There are no more items in your cart

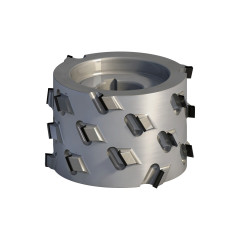

PFO7517

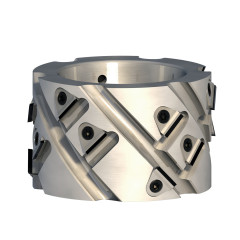

PFO7518

PFO7521

PFO7504

.jpg)