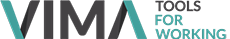

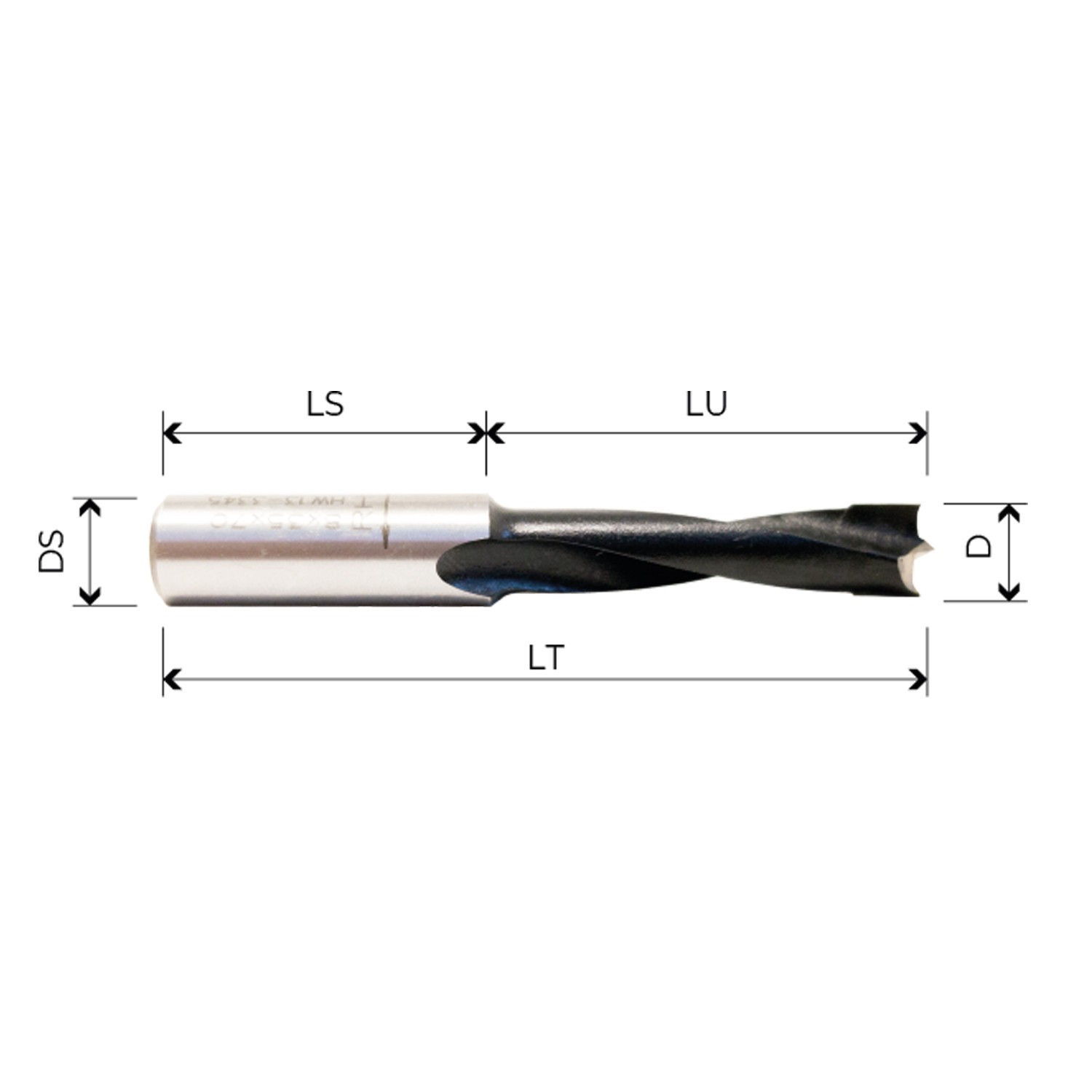

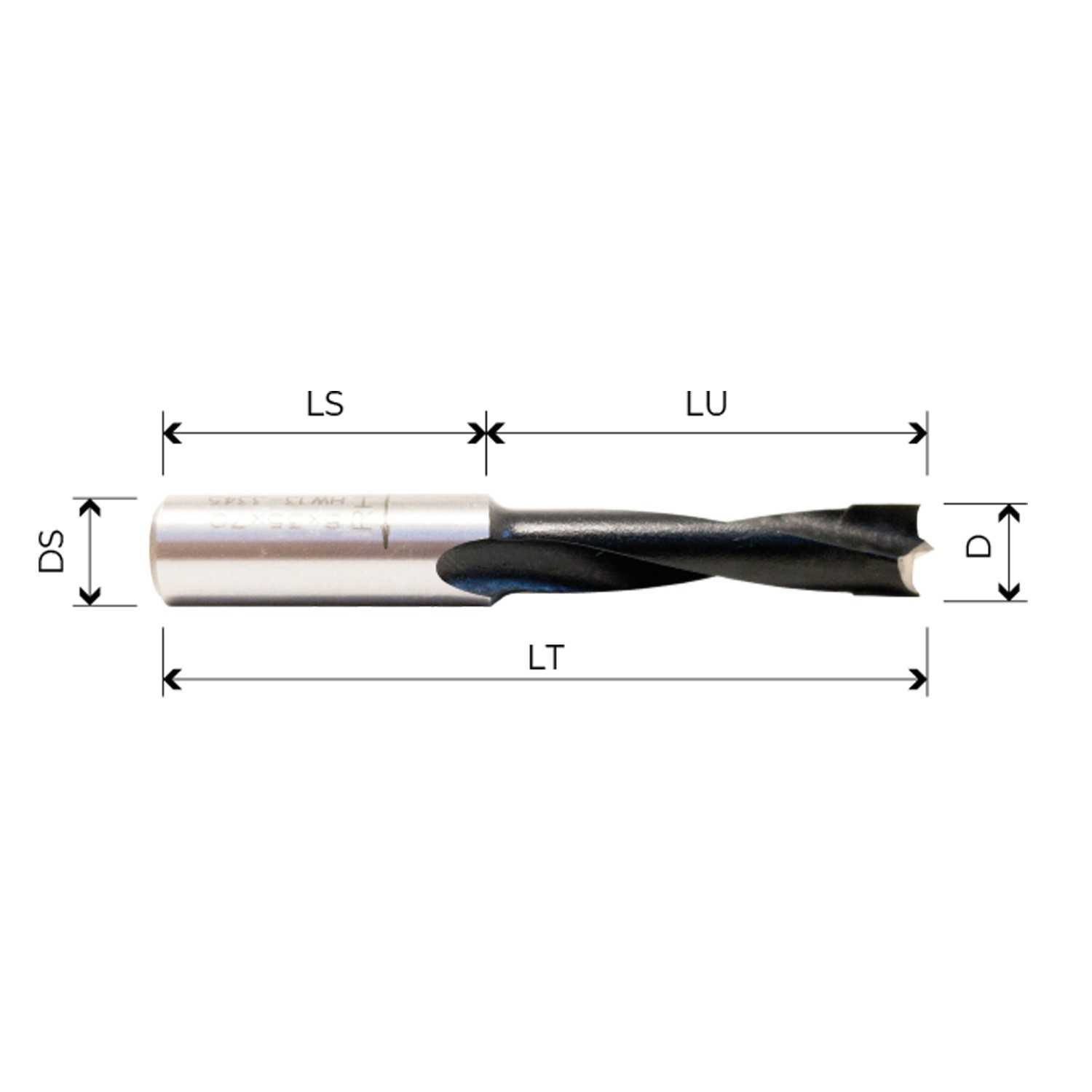

Super-strLENGTH steel, Spiral portion coated with orange or black P.T.F.E.. HW head with precision balanced centre point, 2 HW precision ground cutting edges (Z2), 2 negatively ground spurs (V2), 2 spiral flutes. Parallel shank with driving flat and LENGTH adjusting screw.

Super-strLENGTH steel, Spiral portion coated with orange or black P.T.F.E.. HW head with precision balanced centre point, 2 HW precision ground cutting edges (Z2), 2 negatively ground spurs (V2), 2 spiral flutes. Parallel shank with driving flat and LENGTH adjusting screw.

Super-strLENGTH steel, Spiral portion coated with orange or black P.T.F.E.. HW head with precision balanced centre point, 2 HW precision ground cutting edges (Z2), 2 negatively ground spurs (V2), 2 spiral flutes. Parallel shank with driving flat and LENGTH adjusting screw.

Super-strLENGTH steel, cutter portion coated with black or orange P.T.F.E.. HW head with precision balanced centre point, 2 HW precision ground cutting edges (Z2), 2 negatively ground spurs (V2), 4 spiral flutes. Parallel shank with driving flat and LENGTH adjusting screw.

Super-strLENGTH steel, cutter portion coated with black or orange P.T.F.E.. HW head with precision balanced centre point, 2 HW precision ground cutting edges (Z2), 2 negatively ground spurs (V2), 4 spiral flutes. Parallel shank with driving flat and LENGTH adjusting screw.

Super-strLENGTH steel, cutter portion coated with black or orange P.T.F.E.. HW head with precision balanced centre point, 2 HW precision ground cutting edges (Z2), 2 negatively ground spurs (V2), 4 spiral flutes. Parallel shank with driving flat and LENGTH adjusting screw.

Super-strLENGTH steel, cutter portion coated with black or orange P.T.F.E.. HW head with precision balanced centre point, 2 HW precision ground cutting edges (Z2), 2 negatively ground spurs (V2), 4 spiral flutes. Parallel shank with driving flat and LENGTH adjusting screw.

Super-strLENGTH steel, cutter portion coated with black or orange P.T.F.E.. HW head with precision balanced centre point, 2 HW precision ground cutting edges (Z2), 2 negatively ground spurs (V2), 4 spiral flutes. Parallel shank with driving flat and LENGTH adjusting screw.

Super-strLENGTH steel, cutter portion coated with black or orange P.T.F.E.. HW head with precision balanced centre point, 2 HW precision ground cutting edges (Z2), 2 negatively ground spurs (V2), 4 spiral flutes. Parallel shank with driving flat and LENGTH adjusting screw.

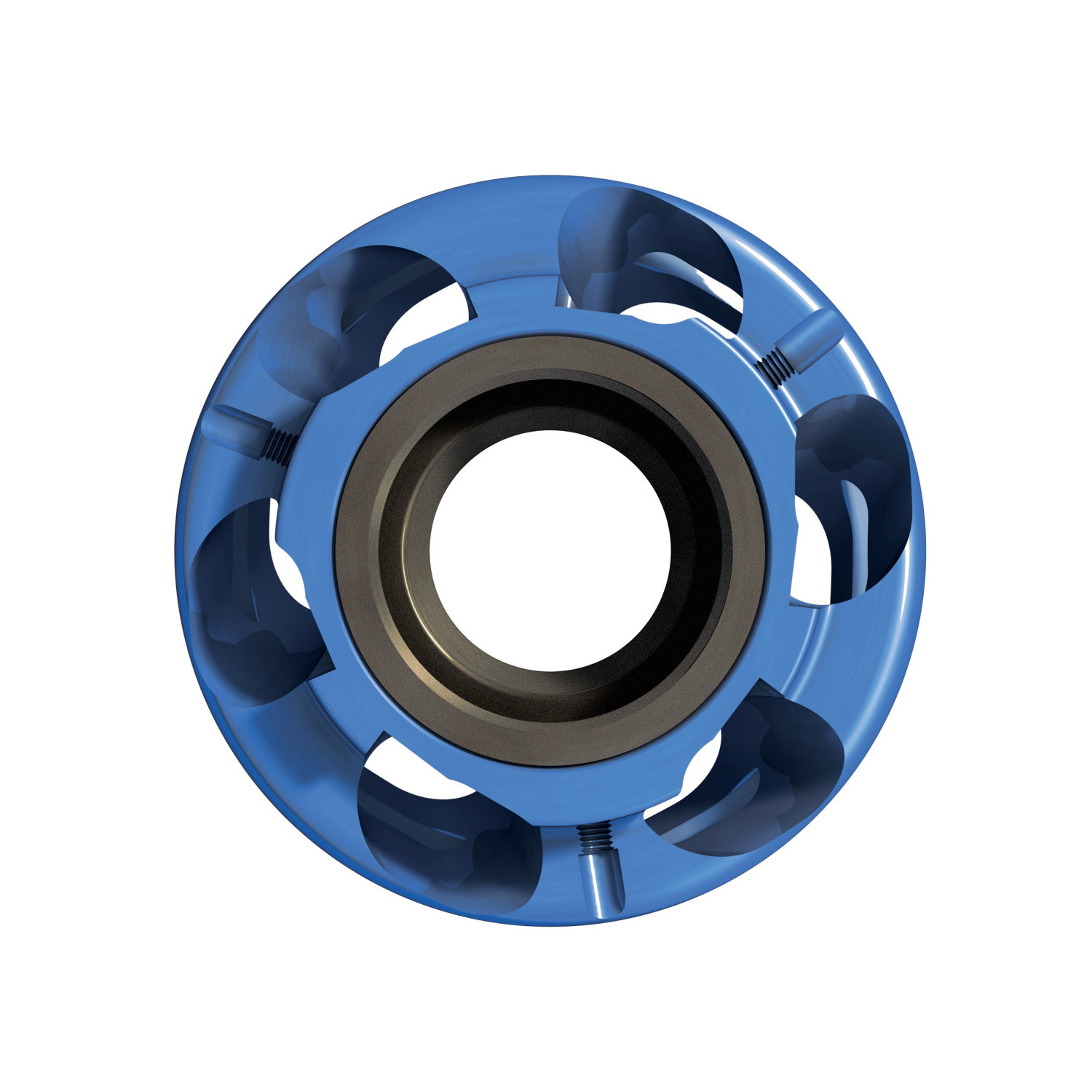

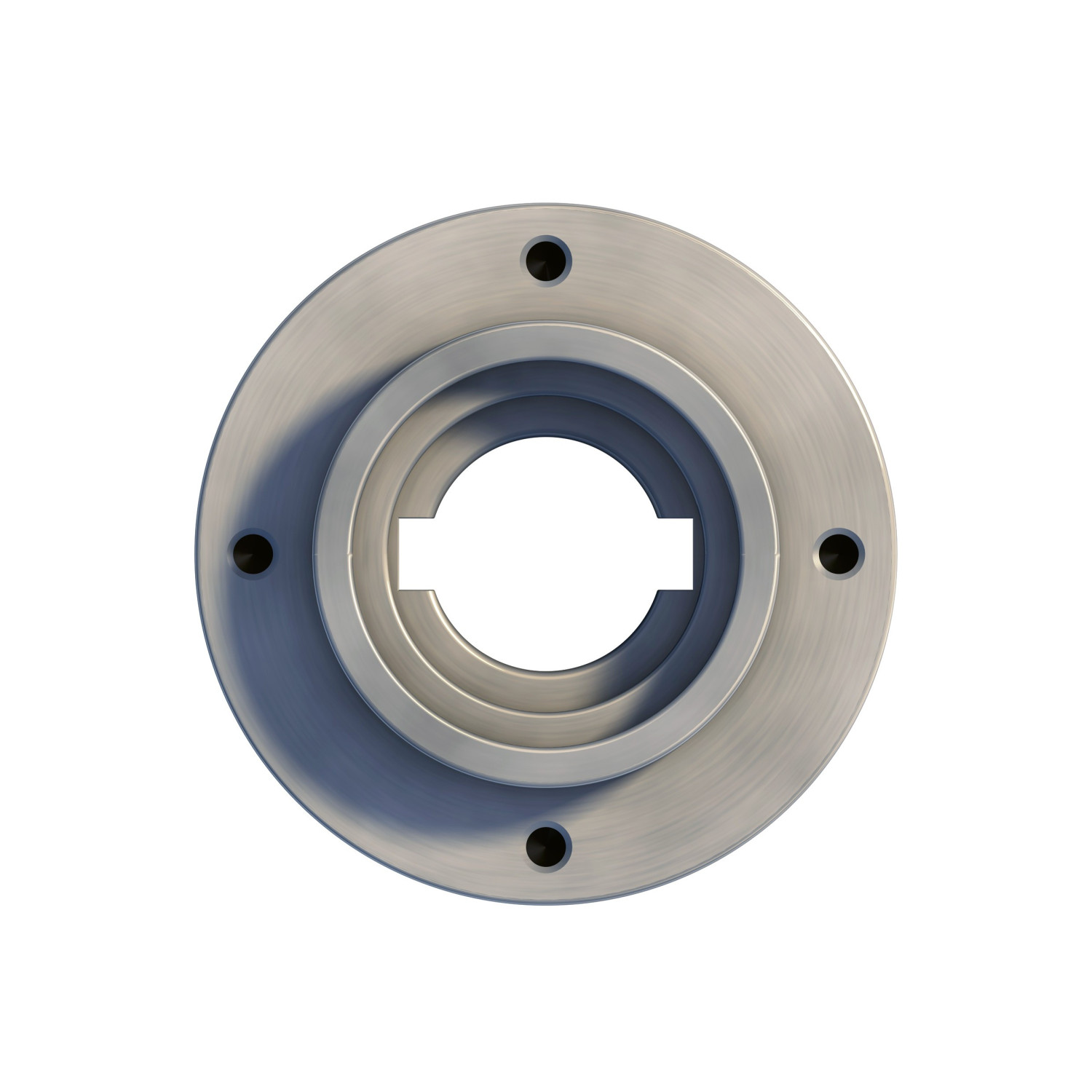

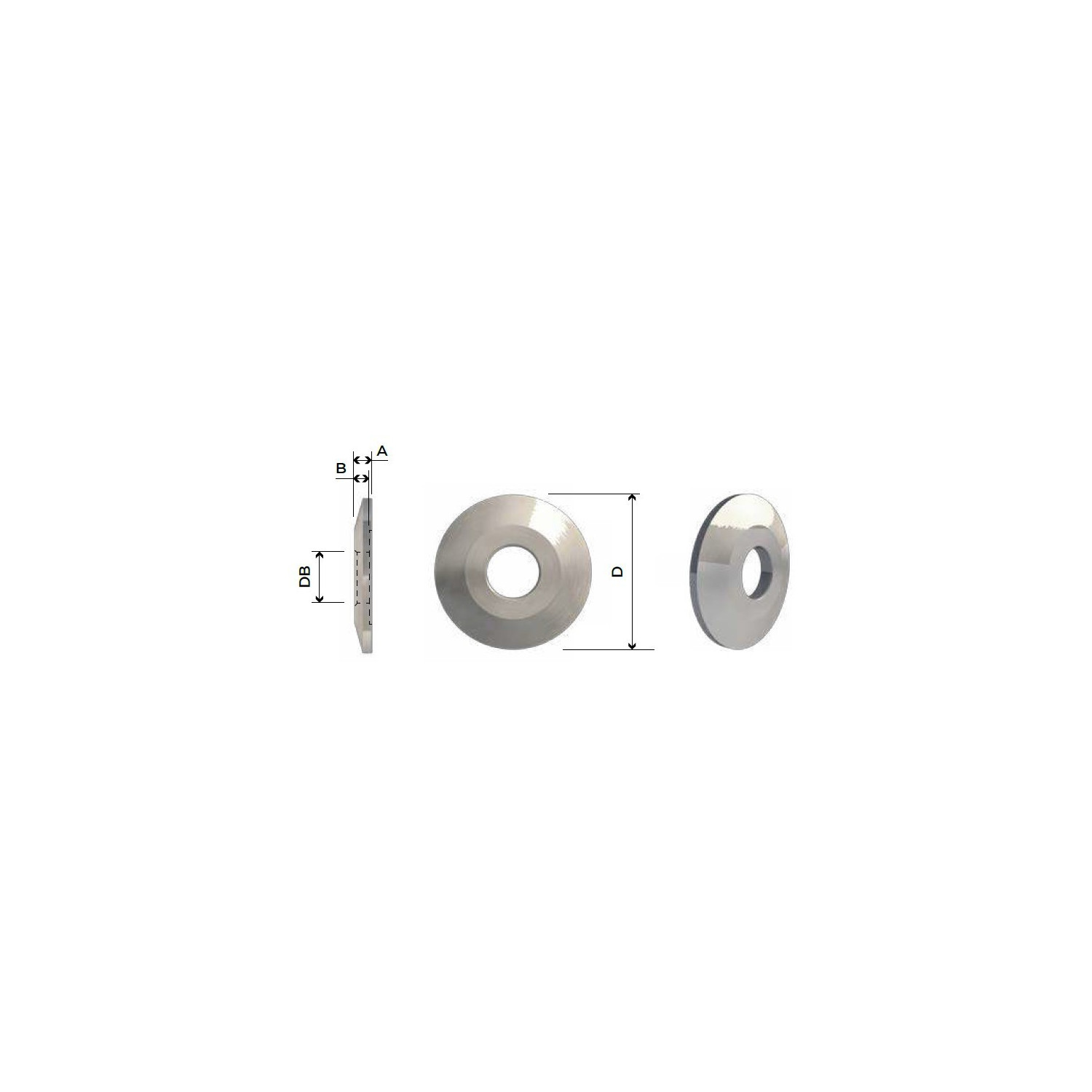

Adjustable HW scoring blade engineered for precise and chip-free scoring on laminated panels and wood-based materials.

• WZ geometry for clean scoring

• Low-noise body for reduced vibration

• Ideal for manual and mechanical panel saws

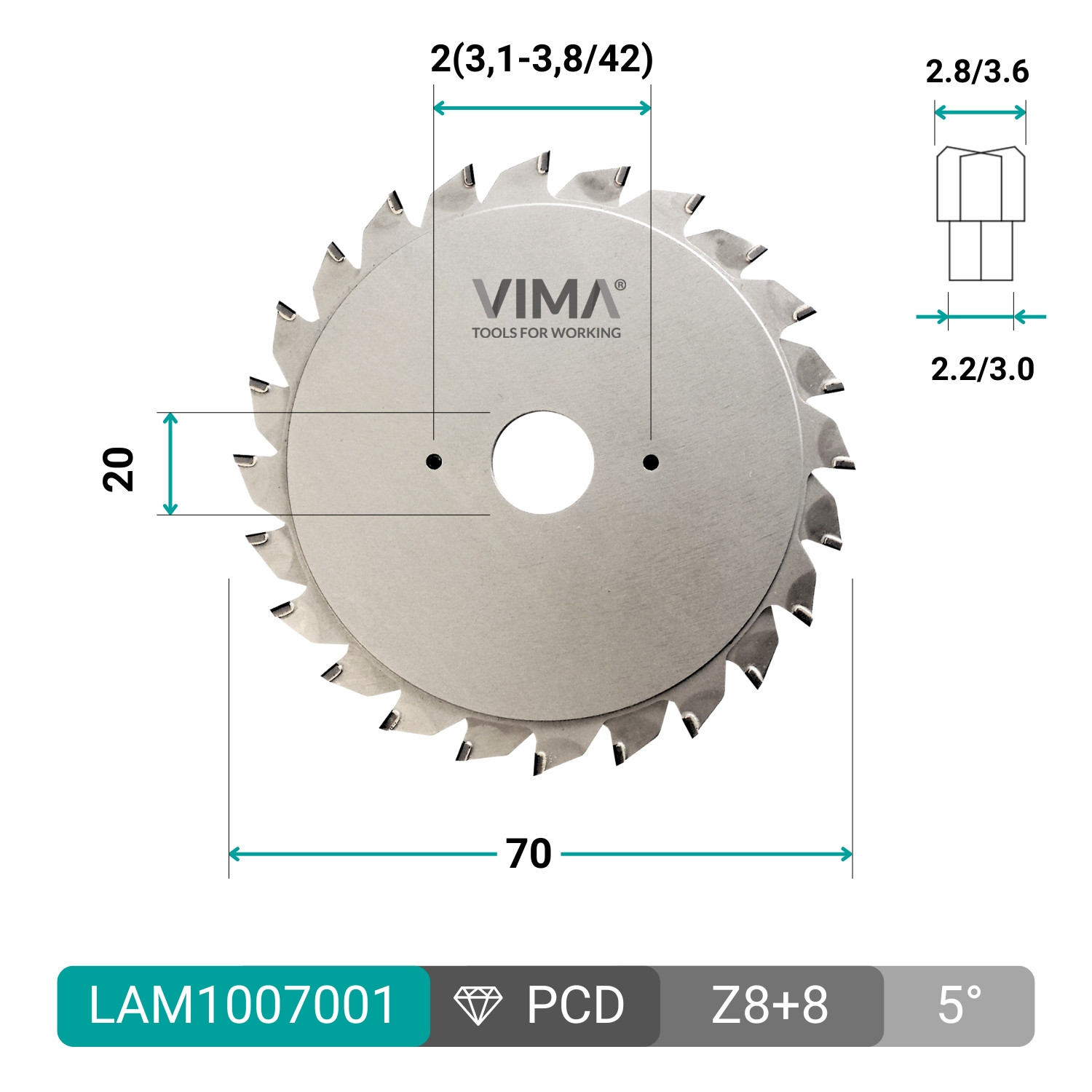

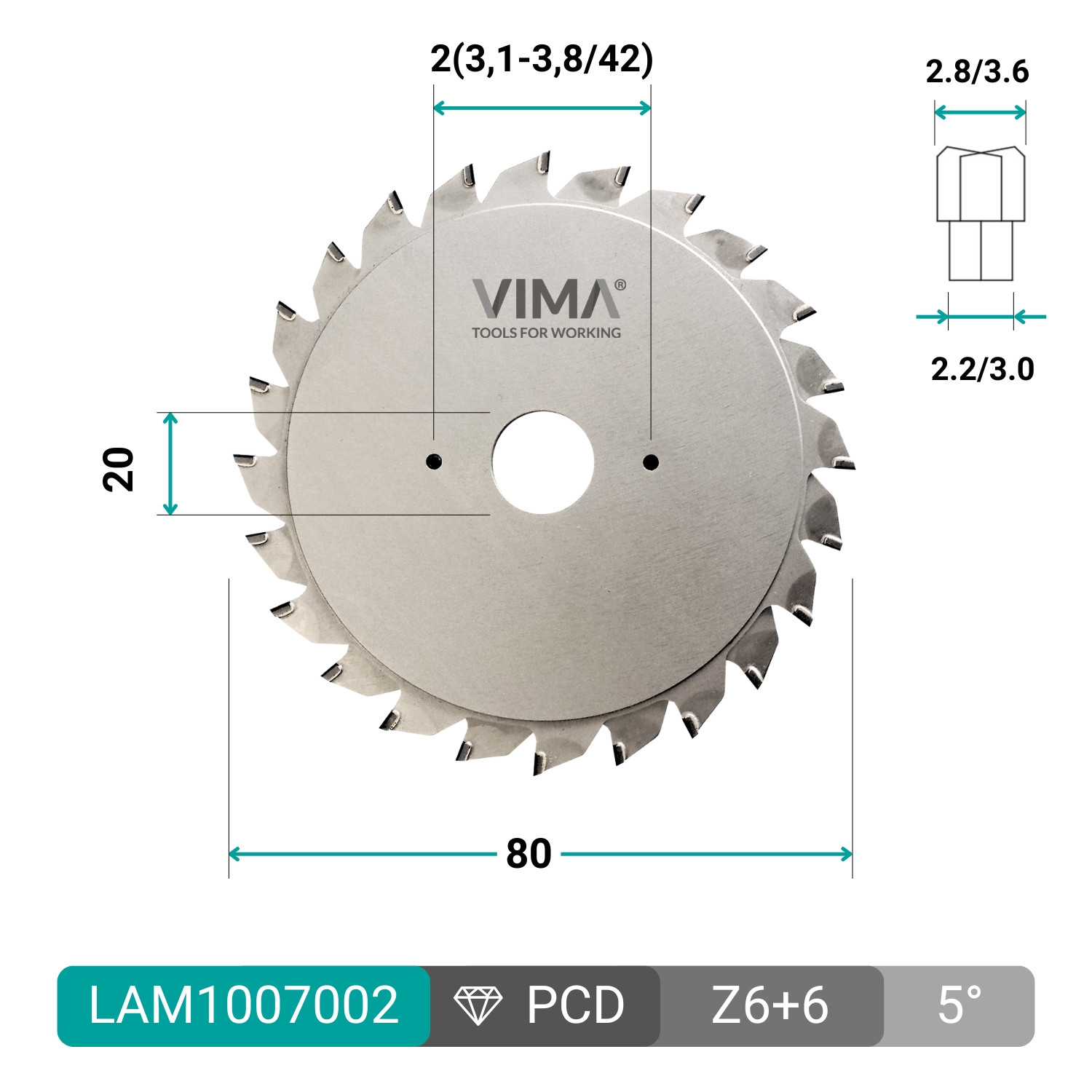

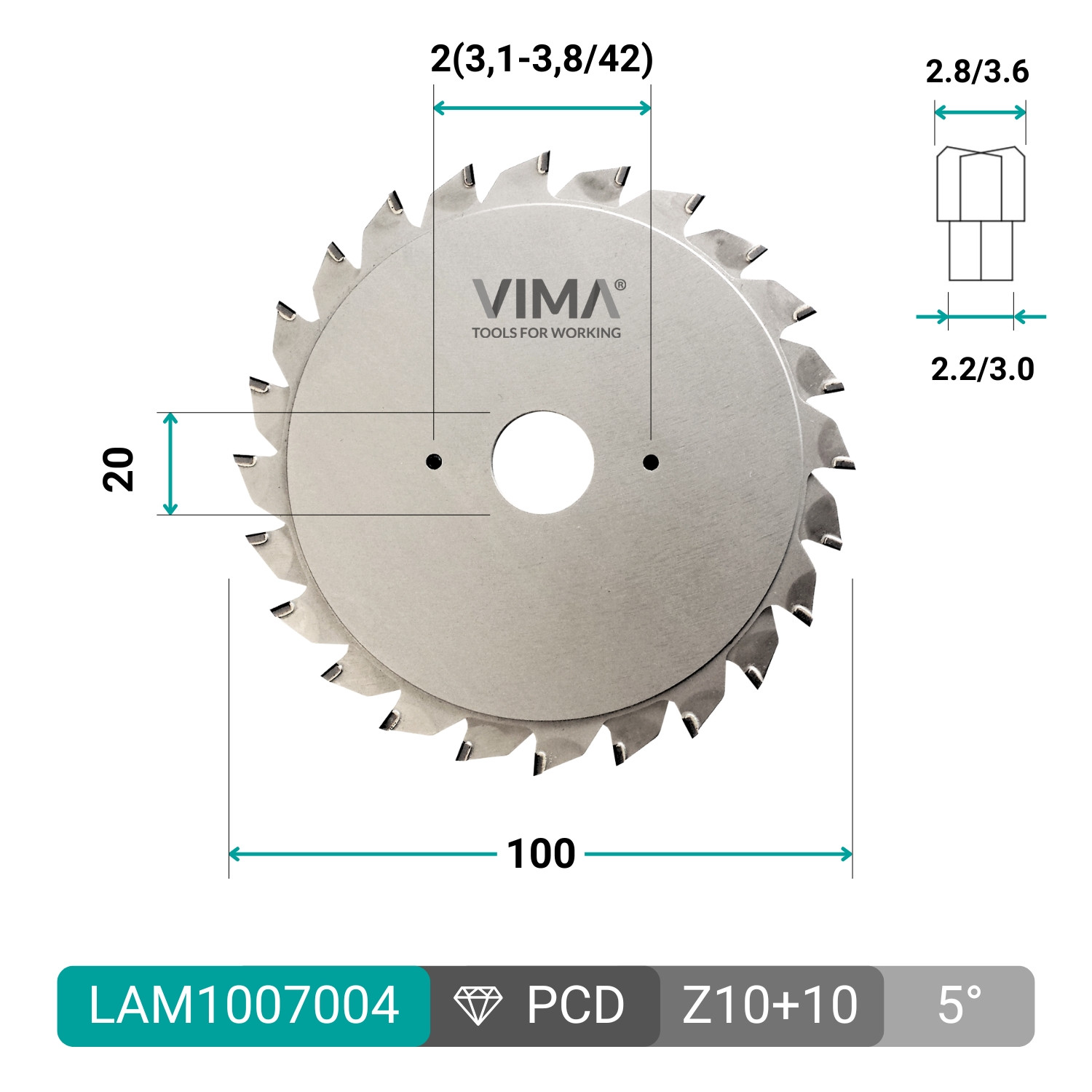

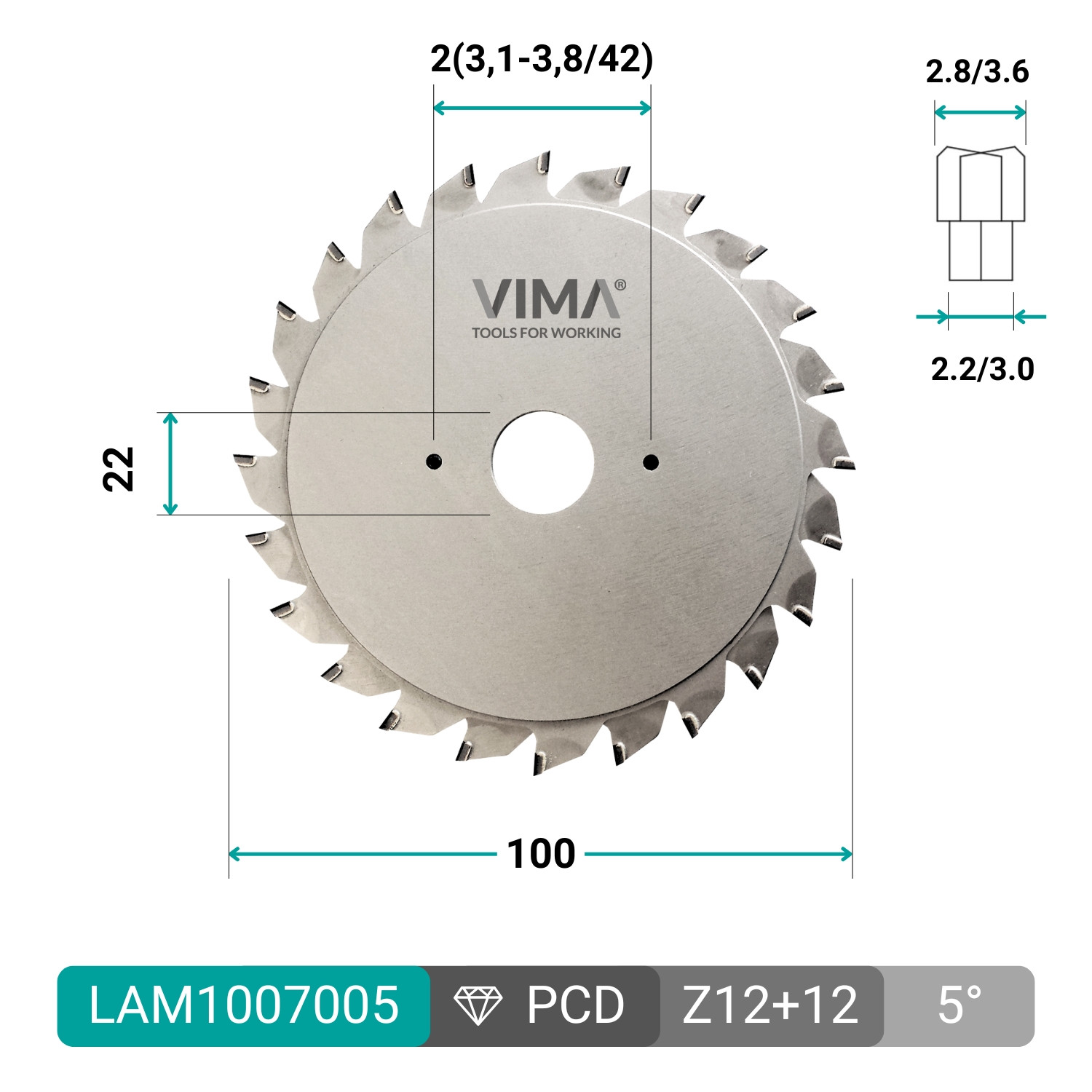

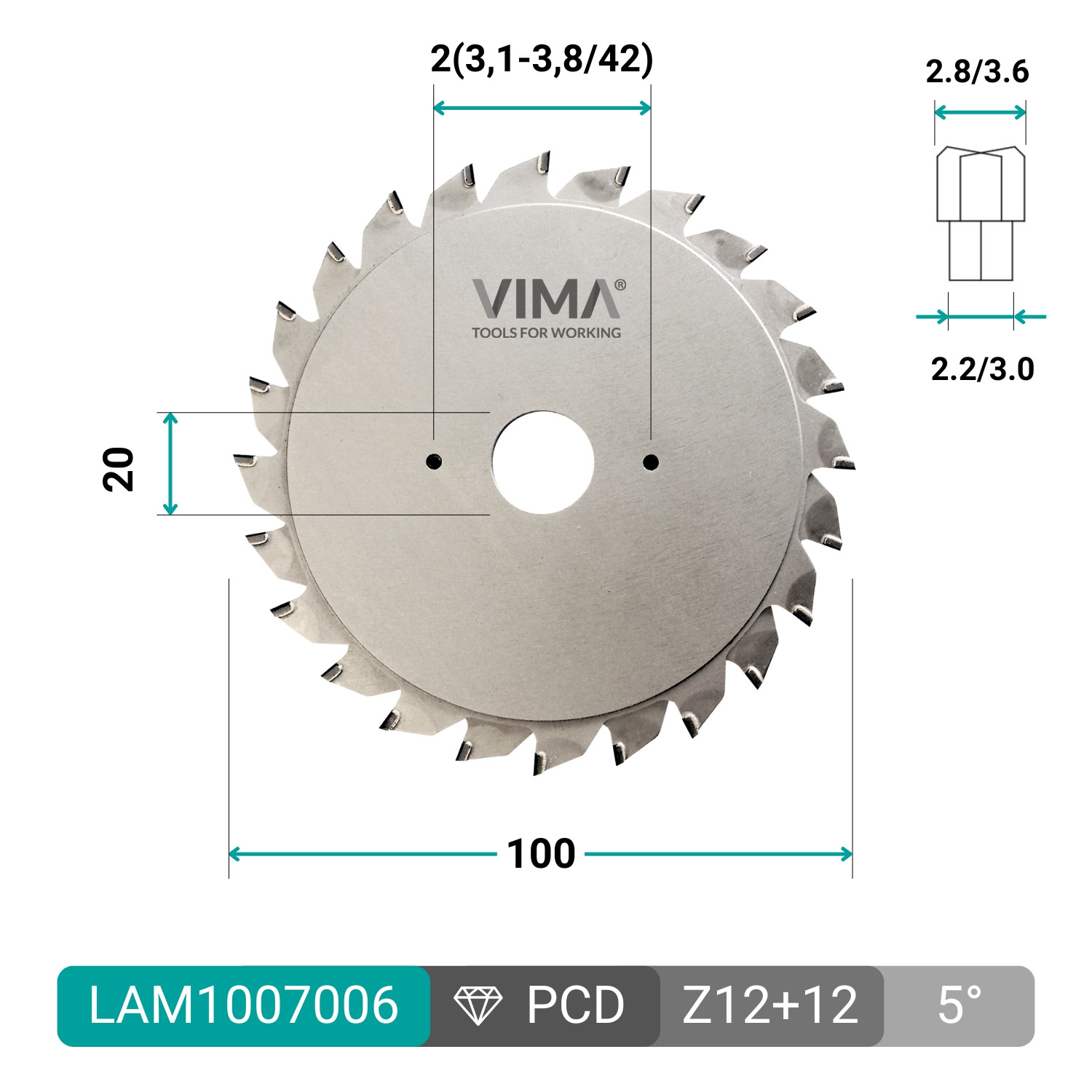

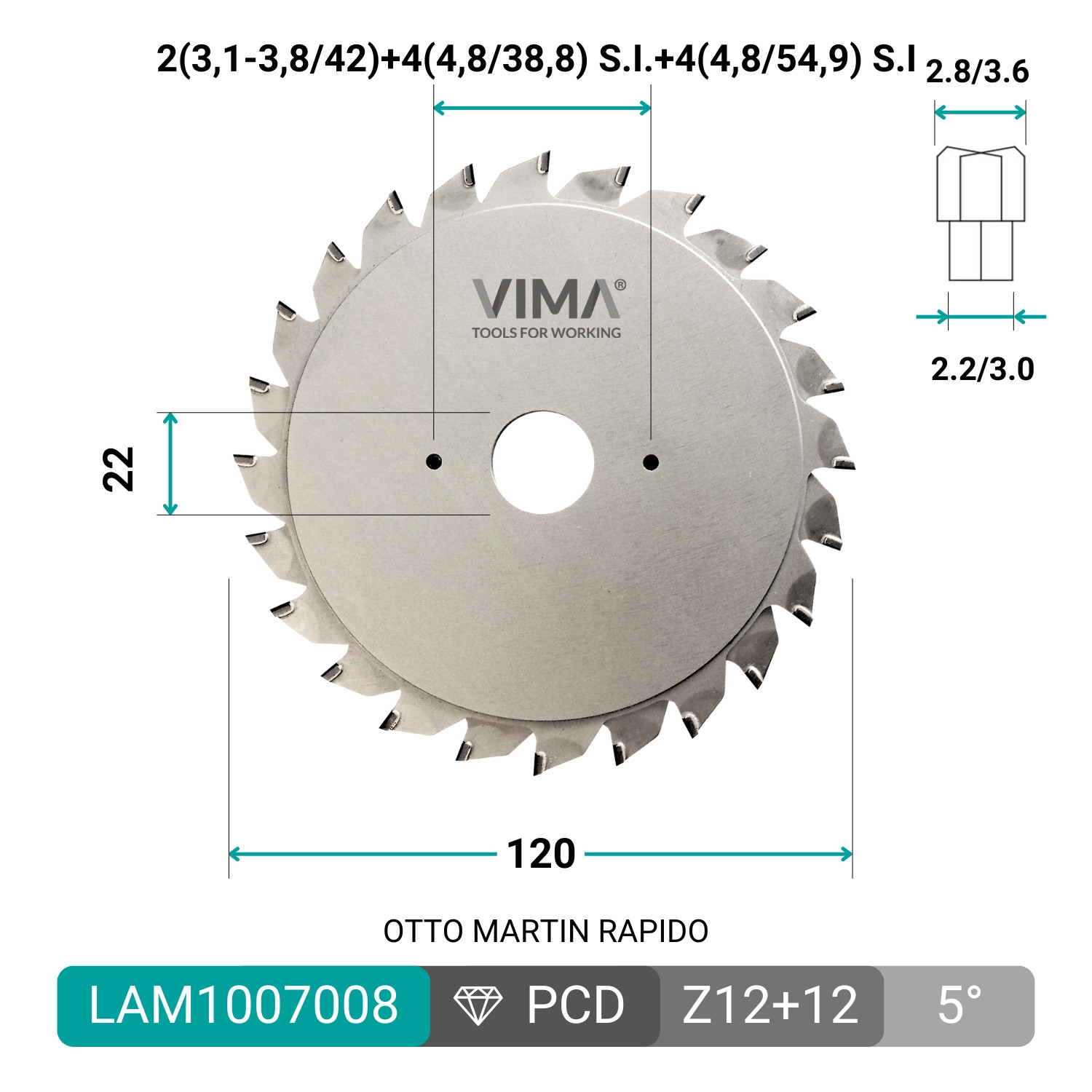

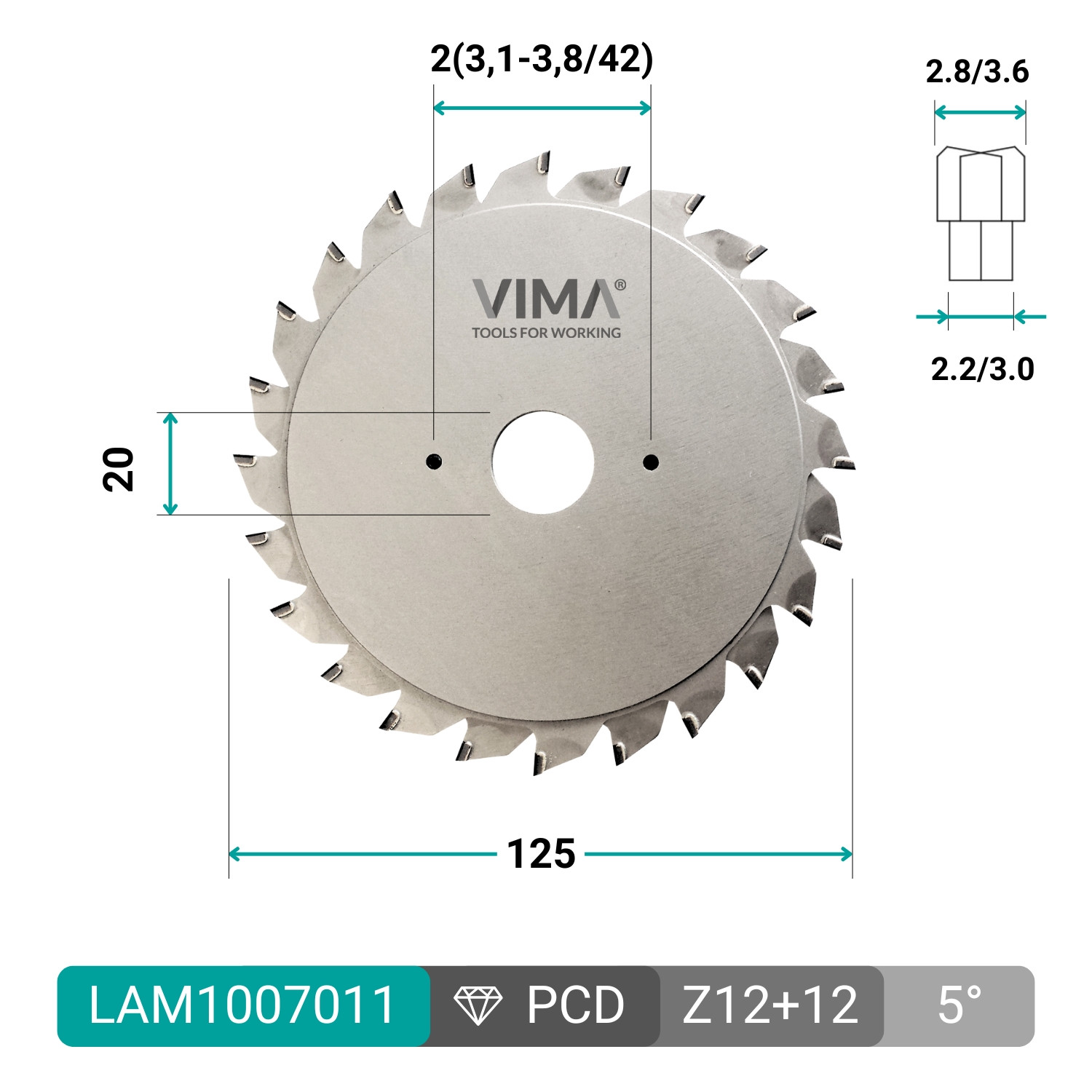

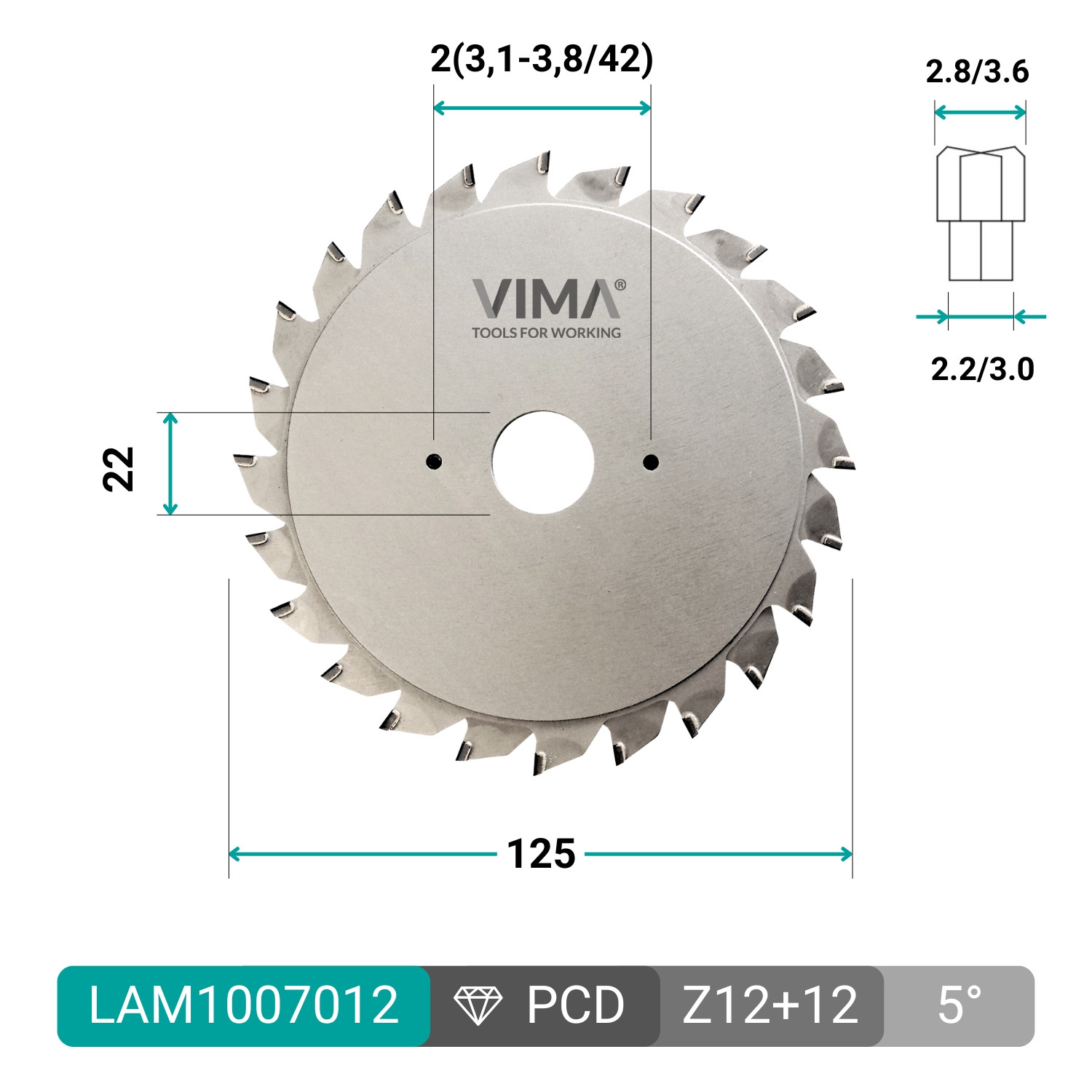

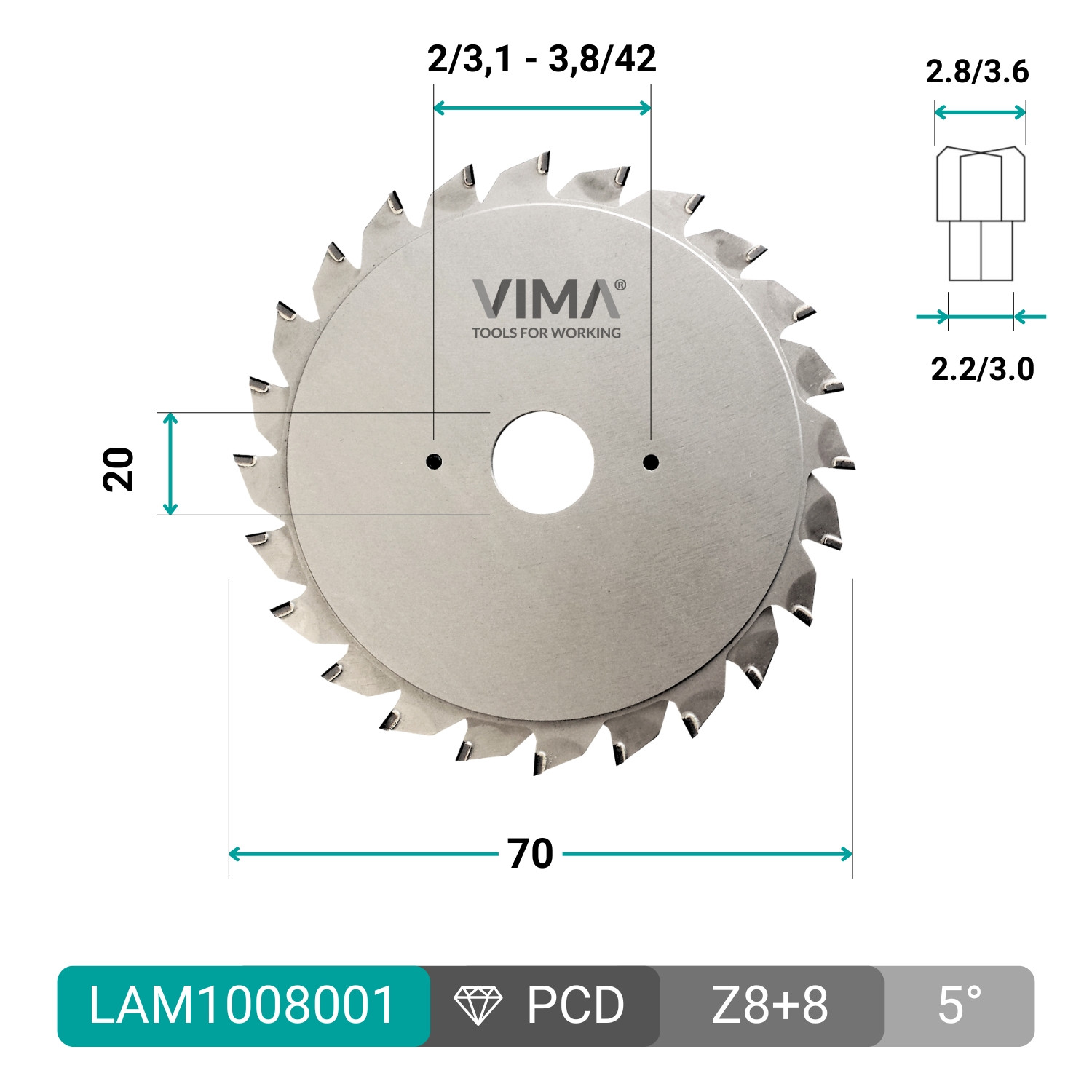

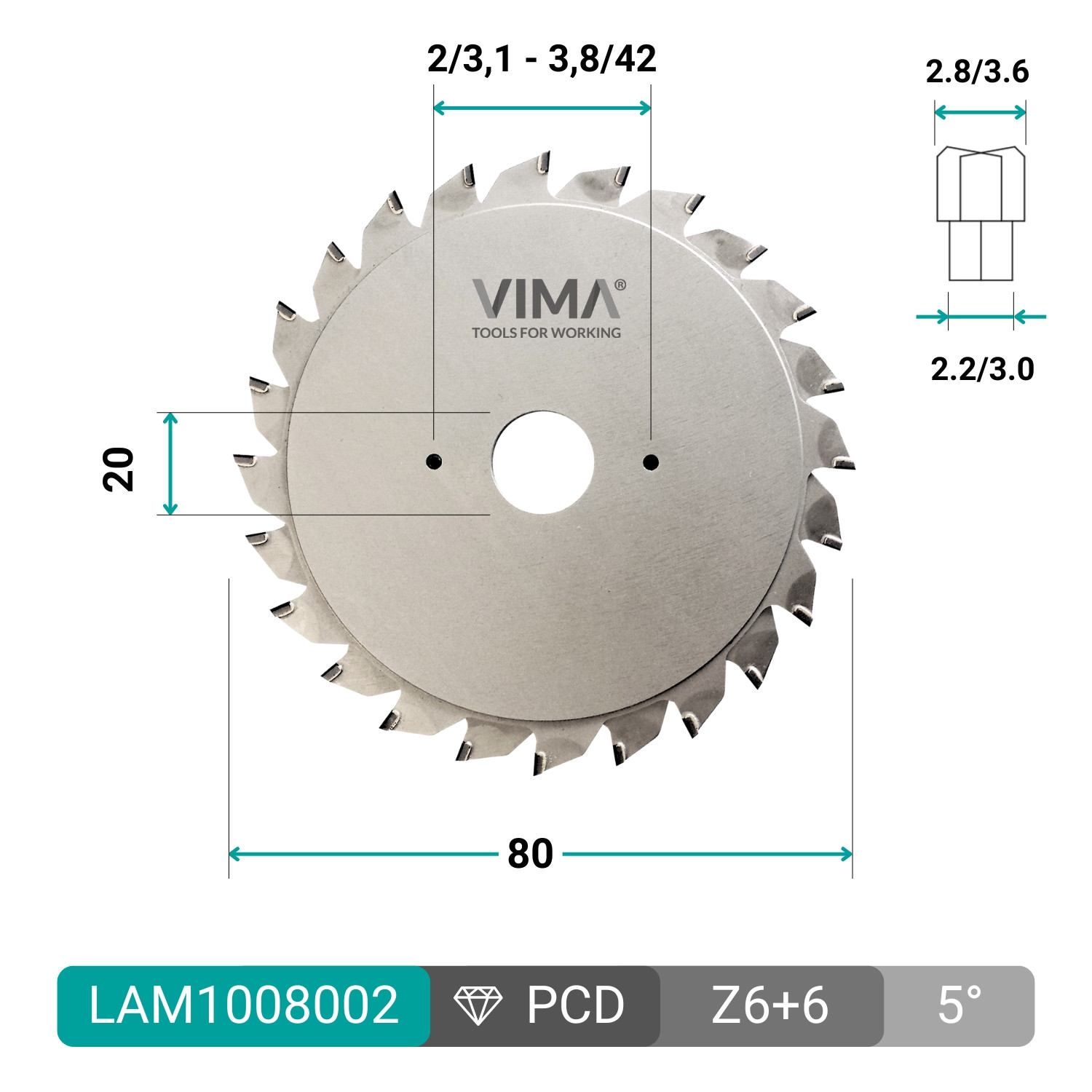

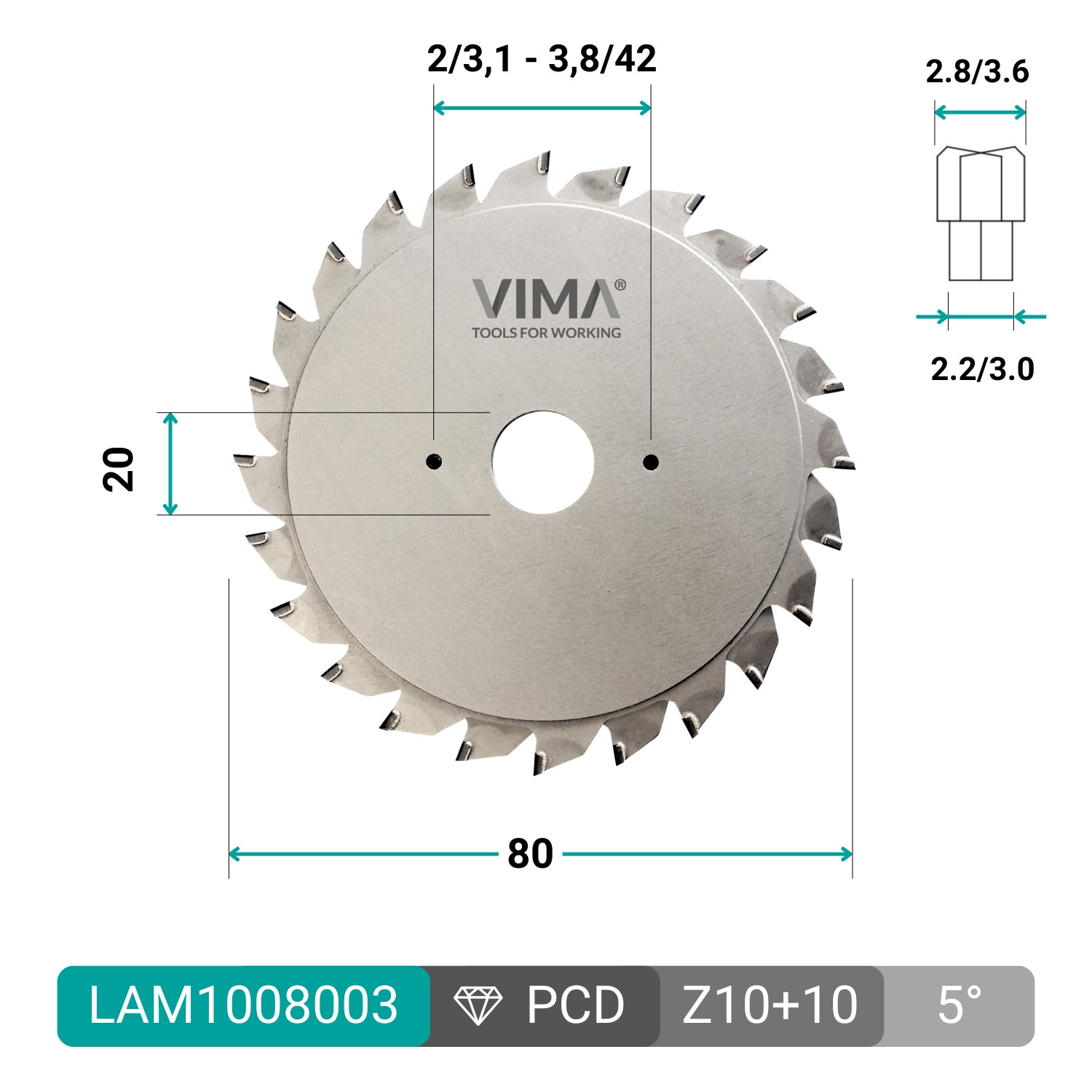

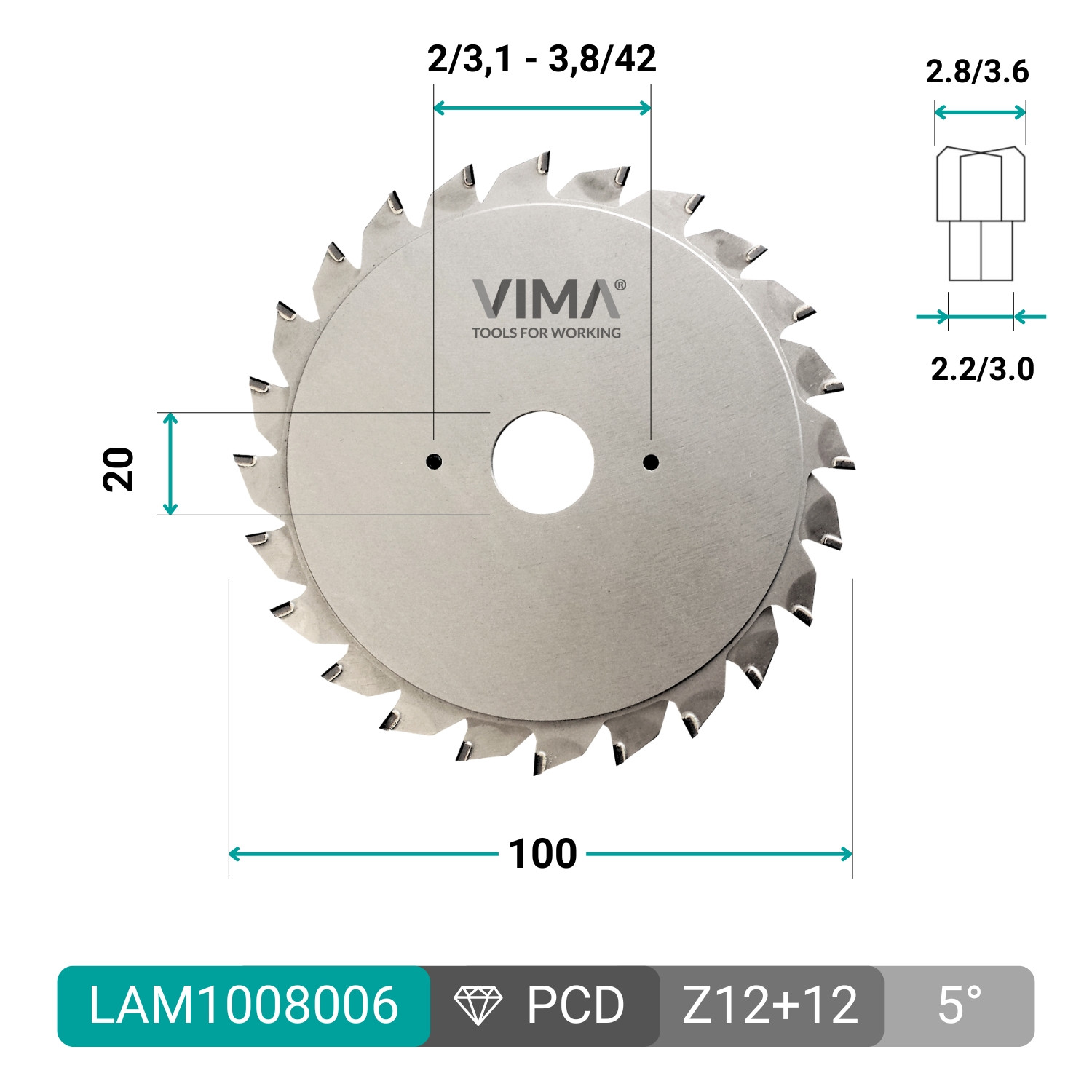

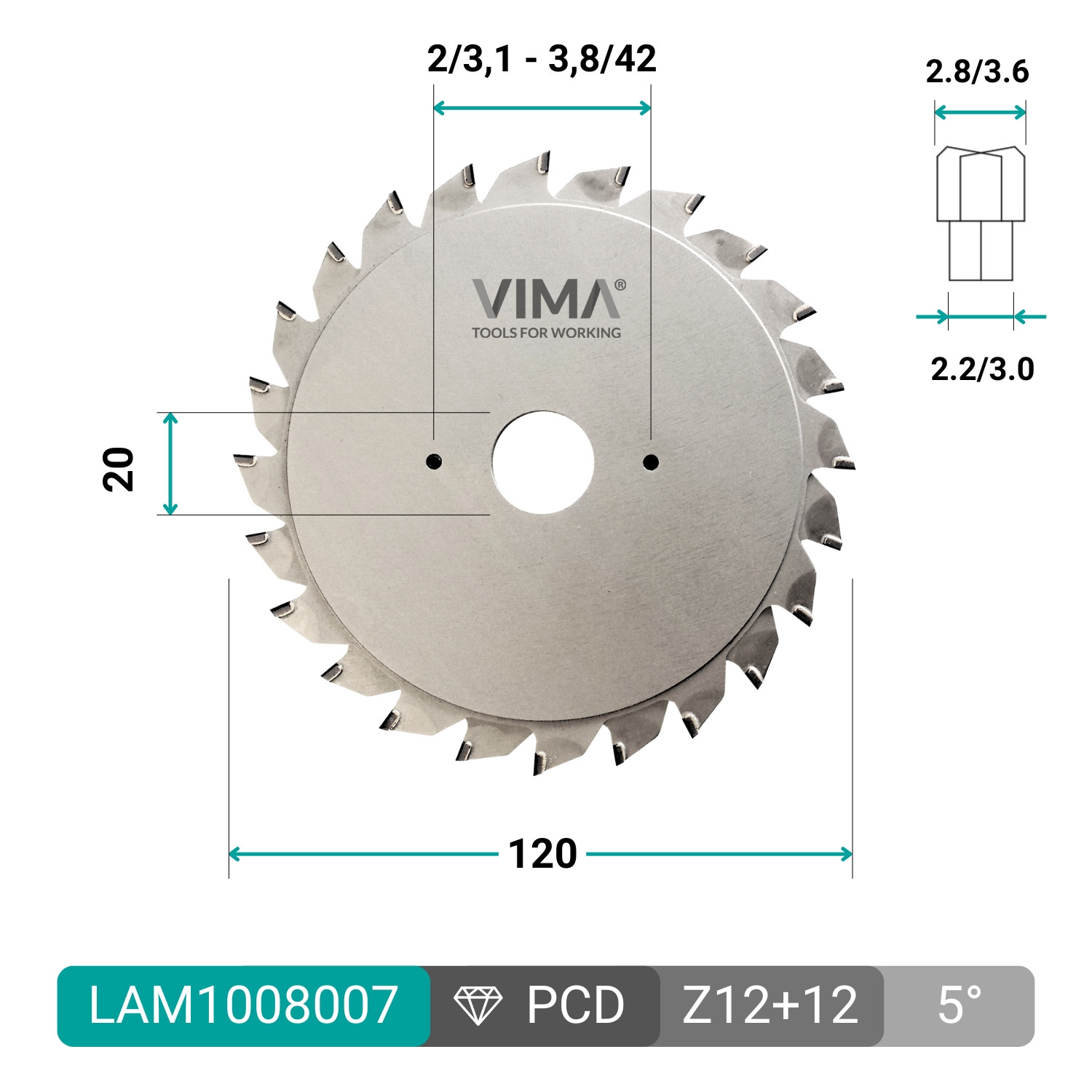

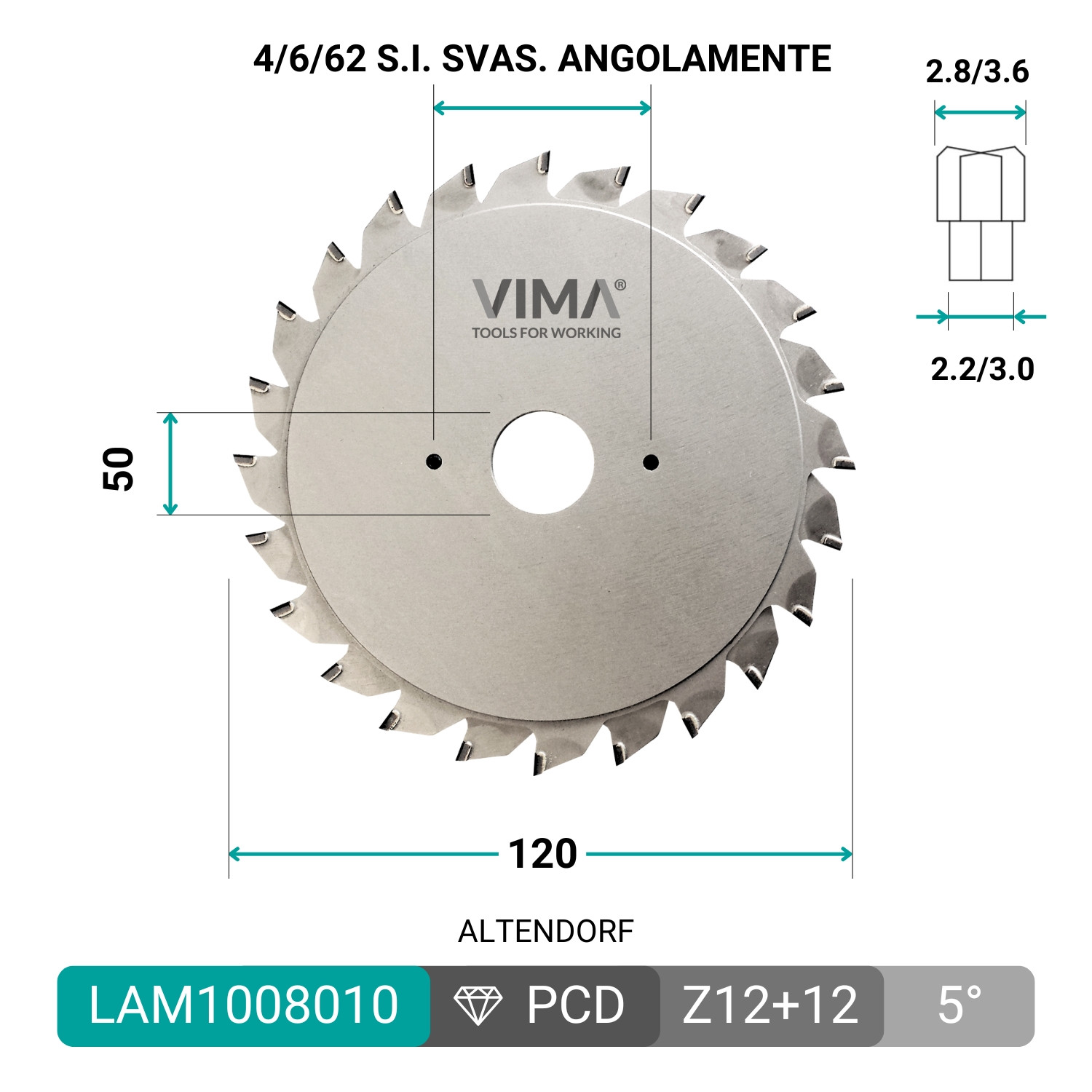

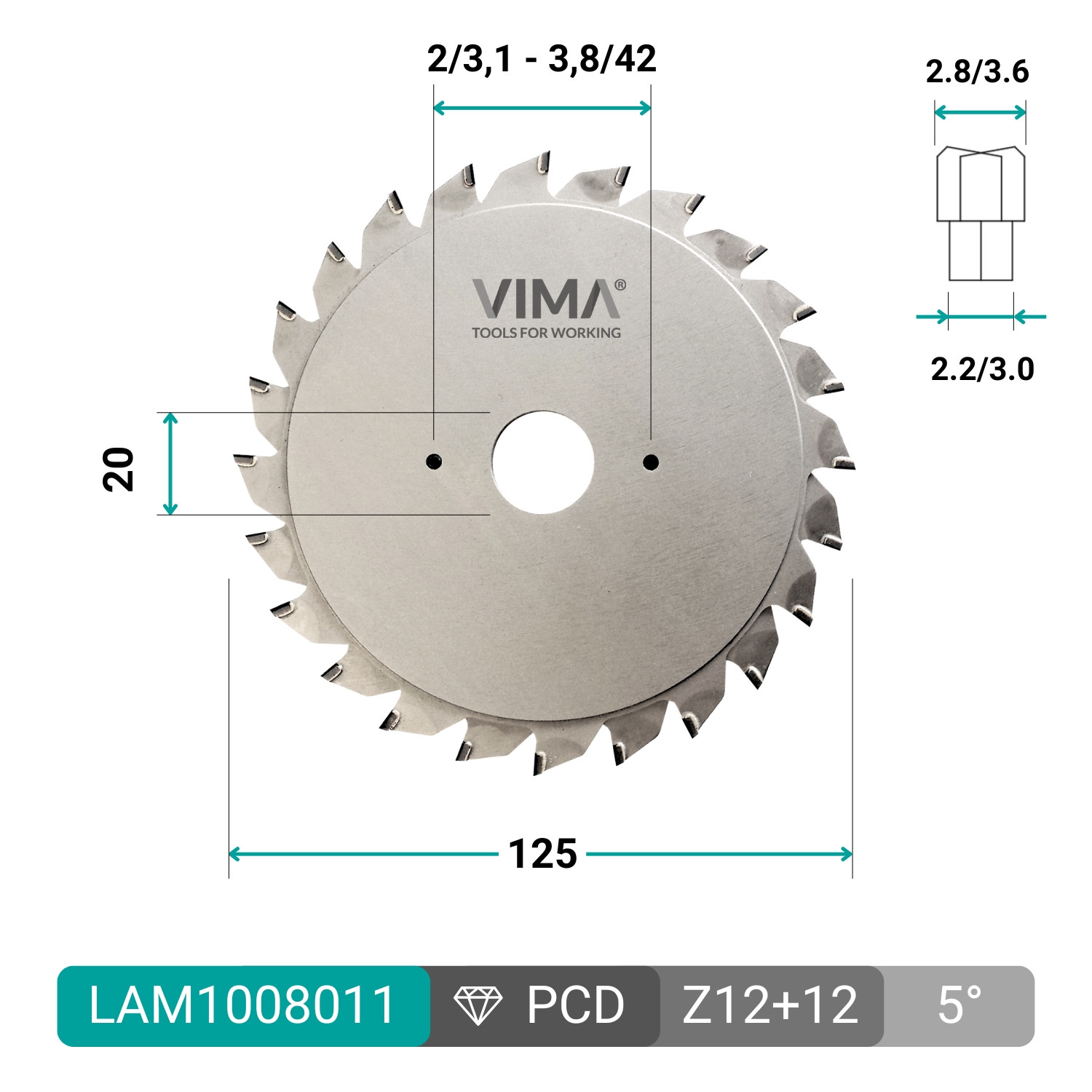

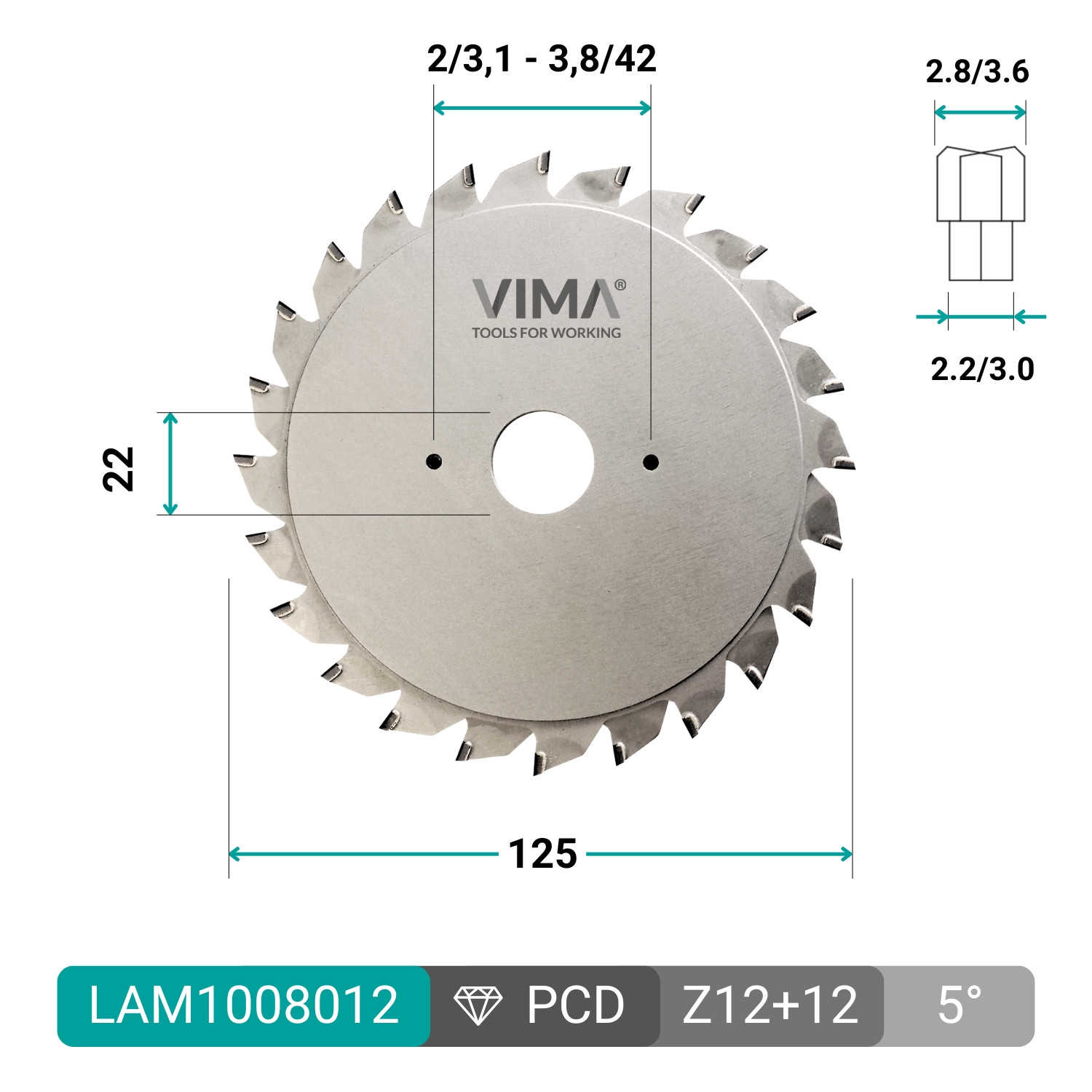

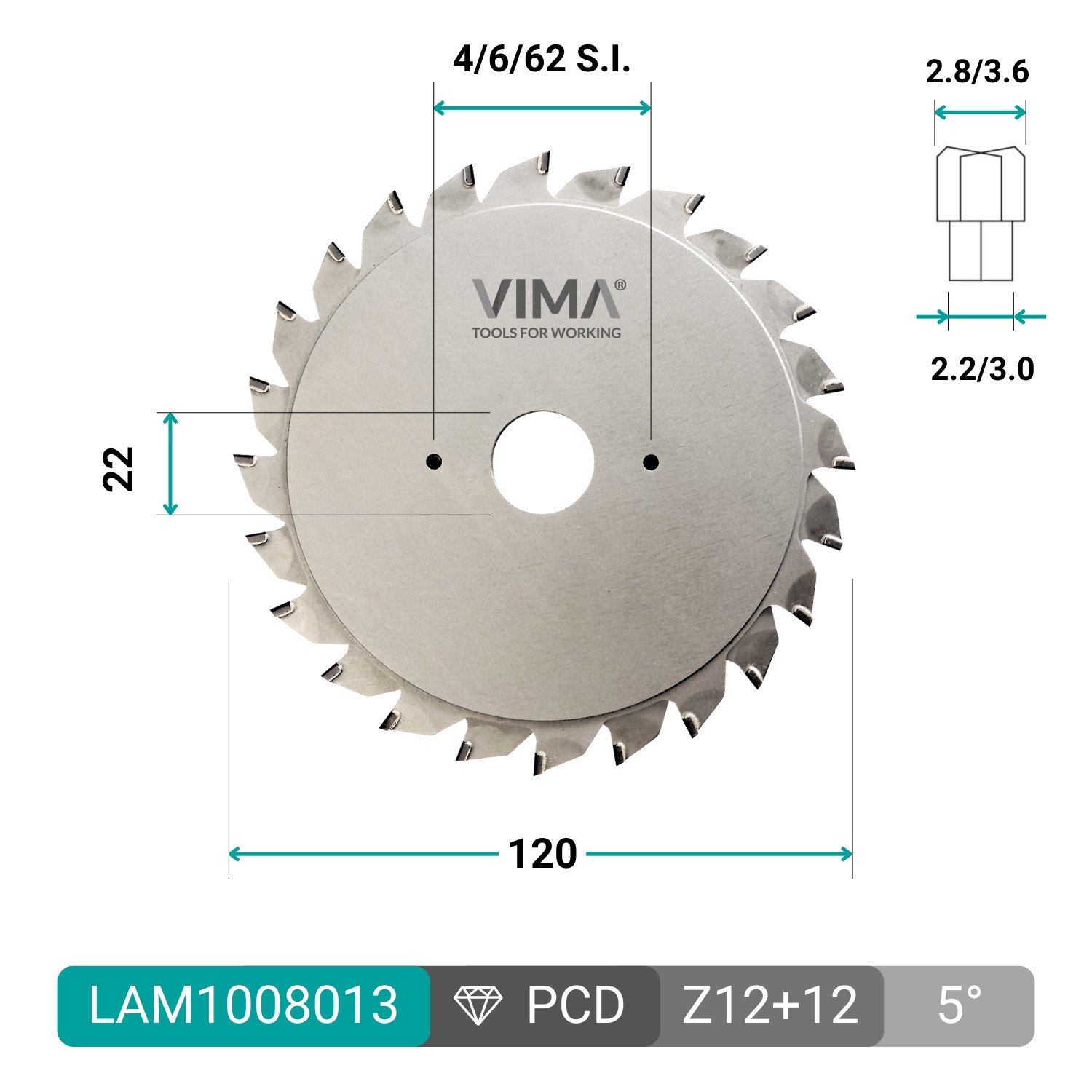

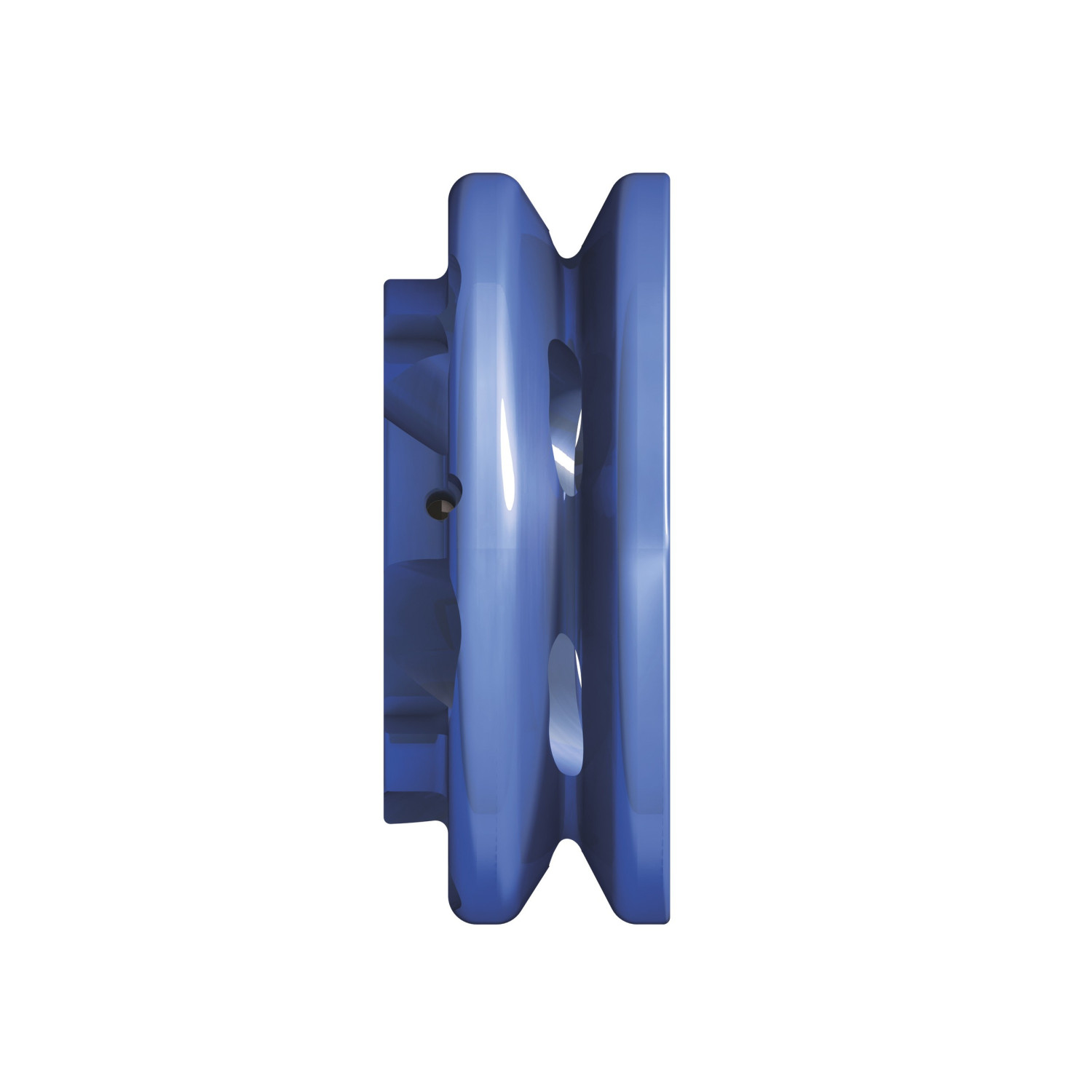

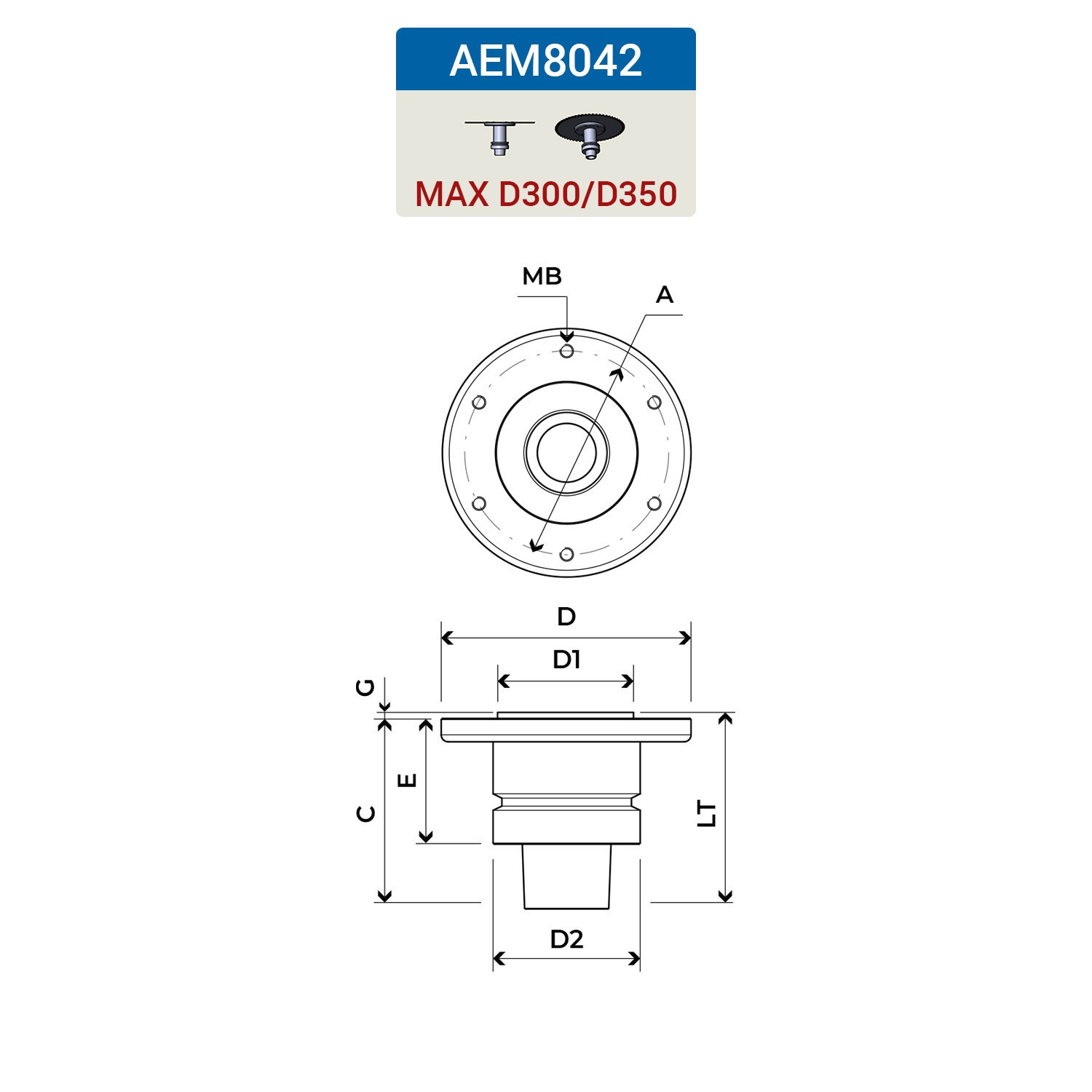

Adjustable PCD scoring blade designed for clean and accurate scoring on laminated panels. The PCD construction ensures superior wear resistance, while the adjustable width allows perfect alignment with the main saw blade. Suitable for professional horizontal panel saws.

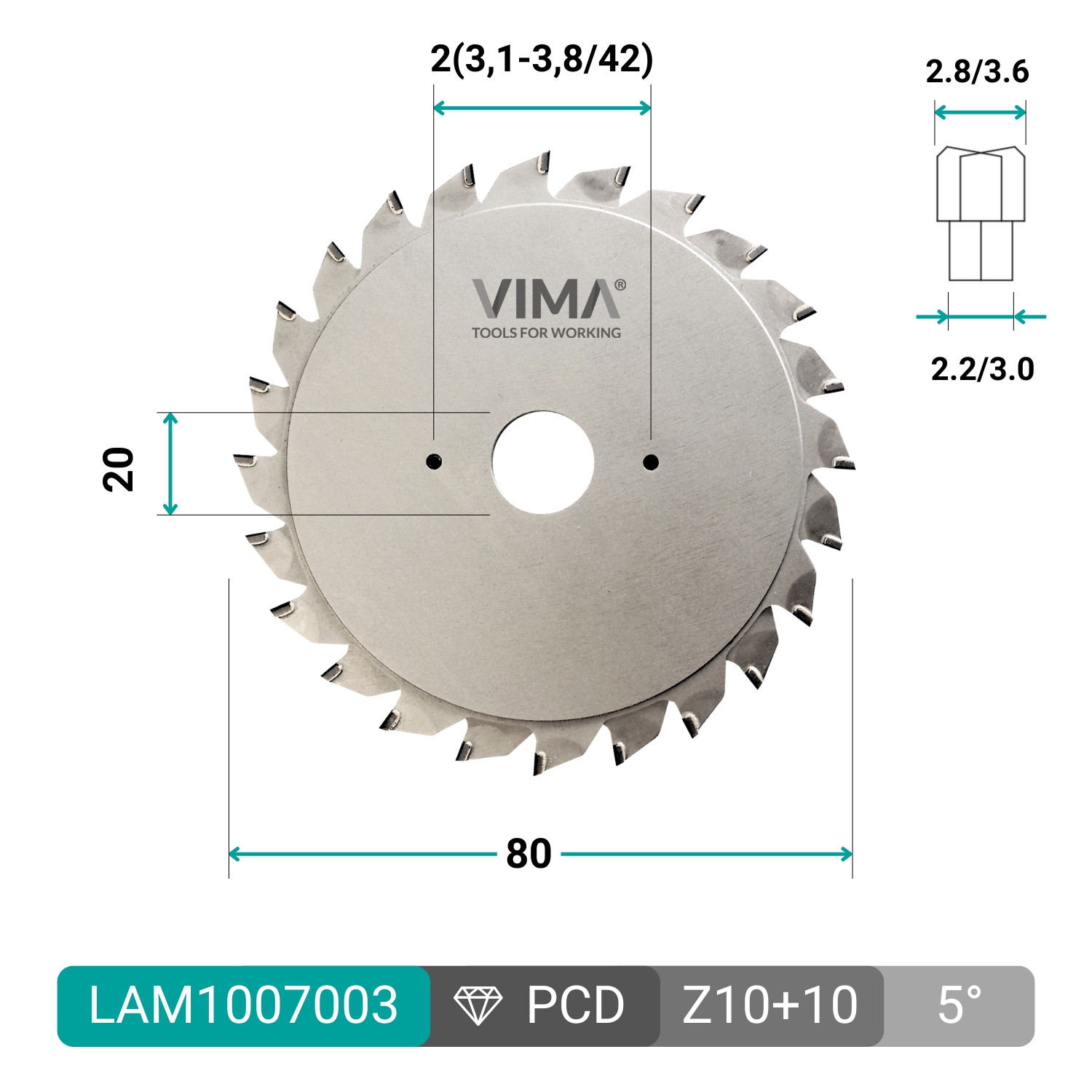

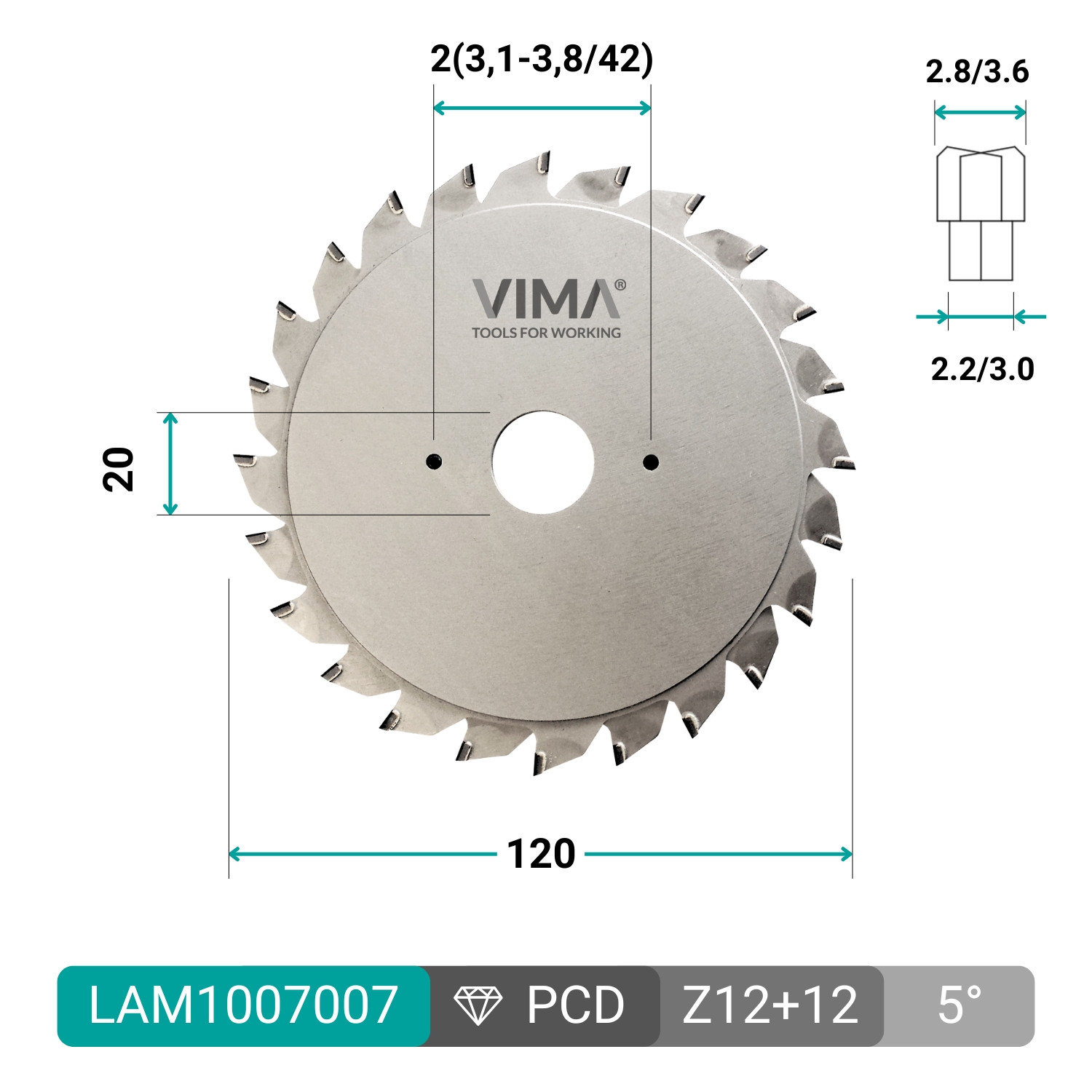

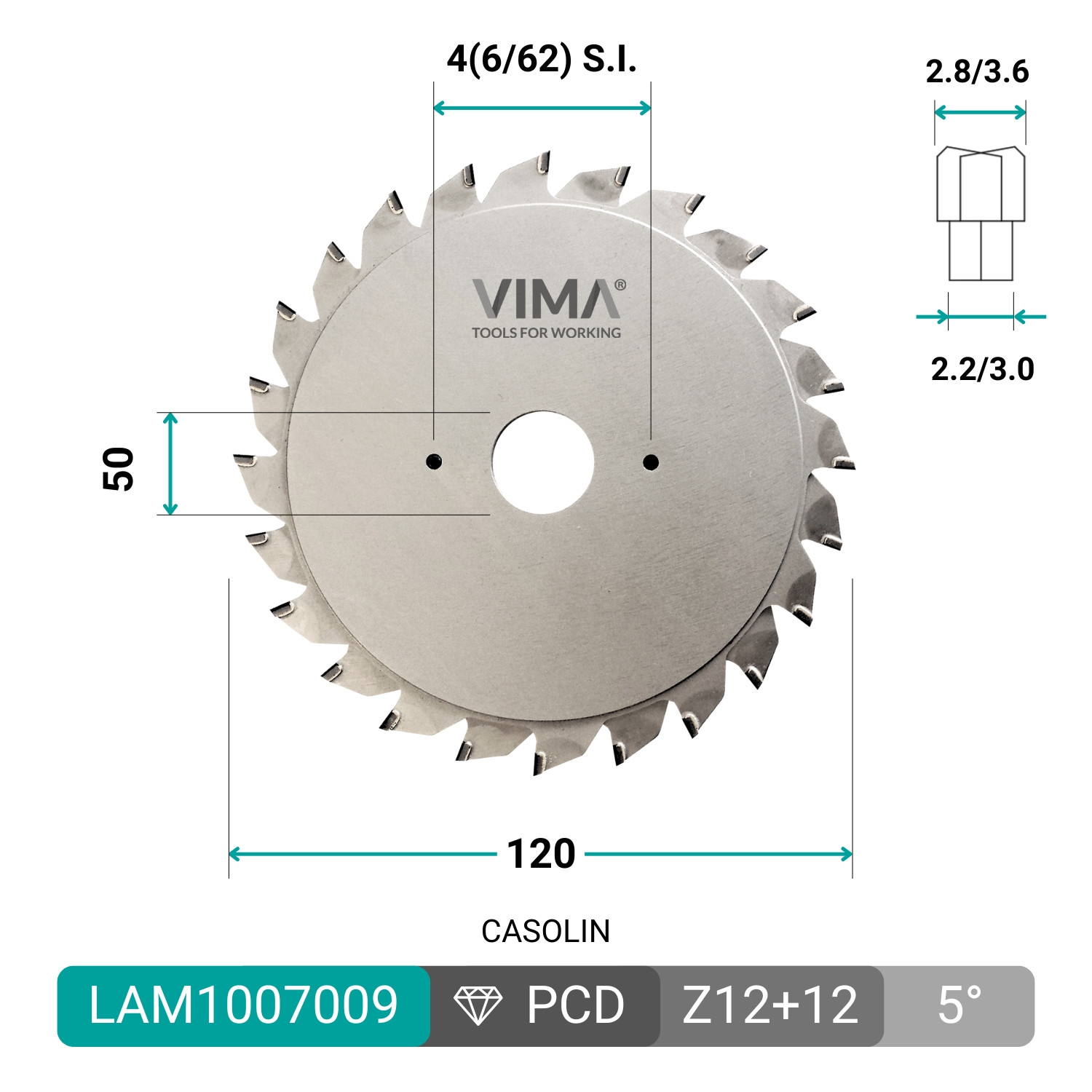

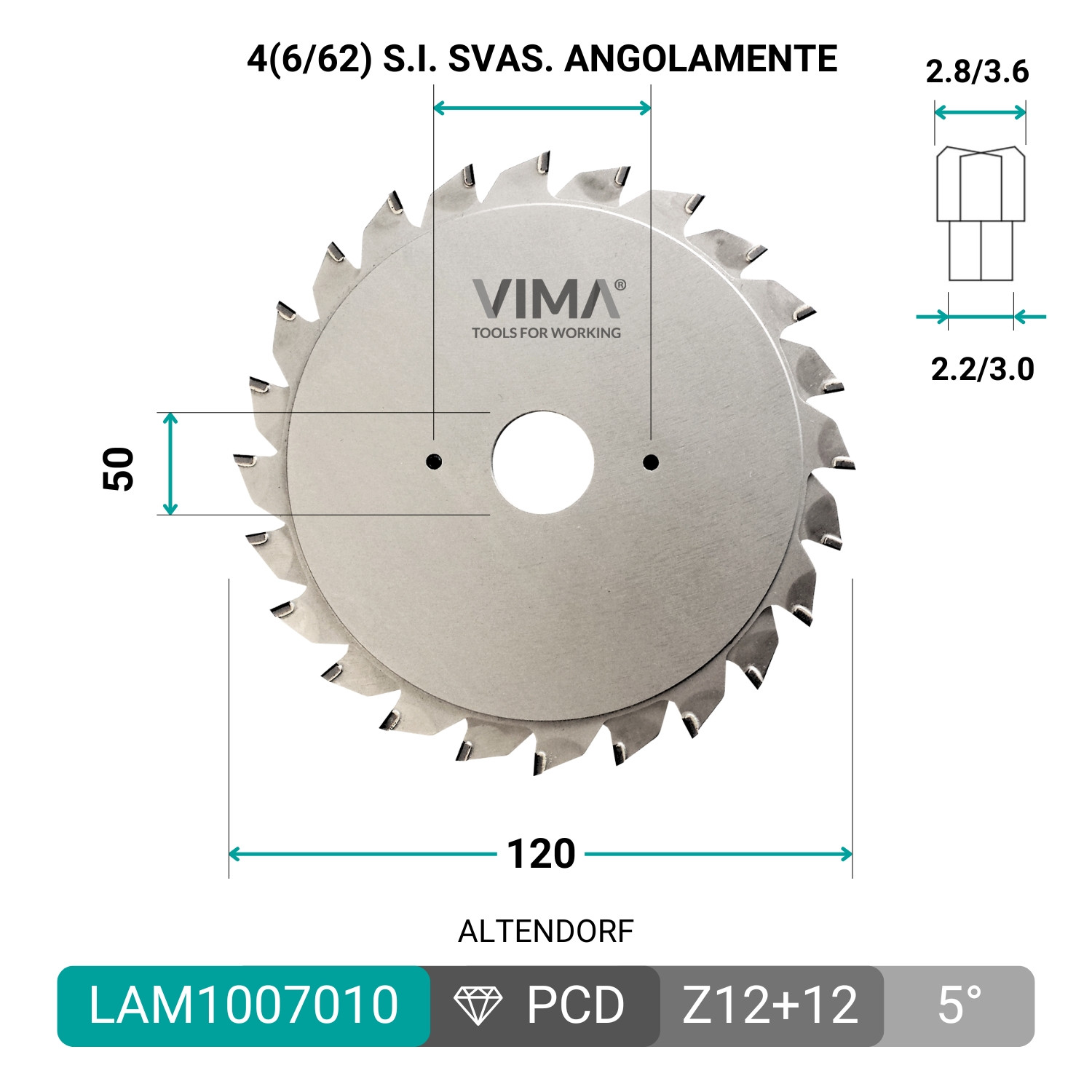

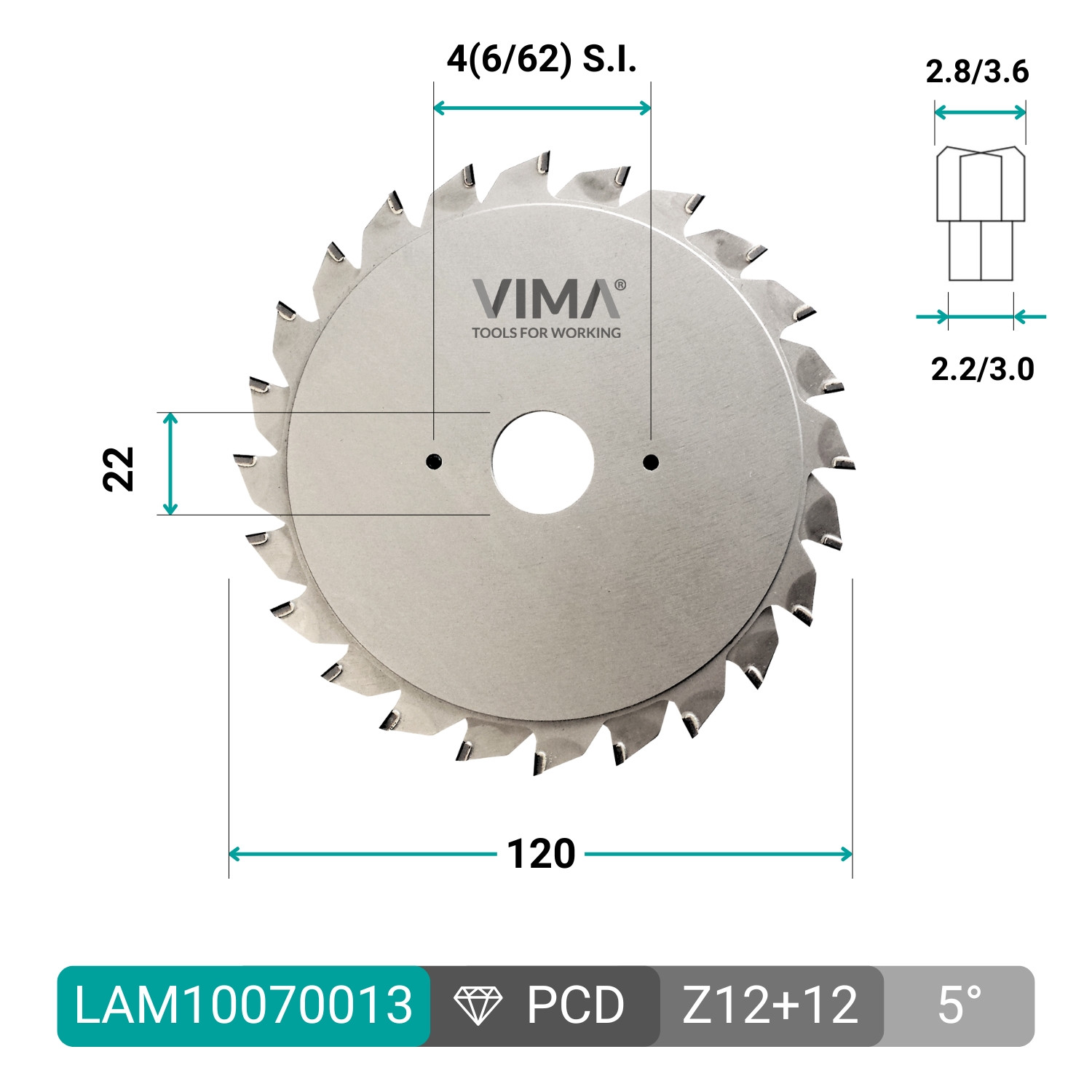

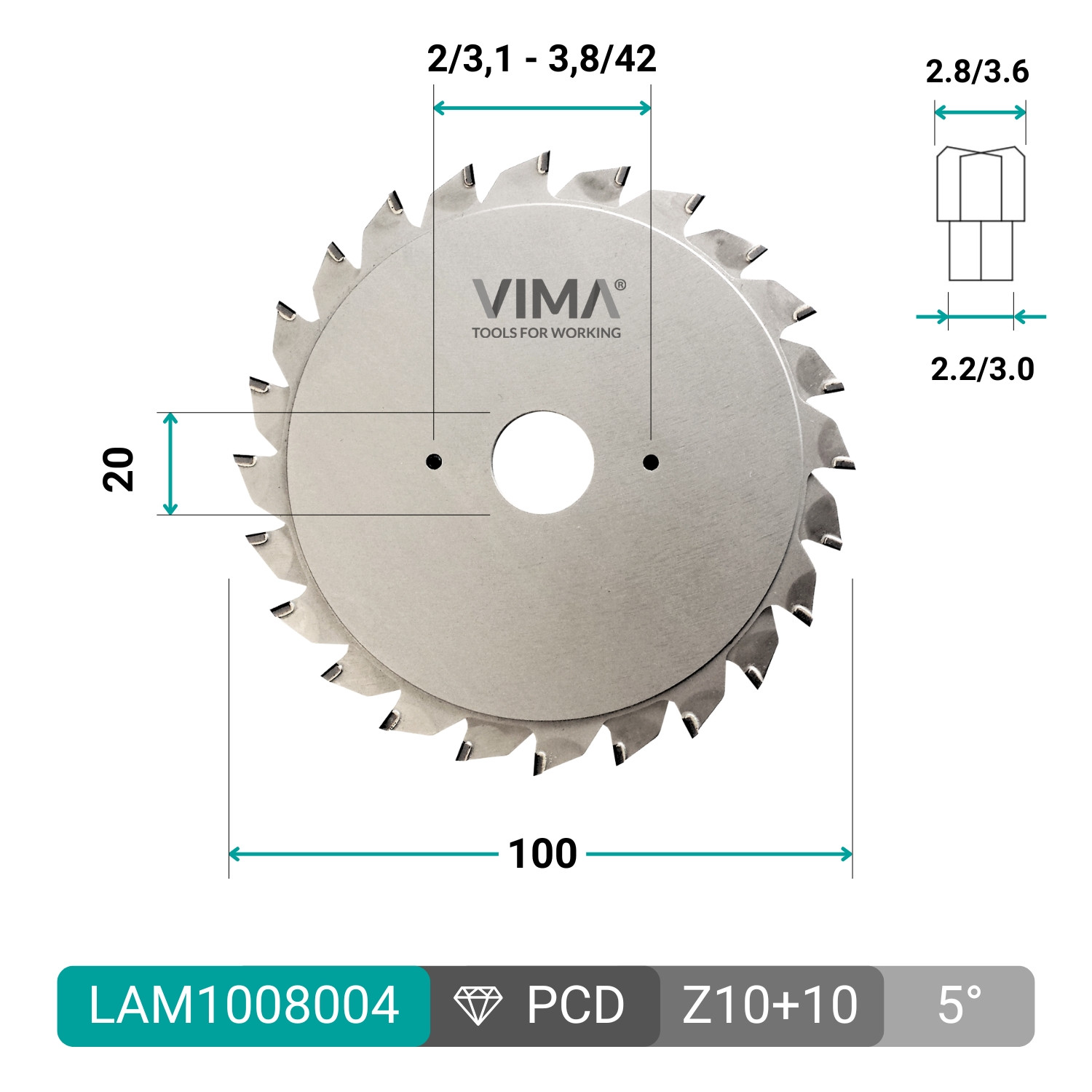

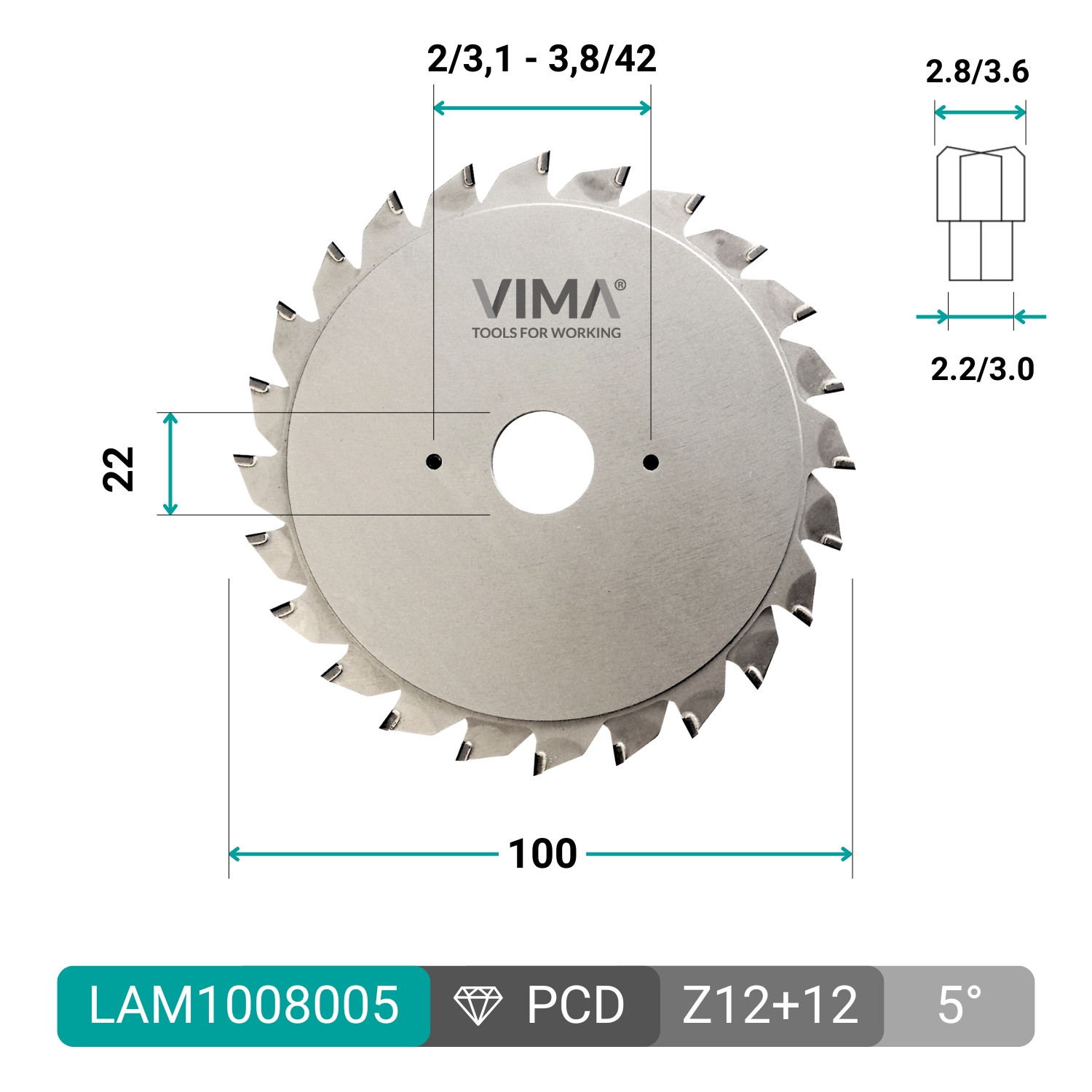

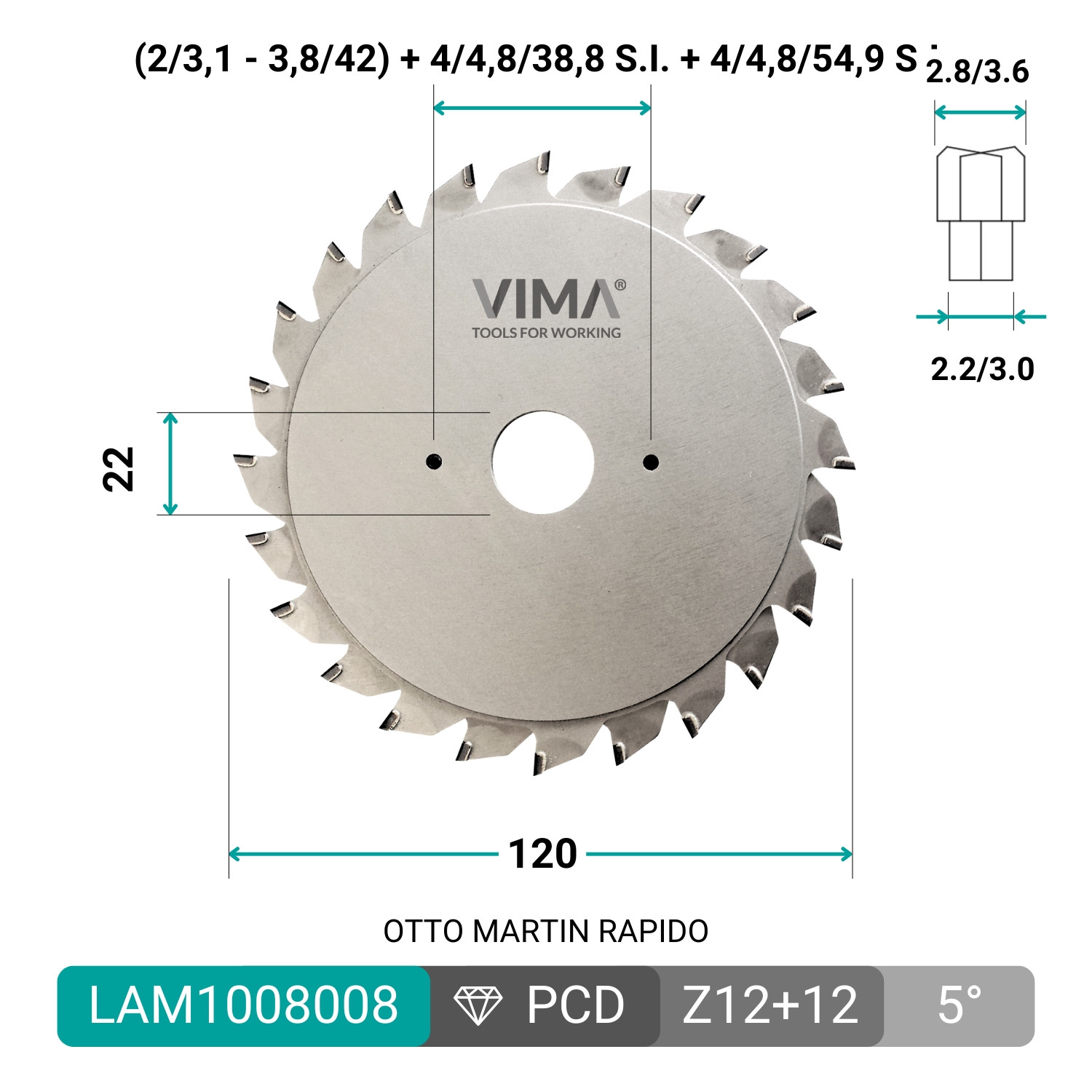

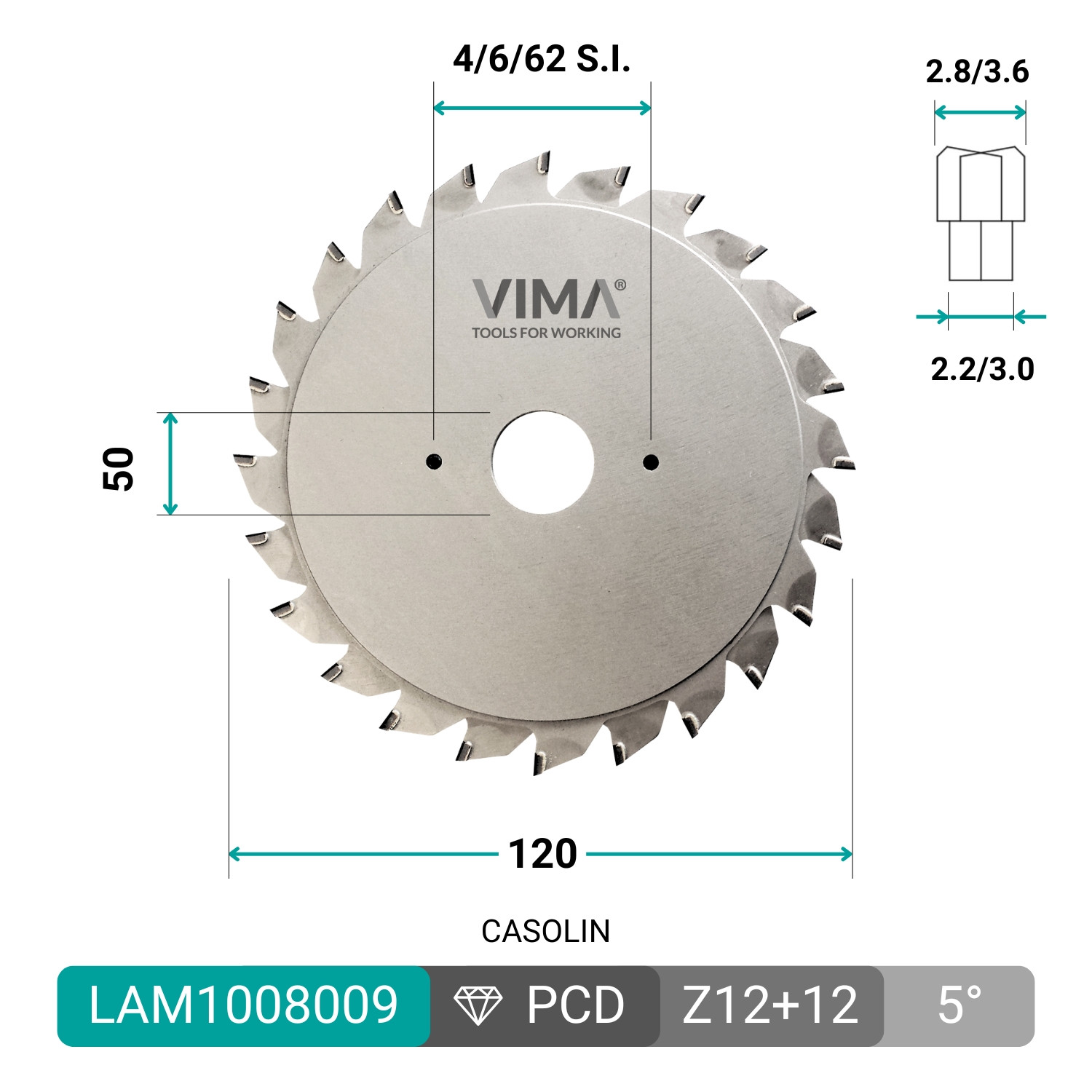

Adjustable PCD scoring blade designed for accurate, chip-free scoring on laminated panels. The 6 mm PCD height ensures exceptional durability, while the adjustable width allows perfect alignment with the main blade. Ideal for professional horizontal panel saws.

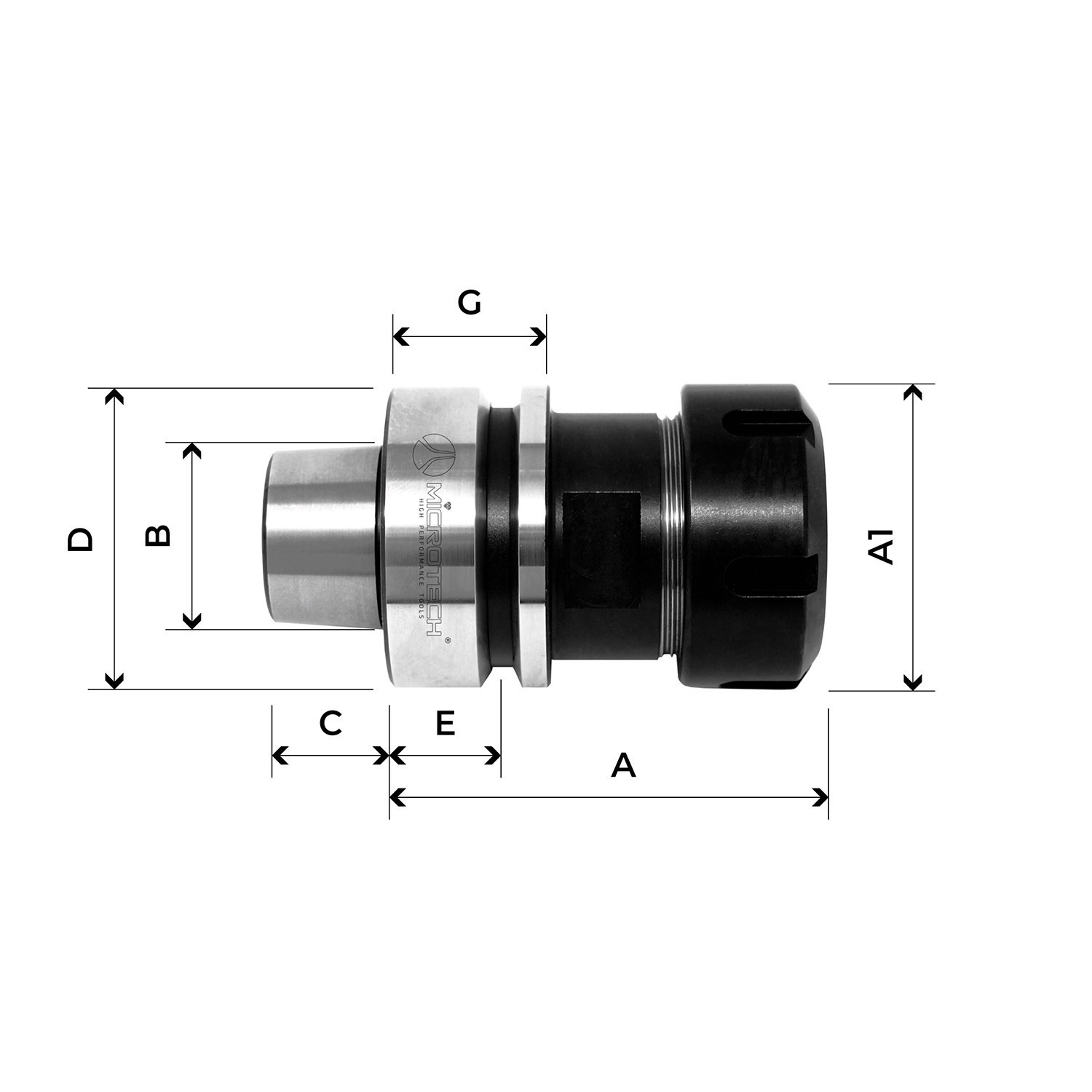

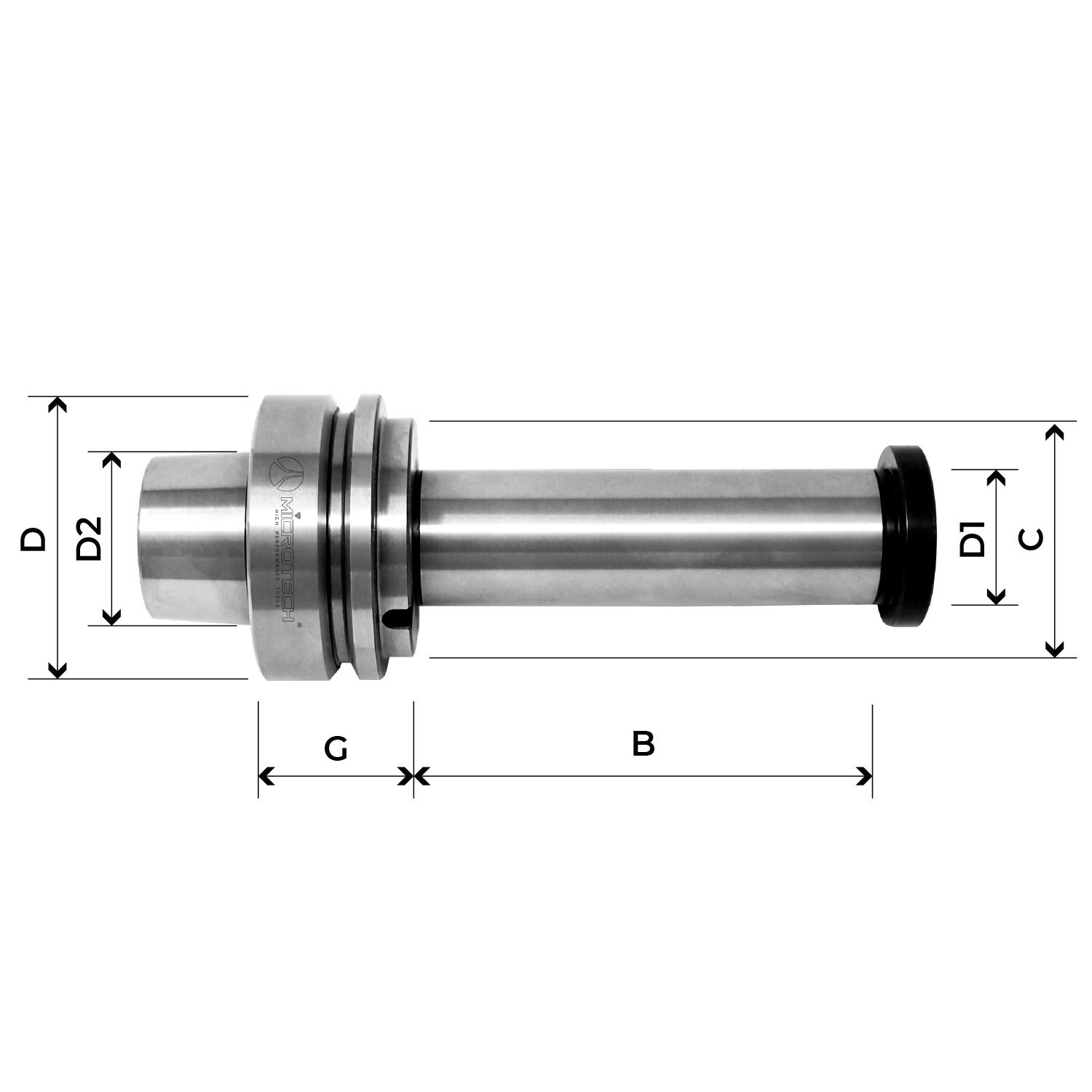

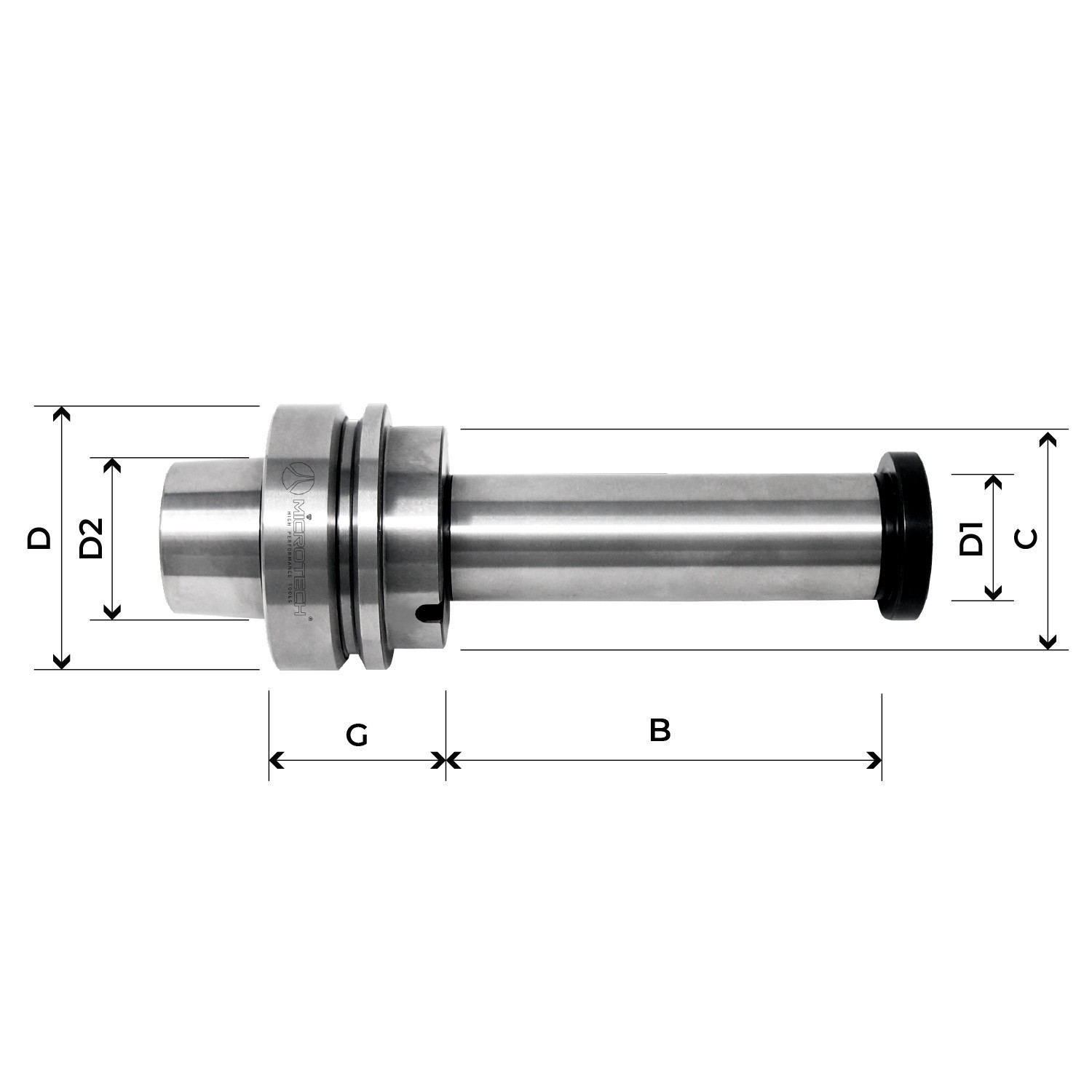

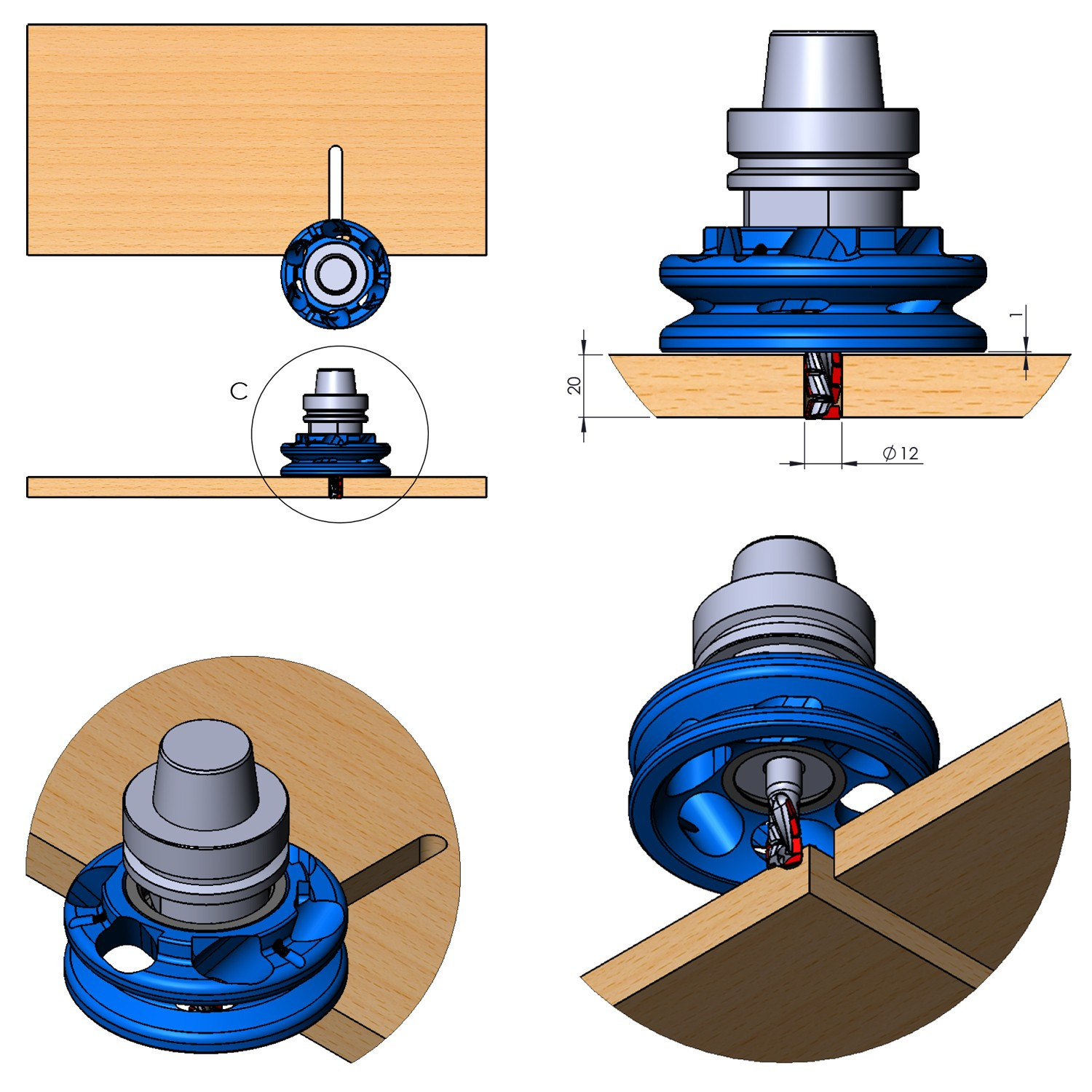

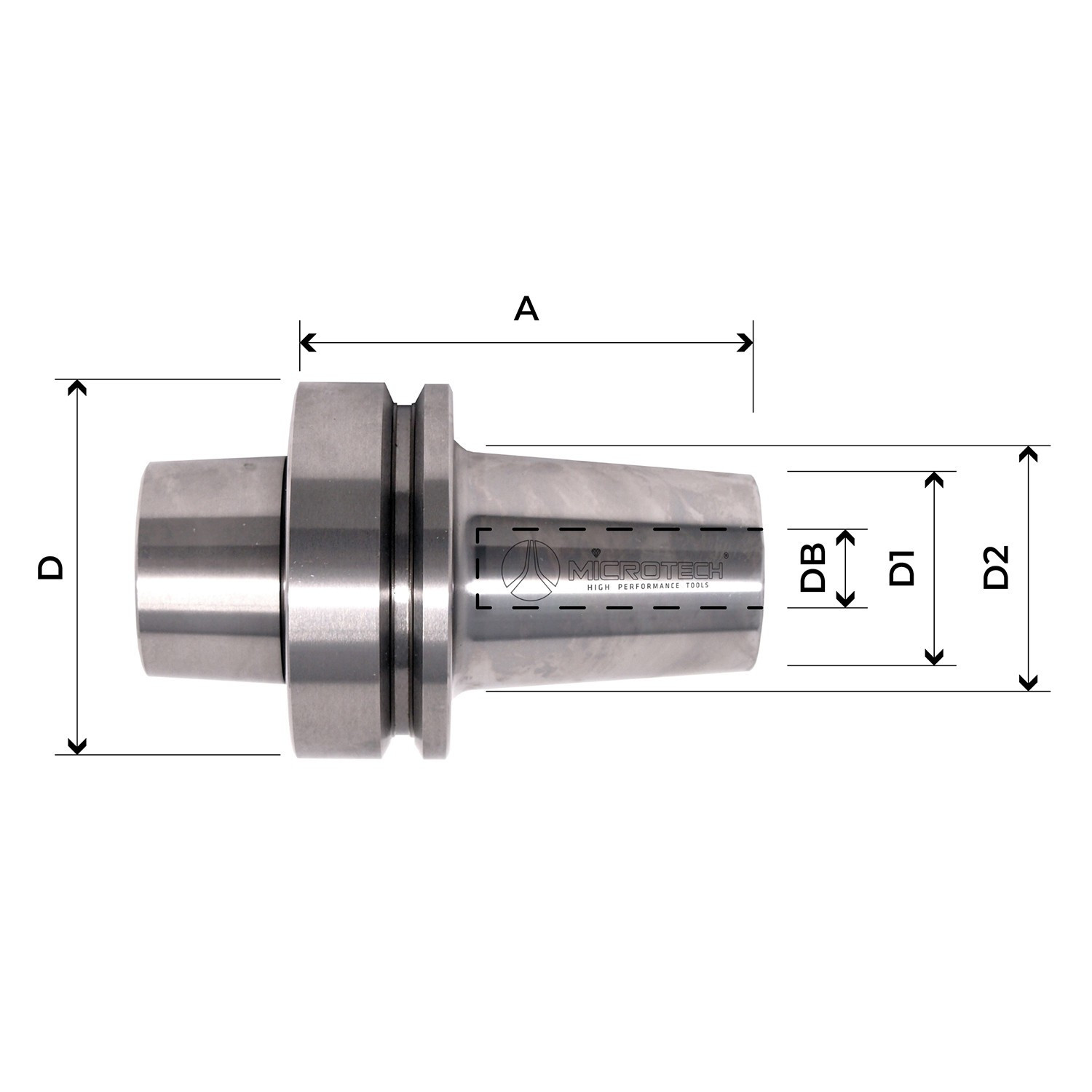

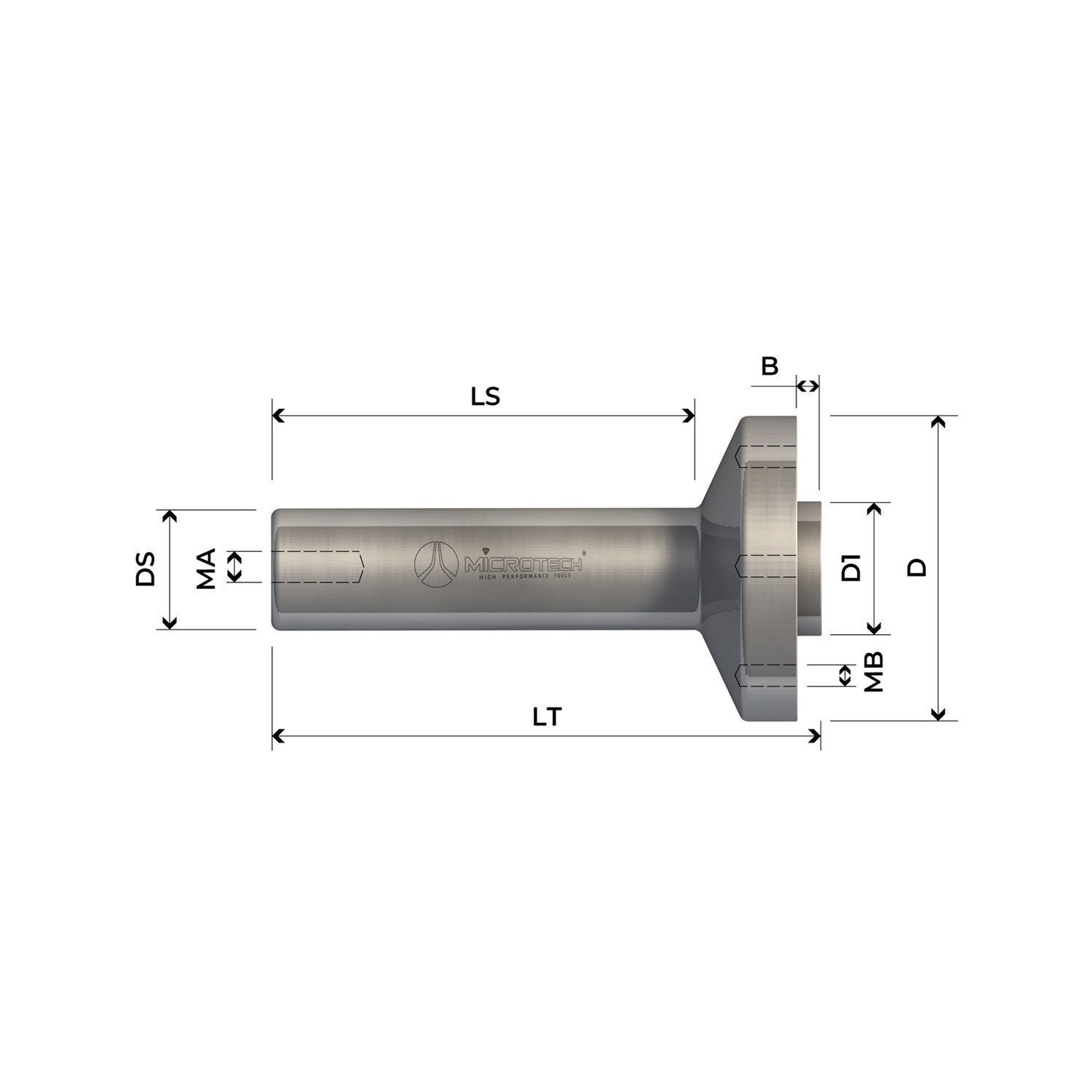

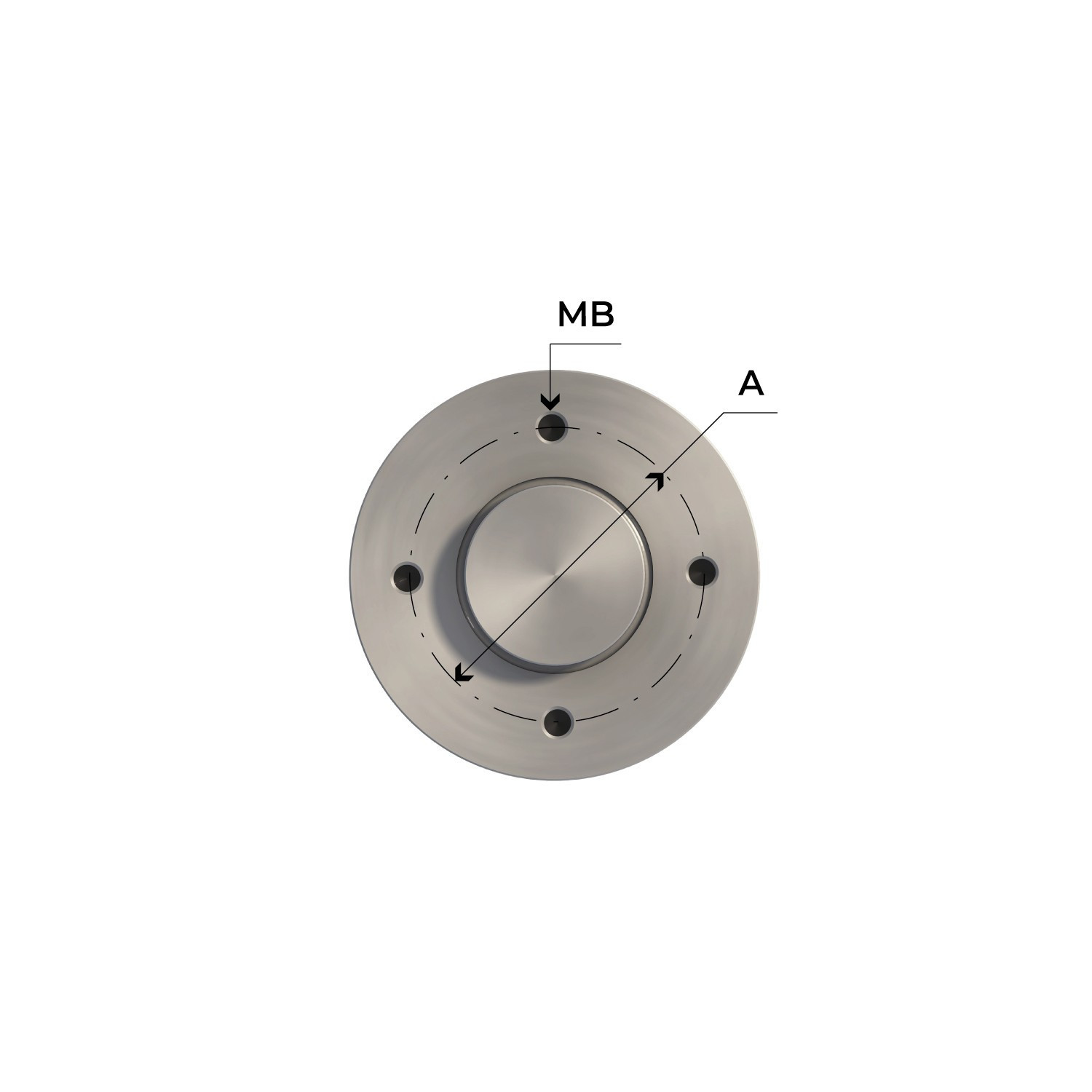

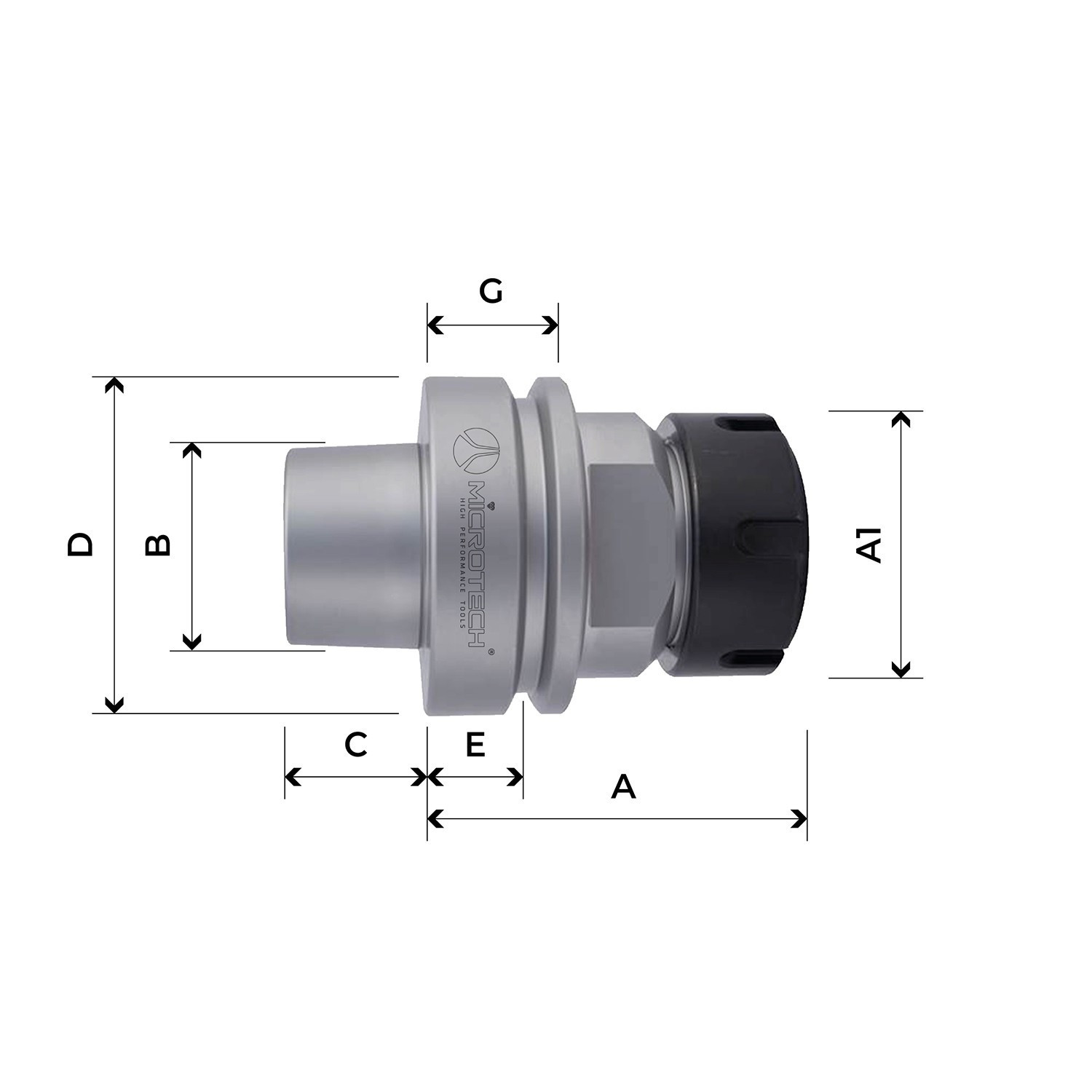

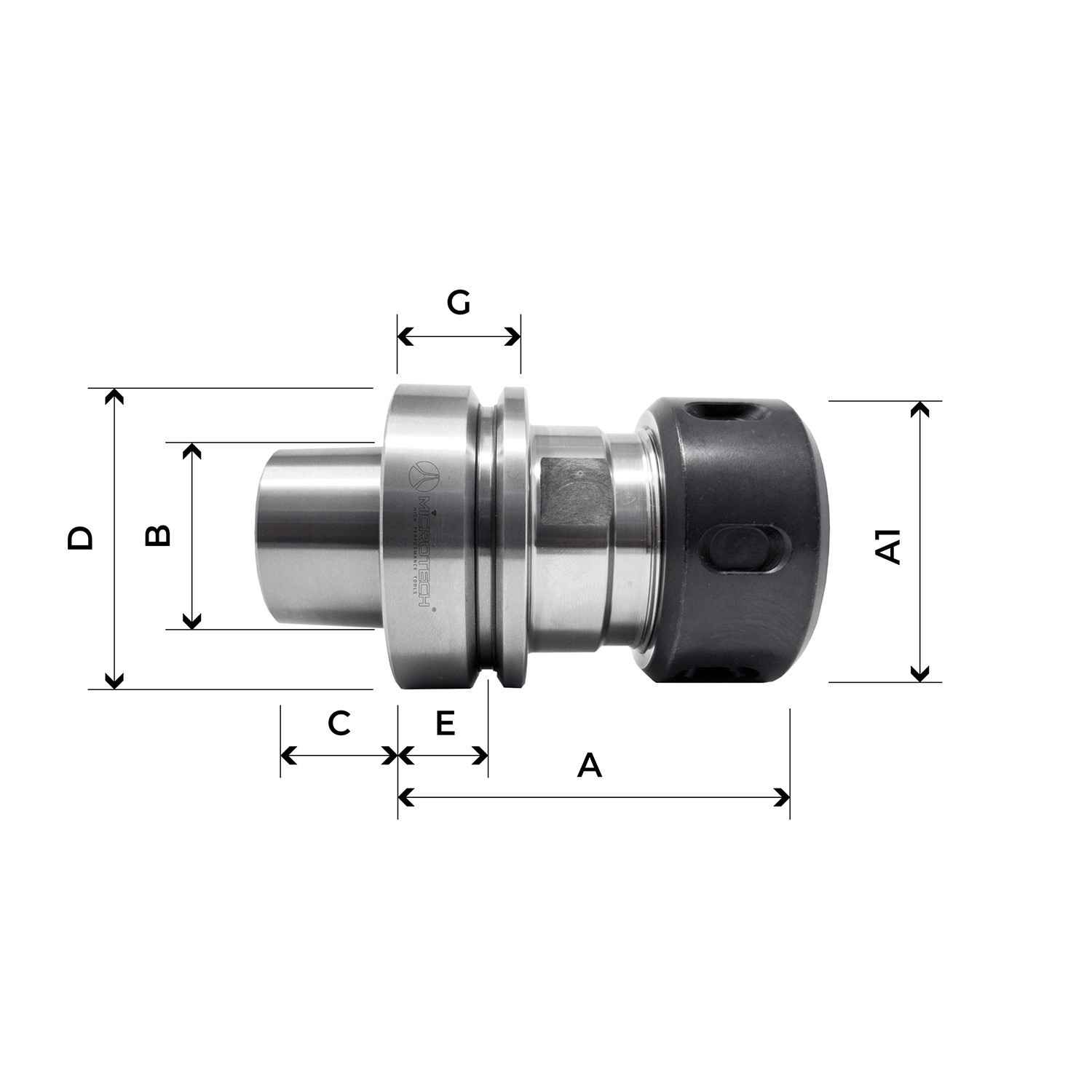

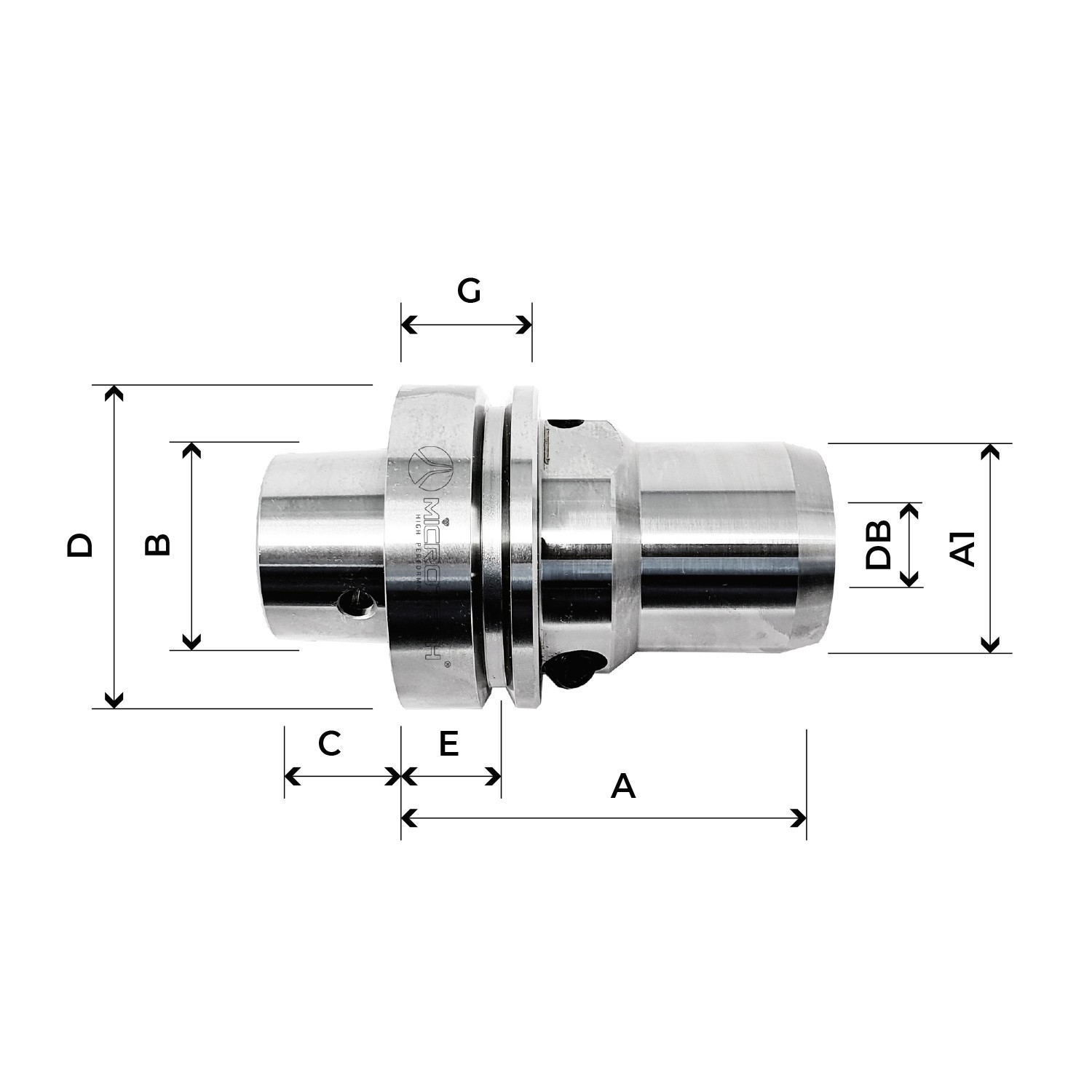

HYDRO HSK63F spindle with shaft/bore tolerance +/- 0.006. HSK63F high precision spindle and clamping force. TheTOOL shank must be with tolerance H6. Do not tighten the clamping screw if there is no tool inside. Clean the tool shank and the spindle hole thoroughly before inserting the cutter.

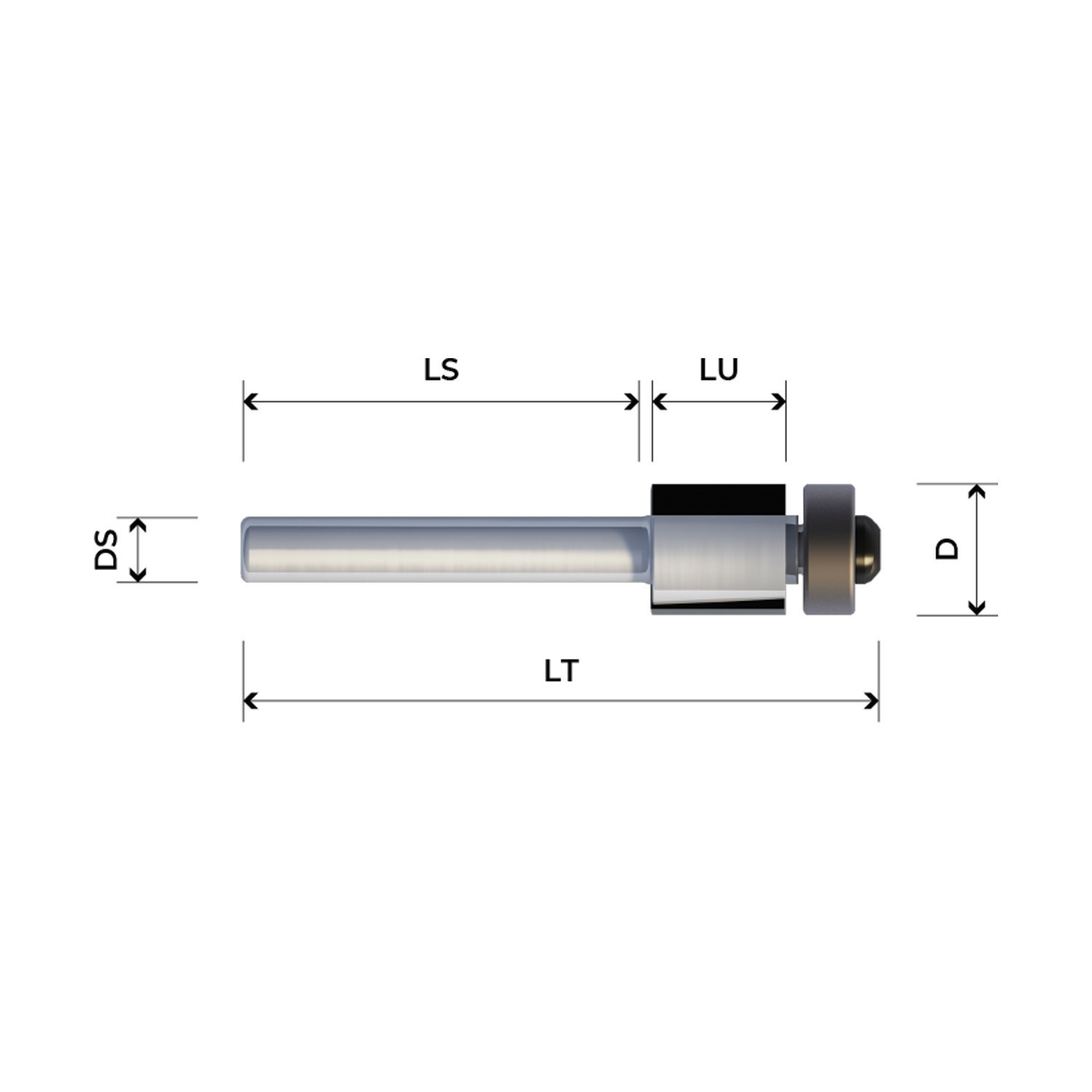

Bearing guided trimming bit in PCD diamond developed for precise, controlled manual trimming on panels and compact materials. The Z2 negative cutting geometry and the reduced axial angle provide stable cutting and a clean finish, even on delicate or coated surfaces.

• PCD cutting edge H2.5mm for extended service life

• Z2 negative geometry for stable, chip free edges

• Integrated bearing for accurate and repeatable trimming

Solid hardmetal helical tool with Z1 positive geometry designed for aluminium machining on CNC routers and machining centres, delivering stable cutting action and a clean surface finish.

• Z1 geometry for efficient chip flow

• Polished inner and outer flutes to reduce built up edge

• Suitable for high speed CNC work up to 24000 rpm

.jpg)