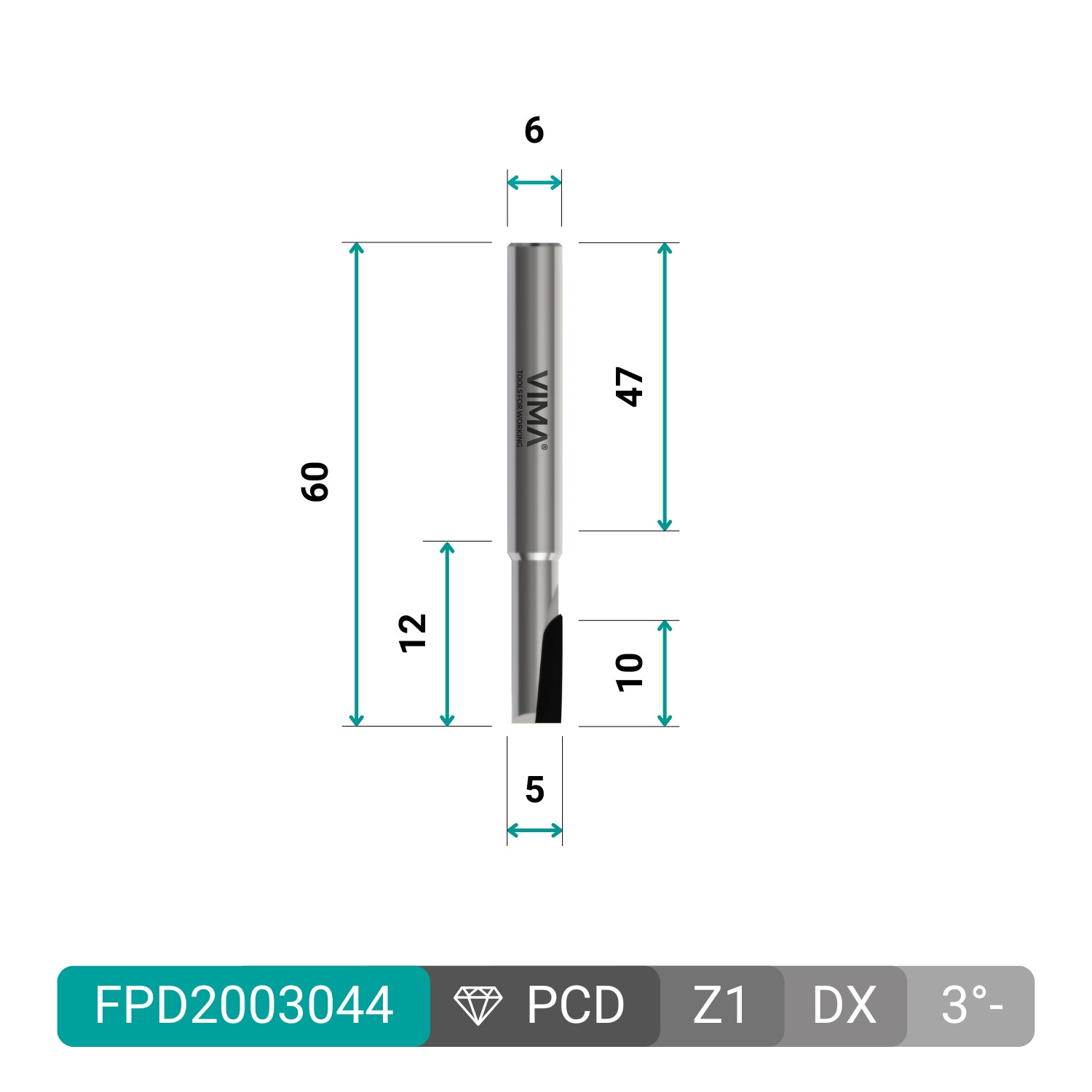

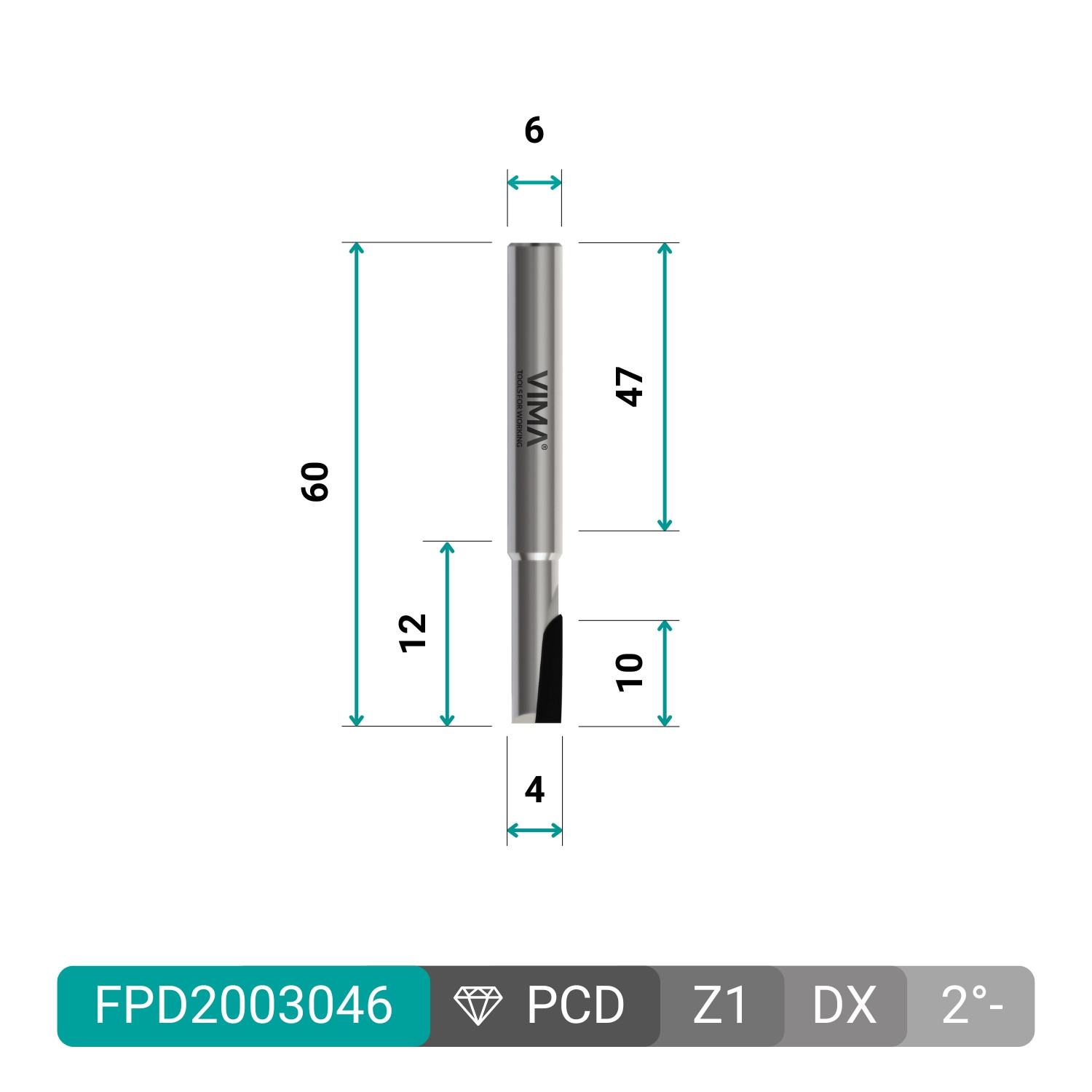

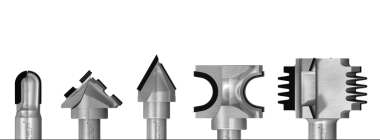

PCD diamond router bit designed for groove cutting with high surface quality on coated panels. The negative Z1 cutting edge and solid carbide body ensure maximum stability, controlled material removal and clean finishes even on delicate surfaces.

• PCD cutting edge H 3.5 mm for long tool life

• Negative Z1 cutting edge for superior panel finish

• Solid carbide body for high rigidity and stability

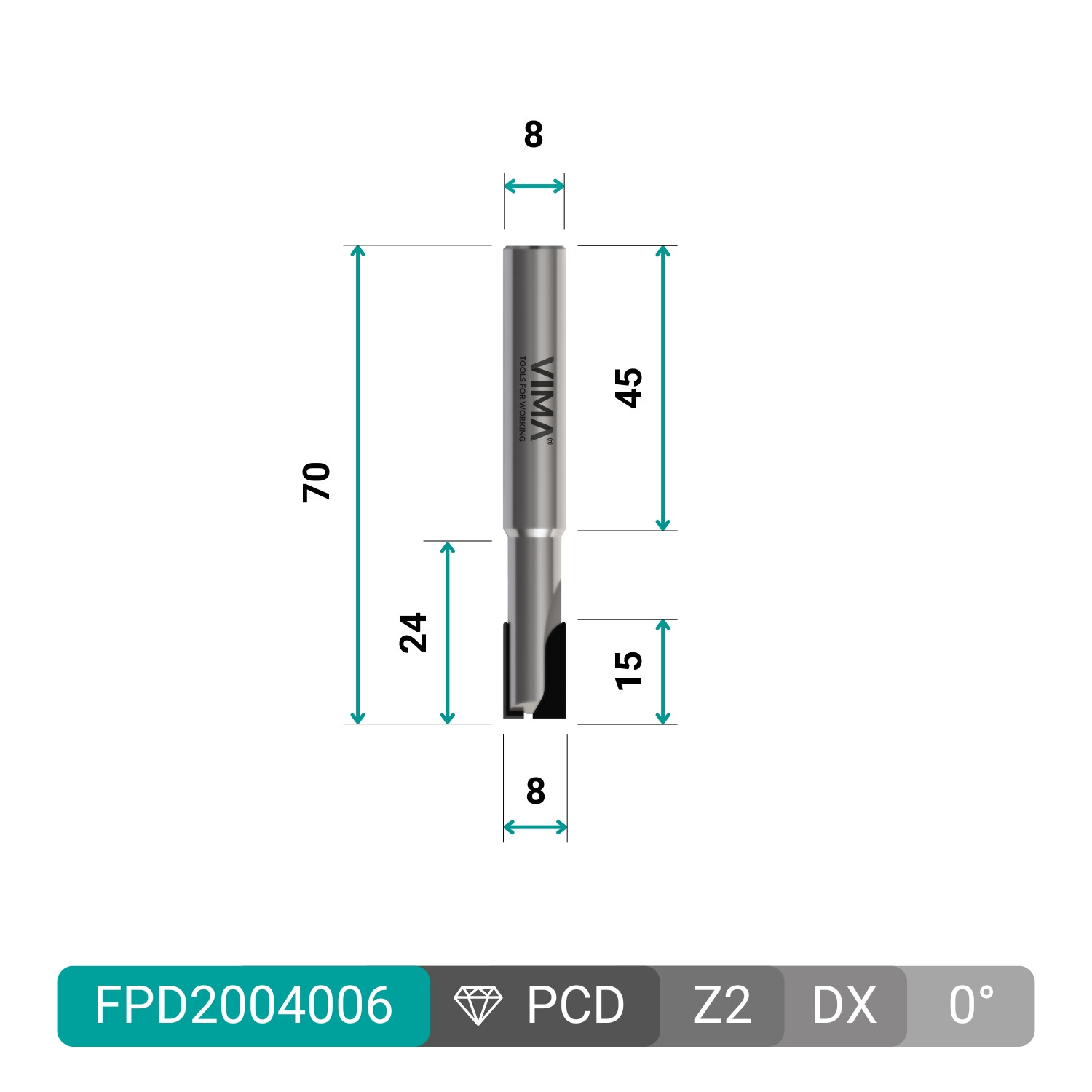

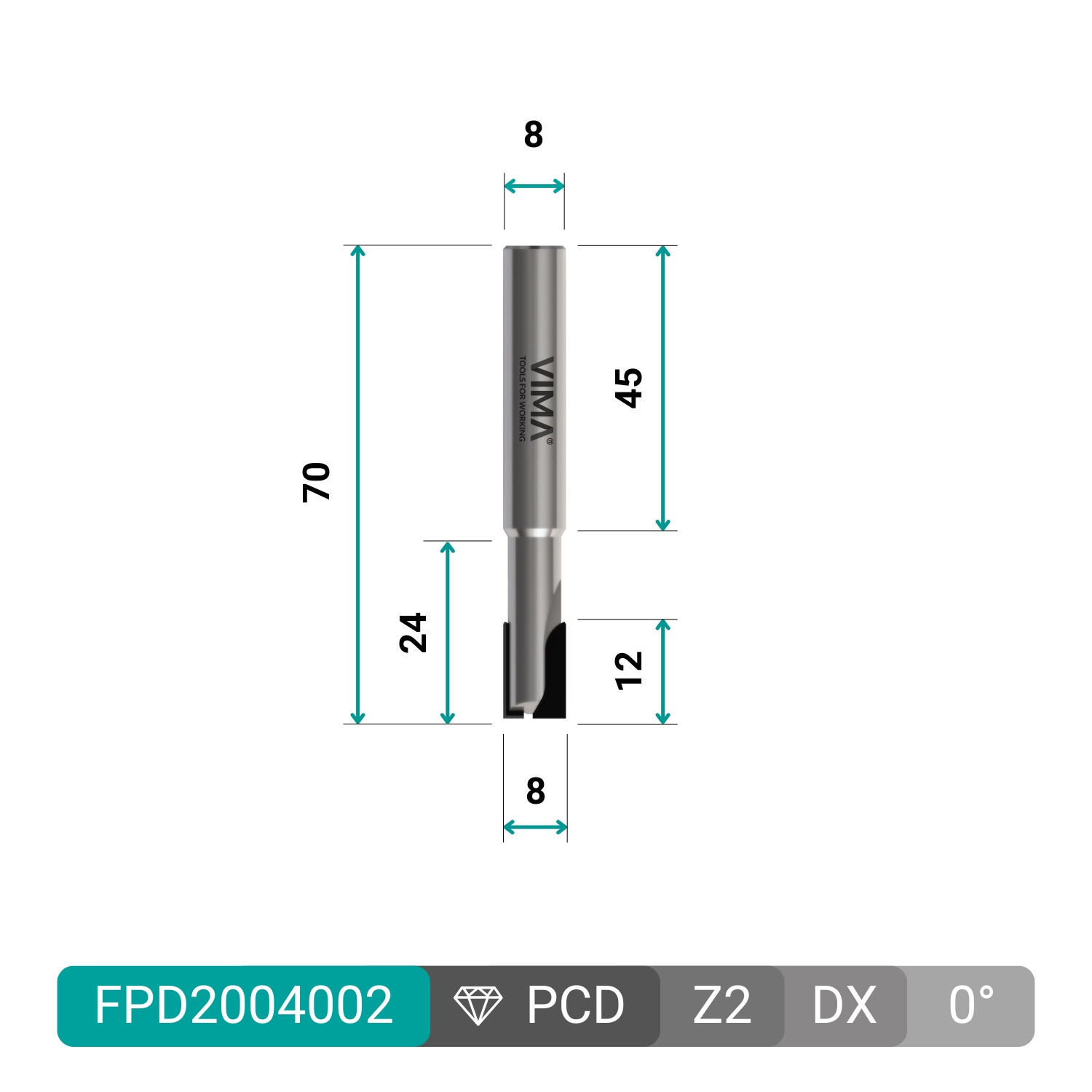

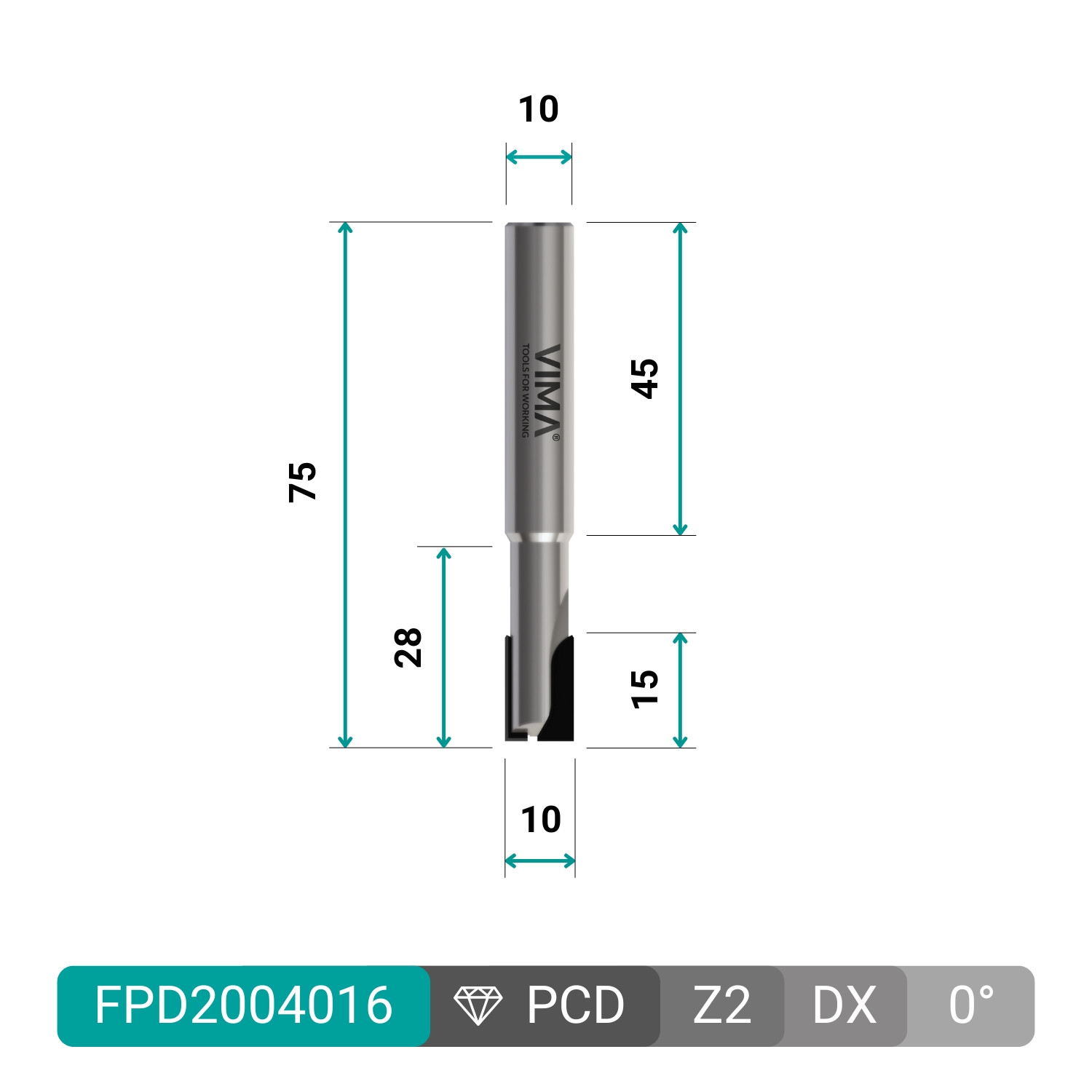

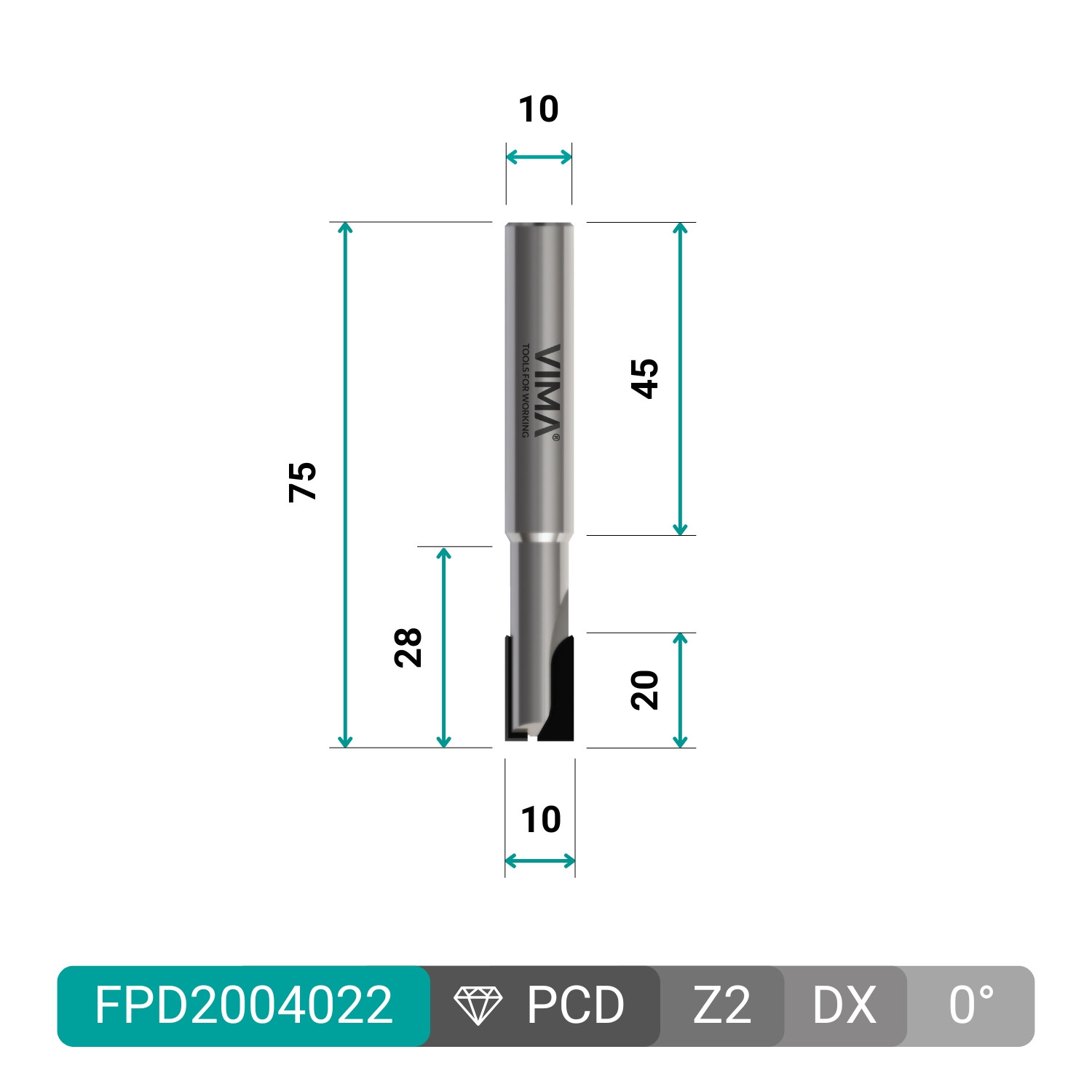

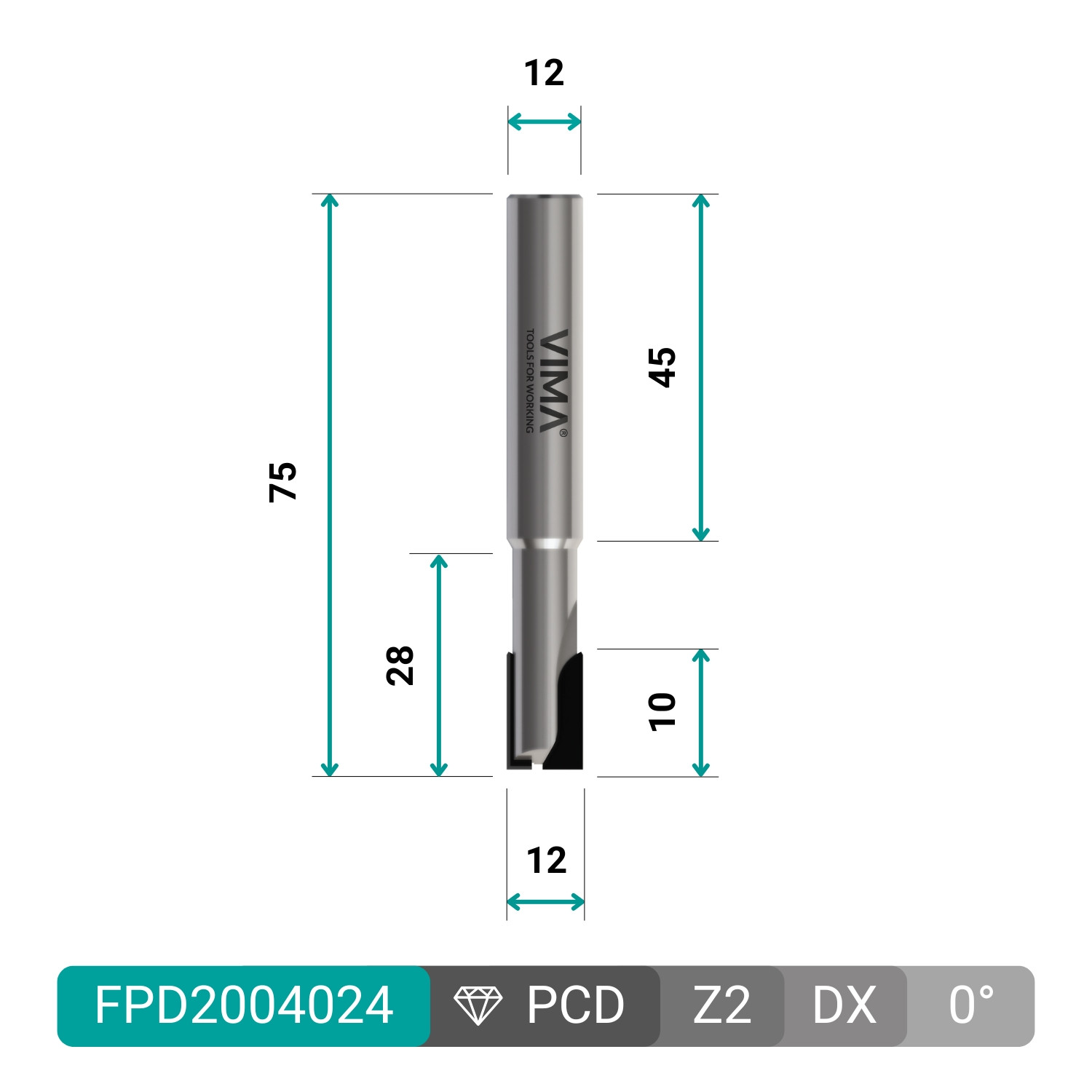

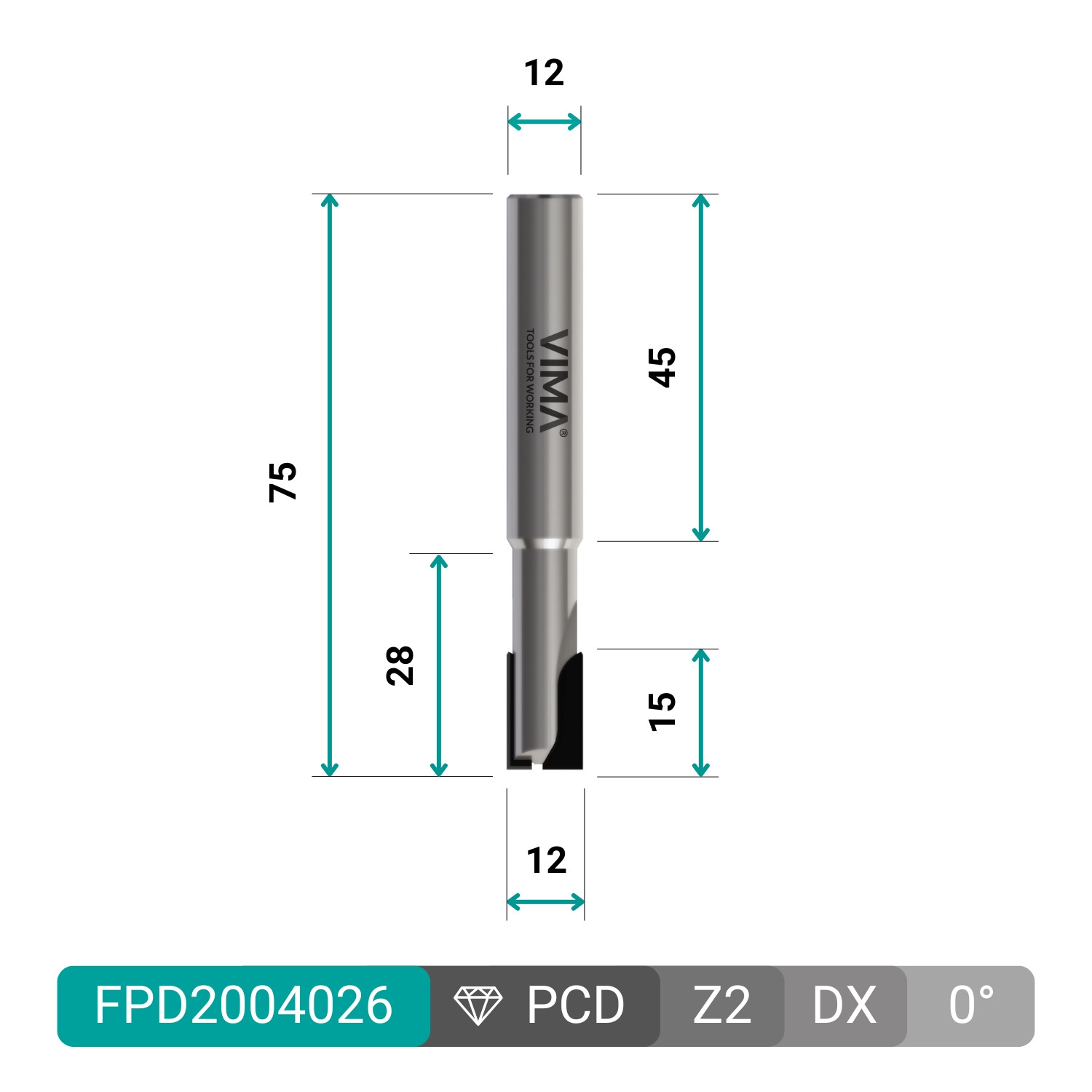

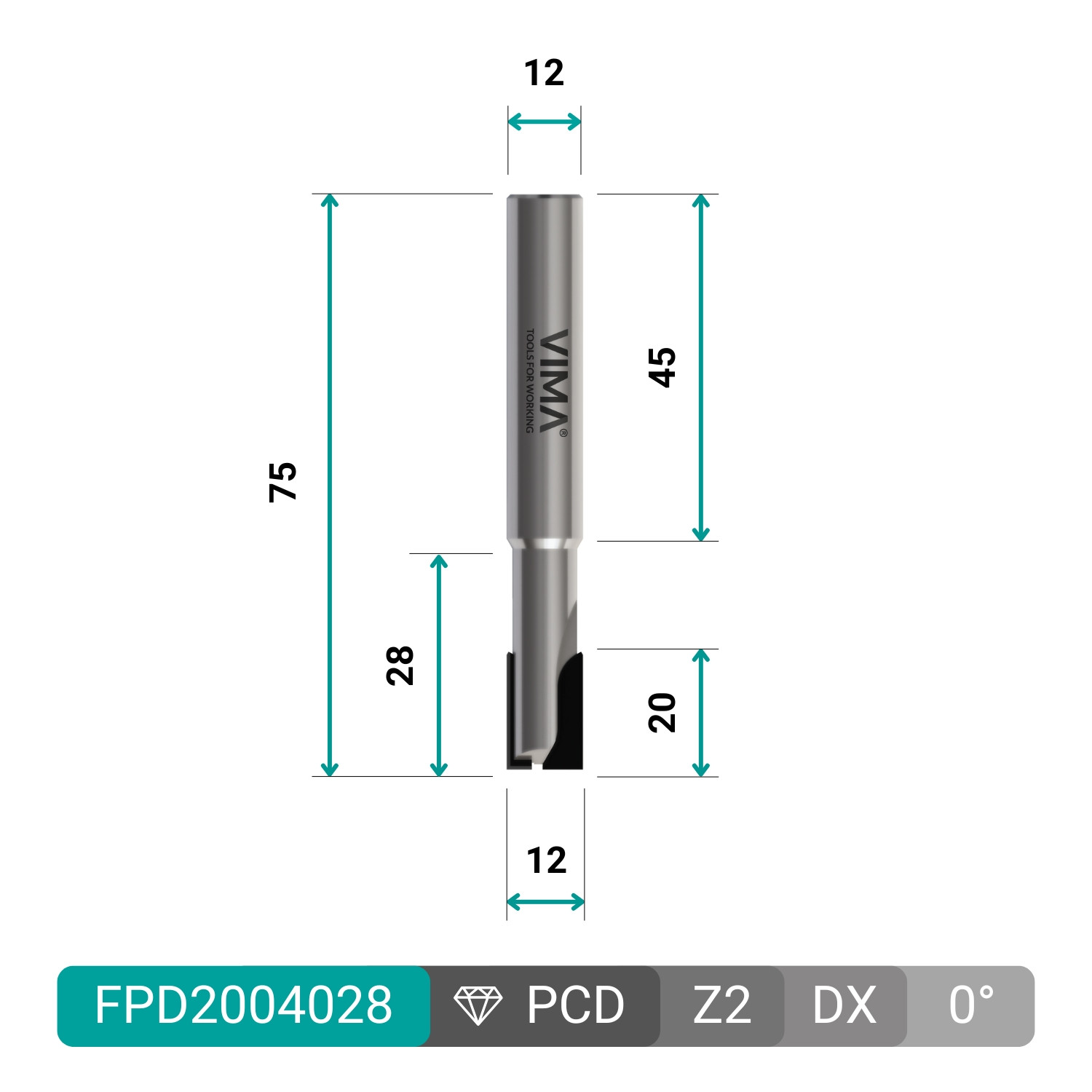

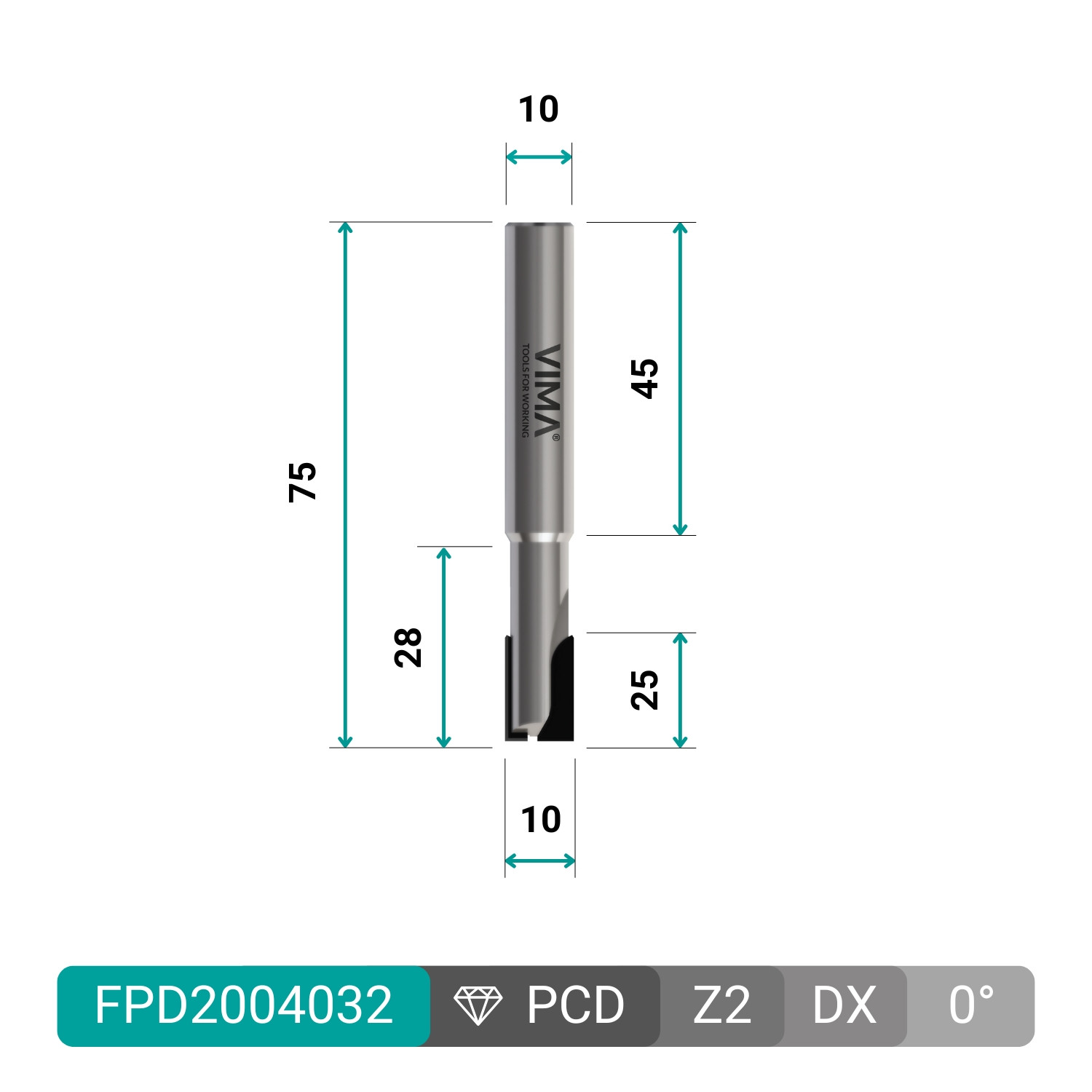

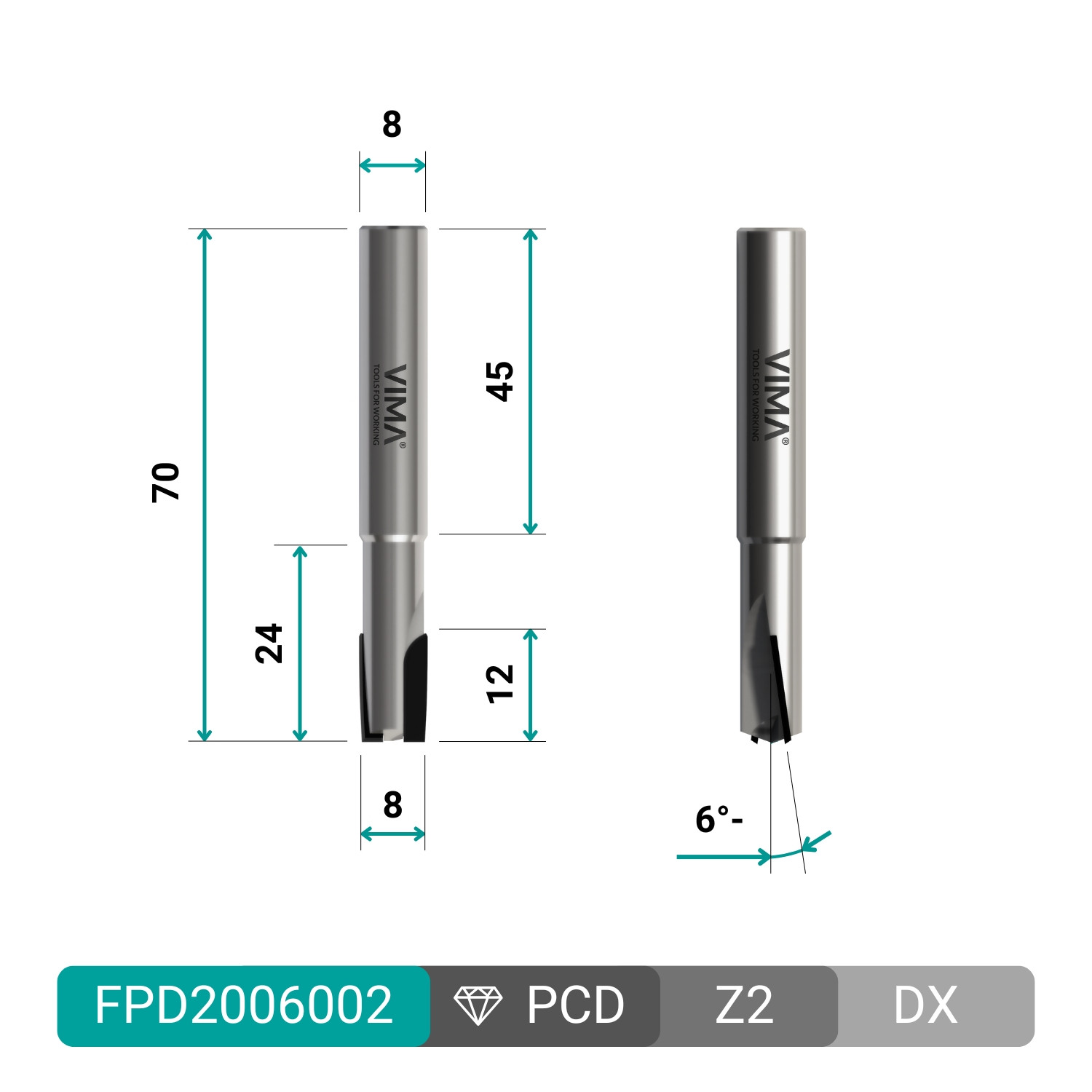

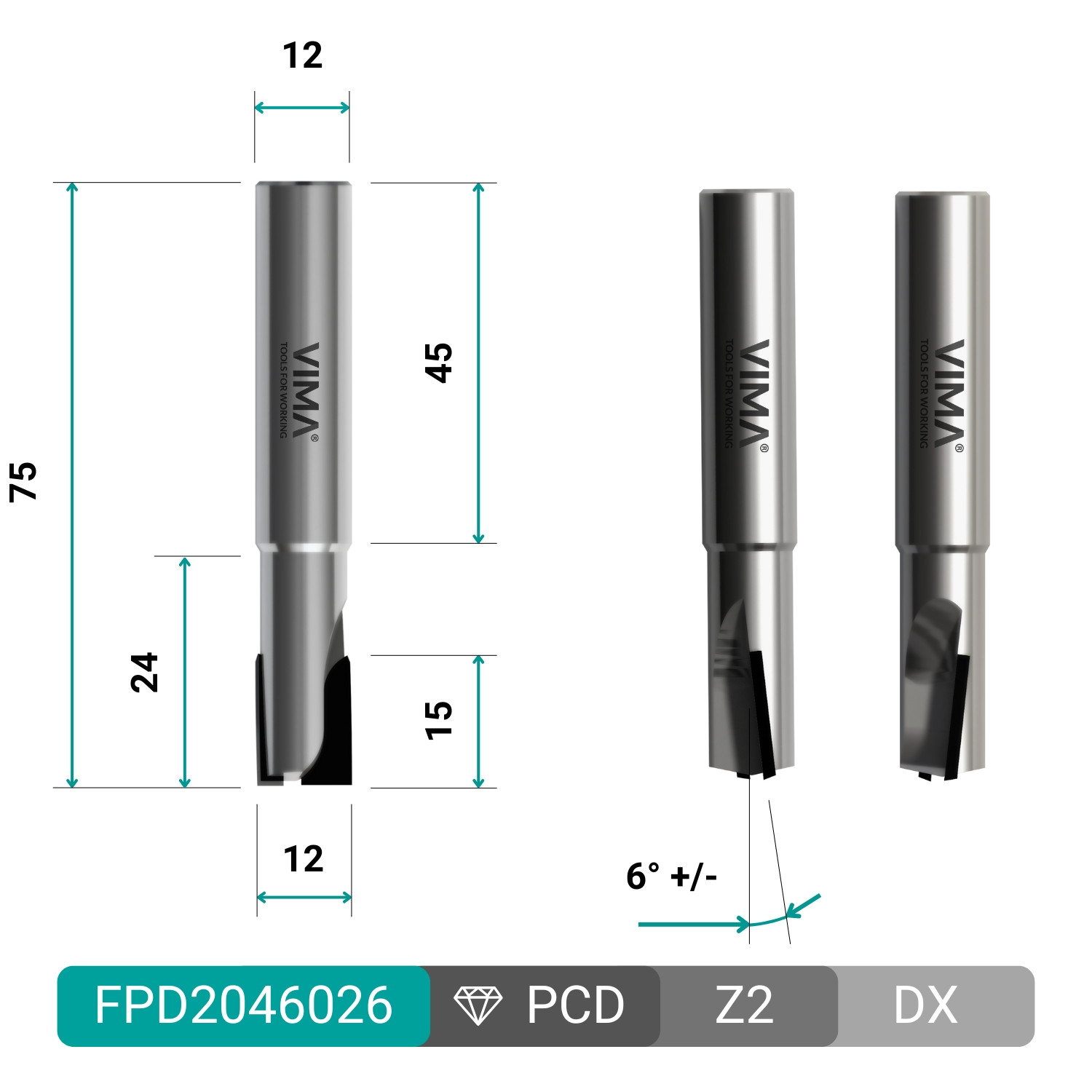

PCD diamond router bit designed for groove cutting and contouring on CNC machines with mechanical feed. The two straight Z2 cutting edges and solid carbide body provide balanced cutting action, improved stability and consistently high finish quality.

• PCD cutting edges H 3.5 mm for high durability

• Z2 configuration for higher stability and productivity

• Solid carbide body for rigidity and operational precision

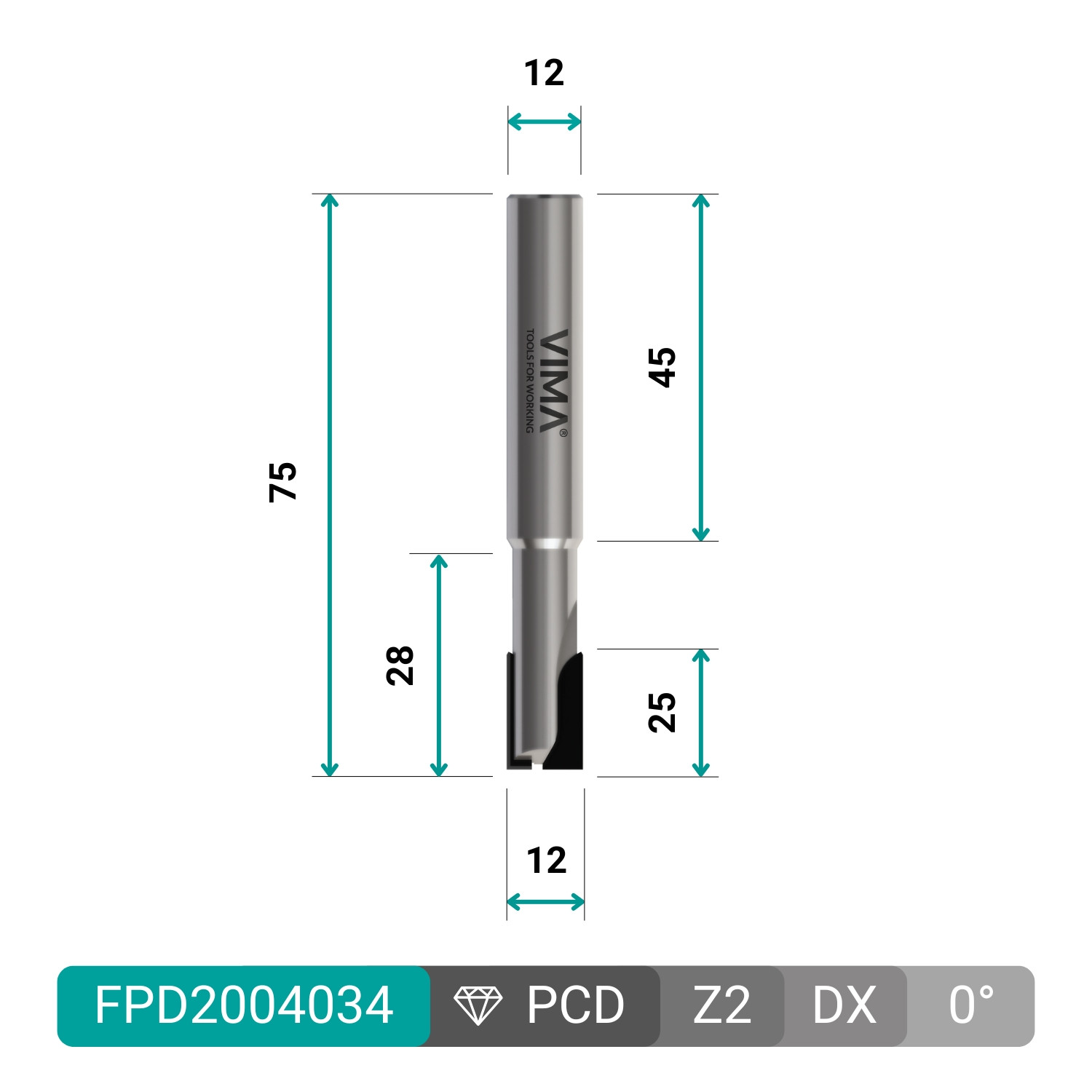

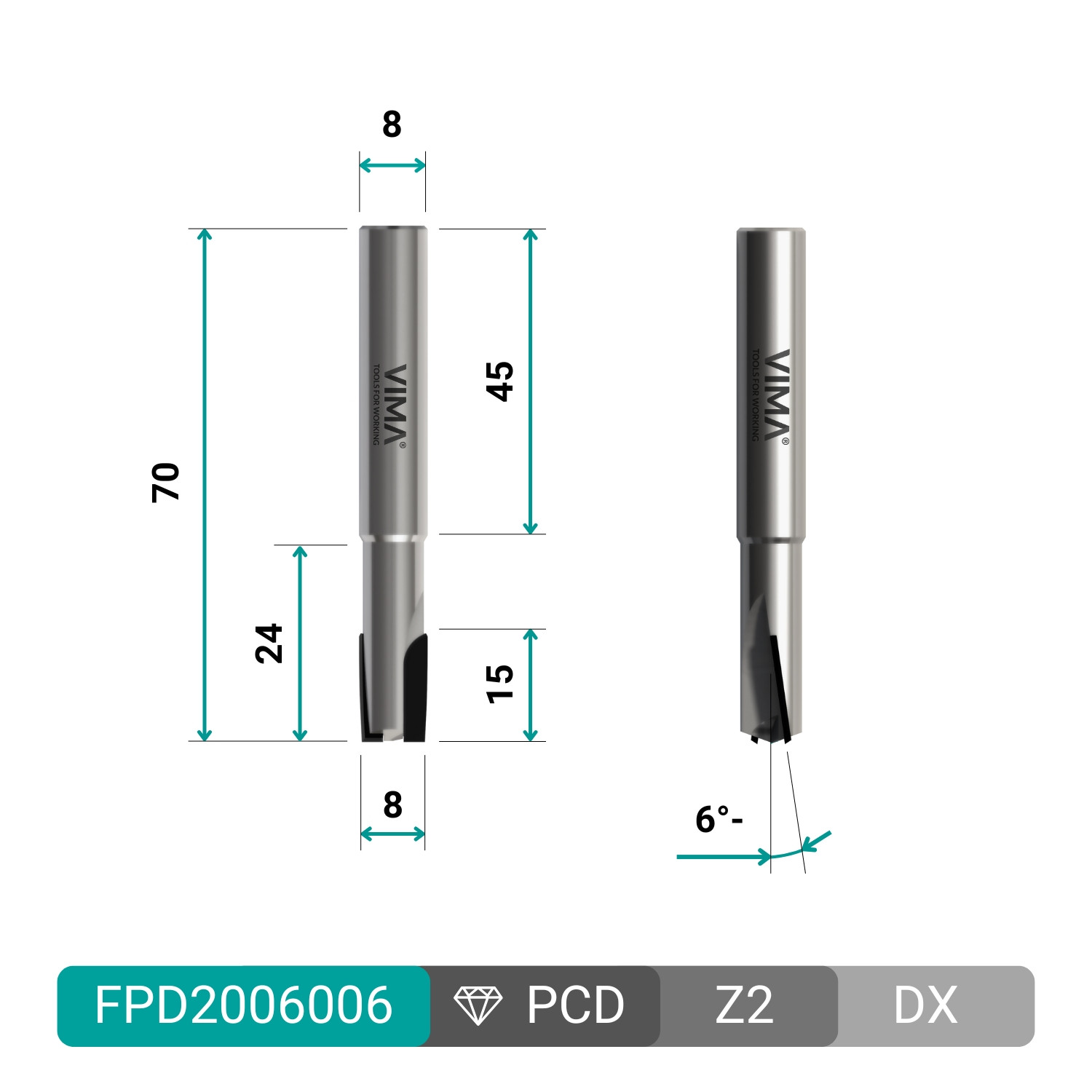

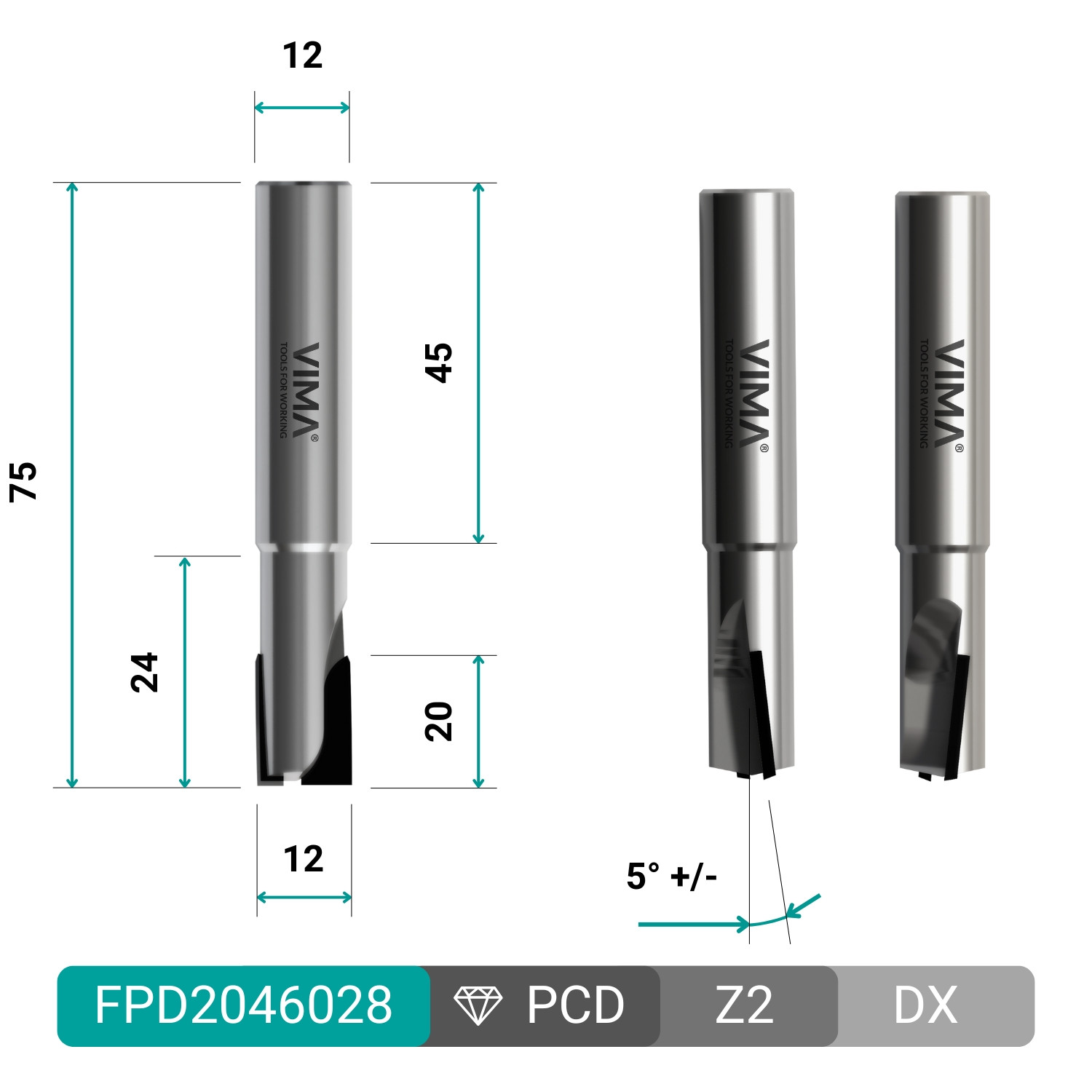

PCD diamond router bit designed for grooving coated panels where the highest surface quality is required. The negative Z2 cutting edges and solid carbide body ensure stability, controlled material removal and clean finishing even on delicate surfaces.

• PCD cutting edges H 3.5 mm for long tool life

• Negative Z2 cutting edges for superior surface finish

• Solid carbide body for rigidity and operational stability

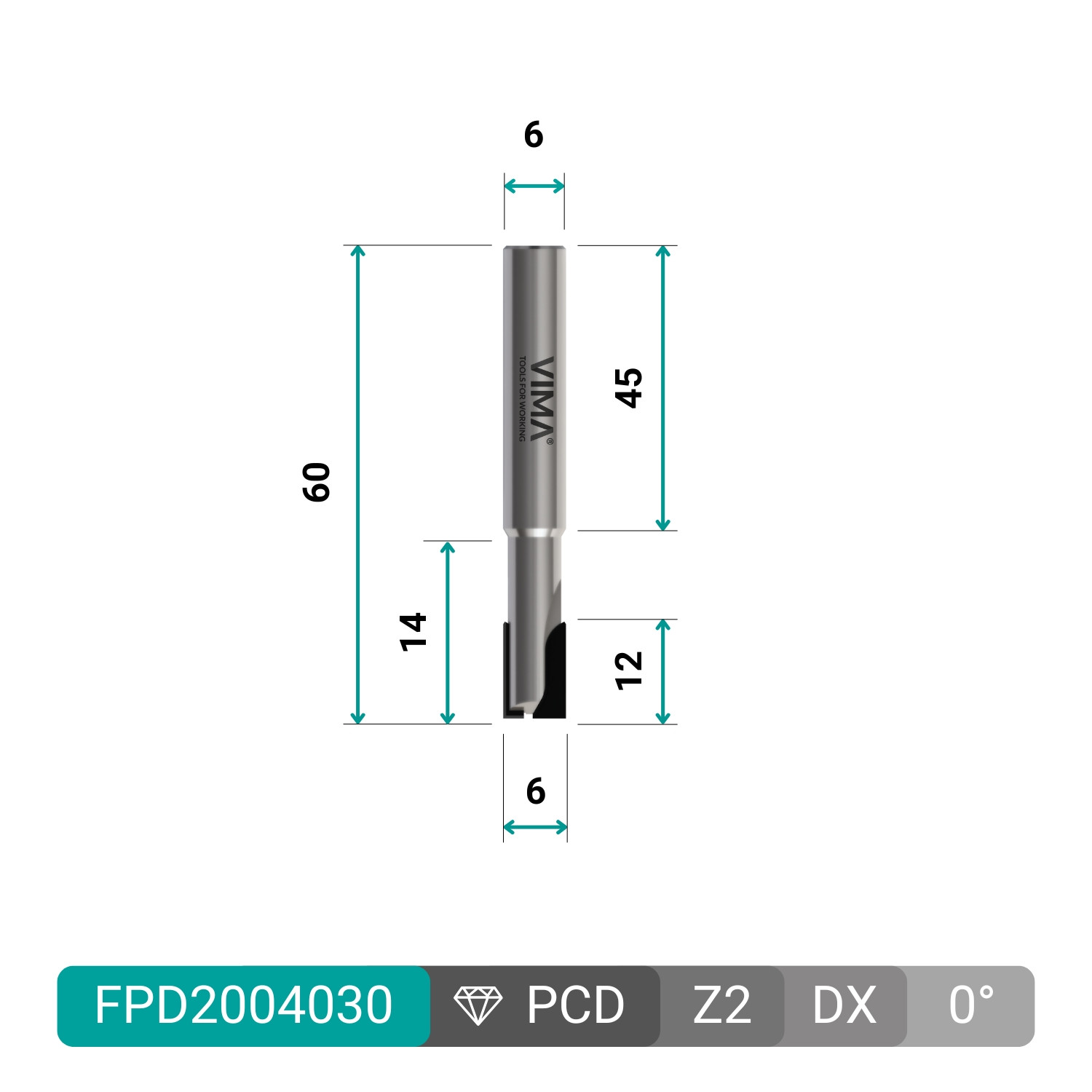

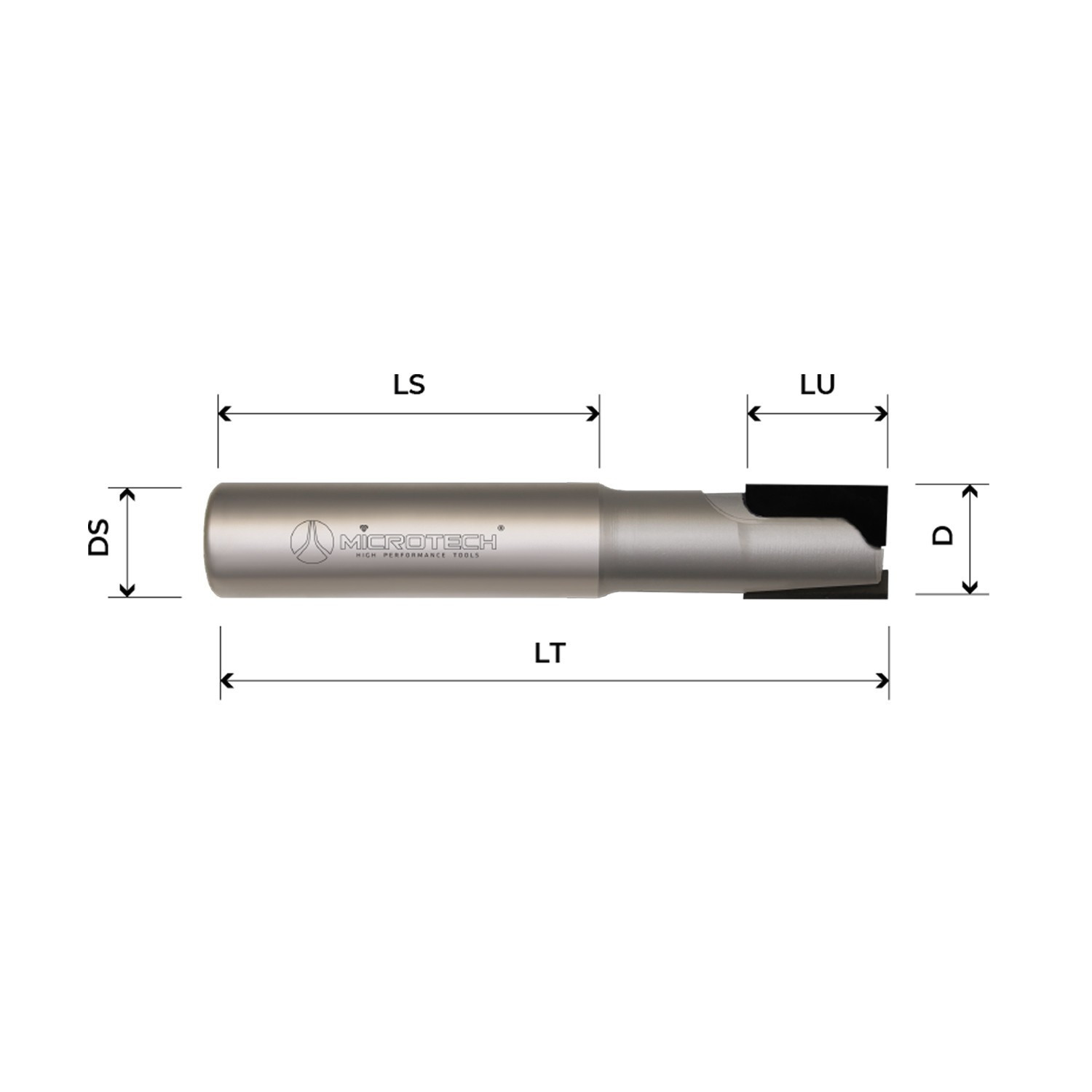

PCD diamond router bit designed for grooving, contouring and surfacing operations on CNC machines with manual or mechanical feed. The two straight Z2 cutting edges and the steel body ensure cutting stability, controlled material removal and consistent surface finish.

• PCD cutting edges H 4 mm for long tool life

• Z2 configuration for balanced and productive cutting

• Steel body for robustness and reliability

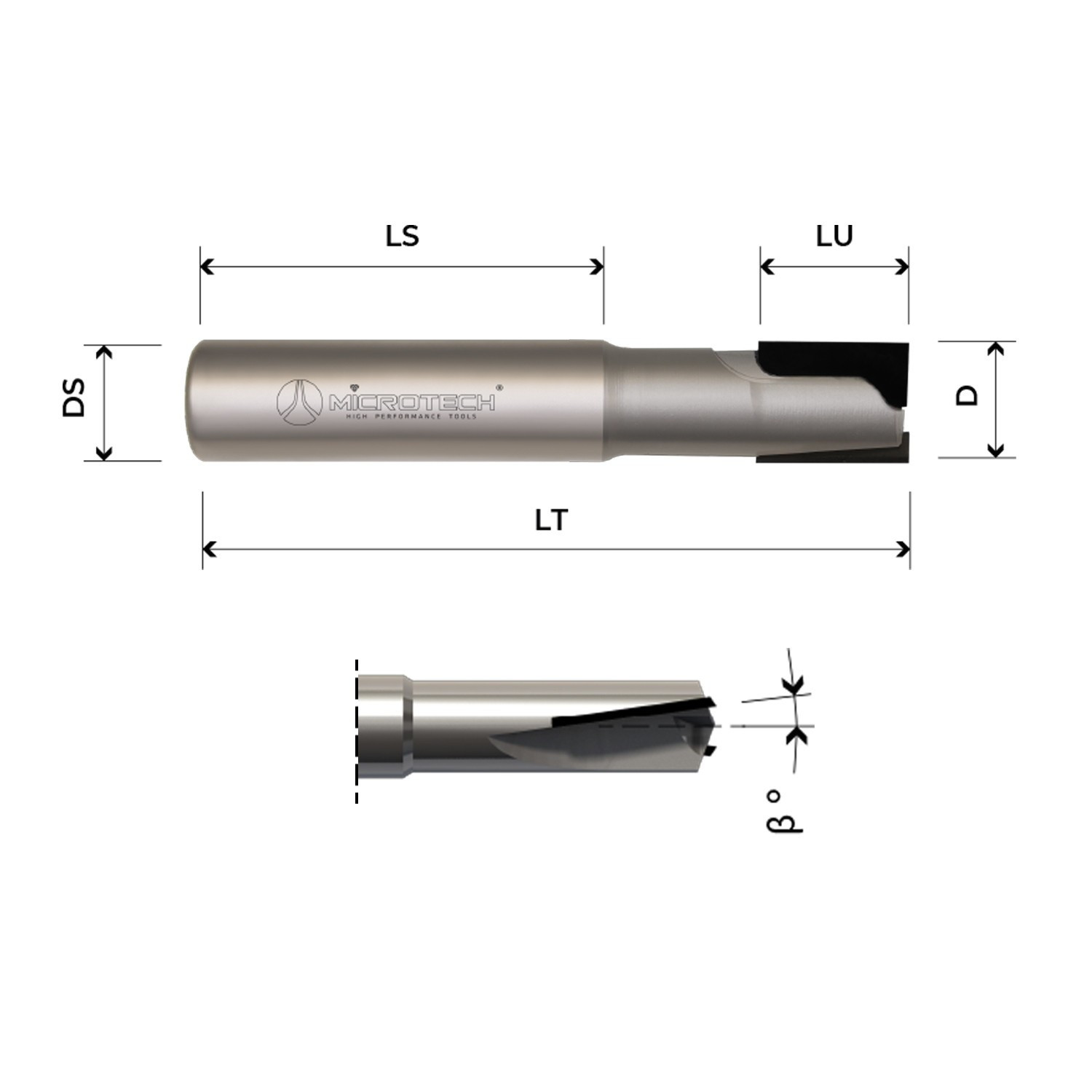

PCD diamond router bit engineered for grooving operations on coated panels and wood-based materials when an excellent surface finish is required. The negative Z2 cutting geometry together with the steel body provides high stability, controlled chip removal and a clean, tear-free result.

• PCD cutting edges H 4 mm for extended tool life

• Negative Z2 geometry for chip-free surfaces and clean edges

• Steel body for robustness and machining accuracy

PCD diamond cutter designed for contouring operations on compact and technical materials where high edge quality is required. The alternating positive and negative cutting geometry ensures balanced cutting action, stability and consistent edge finish.

• PCD cutting edges 3.5 mm for long tool life

• Alternating positive/negative edges for superior edge quality

• Solid HW body for rigidity and precision

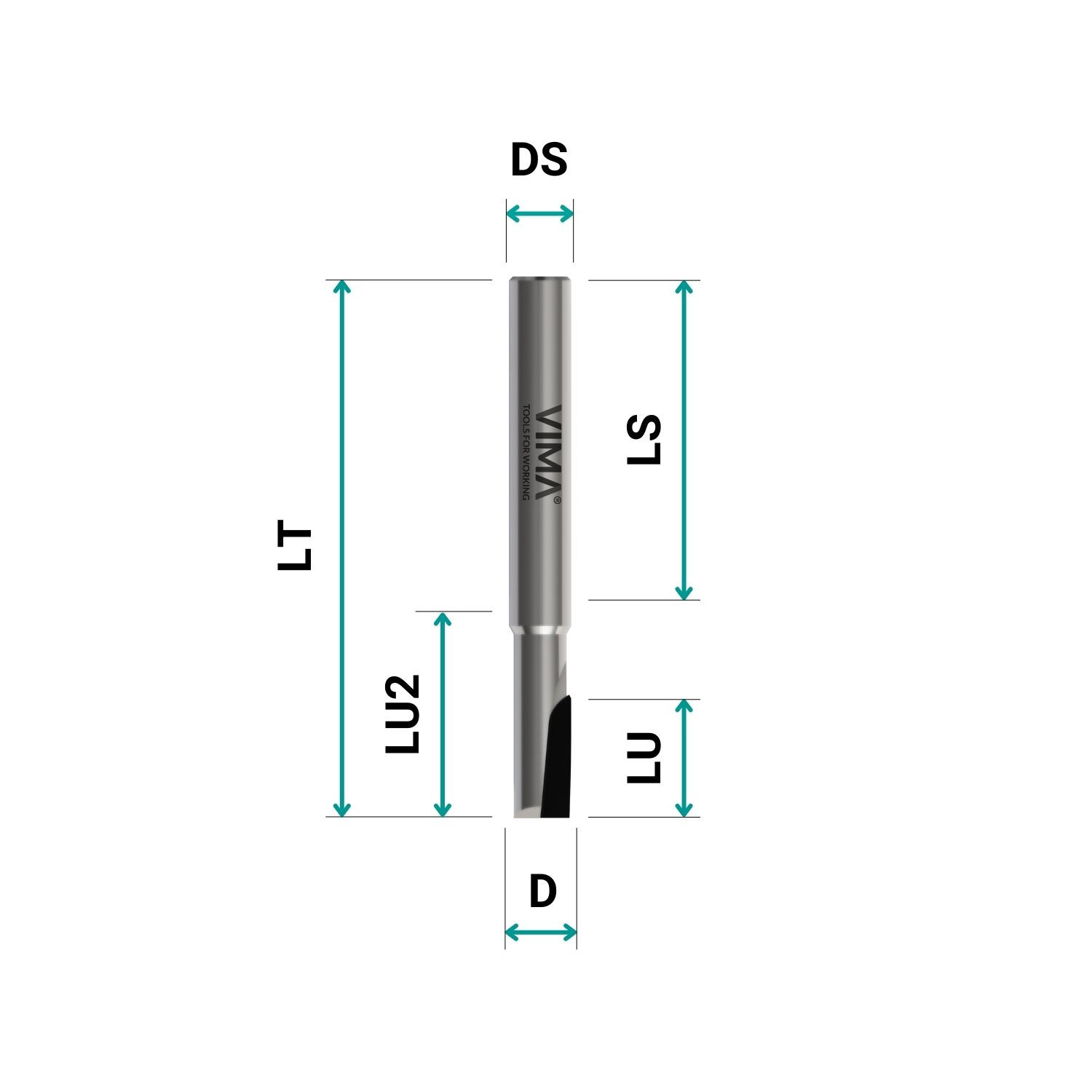

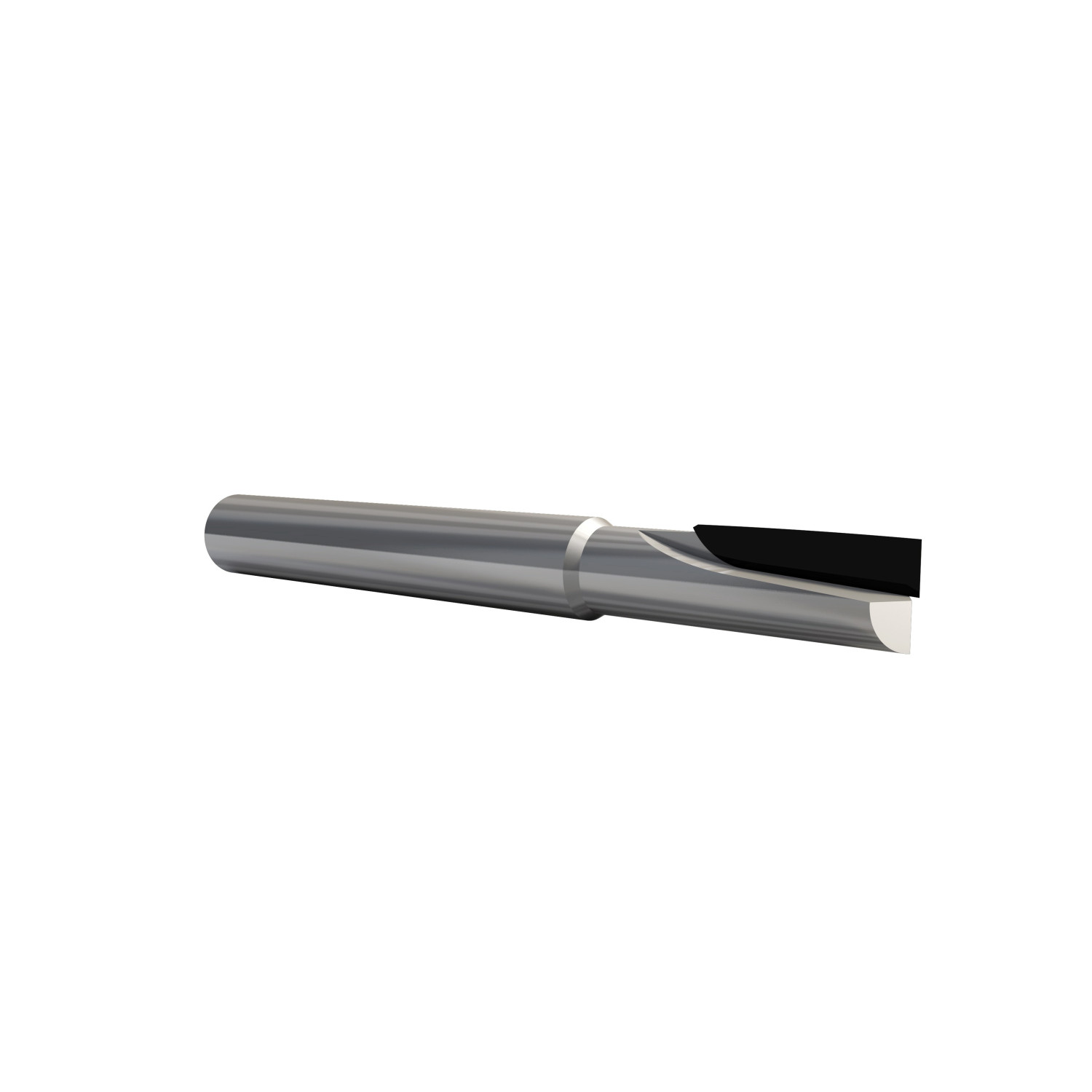

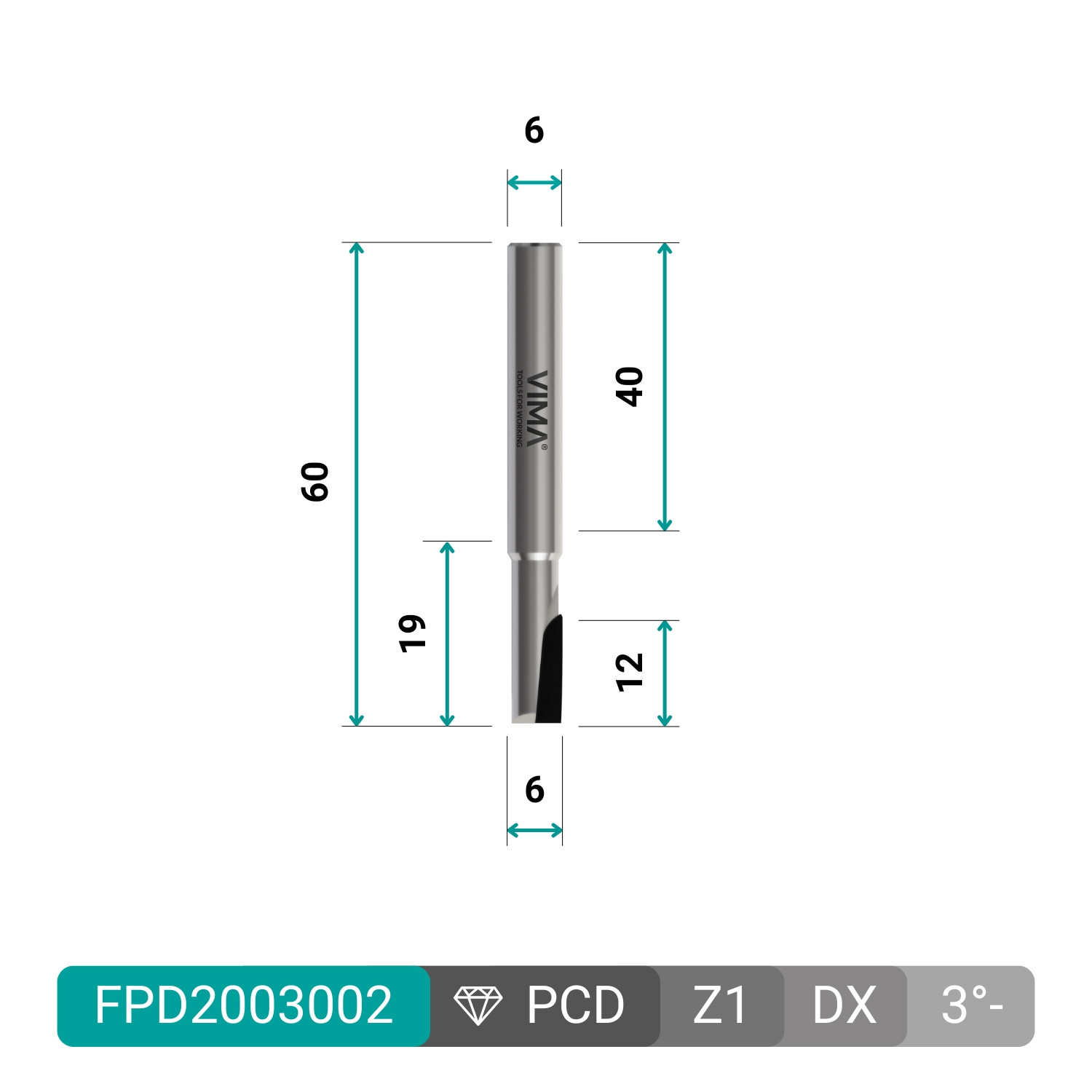

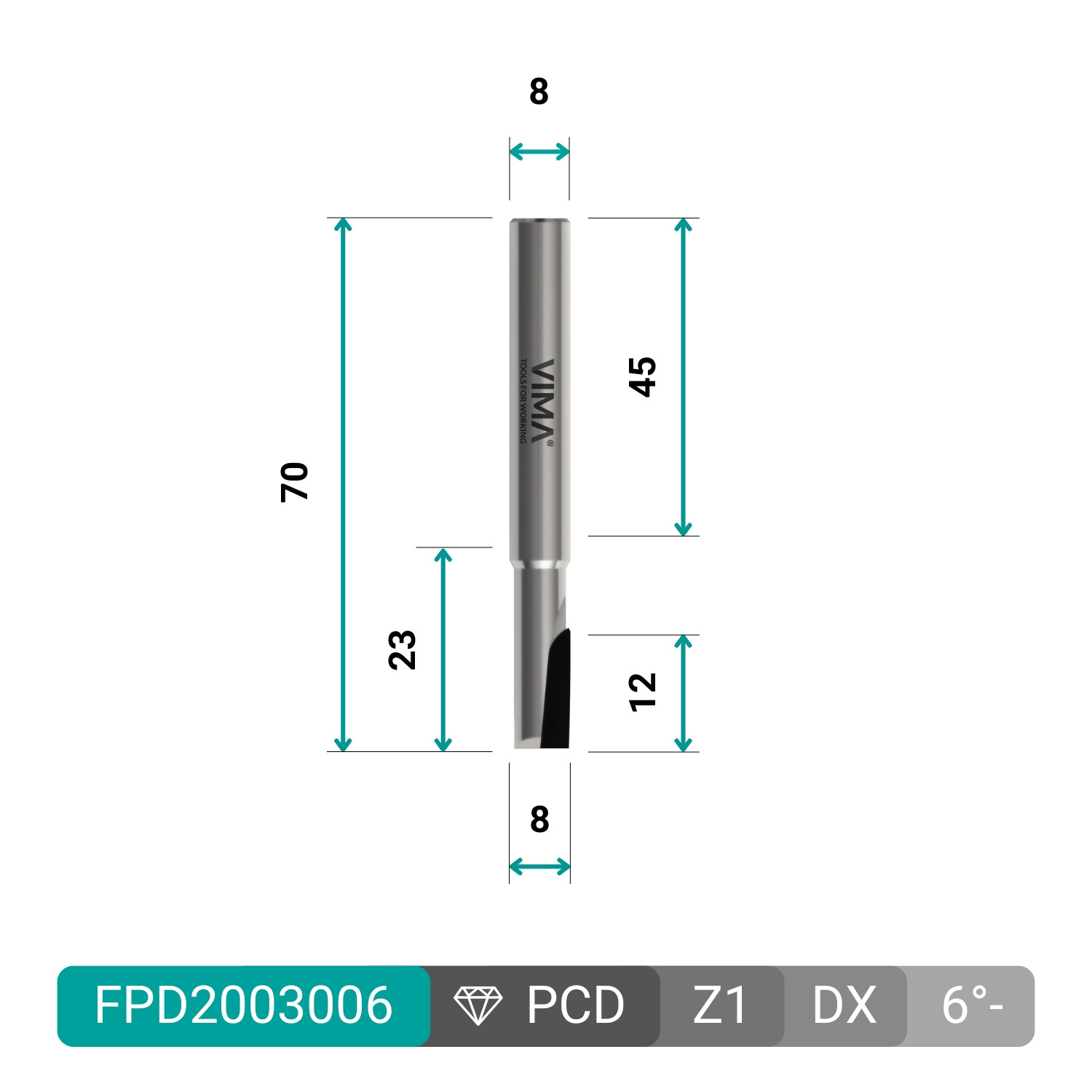

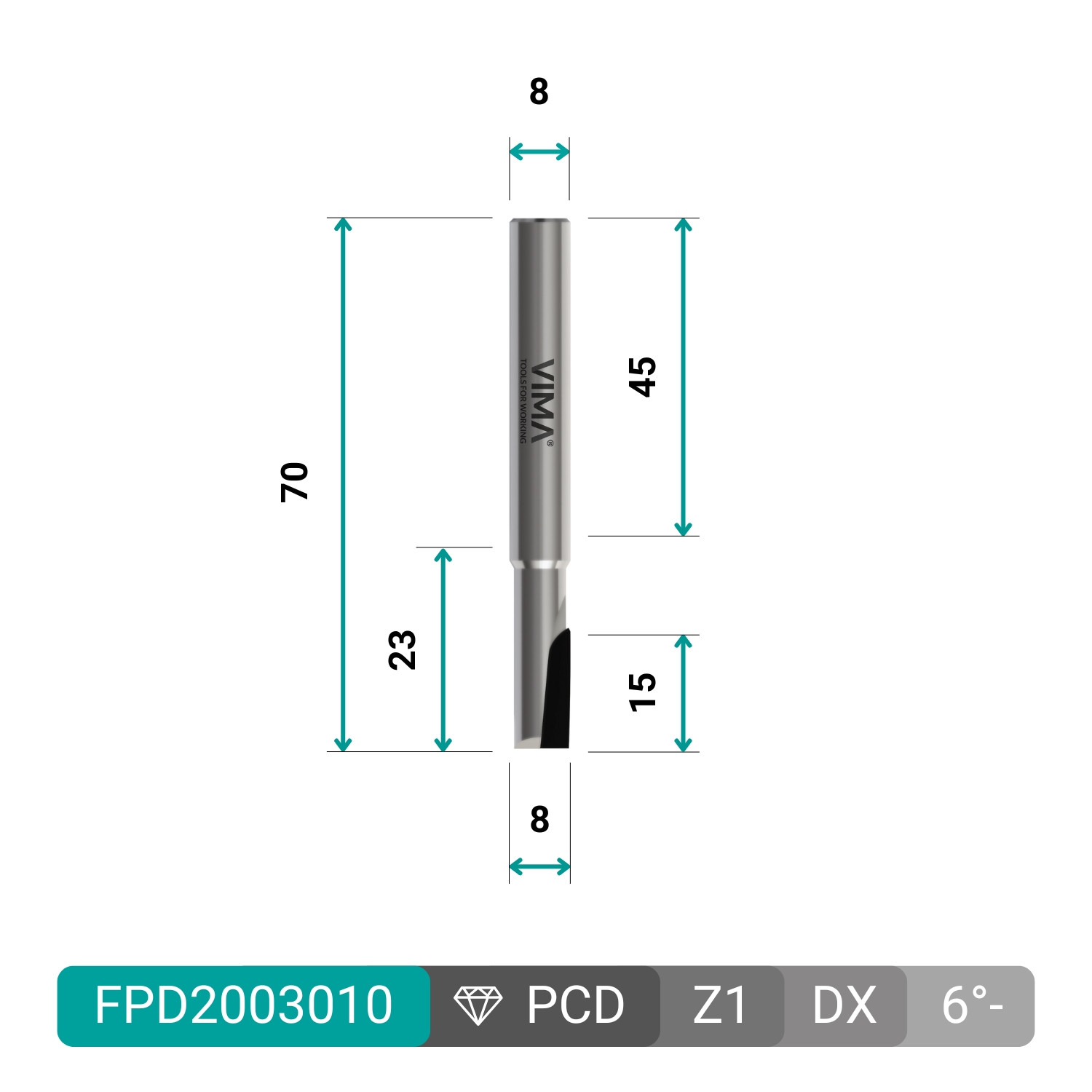

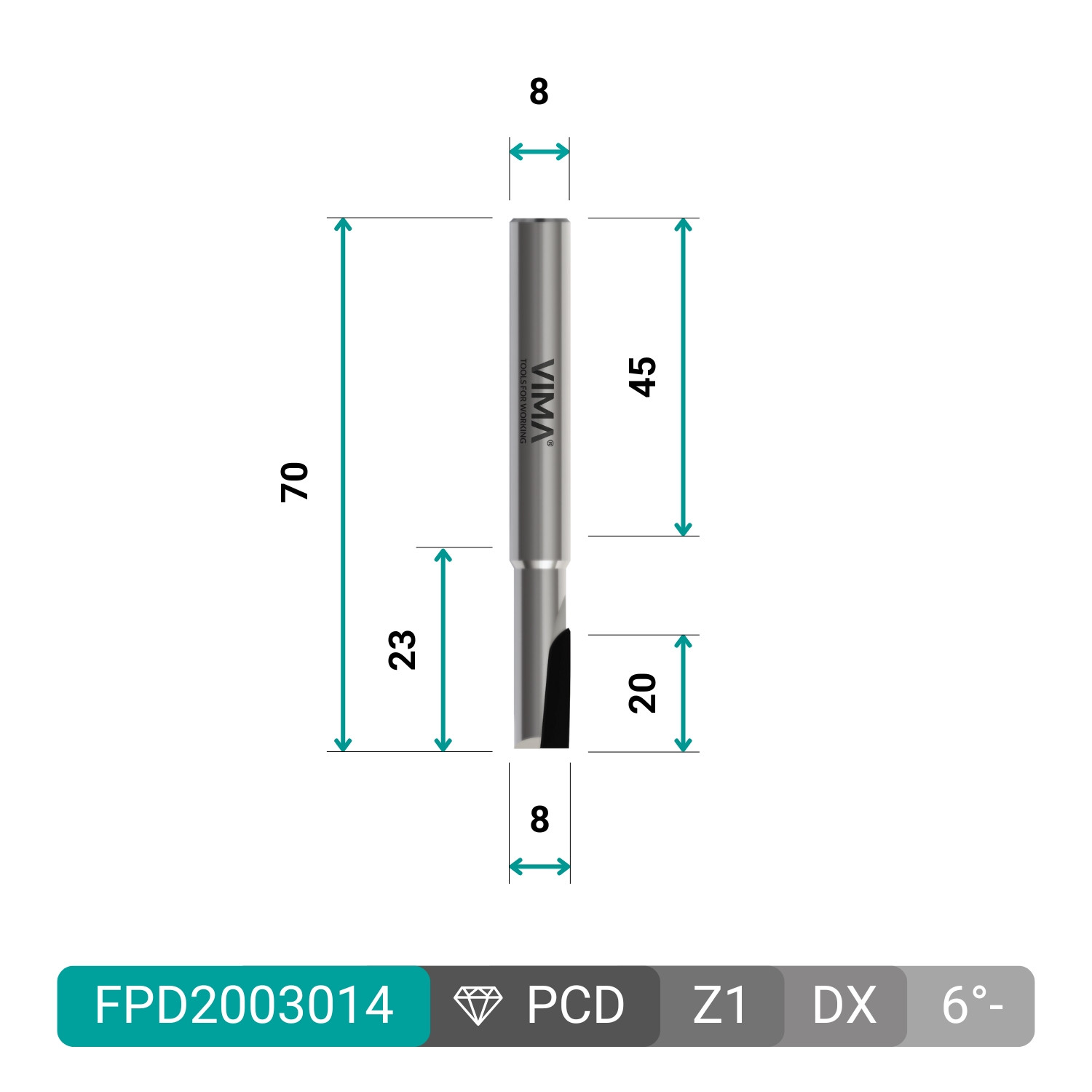

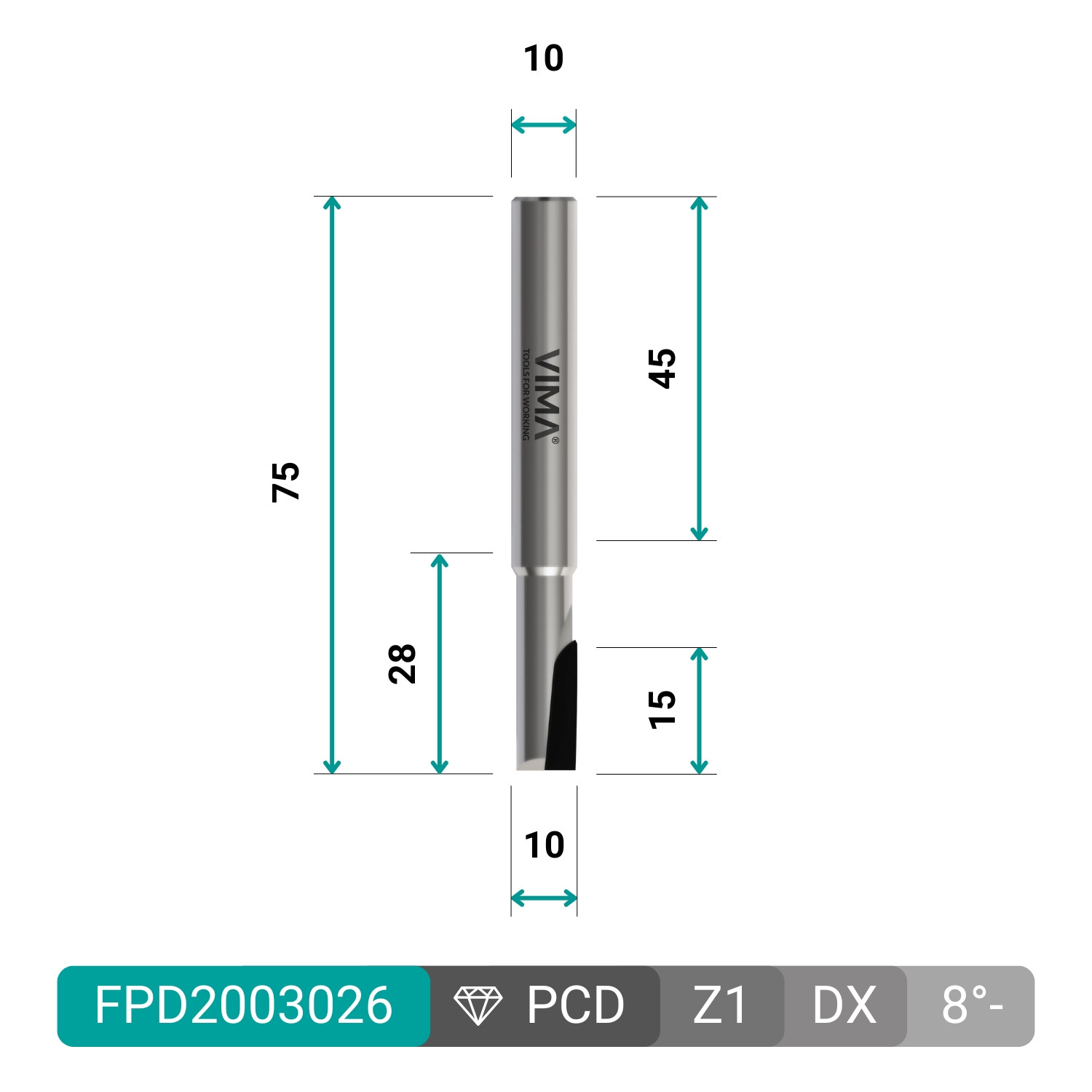

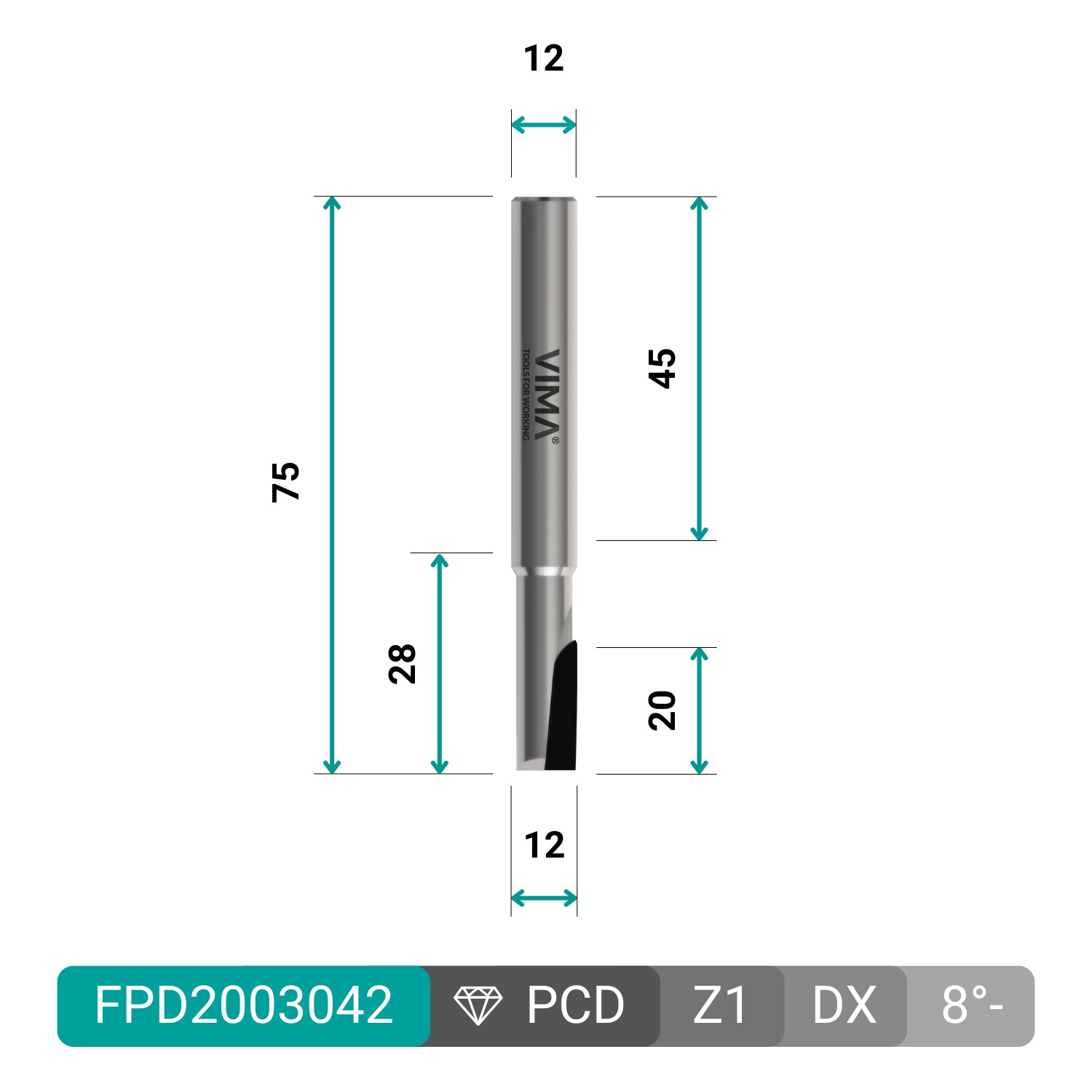

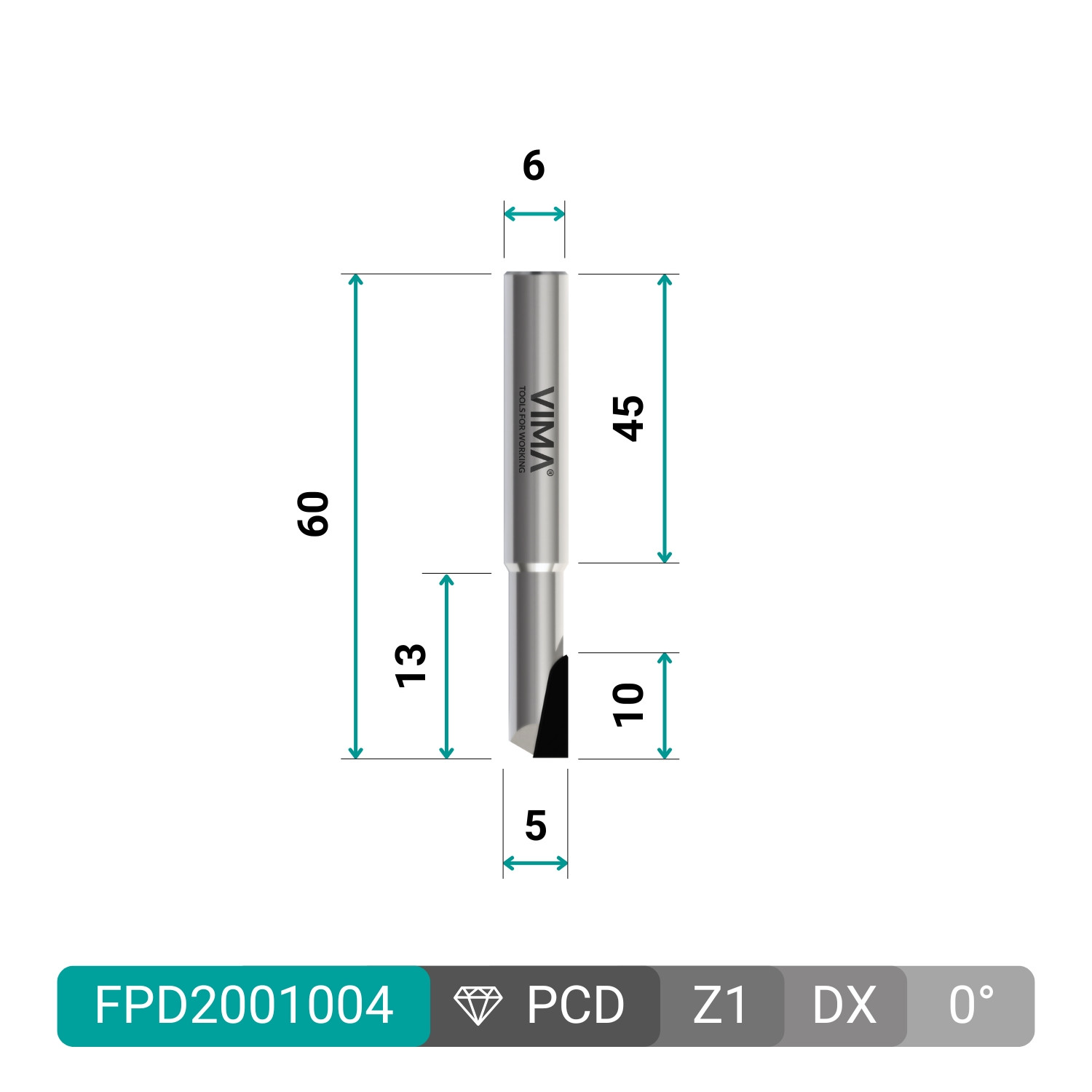

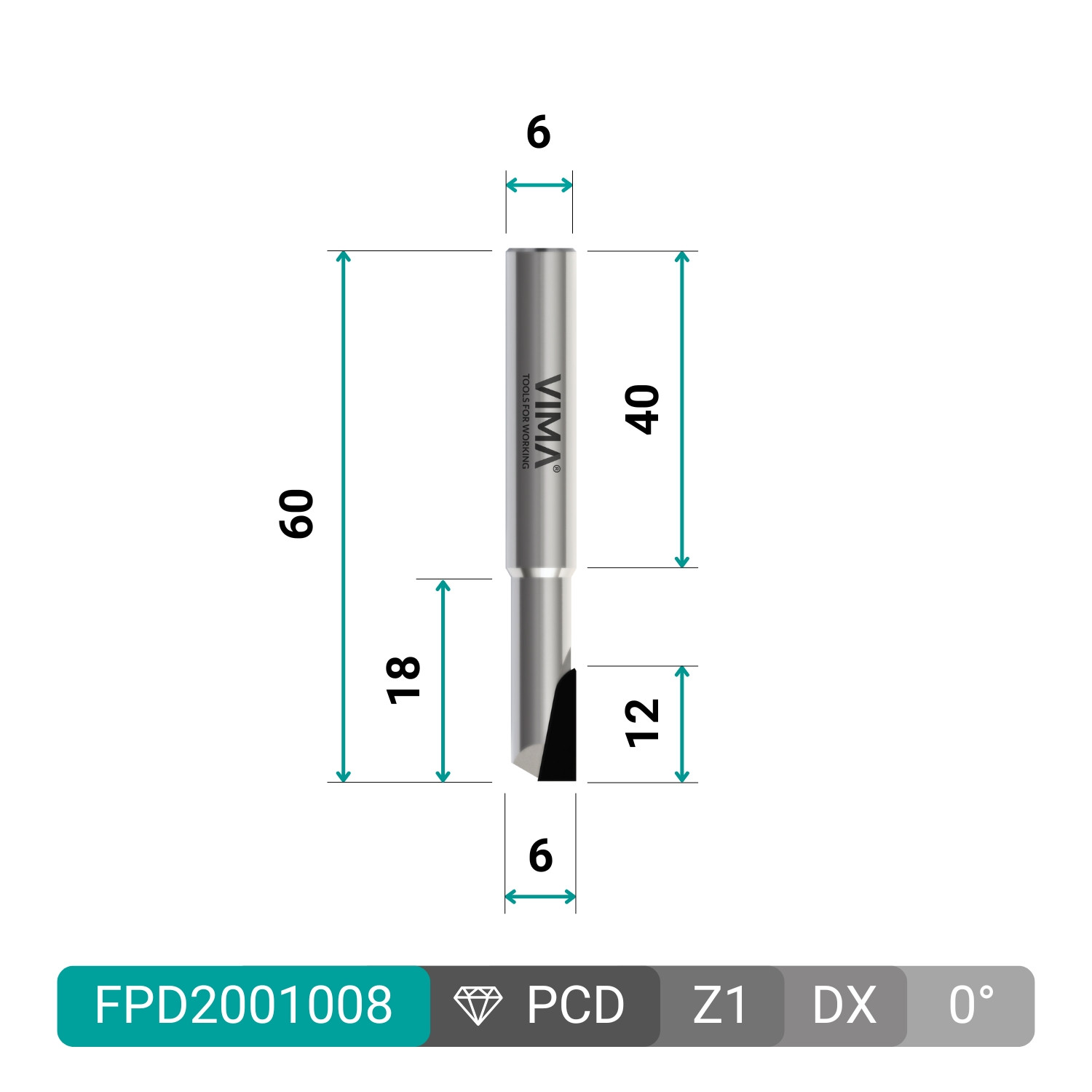

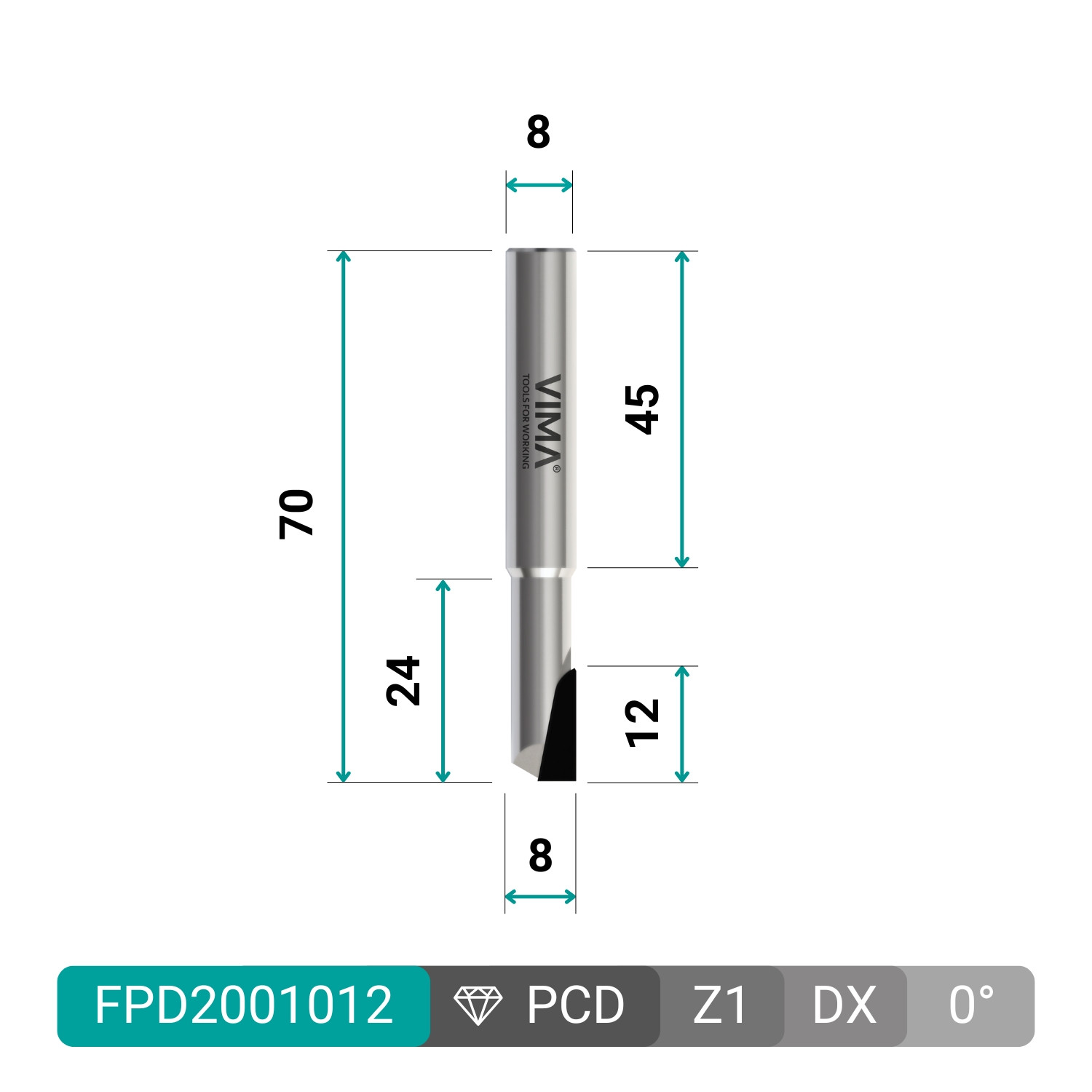

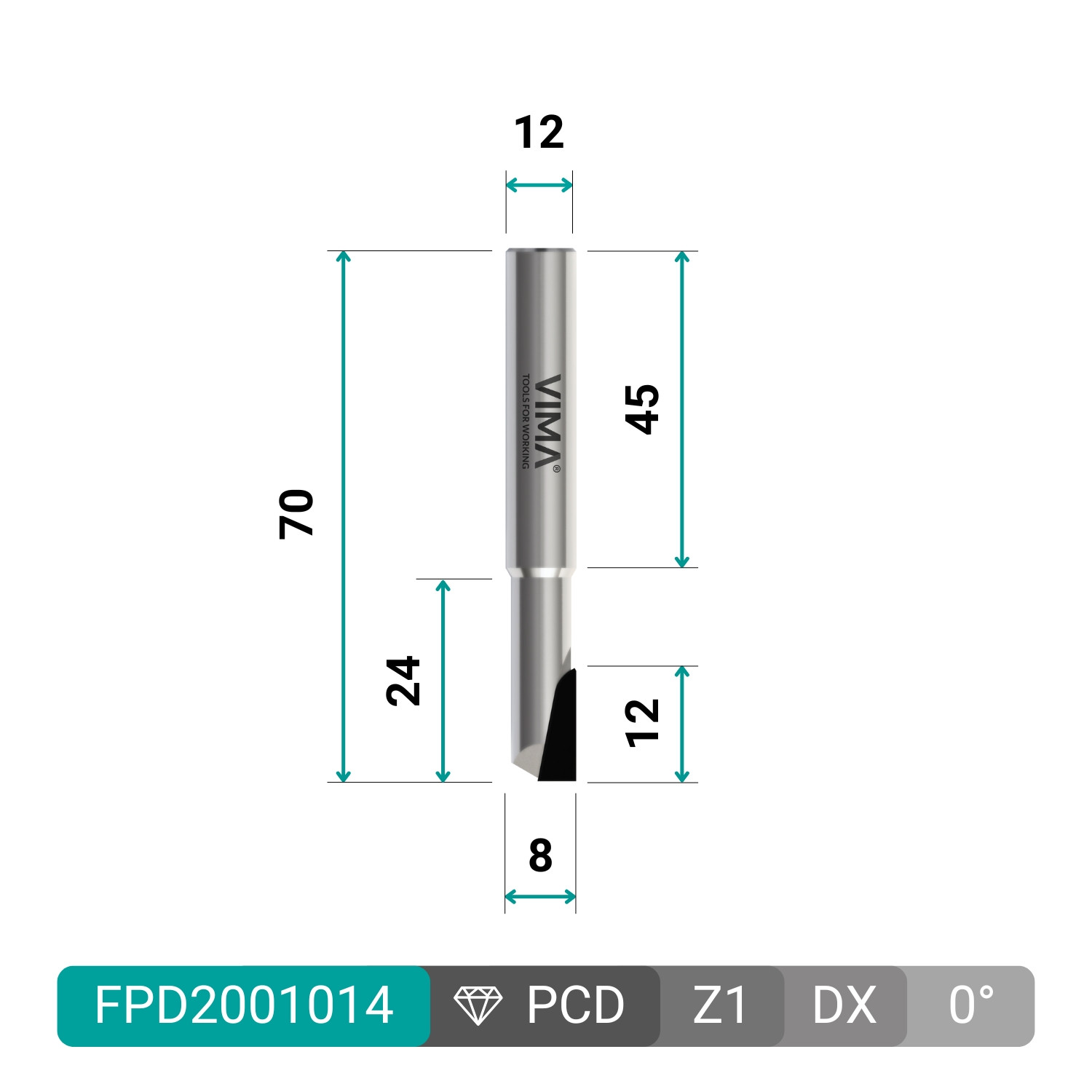

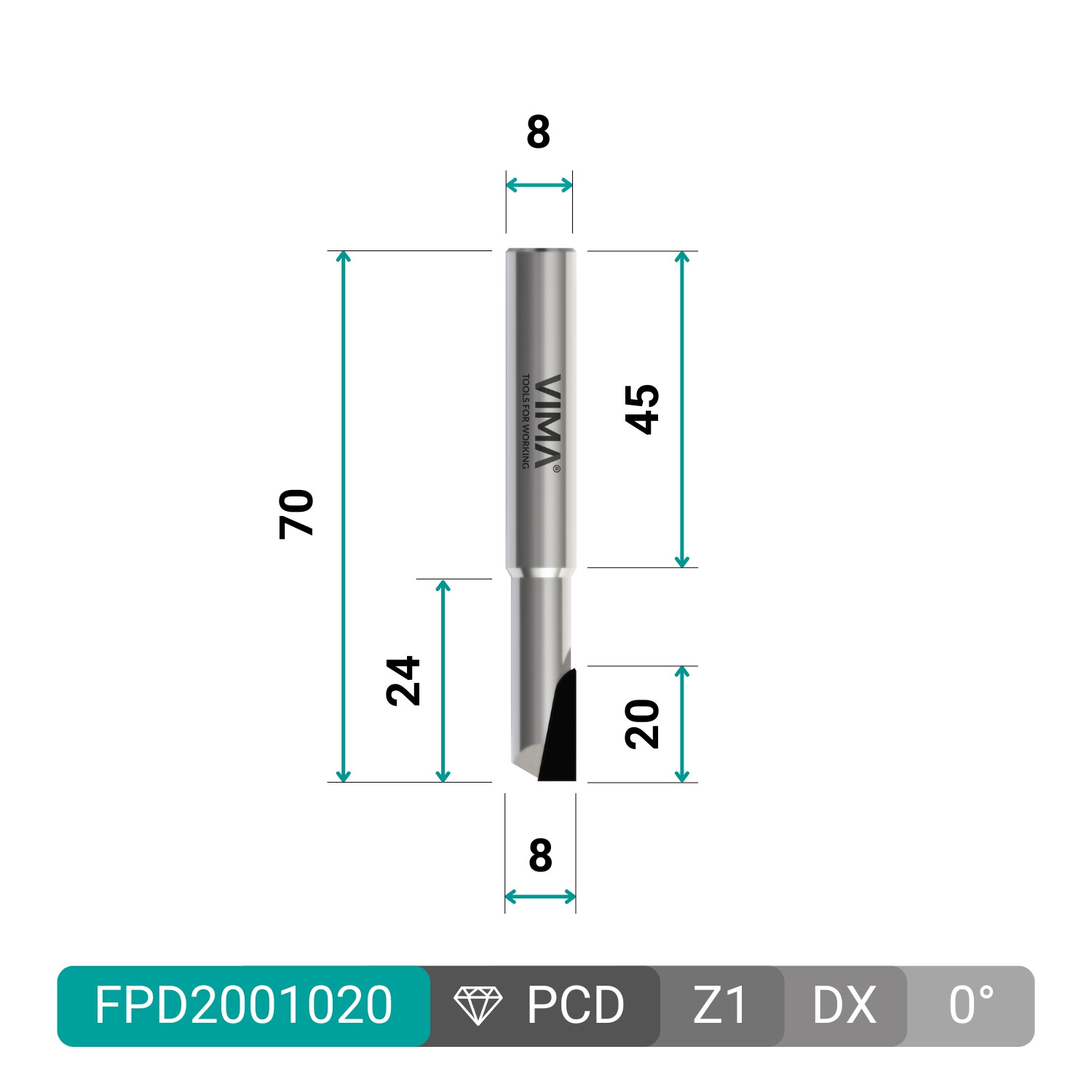

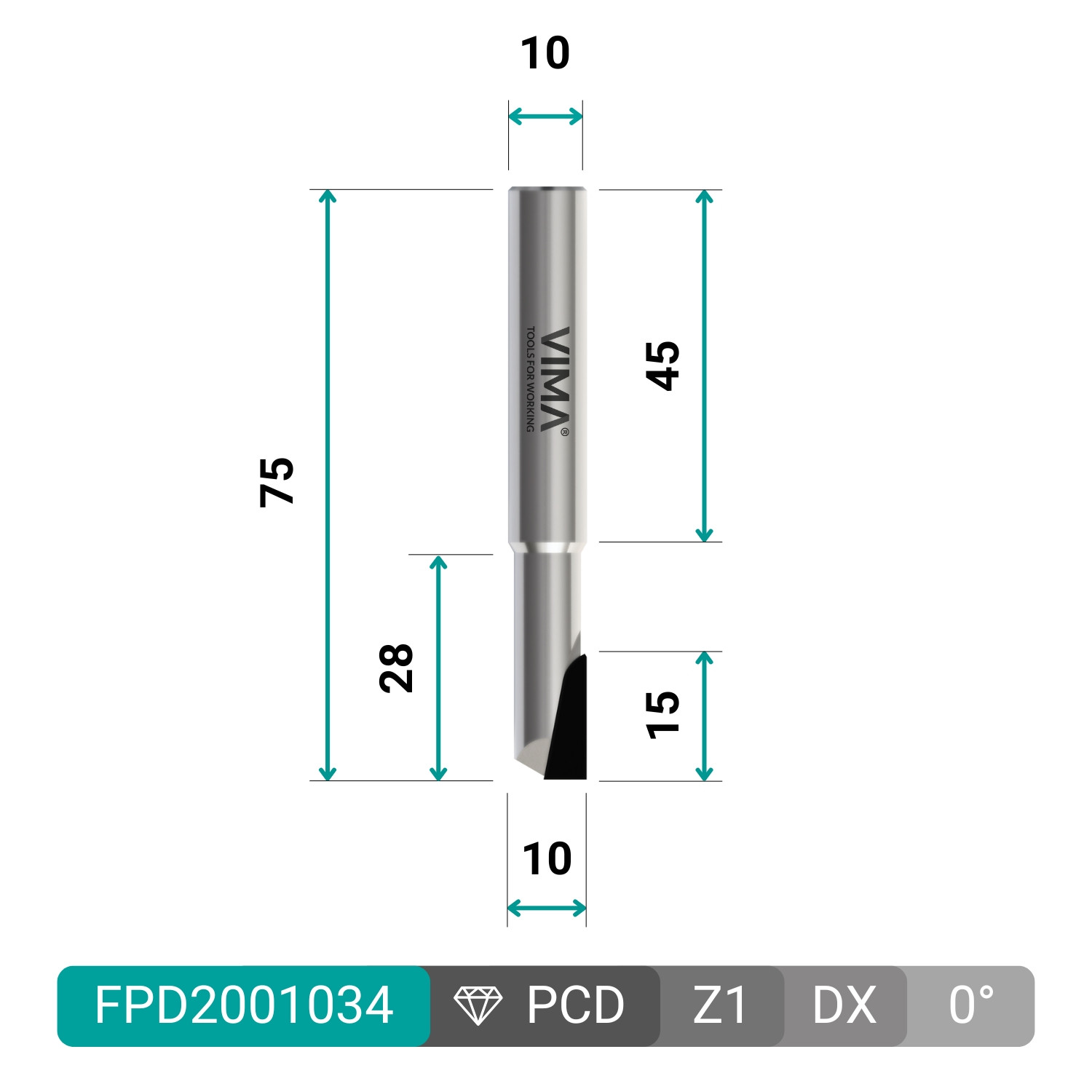

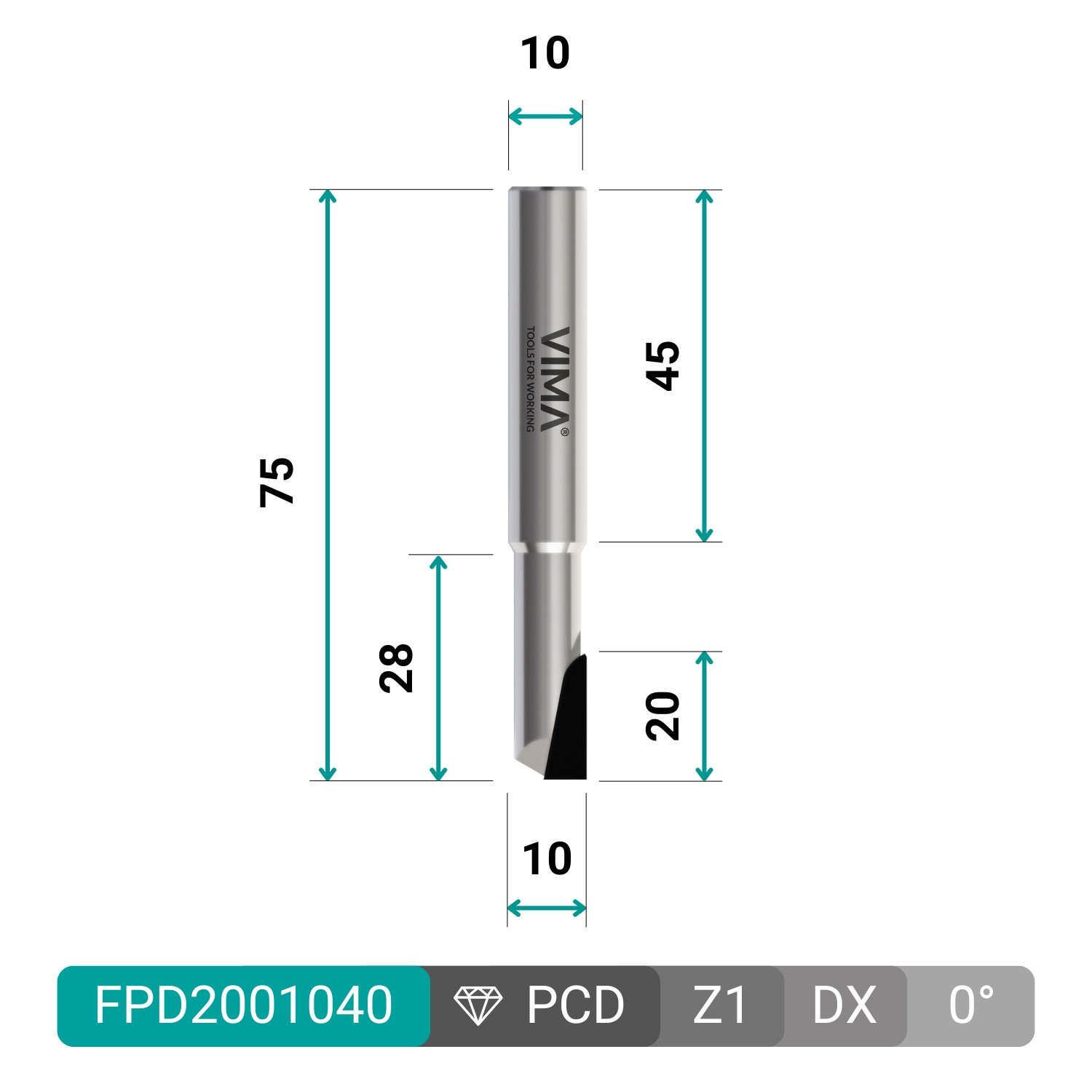

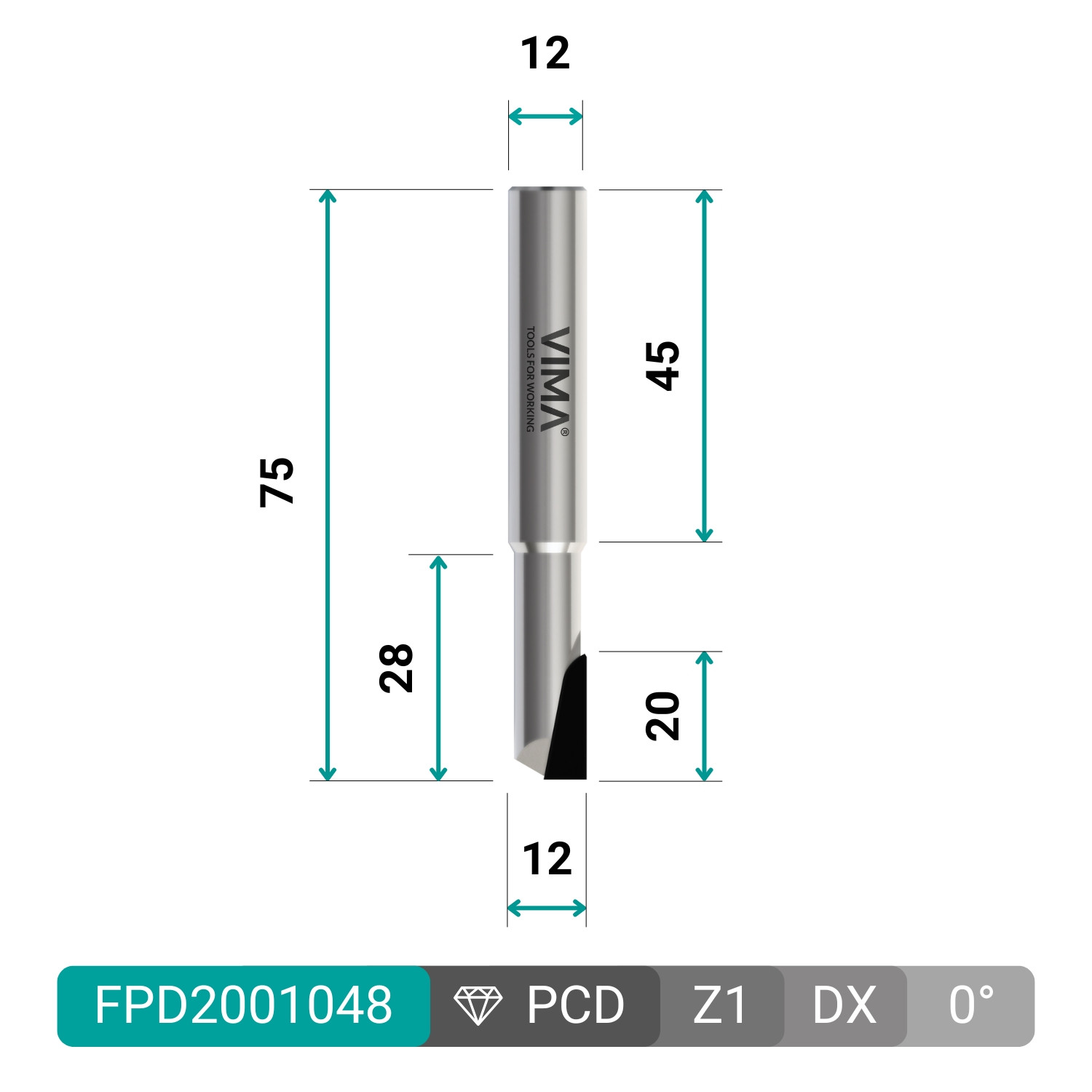

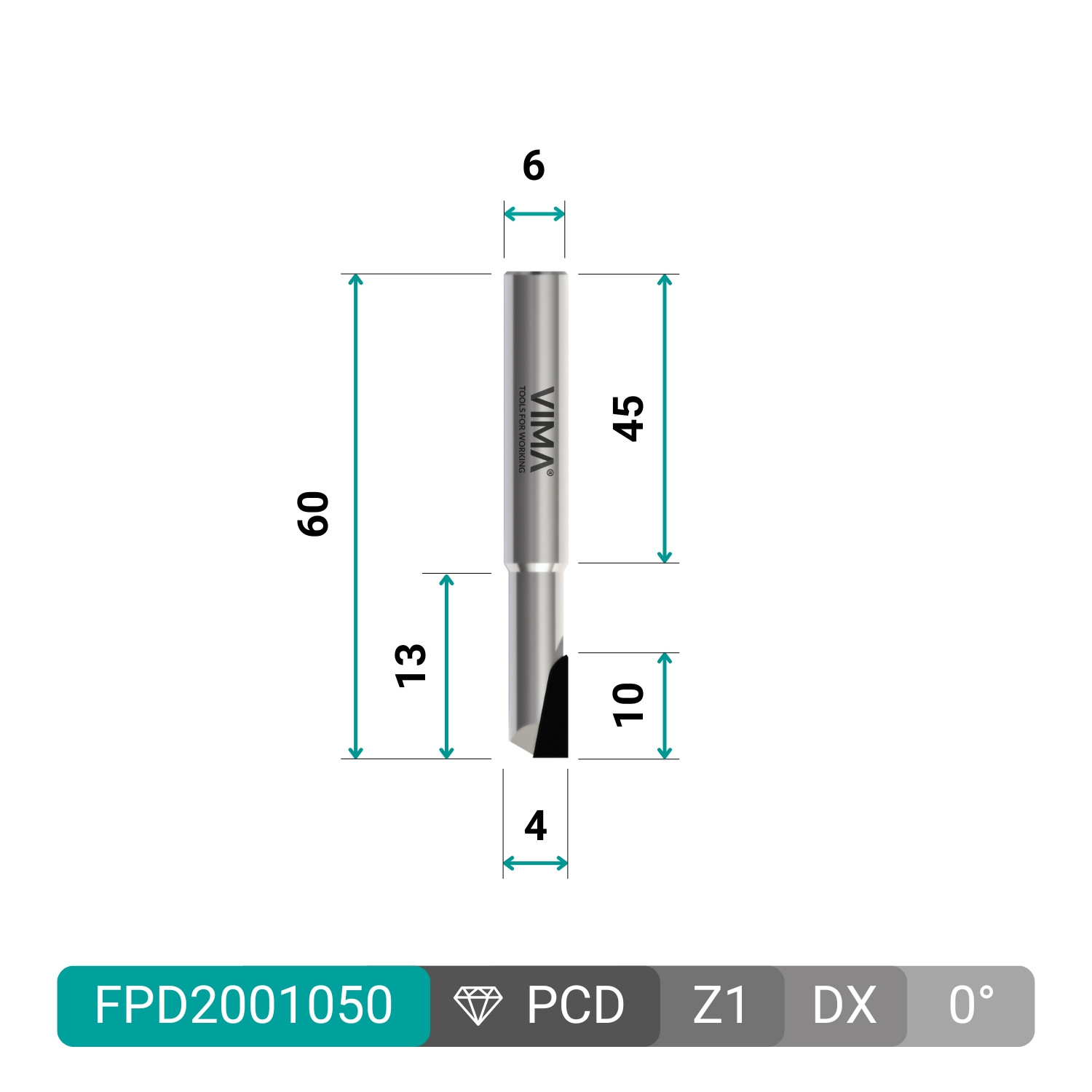

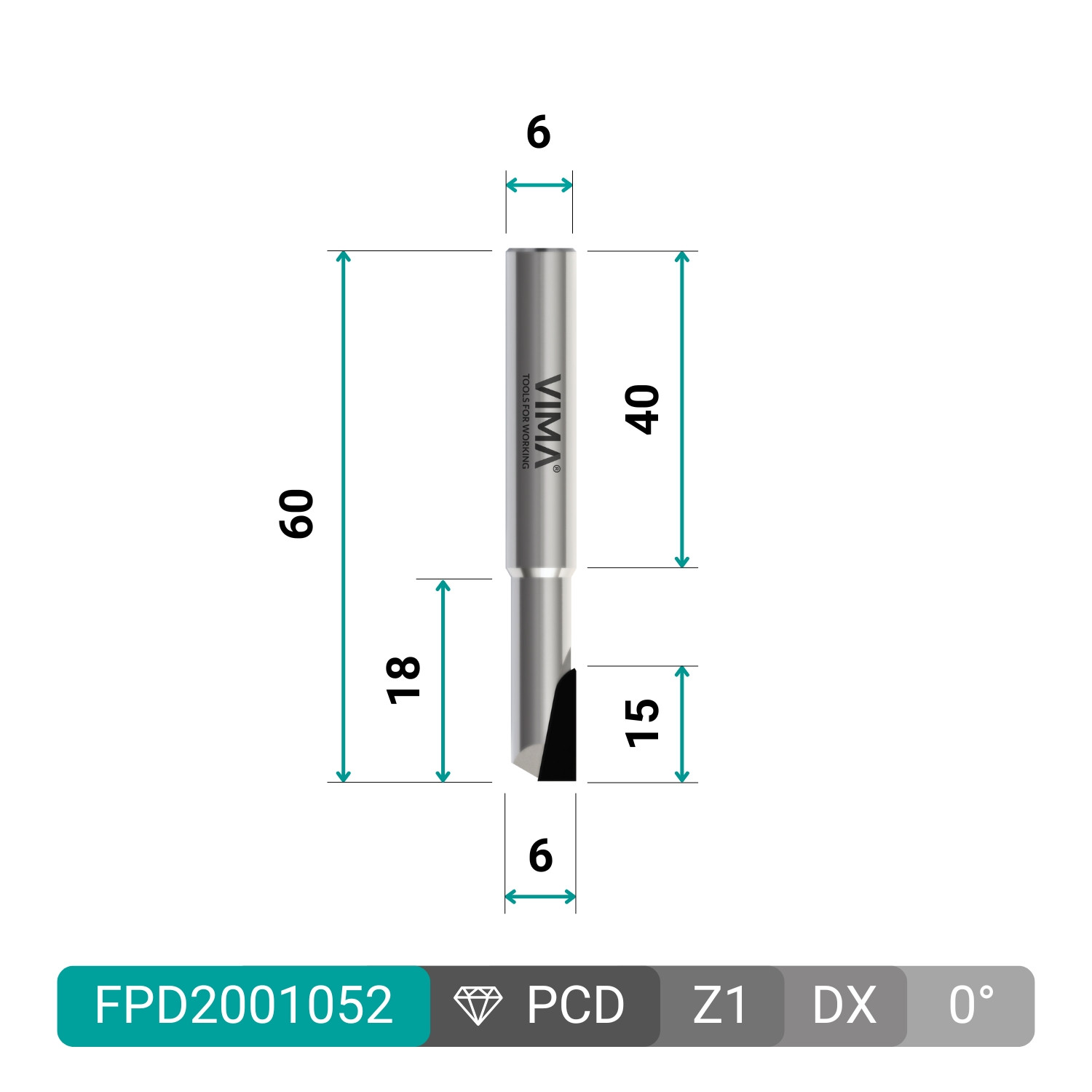

PCD diamond router bit designed for grooving and contouring operations on CNC machines with manual or mechanical feed. The straight Z1 cutting edge and solid HW body ensure cutting stability, clean finishing and extended tool life.

• PCD cutting edge H 3.5 mm for long service life

• Straight Z1 geometry for controlled cutting

• Solid HW body for rigidity and precision

.jpg)