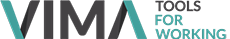

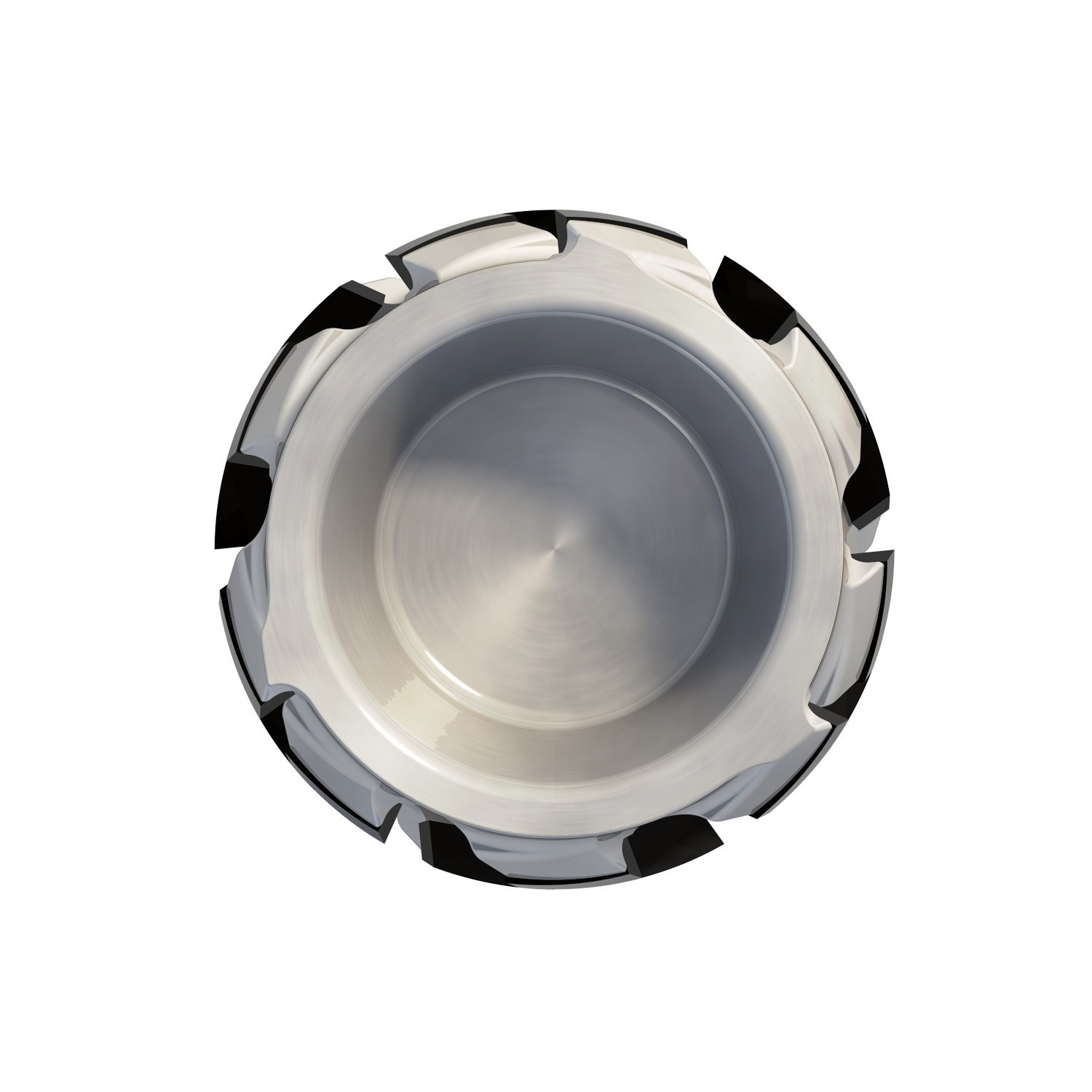

PCD diamond cutter with right/left double rotation designed for contouring laminated panels where high surface quality on both sides is required. The helical geometry with balanced cutting edges ensures stable cutting, reduced chipping and smooth machining.

• PCD inserts 4.5 mm regrindable up to 8 times

• Right/left double rotation for superior top and bottom finish

• 3 helical divisions for stable, smooth cutting

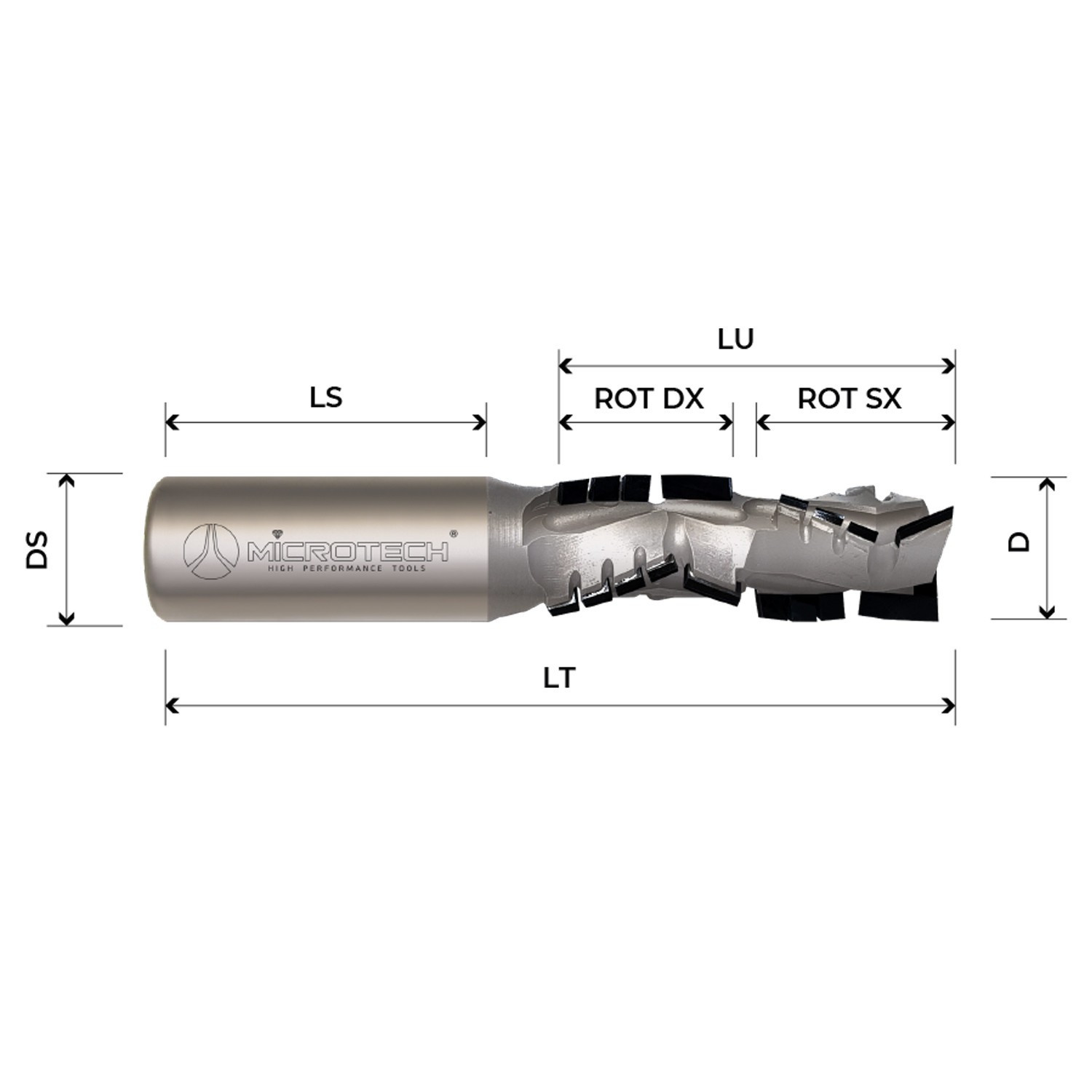

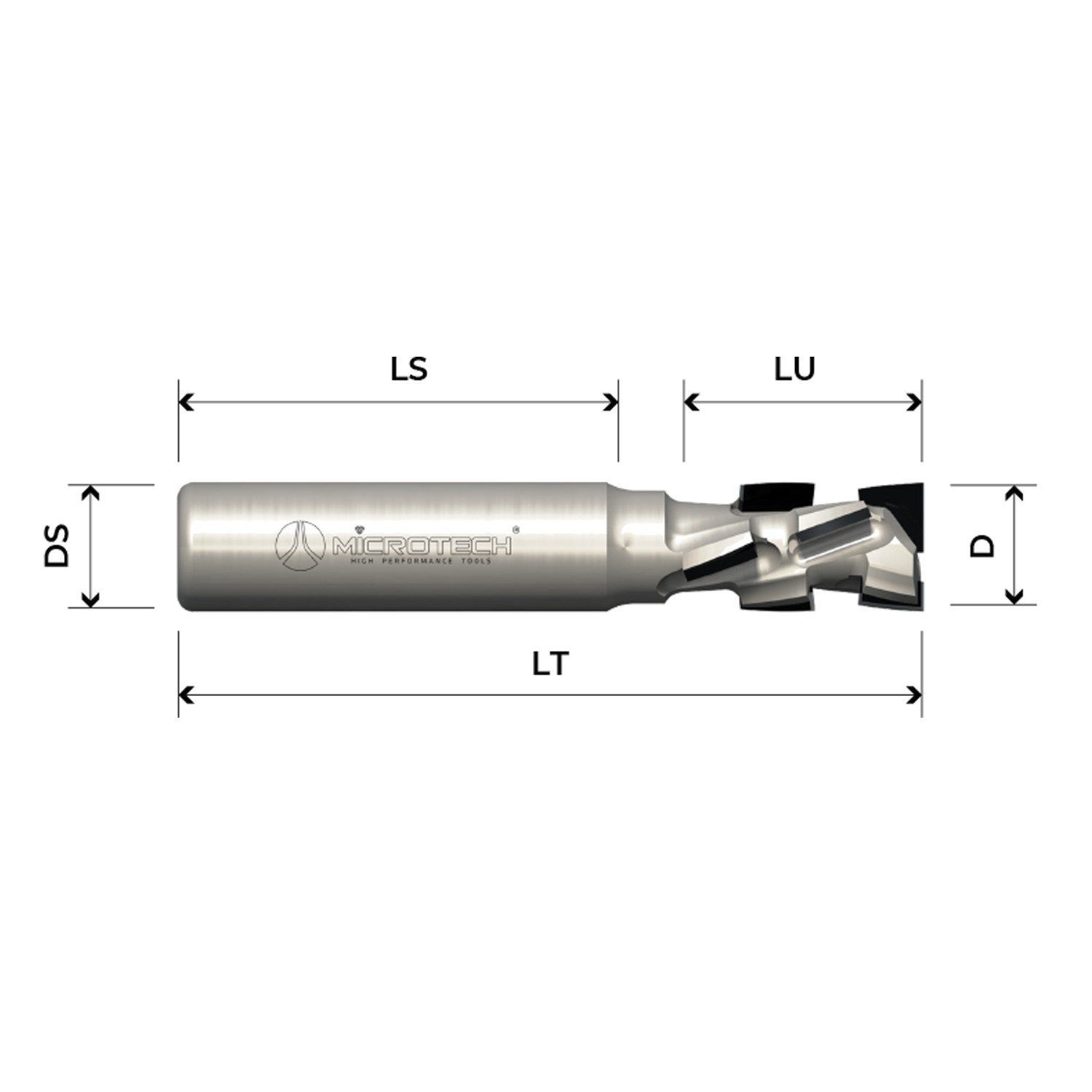

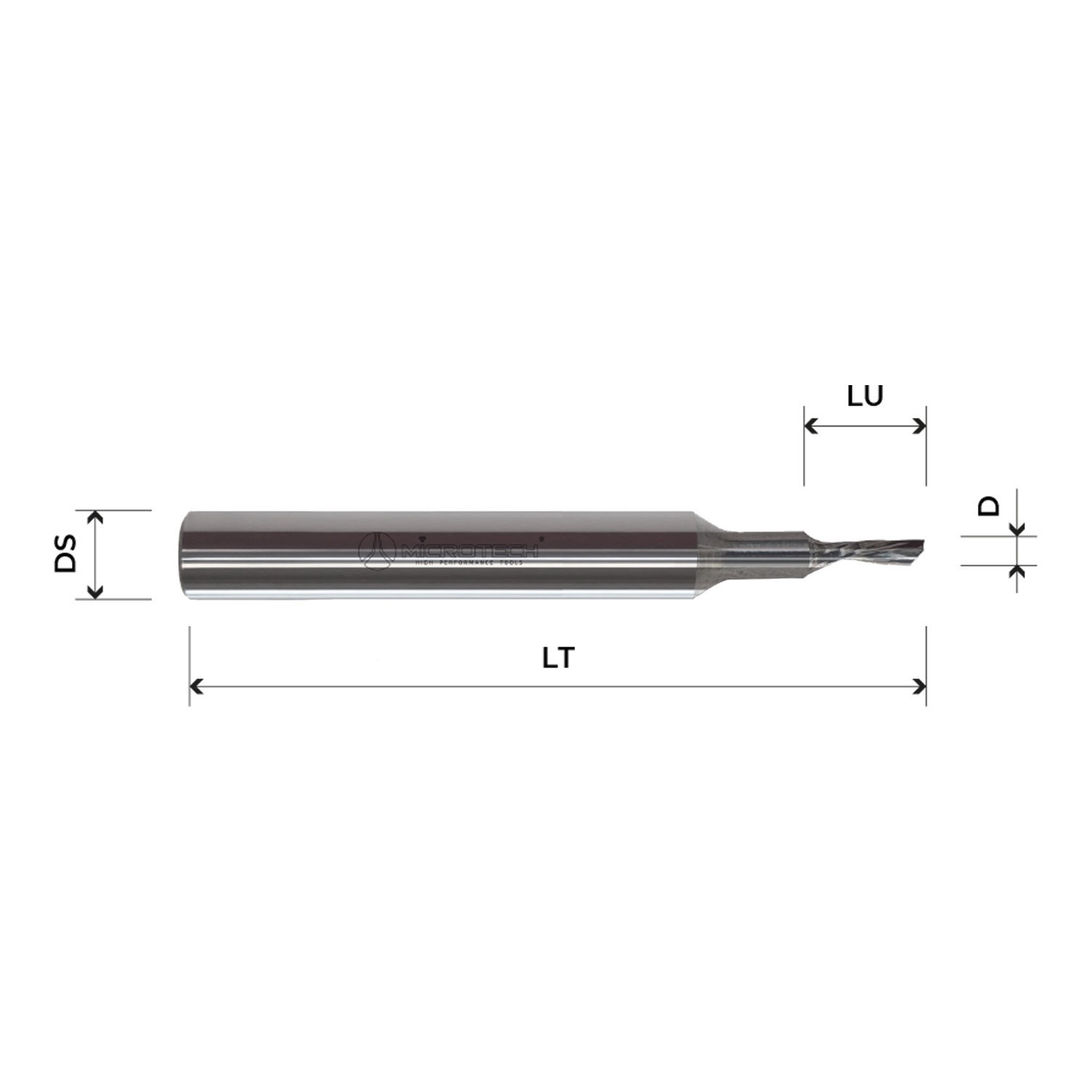

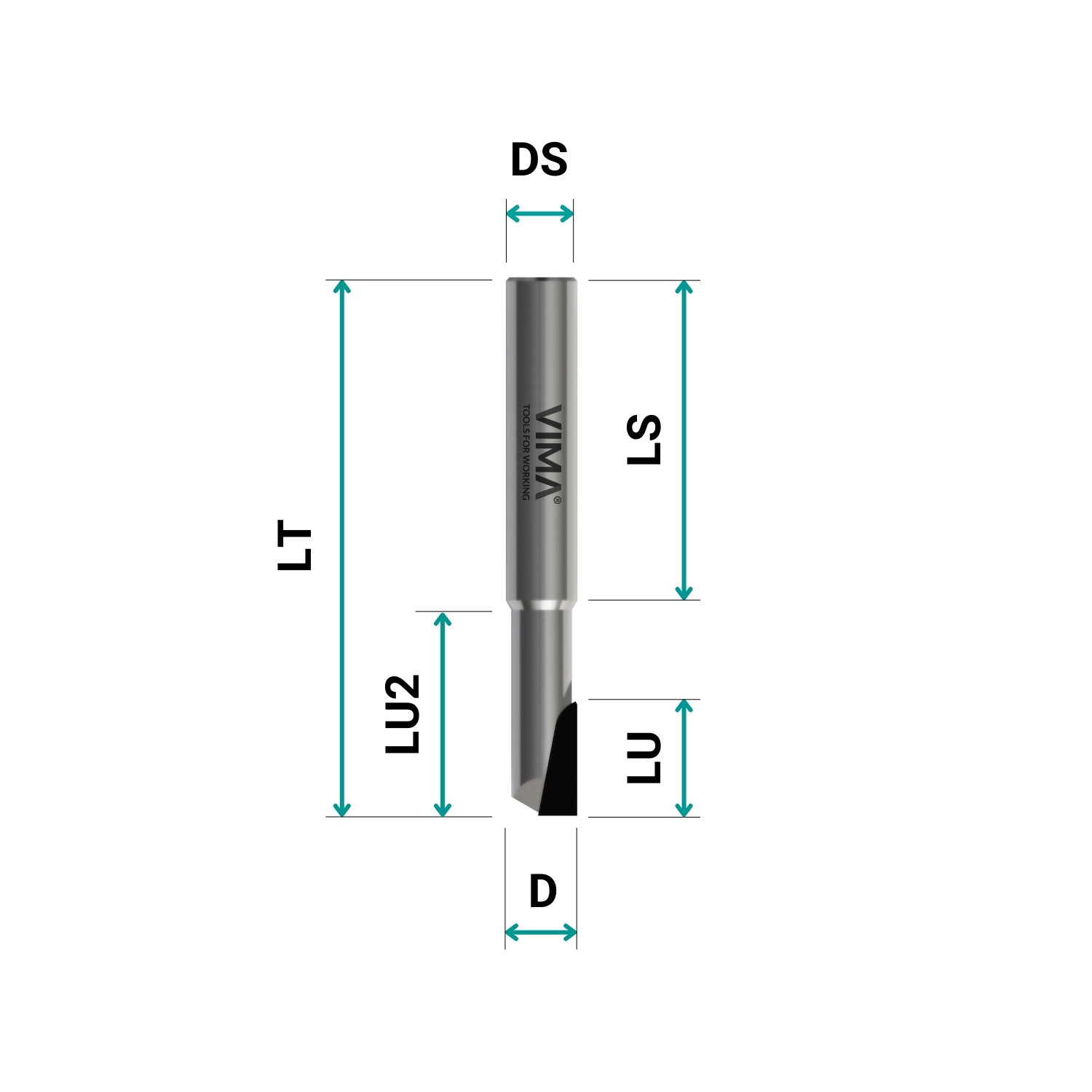

PCD diamond Z1+1 router bit designed for cutting channels and profiling on panels and wood-based materials with high accuracy. The cost-effective H2.5 mm PCD tip and the heavy DENSIMET body deliver stability on small diameters and consistent finish. Made in Italy.

• PCD H2.5 mm tip resharpenable up to 3 times

• Z1+1 geometry for clean channels and profiling

• Heavy DENSIMET body for rigidity and low vibration

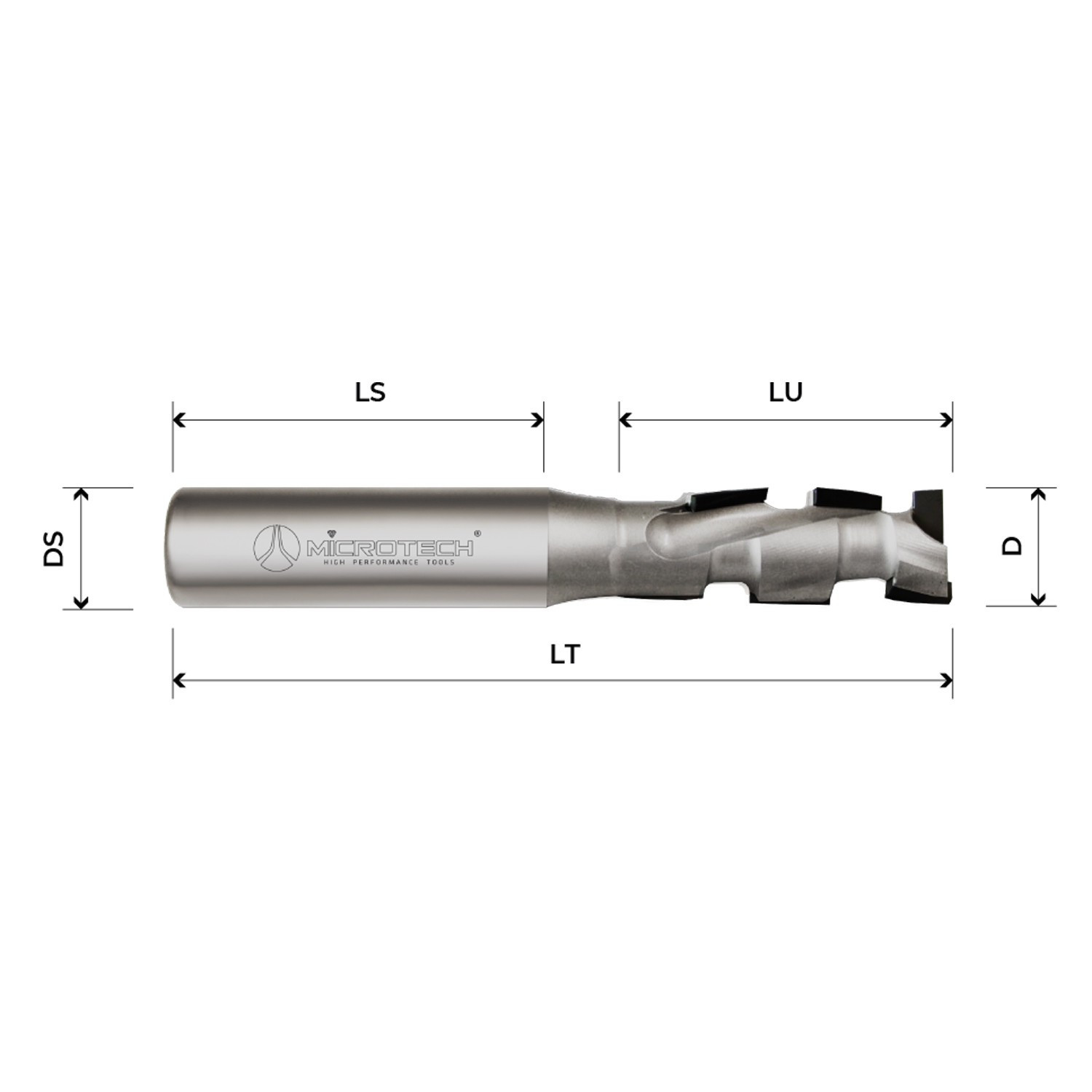

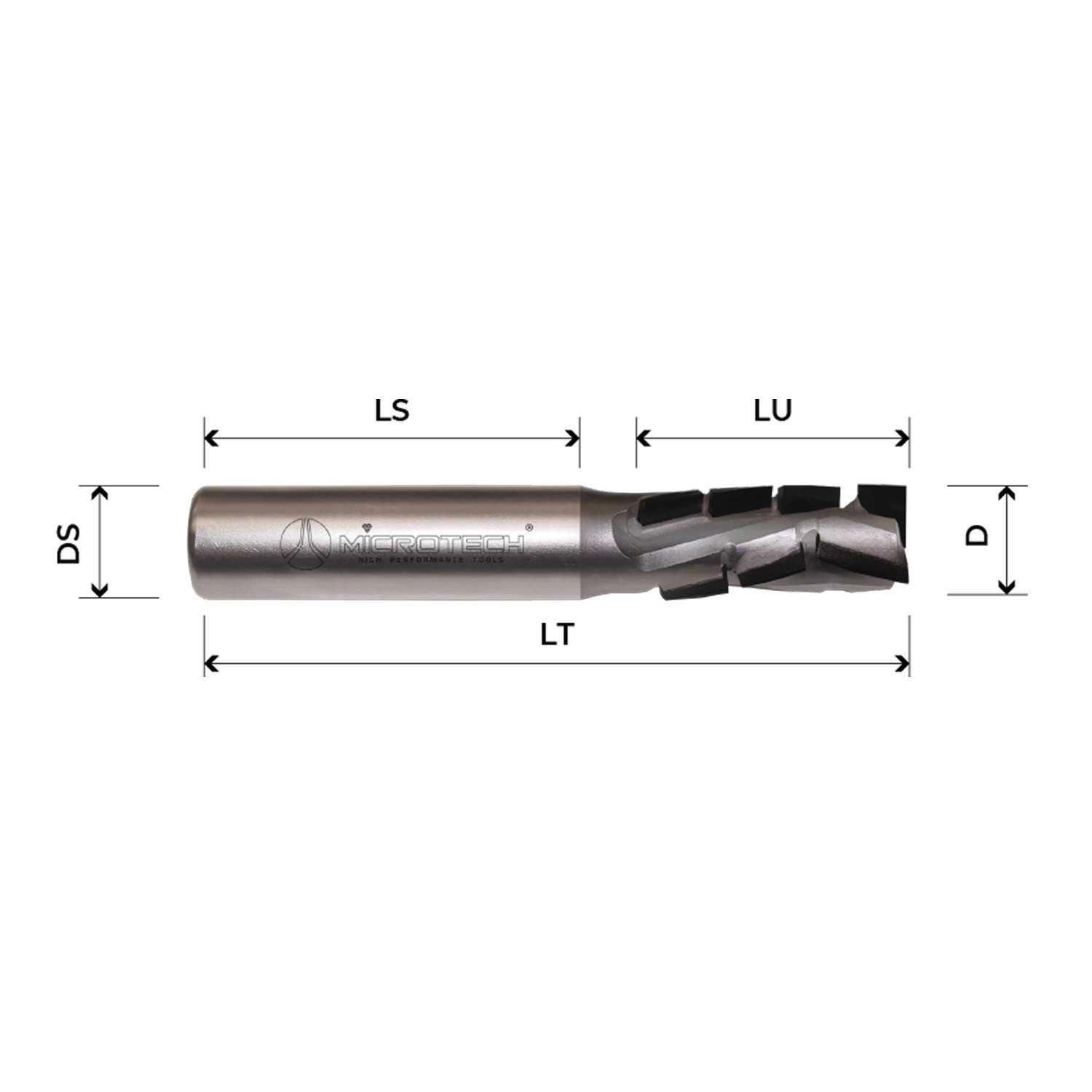

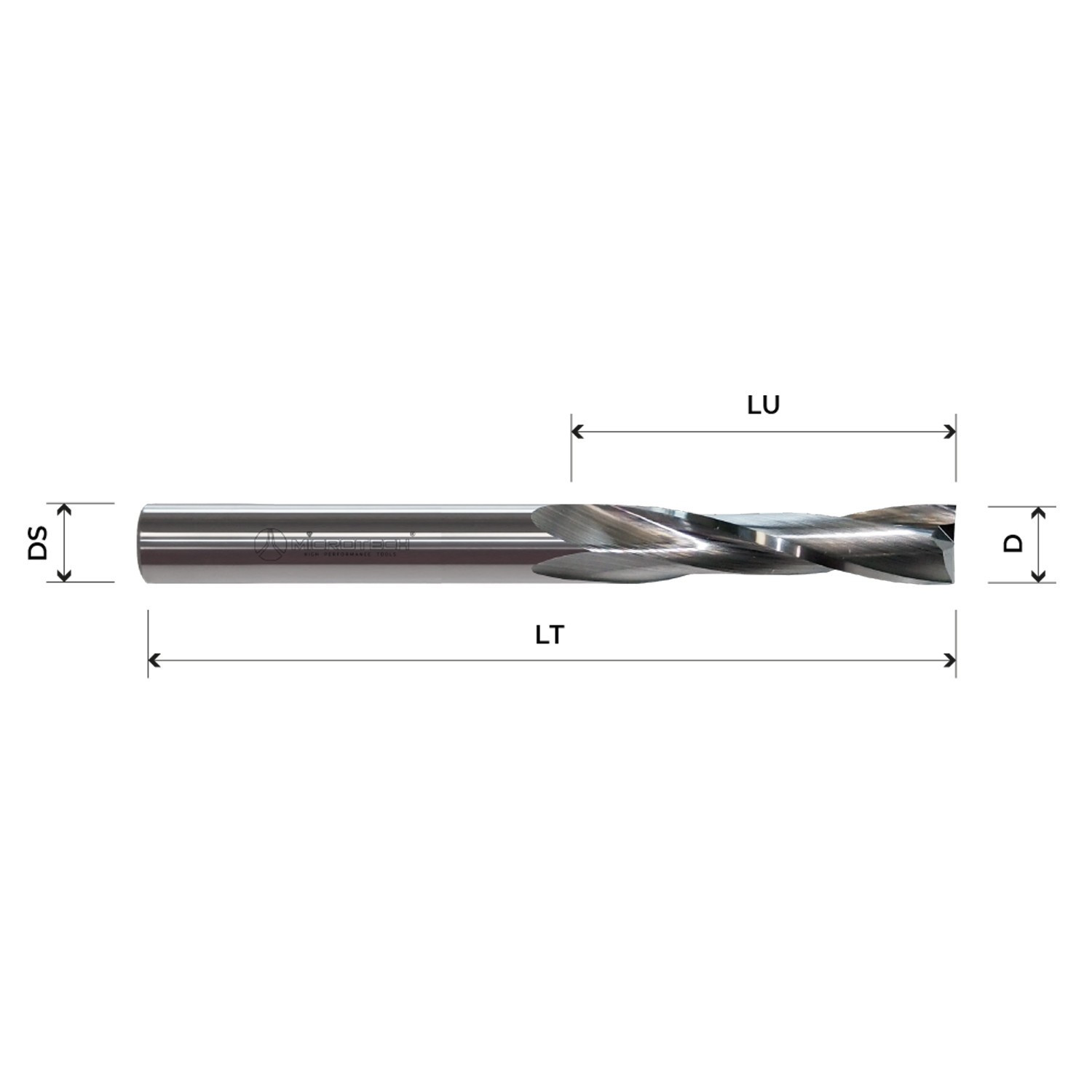

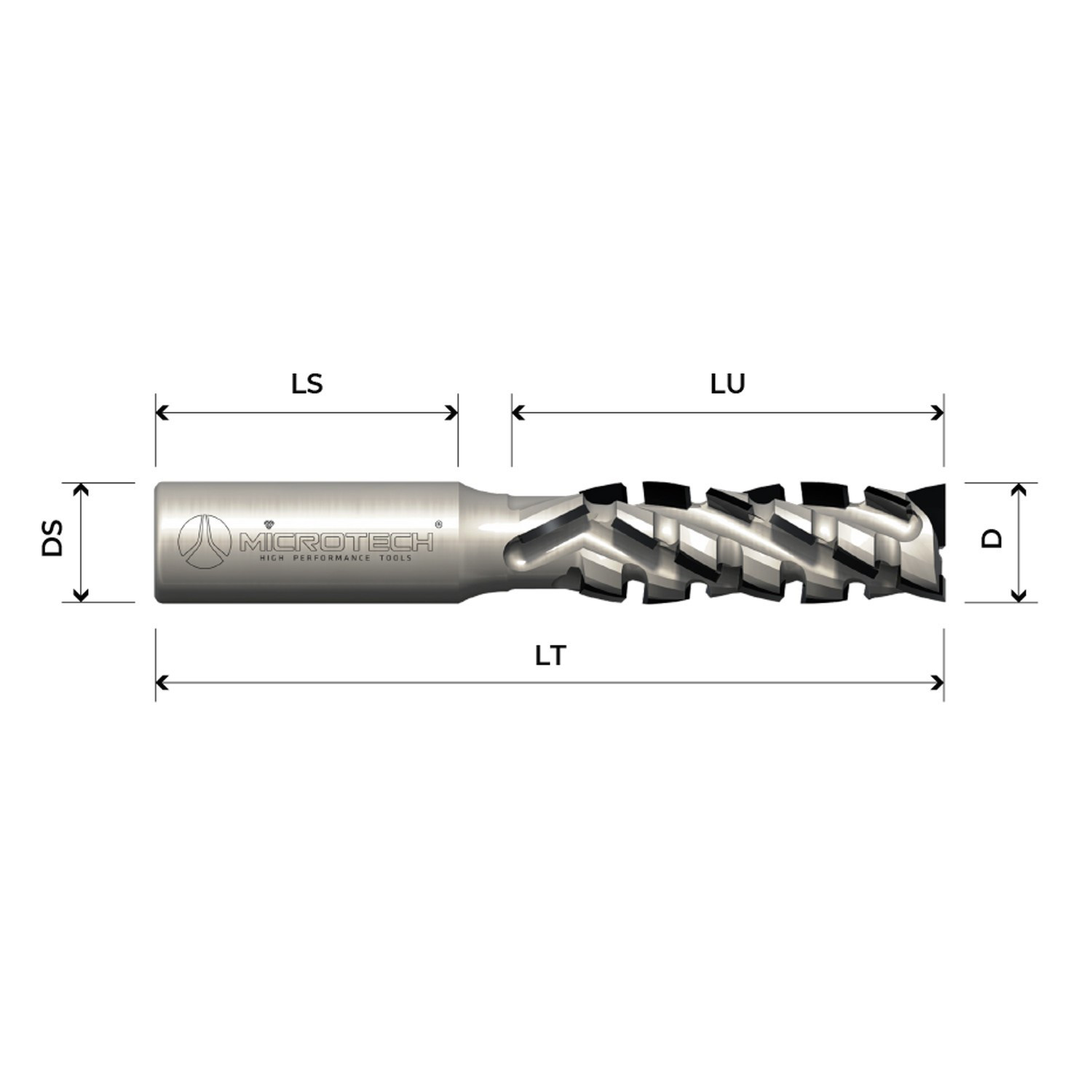

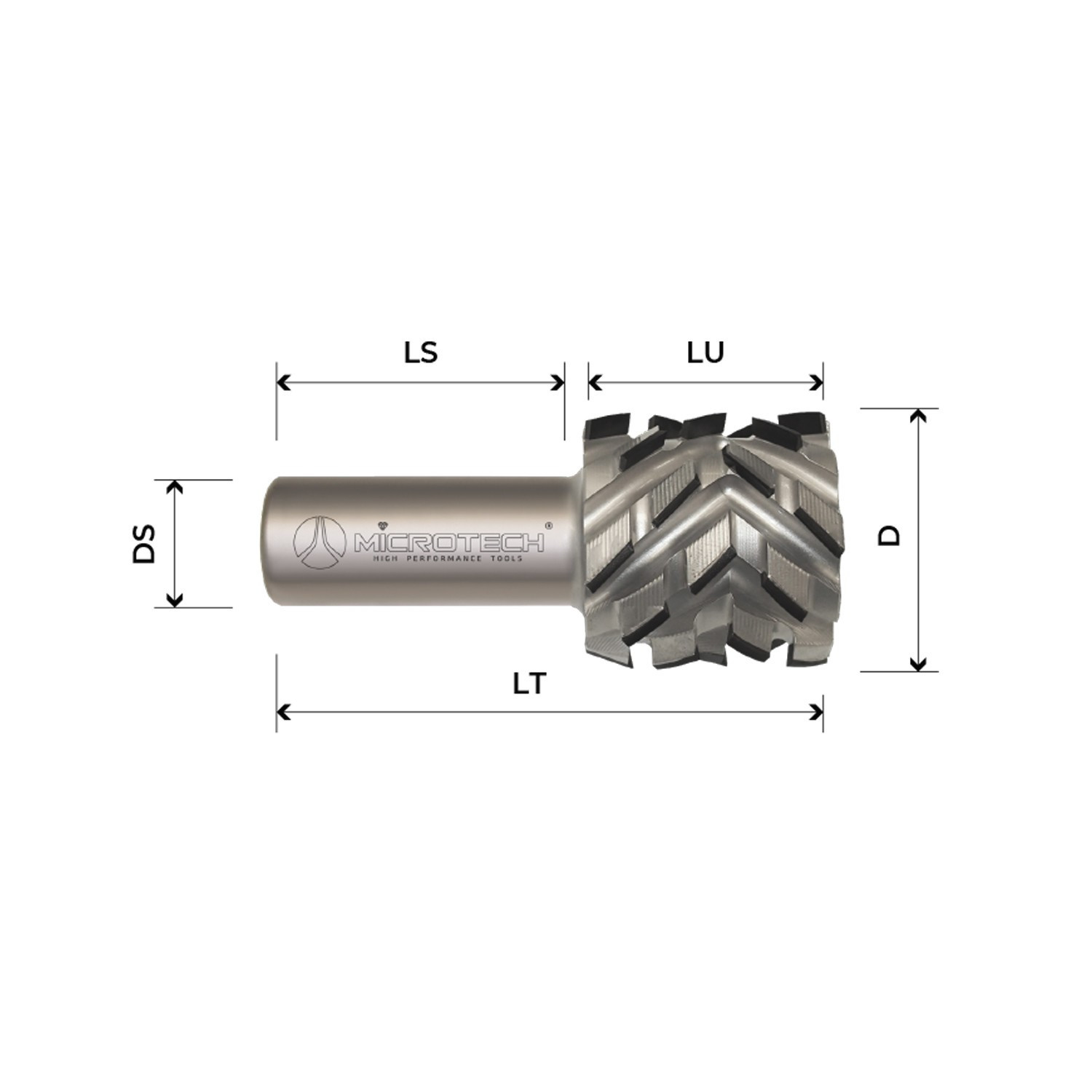

Nesting helical cutter in PCD diamond with Z2+2 geometry and 25° axial angle, built for CNC profiling and nesting with mechanical feed. The steel body delivers stiffness and stable cutting, while the enlarged chip gullet supports high feed rates and clean edges on coated panels and plywood.

• PCD H3.5mm for extended tool life and consistent cuts

• 2 flutes Z2+2 for efficient chip evacuation

• Steel body for maximum stability in nesting jobs

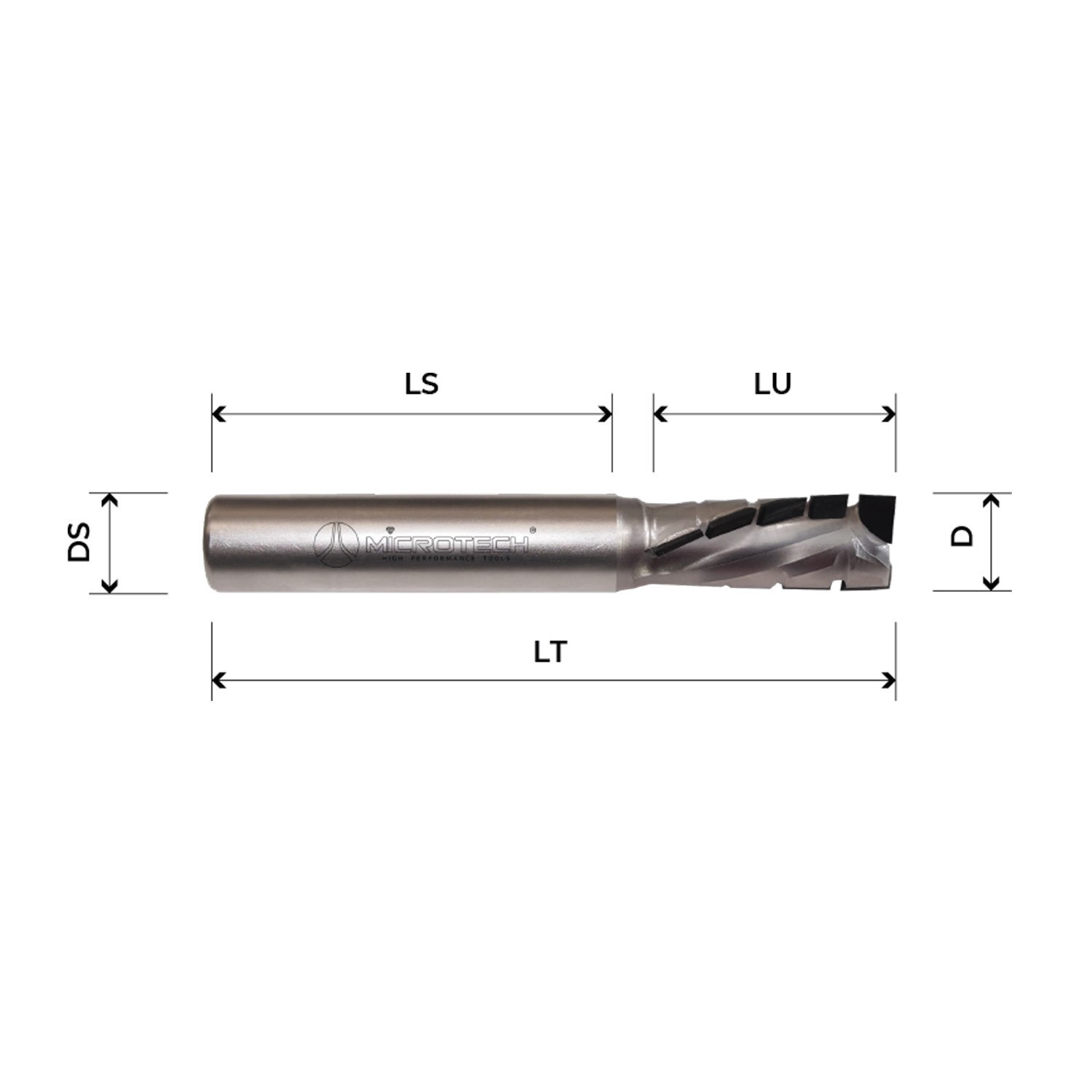

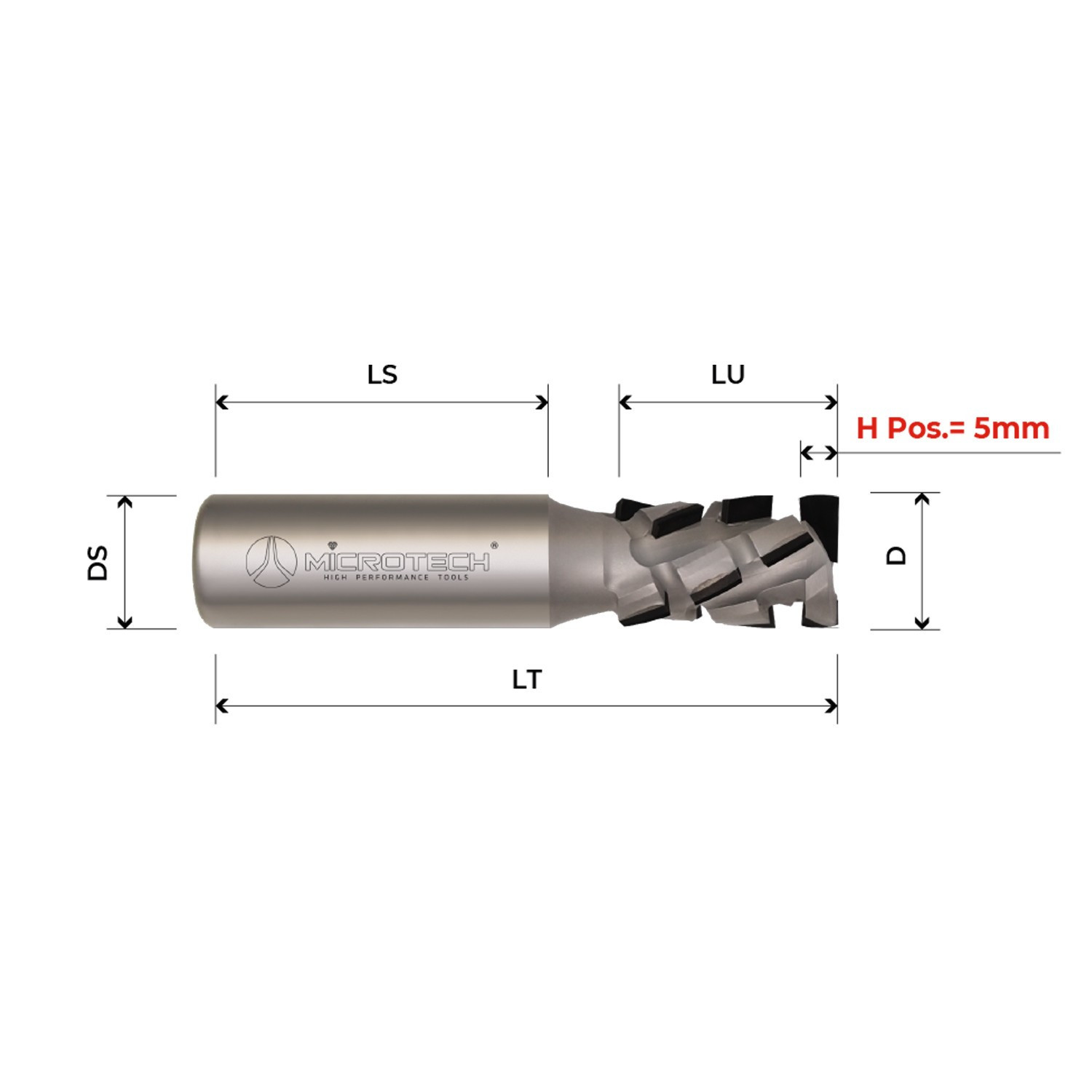

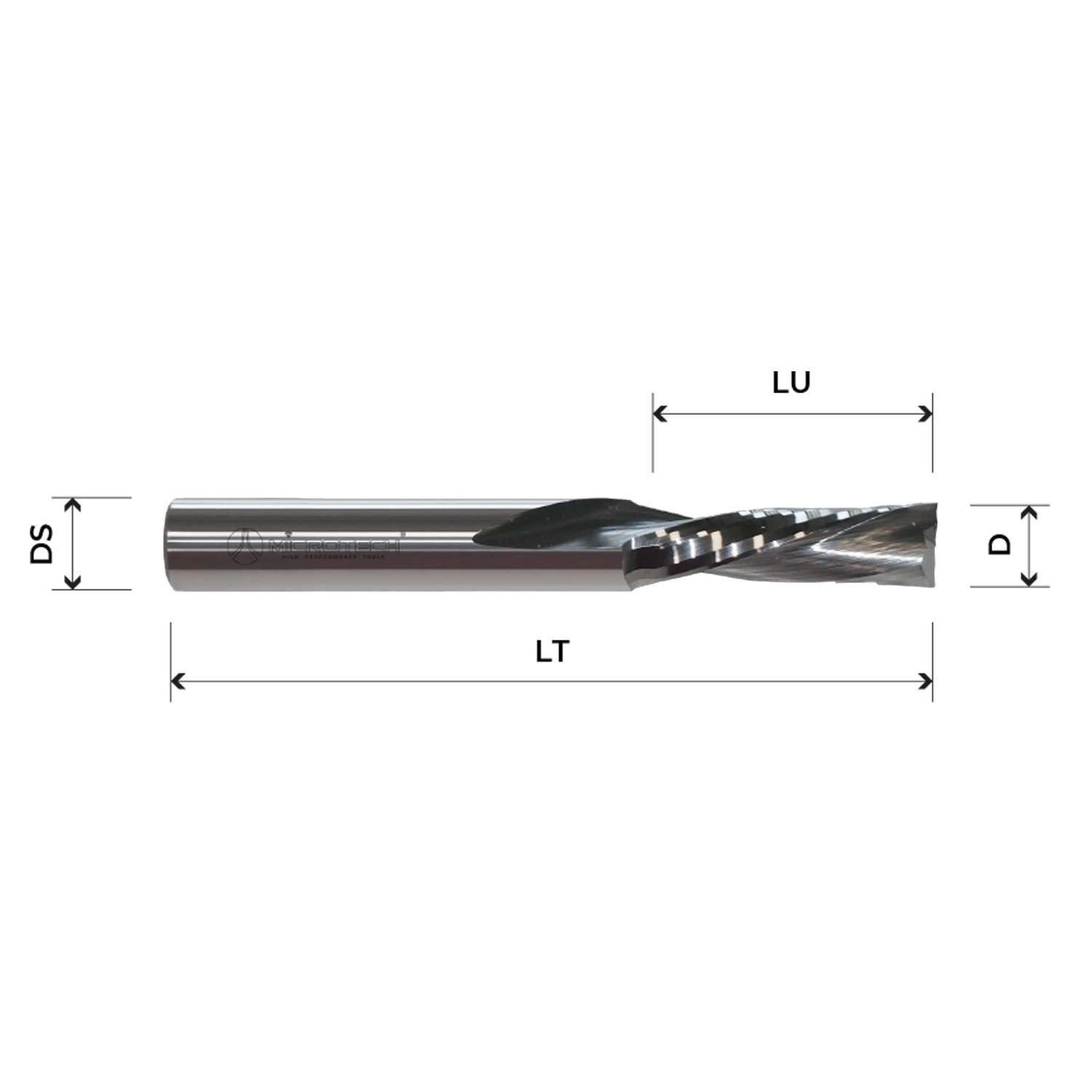

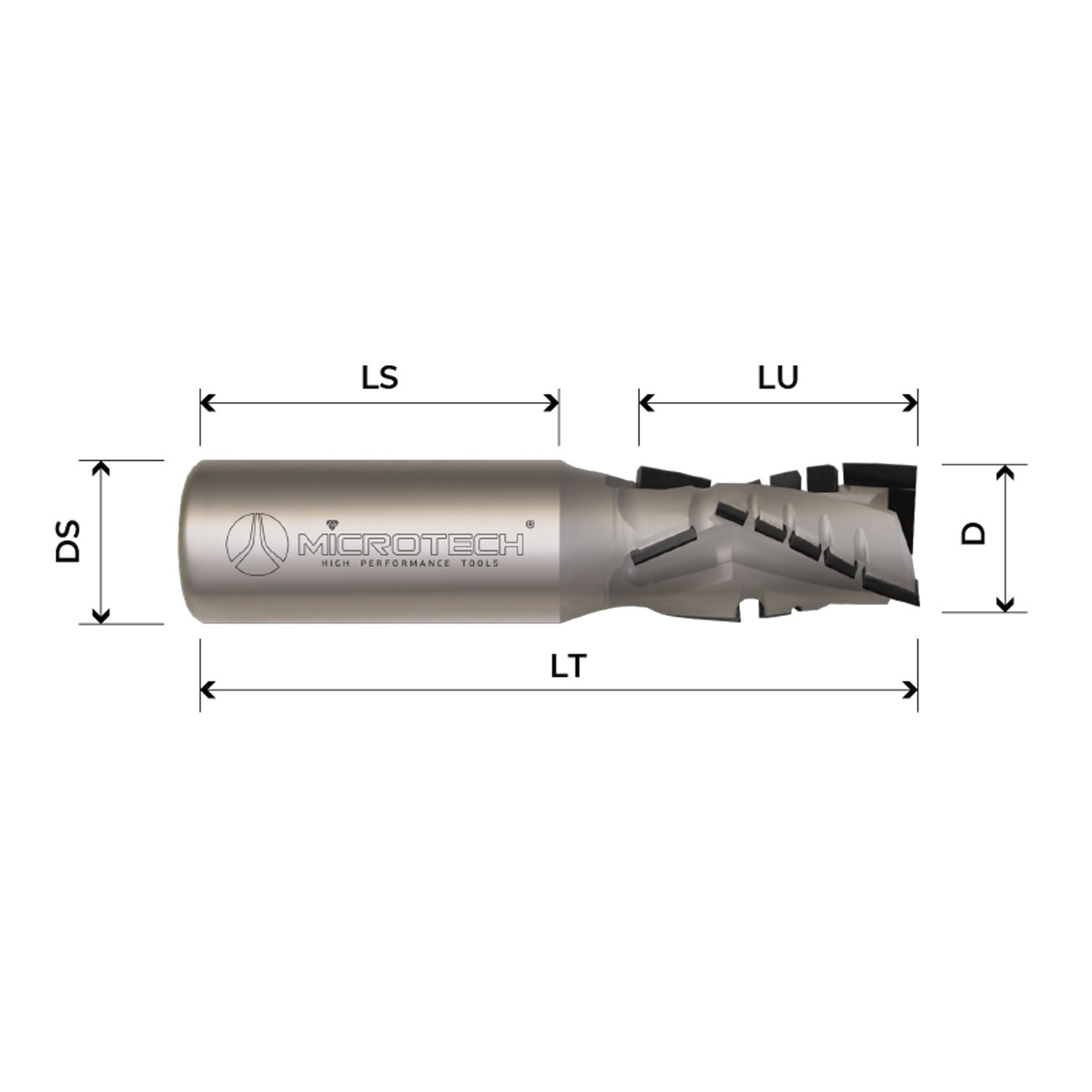

PCD helical diamond router bit Z2+2 designed for machining thin panels with mechanical feed. The 5mm positive pulling lead insert improves entry, while the following negative inserts increase stability and control, delivering excellent finishes on delicate and coated surfaces.

• PCD H4.5mm resharpenable up to 8 times for long tool life

• 5mm positive lead PCD for clean cutting on thin panels

• 30° axial angle and 4 helical divisions for finish and chip evacuation

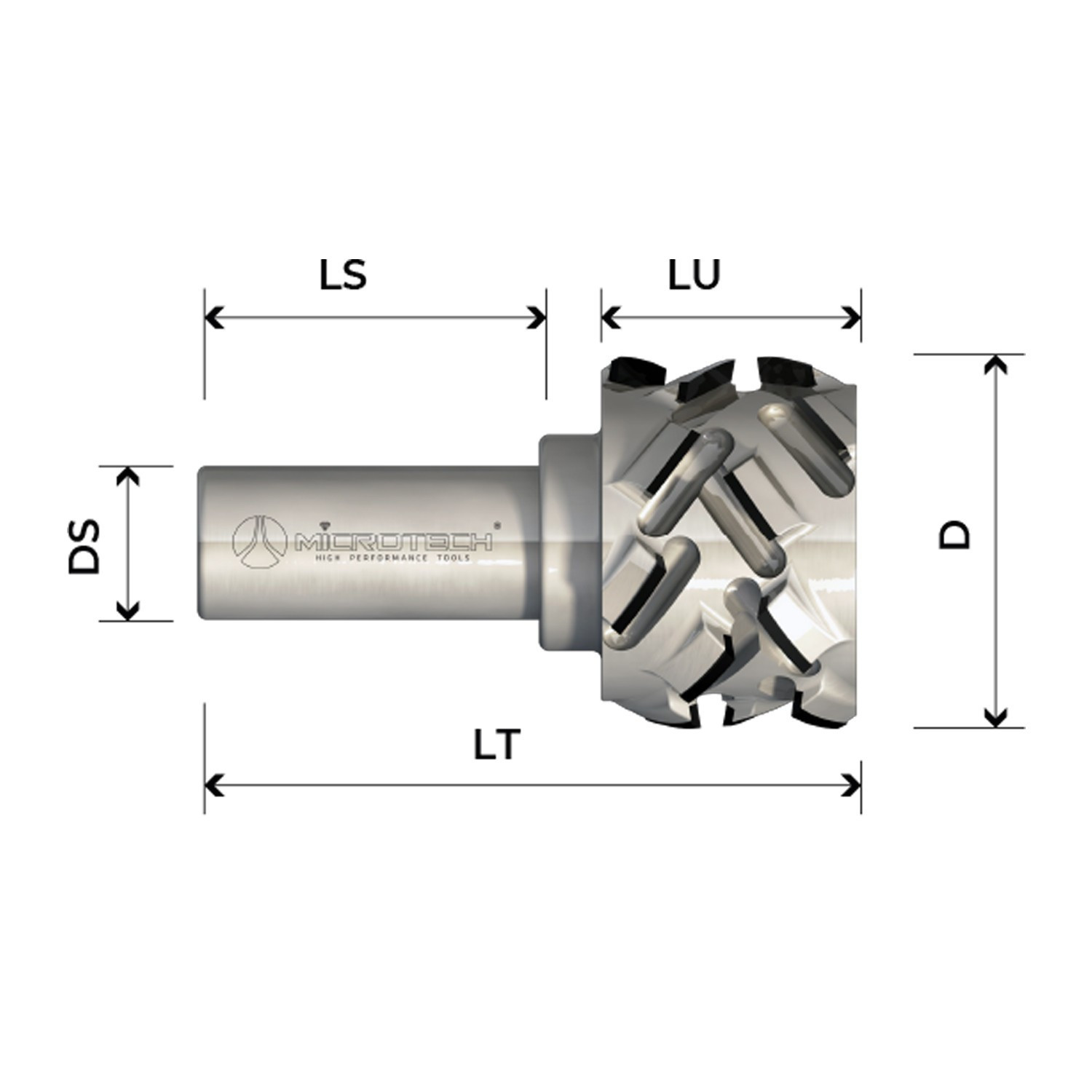

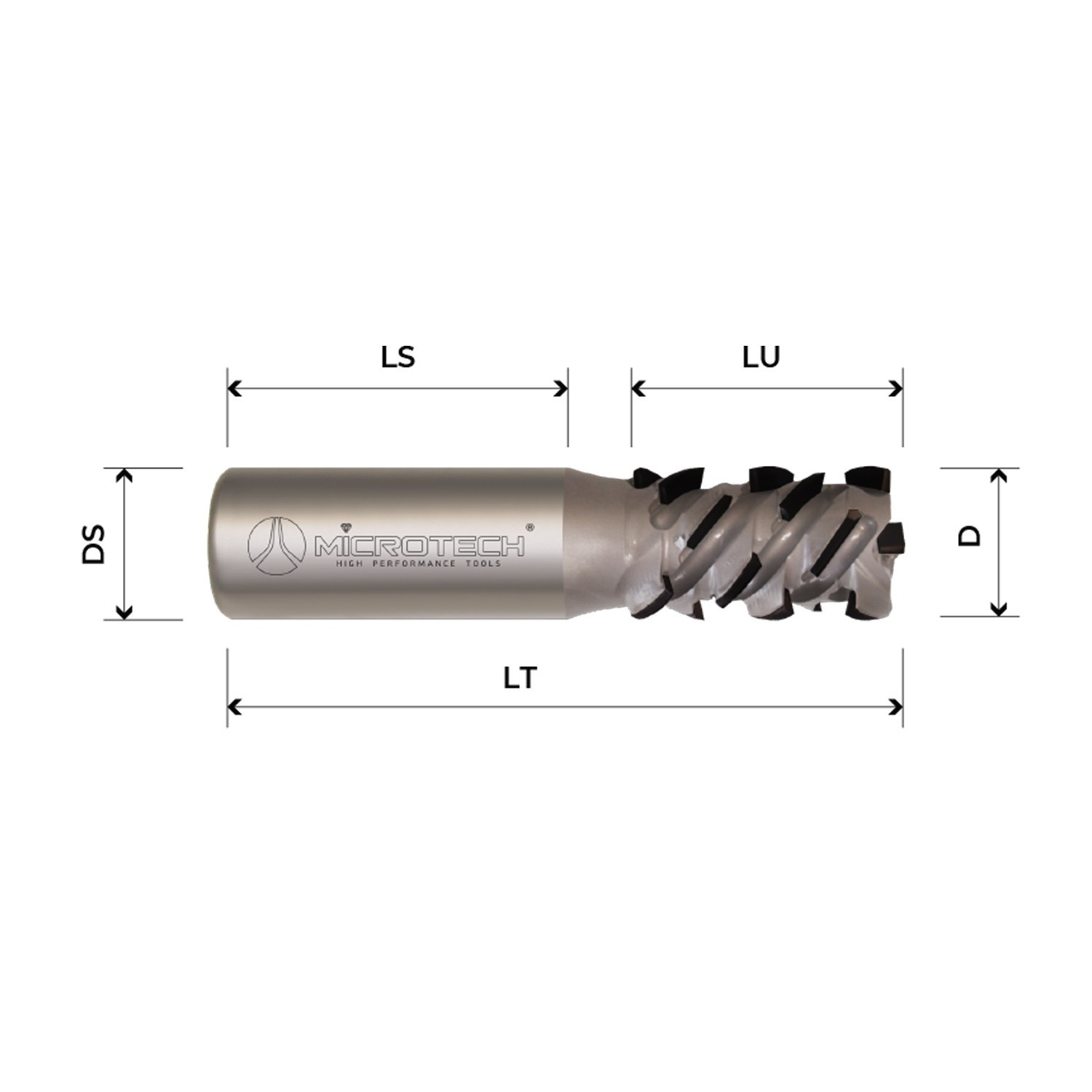

PCD helical nesting router bit Z3+3 engineered for shank profiling and high output nesting on CNC machines with mechanical feed. The interrupted helix with top and bottom cutting edges delivers stable cutting, efficient chip evacuation and a clean finish, while keeping noise and vibration low on coated panels.

• PCD Z3+3 cutting edges for stable top and bottom panel cutting

• Steel body and PCD center cutting for rigidity and accurate entry

• Interrupted helix with positive negative layout for finish and chip flow

PCD nesting diamond router bit, resharpenable and built with an interrupted helix in four divisions for CNC machining with mechanical feed on coated and decorative panels. The HDM heavy metal body boosts rigidity and enables very high feed rates with low noise, efficient chip evacuation and a clean, consistent finish.

• 3.5mm PCD, resharpenable edge for long service life and output

• HDM heavy metal body for maximum stability and reduced vibration

• Z2+2 with positive negative edges for crisp, accurate panel edges

Helical PCD diamond grinding router bit designed for profiling and edging operations on coated panels and wood based materials. The Z3+3 geometry with symmetric helix and 54.9° axial angle ensures an exceptionally clean finish even on delicate surfaces.

• 4.5 mm PCD inserts, resharpenable up to 8 times

• Z3+3 geometry for smooth and continuous finish

• 54.9° axial angle for superior surface quality

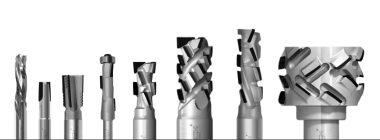

HW helical end mill with 1 flute and a positive Z1 cutting geometry, designed for grooving and shank profiling on CNC routers with mechanical feed. The positive helix promotes smooth chip evacuation and helps deliver a consistent surface finish while reducing vibration and material build-up on non-ferrous jobs.

• Single-flute HW Z1 edge for smooth cutting and clean sidewalls

• Positive helix for steady chip evacuation and less material welding

• Ideal for grooving and profiling on CNC machines with mechanical feed

HW helical end mill with a single flute and negative Z1 cutting geometry, designed for profiling and grooving with shank on CNC routers. The negative helix improves cutting control and helps prevent material lifting, delivering cleaner edges on coated and laminated panels.

• HW negative Z1 edge for controlled cutting and clean finishes

• Negative helix to reduce chipping on laminated materials

• Ideal for profiling and grooving on CNC routers

HW helical end mill with 2 flutes and a positive Z2 cutting geometry, designed for profiling, cutting and shaping with shank on CNC routers. The positive helix promotes smooth chip flow and stable cutting behaviour, ensuring consistent surface quality across a wide range of materials.

• Positive Z2 HW cutting edge for smooth and accurate cutting

• Two flutes for improved stability and controlled material removal

• Ideal for profiling, cutting and shaping on CNC machines

HW helical end mill with 2 flutes and a negative Z2 cutting geometry, designed for profiling cutting and shaping with shank on CNC machines. The negative helix improves cutting control and surface quality, reducing fibre lifting on coated and composite panels.

• Negative Z2 HW cutting edge for clean surfaces

• Two flutes for improved stability and control

• Ideal for profiling cutting and shaping on CNC

HW helical cutter with positive Z3 cutting edges designed for contouring, cutting and shaping operations on solid wood, wood based panels and plastic materials. The positive helix geometry ensures smooth cutting action, reduced cutting forces and improved surface finish even during continuous machining.

• HW Z3 cutting edges for clean and consistent finish

• Positive helix for efficient chip evacuation

• Ideal for CNC routers and mechanical feed systems

HW helical cutter with negative Z3 cutting edges designed for contouring, cutting and shaping operations on solid wood and wood based panels. The negative helix improves process control, helps reduce chipping on laminated surfaces and provides stable cutting performance with mechanical feed.

• HW Z3 cutting edges with negative helix for cleaner edges

• Better control and stability on laminated panels

• Ideal for CNC routers and pantographs up to 24,000 rpm

Coated carbide helical cutter with up down Z2+2 geometry, developed for high speed nesting applications on wood based panels and composite materials. Provides clean finishing on both top and bottom surfaces with long tool life.

• Up down Z2+2 geometry for double side finishing

• Coated carbide for extended durability

• Ideal for high speed nesting operations

PCD pantograph router bit designed for contouring on pantographs and CNC machines. The Z3+3 configuration and predominantly positive axial geometry promote excellent chip evacuation and a clean finish, even on coated panels.

• PCD inserts H 4.5 mm, regrindable up to 8 times

• Z3+3 geometry for precise, stable contouring

• Special steel body for rigidity and long service life

Helical CNC PCD router bit designed for contouring on pantographs and CNC machines. The predominantly positive axial geometry combined with a 30° axial angle promotes efficient chip evacuation toward the shank and superior surface finishes on panels.

• PCD inserts H 4.5 mm, regrindable up to 8 times

• Z2+2 geometry for stable, precise contours

• 30° axial angle for high-quality finishing

PCD pantograph router bit designed for high-precision contouring on coated panels, MDF and plywood. The 54.9° axial angle ensures optimal chip evacuation and clean surfaces even when cutting against the grain.

• High-strength PCD diamond cutting edges H 4.5 mm

• Positive axial geometry for superior finishing on delicate panels

• Ideal for pantographs and CNC machines

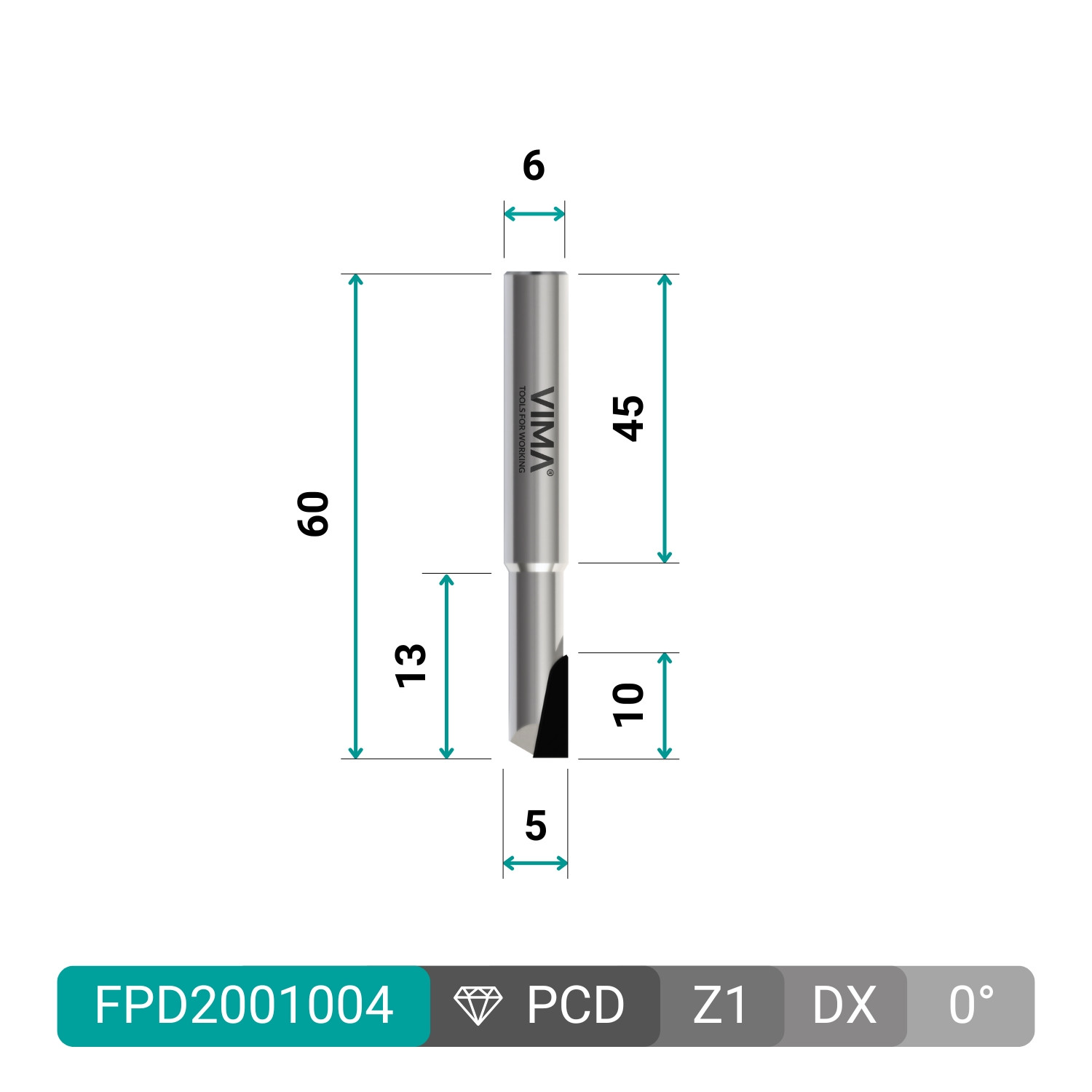

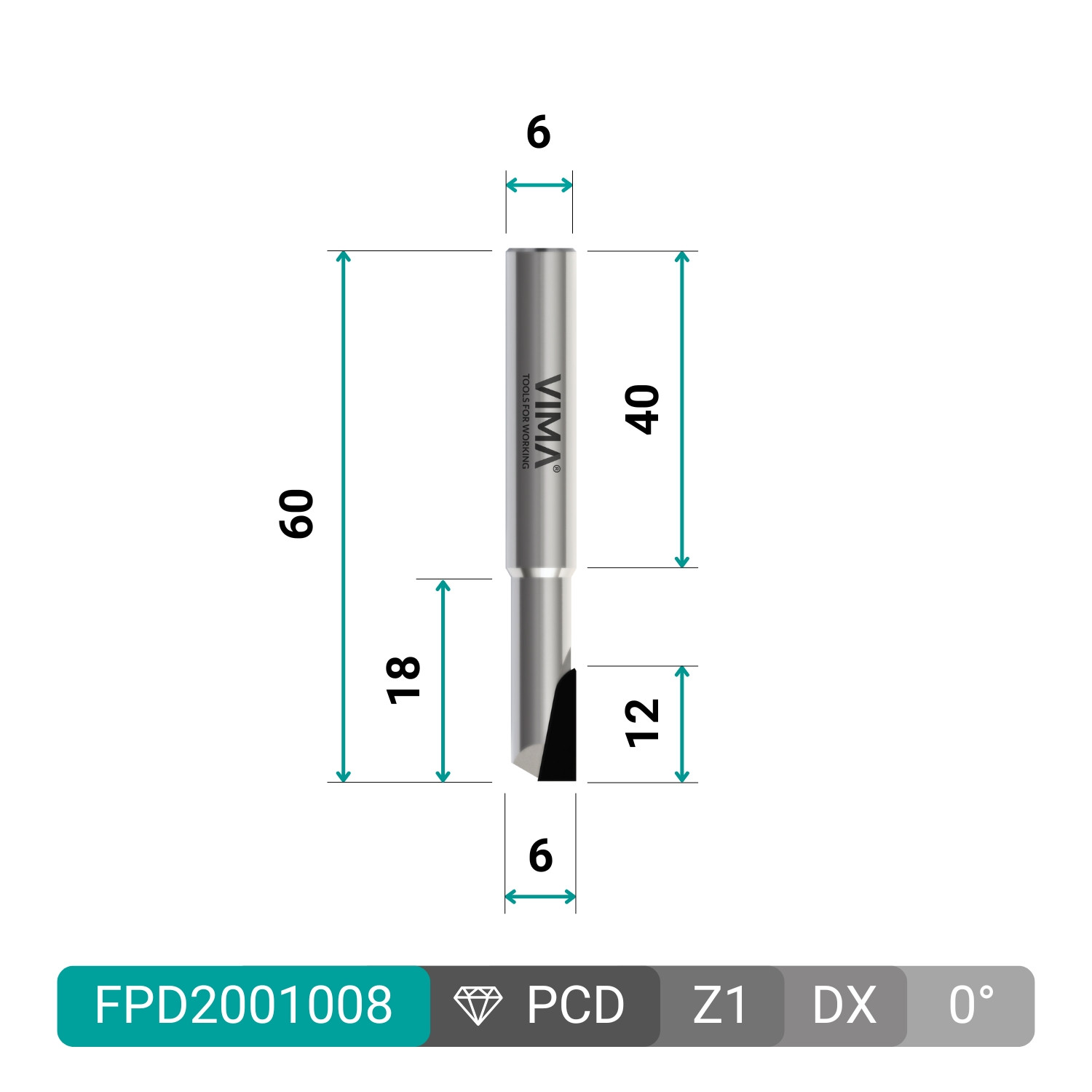

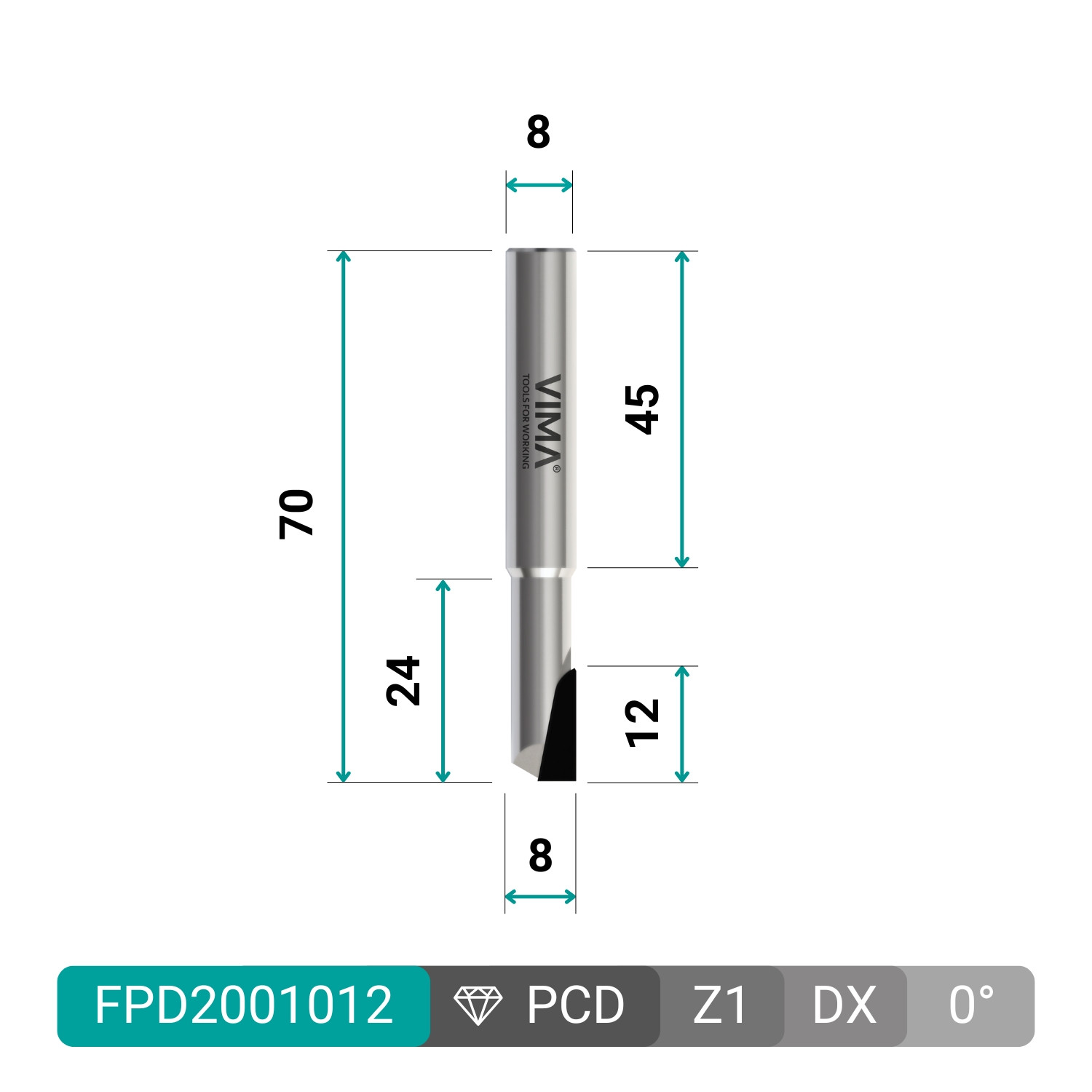

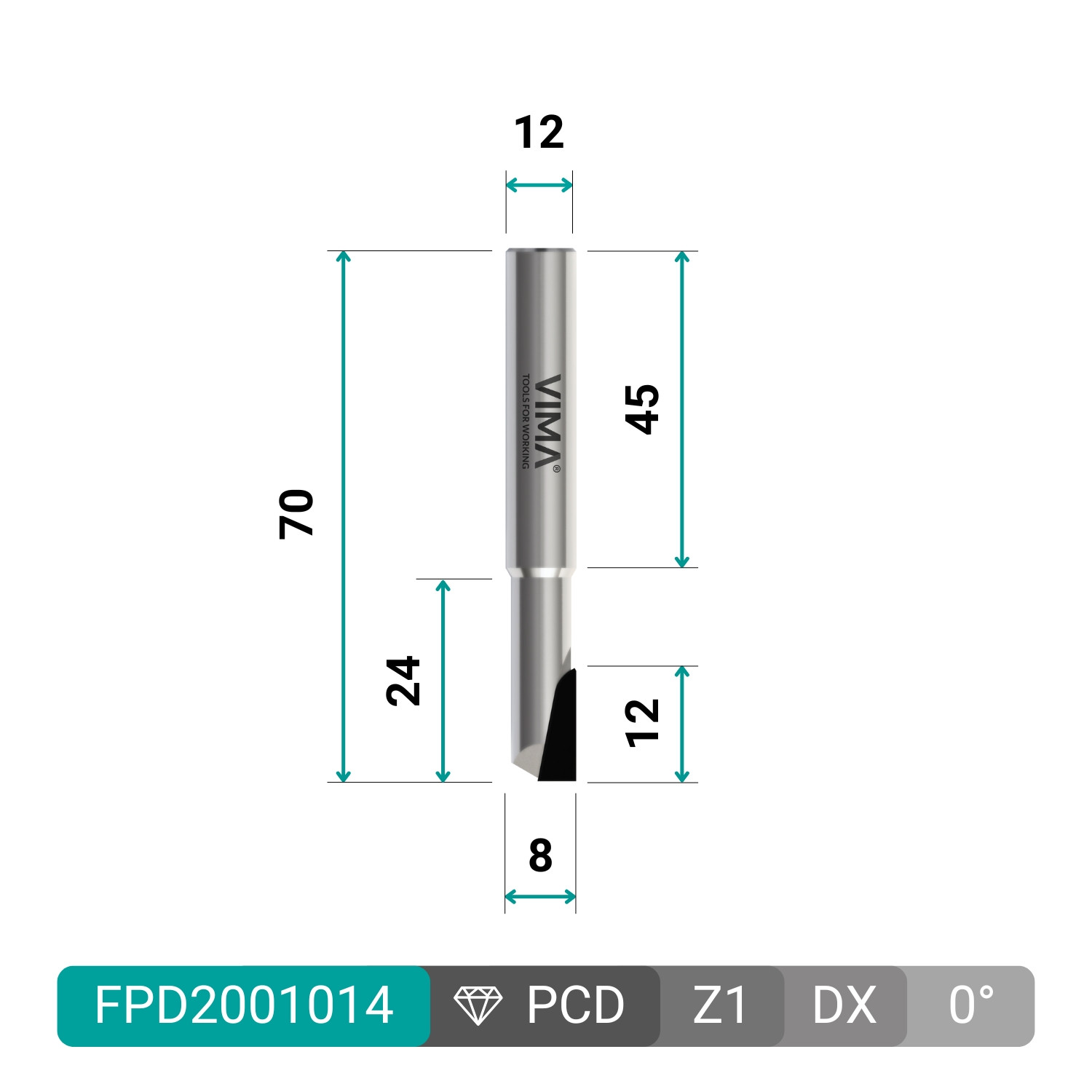

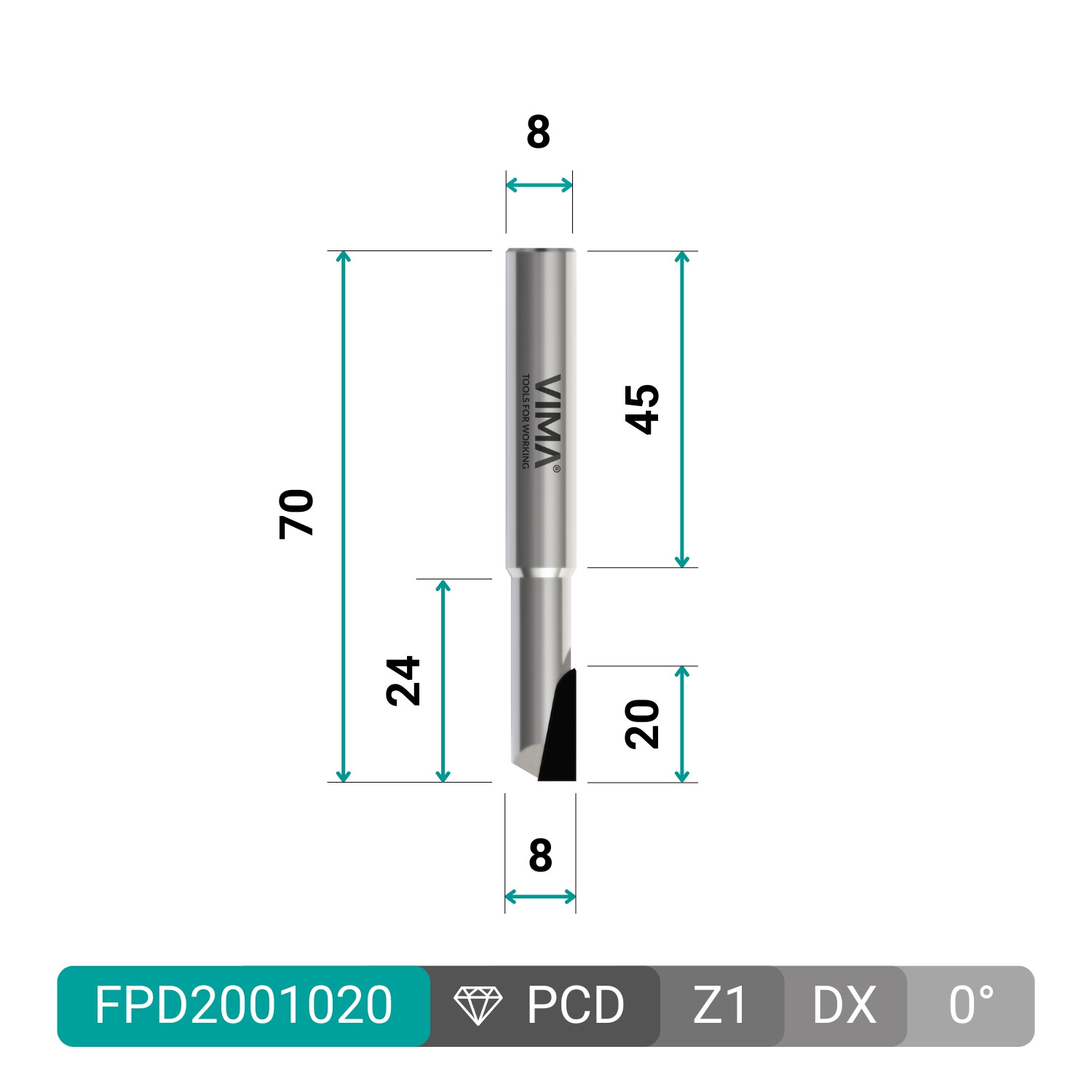

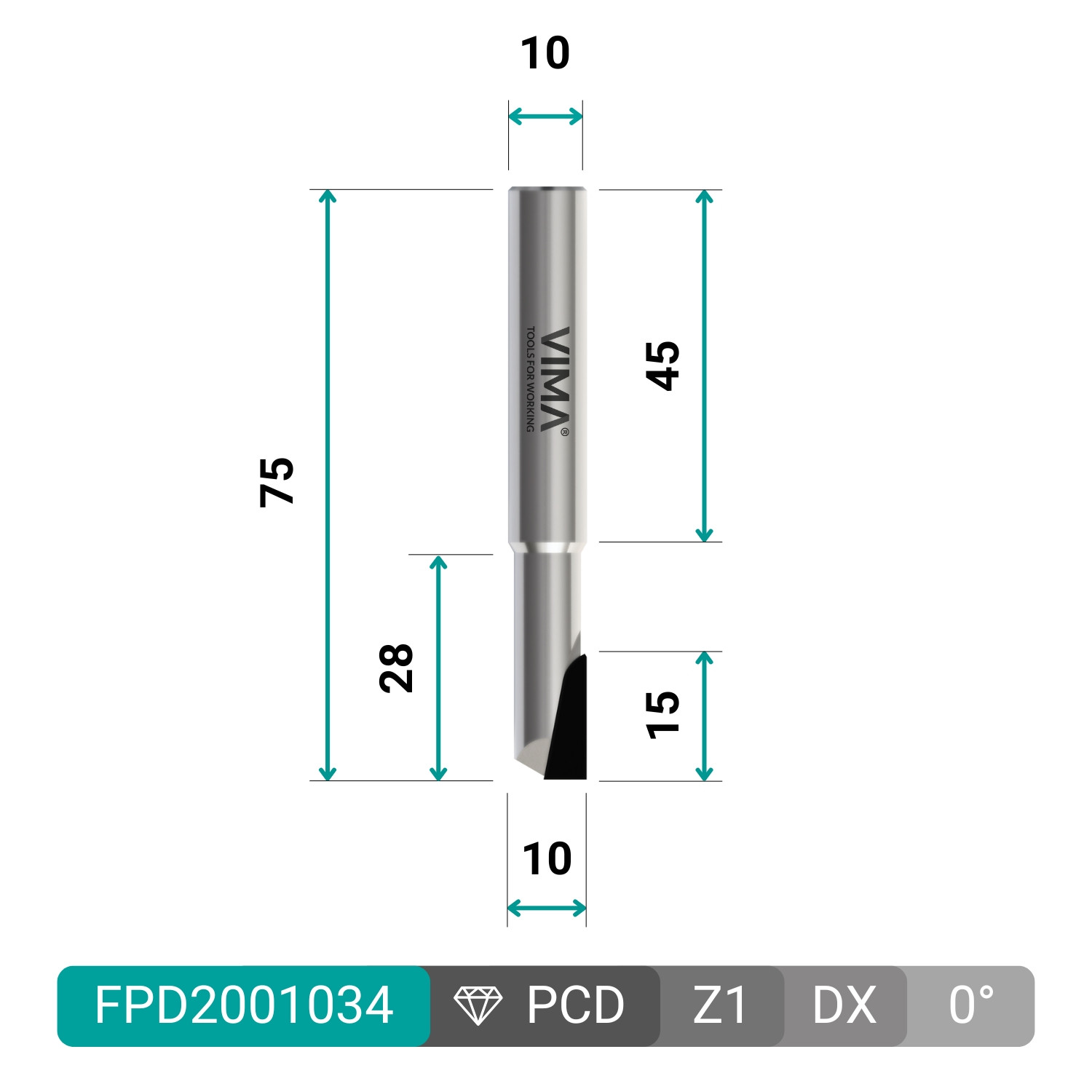

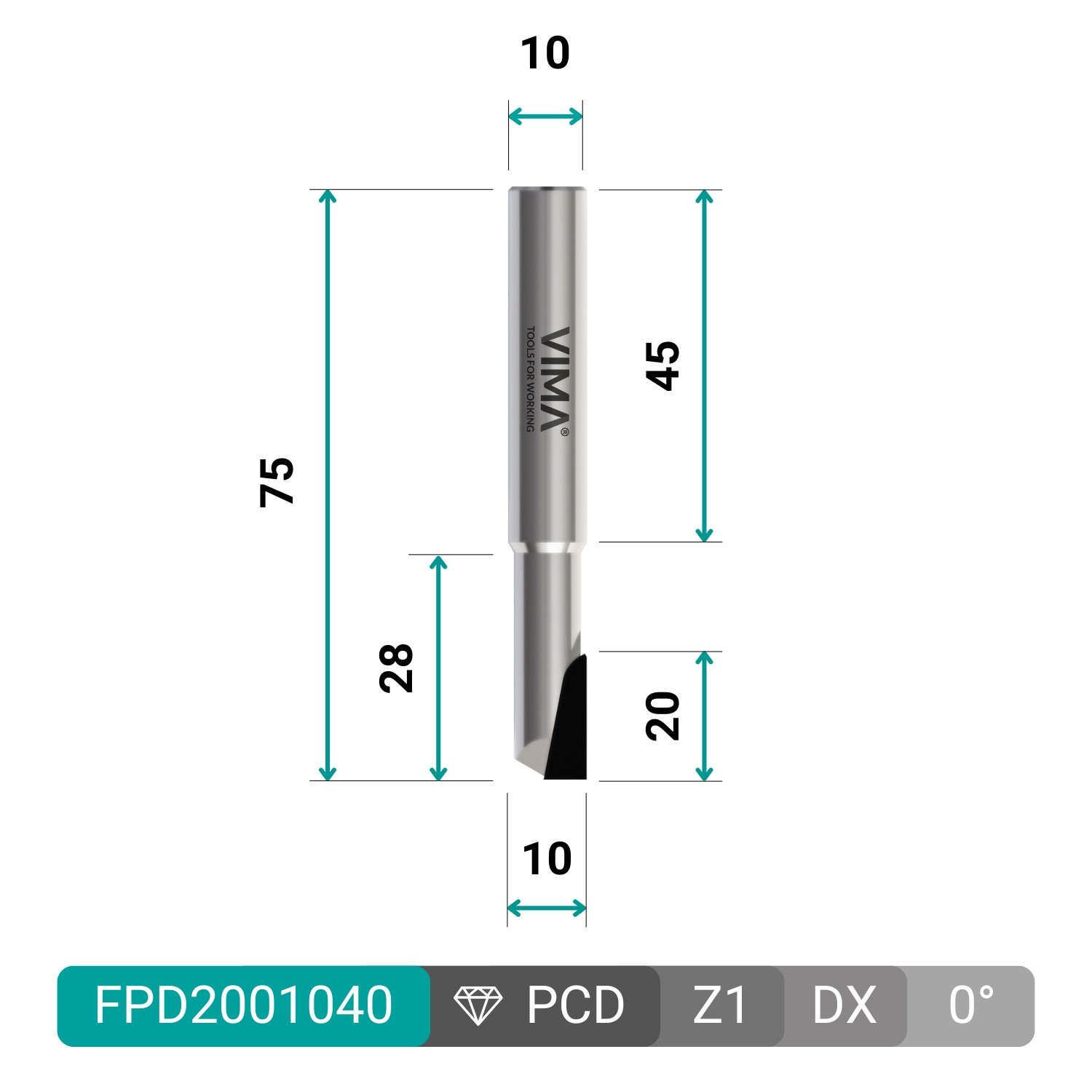

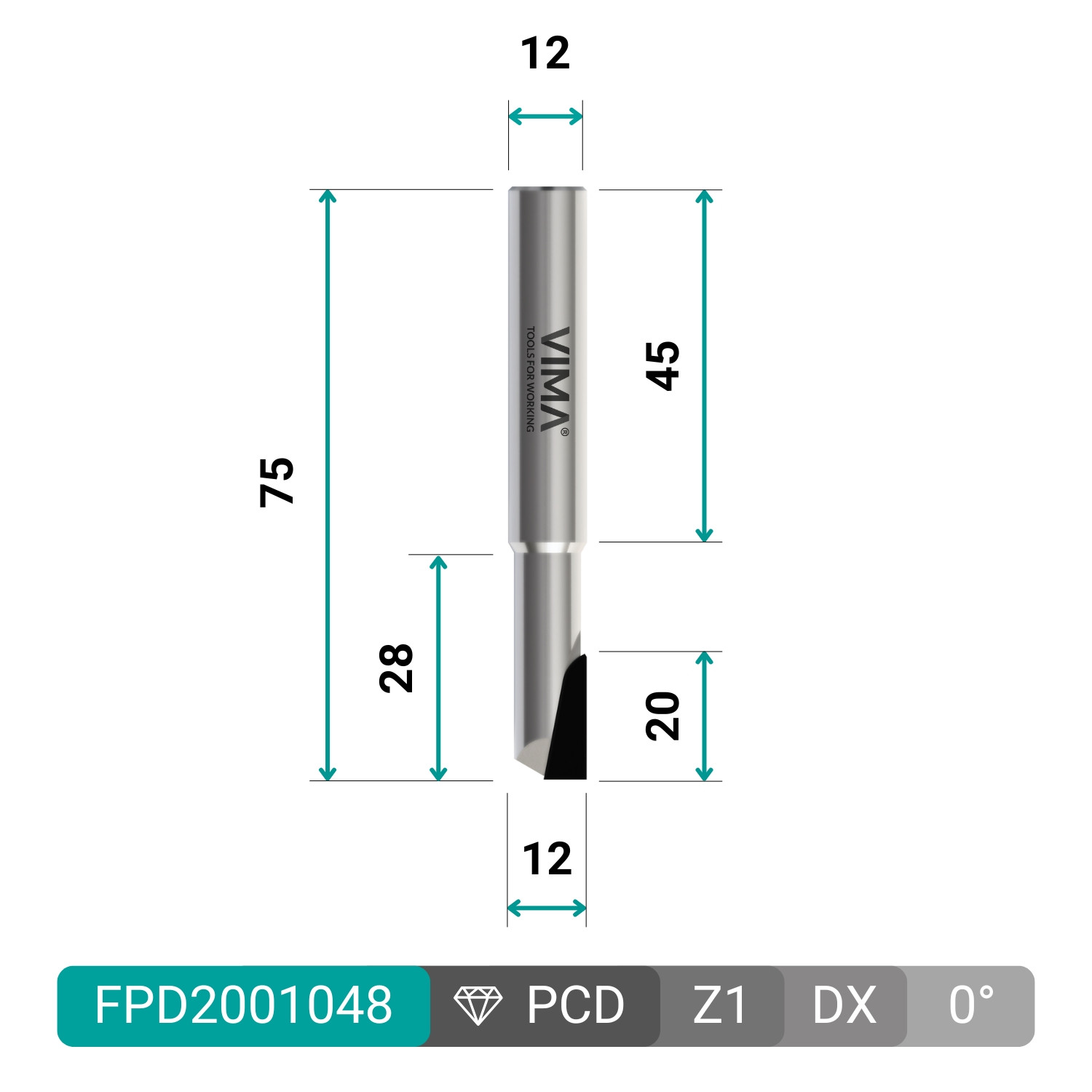

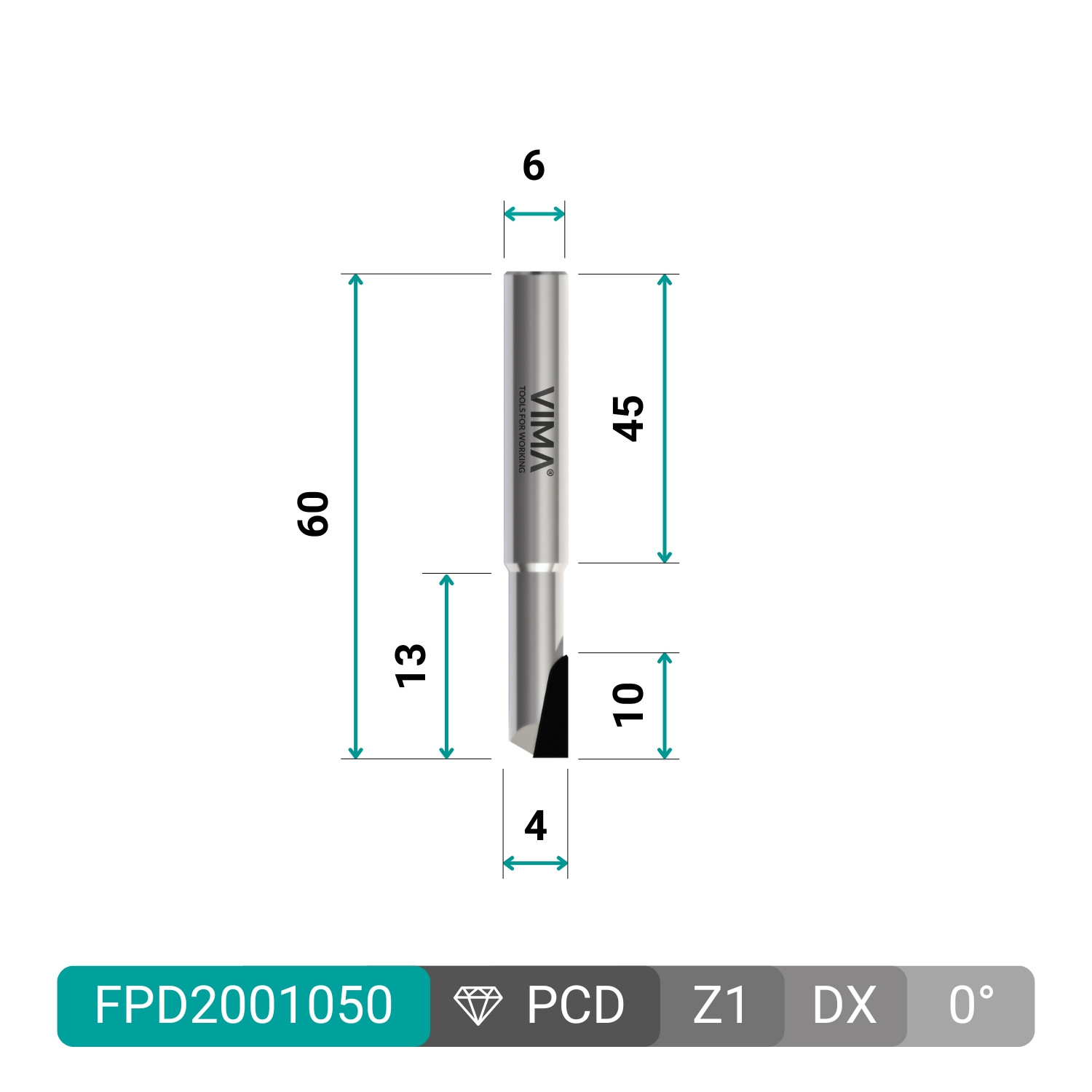

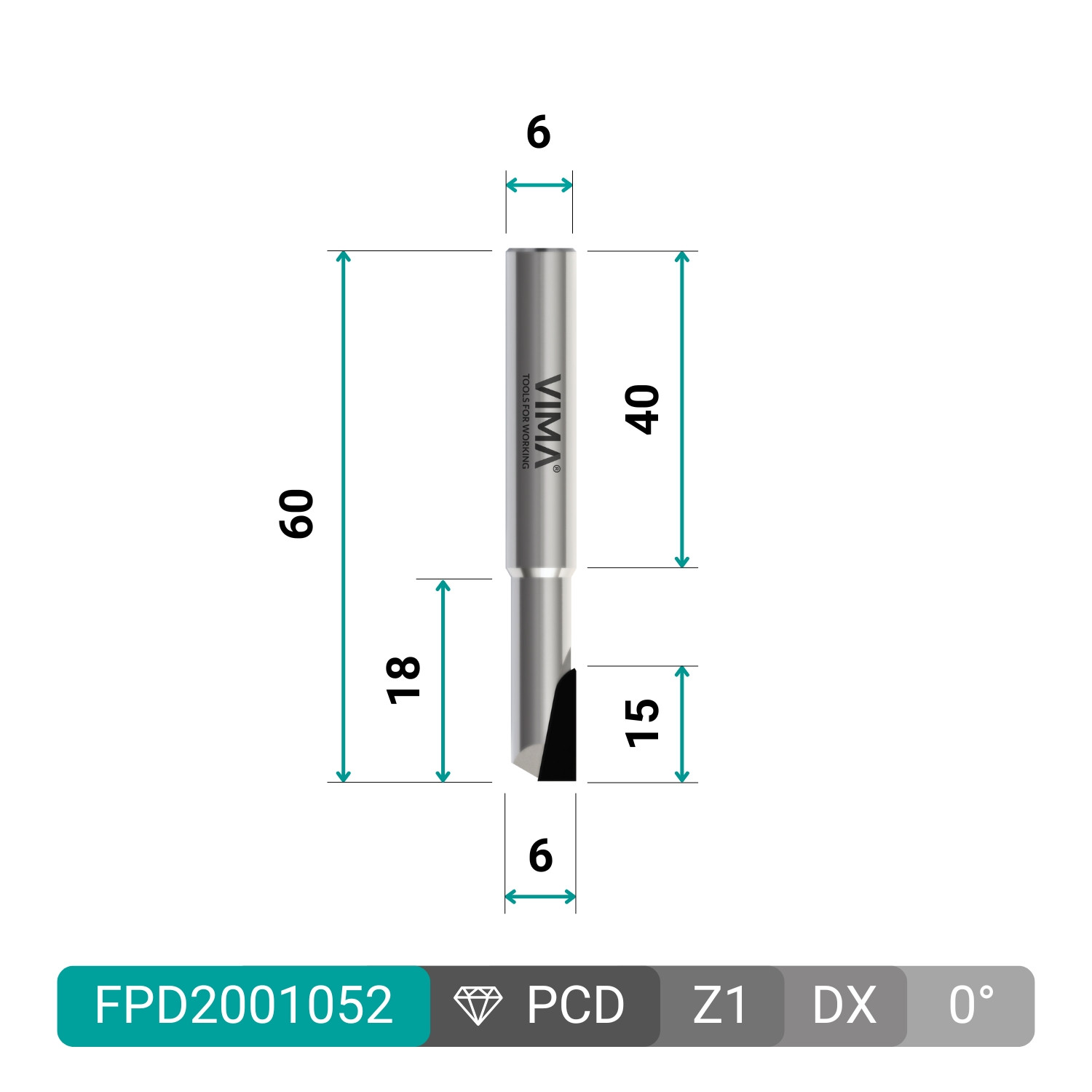

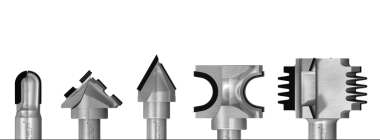

PCD diamond router bit designed for grooving and contouring operations on CNC machines with manual or mechanical feed. The straight Z1 cutting edge and solid HW body ensure cutting stability, clean finishing and extended tool life.

• PCD cutting edge H 3.5 mm for long service life

• Straight Z1 geometry for controlled cutting

• Solid HW body for rigidity and precision

PCD diamond tool developed for edge finishing and trimming on laminated panels where high edge quality is required. The helical layout with centre-converging symmetry and 40° axial angle delivers stable cutting and a uniform surface even in intensive CNC cycles.

• PCD inserts H 4.5 mm regrindable up to 8 times

• 8 helical divisions with symmetric geometry for consistent finish

• Steel body for rigidity and accuracy with mechanical feed

Carbide helical cutter with up down Z2+2 geometry, designed to achieve clean finishes on both top and bottom surfaces of the workpiece. Ideal for contouring cutting and shaping operations on wood based materials and plastics.

• Up down Z2+2 geometry for double side finishing

• Solid carbide cutting edges for precision

• Suitable for contouring cutting and shaping

Positive helix carbide end mill Z3 with chipbreaker designed for finishing contouring, cutting and profiling on wood and composite materials. Provides high surface quality and controlled chip evacuation.

• Positive helix Z3 carbide cutting edges

• Integrated chipbreaker for smooth chip control

• Ideal for finishing contouring and profiling

.jpg)