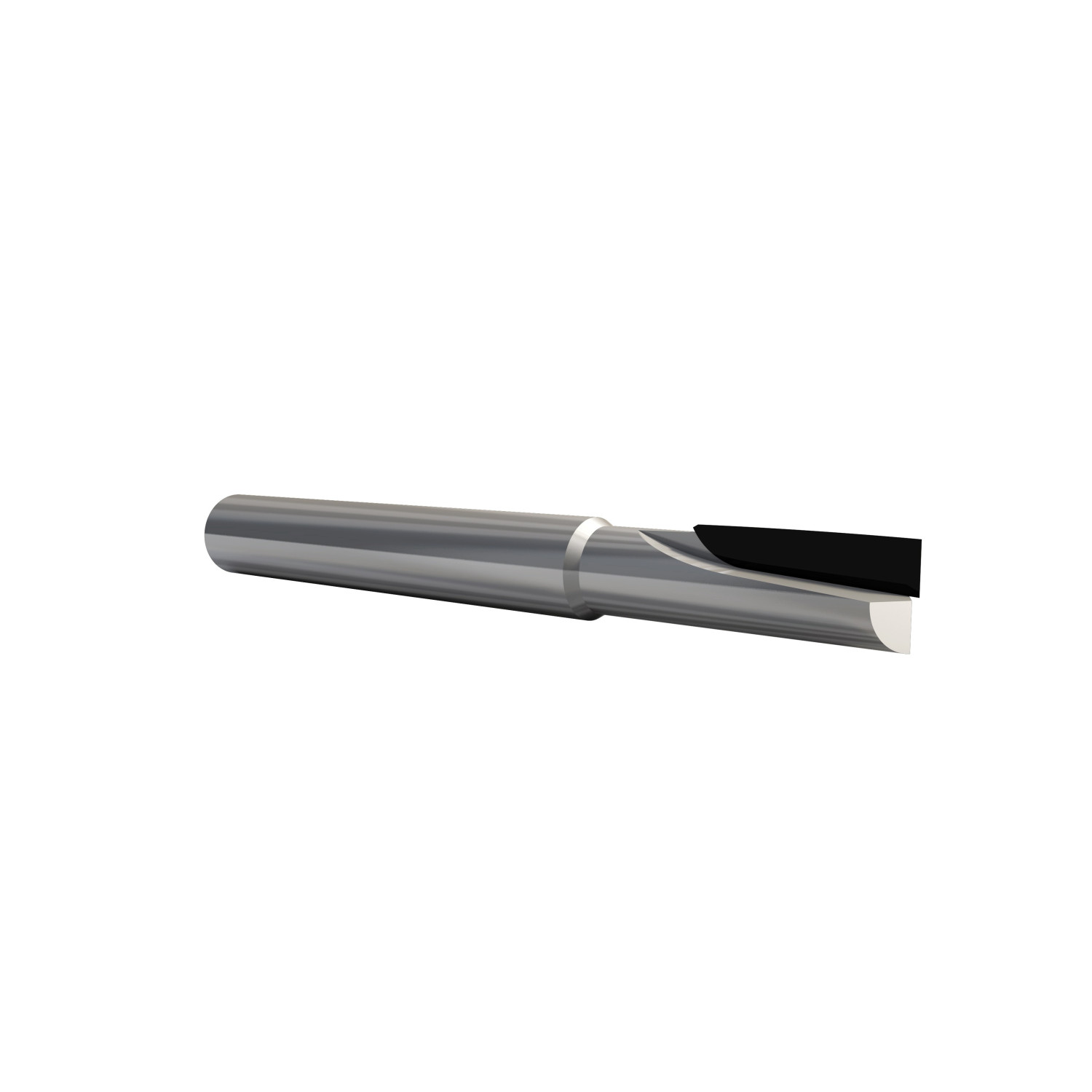

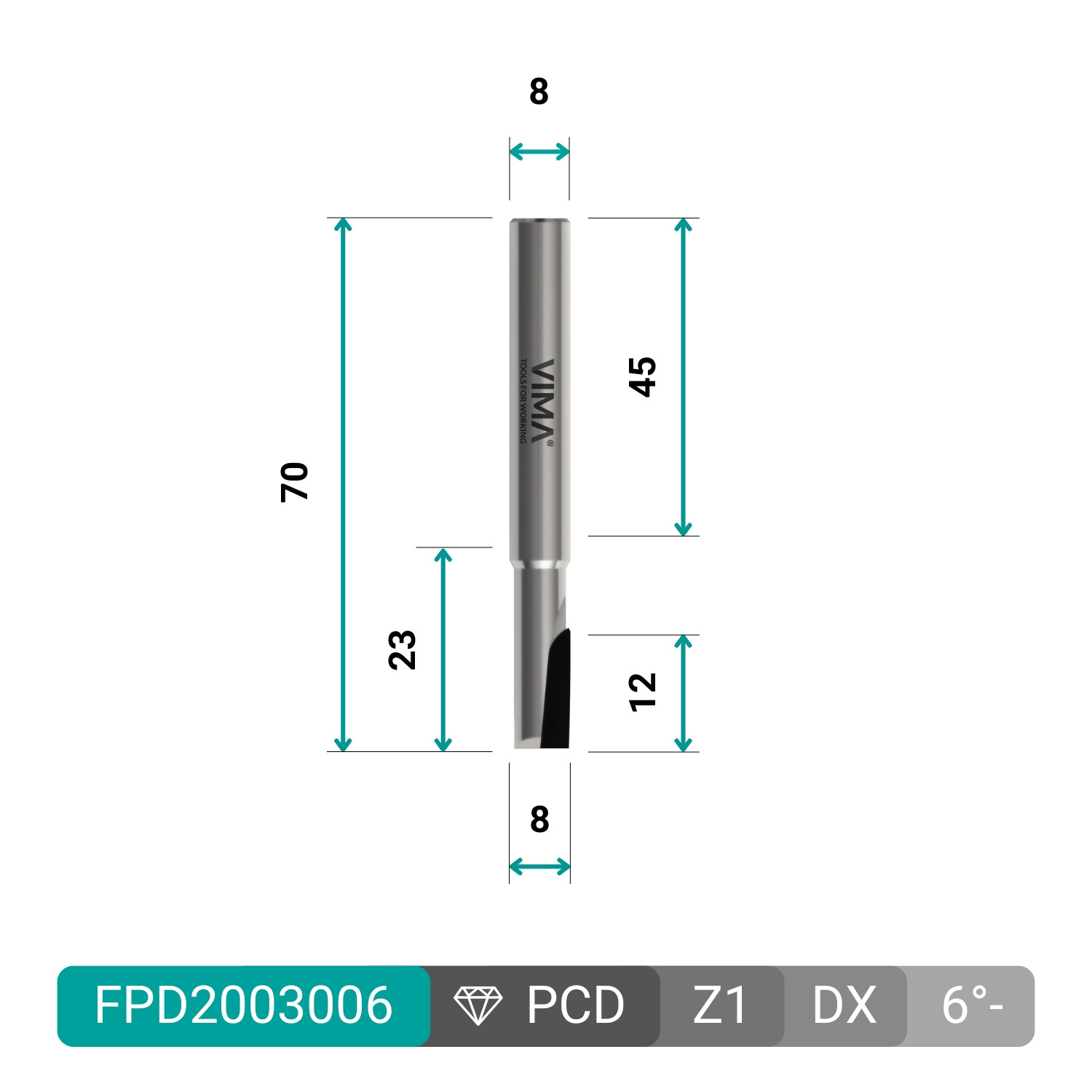

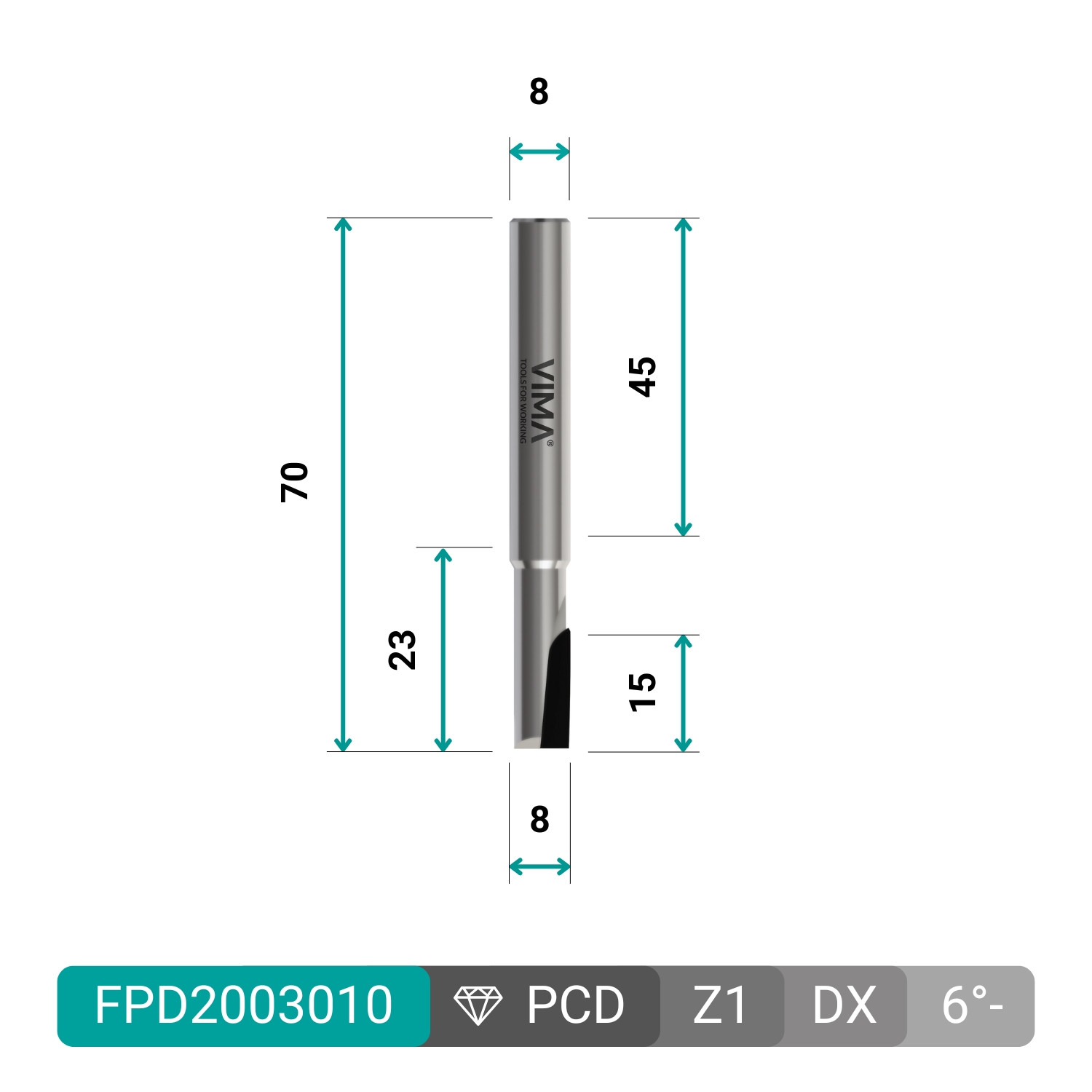

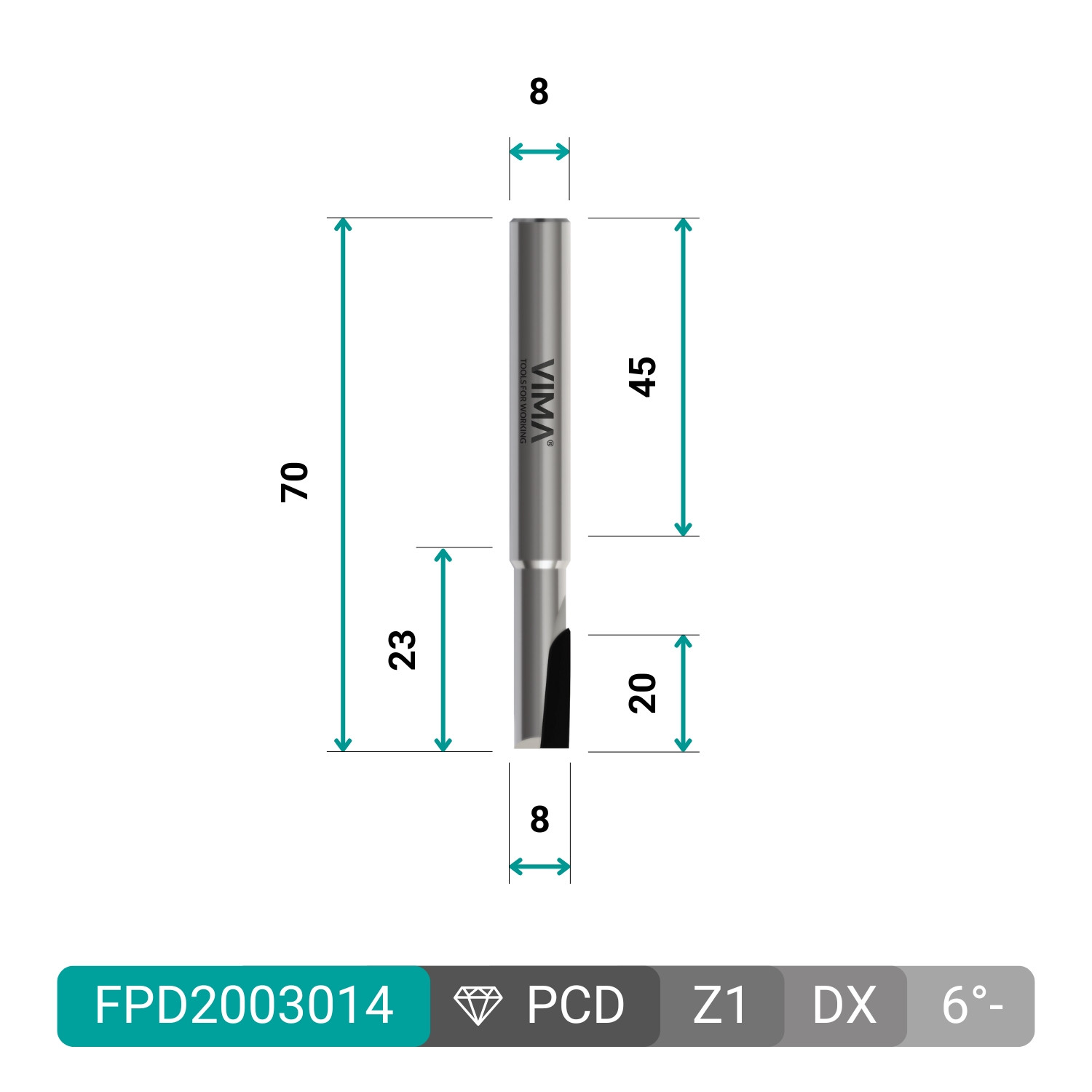

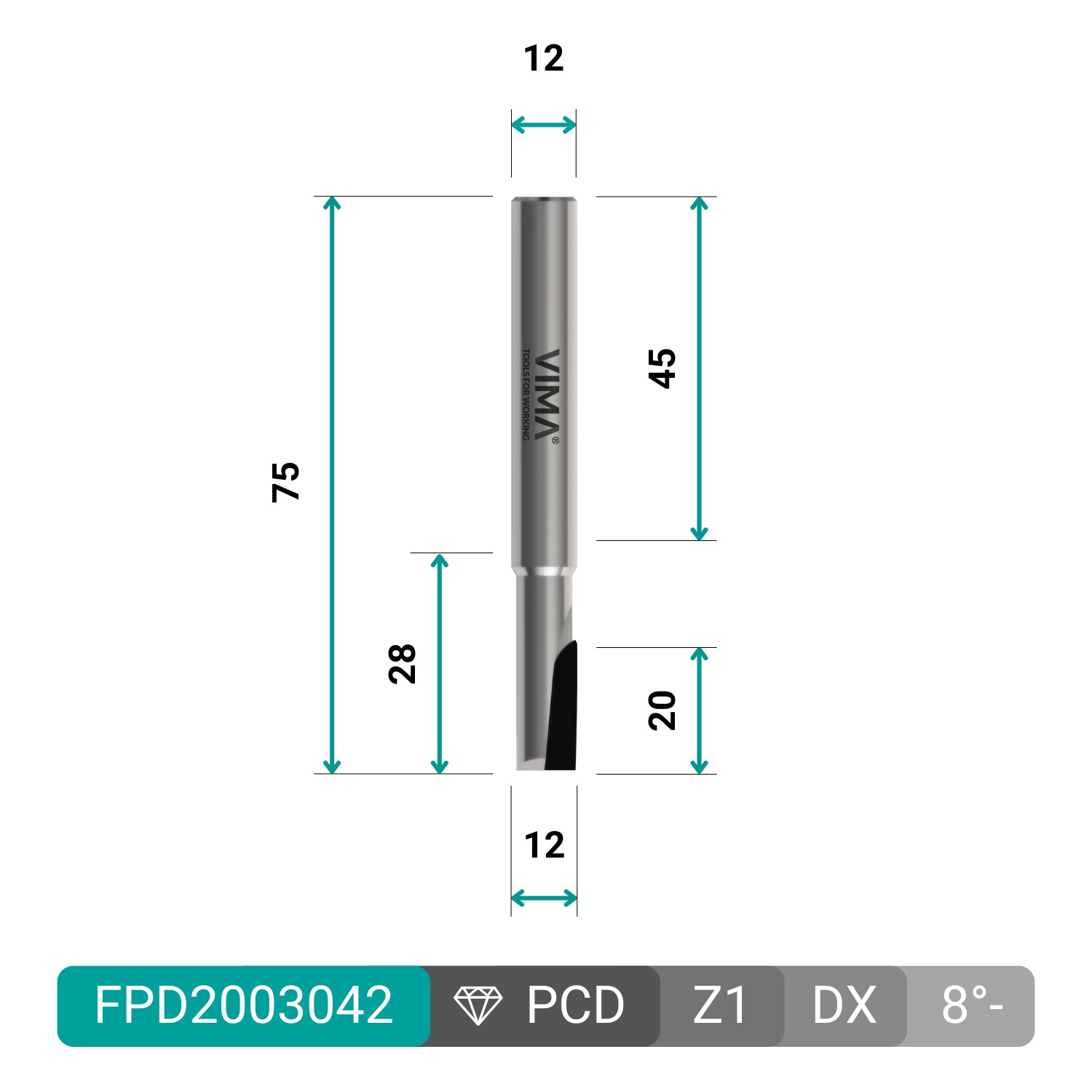

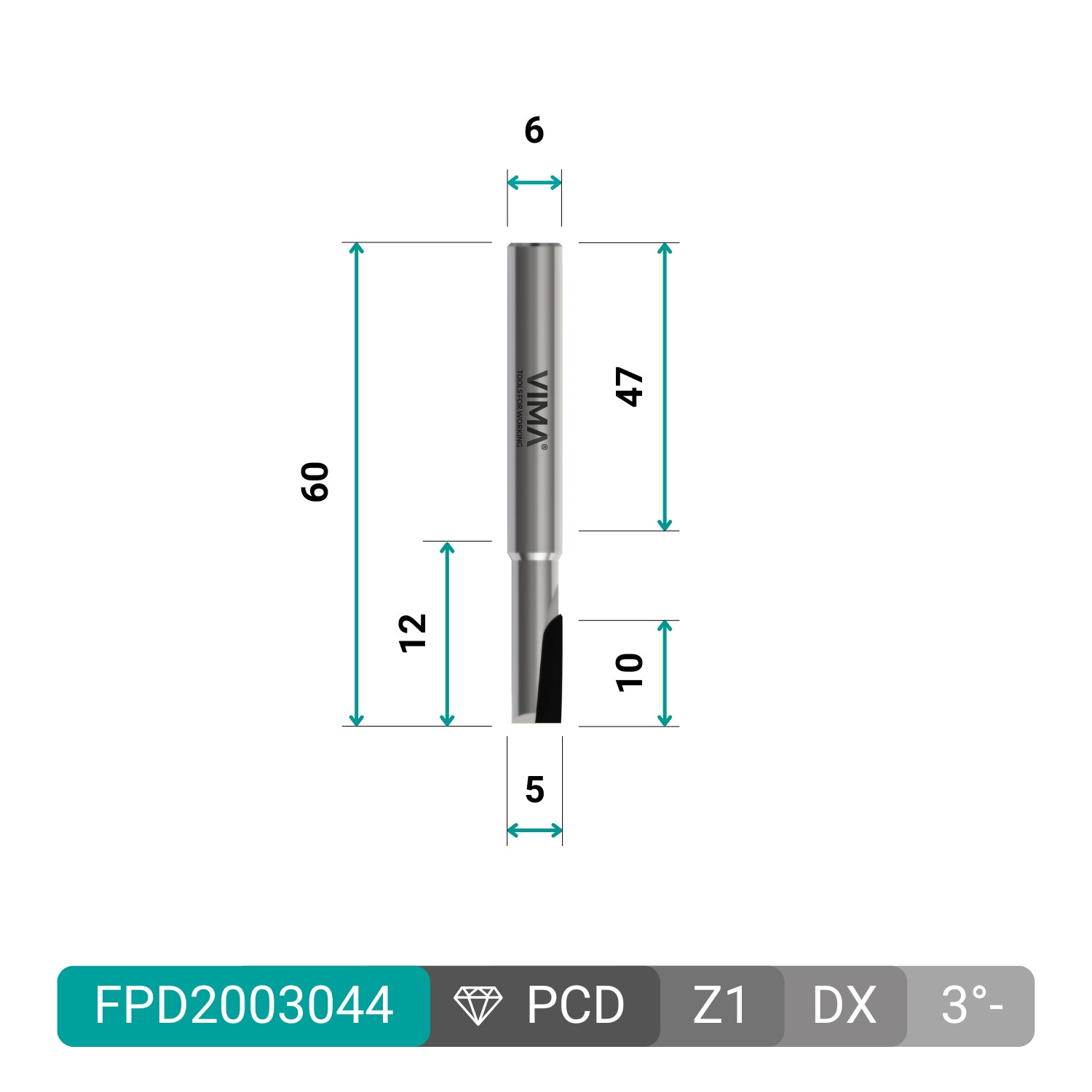

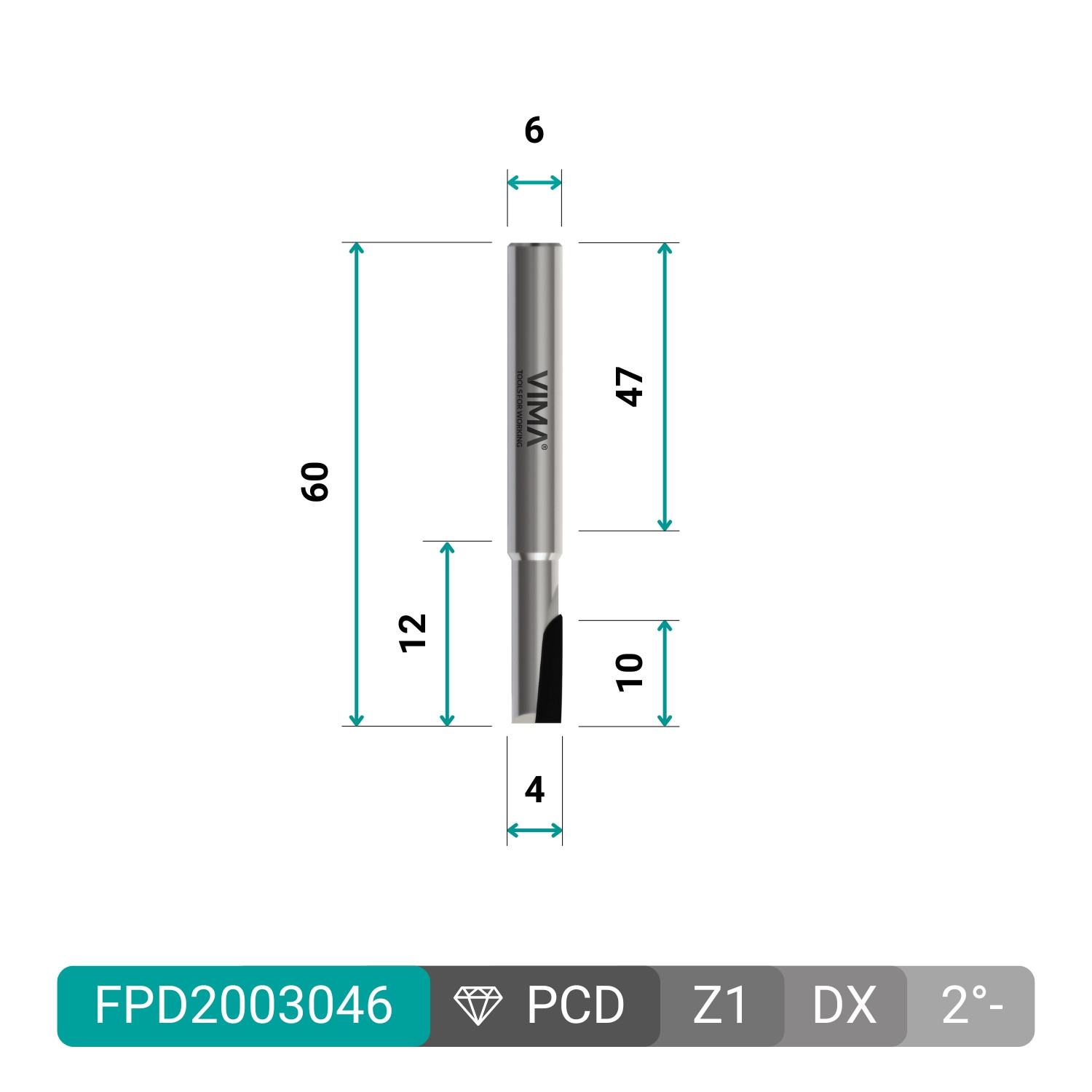

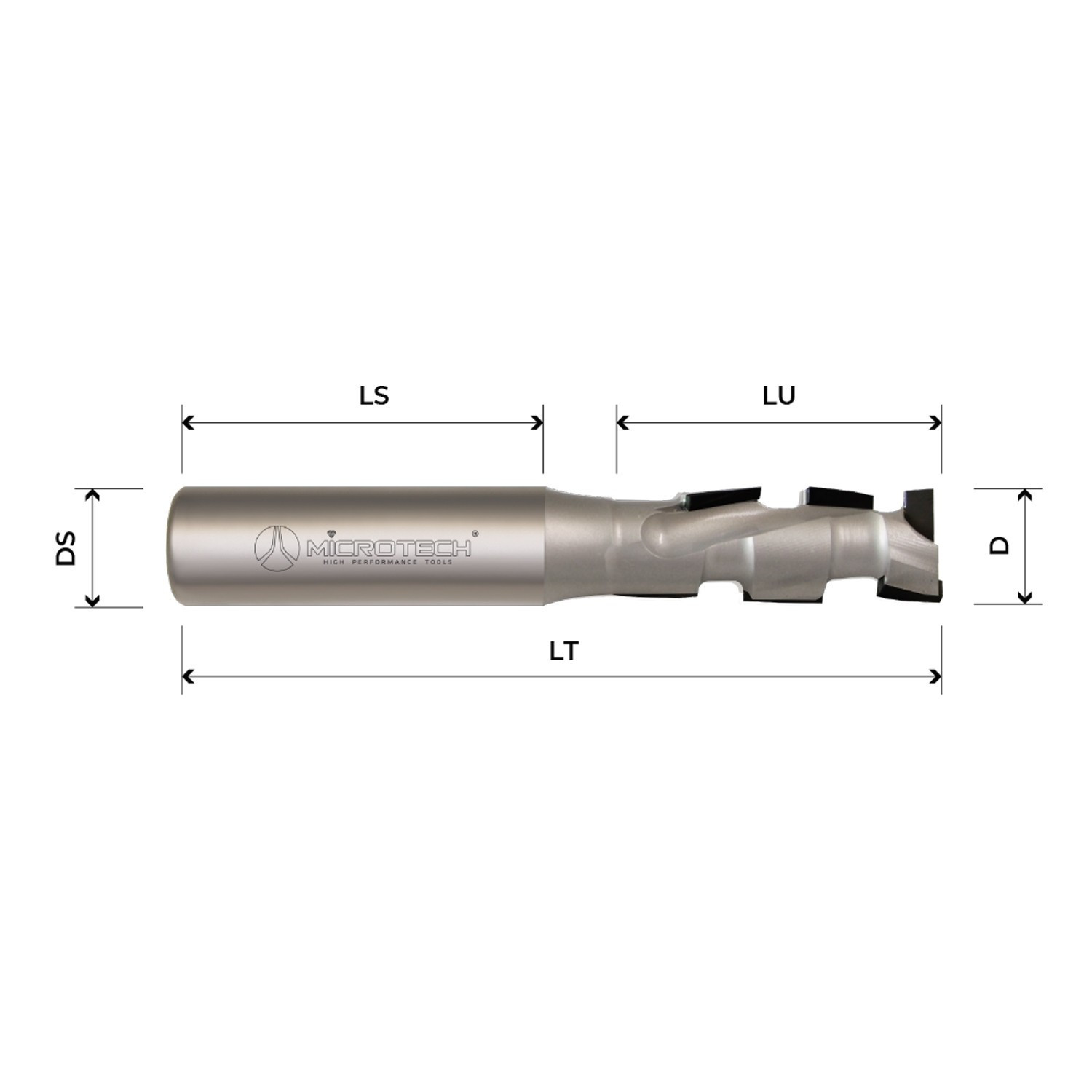

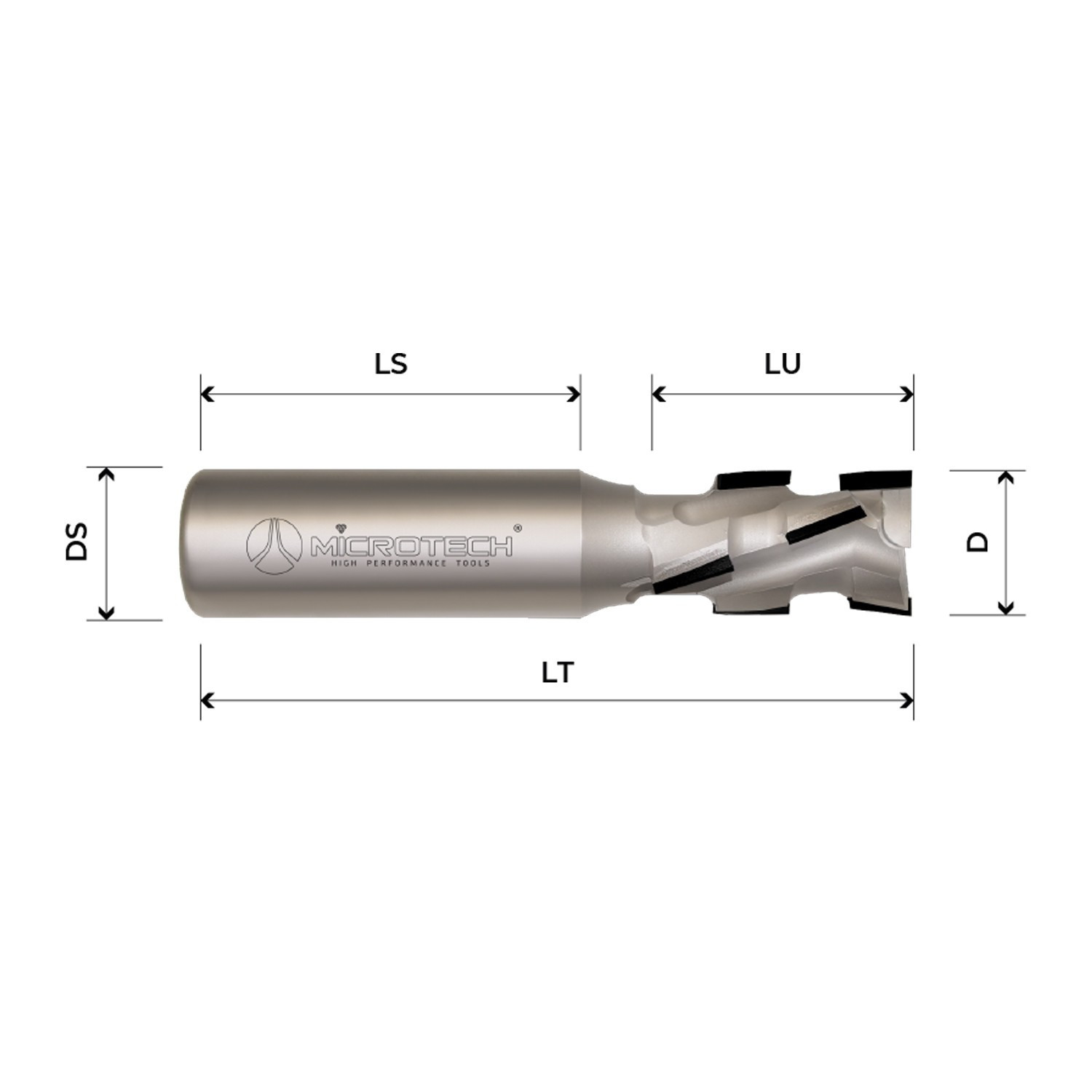

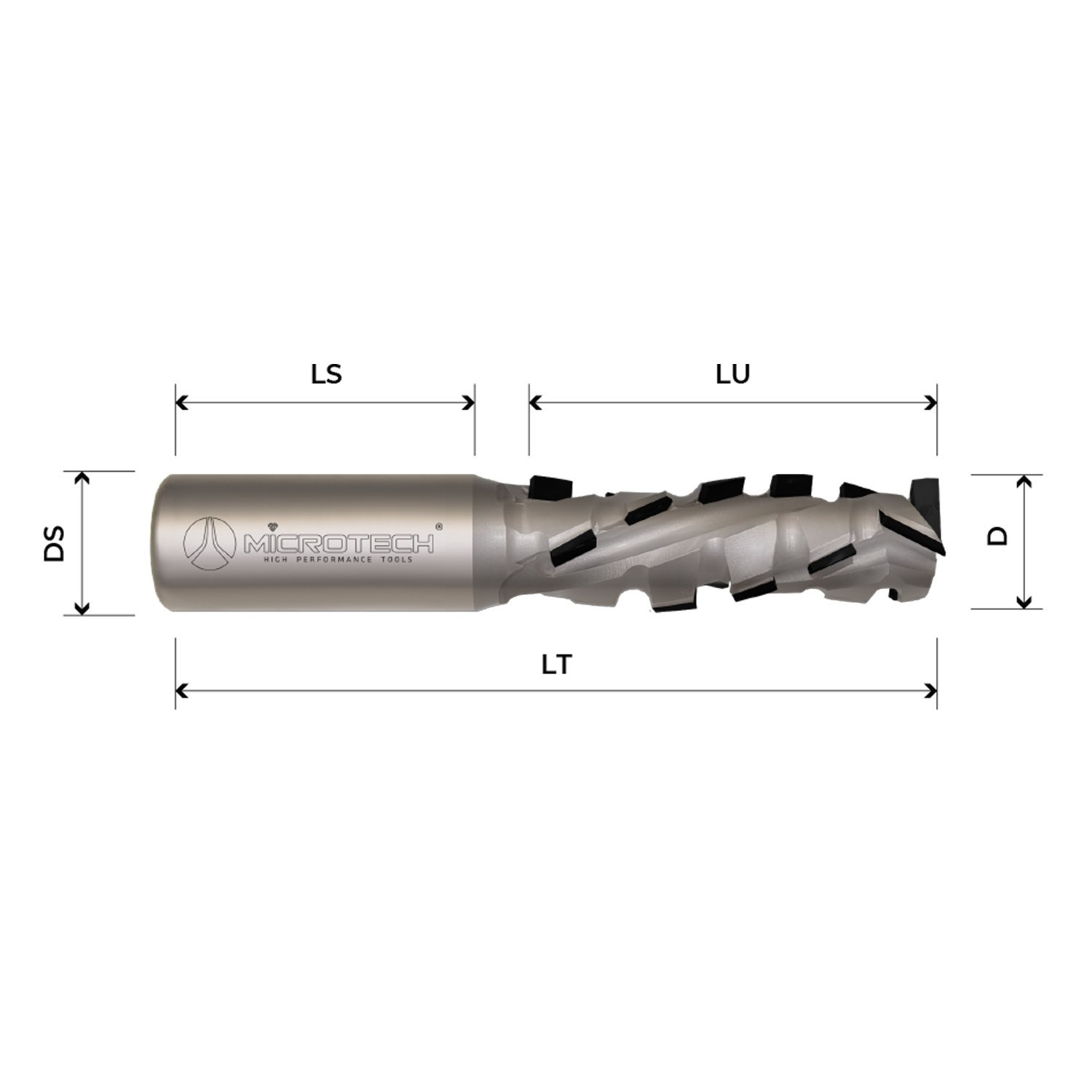

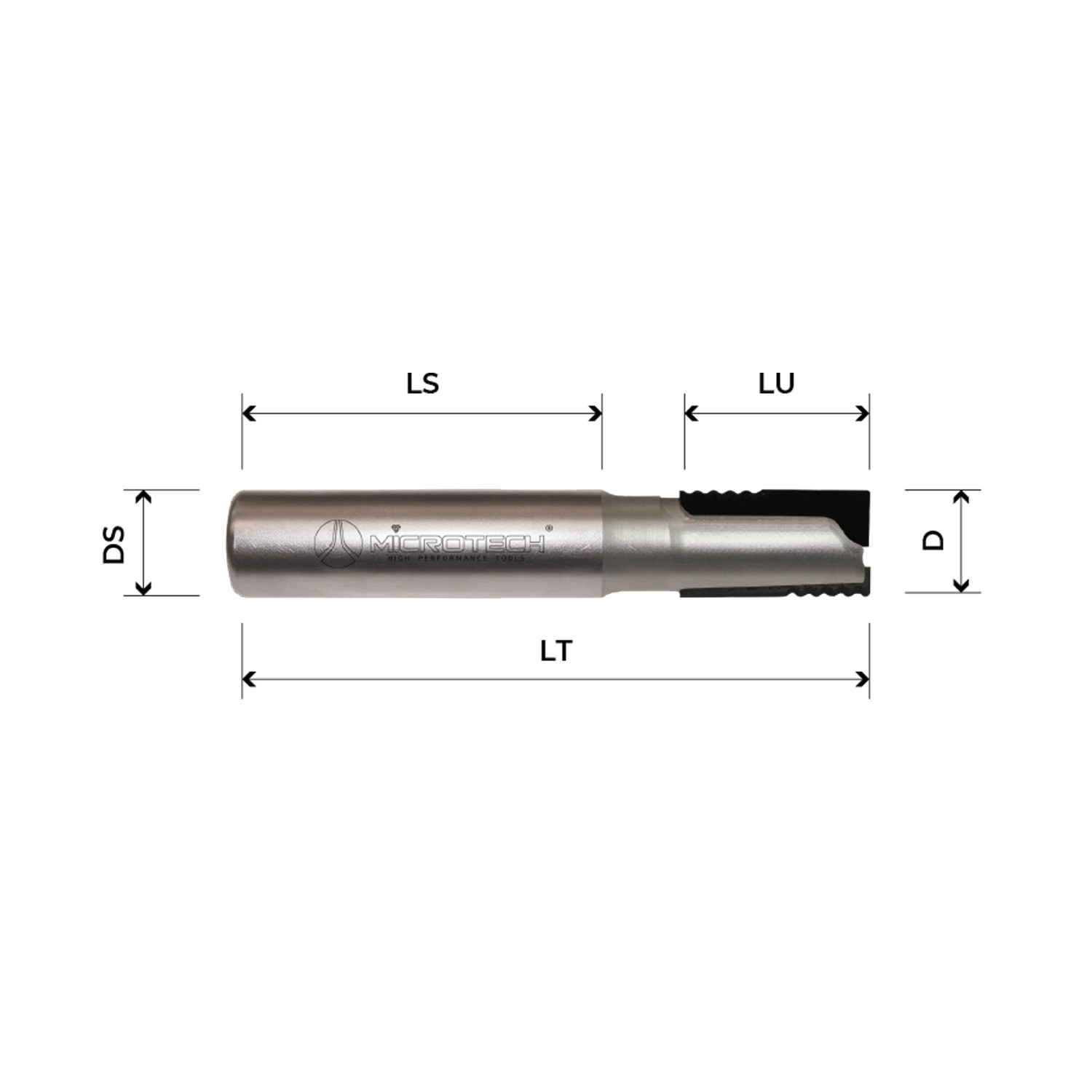

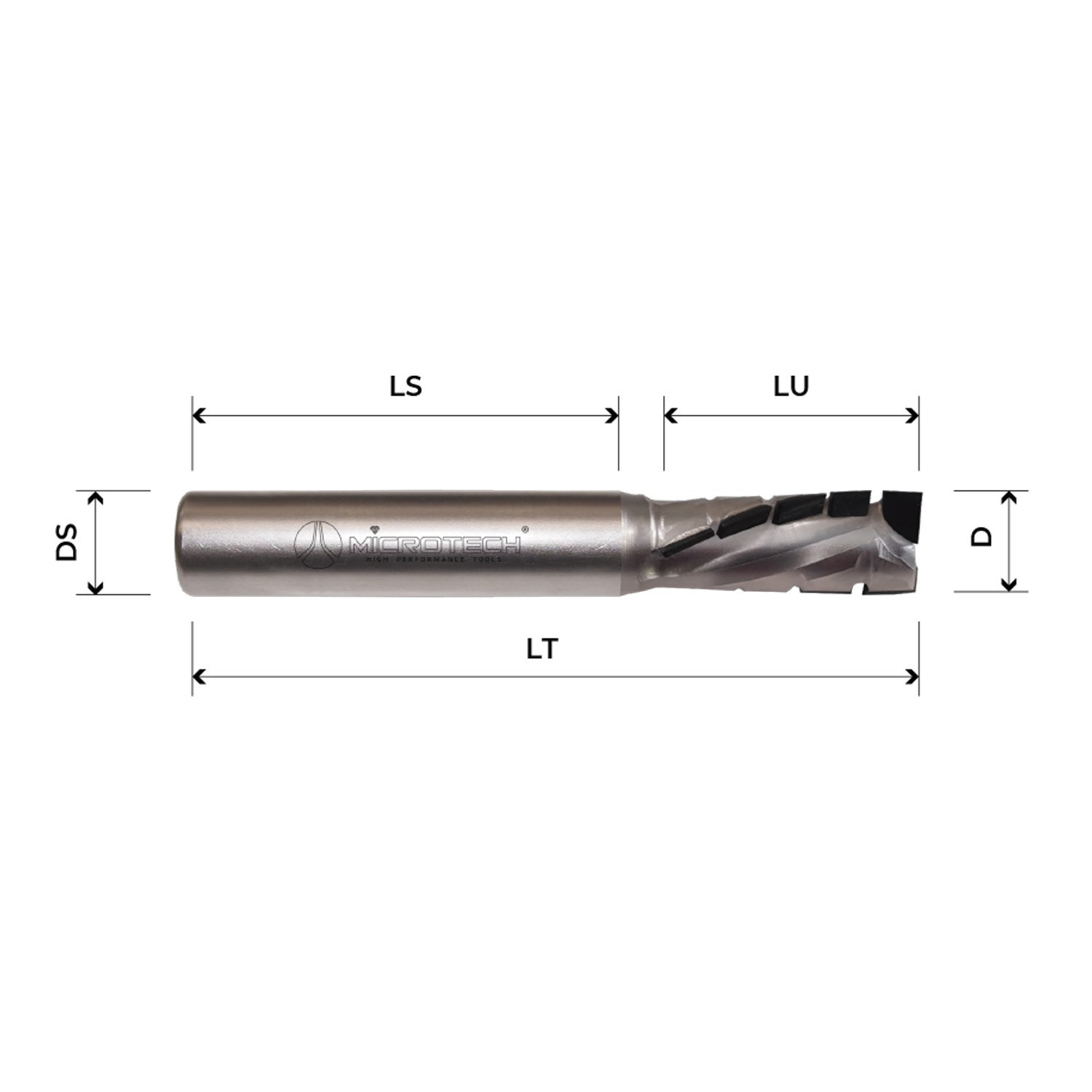

PCD diamond router bit designed for groove cutting with high surface quality on coated panels. The negative Z1 cutting edge and solid carbide body ensure maximum stability, controlled material removal and clean finishes even on delicate surfaces.

• PCD cutting edge H 3.5 mm for long tool life

• Negative Z1 cutting edge for superior panel finish

• Solid carbide body for high rigidity and stability

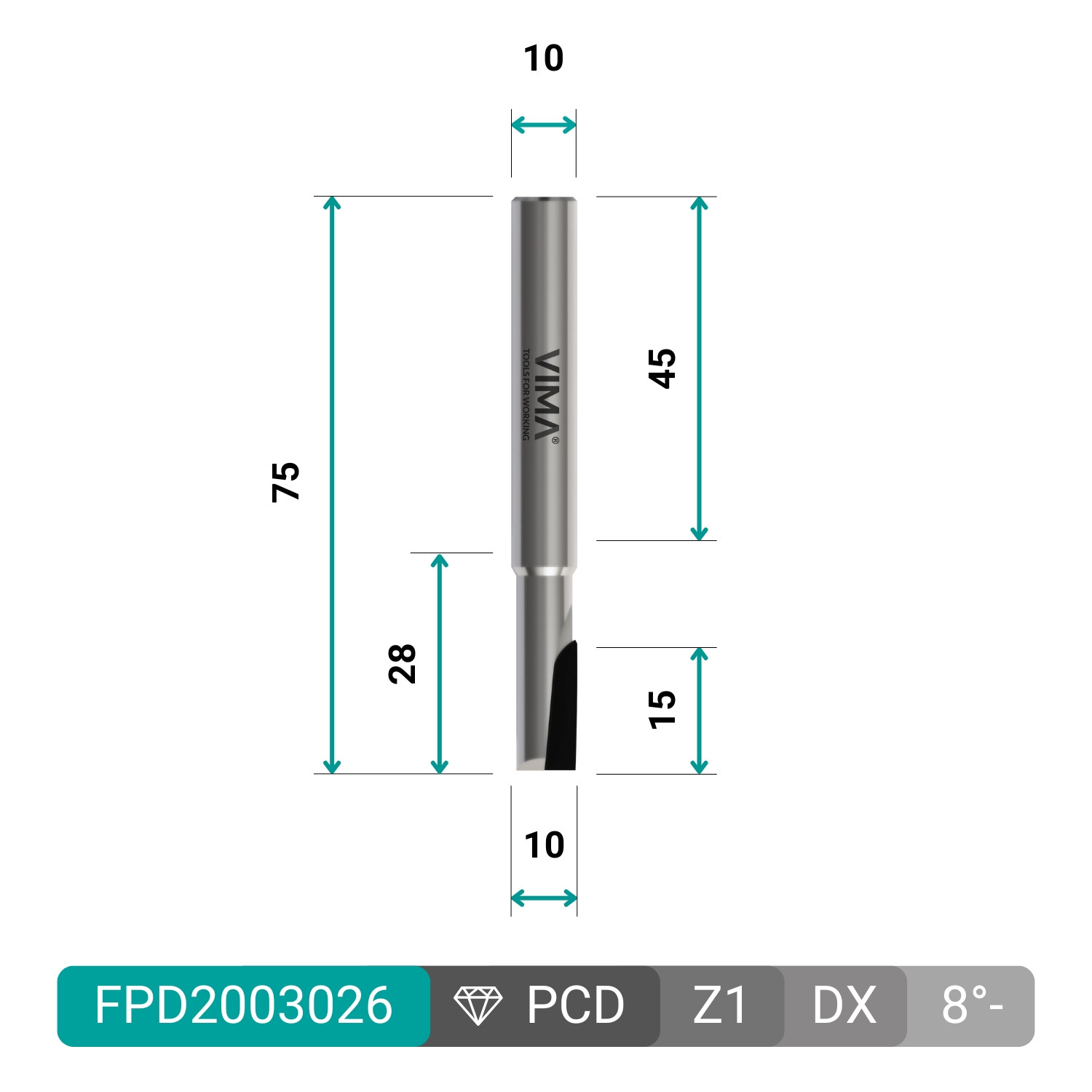

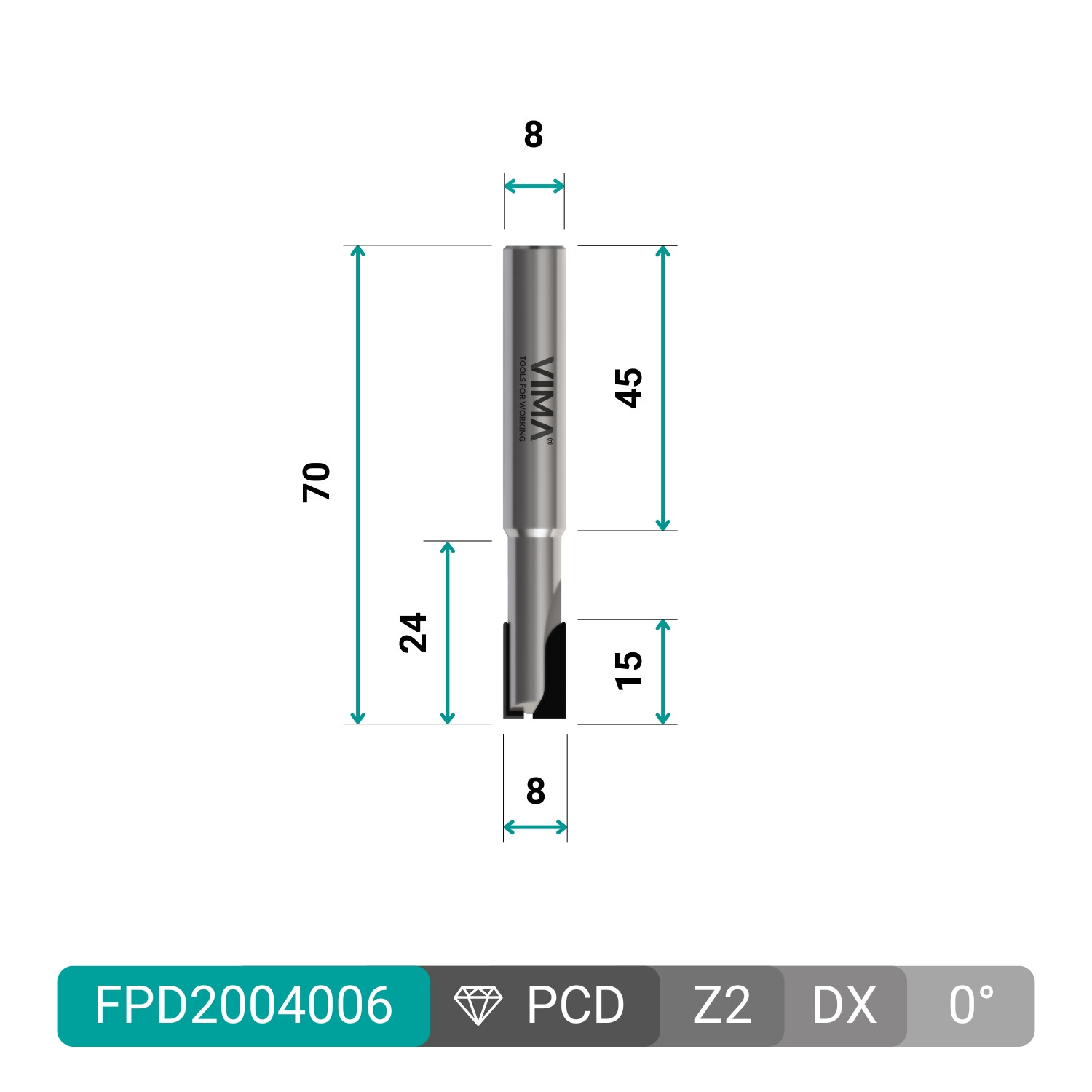

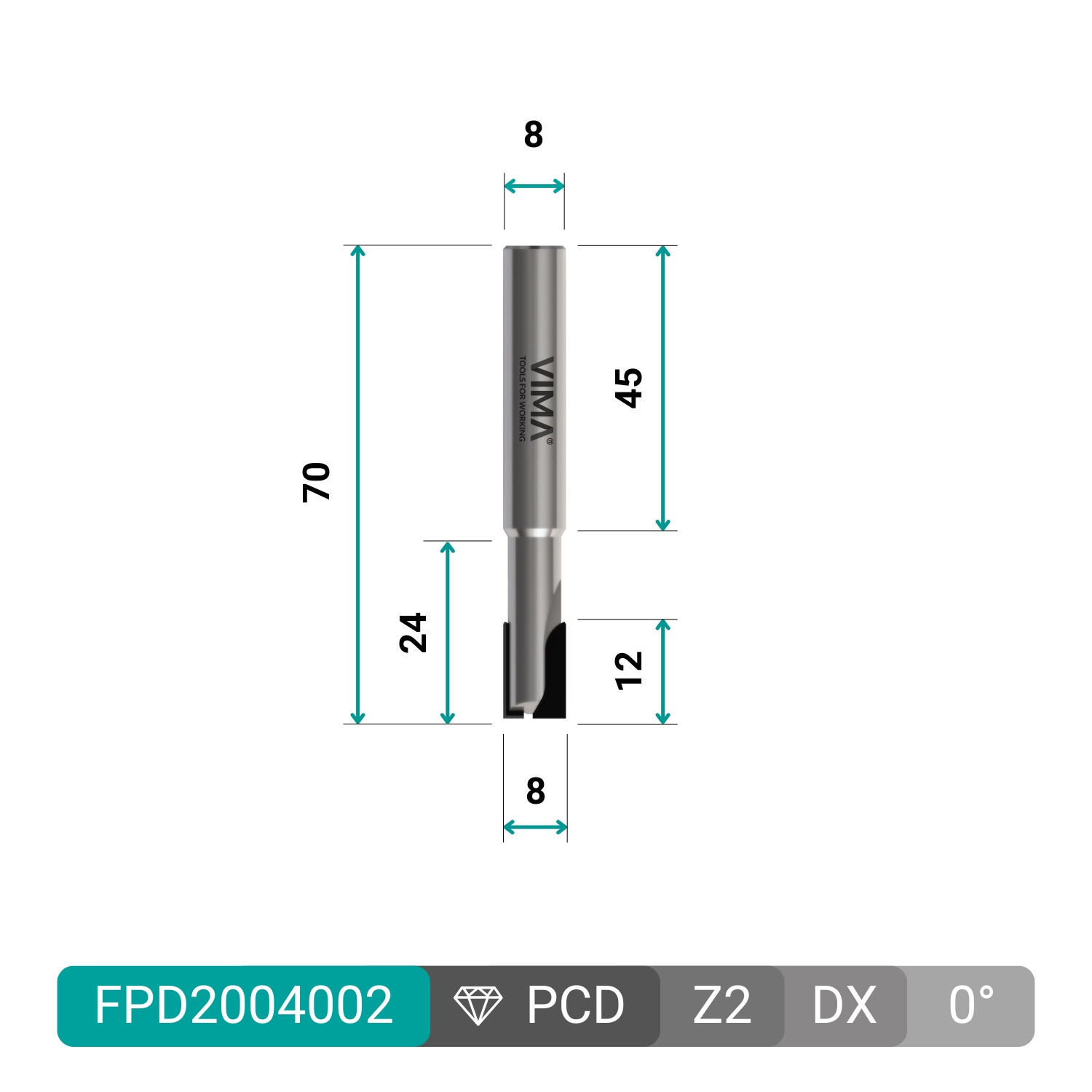

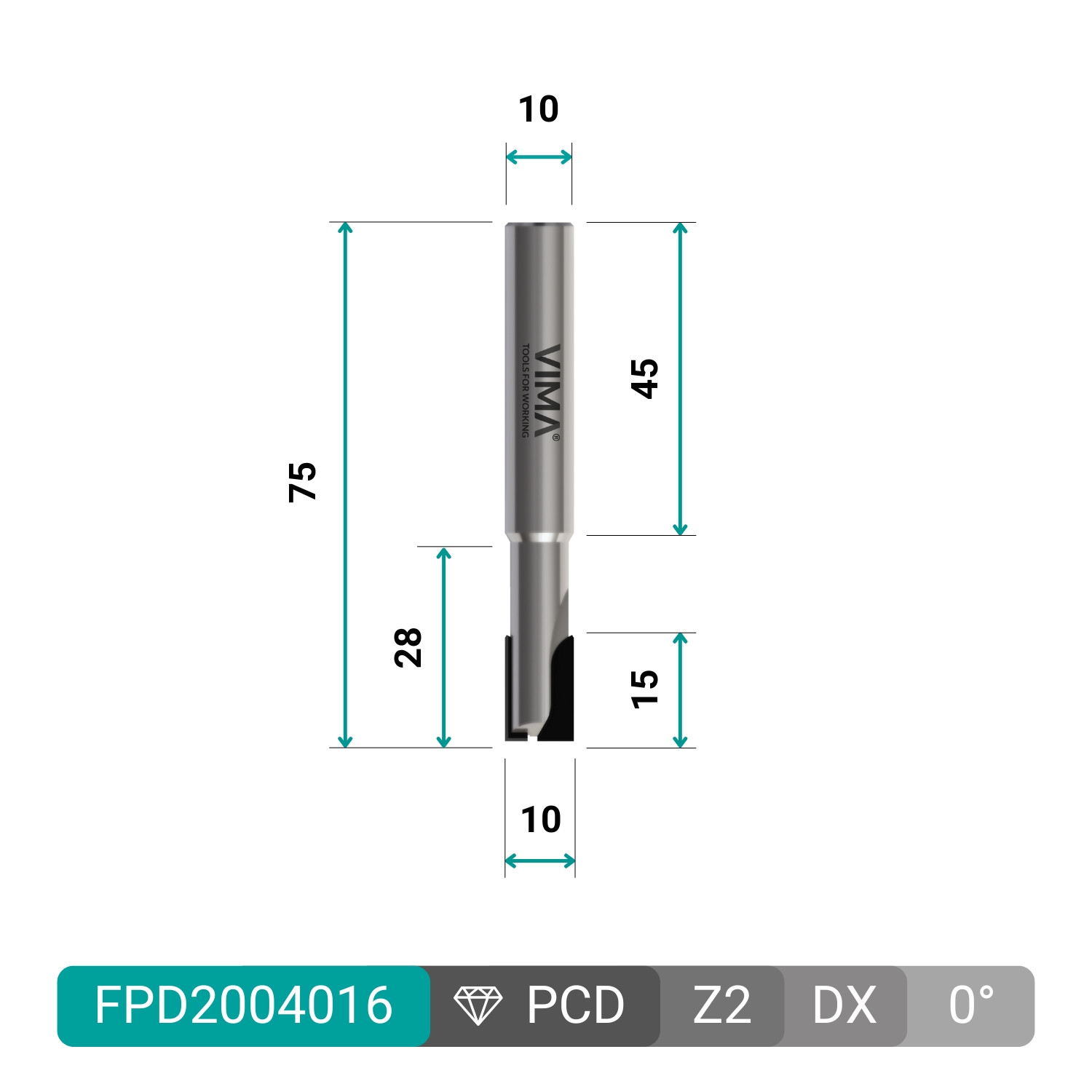

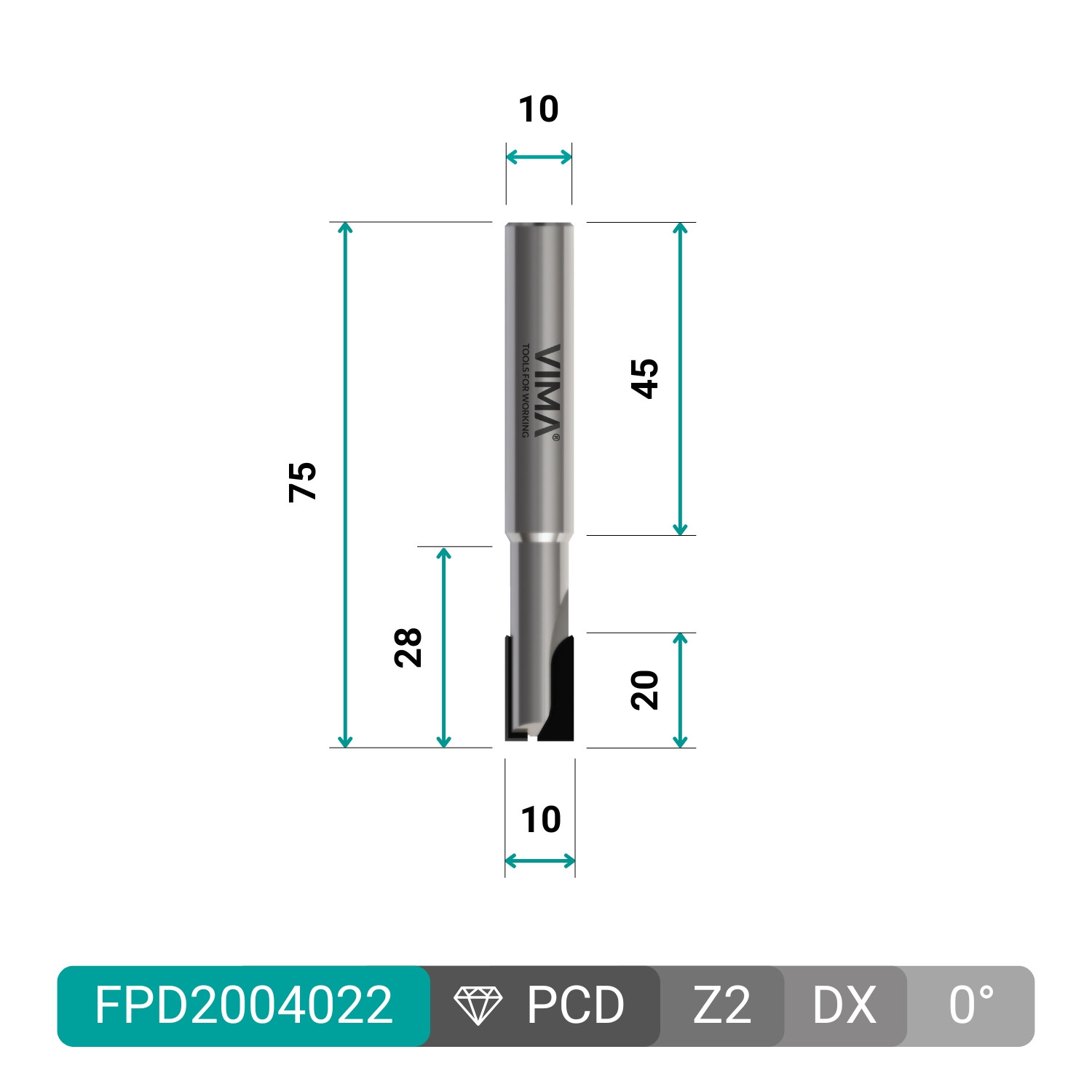

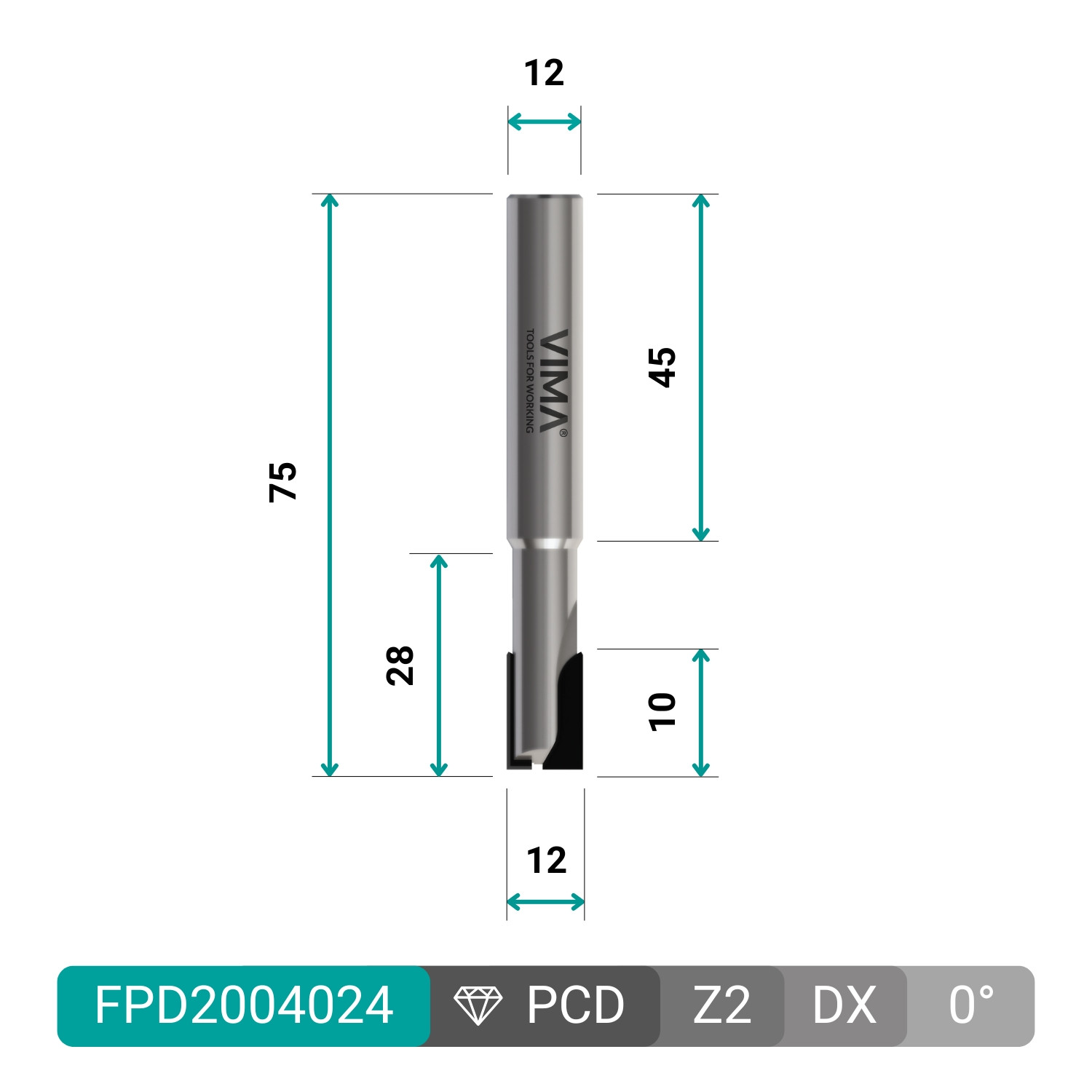

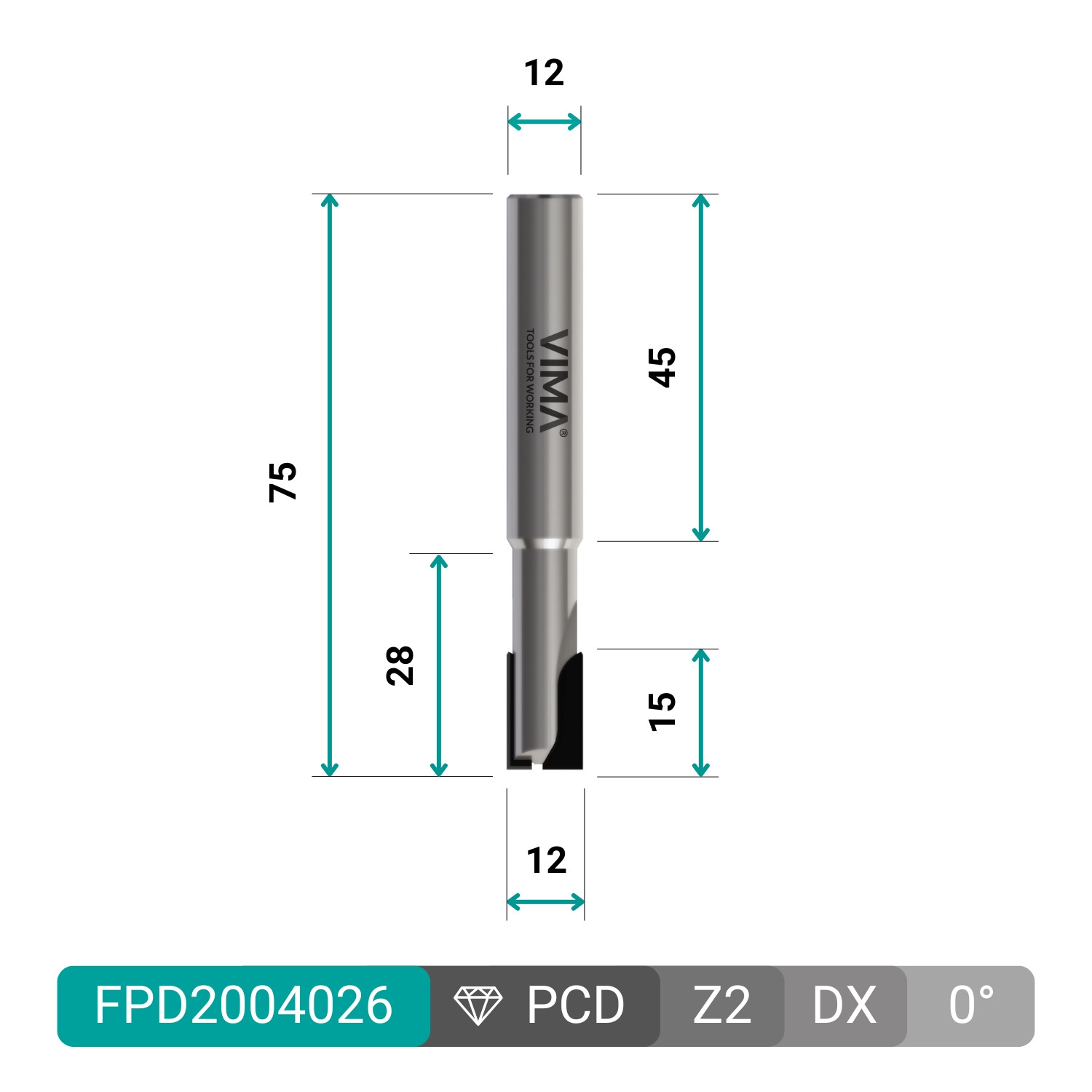

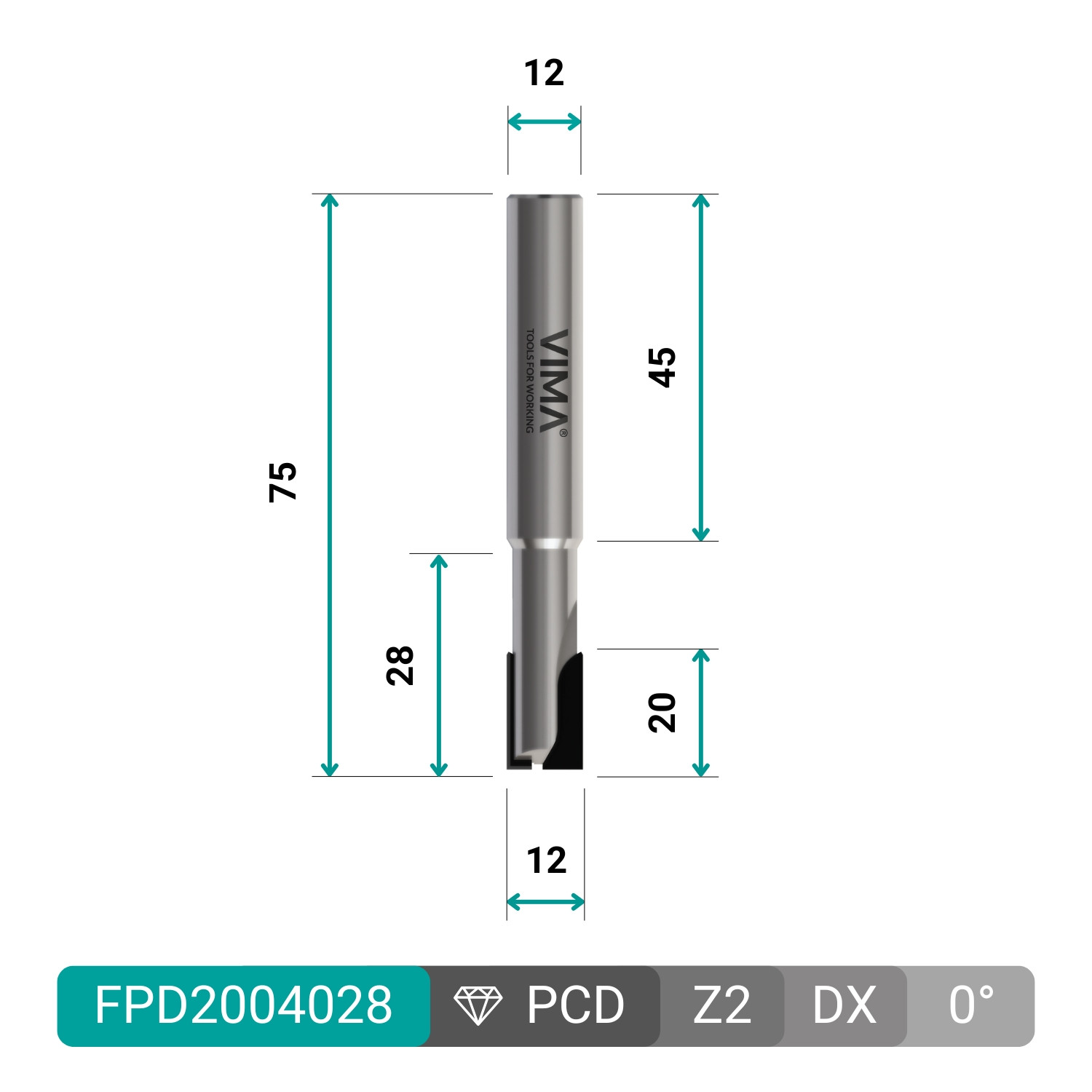

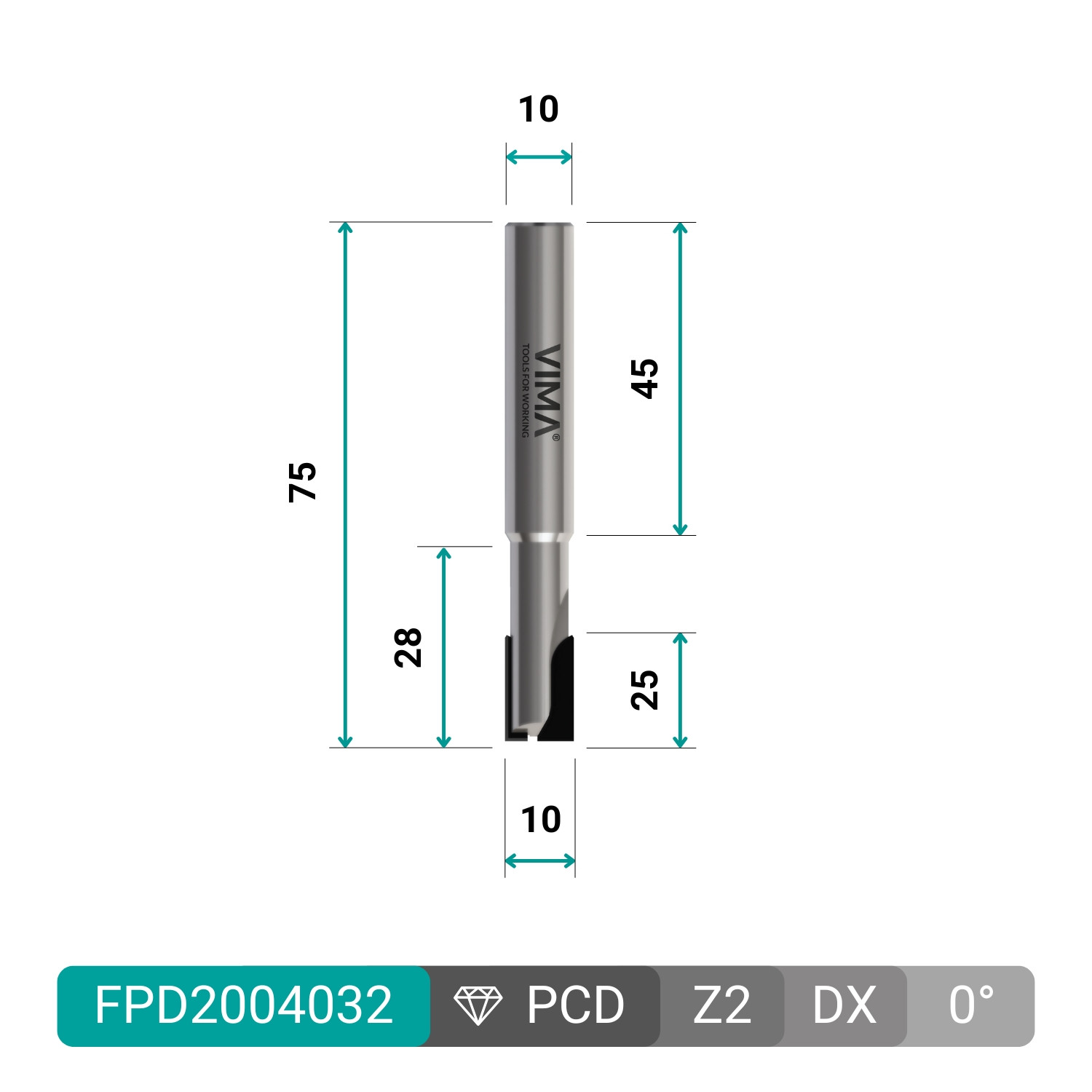

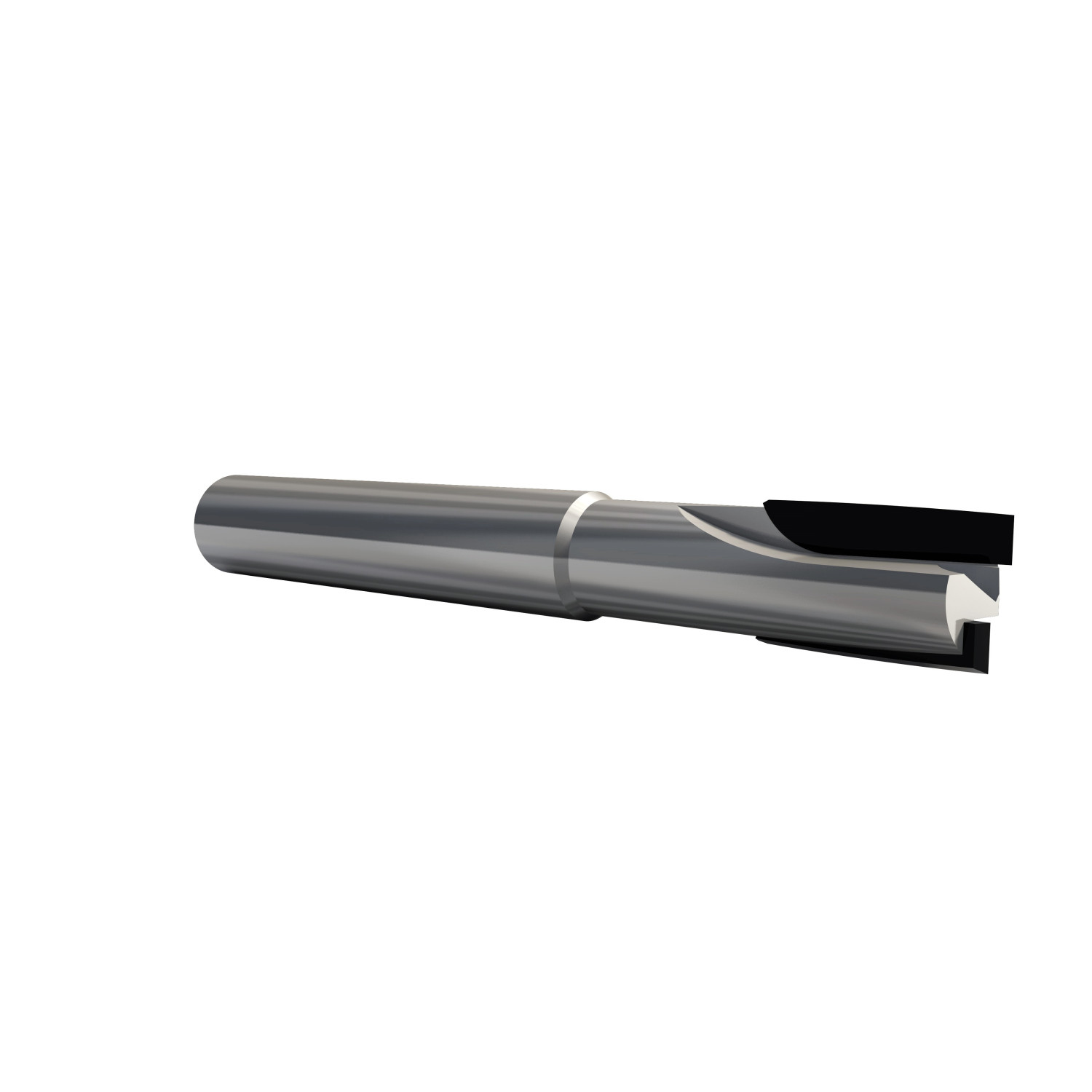

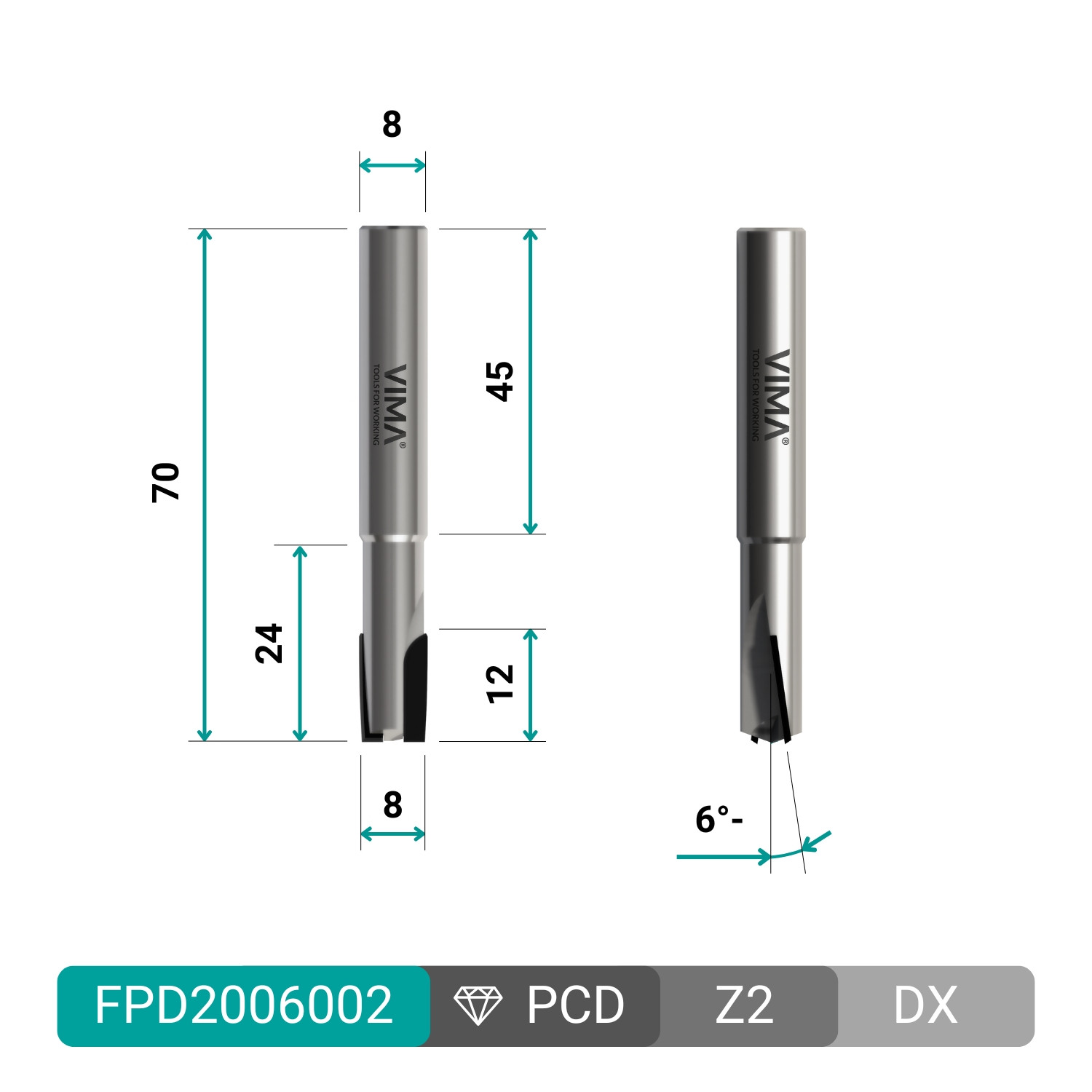

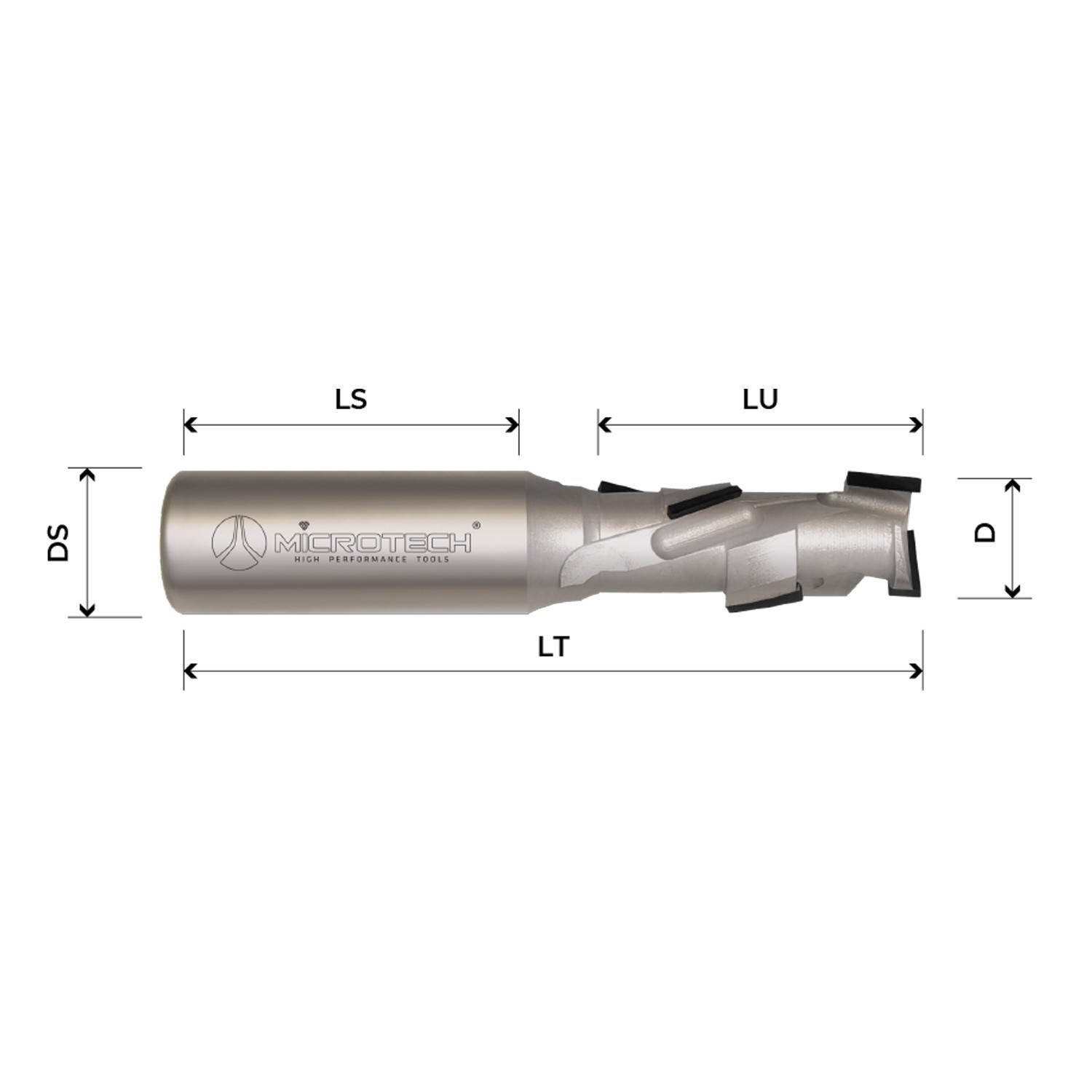

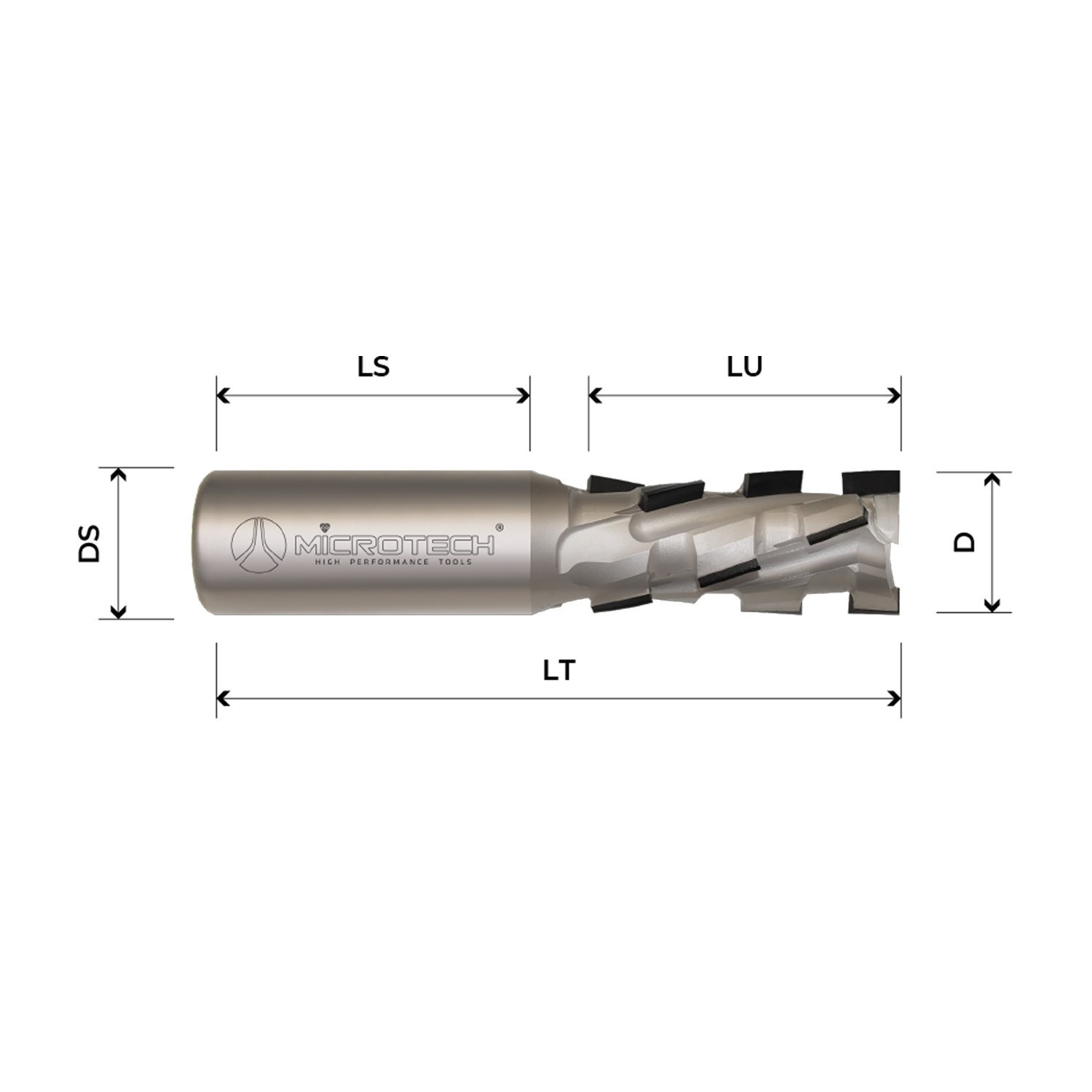

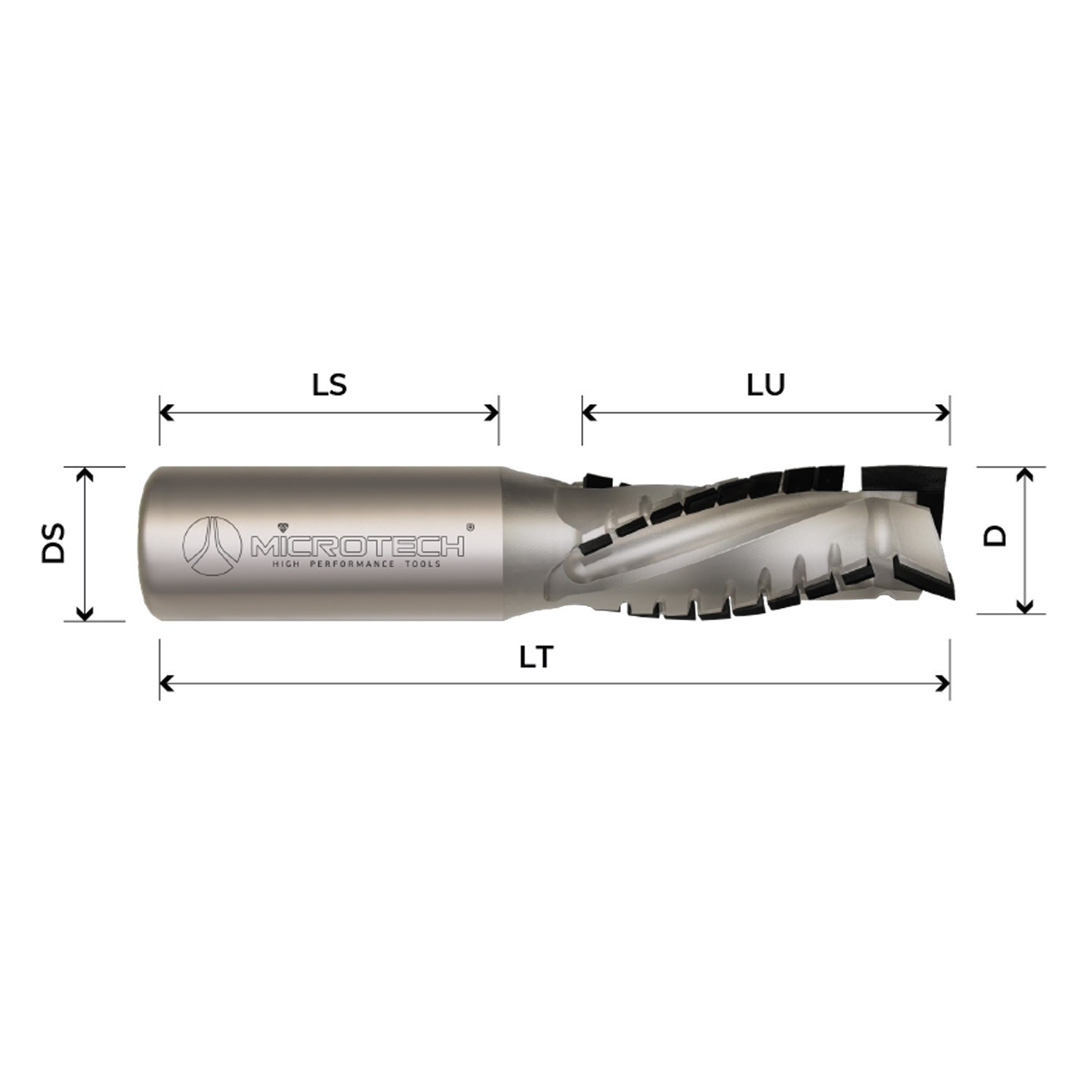

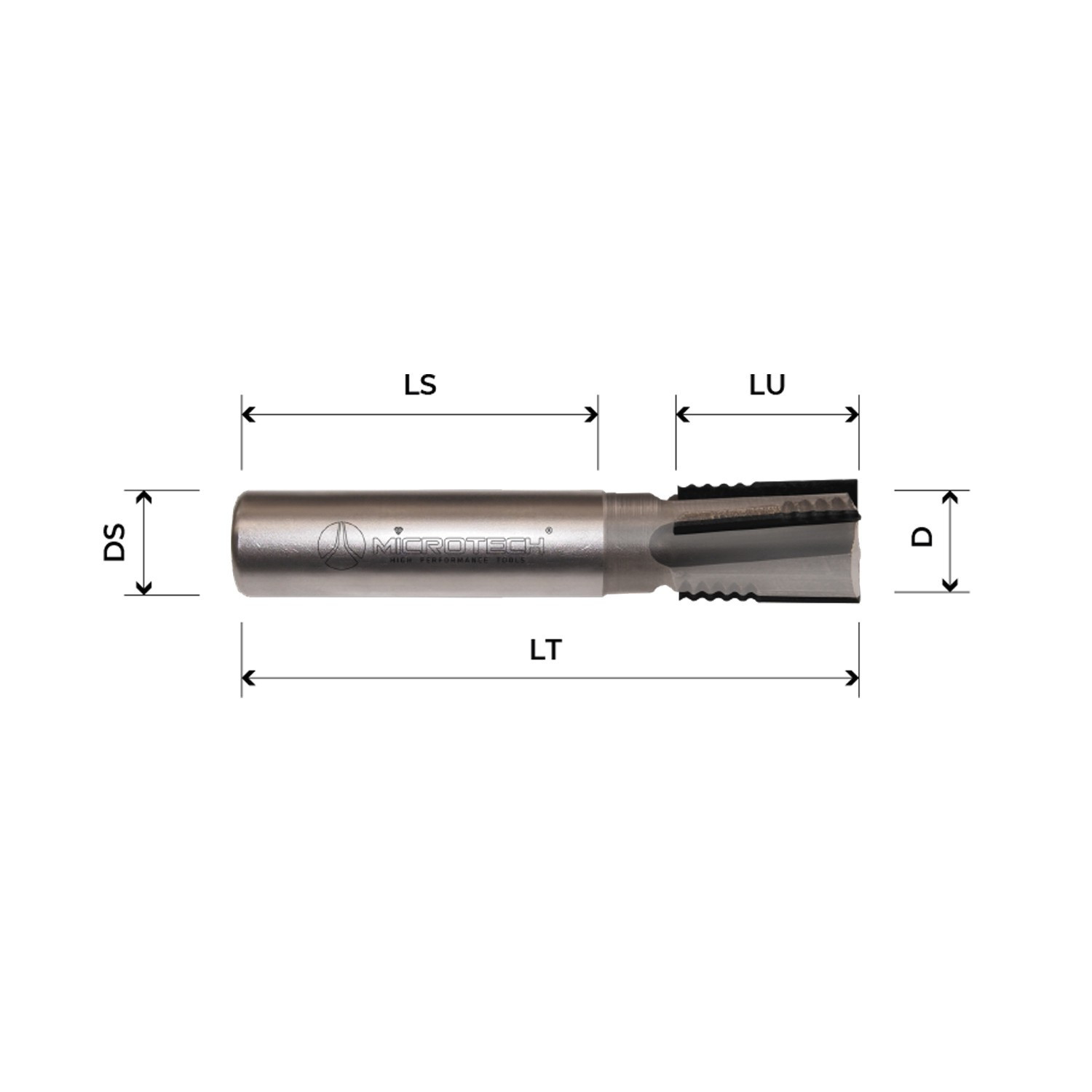

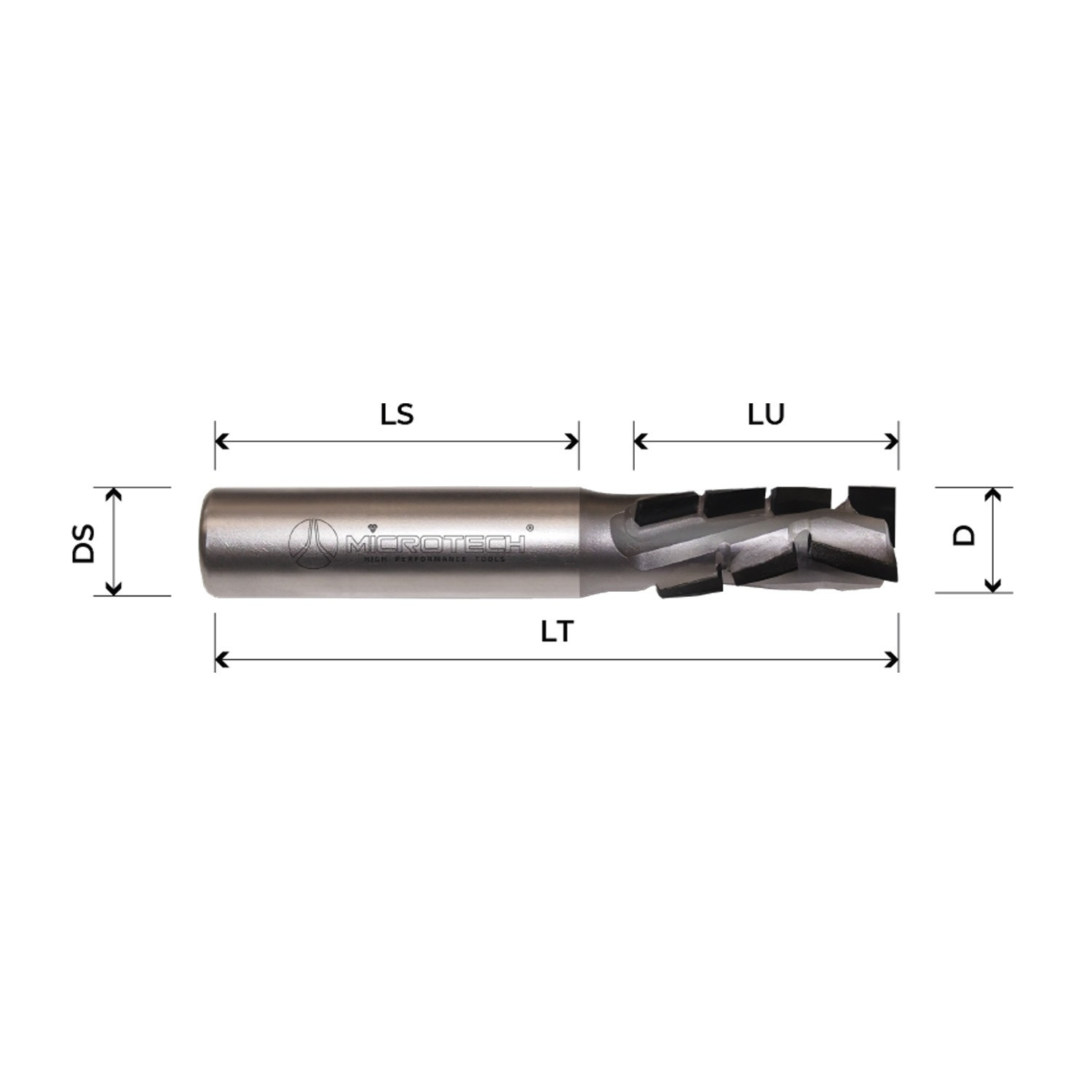

PCD diamond router bit designed for groove cutting and contouring on CNC machines with mechanical feed. The two straight Z2 cutting edges and solid carbide body provide balanced cutting action, improved stability and consistently high finish quality.

• PCD cutting edges H 3.5 mm for high durability

• Z2 configuration for higher stability and productivity

• Solid carbide body for rigidity and operational precision

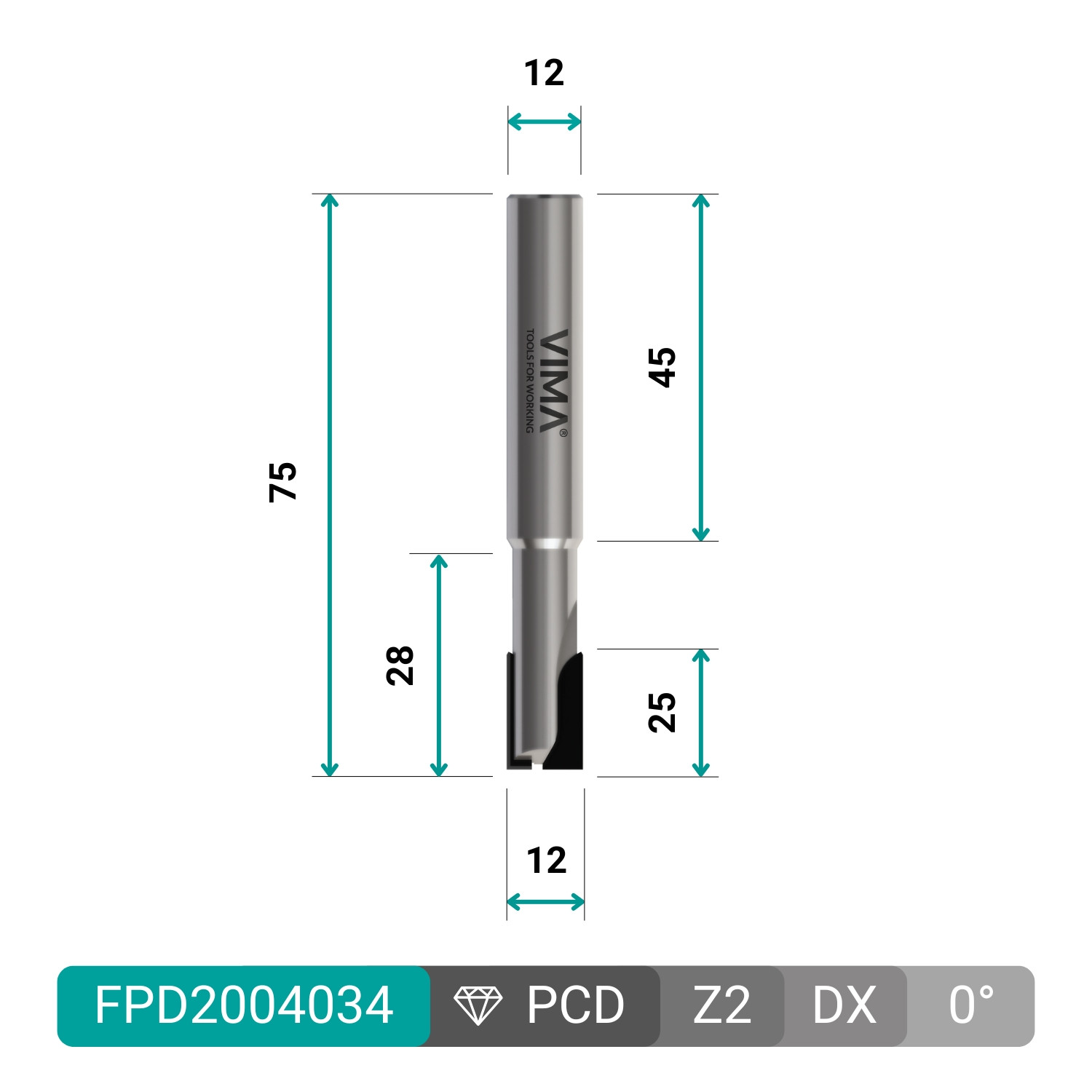

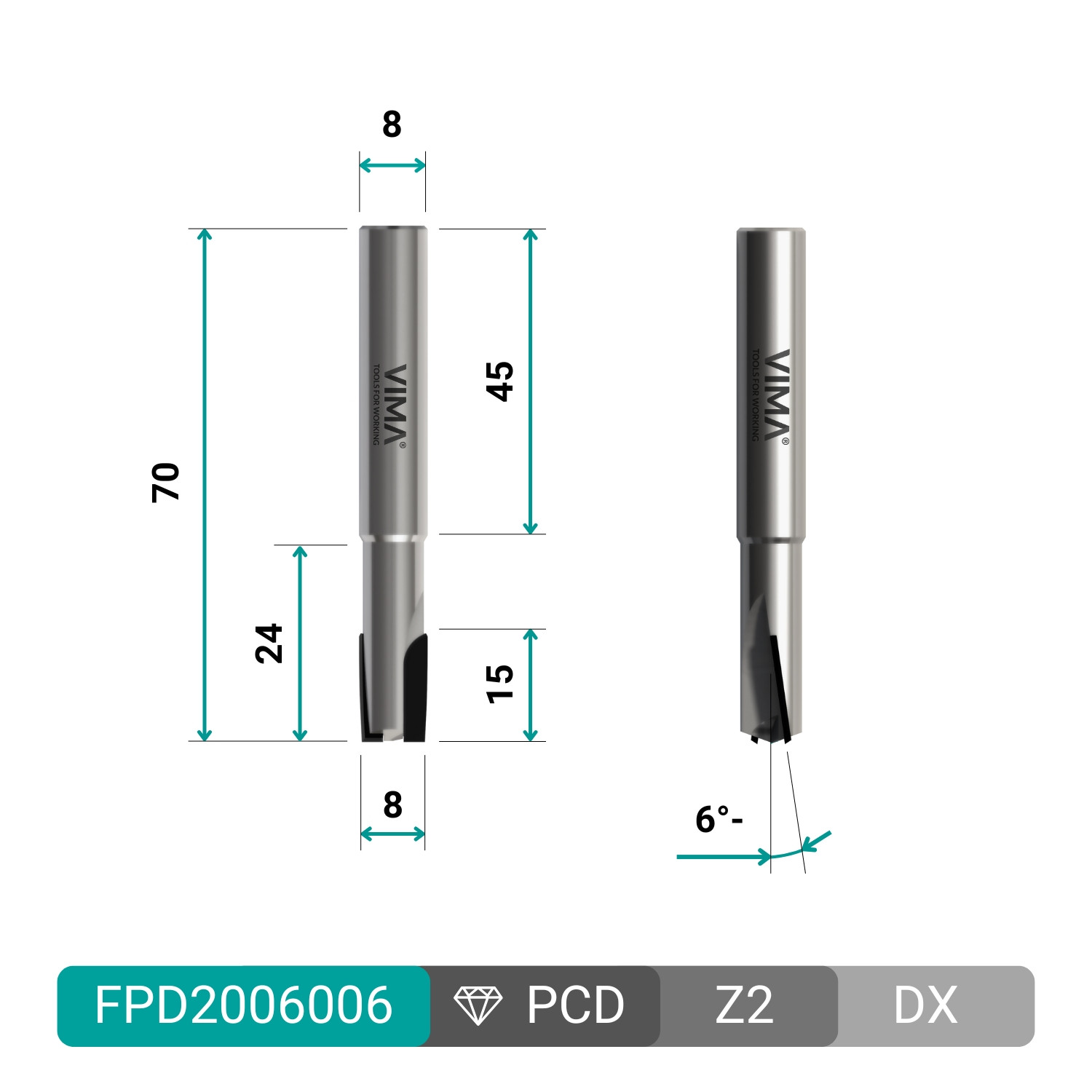

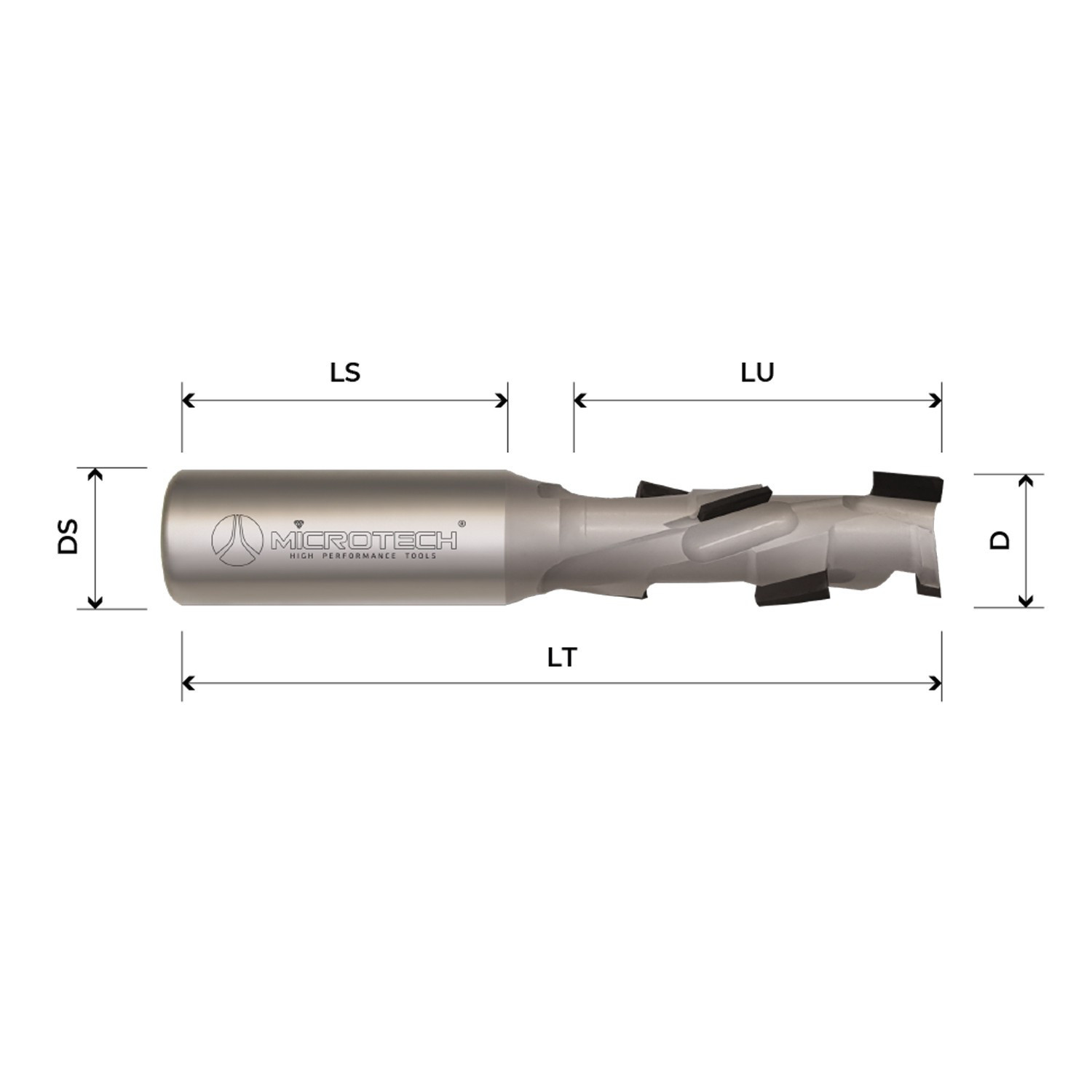

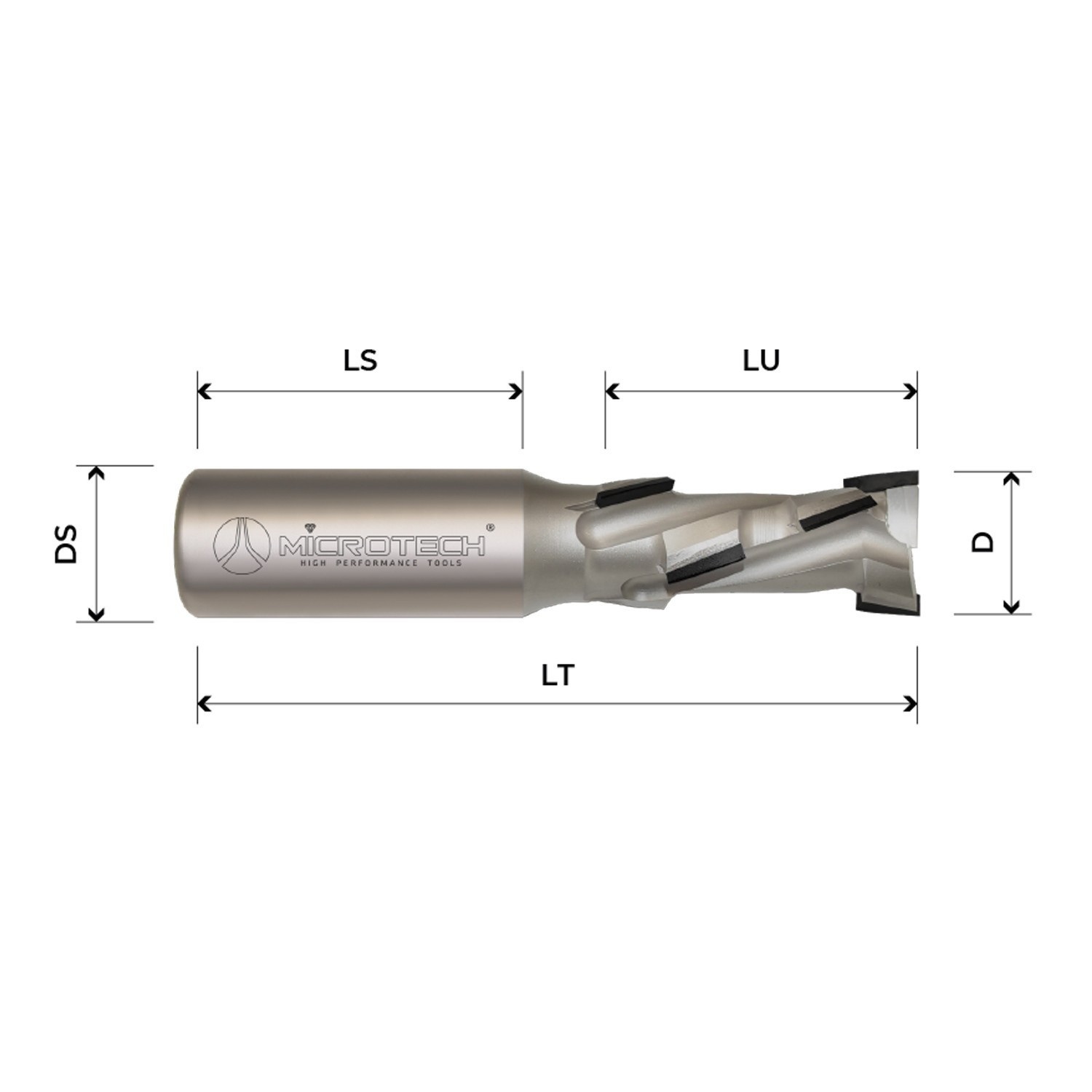

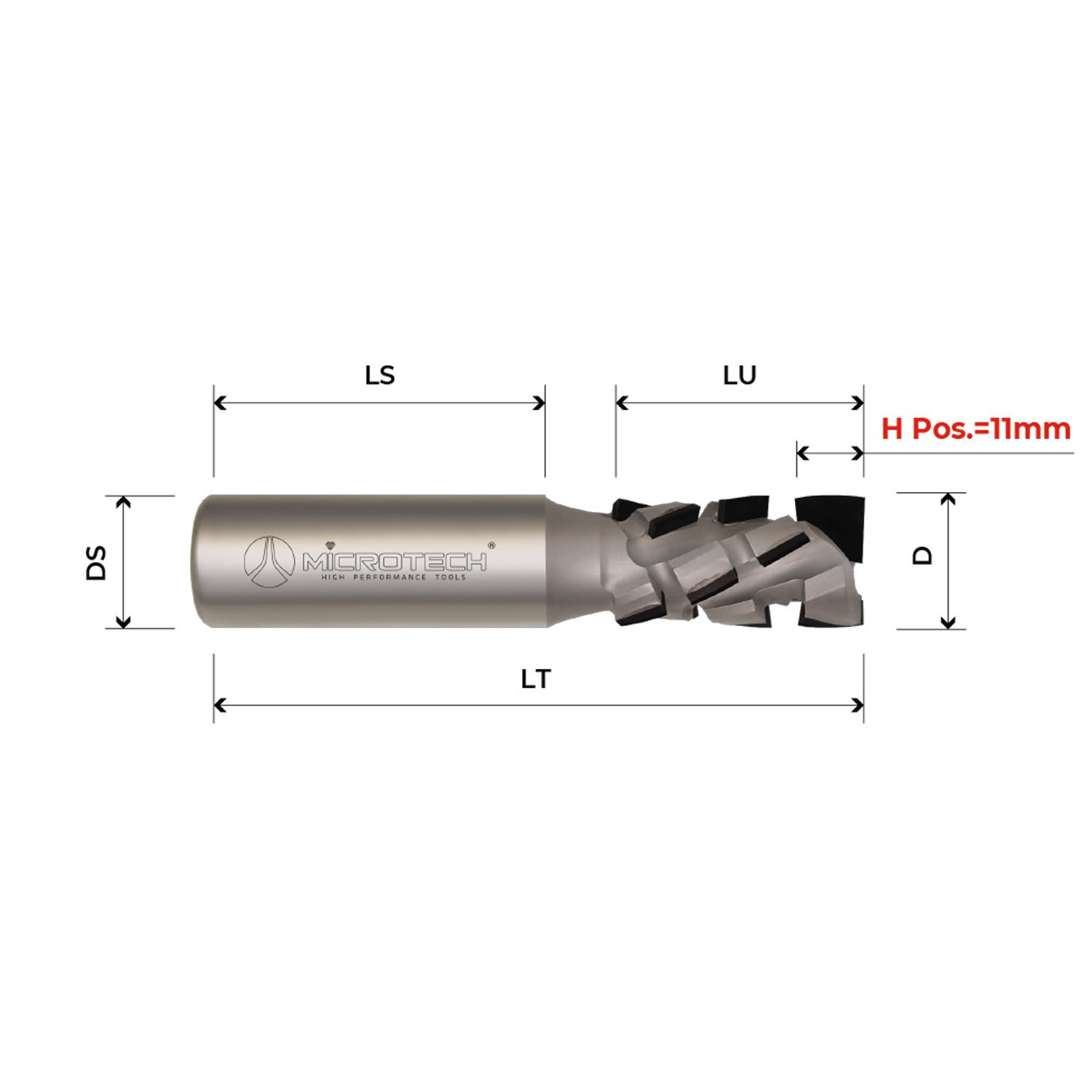

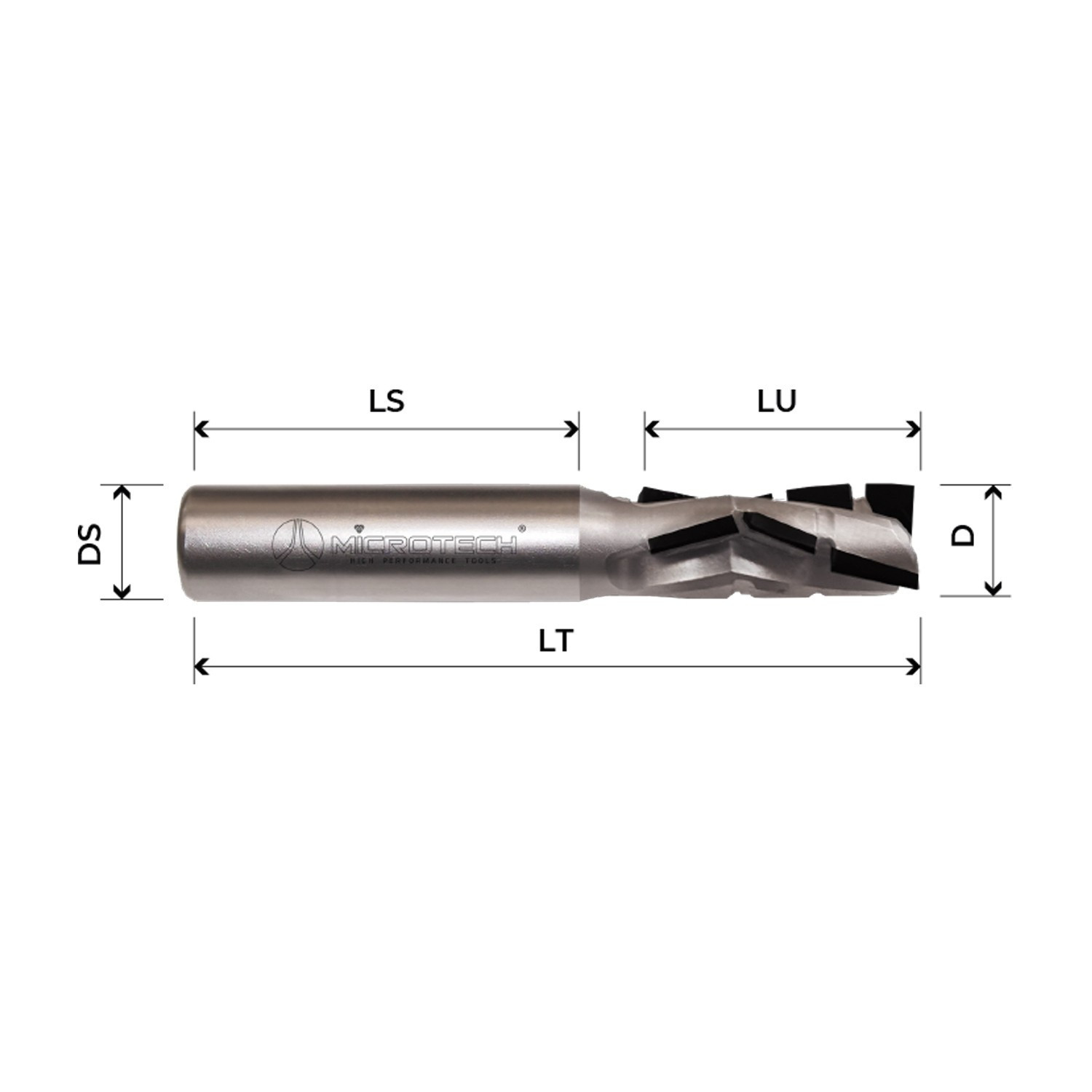

PCD diamond router bit designed for grooving coated panels where the highest surface quality is required. The negative Z2 cutting edges and solid carbide body ensure stability, controlled material removal and clean finishing even on delicate surfaces.

• PCD cutting edges H 3.5 mm for long tool life

• Negative Z2 cutting edges for superior surface finish

• Solid carbide body for rigidity and operational stability

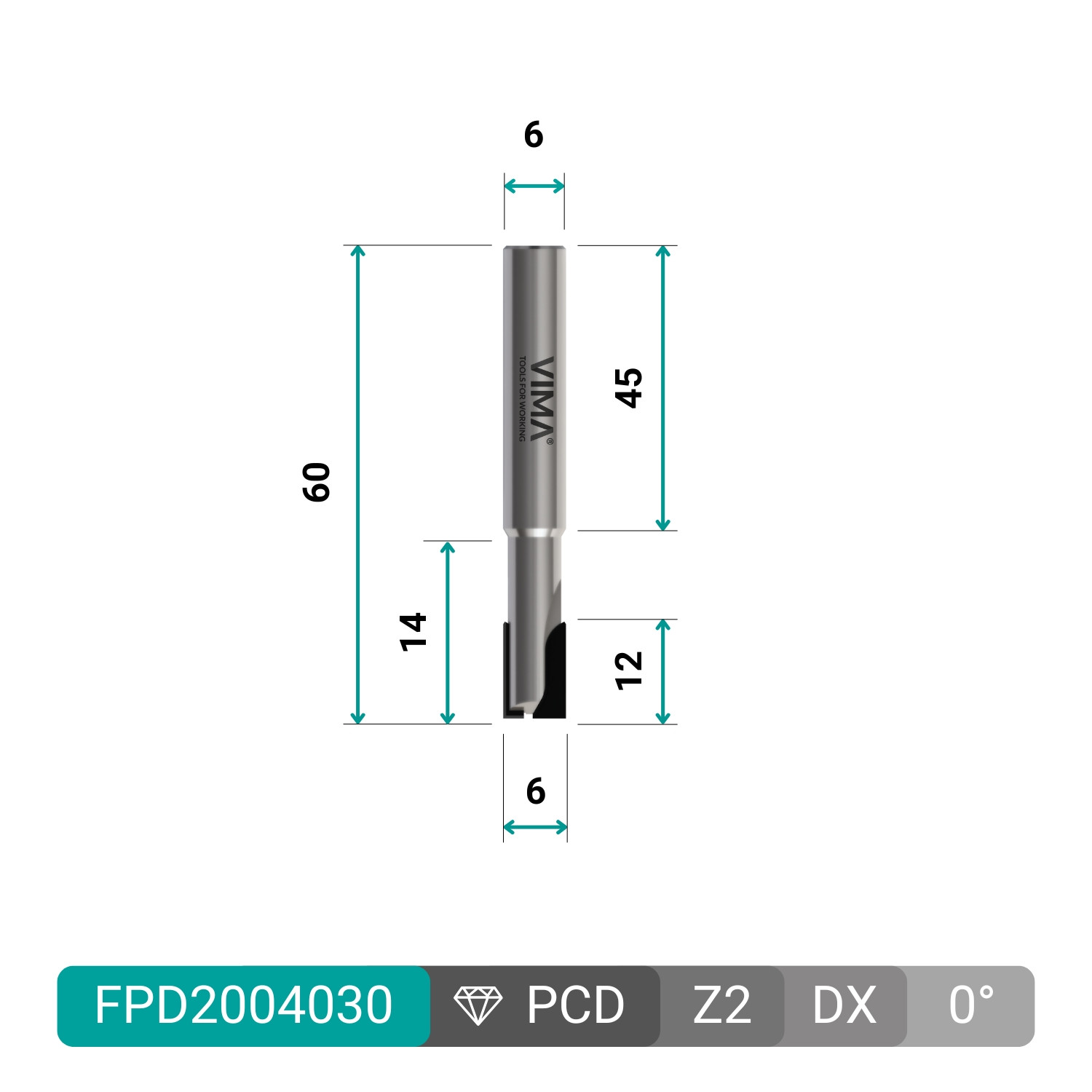

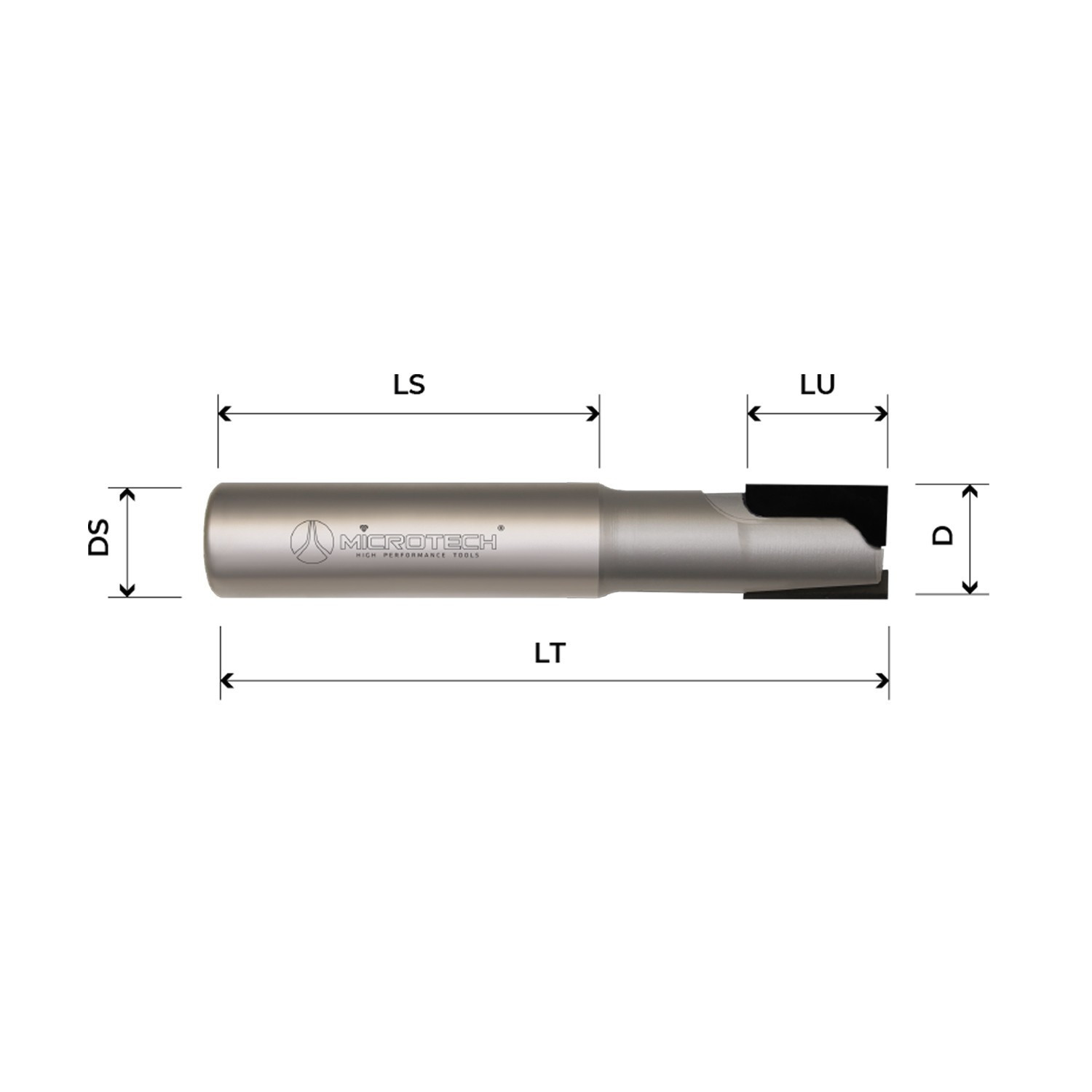

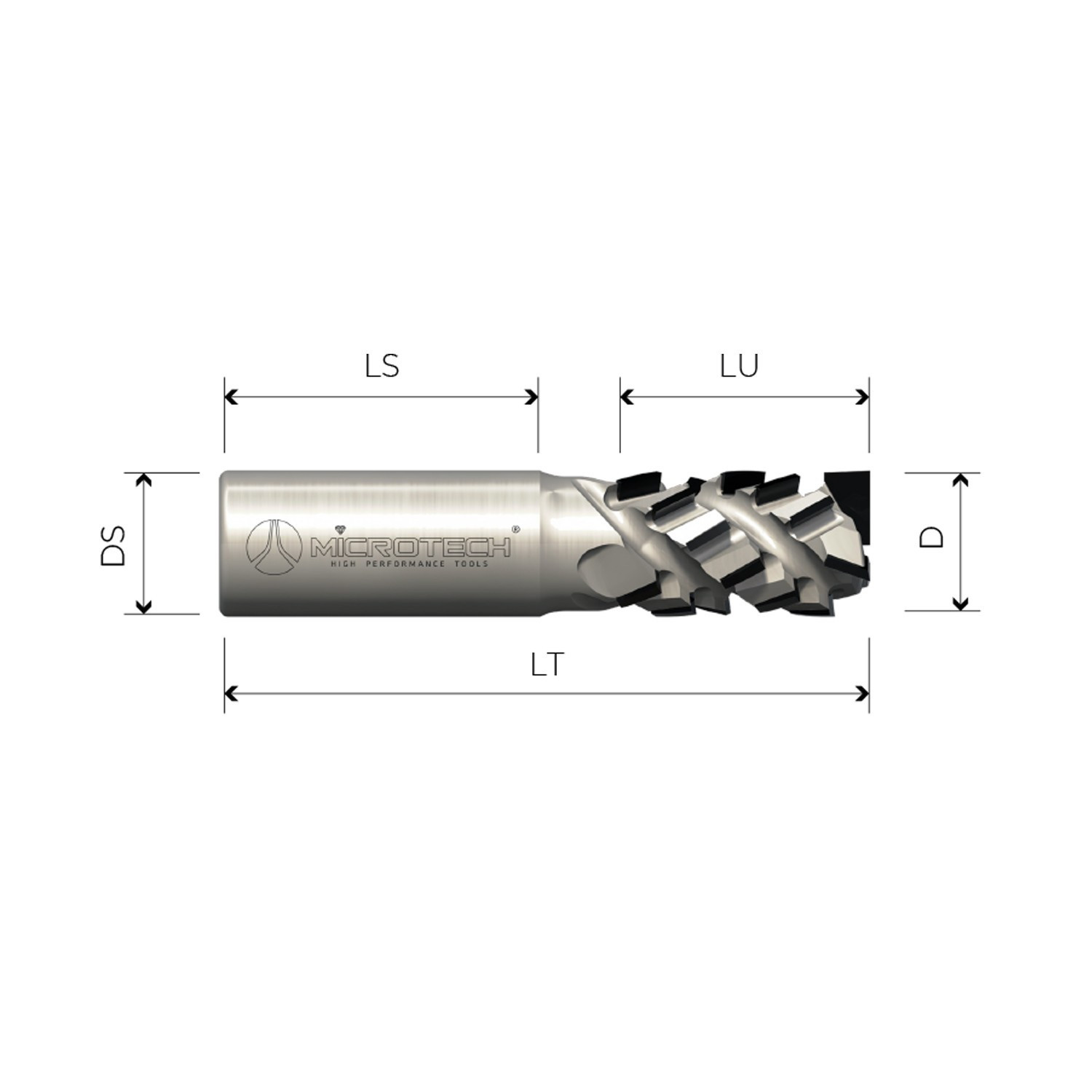

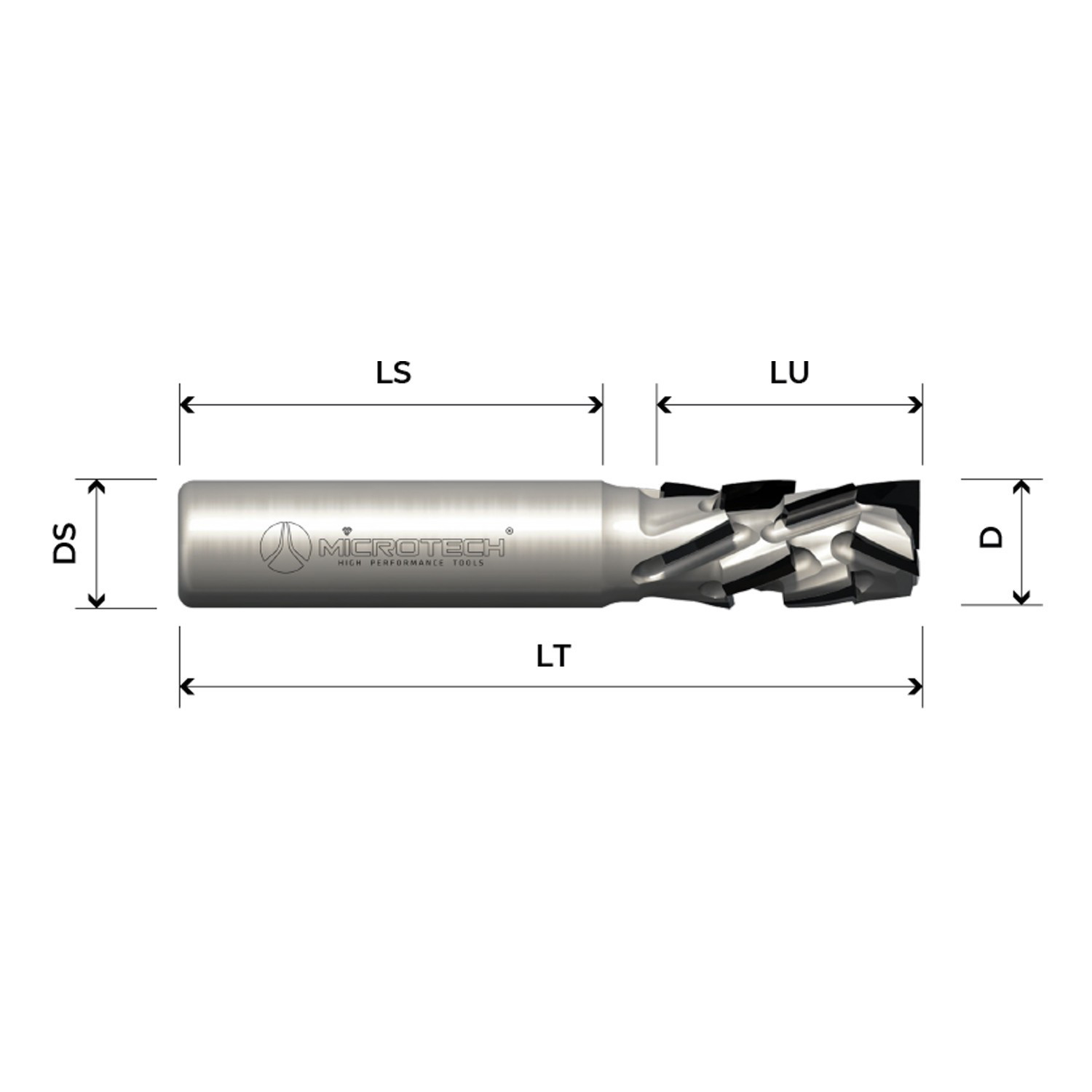

PCD diamond router bit designed for grooving, contouring and surfacing operations on CNC machines with manual or mechanical feed. The two straight Z2 cutting edges and the steel body ensure cutting stability, controlled material removal and consistent surface finish.

• PCD cutting edges H 4 mm for long tool life

• Z2 configuration for balanced and productive cutting

• Steel body for robustness and reliability

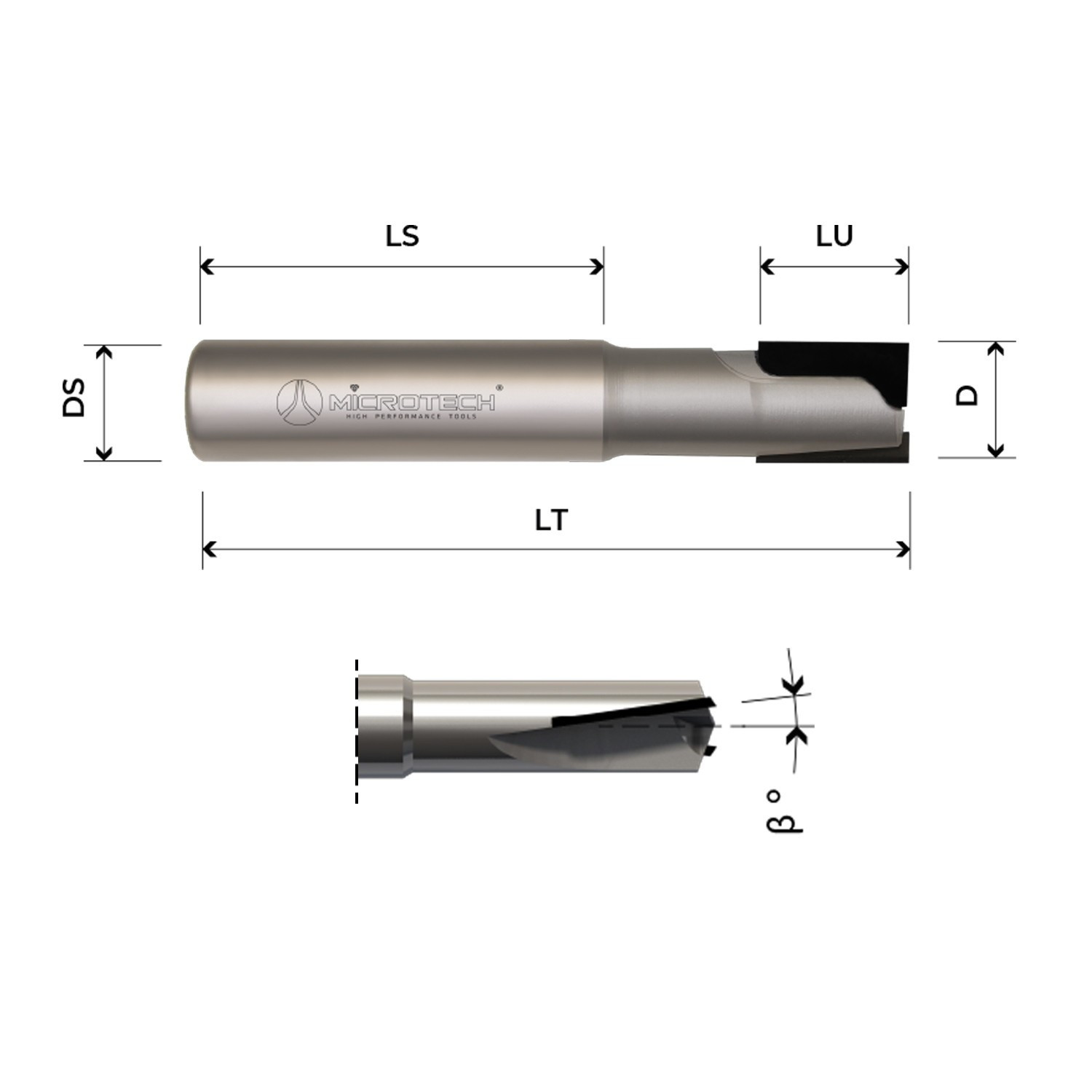

PCD diamond router bit engineered for grooving operations on coated panels and wood-based materials when an excellent surface finish is required. The negative Z2 cutting geometry together with the steel body provides high stability, controlled chip removal and a clean, tear-free result.

• PCD cutting edges H 4 mm for extended tool life

• Negative Z2 geometry for chip-free surfaces and clean edges

• Steel body for robustness and machining accuracy

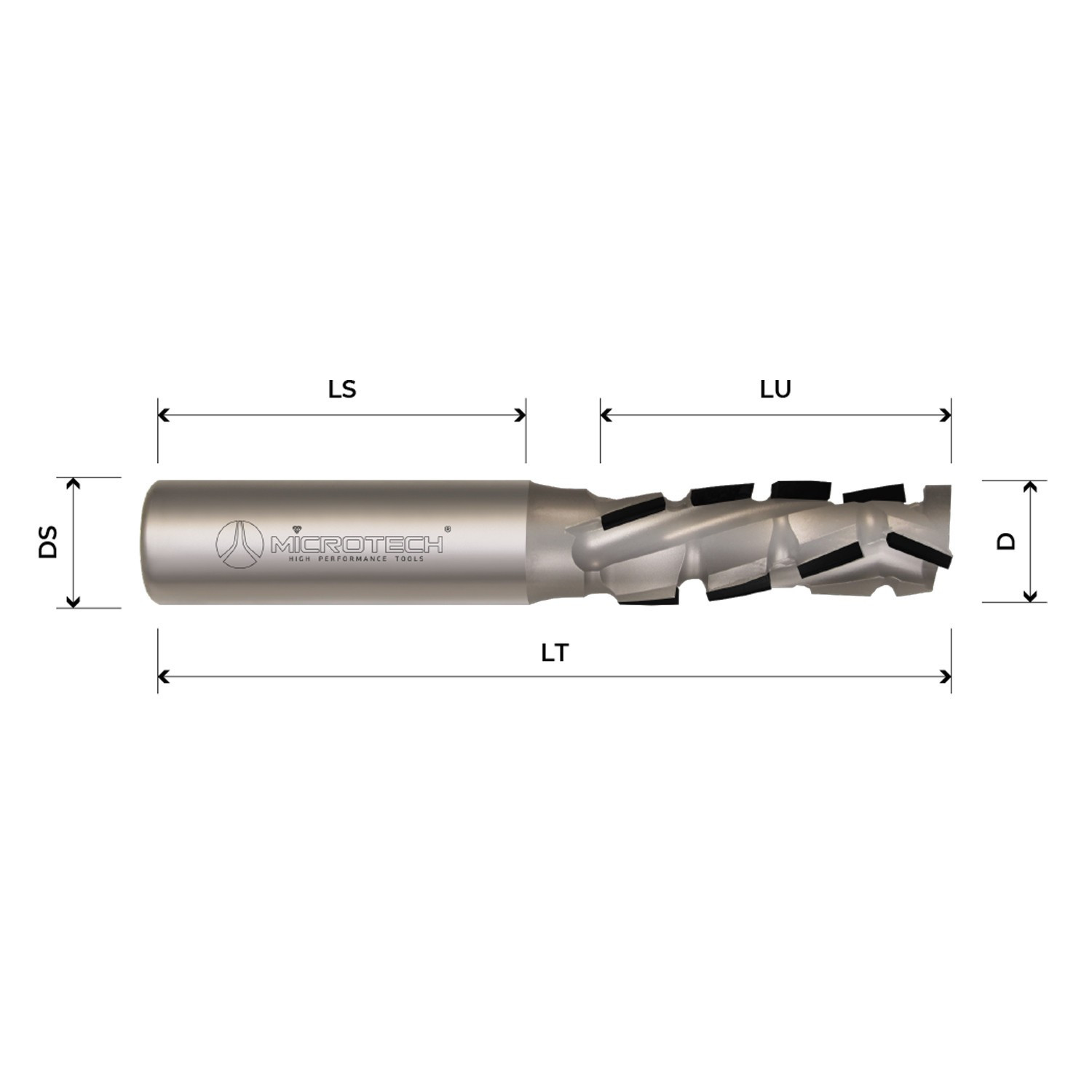

PCD helical router bit designed for contouring and grooving on both CNC and manual machines. The Z1+1 layout with two helical sections offers a solid balance between material removal, cutting stability and surface finish, especially on coated panels.

• Z1+1 configuration with positive and negative helix

• PCD diamond insert H 2.5 mm, regrindable

• Ideal for laminated panels and coated MDF

PCD Z1+1 helical router bit designed for CNC grooving and contouring on panels and wood-based materials. The cost-effective PCD insert H 2.5 mm, regrindable up to three times, combined with the steel body, offers a balanced solution in terms of performance, durability and cost.

• PCD insert H 2.5 mm, regrindable

• Z1+1 geometry with positive and negative helix

• Steel body for stability and reliability

PCD Z1+1 helical router bit designed for CNC contouring applications with shank. The PCD diamond insert H 4.5 mm, regrindable up to eight times, combined with the steel body ensures long tool life, cutting stability and consistent quality even on coated panels.

• PCD insert H 4.5 mm, regrindable up to 8 times

• Z1+1 geometry with positive and negative helix

• Steel body for rigidity and reliability

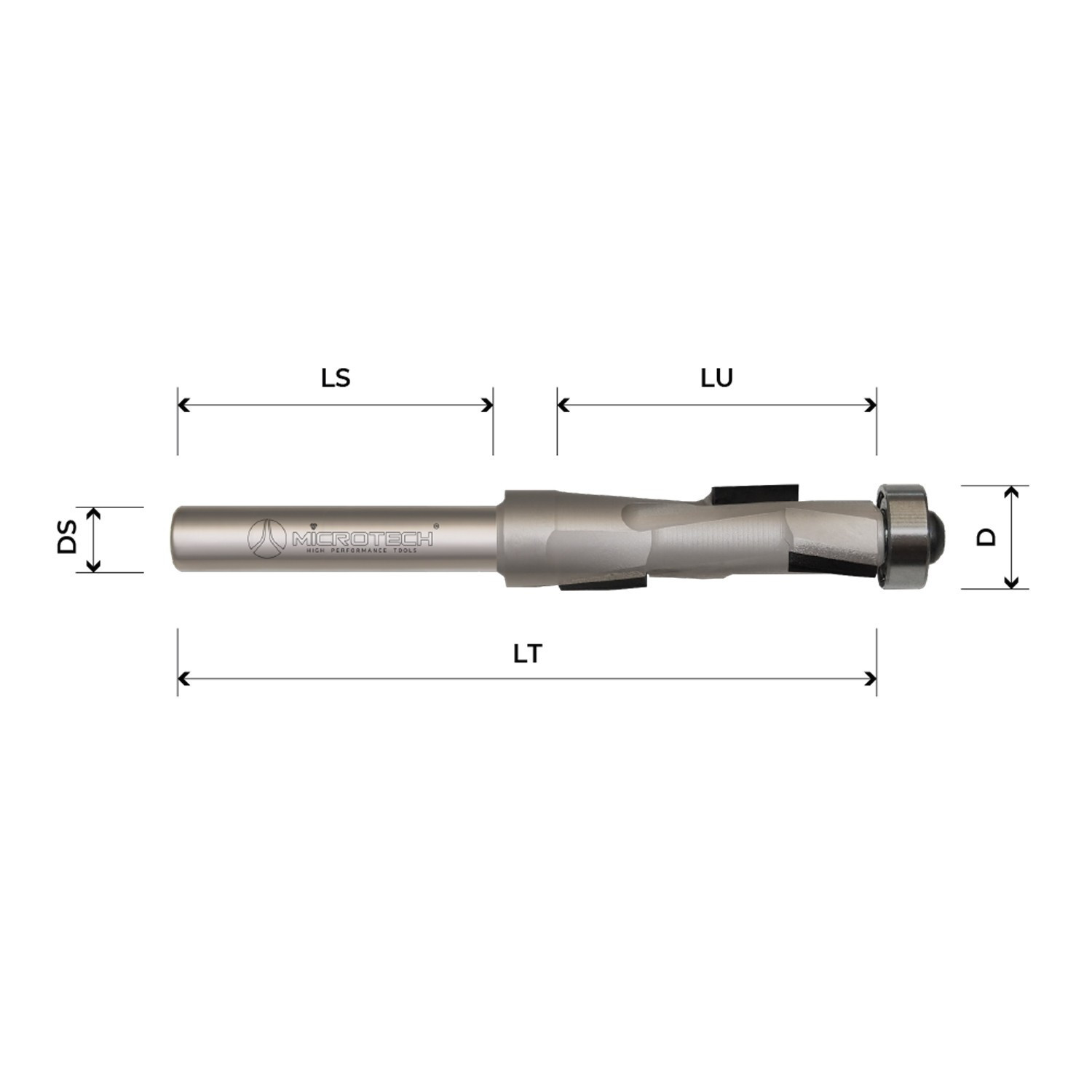

PCD Z1+1 router bit with guide bearing designed for trimming and contouring on CNC machines with manual or mechanical feed. The cost-effective PCD insert H 2.5 mm, regrindable up to three times, ensures cutting stability and a clean finish on coated panels.

• Guide bearing for precise trimming operations

• PCD insert H 2.5 mm, regrindable up to 3 times

• 3 helical divisions with positive/negative geometry

PCD Z2+2 helical router bit designed for shank contouring on CNC machines with mechanical feed. The 4 helical divisions and the pulling geometry with a first positive insert ensure efficient chip evacuation, cutting stability and consistent quality on panels and wood-based materials.

• Z2+2 with 4 helices for productive, stable machining

• PCD insert H 2.5 mm for good tool life and a clean finish

• Special steel body with HW drilling tip

PCD Z2+2 CNC/router bit for shank contouring with mechanical feed, designed for CNC routers and pantographs. The 4 helical divisions and pulling geometry deliver efficient chip evacuation, cutting stability and a clean finish on coated panels and plywood.

• PCD H 4.5 mm with up to 8 regrinds for extended service life

• Z2+2 and 4 helices for productive, stable CNC contouring

• Special steel body with HW drilling tip

Helical PCD CNC router bit developed for contouring and finishing on coated panels and technical materials. The cutting layout combines Z2+2 on the top and bottom with Z1+1 in the central section, ensuring stable cutting, controlled material removal and a clean finish even on abrasive substrates.

• PCD insert H 2.5 mm, regrindable up to 3 times

• Combined Z1+1 / Z2+2 geometry for a stable cut

• Special steel body for rigidity and precision

PCD CNC router bit designed for contouring on coated panels and technical materials. The Z2+2 geometry with 3 helical divisions delivers cutting stability, controlled material removal and a clean finish, even on abrasive substrates.

• PCD insert H 2.5 mm, regrindable up to 3 times

• Z2+2 geometry for stable, precise contouring

• Special steel body for rigidity and reliability

Helical PCD router bit designed for shank contouring on coated panels and technical materials. The Z2+2 geometry with 3 helical divisions provides cutting stability, controlled material removal and a clean finish, even on abrasive substrates.

• PCD insert H 4.5 mm, regrindable up to 8 times

• Z2+2 geometry for stable, precise contouring

• Special steel body for rigidity and reliability

Helical PCD router bit designed for high-performance contouring on coated panels and technical materials. The Z3+3 geometry with 3 helical divisions delivers high material removal rates, cutting stability and a clean finish even on abrasive substrates.

• PCD insert H 4.5 mm, regrindable up to 8 times

• Z3+3 geometry for high-performance CNC contouring

• Special steel body for maximum rigidity

Helical PCD router bit designed for contouring on pantographs and CNC machines. The 30° axial angle ensures superior edge finishing and excellent surface quality on coated panels.

• PCD inserts H 4.5 mm, regrindable up to 8 times

• Z2+2 geometry for precise, stable contours

• 30° axial angle for high-quality finishes

PCD diamond CNC router bit for grooving and contouring on pantographs and machining centers with mechanical feed. Z3+3 geometry and a 30° axial angle deliver superior finishing and stable cutting on coated panels and abrasive materials.

• PCD insert H 4.5 mm, regrindable (up to 8 times)

• Z3+3 with 6 helices for smooth, precise machining

• Special steel body for rigidity and long service life

Z2+2 PCD CNC router bit with a 45° axial angle, designed for high-precision contouring on wood-based panels and engineered materials. Polycrystalline diamond delivers premium finishing and extended tool life, even on abrasive substrates.

• PCD cutting edge H 4.5 mm for long service life

• 45° axial angle for clean, stable finishing

• Ideal for MDF, plywood and coated panels

PCD diamond pantograph router bit H 4.5 mm designed for high-precision CNC contouring on wood-based panels and engineered materials.

• Regrindable PCD cutting edge for long service life

• 45° axial angle for a clean finish

• Ideal for MDF, chipboard and plywood

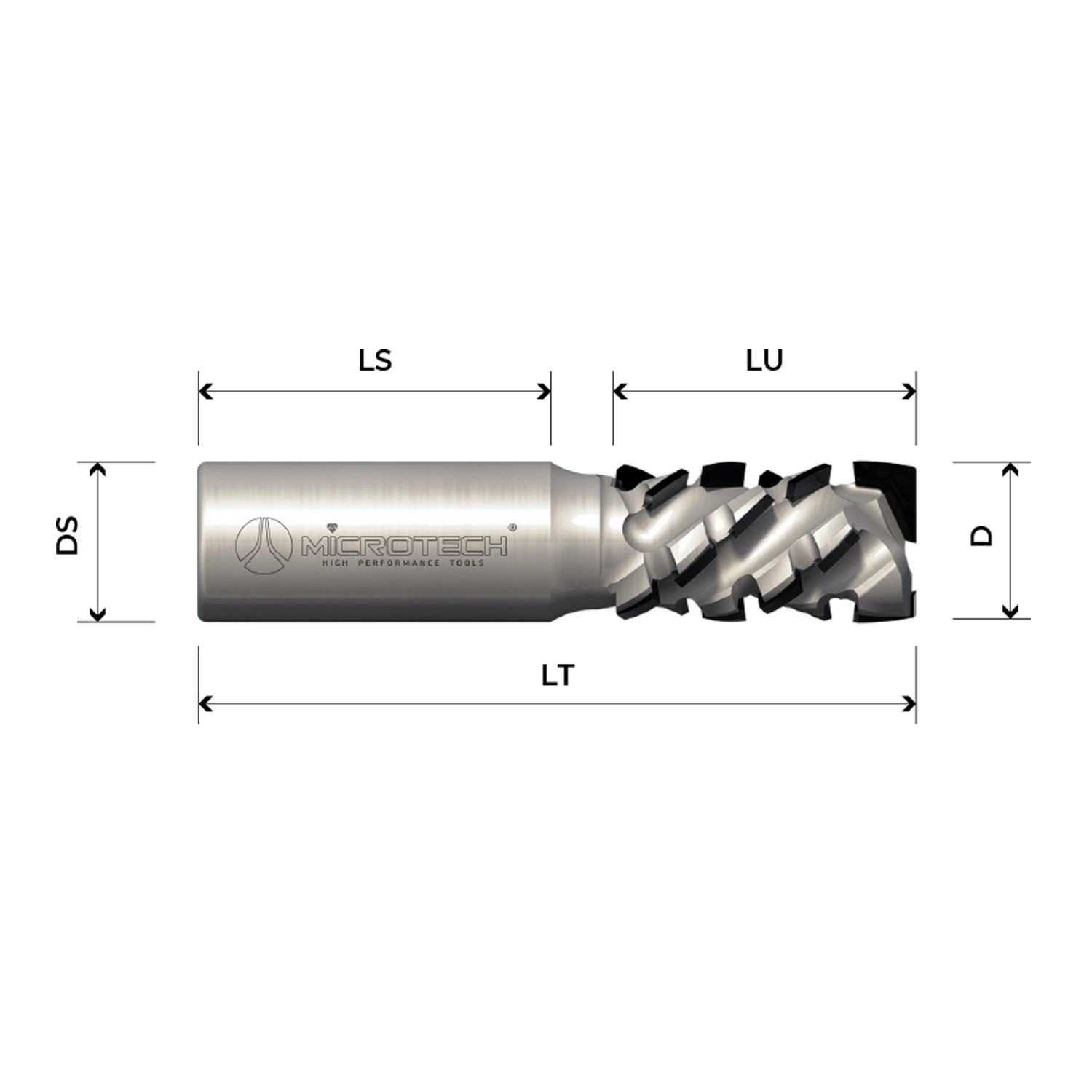

PCD diamond router bit designed for nesting and contouring on compact and abrasive materials. Alternating positive/negative cutting edges with a chipbreaker provide a combined roughing-and-finishing action, delivering excellent edge quality.

• PCD cutting edges H 3.5 mm, Z2 with alternating positive/negative geometry

• Chipbreaker design to rough and finish in a single pass

• Heavy metal HDM body for maximum stability

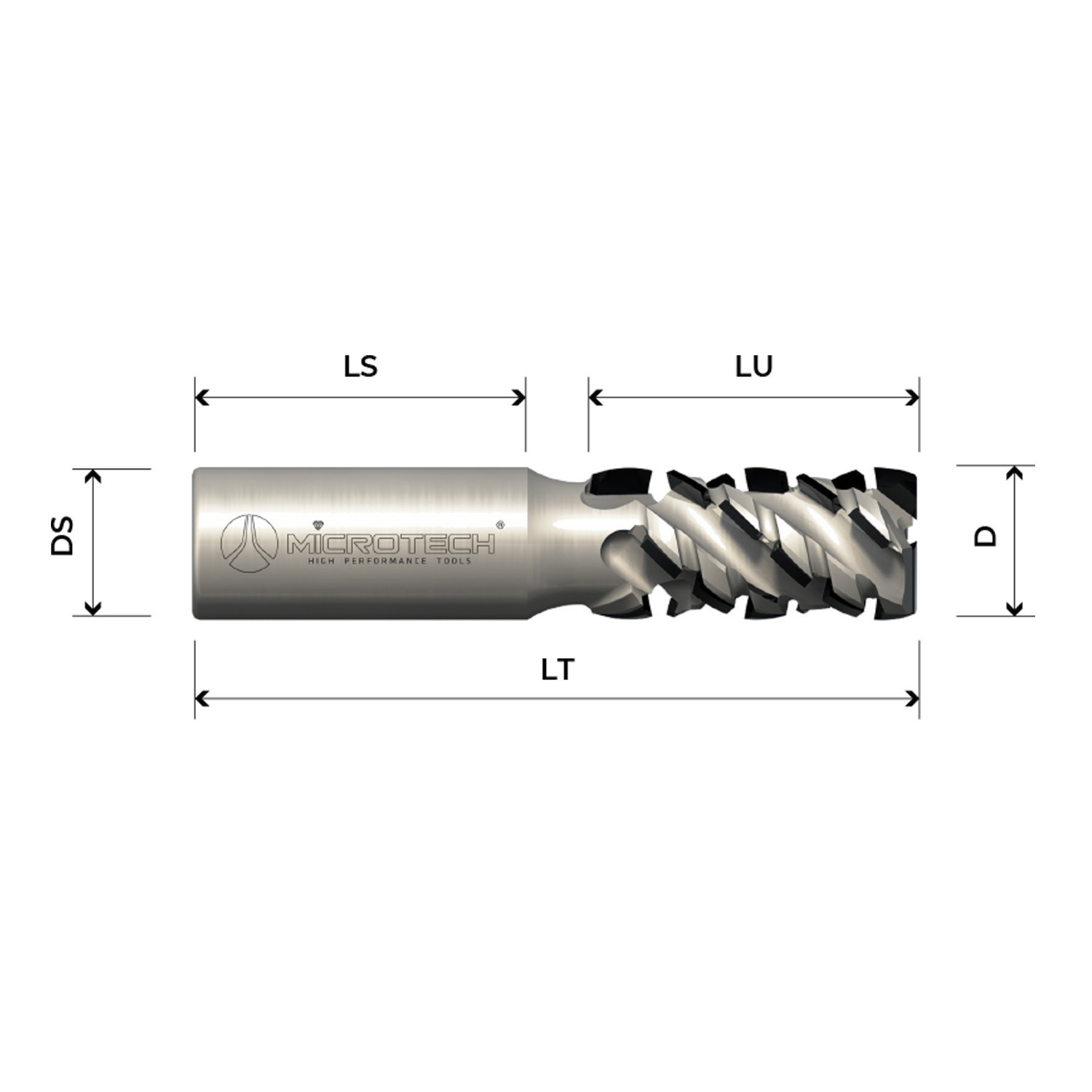

PCD diamond router bit designed for high-performance nesting and contouring on CNC machines. The Z4 layout with alternating positive/negative cutting edges and a chipbreaker delivers efficient stock removal, cutting stability and consistent finishing even on technical and abrasive materials.

• Z4 PCD cutting edges with chipbreaker for high productivity

• Heavy metal HDM body for maximum stability

• Ideal for CNC nesting and precision contouring

PCD diamond nesting router bit designed for high-productivity CNC machining on MDF, plywood and coated chipboard panels. The Z2+2 geometry and a 25° axial angle ensure efficient chip evacuation and clean finishing even in intensive nesting cycles.

• Specifically designed for CNC nesting operations

• PCD diamond H 3.5 mm for long tool life

• High stability and efficient chip evacuation

Regrindable PCD diamond router bit with interrupted helix, three divisions and three cutting edges engaged at the top and bottom. Predominantly negative helix, heavy-metal HDM body, PCD height H 3.5 mm. Built for CNC nesting: high feed rates, efficient chip extraction, good finish and low noise thanks to positive/negative cutting edges.

• PCD Z3+3 cutting edges for stable, continuous cutting

• Heavy-metal body for maximum rigidity

• Ideal for high-speed nesting

Professional regrindable PCD diamond cutter with interrupted helix and three effective cutting edges, designed for nesting and shank contouring on CNC machining centres. The heavy metal body and predominantly positive helix ensure stability, efficient chip evacuation and consistent surface quality even at high feed rates.

• Z3+3 PCD cutting edges with 3.5 mm height for long service life

• Interrupted helix for efficient chip evacuation

• Heavy metal body for rigidity and cutting accuracy

Professional PCD diamond cutter with six-division helix and three effective cutting edges, designed for nesting and shank contouring on CNC machining centres. The predominantly negative axial angle and heavy metal body ensure stability, chip control and consistent surface quality on coated panels.

• Z3 PCD cutting edges with 3.5 mm height for long service life

• Six-division helix with negative angle for controlled finish

• Heavy metal body for rigidity and accuracy

.jpg)