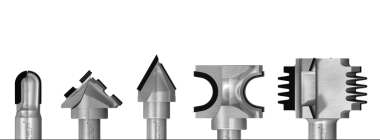

Re-sharpening compact hogger in diamond with positive cut angle, height PCD 6 mm, suitable for working on chipboard panels, laminated, M.D.F., it can be used on squaring machines and squaring-edging machines.

Re-sharpening compact hogger in diamond with negative cut angle, height PCD 6 mm, suitable for working on chipboard panels, laminated, M.D.F., it can be used on squaring machines and squaring-edging machines.

Re-sharpening radius hogger in diamond with negative cut angle, height PCD 6 mm, suitable for working on chipboard panels, laminated, M.D.F., it can be used on squaring machines and squaring-edging machines

Re-sharpening hogger in diamond step design, with negative cut angle, height PCD 6 mm, suitable for working on chipboard panels, laminated, M.D.F., it can be used on squaring machines and squaring-edging machines.

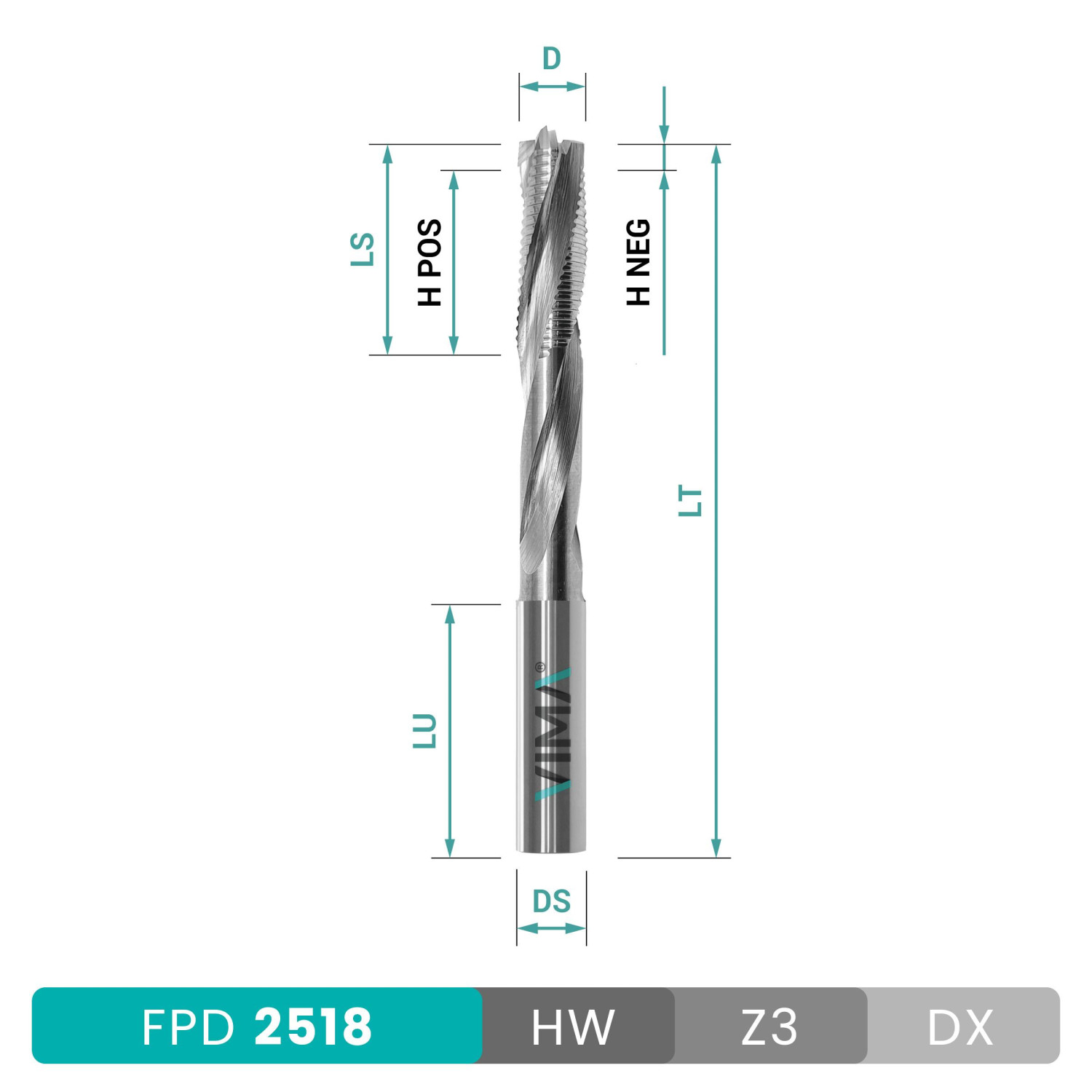

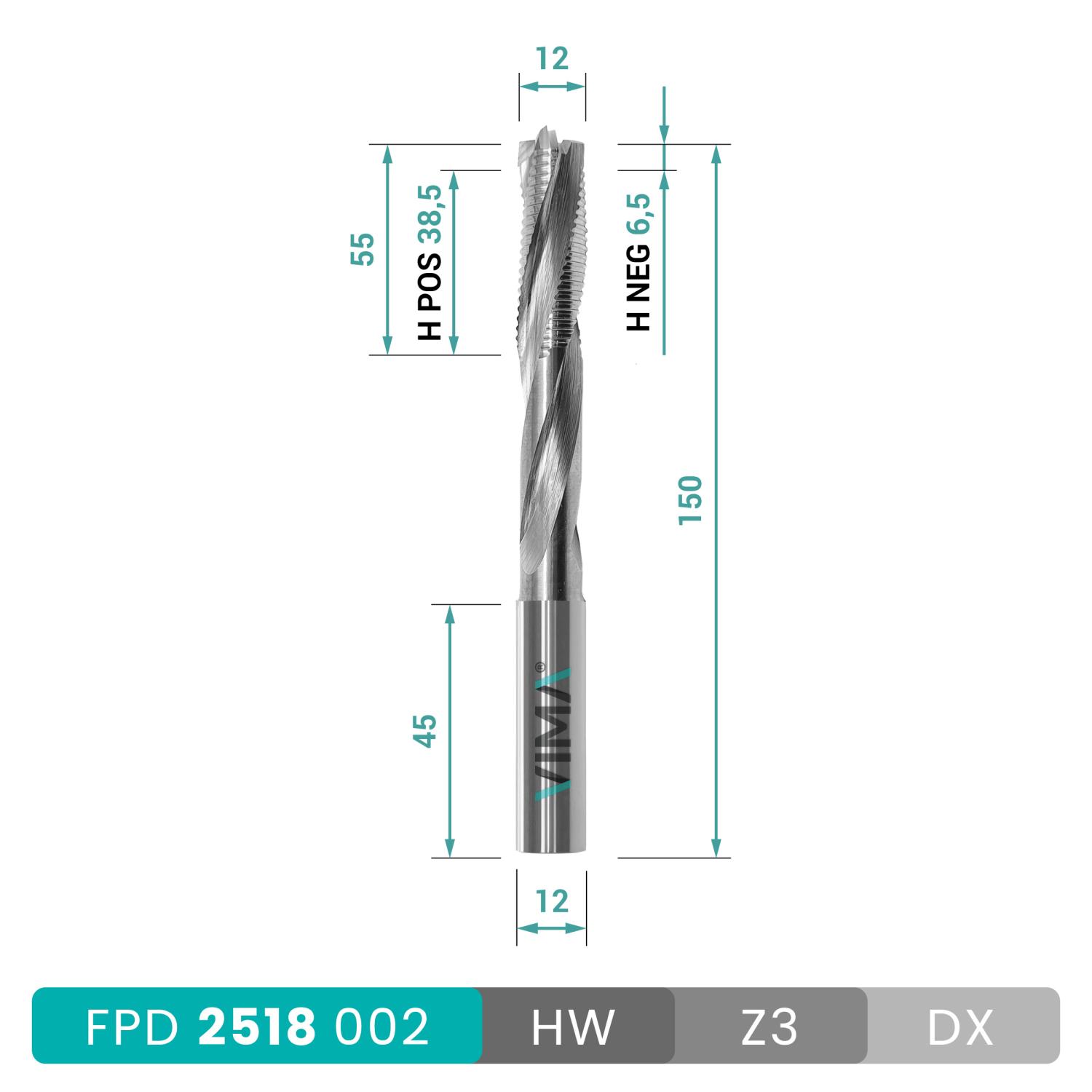

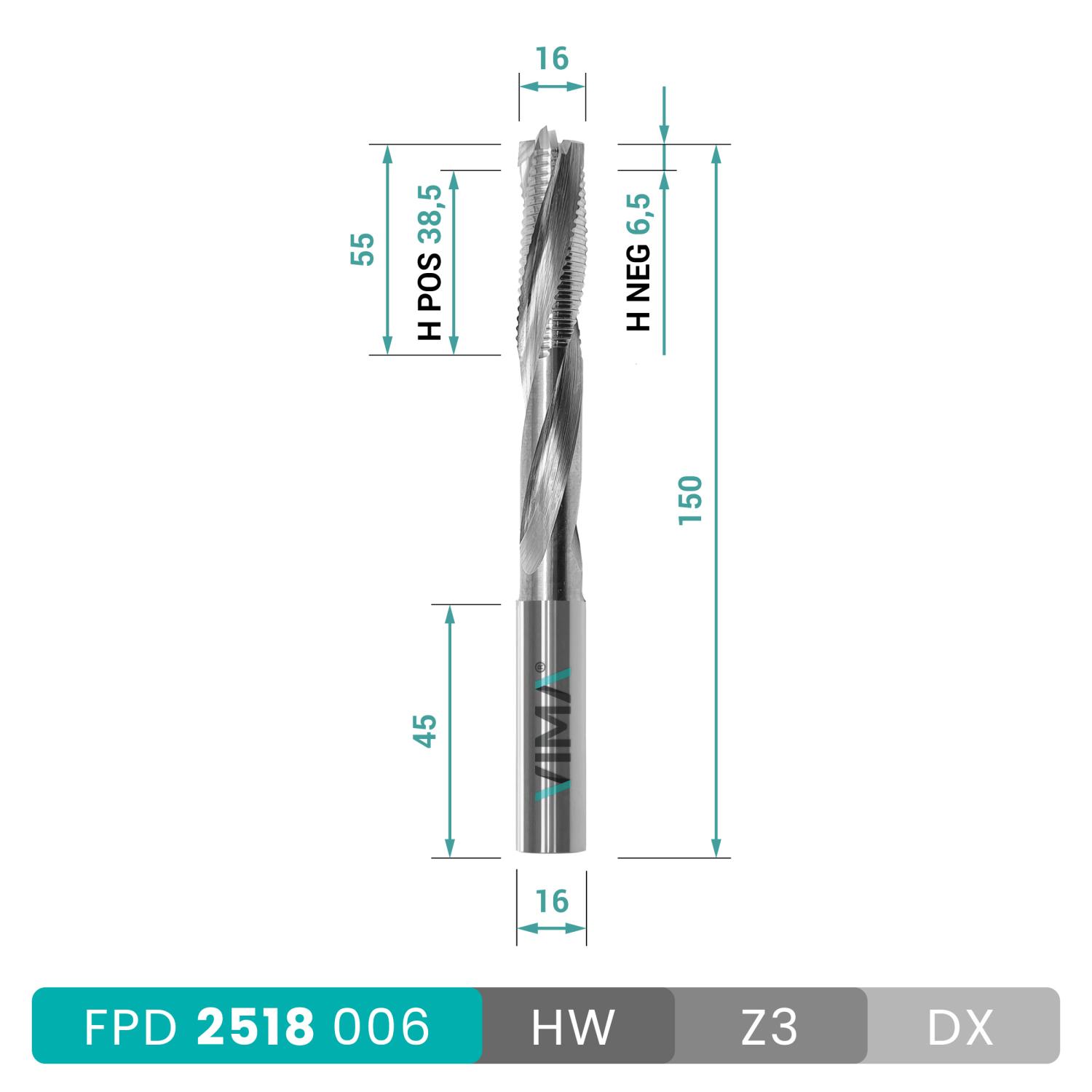

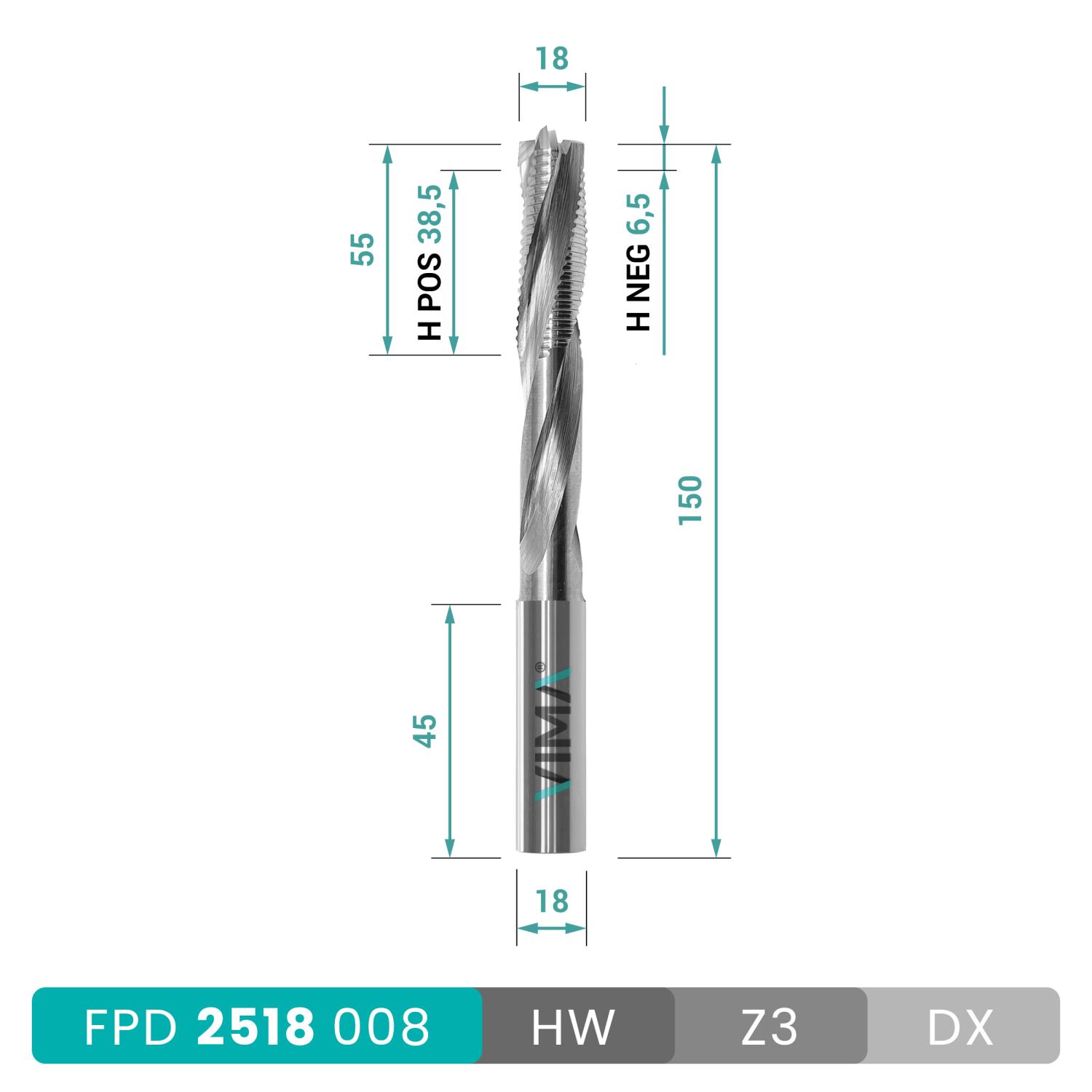

HW positive shank cutter to work door lock slot. chip breaker Z3 with negative part for better finshing of plate house. Suitable to realize door lock slot and for routing, cutting on solid wood , laminated chipboard and plastic material.

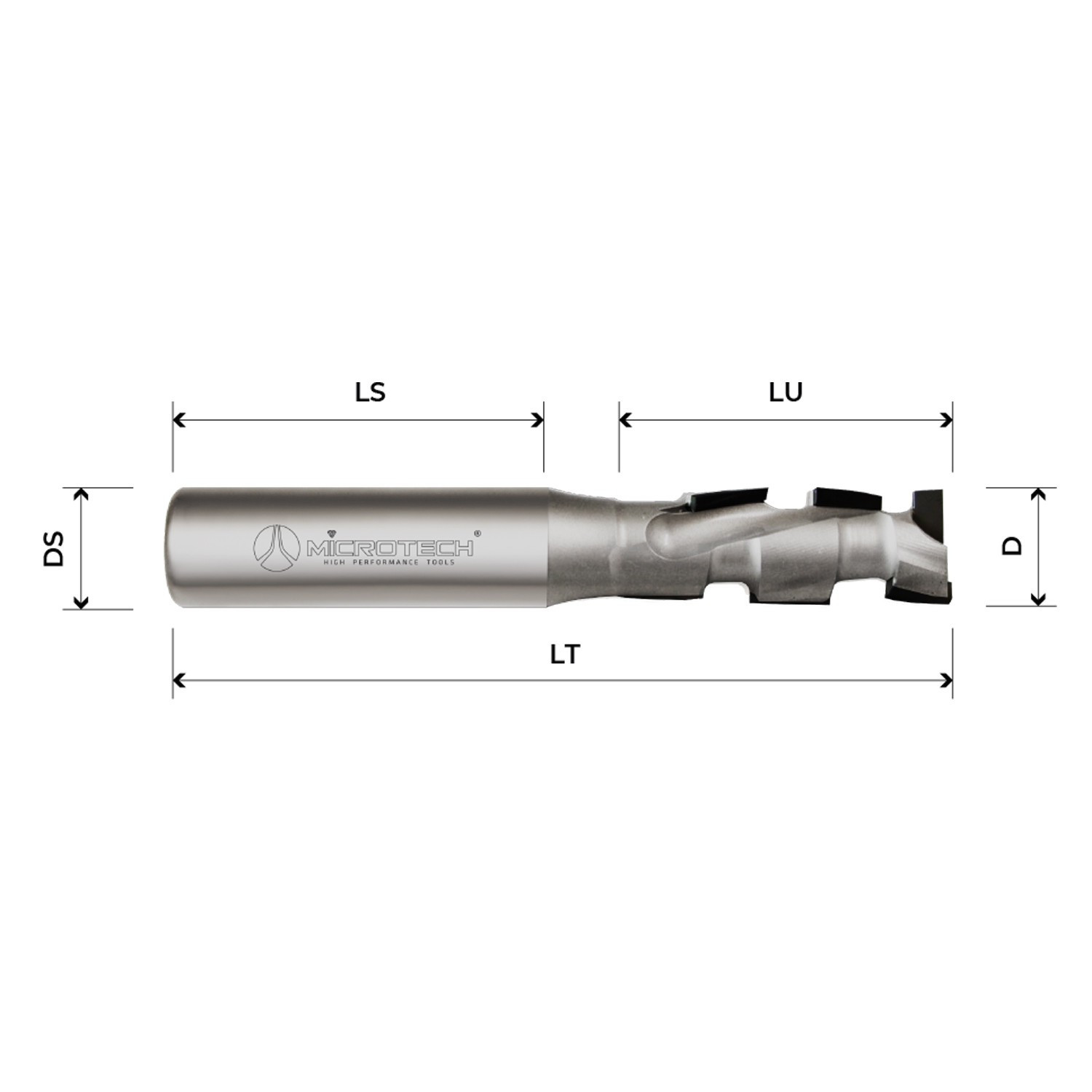

PCD shank cutter Z1+1 with eco PCD tips H2,5mm resharpened up to 3 times two helicoidal wing, firt tip positive all the others negative, plunge tip in DIA steel body or HDM body. Suitable for working on chipboard panels, playwood, laminated, solid wood and MDF.

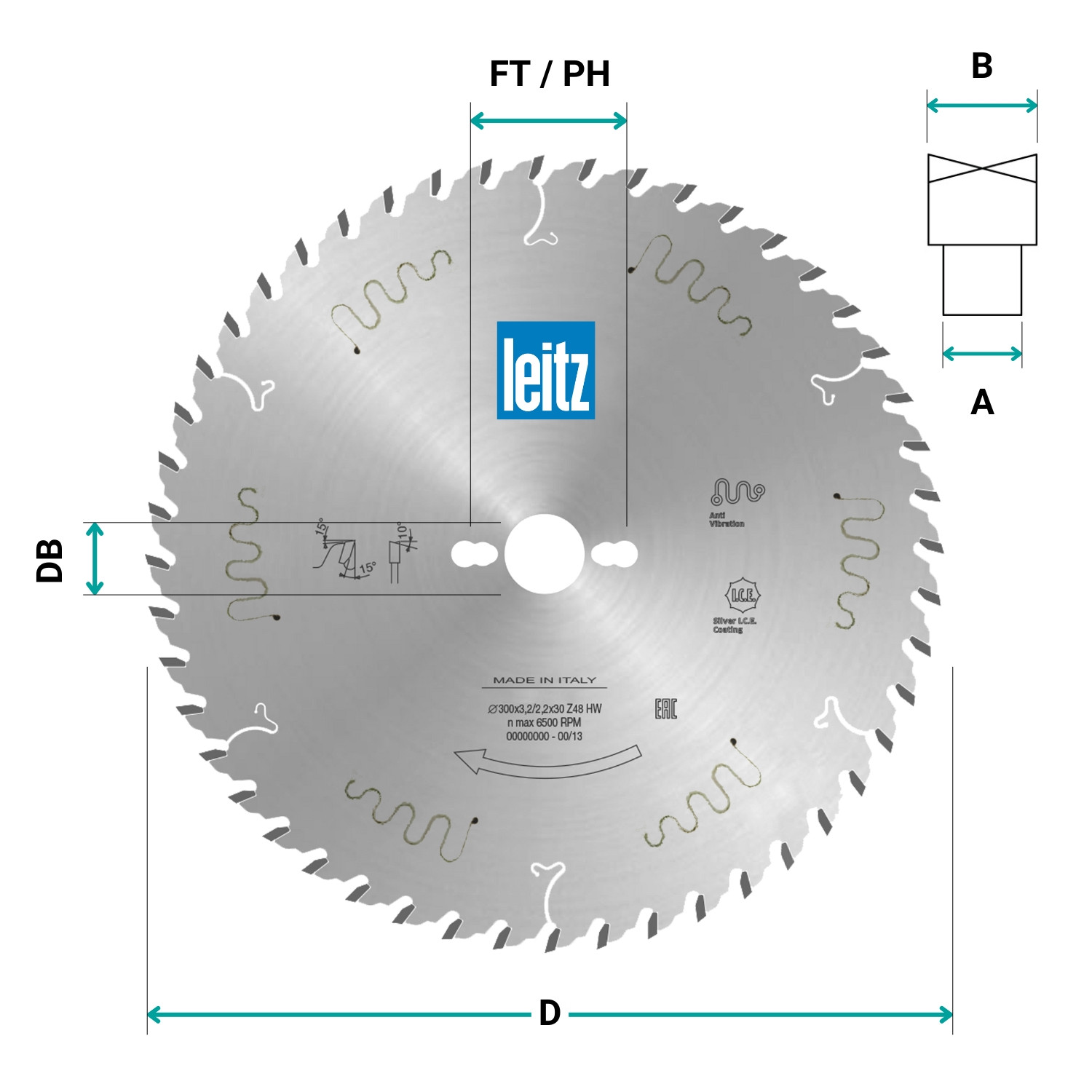

HW circular saw blade by LEITZ engineered for professional cutting of wood and laminated panels. Designed for clean, precise and stable cuts even without a scoring blade, it ensures excellent feed, control and finishing on MDF, HDF, plywood and particleboard.

• Professional LEITZ performance

• Clean cutting on MDF, HDF and plywood

• Works perfectly even without scorer

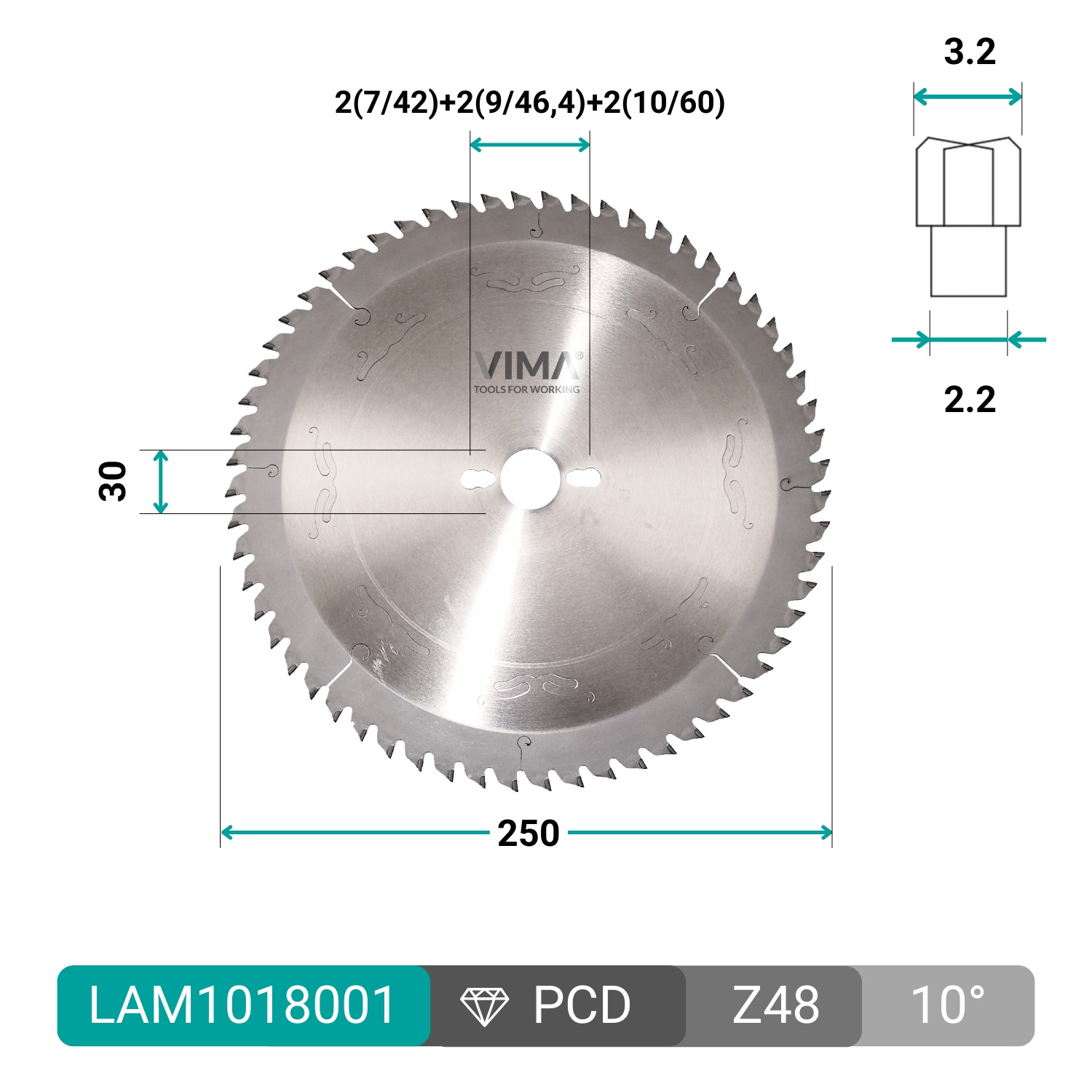

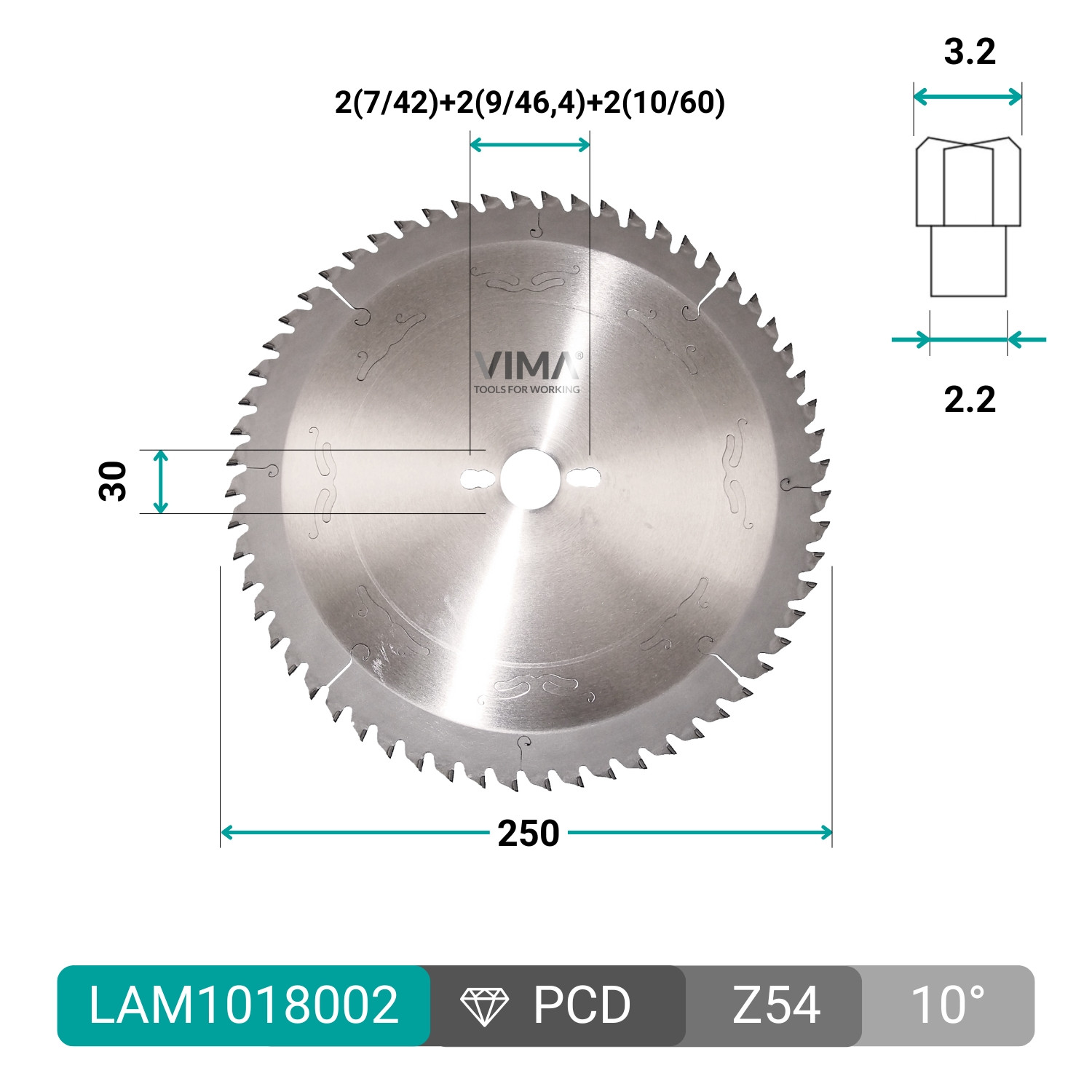

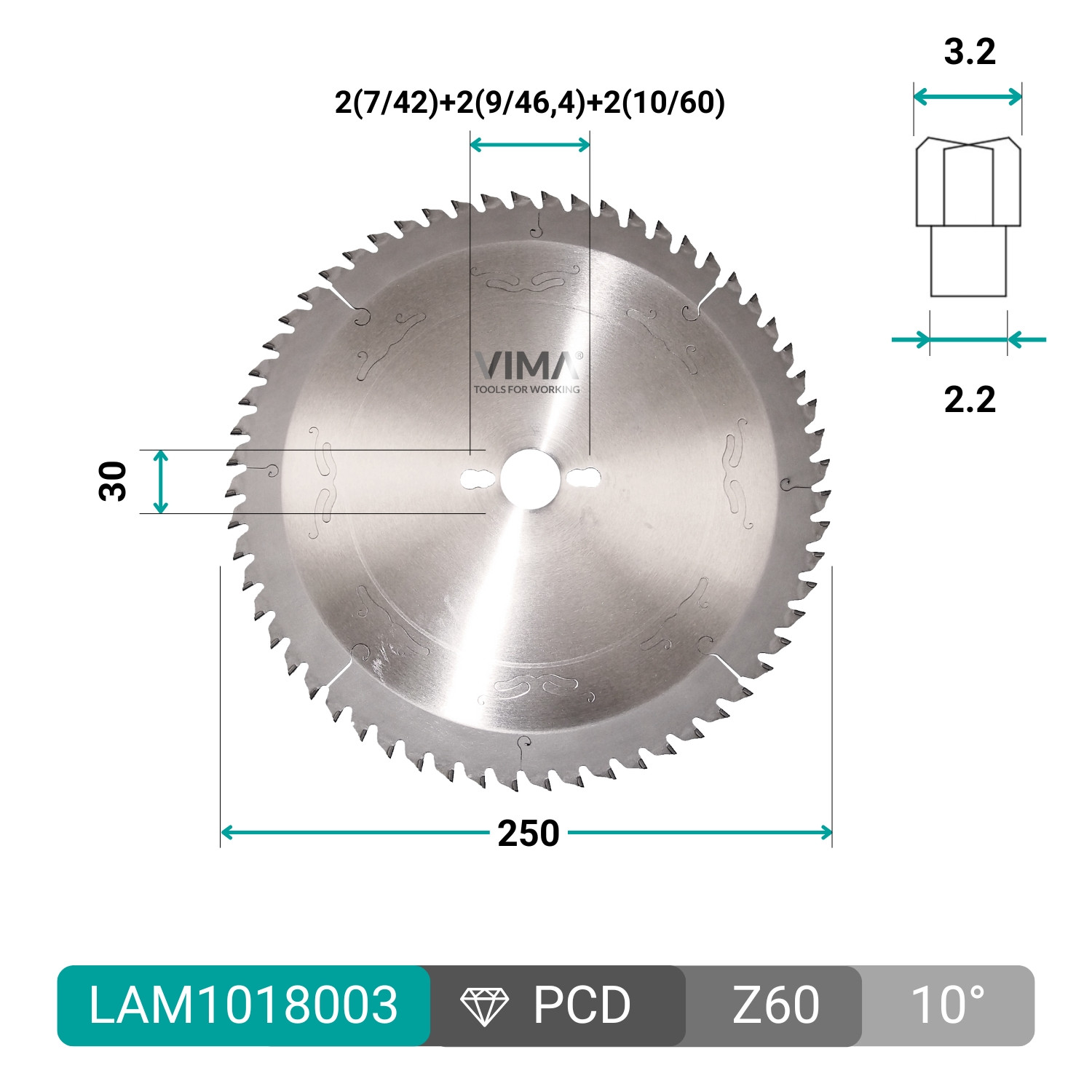

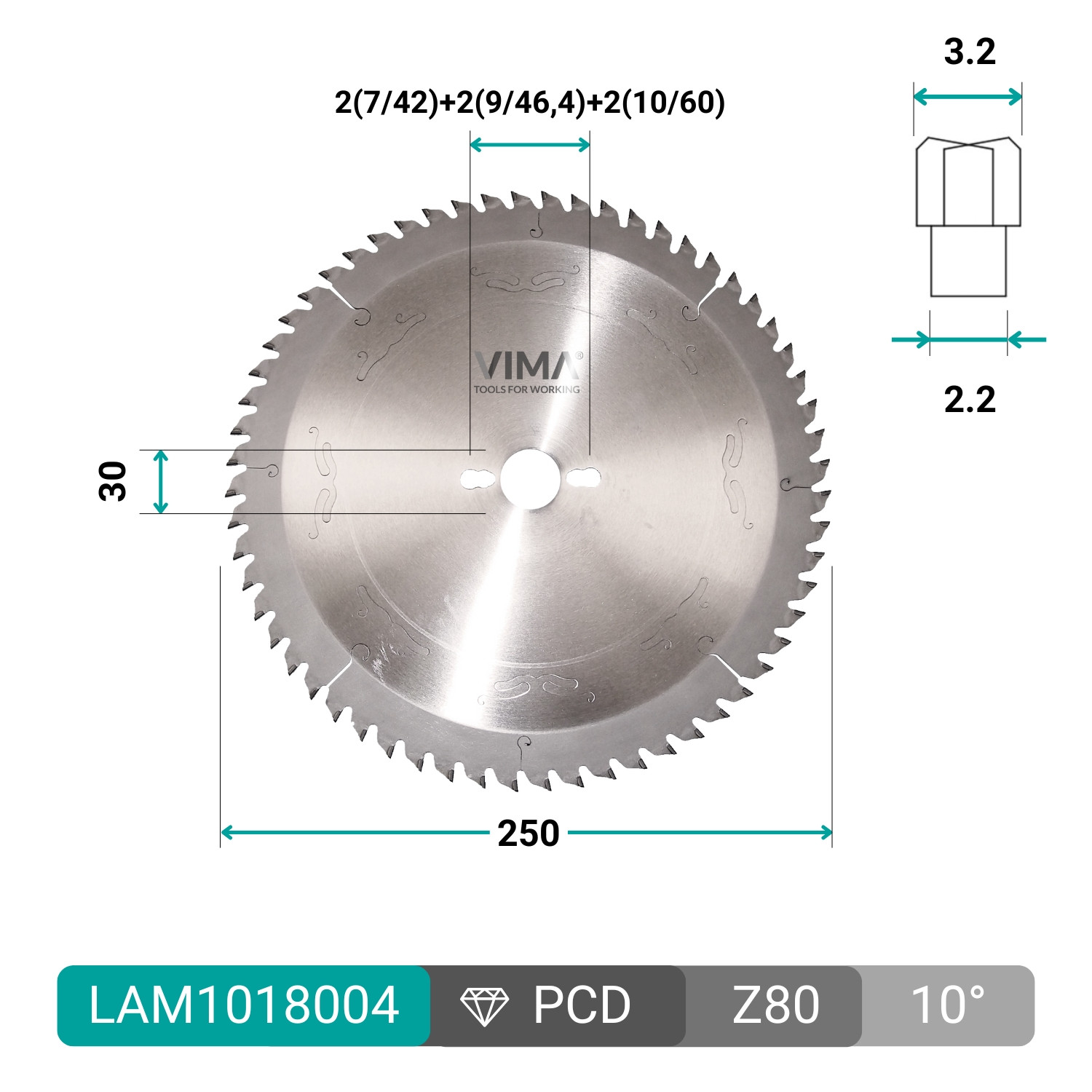

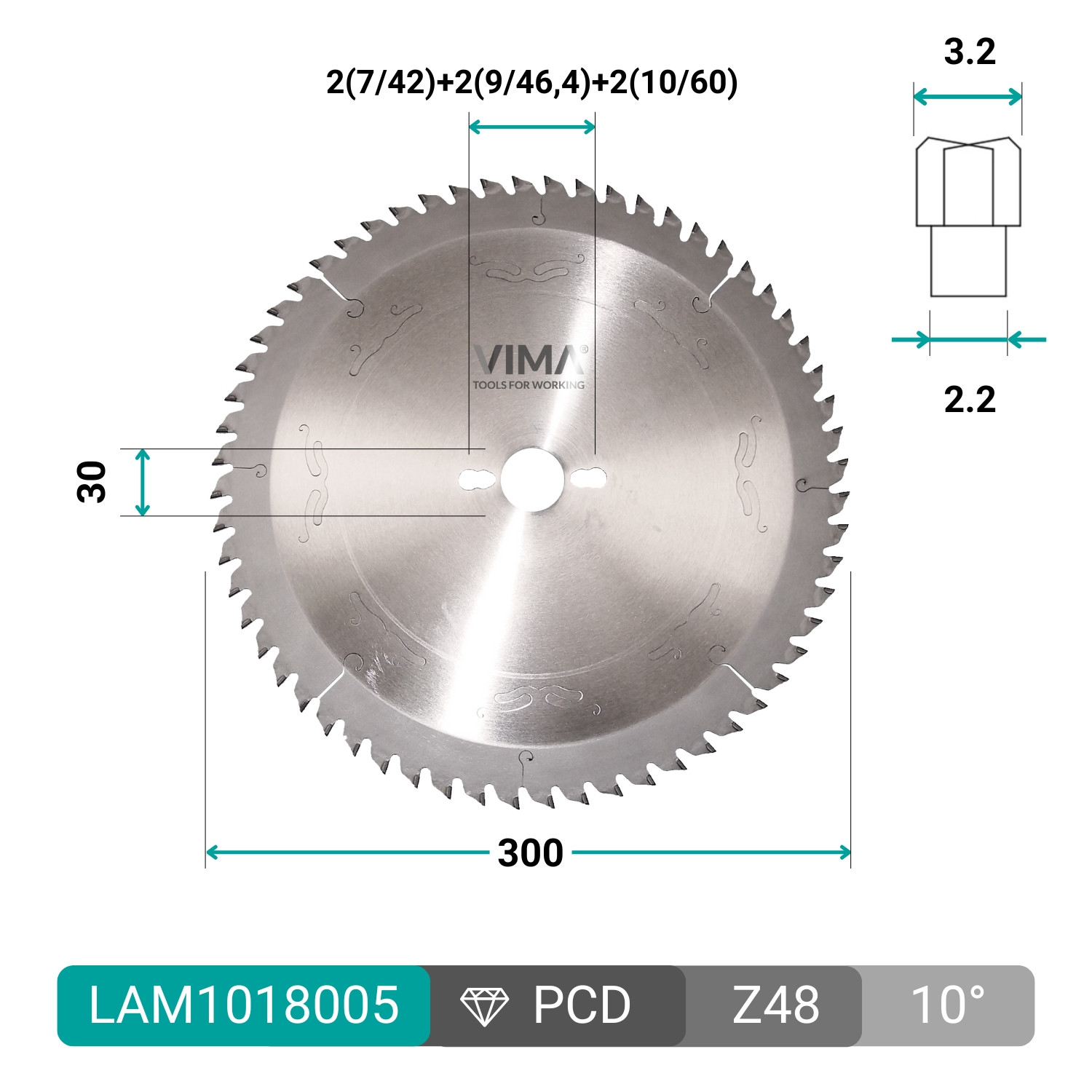

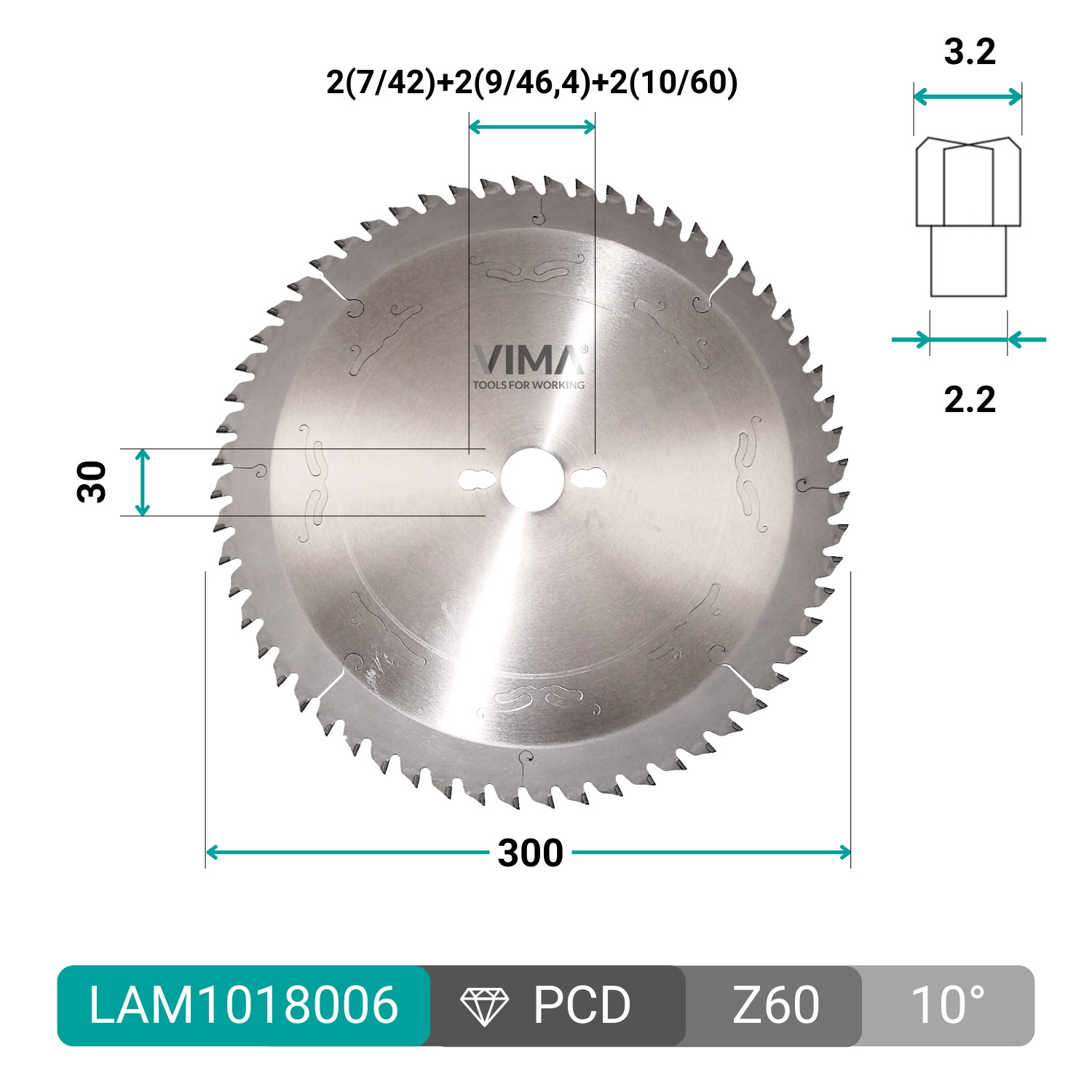

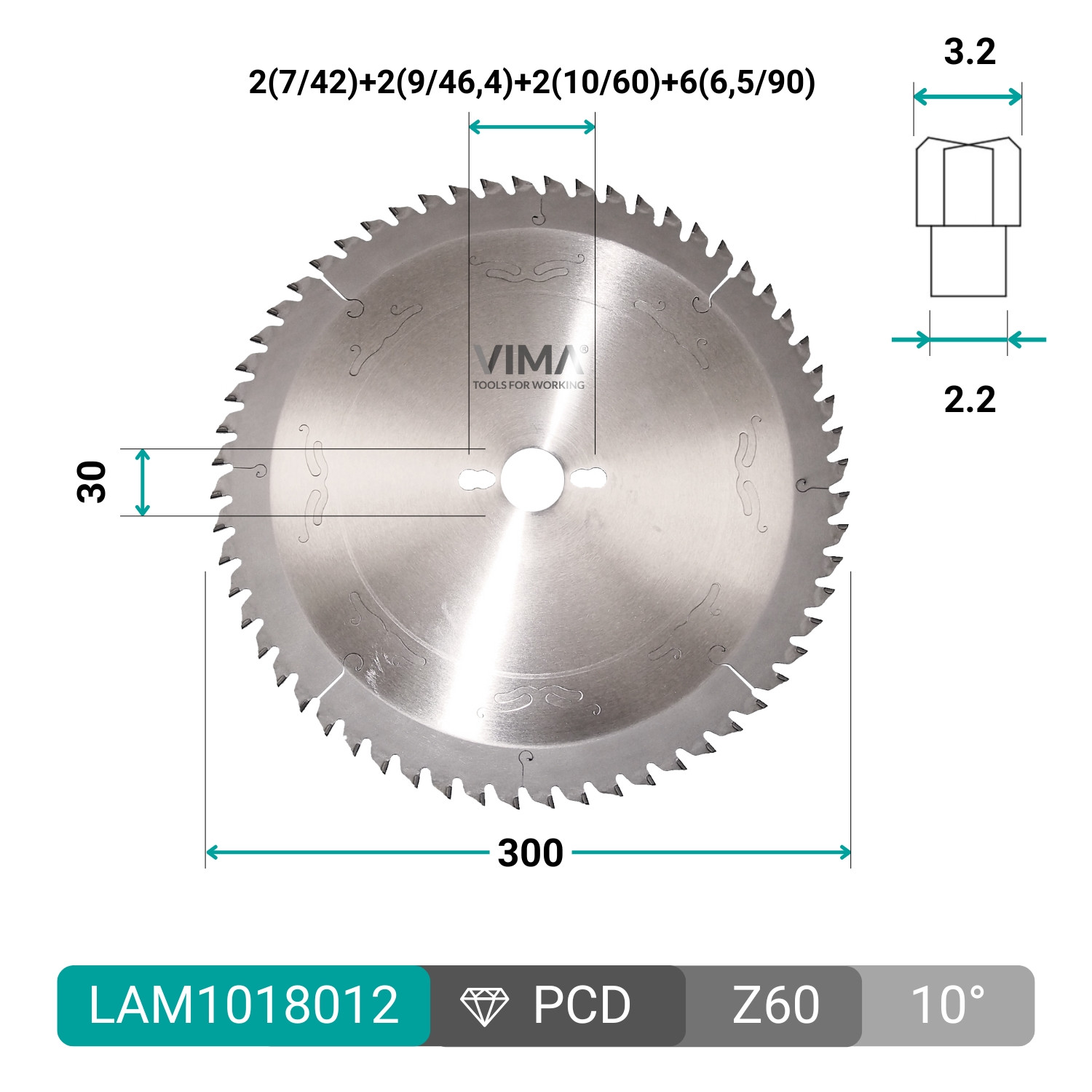

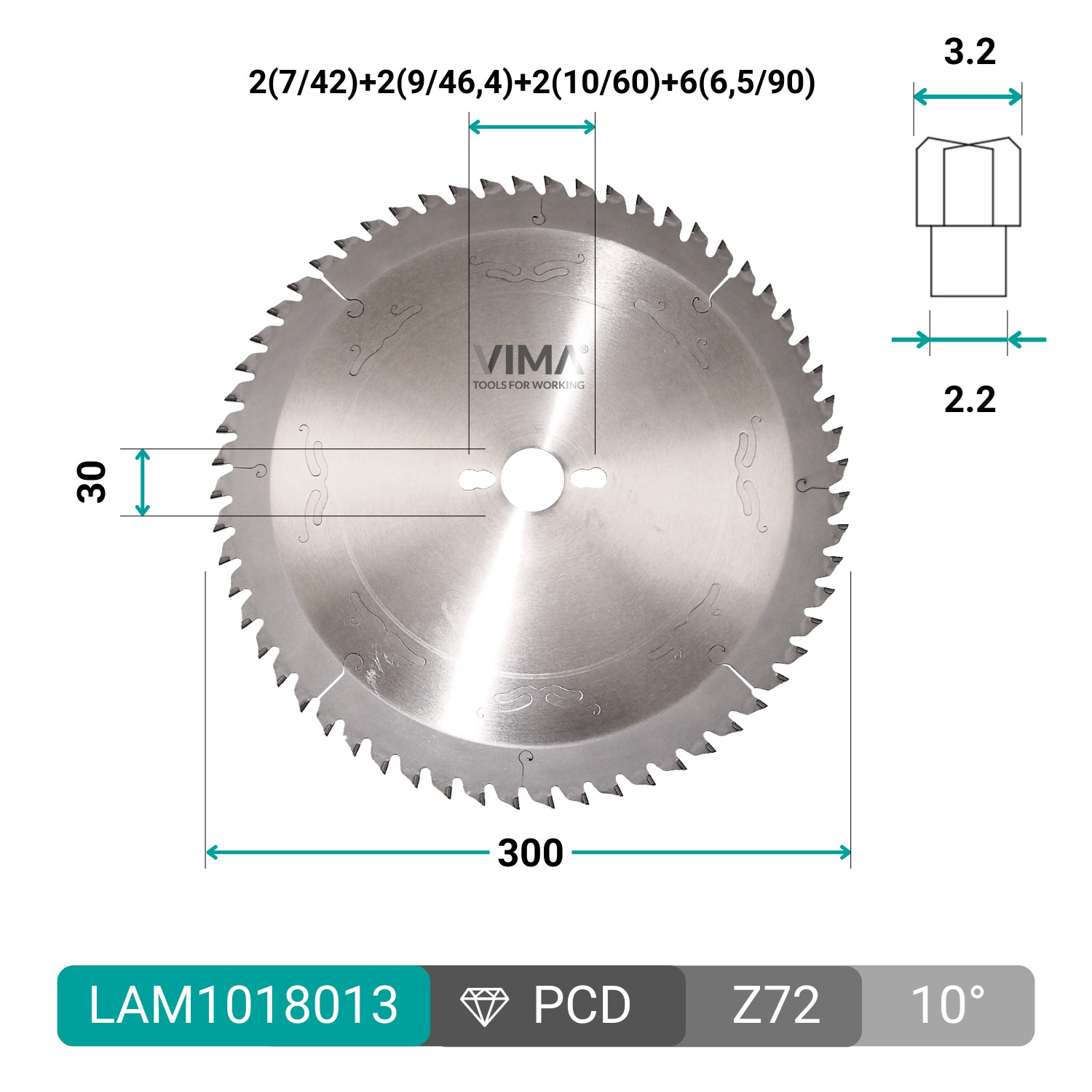

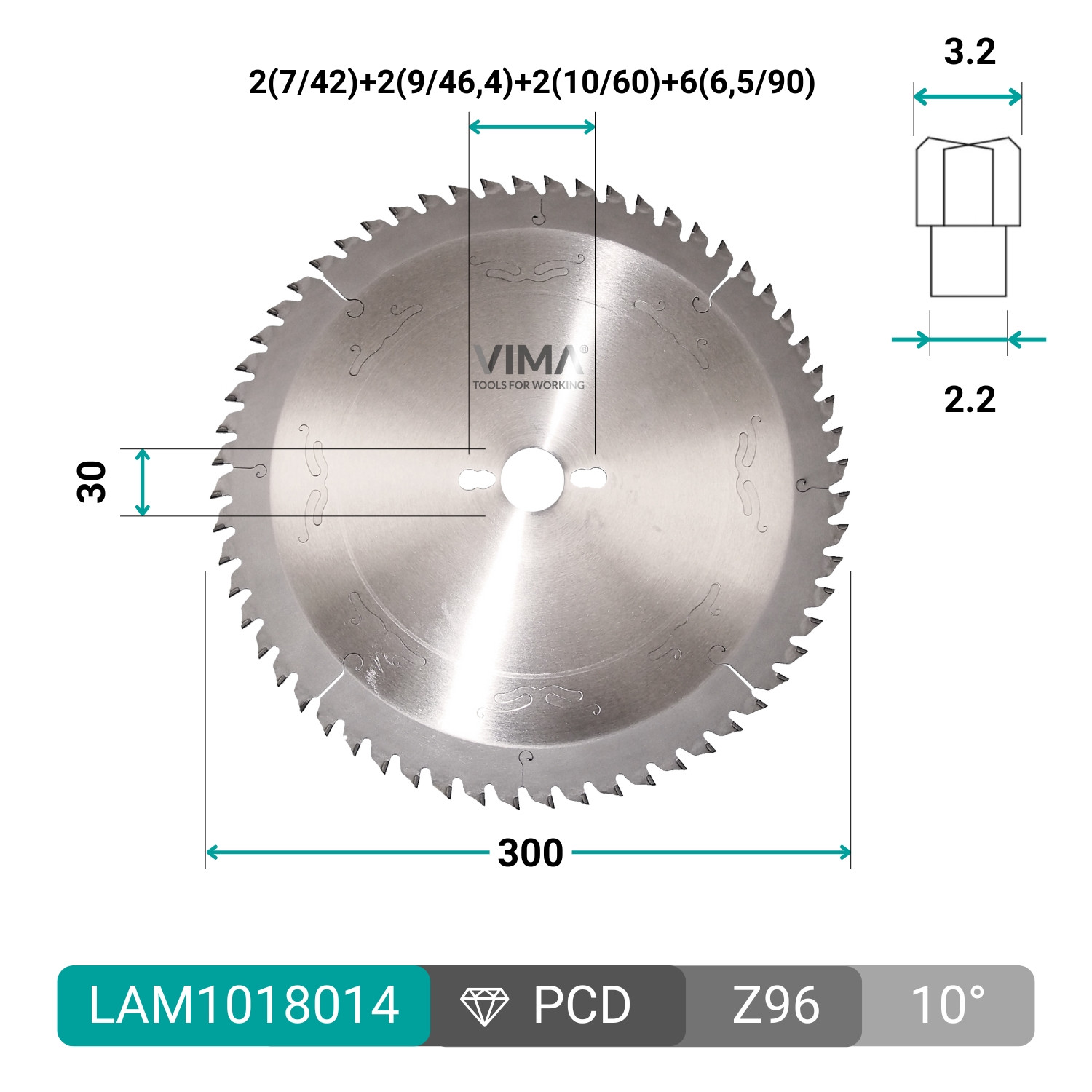

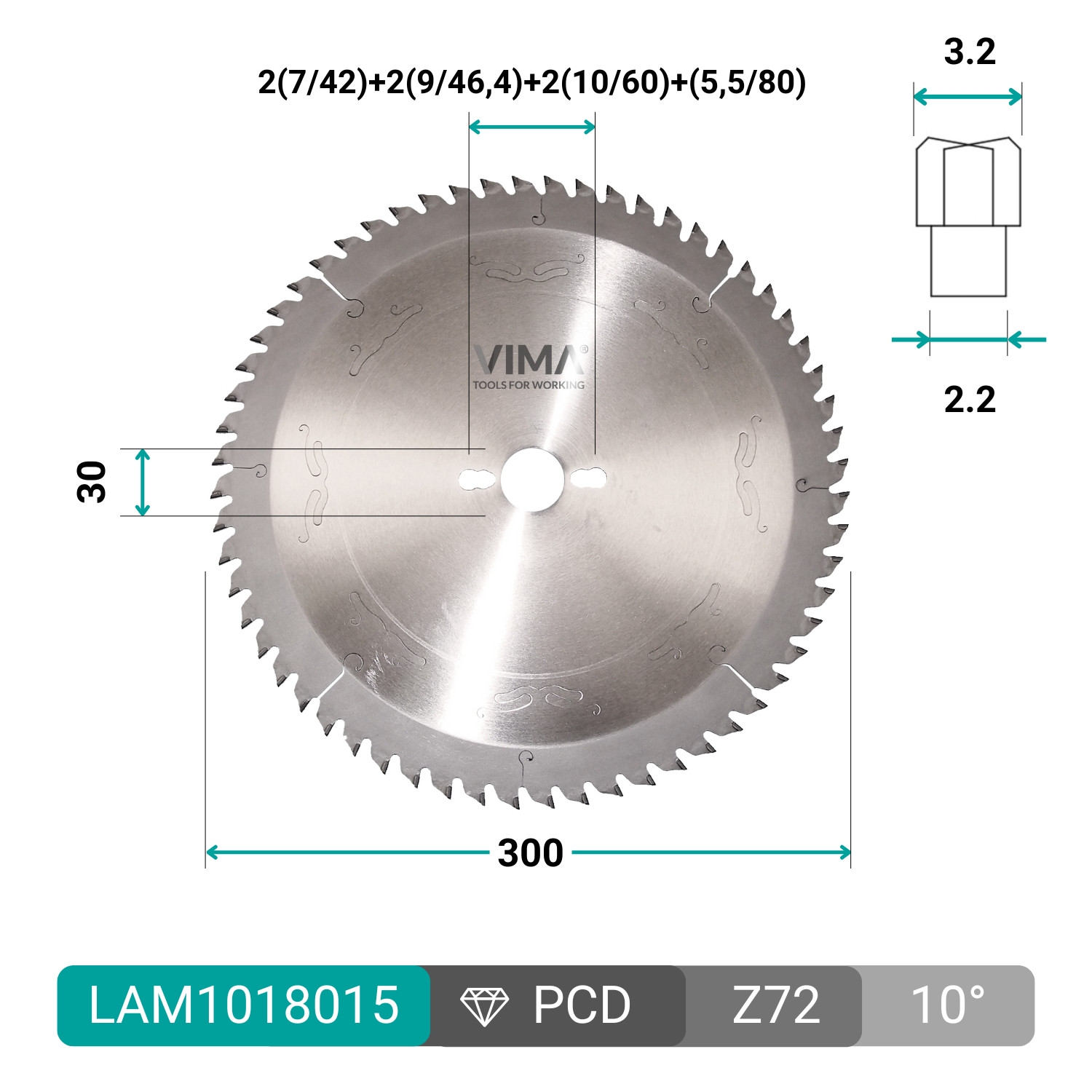

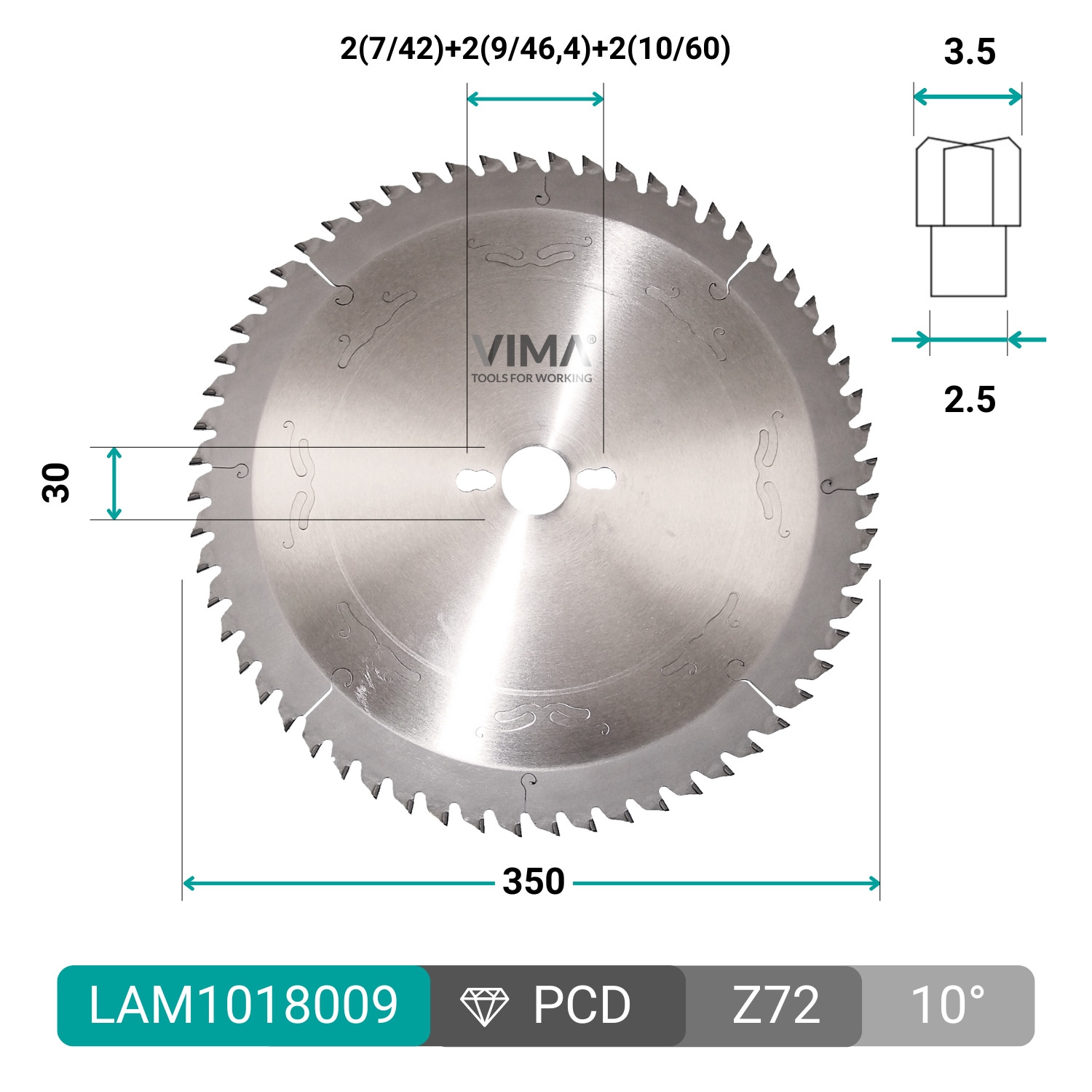

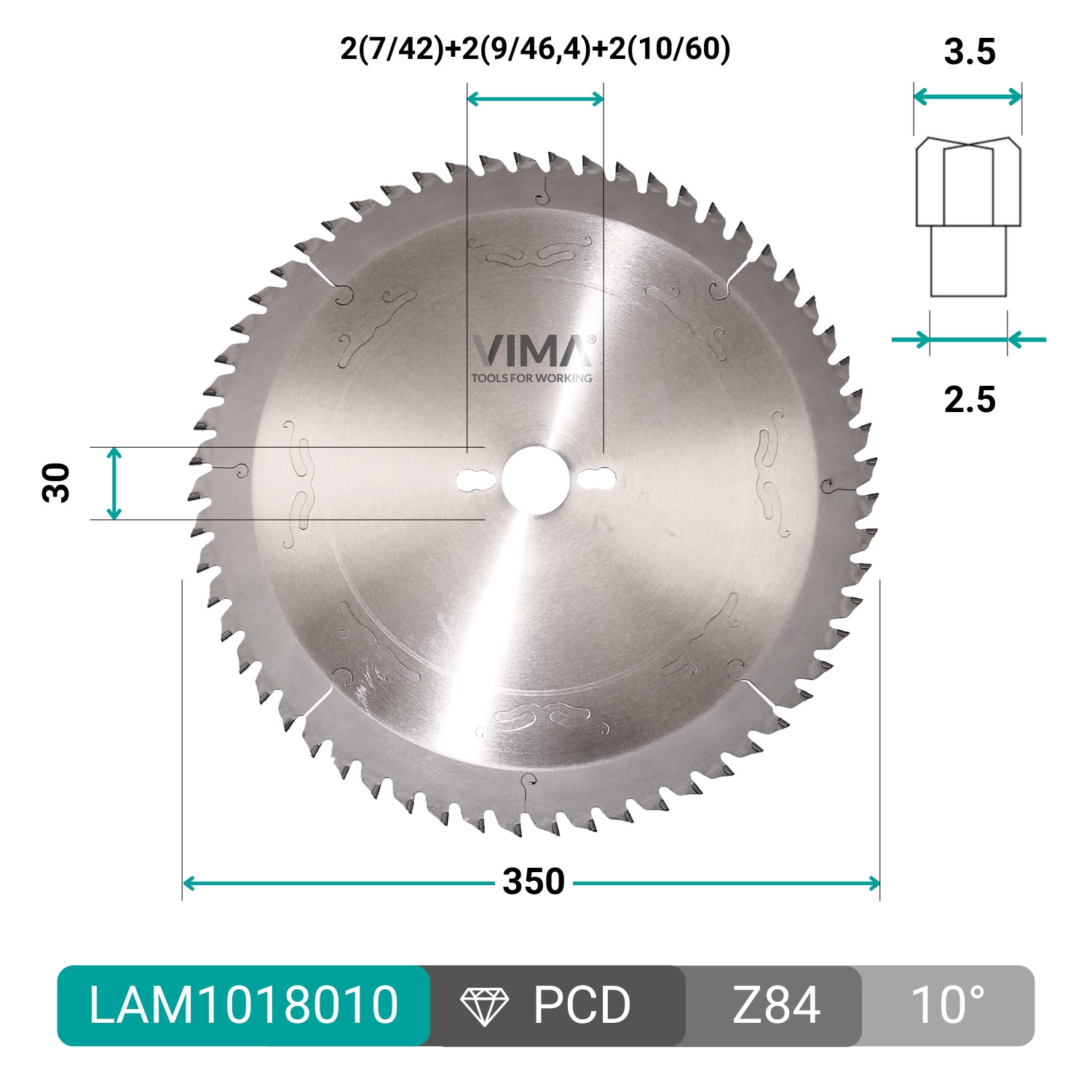

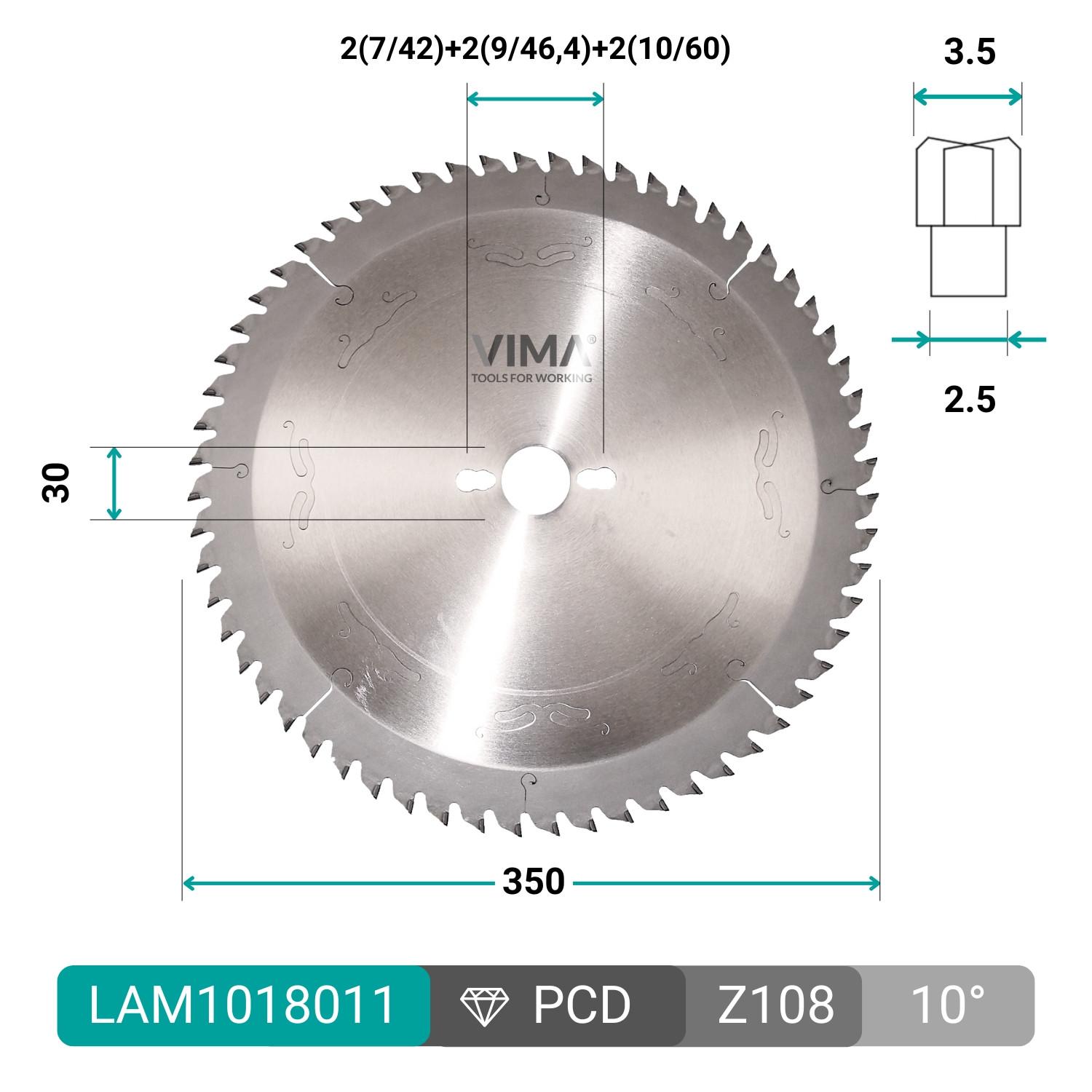

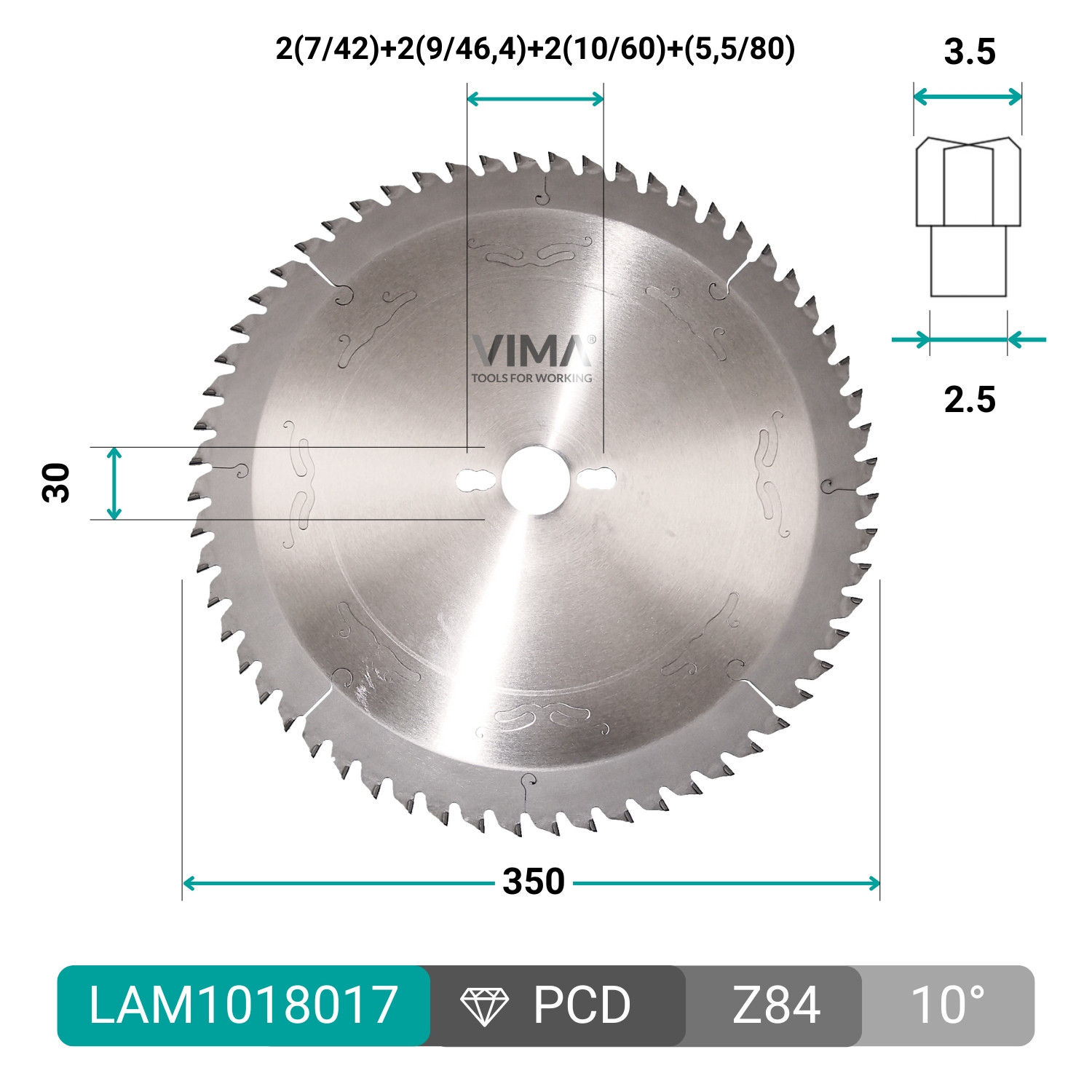

PCD diamond blade designed for bench saws and horizontal panel saws. The 10° internal axial angle ensures superior finishing, smooth feed and outstanding durability on laminated and composite materials.

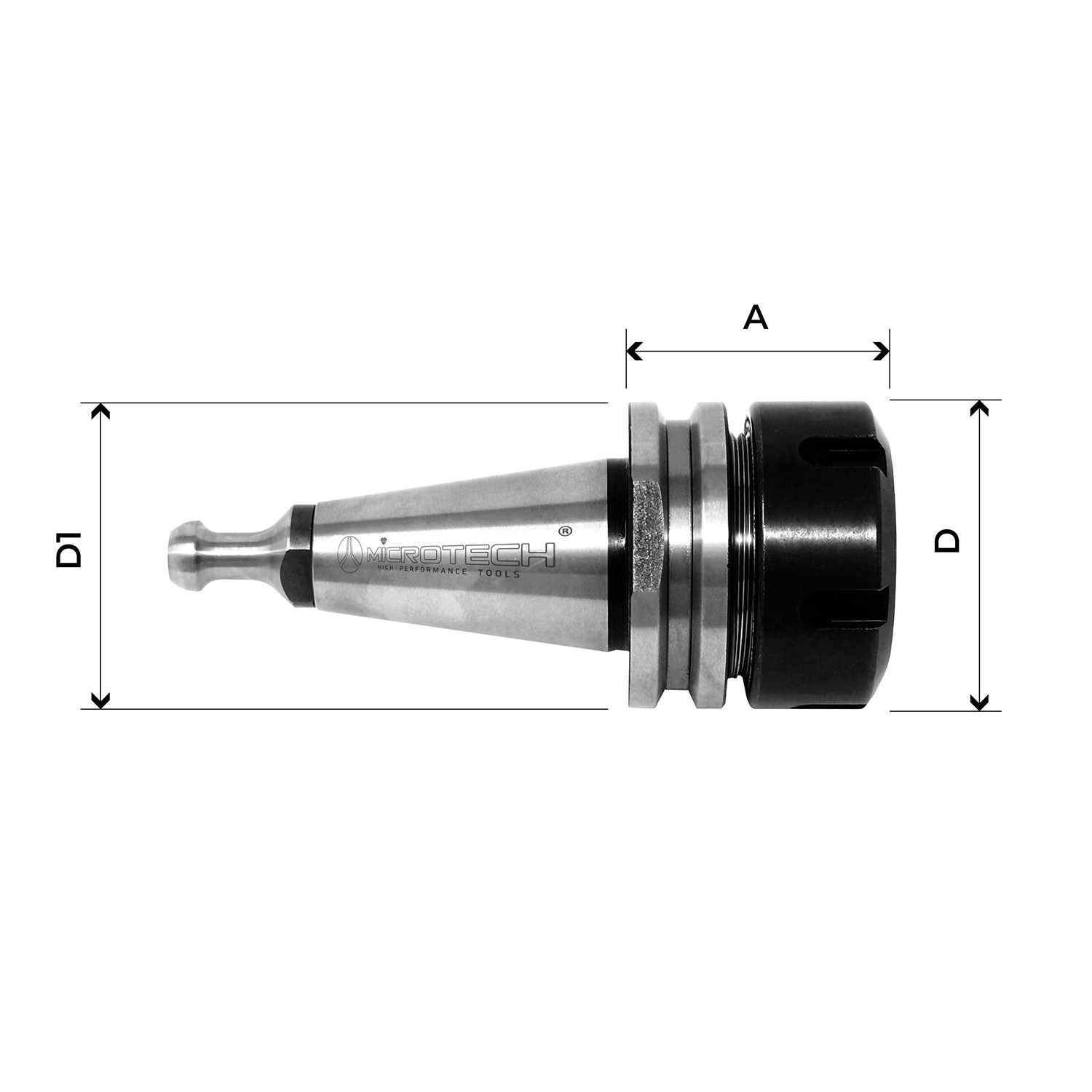

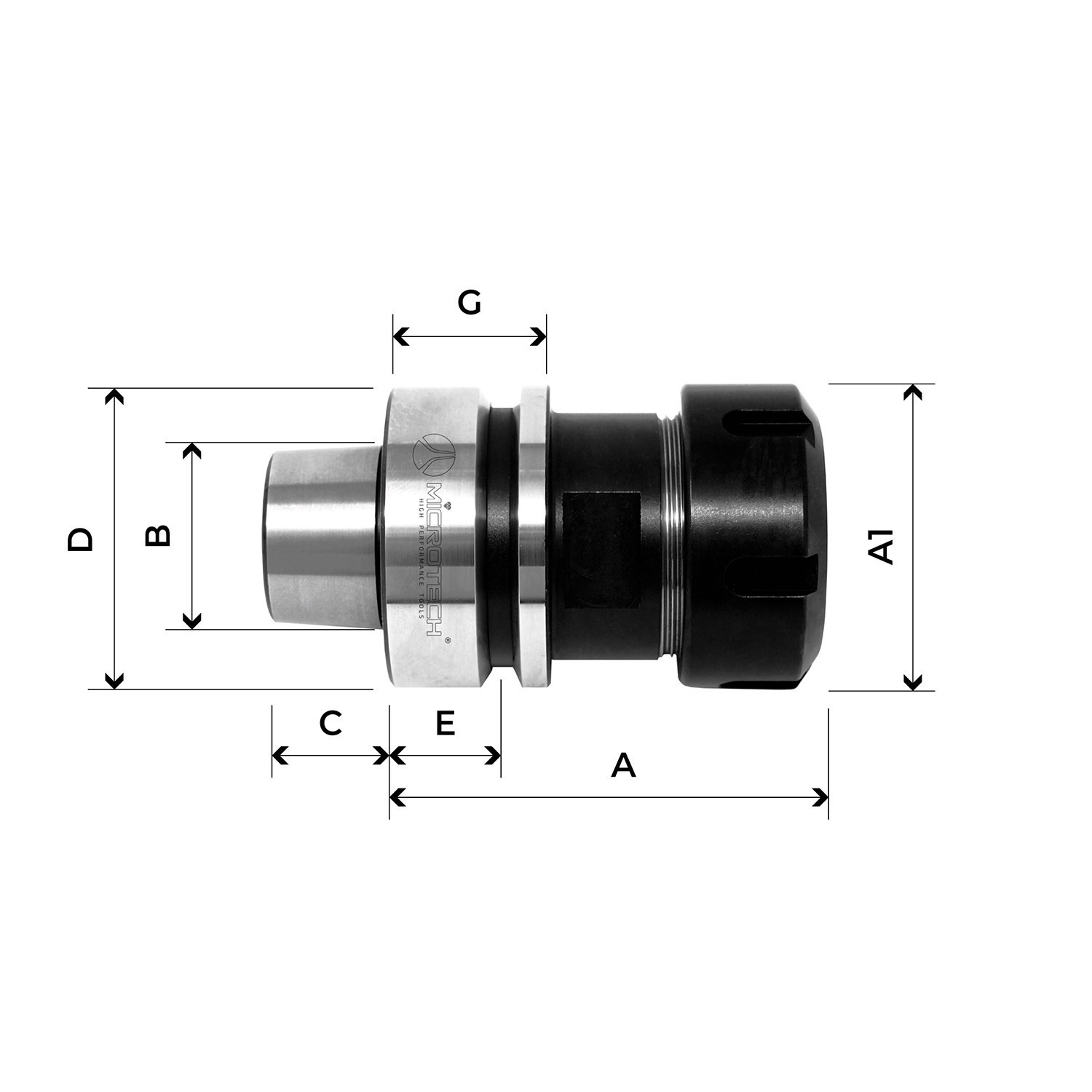

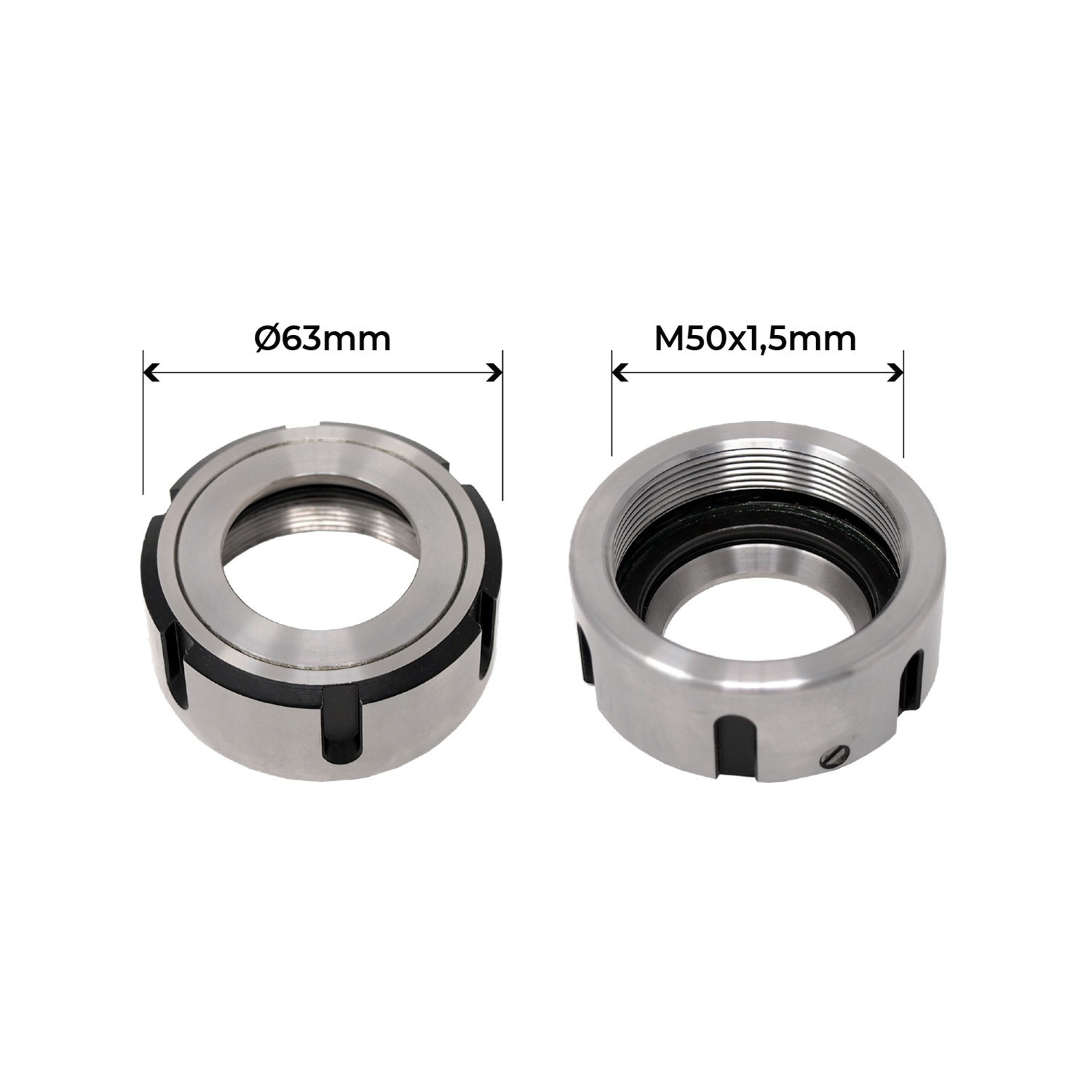

Tool holder HSK63F with tollerance between the tool holder and tool house 0,003 mm.

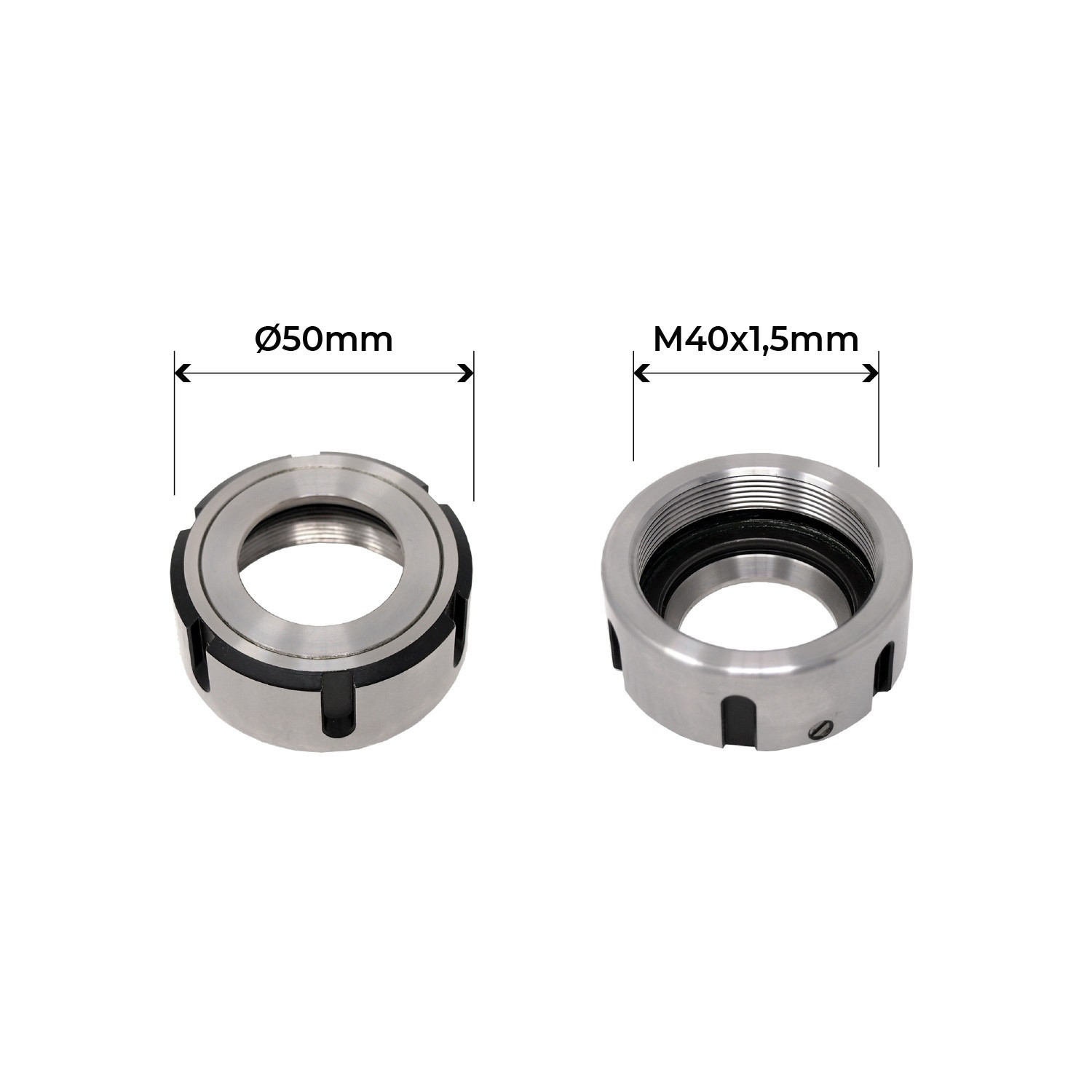

• ER32 - ER40 taper shank toolholders;

• Maximum precision and reliability;

• Total elimination of any rotation imperfections;

• Constructed from high-strength steel for superior performance;

• Precision ground on all contact surfaces;

• Fast and secure tool installation guaranteed.

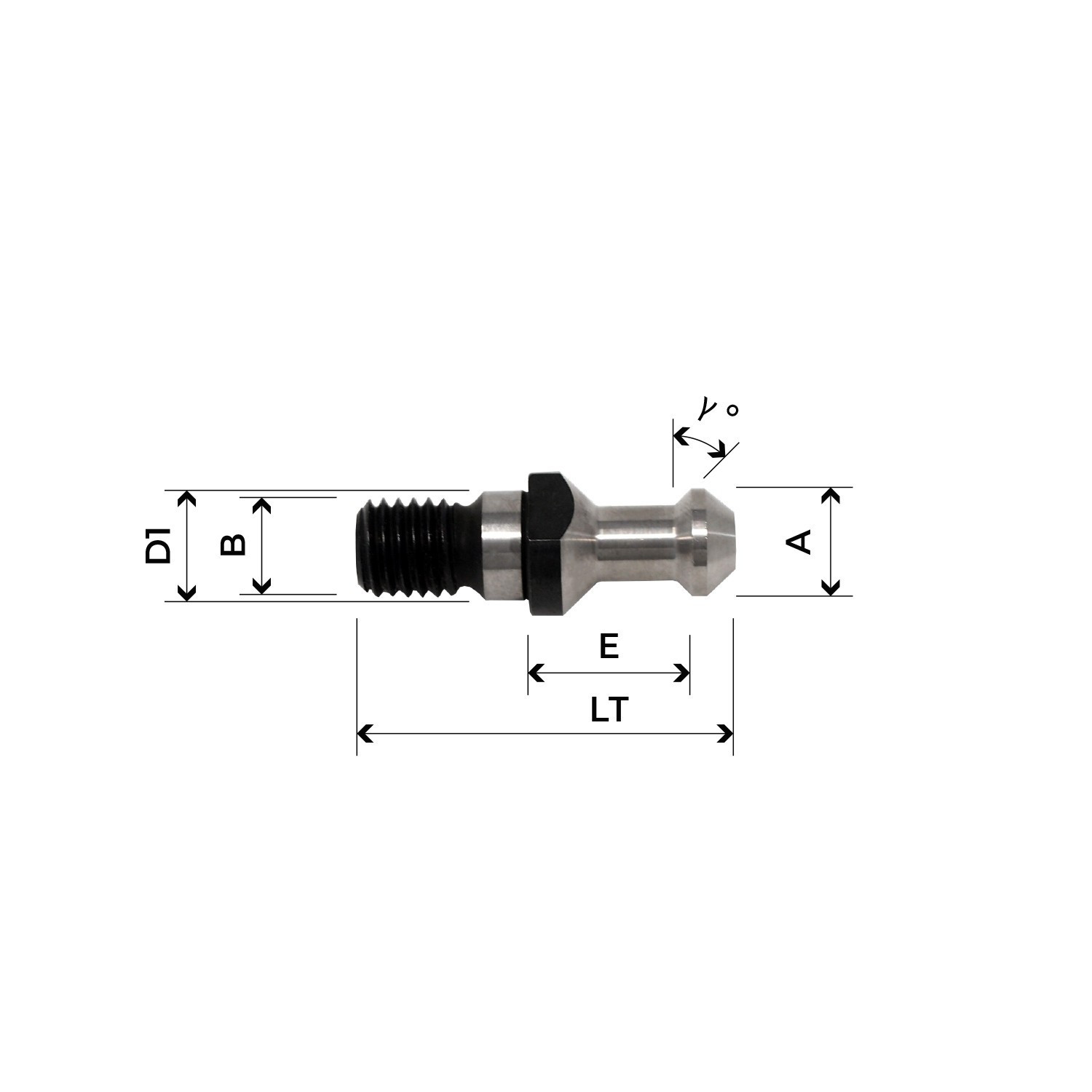

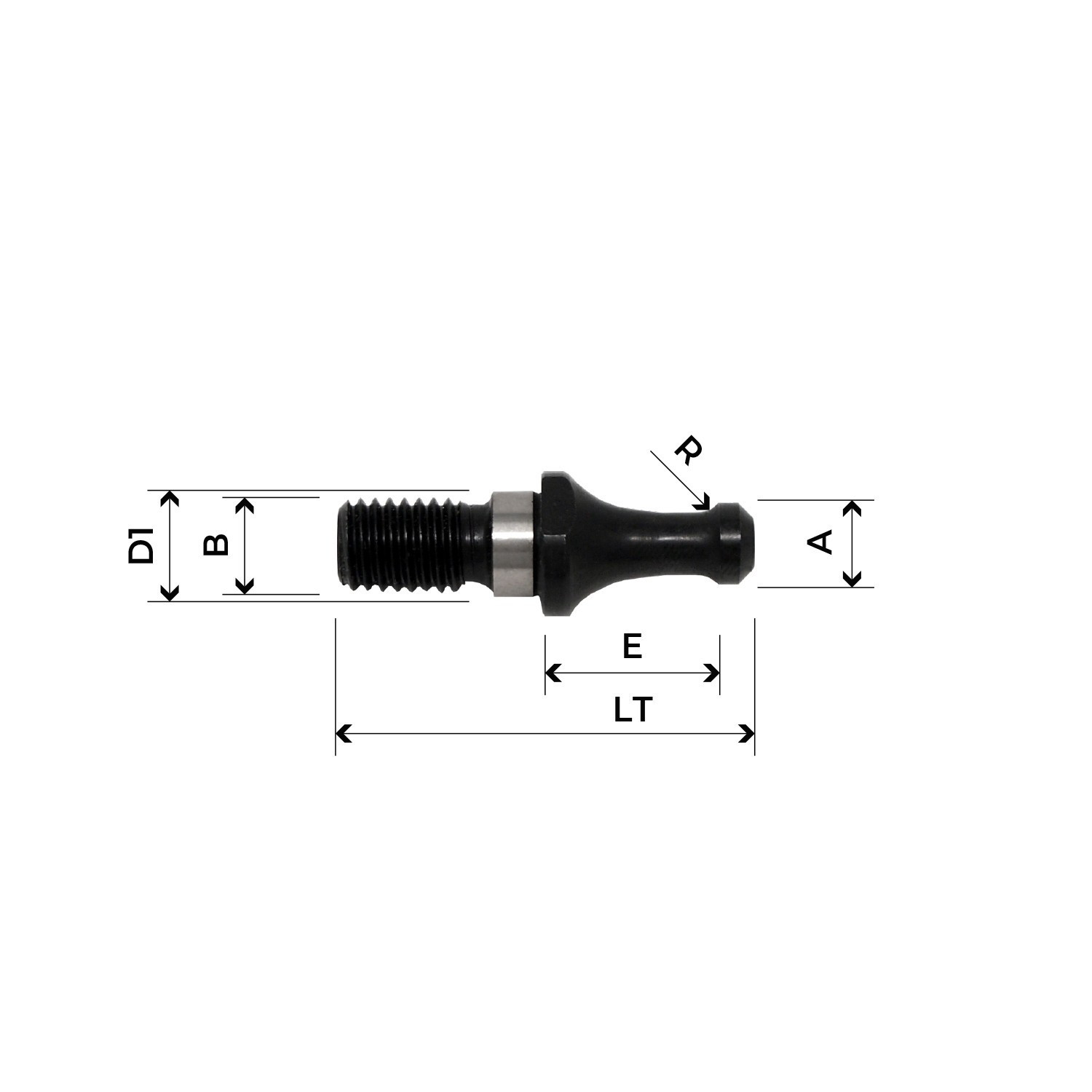

Collet chuck ISO30 for Biesse, Omlat engine, Bulleri, Busellato, CMS, IMA, Alberti, Masterwood machines.

• ISO30 taper toolholder;

• Supplied complete with nut and drawbar (without collet);

• Maximum precision and reliability;

• Total elimination of rotation imperfections;

• HSK63F collet chuck manufactured from high-strength steel for superior performance;

• Precision ground on all contact surfaces;

• Fast and secure tool installation guaranteed.

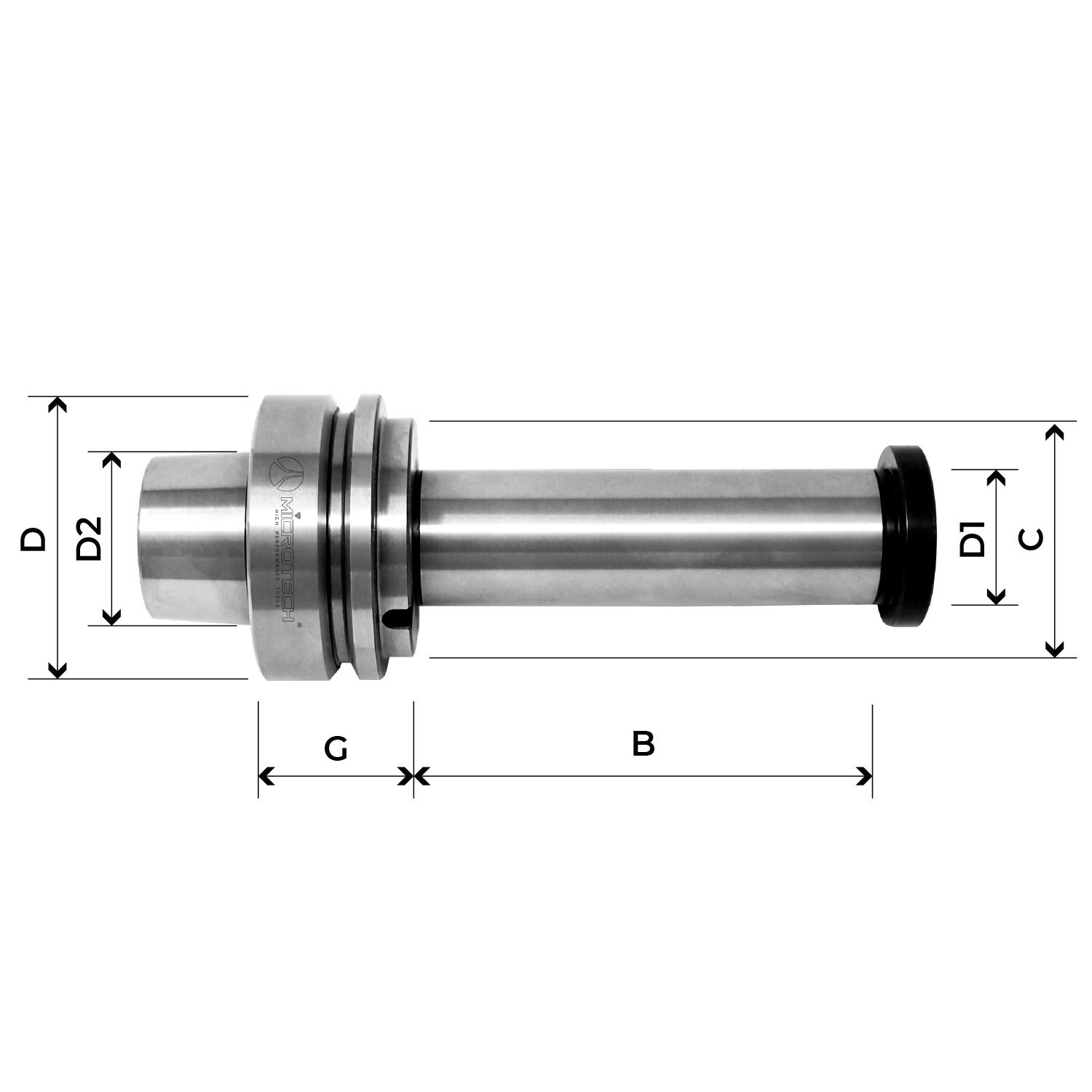

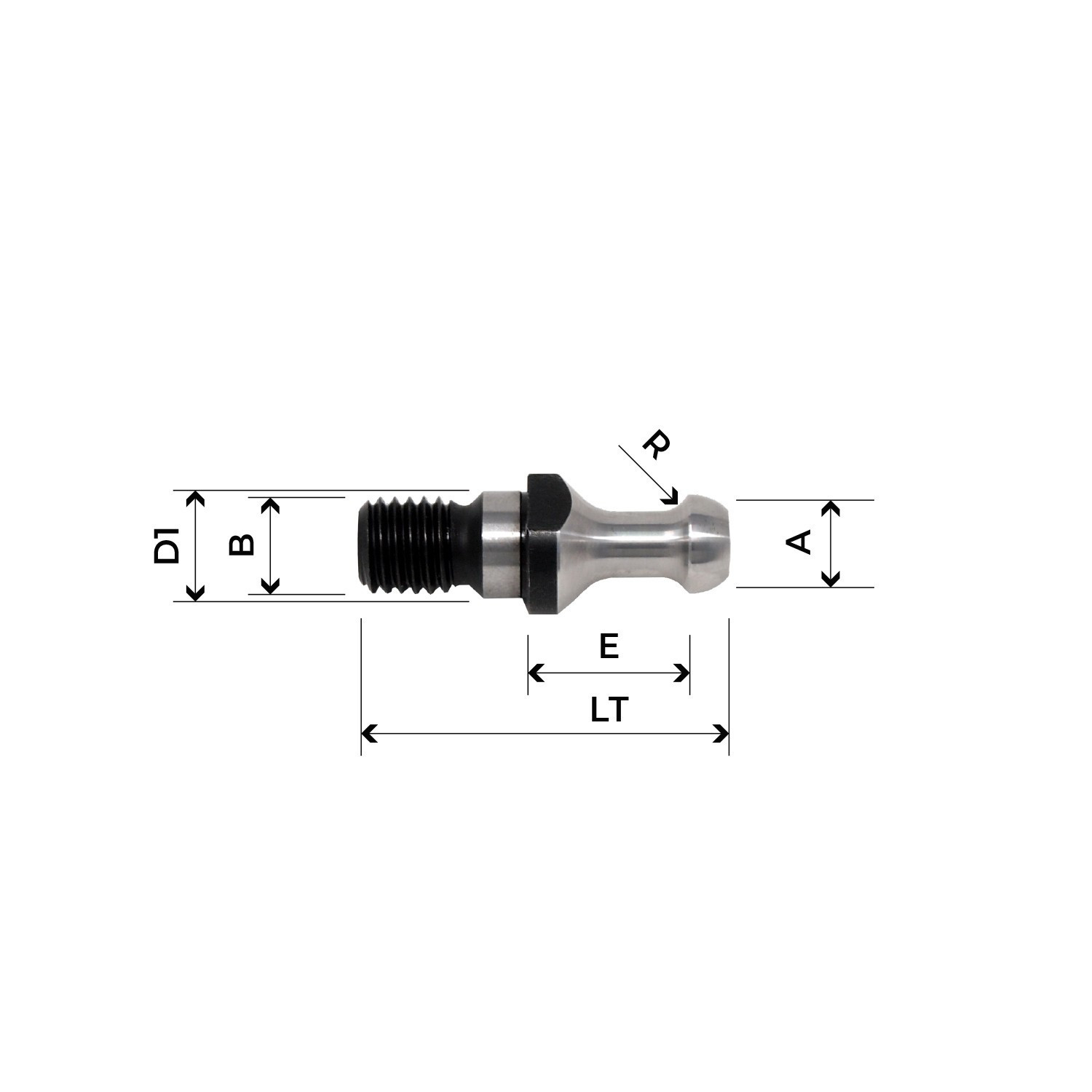

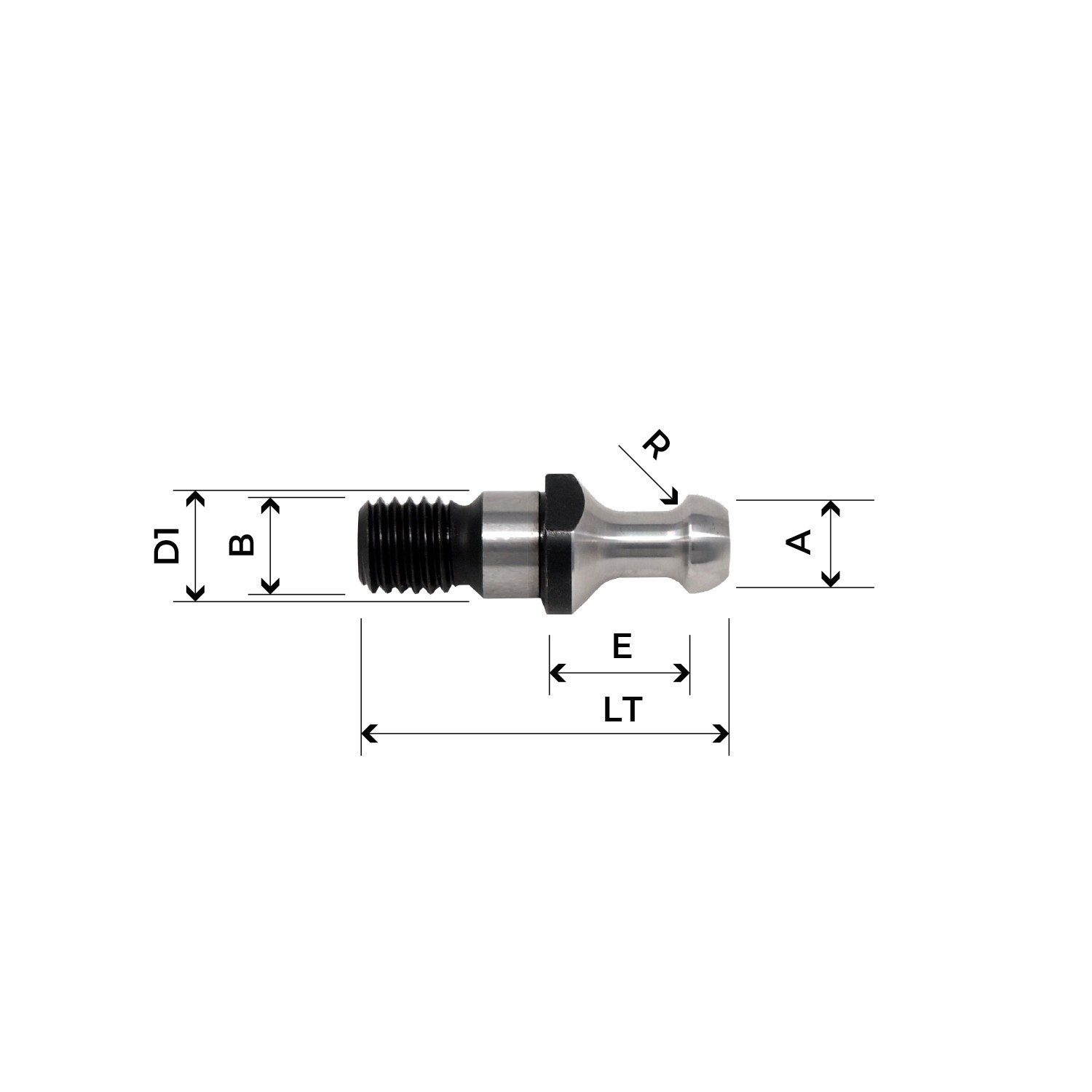

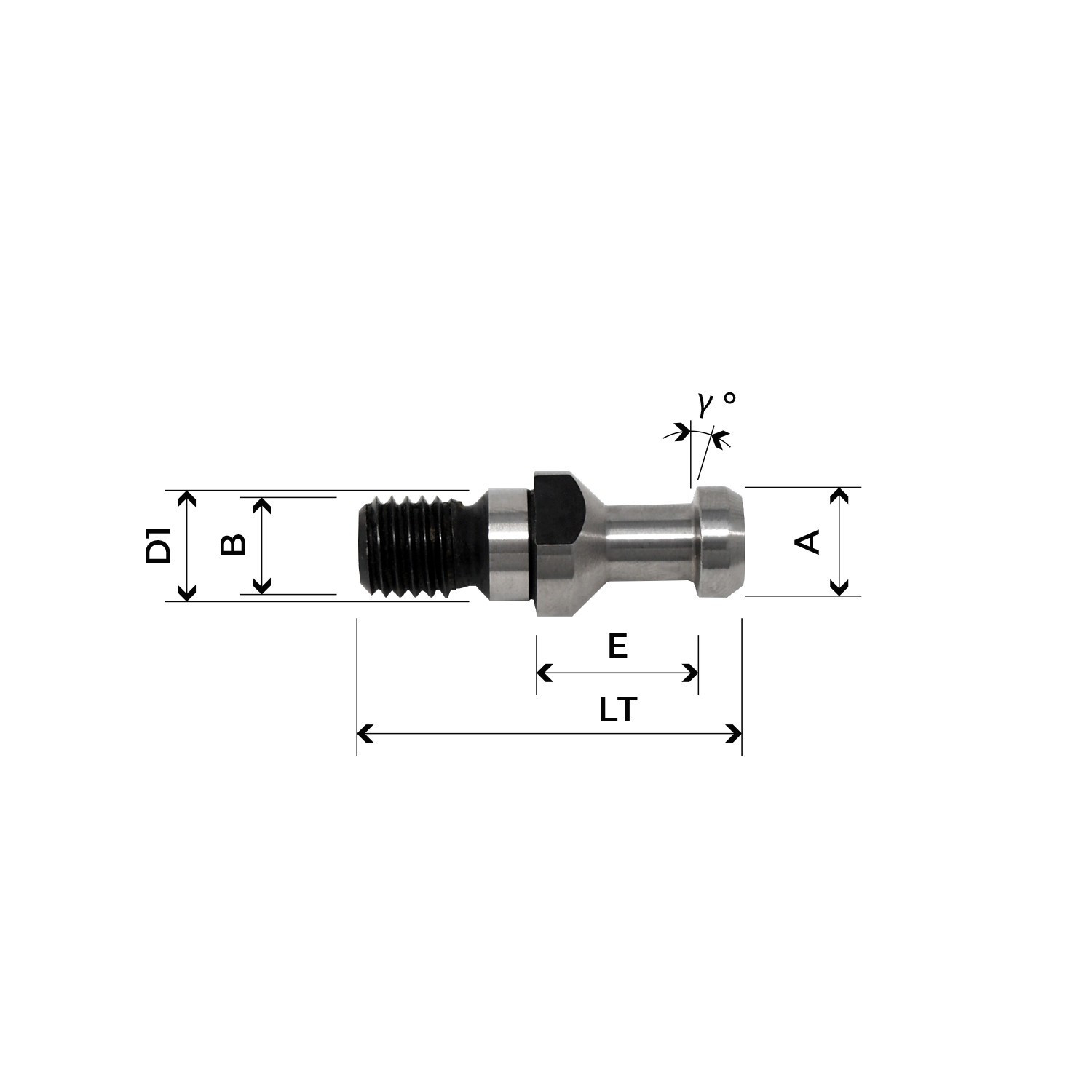

Tool holder ISO30 to be use on Morbidelli and SCM machines.

• Manufactured from special high-strength steel;

• Supplied complete with nut and drawbar (without collet);

• Maximum precision and reliability;

• Total elimination of rotation imperfections;

• For Morbidelli and SCM machines;

• Precision ground on all contact surfaces;

• Fast and secure tool installation guaranteed.

Tool holder HSK50F with tollerance between the tool holder and tool house 0,003 mm.

Tool Holder HSK63F of various heights with arbor different size.

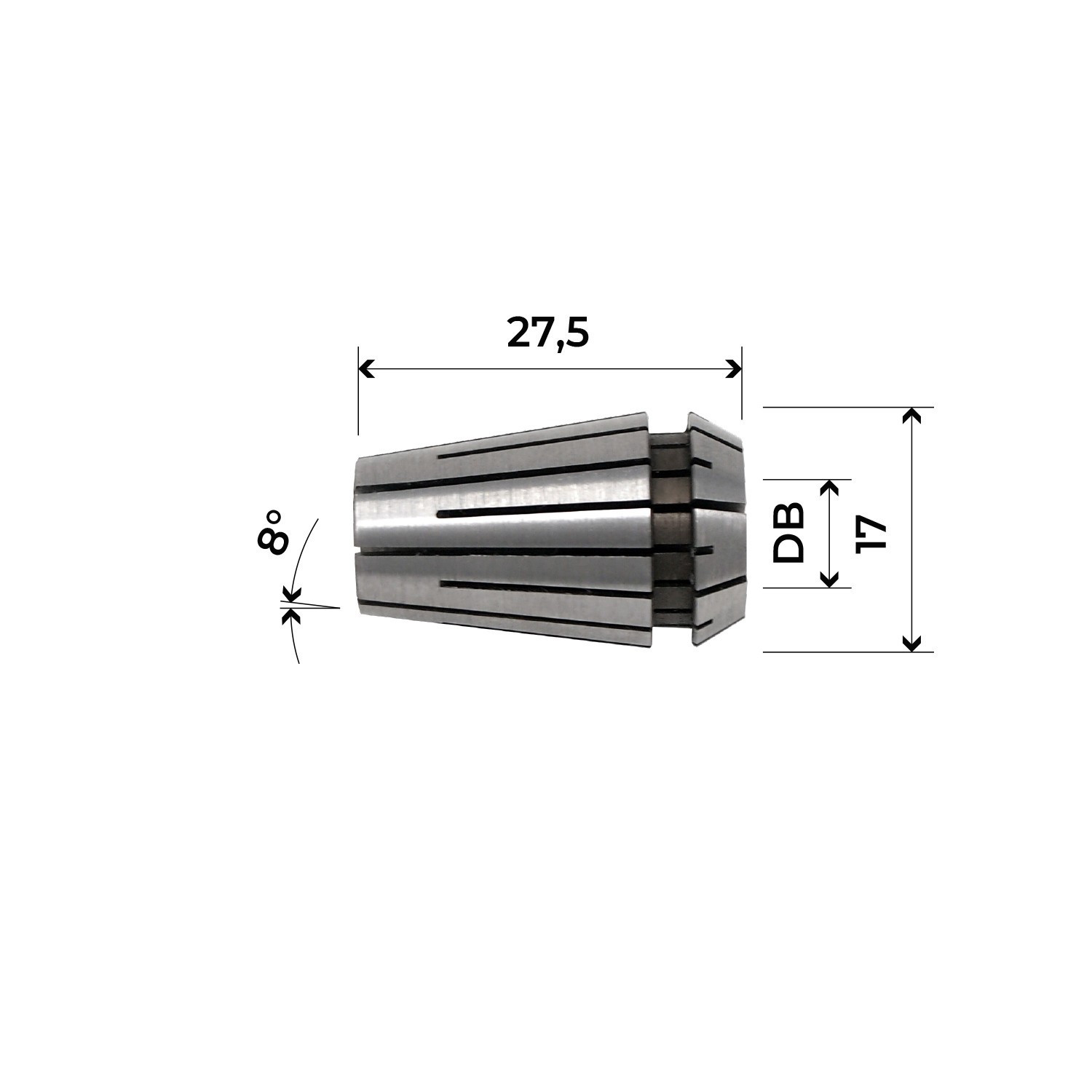

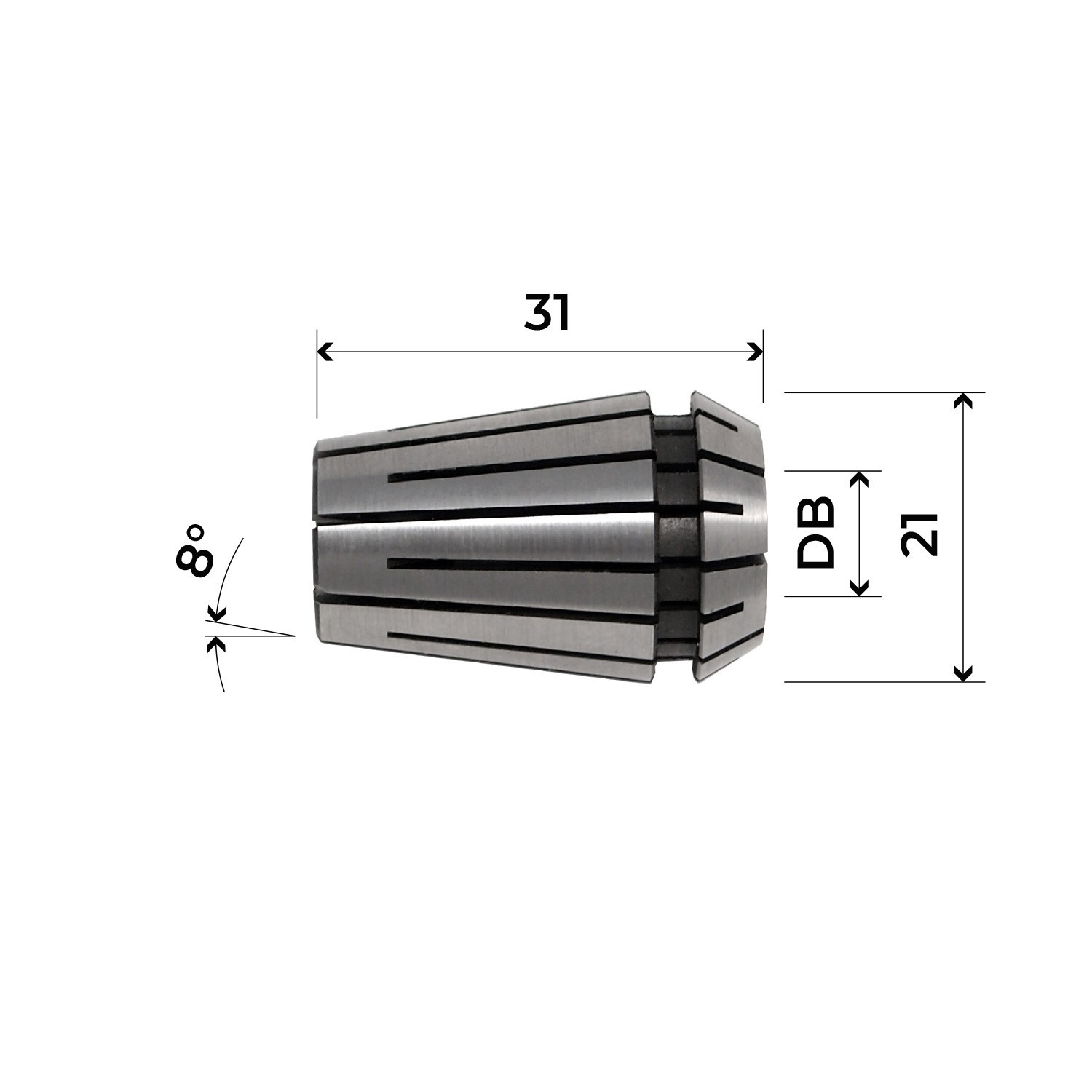

Replaceable standard ”ER16” collets (from 2 mm to 10 mm). Suitable for most conical chucks.

Replaceable standard ”ER20” collets (from 2 mm to 13 mm). Suitable for most conical chucks.

Replaceable standard ”ER25” collets (from 3 mm to 20 mm). Suitable for most conical chucks.

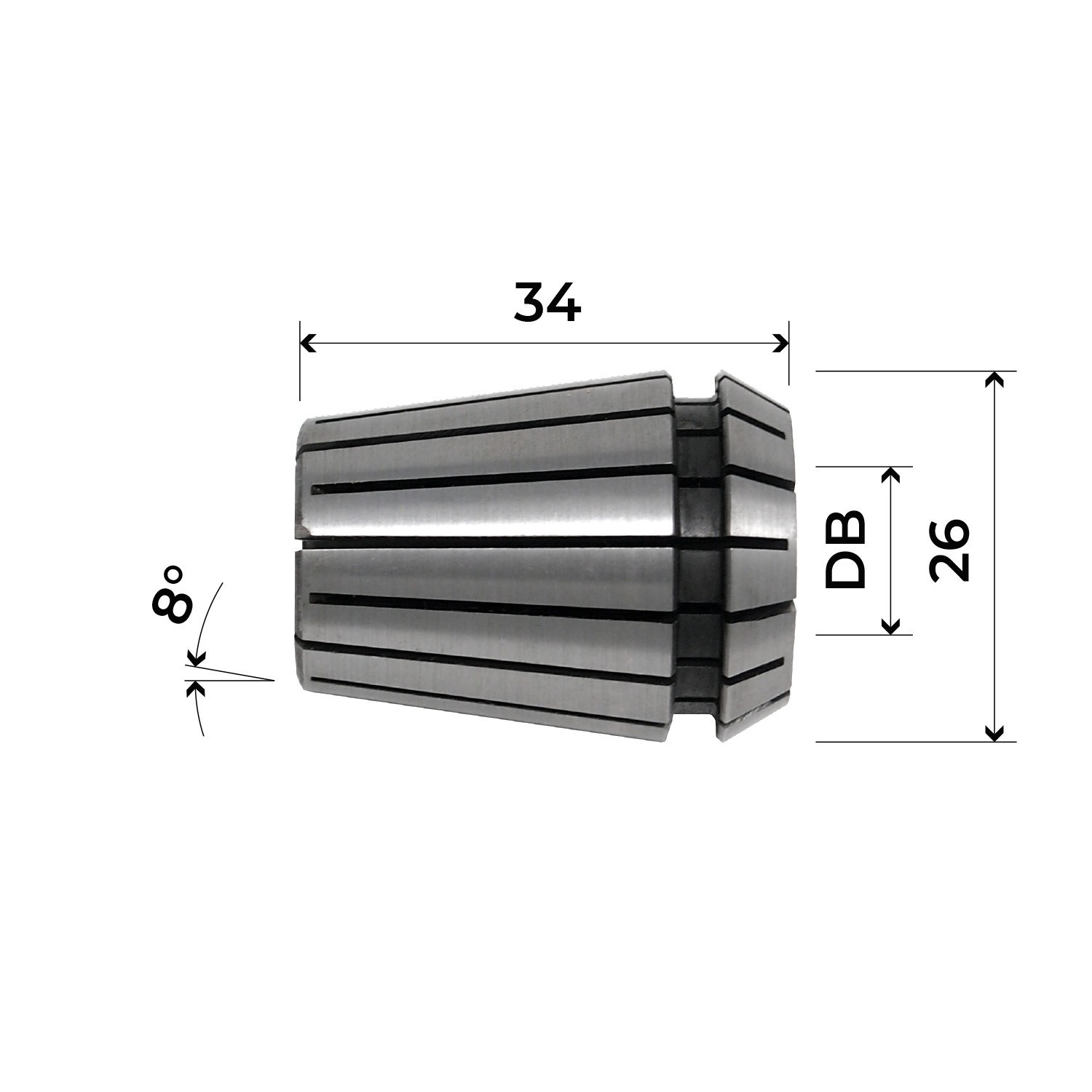

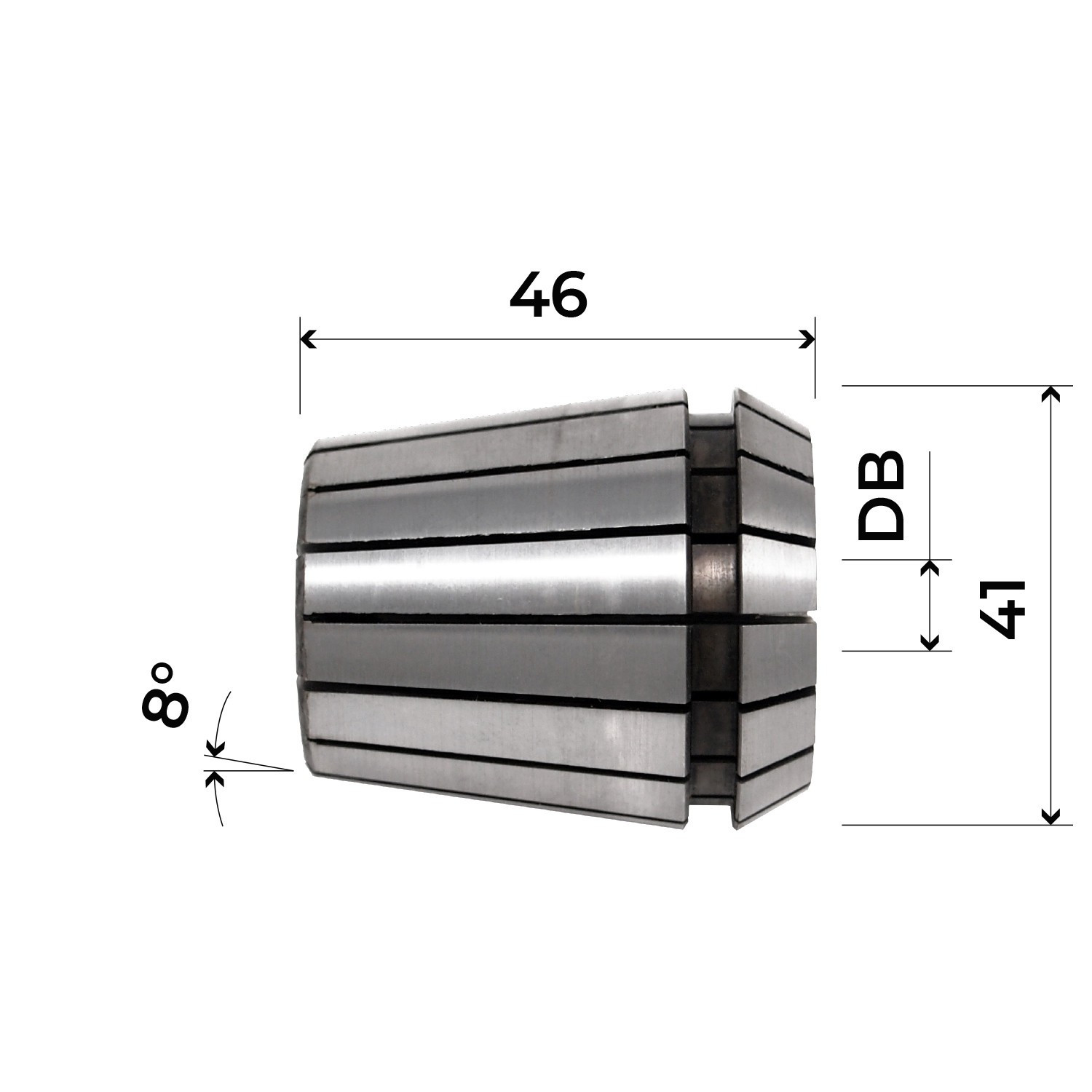

Replaceable standard ”ER32” collets (from 3 mm to 20 mm). Suitable for most conical chucks.

Replaceable high precision standard ”ER32” collets (from 3 mm to 20 mm). Suitable for most conical chucks.

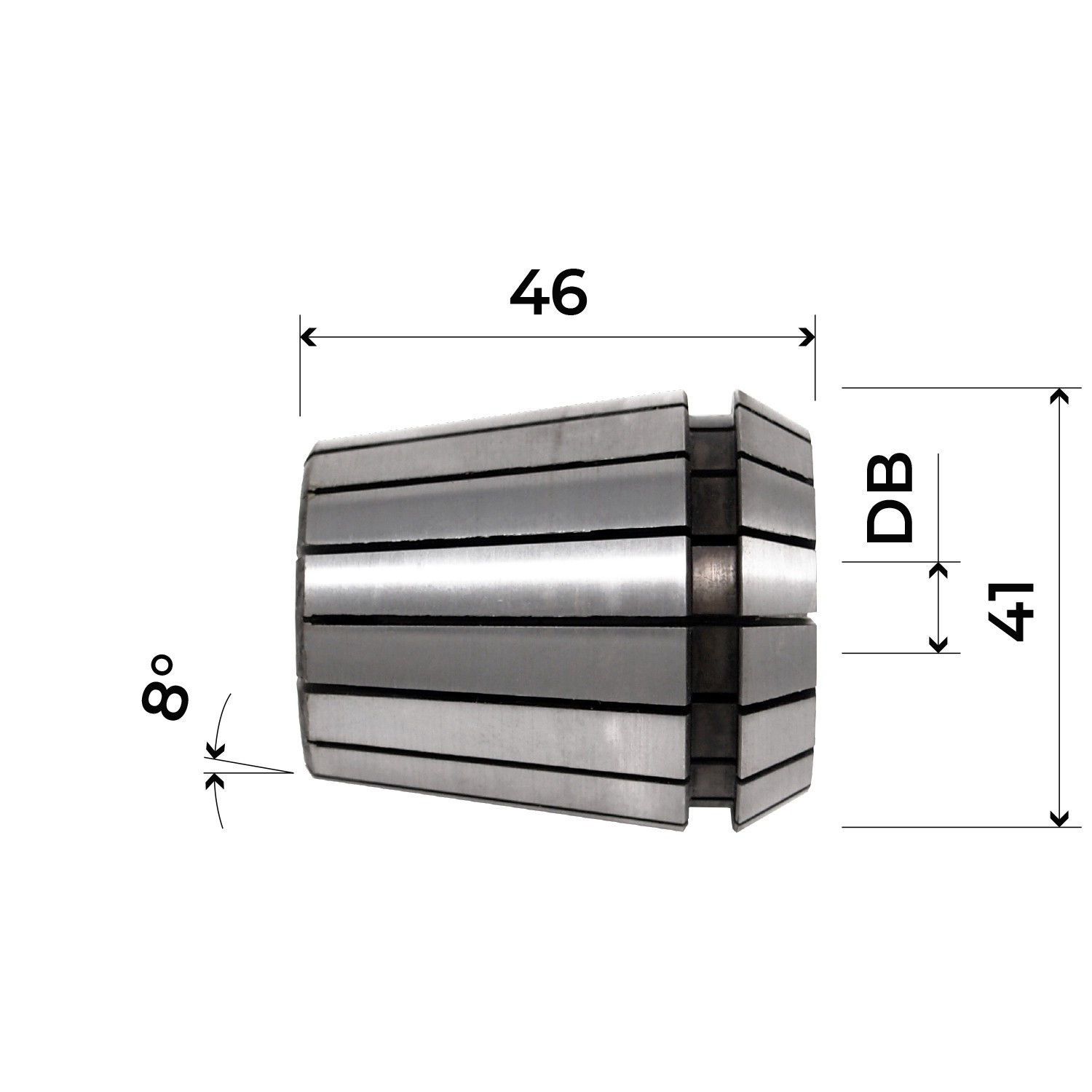

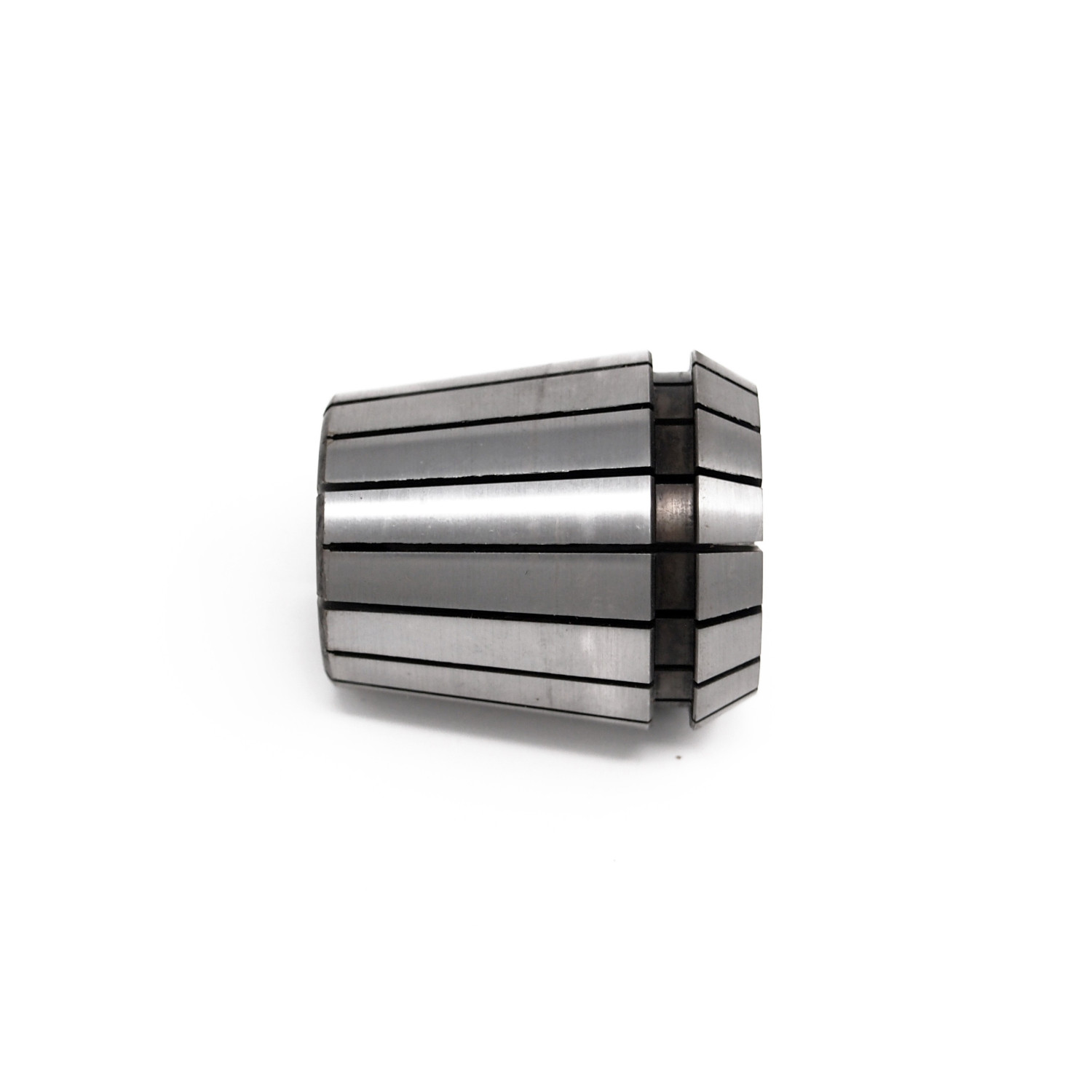

Replaceable standard ”ER40” collets (from 3 mm to 25 mm). Suitable for most conical chucks.

Replaceable high precision standard ”ER40” collets (from 3 mm to 25 mm). Suitable for most conical chucks.

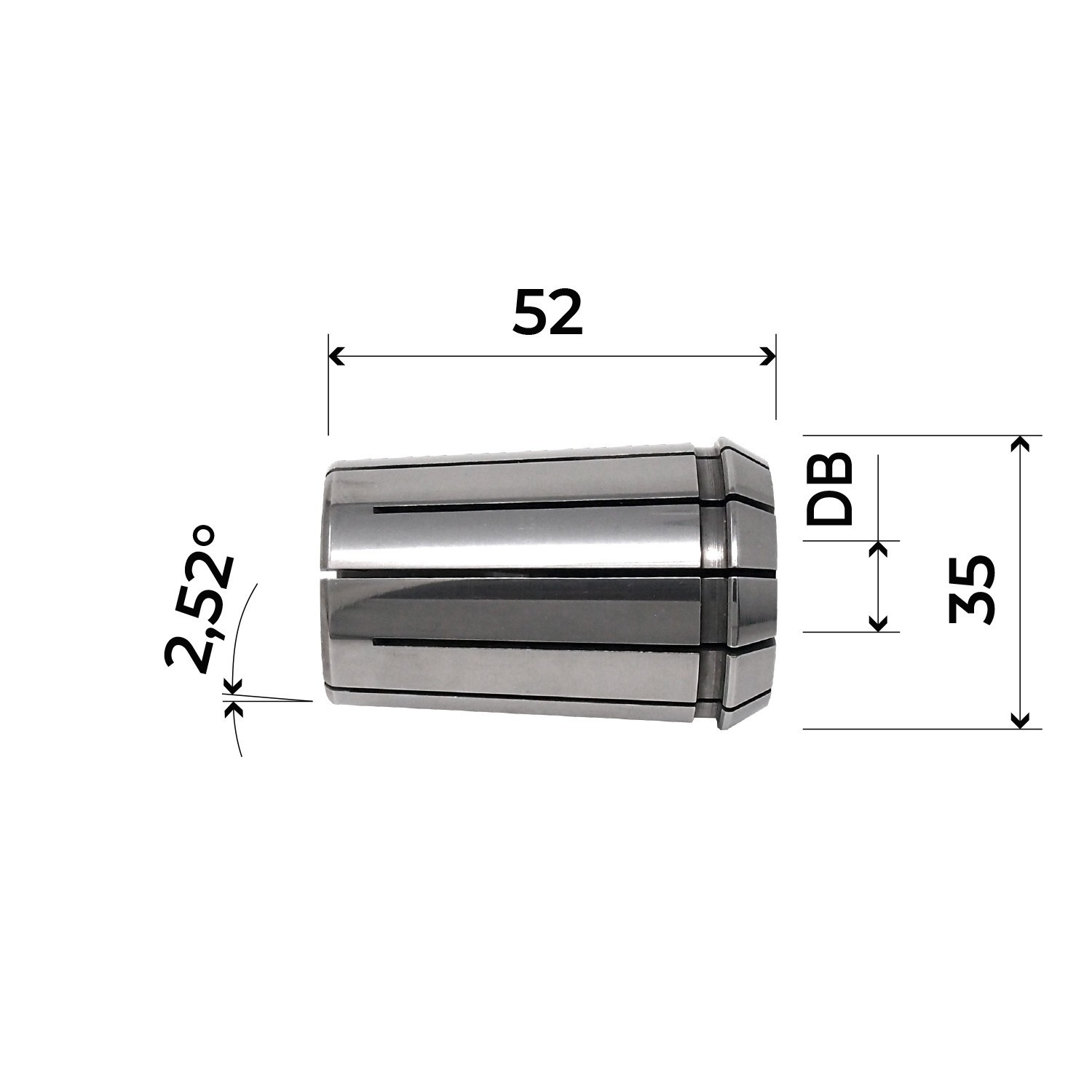

Replaceable standard ”EOC25” collets (from 3 mm to 20 mm). Suitable for most conical chucks.

Universal cone remover for HSK63F and ISO30 TOOLS HOLDERS which allows you to disassemble the TOOL HOLDER without damaging their surfaces. The special bidirectional BEARING cage, blocking the tool holder, allows the flange to be dismantled or mounted.

.jpg)