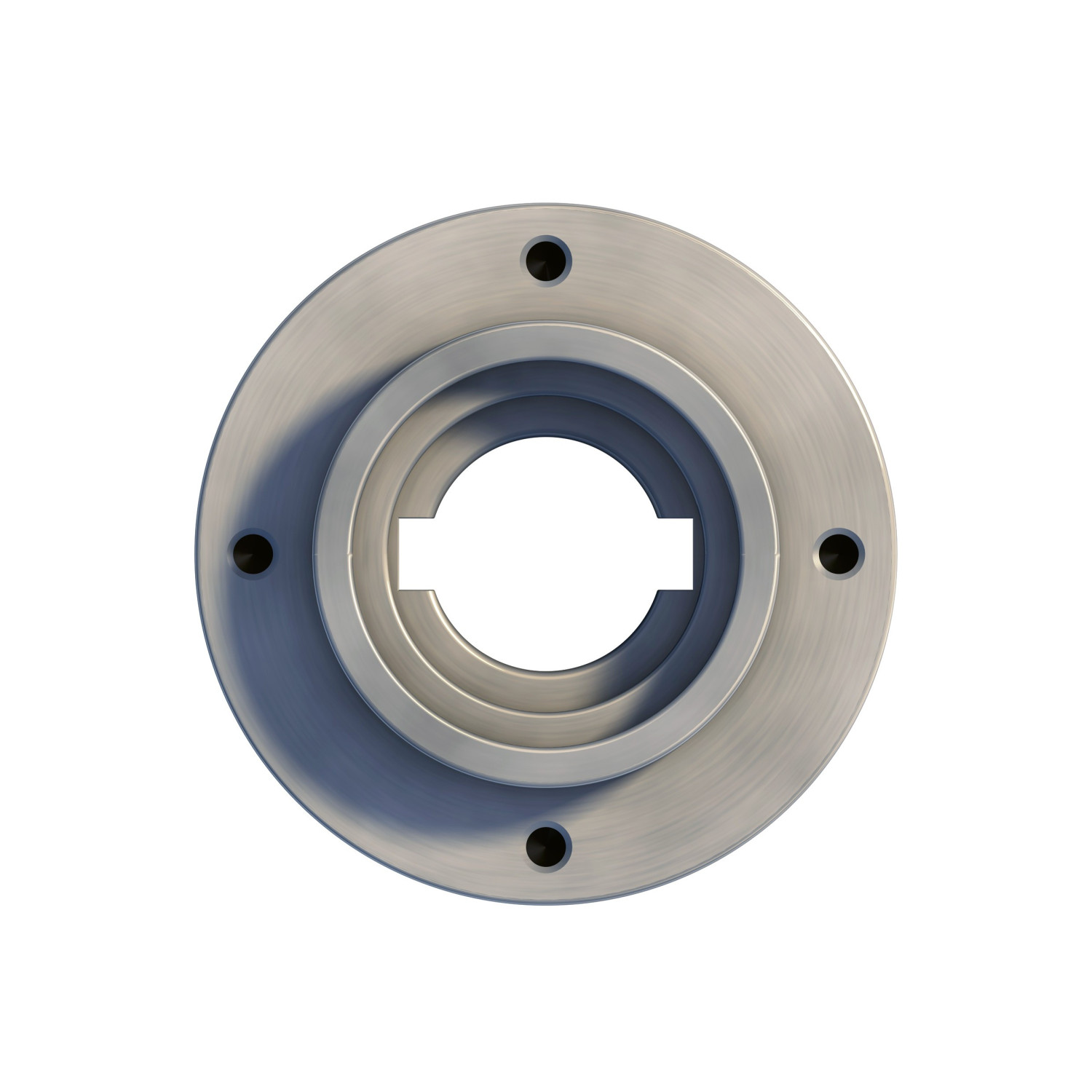

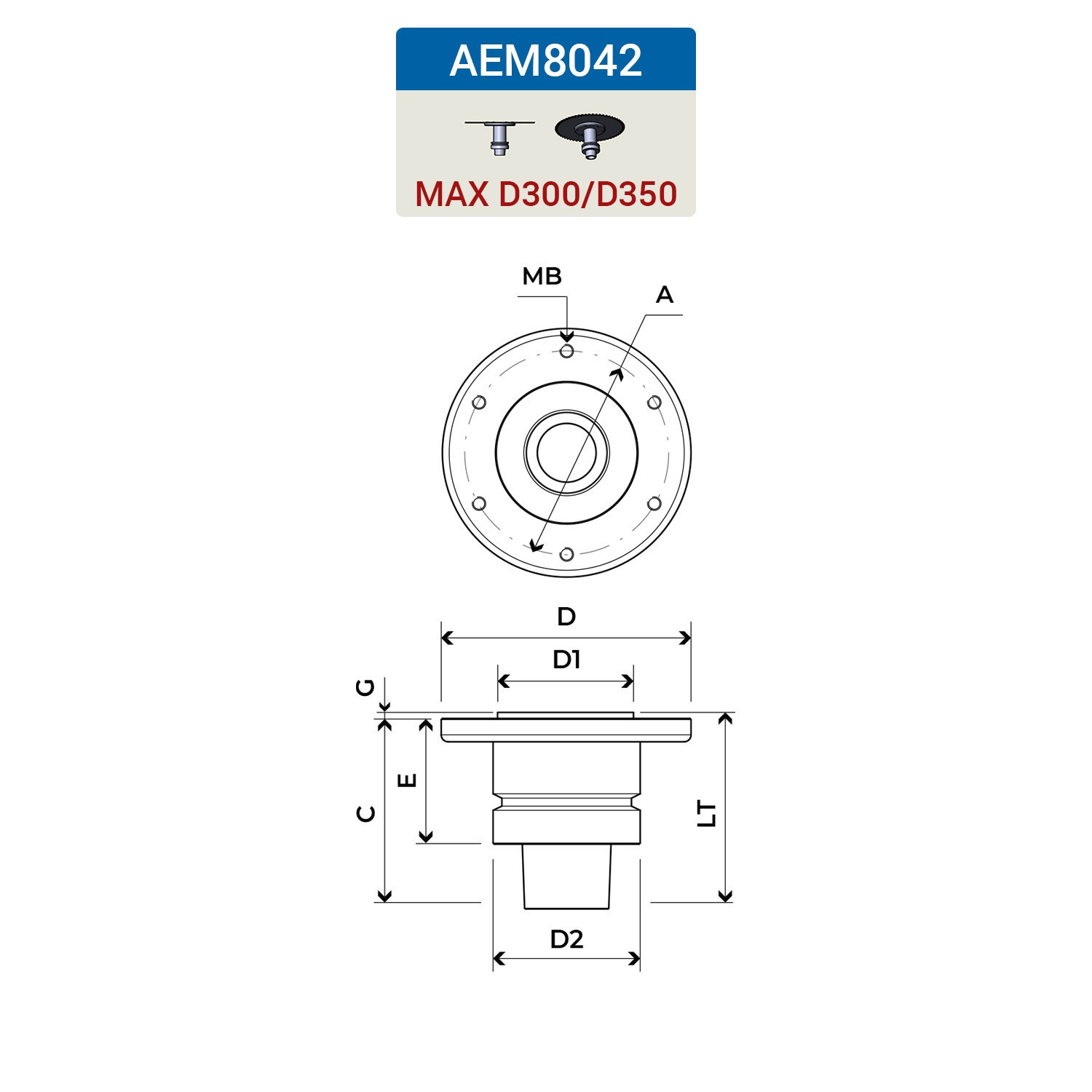

Universal cone remover for HSK63F and ISO30 TOOLS HOLDERS which allows you to disassemble the TOOL HOLDER without damaging their surfaces. The special bidirectional BEARING cage, blocking the tool holder, allows the flange to be dismantled or mounted.

Sawblade tool holder with shank for lamello clemex f22 and sawblades with hole 20/30.

Tool holder HSK63F INOX with tollerance between the tool holder and tool house 0,003 mm. Oxidation resistance.

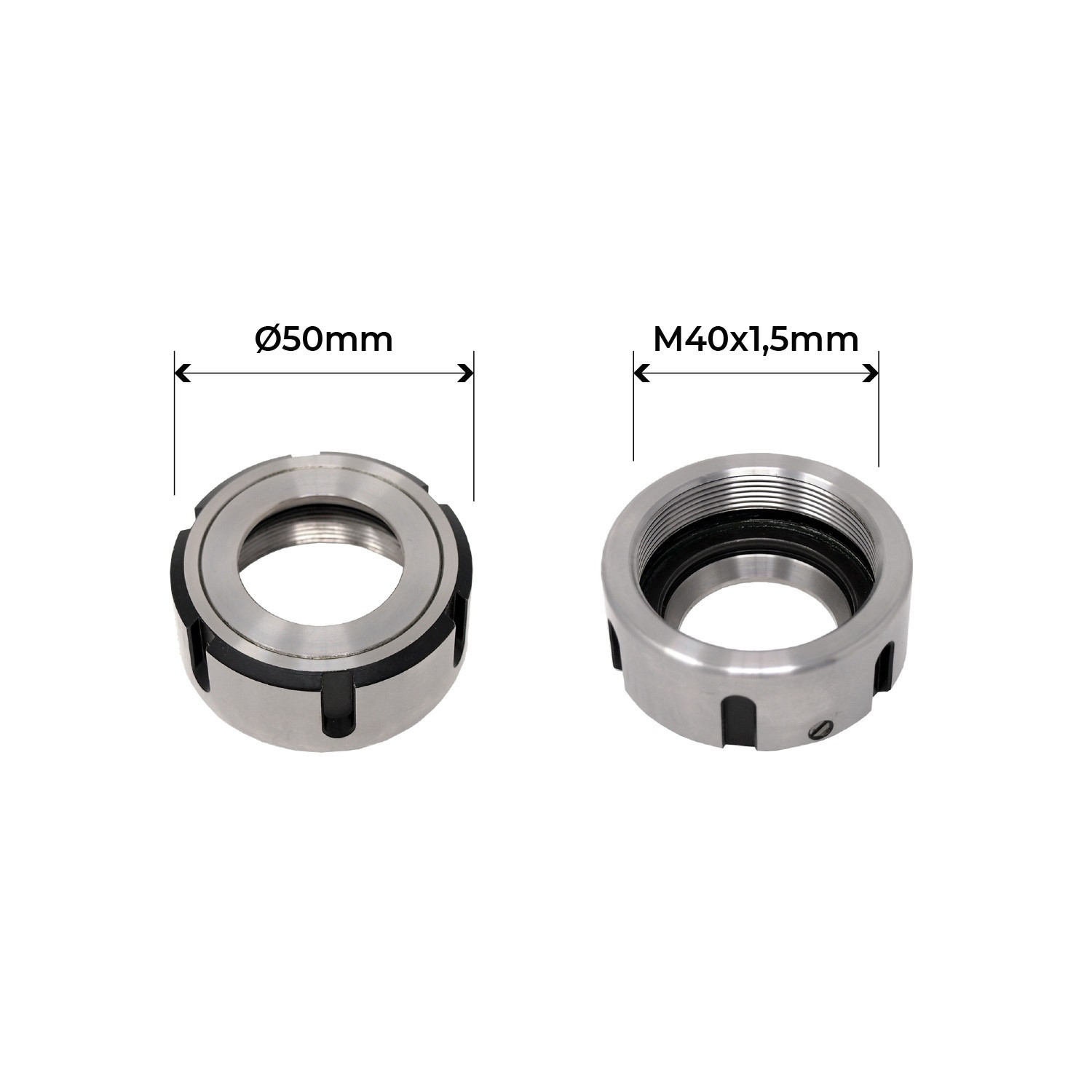

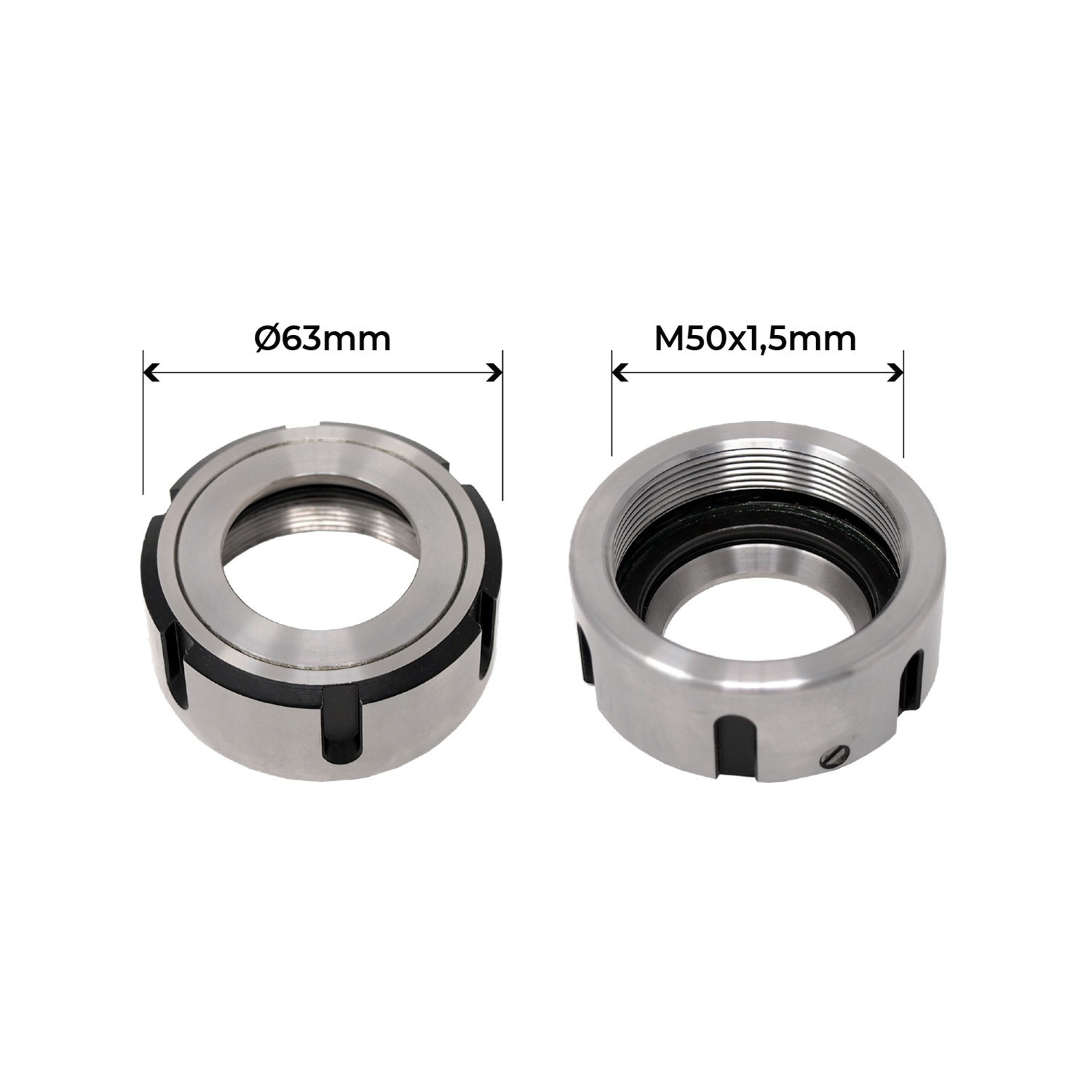

Suitable for Homag, Eima from 9/94, Dubus, Weeke, Biesse, SCM, Morbidelli, Masterwood. Nut with bearing for tools with left or right rotation.

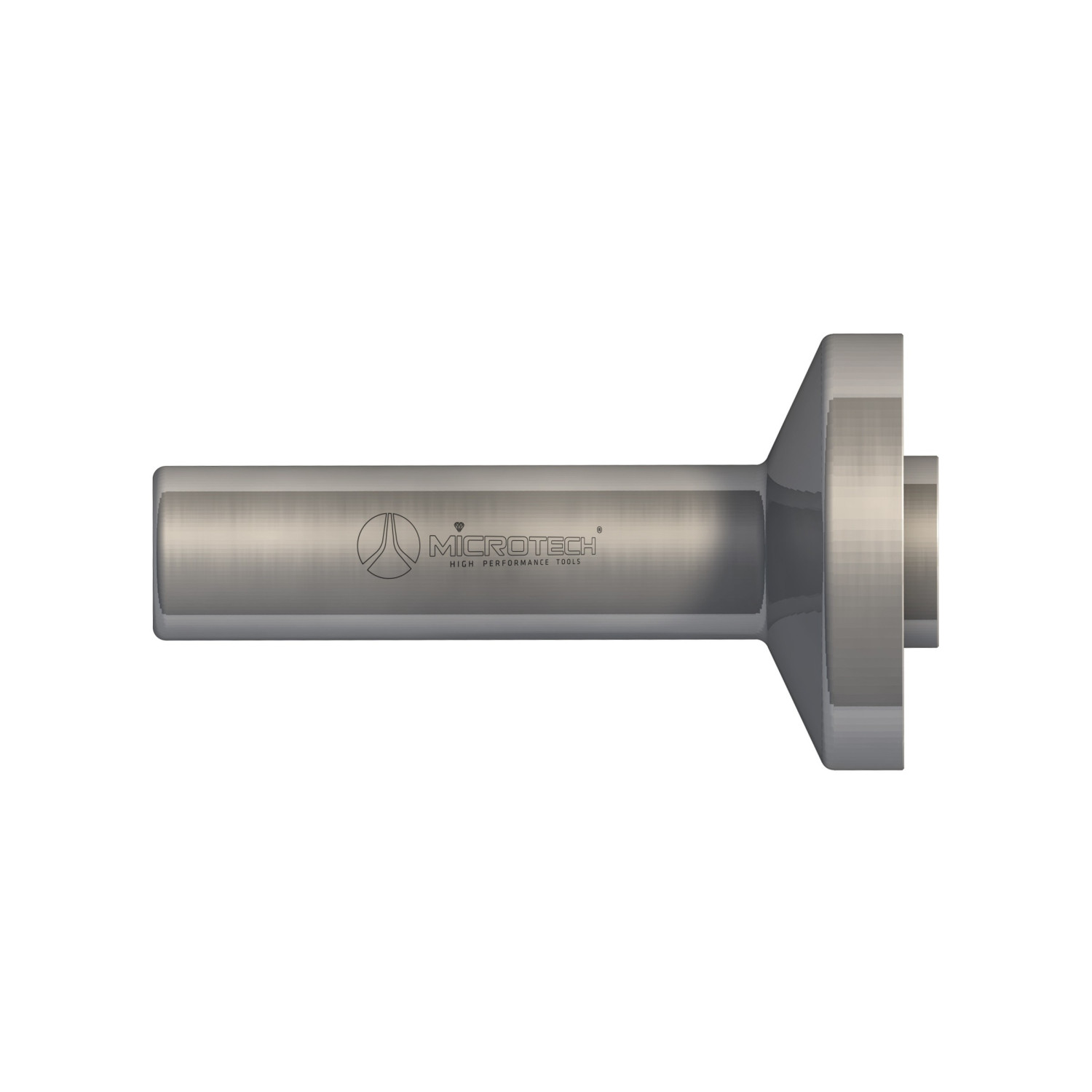

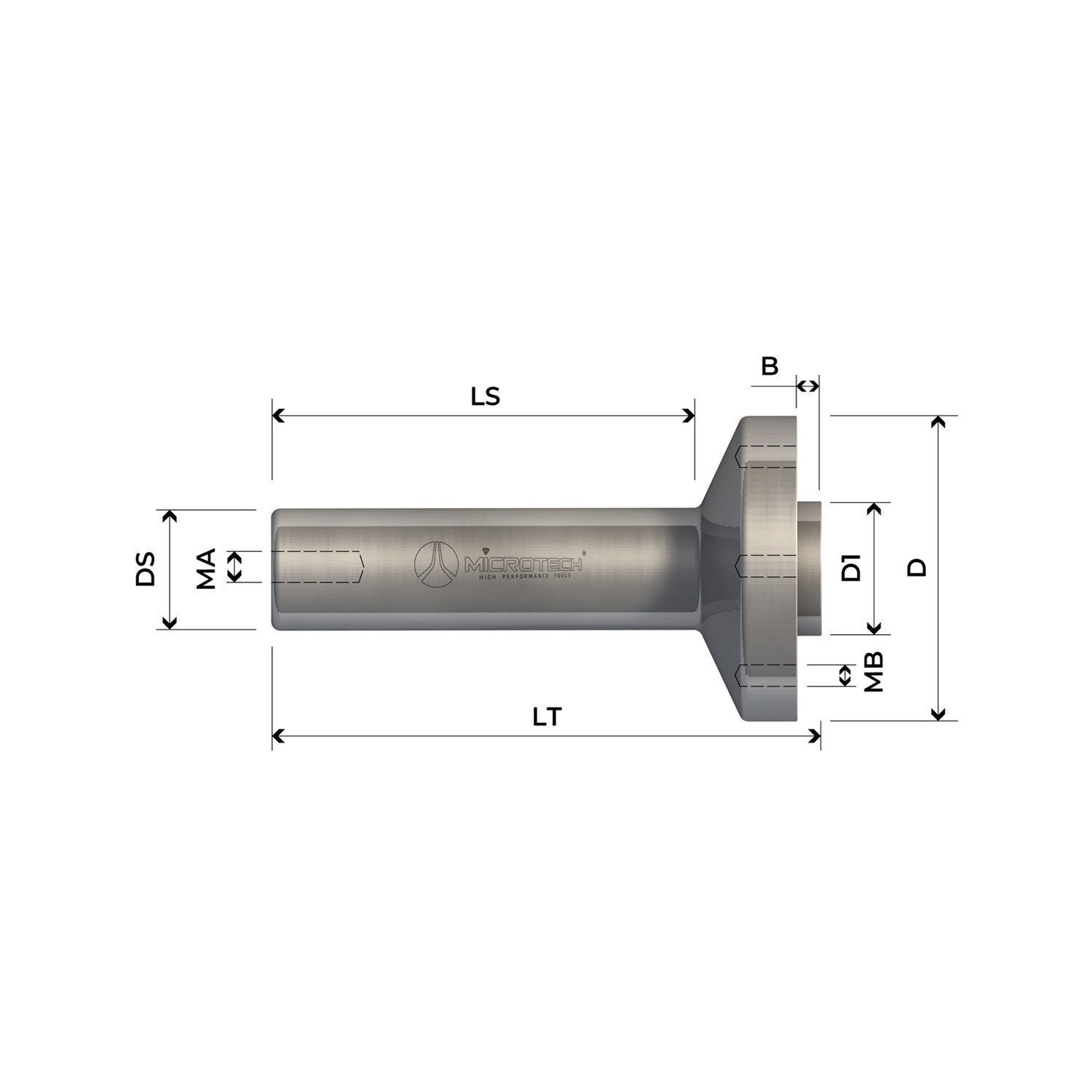

Thermo TOOL HOLDER grip ISO30 without shank. To ma- tch the CORECT shank for the machine, choose between AEM8023 - AEM8024 - AEM8025 - AEM8026 - AEM8027.

HYDRO HSK63F spindle with shaft/bore tolerance +/- 0.006. HSK63F high precision spindle and clamping force. TheTOOL shank must be with tolerance H6. Do not tighten the clamping screw if there is no tool inside. Clean the tool shank and the spindle hole thoroughly before inserting the cutter.

Collet chuck ISO30 for Biesse, Omlat engine, Bulleri, Busellato, CMS, IMA, Alberti, Masterwood machines.

• ISO30 taper toolholder;

• Supplied complete with nut and drawbar (without collet);

• Maximum precision and reliability;

• Total elimination of rotation imperfections;

• HSK63F collet chuck manufactured from high-strength steel for superior performance;

• Precision ground on all contact surfaces;

• Fast and secure tool installation guaranteed.

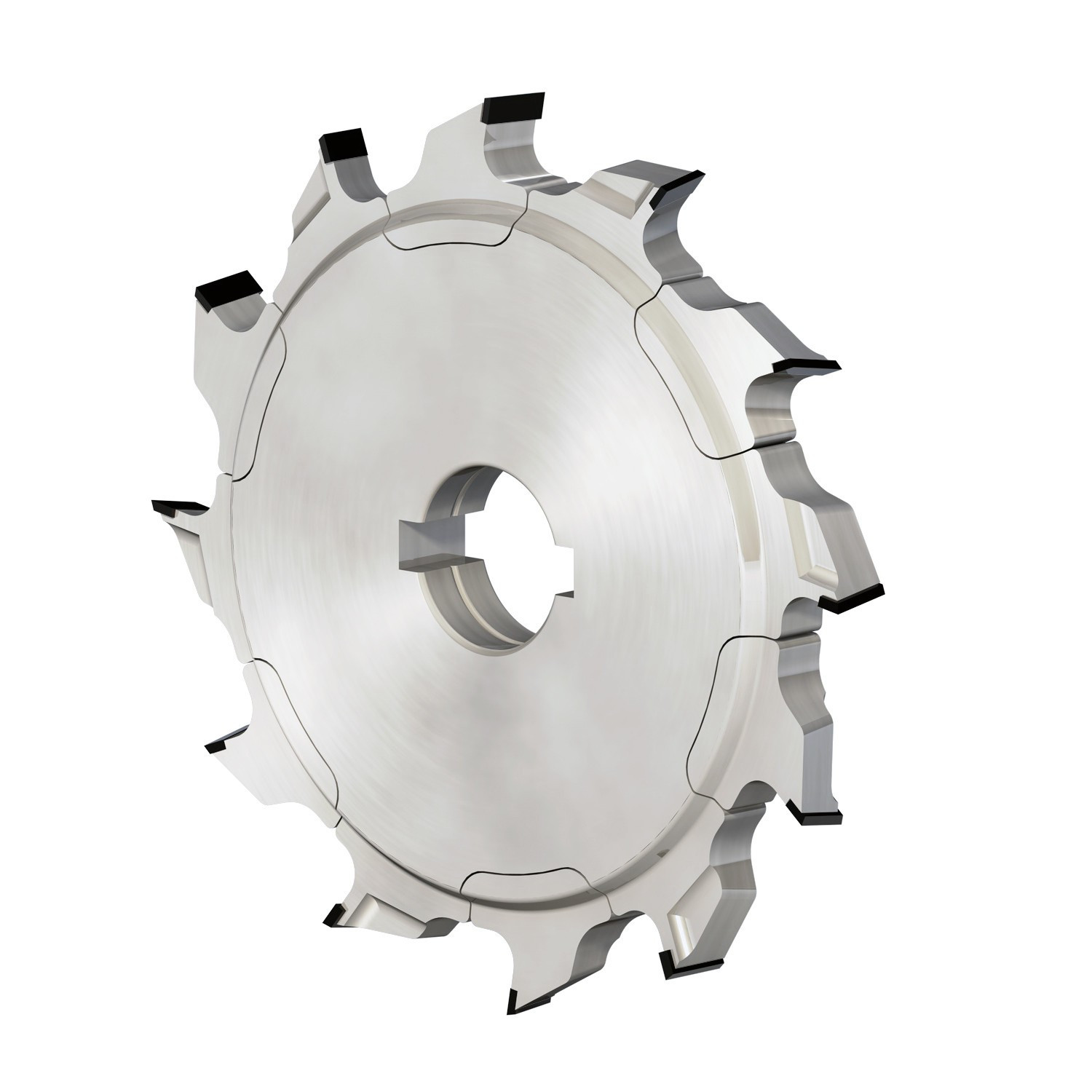

Conical HW scoring blade designed for horizontal panel saws. Ideal for chipboard coated with paper or plastic films, veneered panels and layered woods such as plywood and multilayer. Ensures clean scoring, reduced chipping and high precision in continuous production cycles.

• Conical grind for optimal scoring

• Low Noise body to reduce vibration

• Ideal for coated and laminated panels

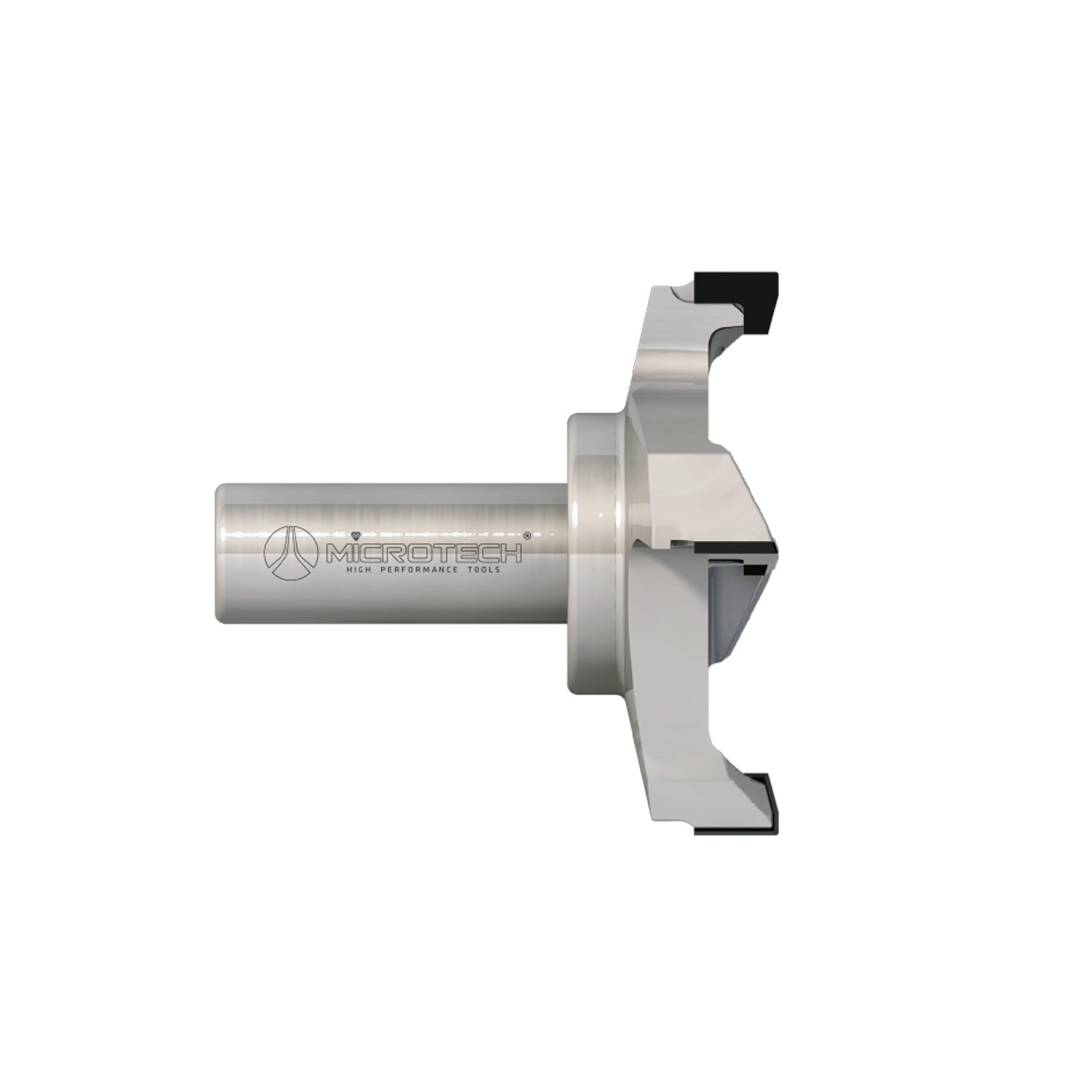

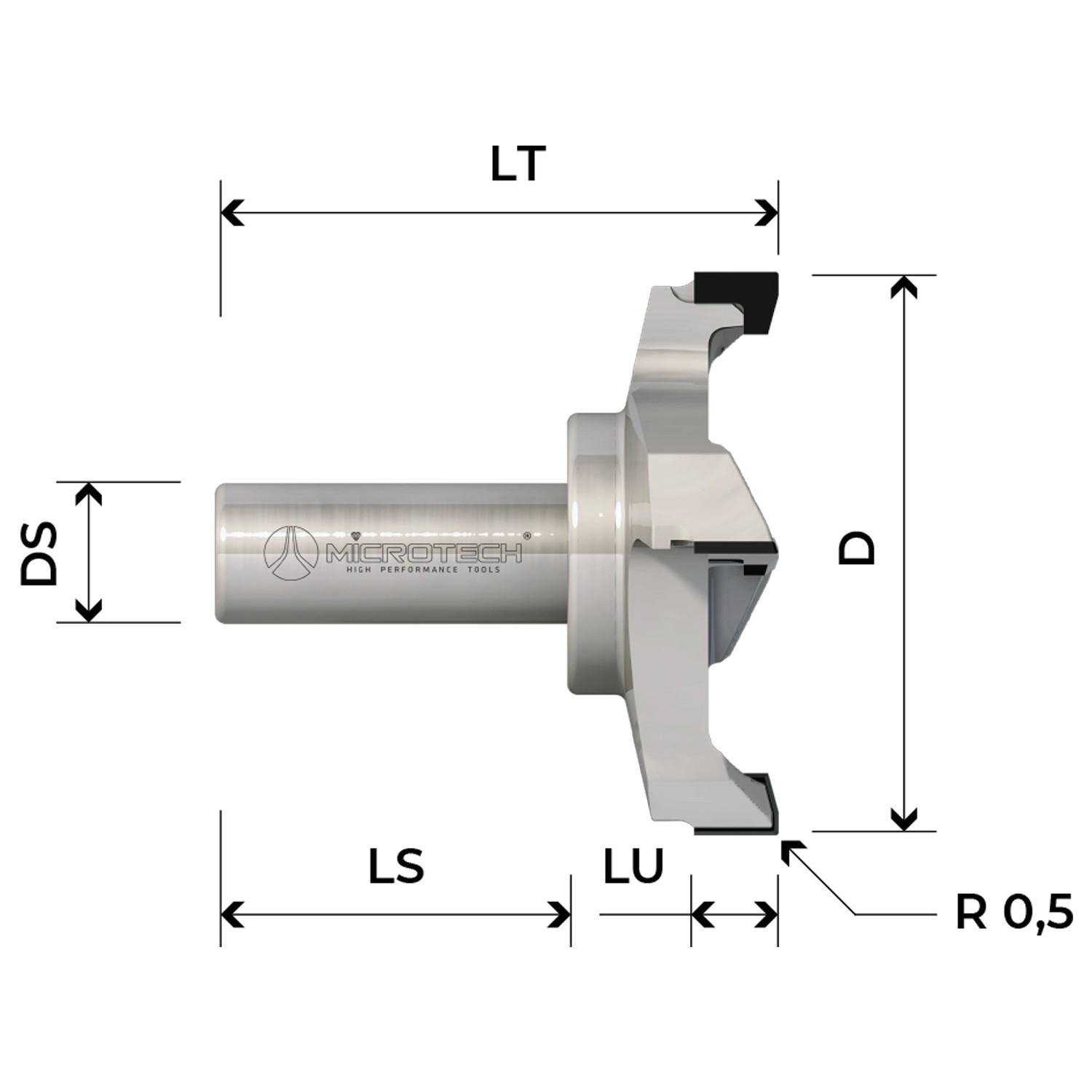

Super-strLENGTH steel. 2 precision ground carbide tipped cutting edges (Z2). Direct clamp on the shank of the drills.

Super-strLENGTH steel. 2 precision ground carbide tipped cutting edges (Z2). Direct clamp on the shank of the drills.

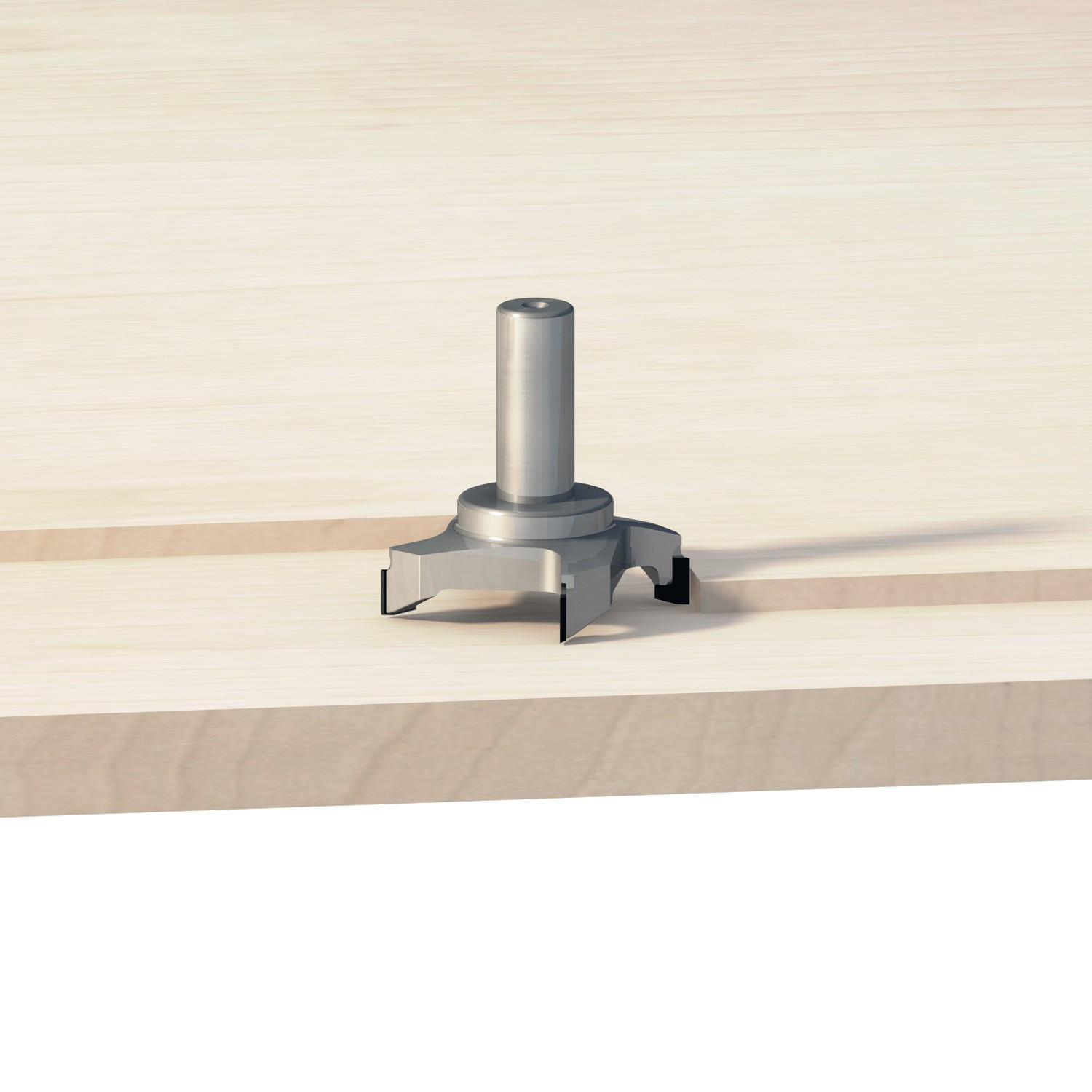

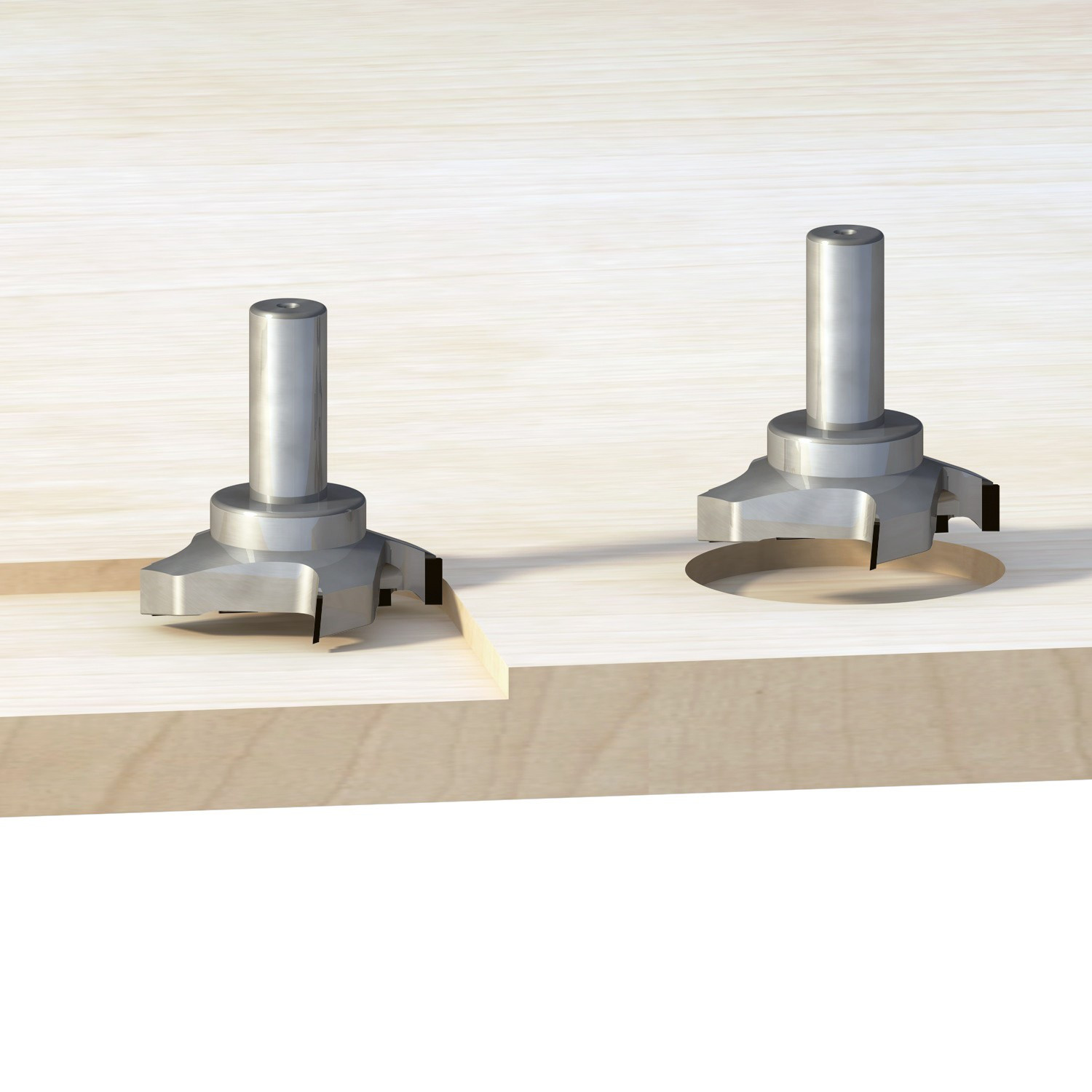

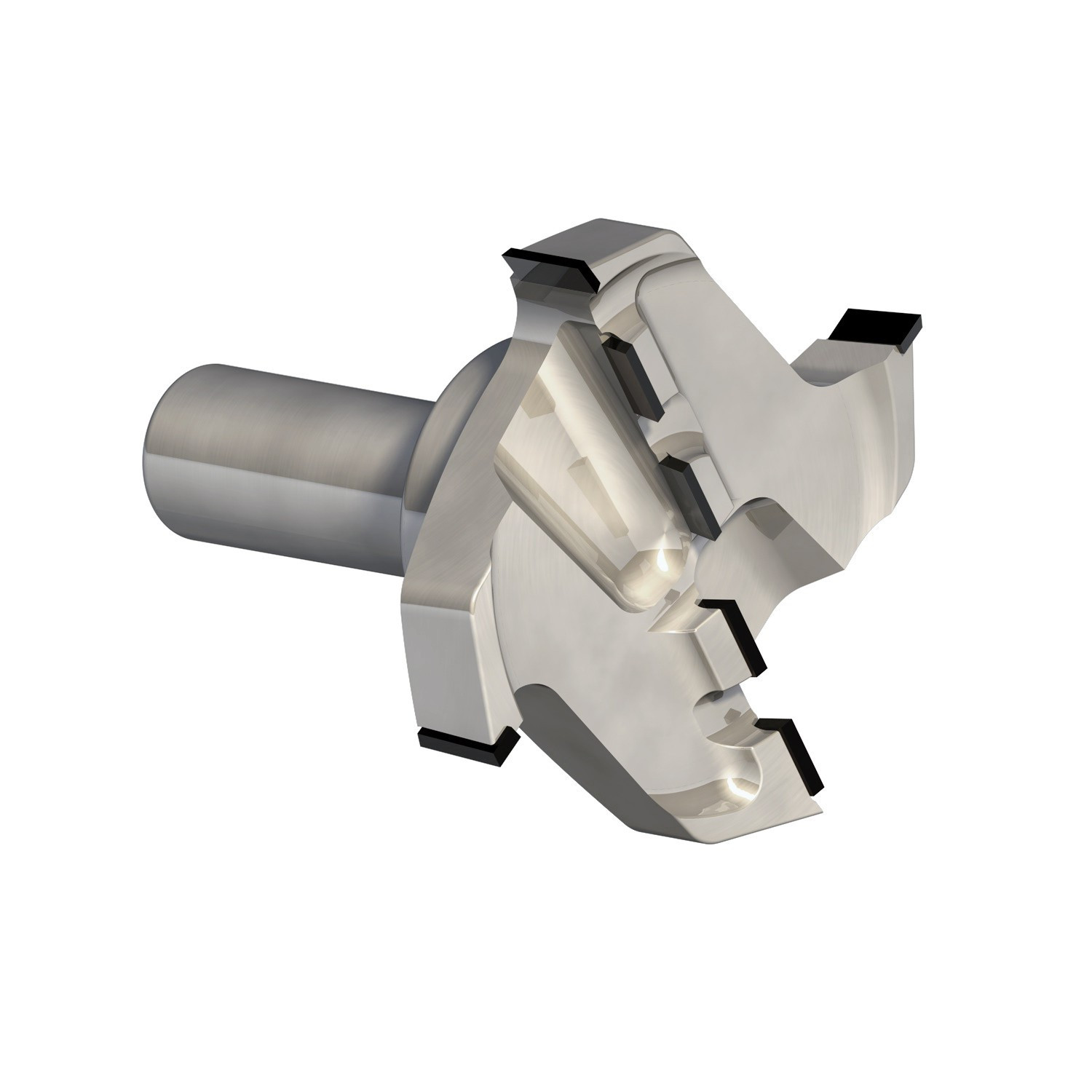

Re-sharpening fly cutter in PCD, suitable to level out panel surfaces on CNC machines, to perform processing of nesting.

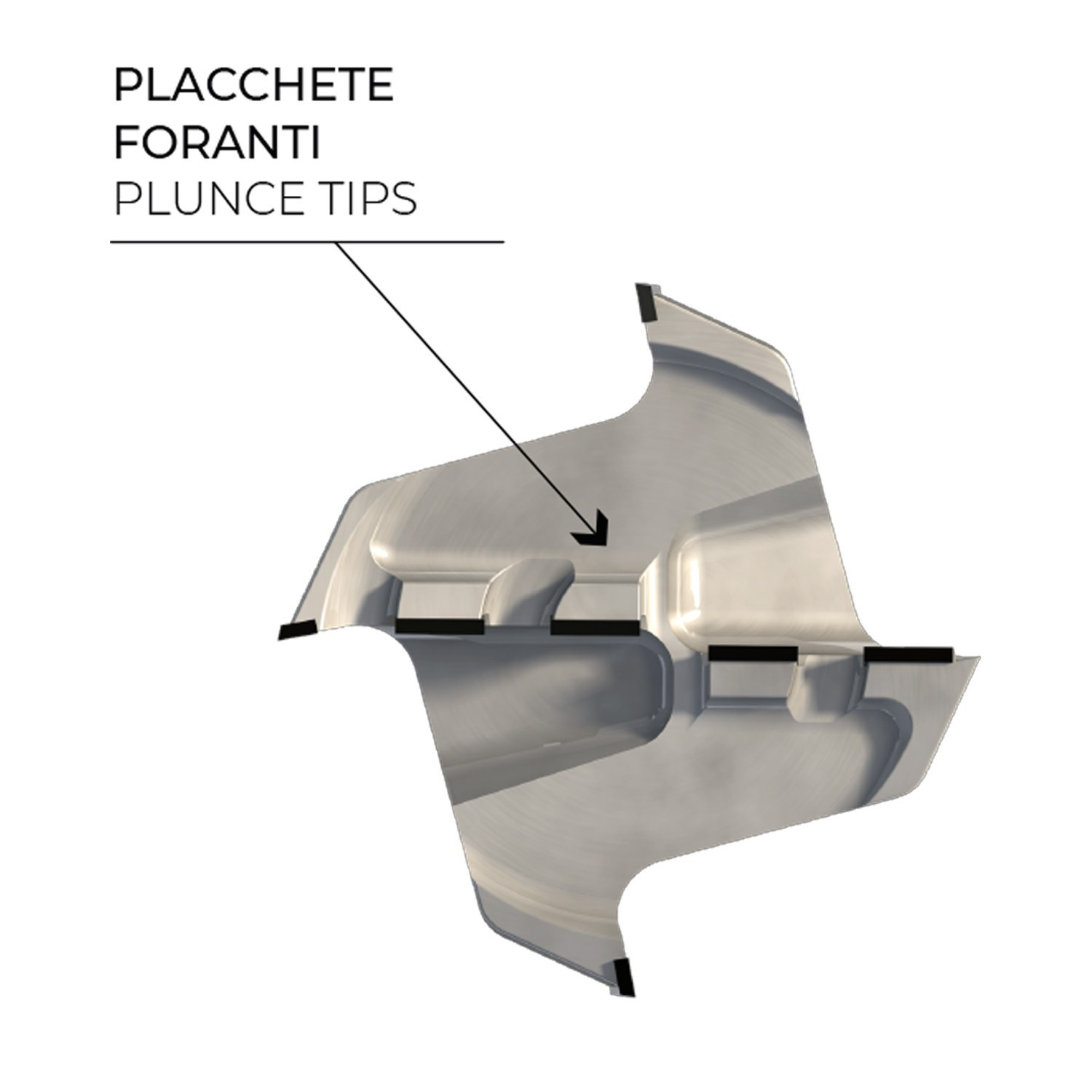

Re-sharpening fly cutter in PCD, plunce tips, suitable to level out panel surfaces on CNC machines, to perform processing of nesting.

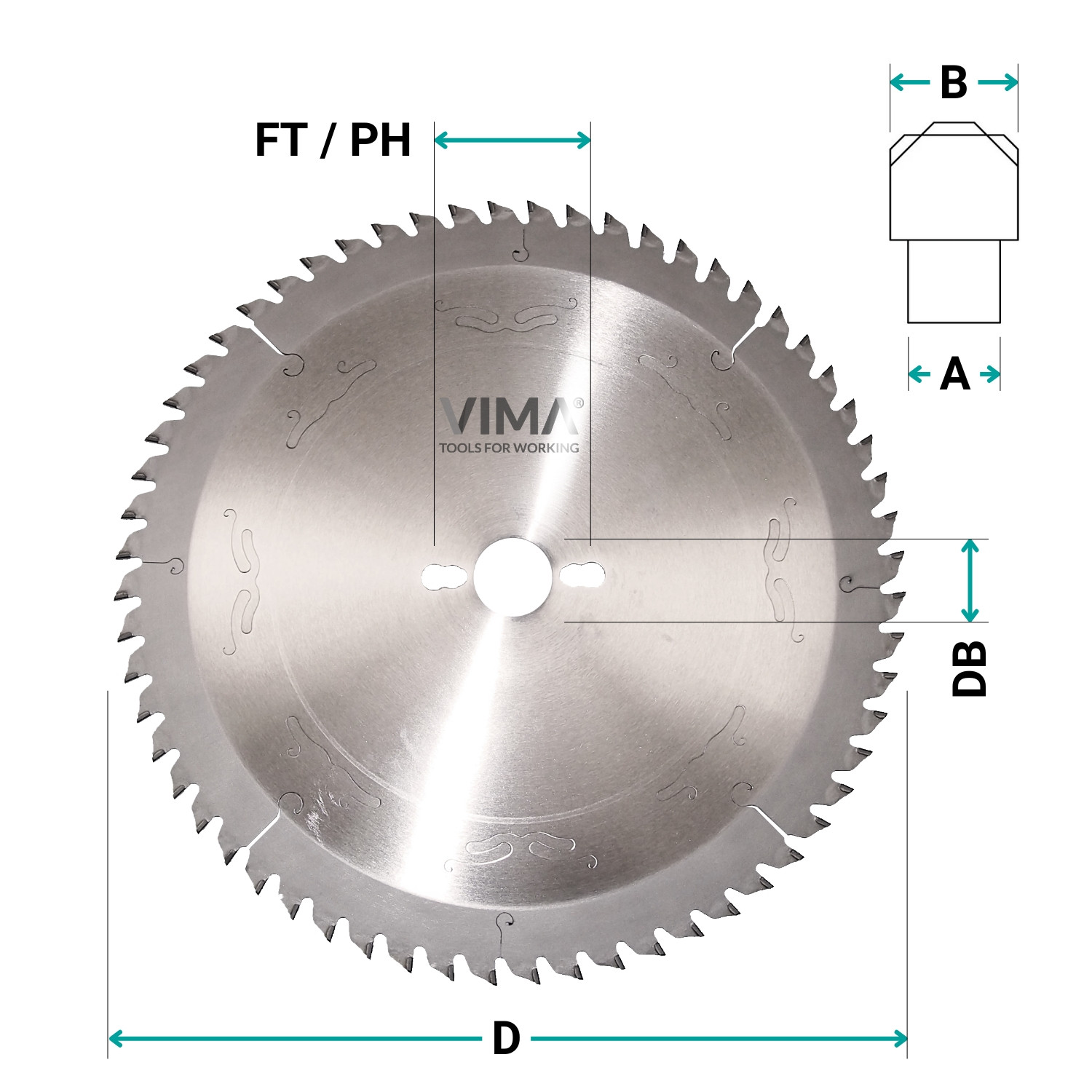

PCD H6 diamond blade engineered for clean, precise and stable panel cutting. The 6 mm diamond layer ensures superior durability, reduced wear and constant cutting quality on wood, composites and non-ferrous materials. FZ/TR/FA geometry provides smooth feed and minimal vibration.

Premium quality super strLENGTH steel for improved resistance and durability. Premium quality HWM spiral portion. 2 cutting edges (Z2) + 2 negatively ground spurs (V2), 2 spiral flutes, parallel shank with driving flat and adjustable screw LENGTH. Recommended feed speed 1÷ 4m/minute –RPM 6000.

Premium quality super strLENGTH steel for improved resistance and durability. Premium quality HWM spiral portion. 2 cutting edges (Z2) + 2 negatively ground spurs (V2), 2 spiral flutes, parallel shank with driving flat and adjustable screw LENGTH. Recommended feed speed 1÷ 4m/minute –RPM 6000.

Tool holder ISO30 to be use on Morbidelli and SCM machines.

• Manufactured from special high-strength steel;

• Supplied complete with nut and drawbar (without collet);

• Maximum precision and reliability;

• Total elimination of rotation imperfections;

• For Morbidelli and SCM machines;

• Precision ground on all contact surfaces;

• Fast and secure tool installation guaranteed.

Diamond jointing cutter diameter 60 with helicoidal wings PCD H2.5mm axial 30°.

Diamond jointing cutter D60 PCD H2.5mm axial 30° with low noise slots.

Diamond jointing cutter diameter 60 with helicoidal wings PCD H4.5 mm axial 30°.

Diamond jointing cutter D60 PCD H4.5mm axial 30° with low noise slots

Diamond jointing cutter diameter 70 with helicoidal wings PCD H2.5 mm axial 30°.

Diamond jointing cutter D60 PCD H2.5 mm axial 30° with low noise slots.

Diamond jointing cutter diameter 70 with helicoidal wings PCD H4.5 mm axial 30°.

Diamond jointing cutter D60 PCD H4.5mm axial 30° with low noise slots.

Diamond jointing cutter with helicoidal wings PCD H2.5 mm axial 30°.

Diamond jointing cutter D60 PCD H2.5 mm axial 30° with low noise slots

Diamond jointing cutter with helicoidal wings PCD H4.5 mm axial 30°

Diamond jointing cutter D60 PCD H4.5mm axial 30° with low noise slots.

Diamond jointing cutter with helicoidal wings D80/85 PCD H4.5 mm axial 45°.

Diamond jointing cutter diameter 100 with helicoidal wings PCD H2.5 mm axial 30°.

Diamond jointing cutter D60 PCD H2.5 mm axial 30° with low noise slots.

Diamond jointing cutter diameter 100 with helicoidal wings PCD H4.5 mm axial 30°.

Diamond jointing cutter D60 PCD H4.5 mm axial 30° with low noise slots

Diamond jointing cutter with helicoidal wings D80/85 PCD H4.5 mm axial 45°.

Diamond jointing cutter with helicoidal wings D100 PCD H4.5 mm axial 54.9°.

Diamond jointing cutter with helicoidal wings PCD H2.5 mm axial 30°.

Diamond jointing cutter D60 PCD H2.5 mm axial 30° with low noise slots.

Diamond jointing cutter with helicoidal wings PCD H4.5 mm axial 30°.

Diamond jointing cutter D60 PCD H4.5mm axial 30° with low noise slots.

Diamond jointing cutter with helicoidal wings D80/85 PCD H4.5 mm axial 45°.

Diamond jointing cutter with helicoidal wings D100 PCD H4.5 mm axial 54.9°.

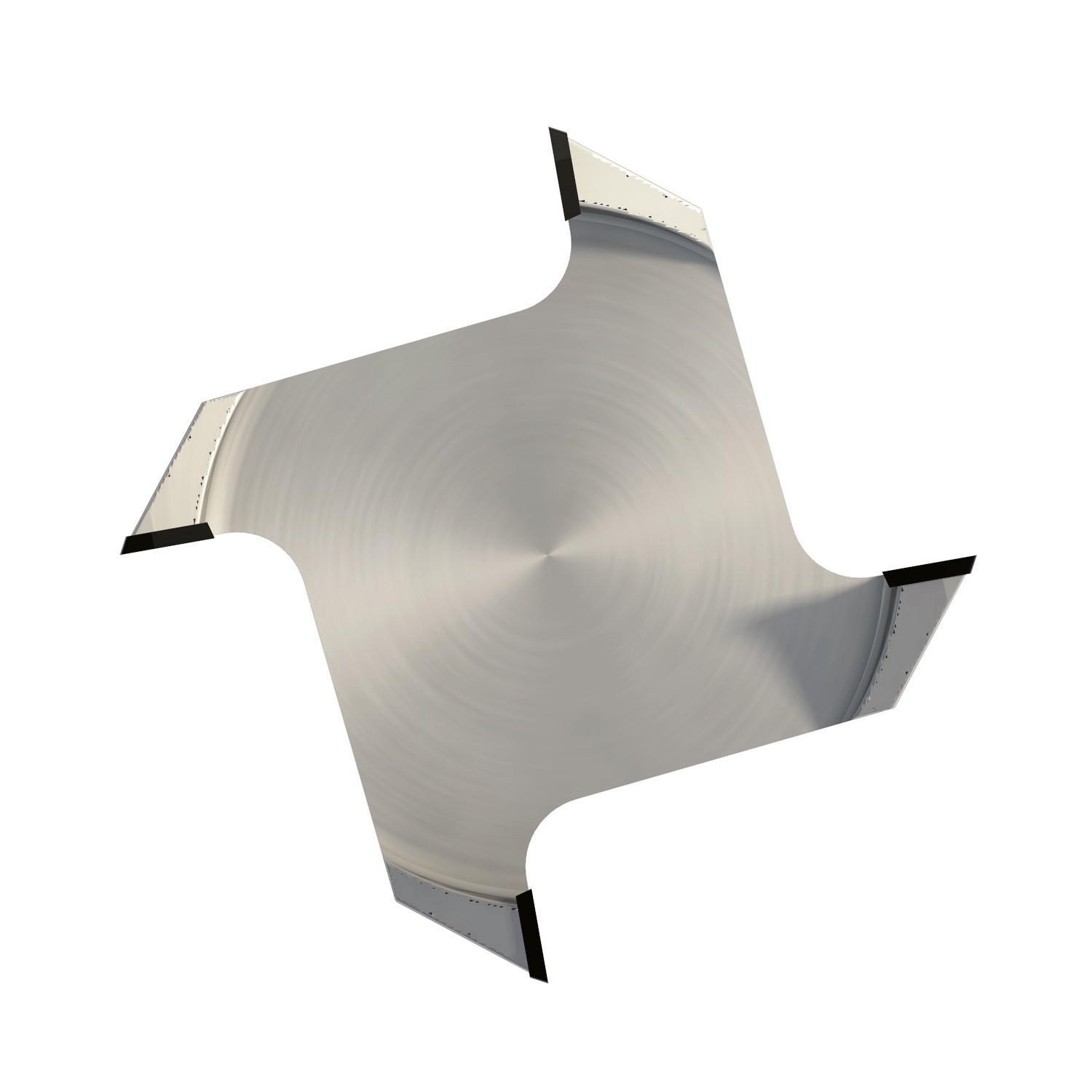

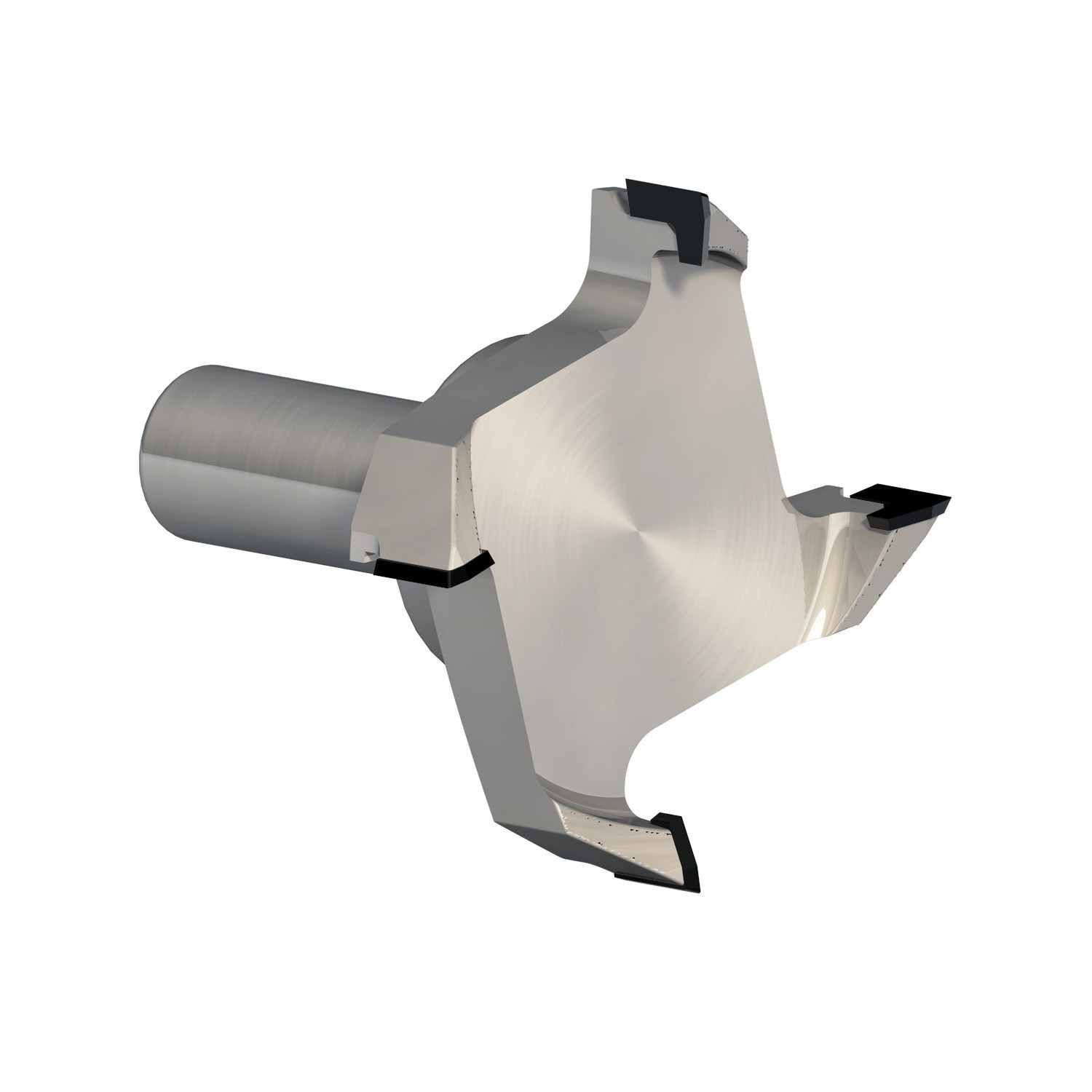

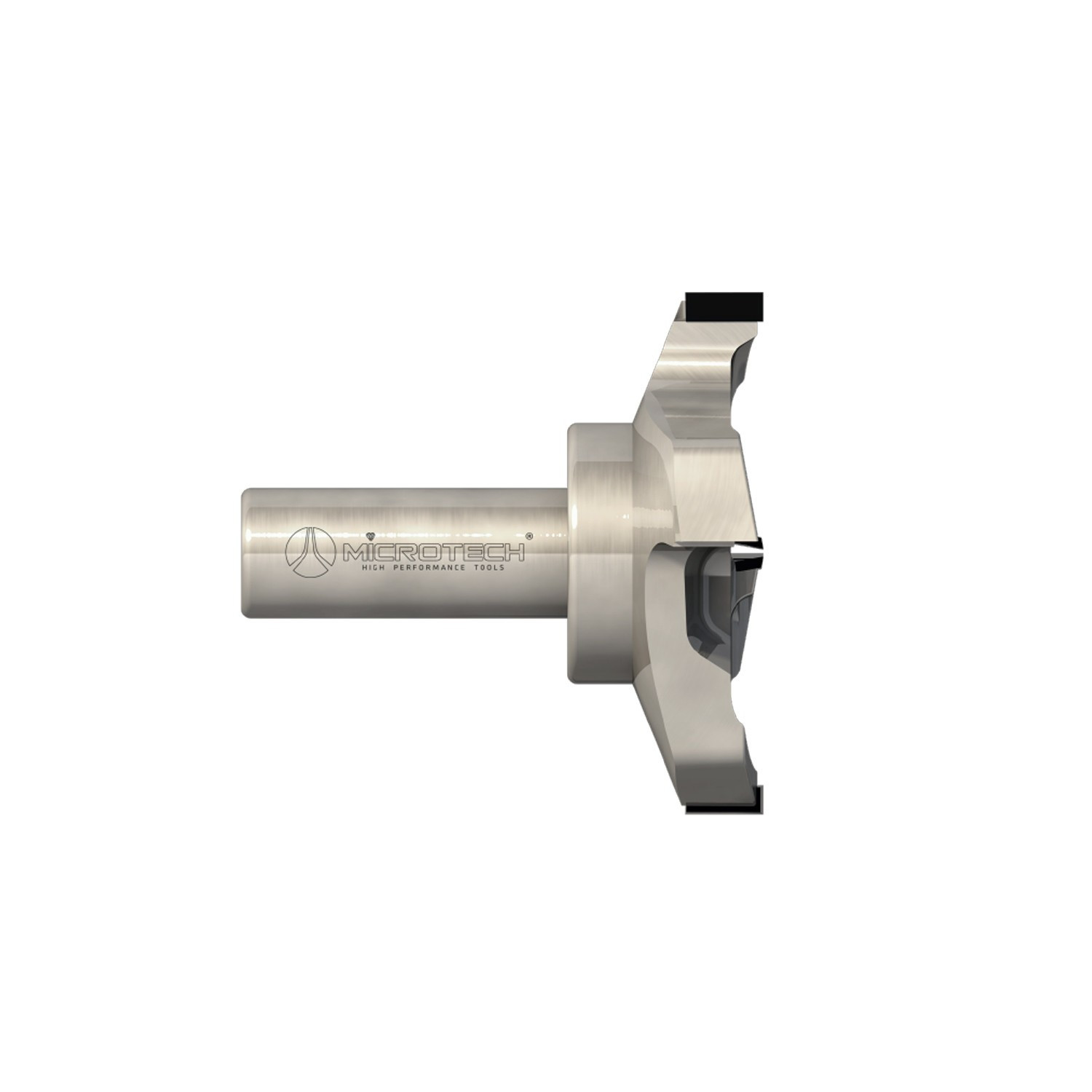

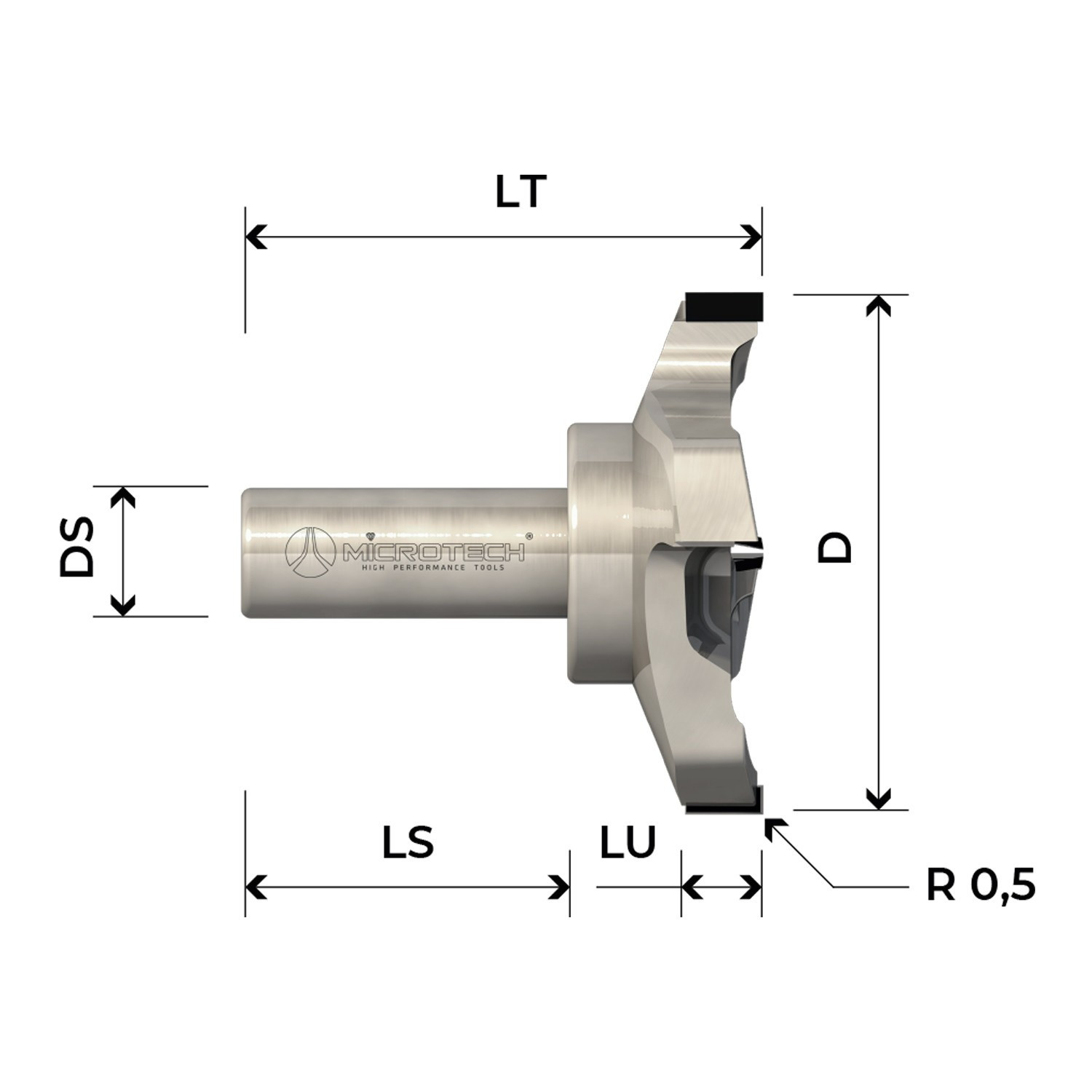

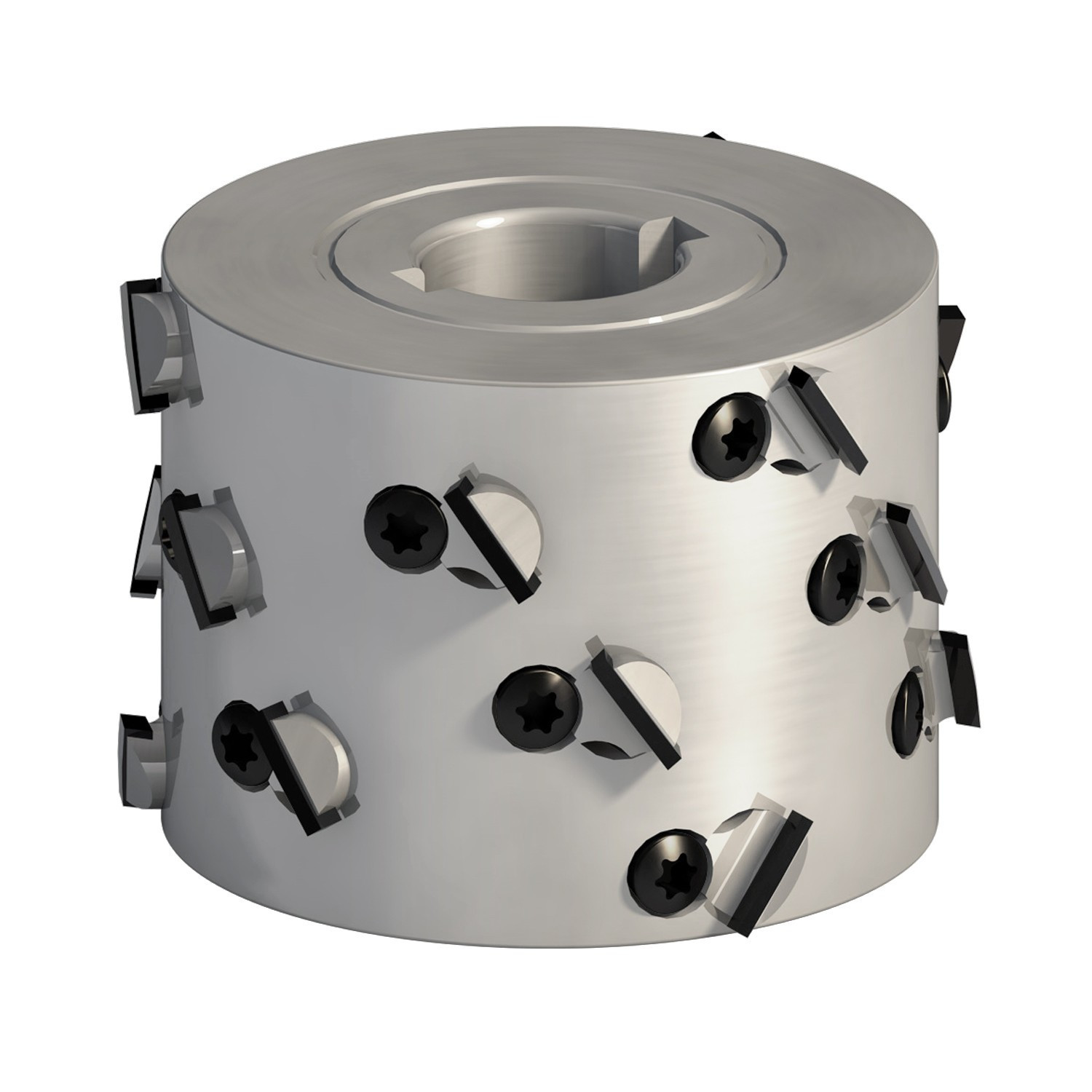

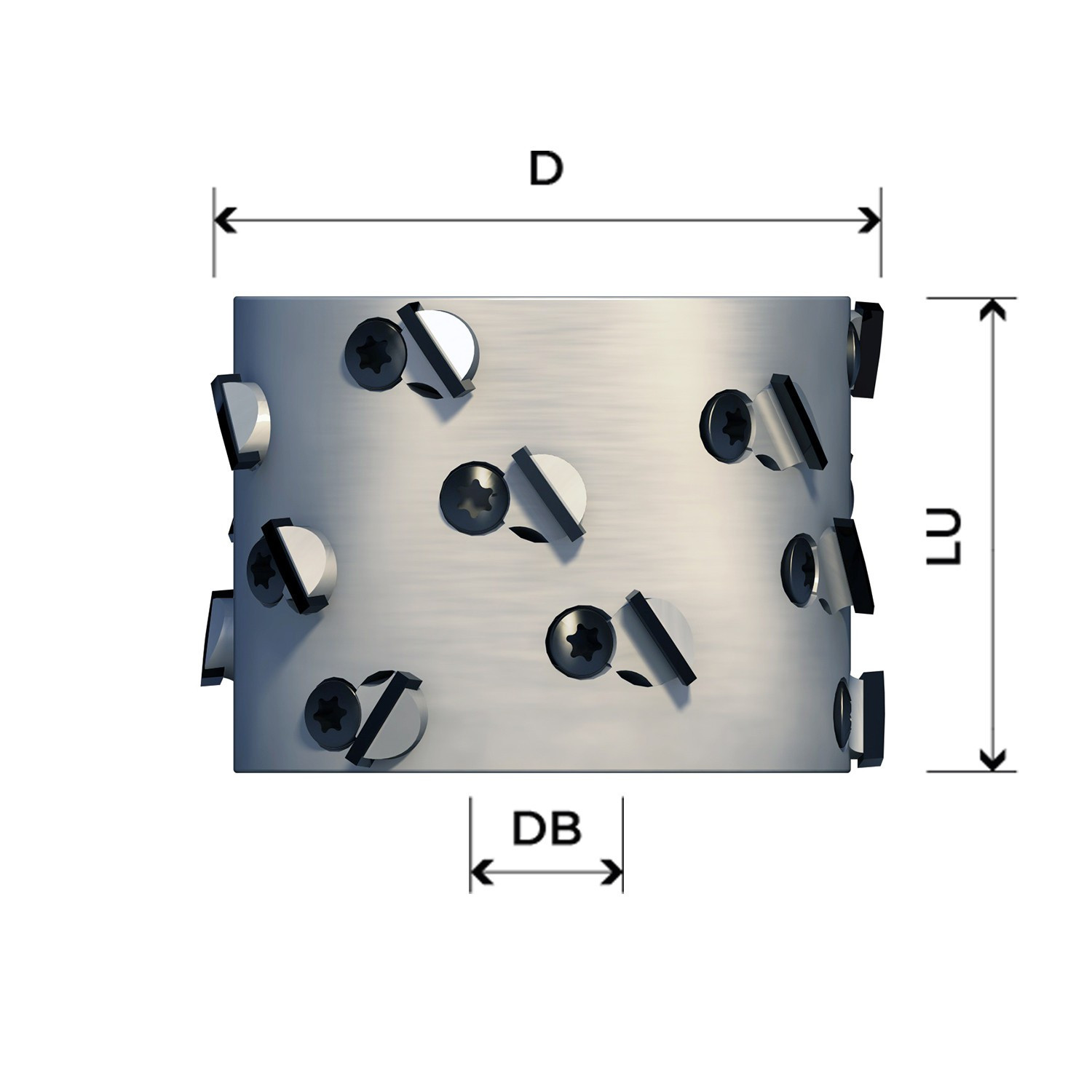

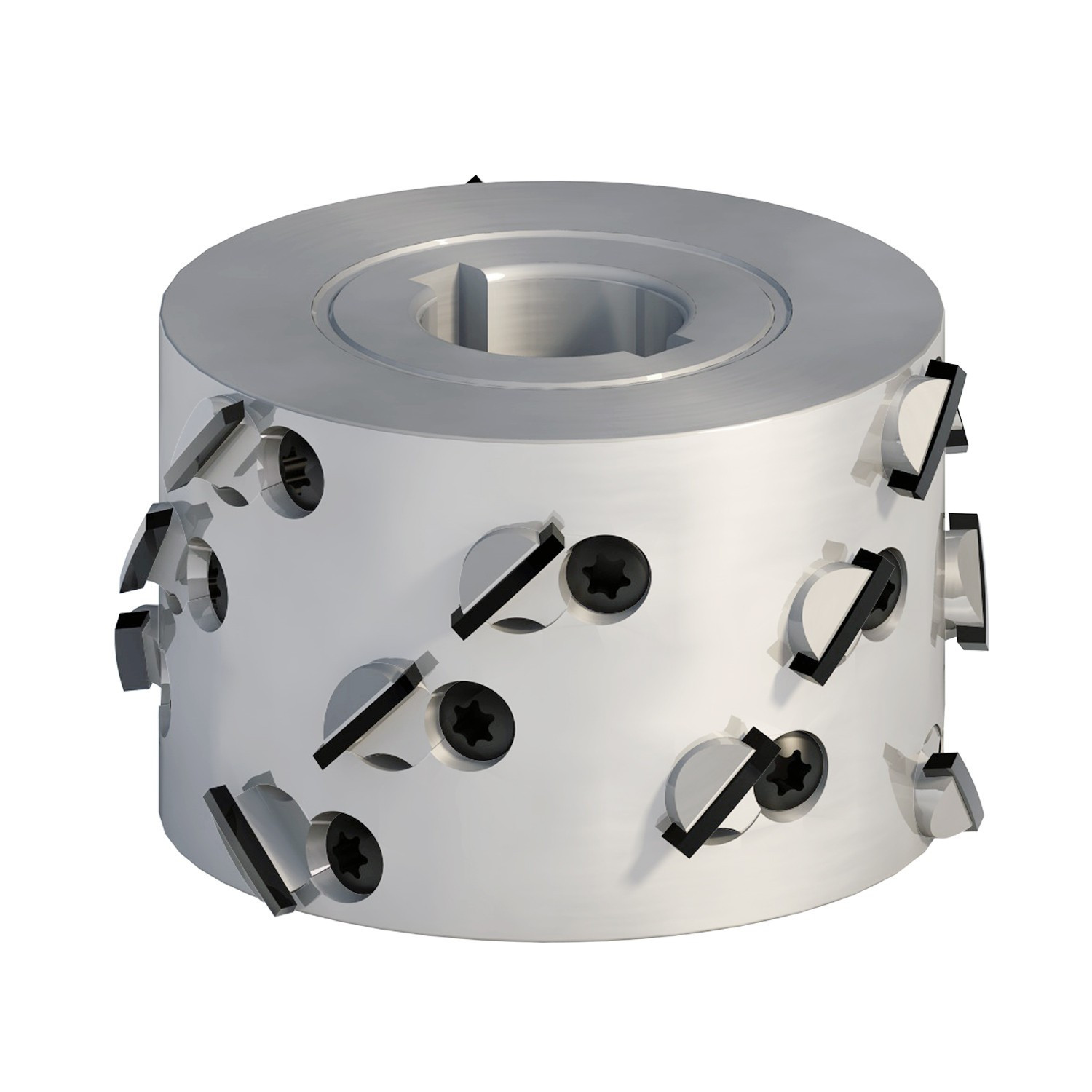

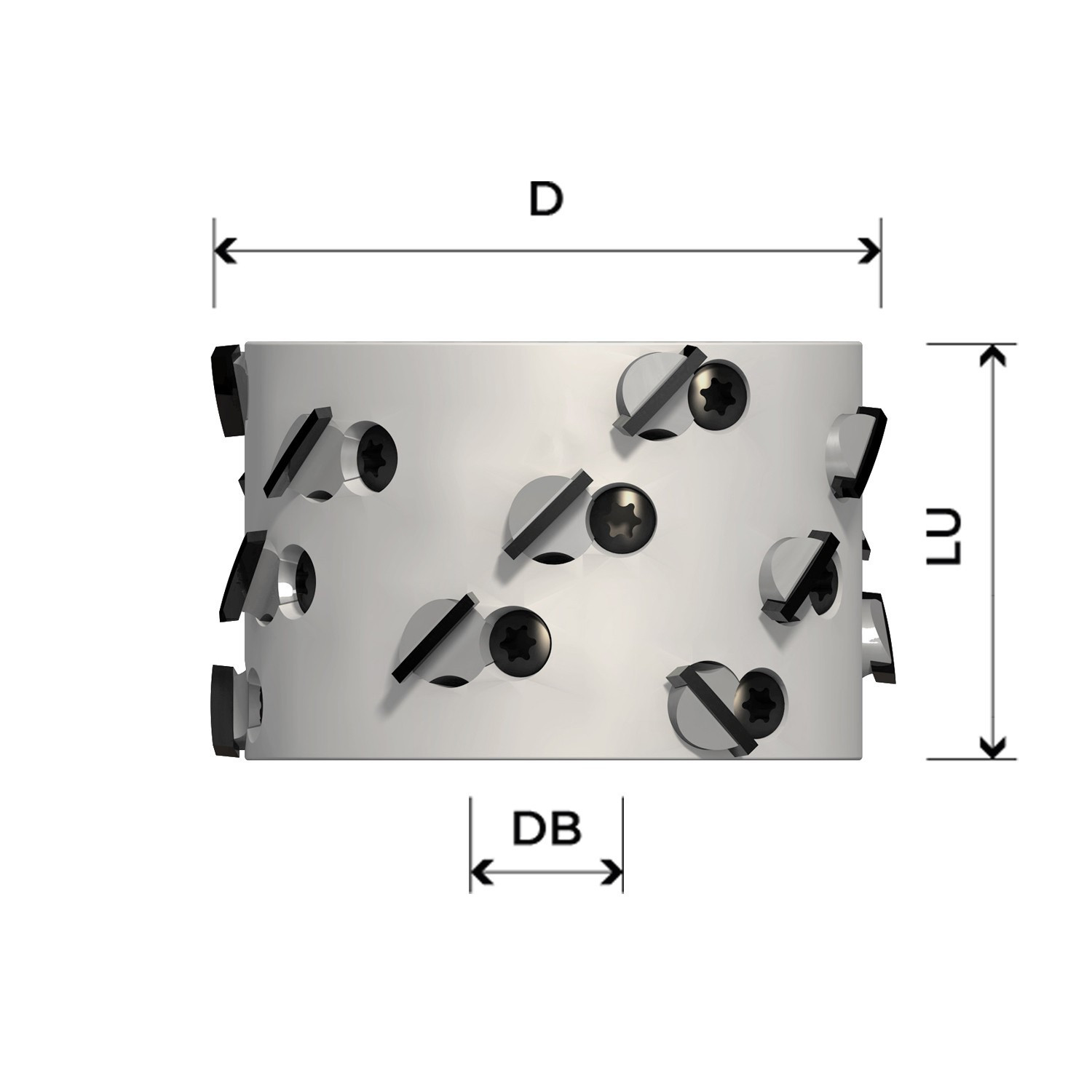

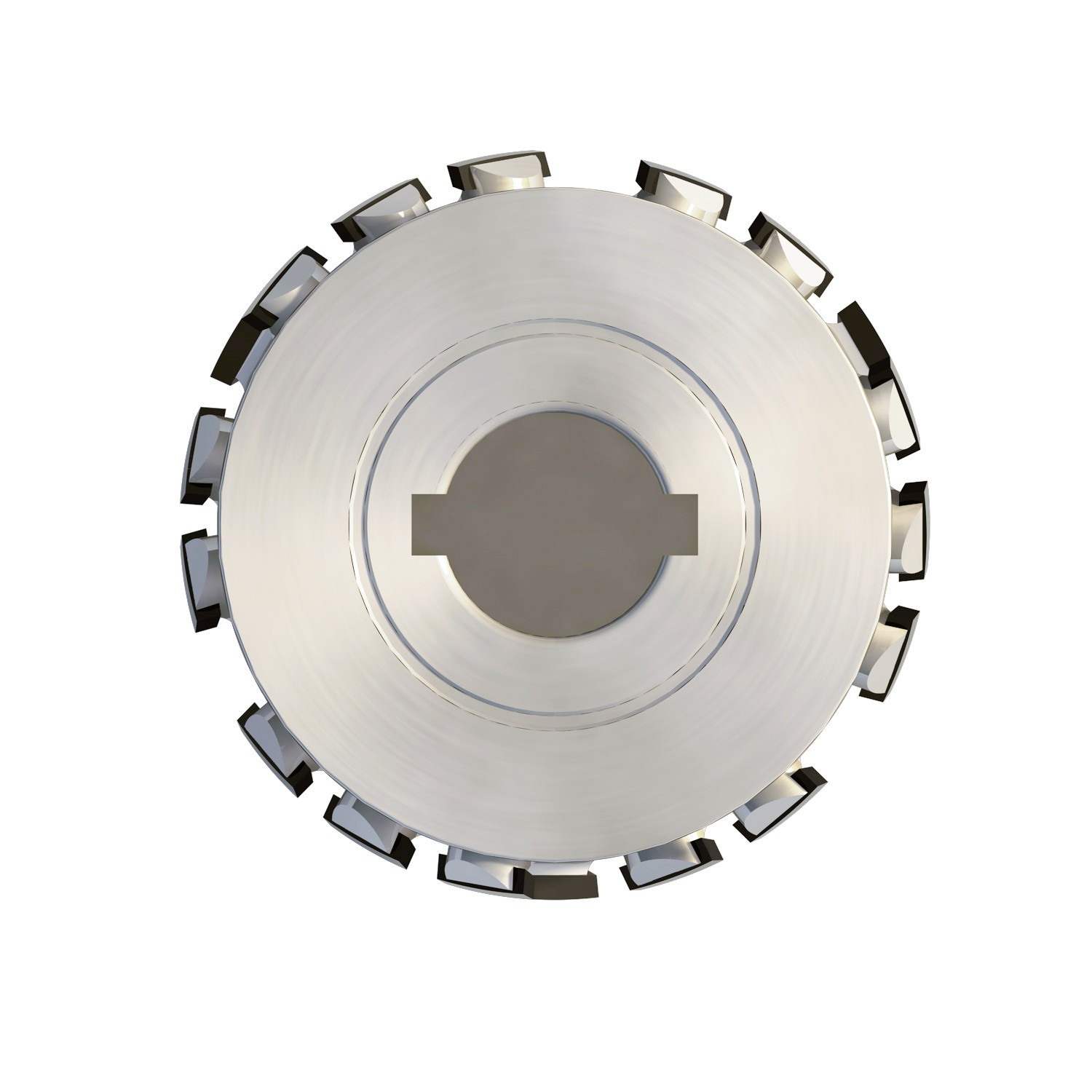

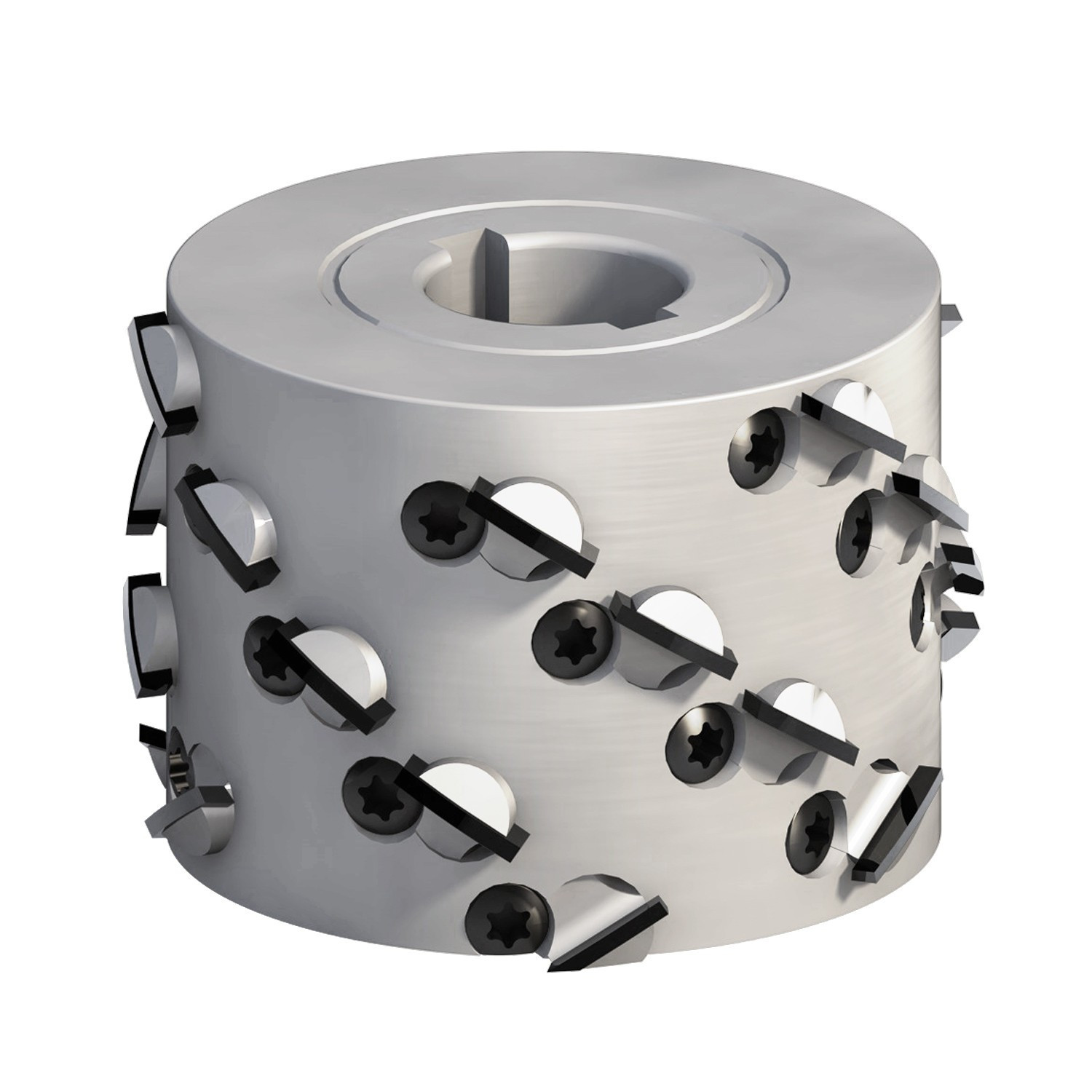

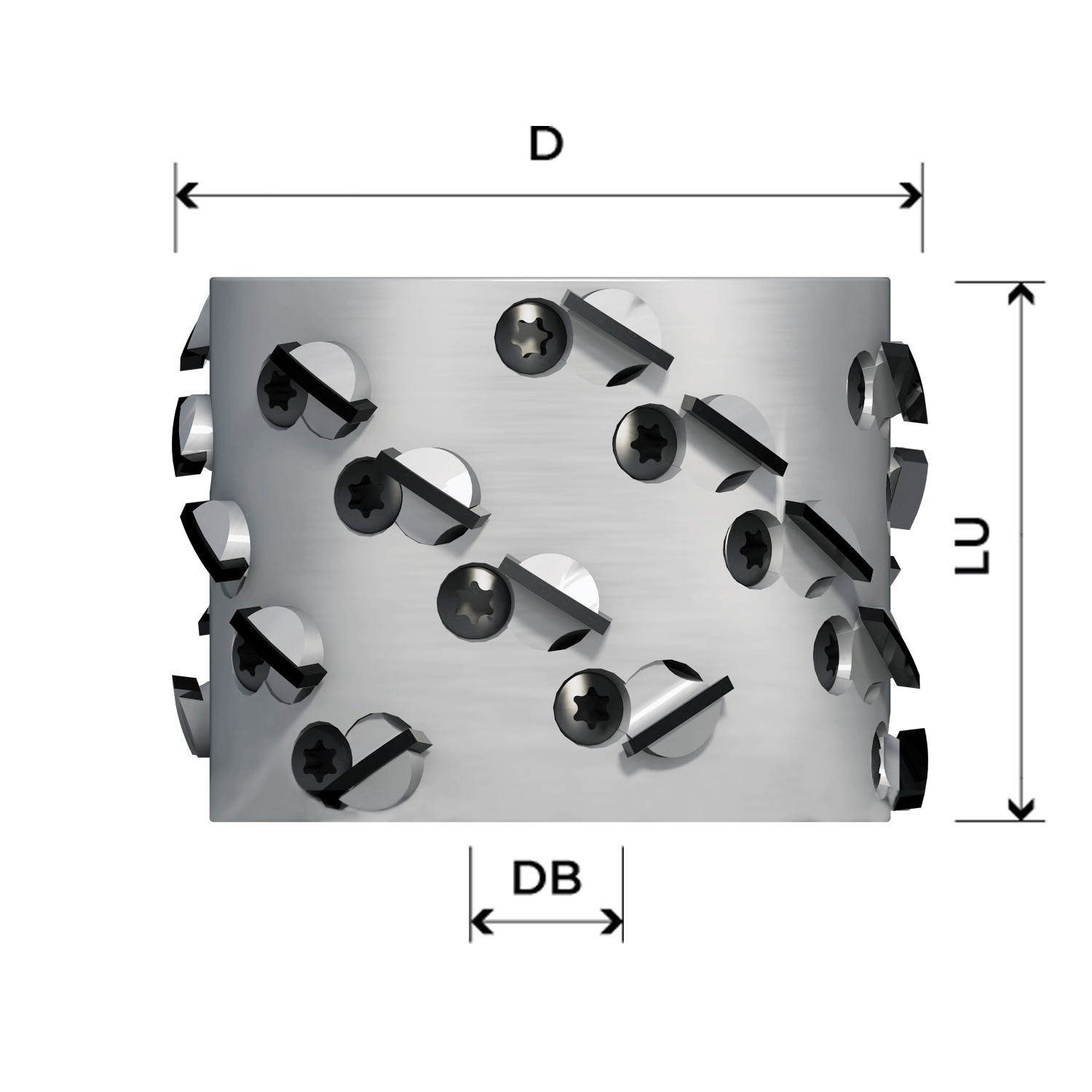

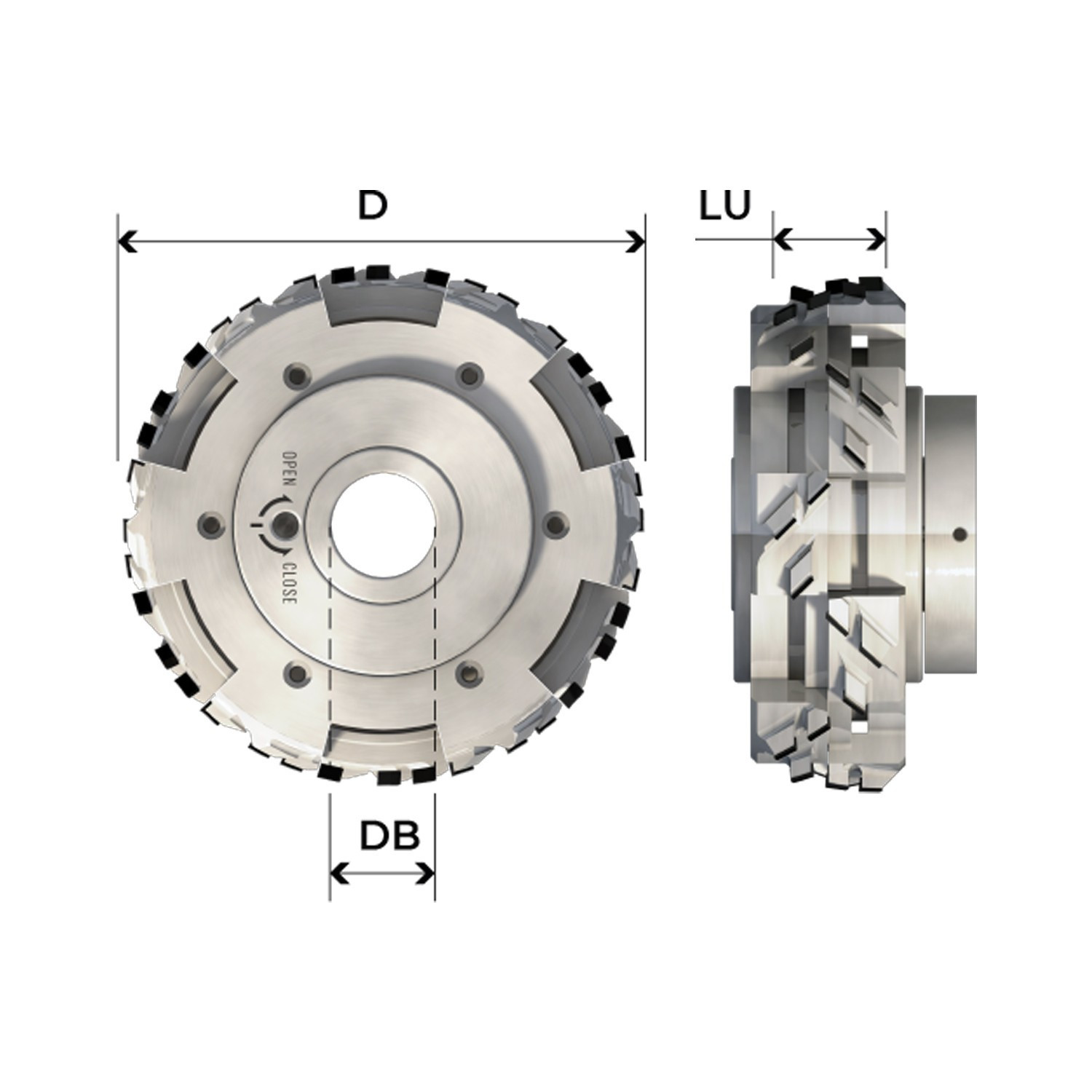

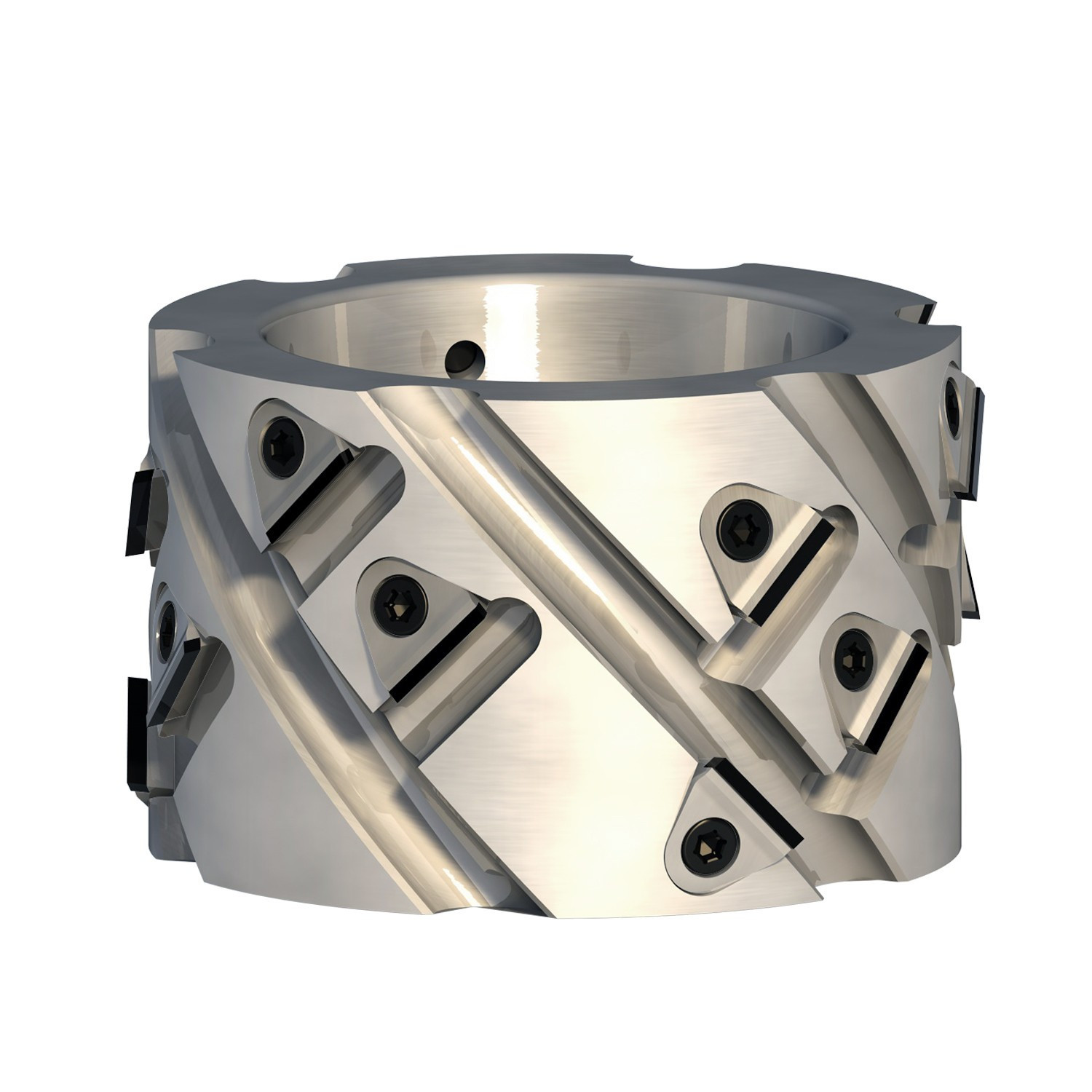

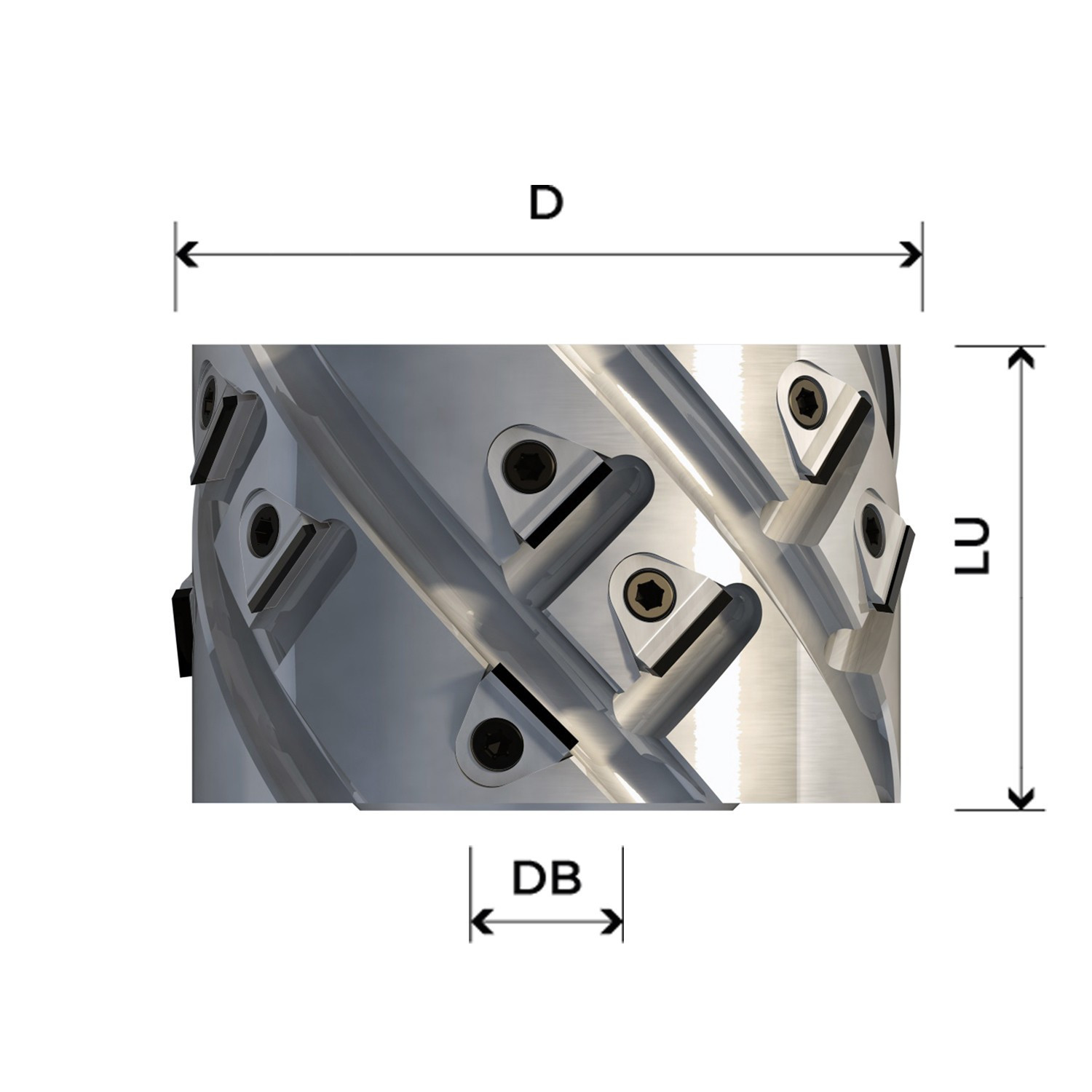

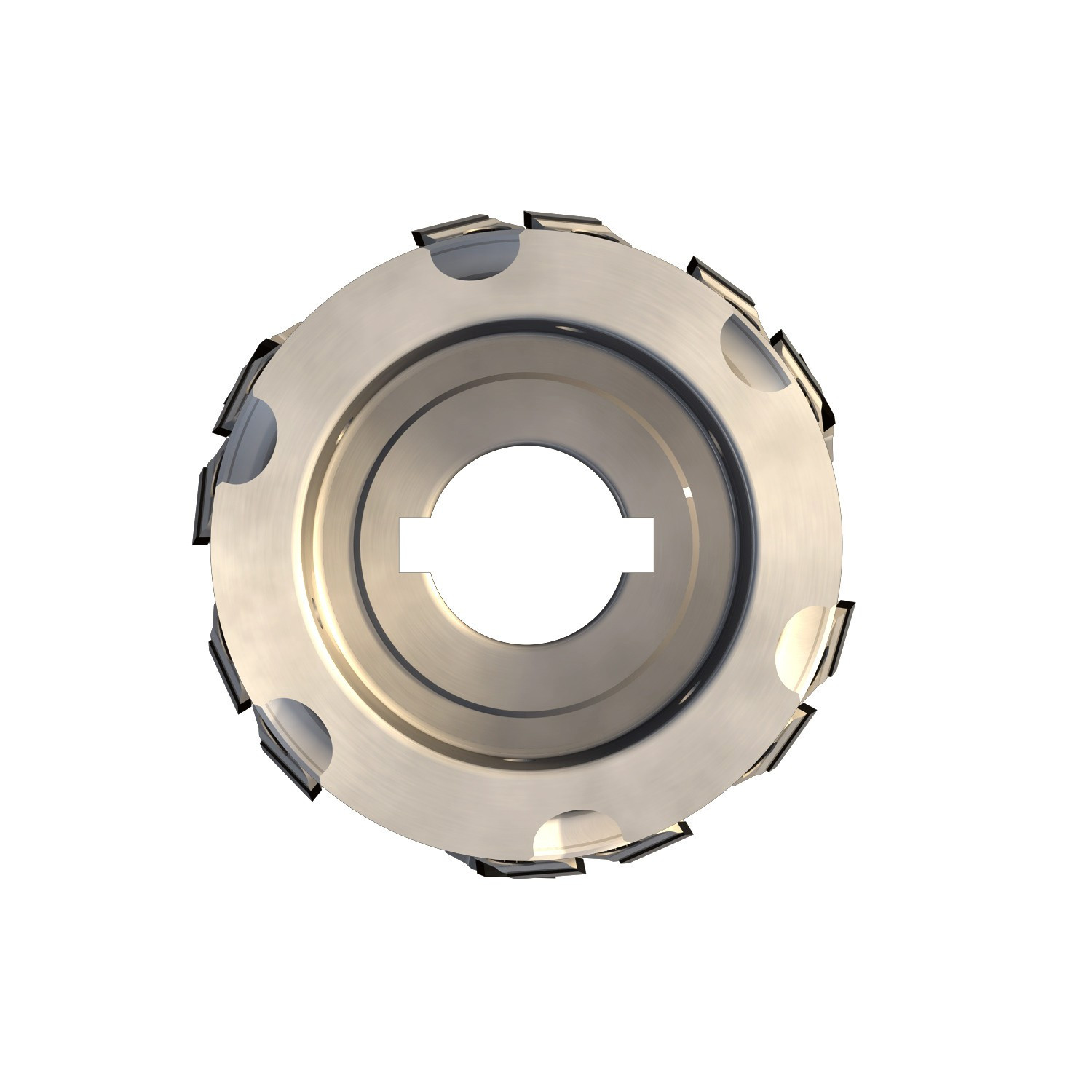

Jointing cutter with pcd inserts, PCD H3, axial 35°. It’s possible to change the inserts position to have symmetrical and asymmetrical cutter.

Jointing cutter with pcd inserts, PCD H3, axial 45°. It’s possible to change the inserts position to have symmetrical and asymmetrical cutter.

Jointing cutter with pcd inserts, PCD H3 mm, axial 54.9°. It’s possible to change the inserts position to have symmetrical and asymmetrical cutter.

Re-sharpening adjustable grooving cutter in diamond with adjustable chanfering knife, suitable for grooving on chipboard panels, used on edgebanding machines.

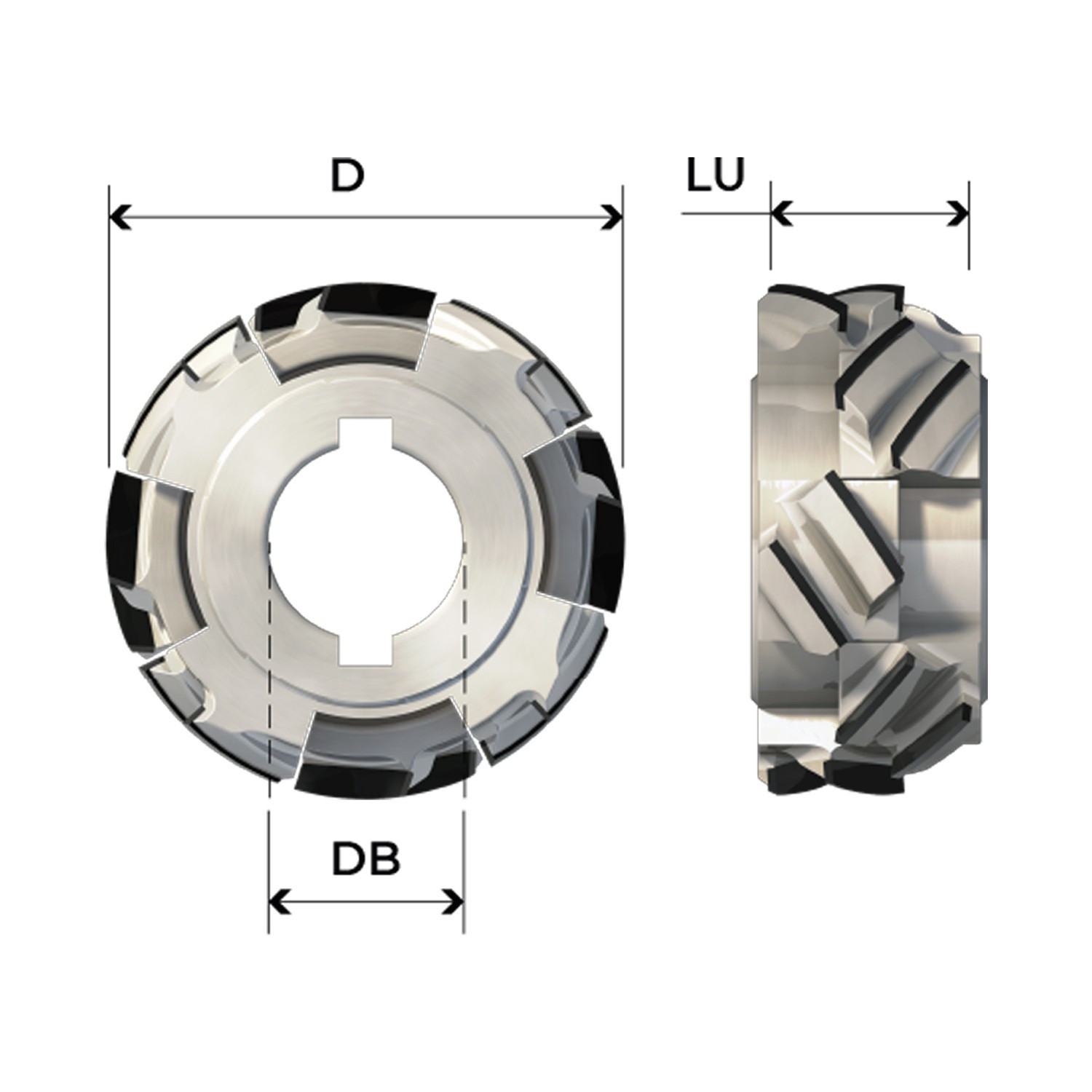

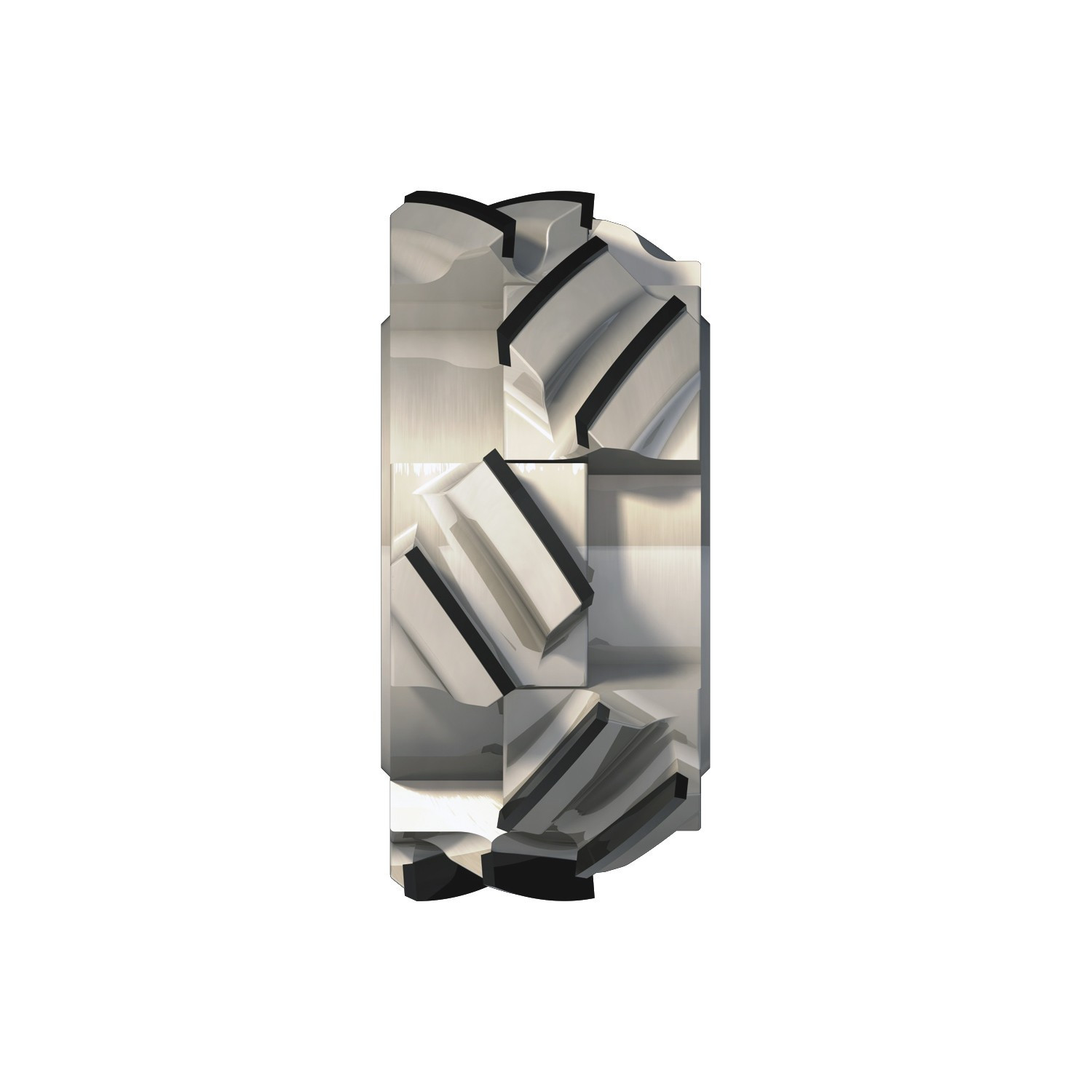

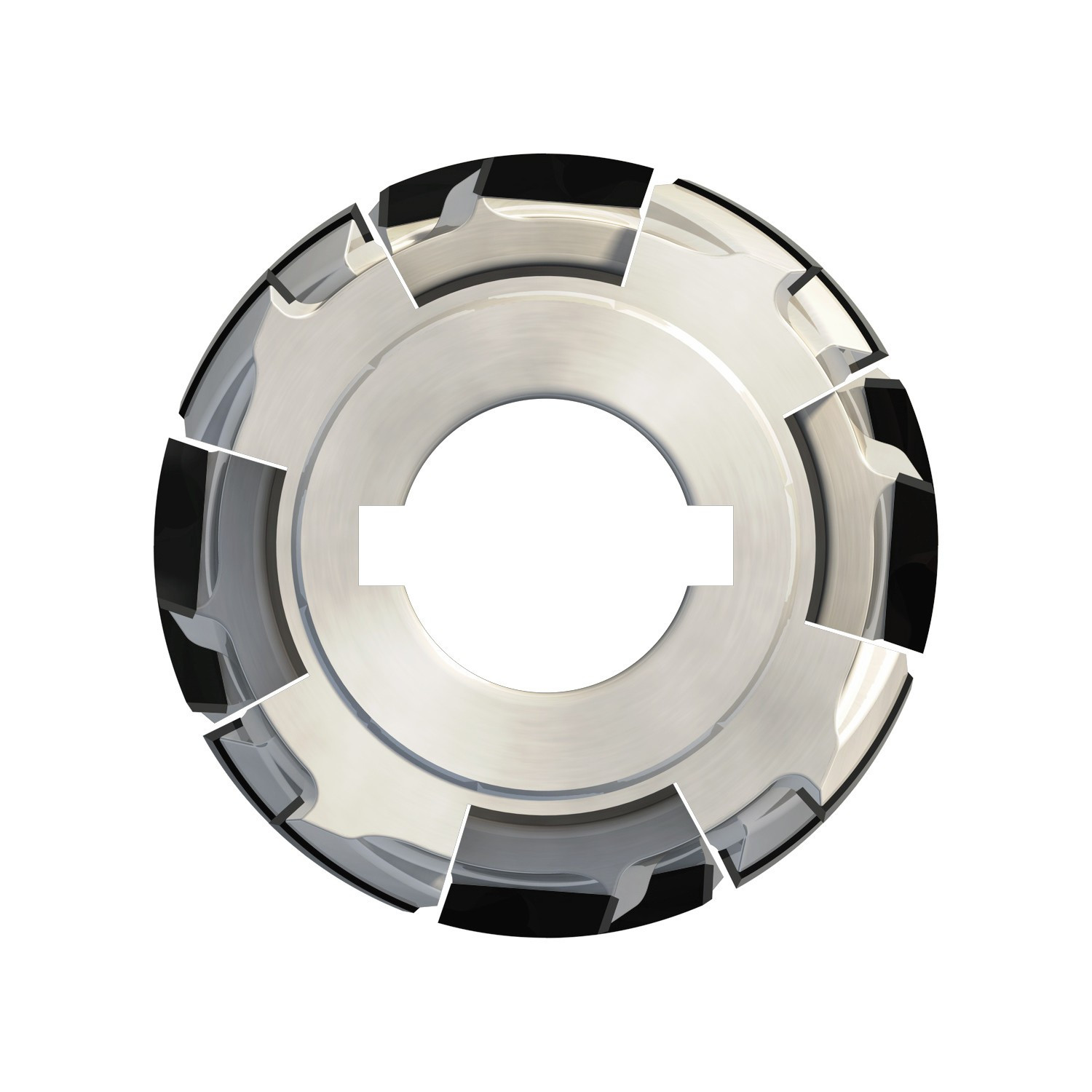

Re-sharpening and adjustable jointing cutter in diamond, made in two pieces adjustable by spacer rings, used on squaring machines.

Re-sharpening and adjustable jointing cutter in diamond, made in two pieces adjustable by spacer rings, used on squaring machines.

Re-sharpening and adjustable jointing cutter in diamond, made in two pieces adjustable by spacer rings, used on squaring machines.

Re-sharpening adjustable grooving cutter in diamond with adjustable chanfering knife, suitable for grooving on chipboard panels, used on edgebanding machines.

To trim edgebandings on horizontal spindles or for bevelling with inclinated spindles, for jointing and flush -cutting of solid wood, veneer and plastic edge bands for machines STEFANI-FRAVOL.

To trim edgebandings on horizontal spindles or for bevelling with inclinated spindles, for jointing and flush -cutting of solid wood, veneer and plastic edge bands for machines HOMAG - IMA.

Jointing cutter with pcd inserts, PCD H2,5 mm, axial 30°.

Jointing cutter with pcd inserts, PCD H2,5 mm, axial 45°.

.jpg)