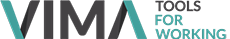

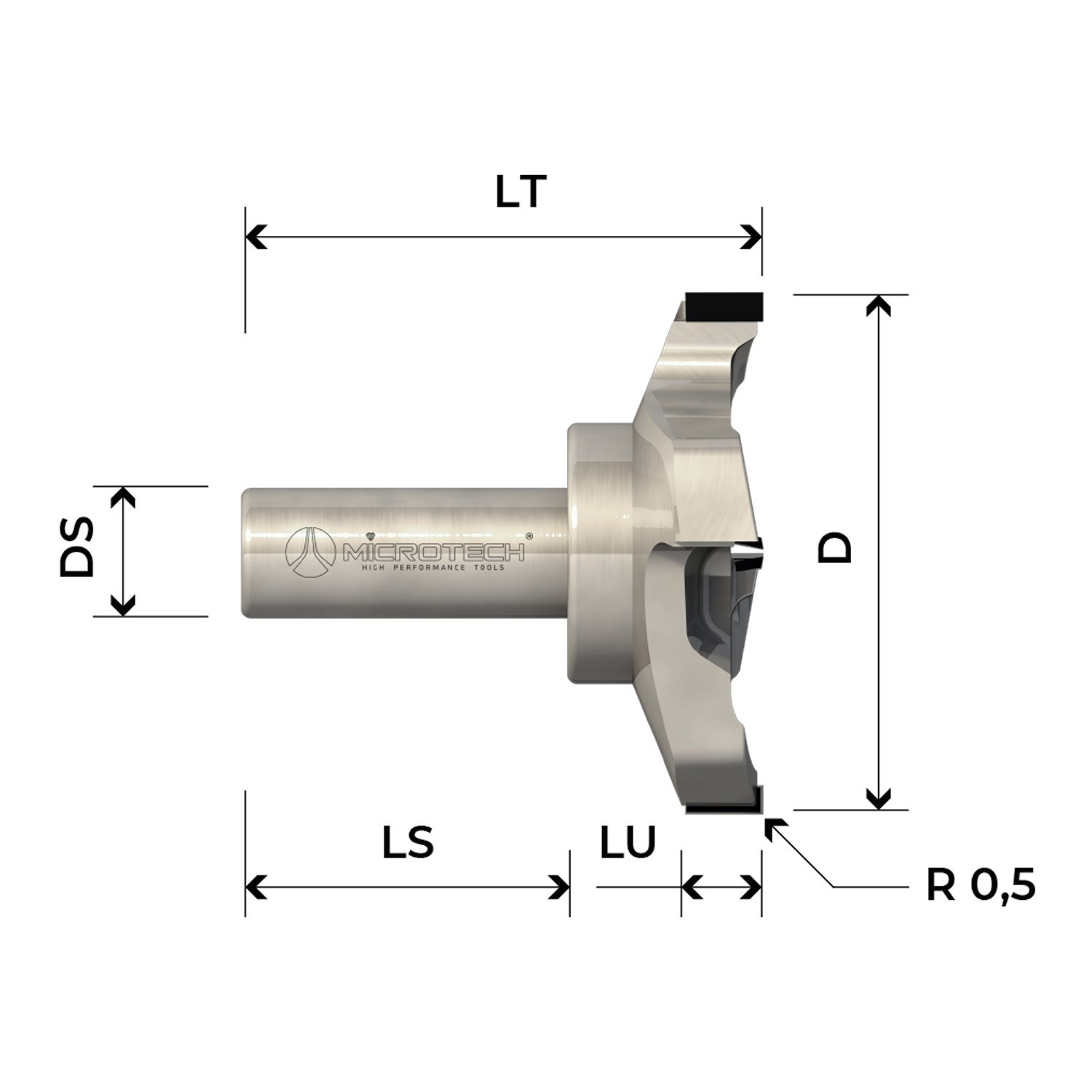

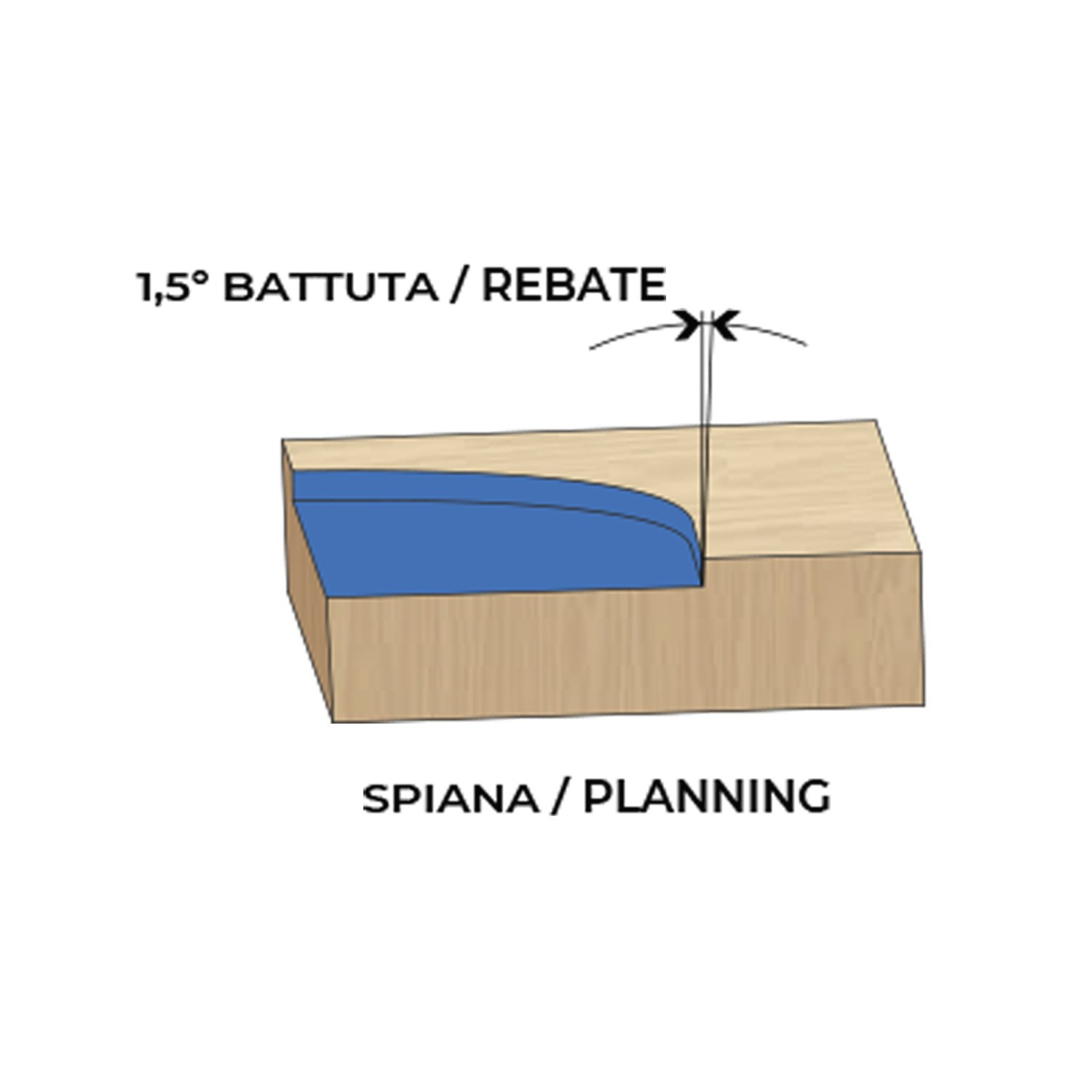

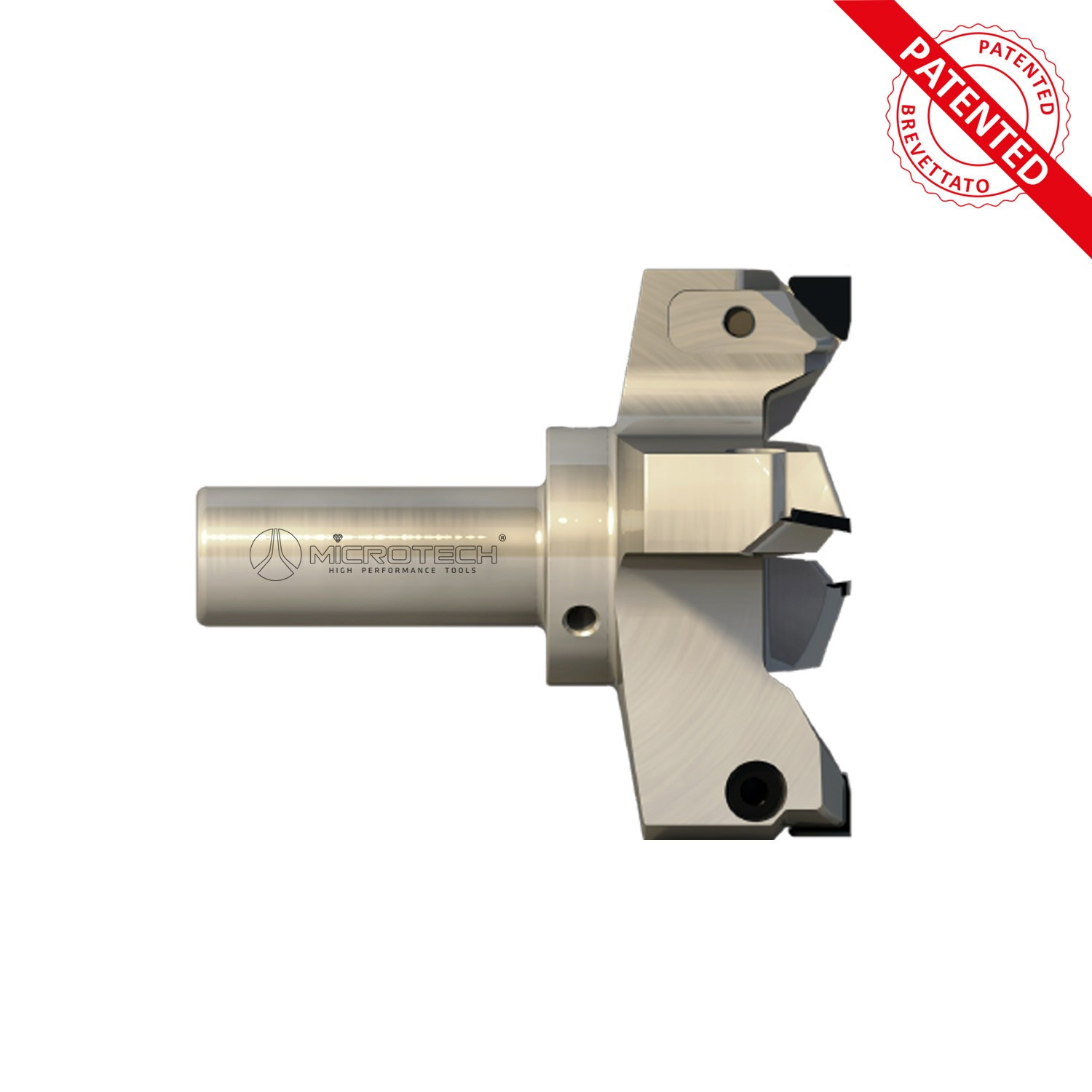

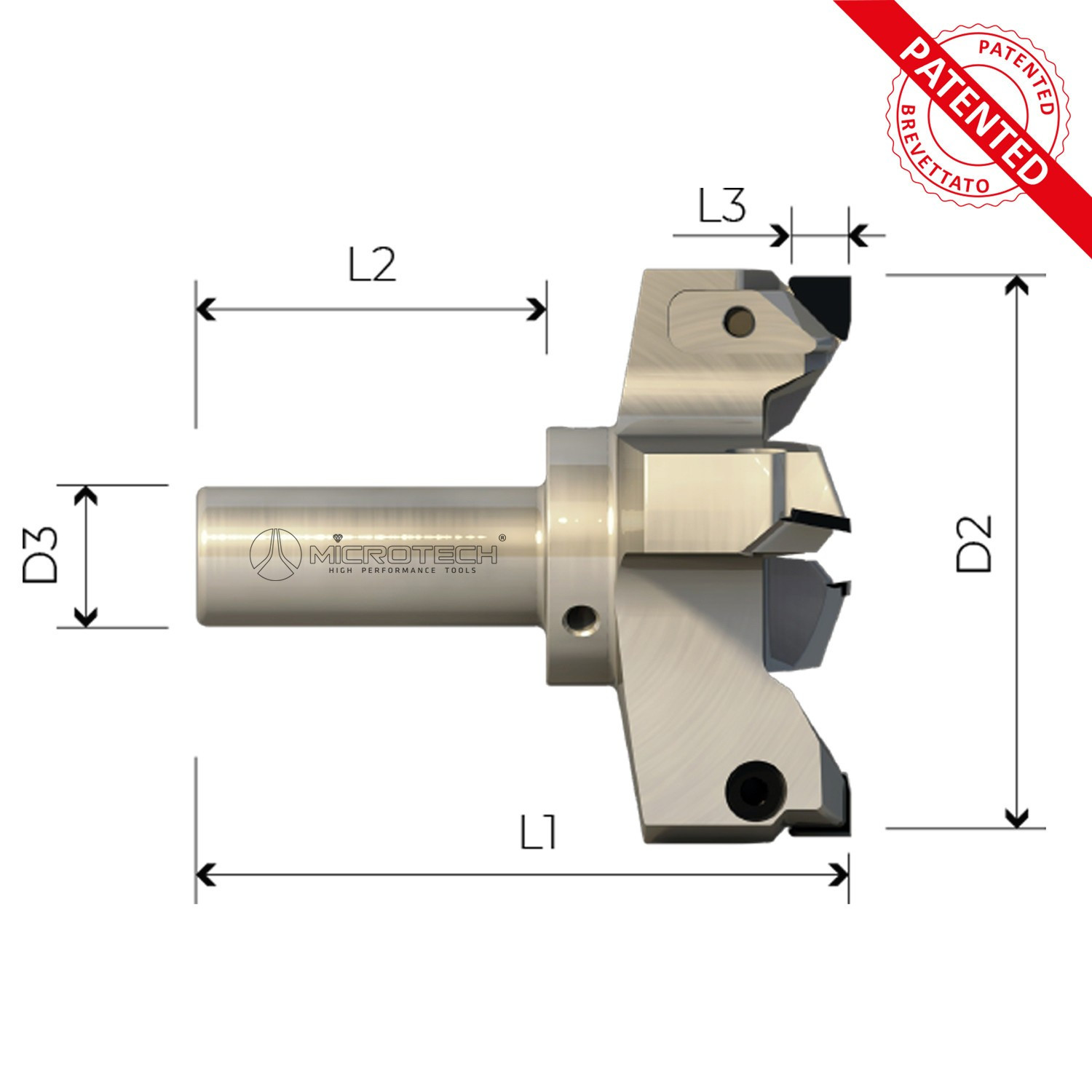

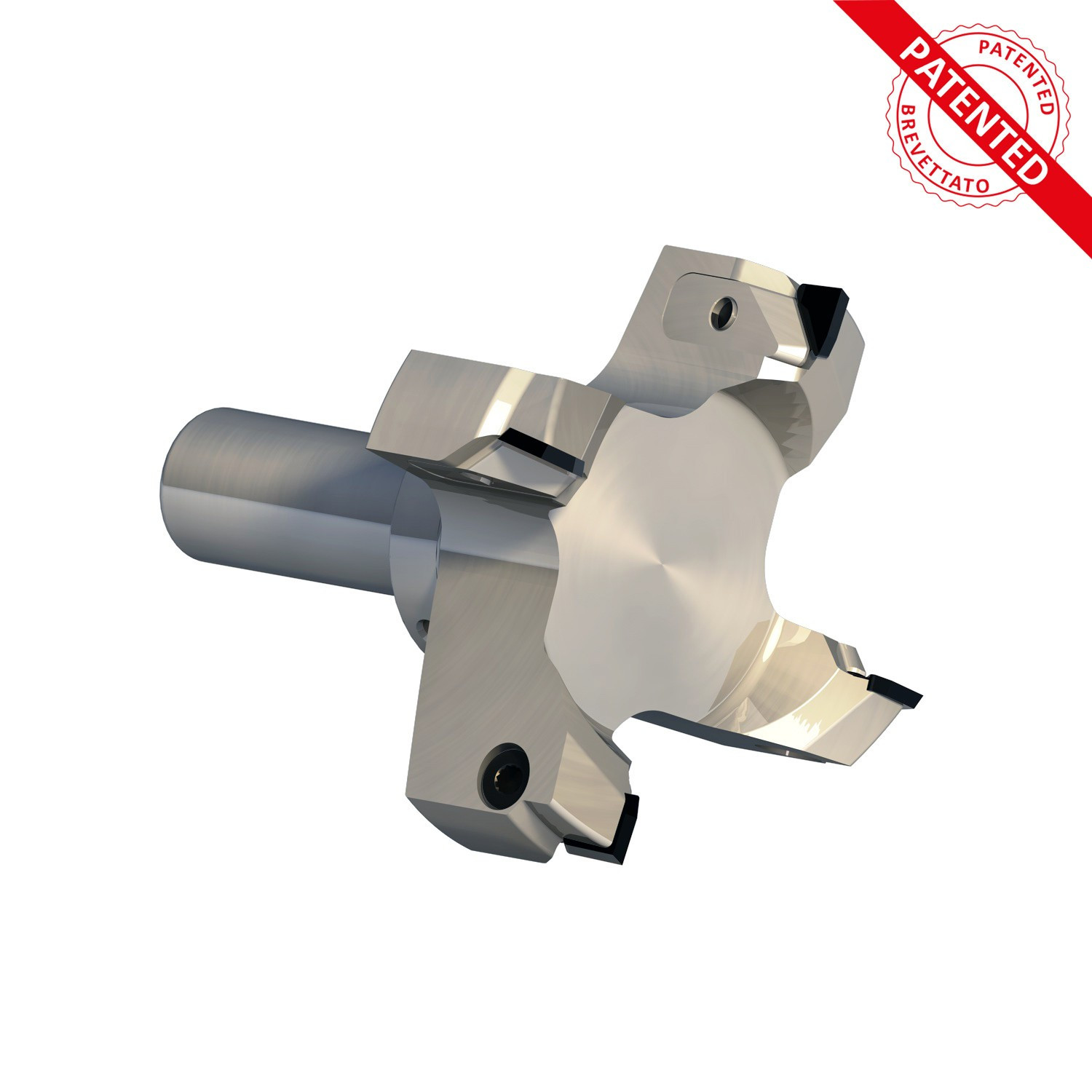

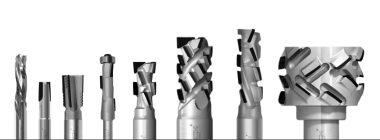

Diamond surfacing cutter designed for accurate planing of panels and for cutting clean rebates on compact materials. The 0° axial angle and the R0.5 edge radius help minimize visible surfacing marks and deliver a more uniform finish, even on coated or delicate surfaces.

• PCD H4.5mm for long life and consistent results

• 0° axial angle for stable, controlled surfacing

• R0.5 radius to reduce marks and improve finish quality

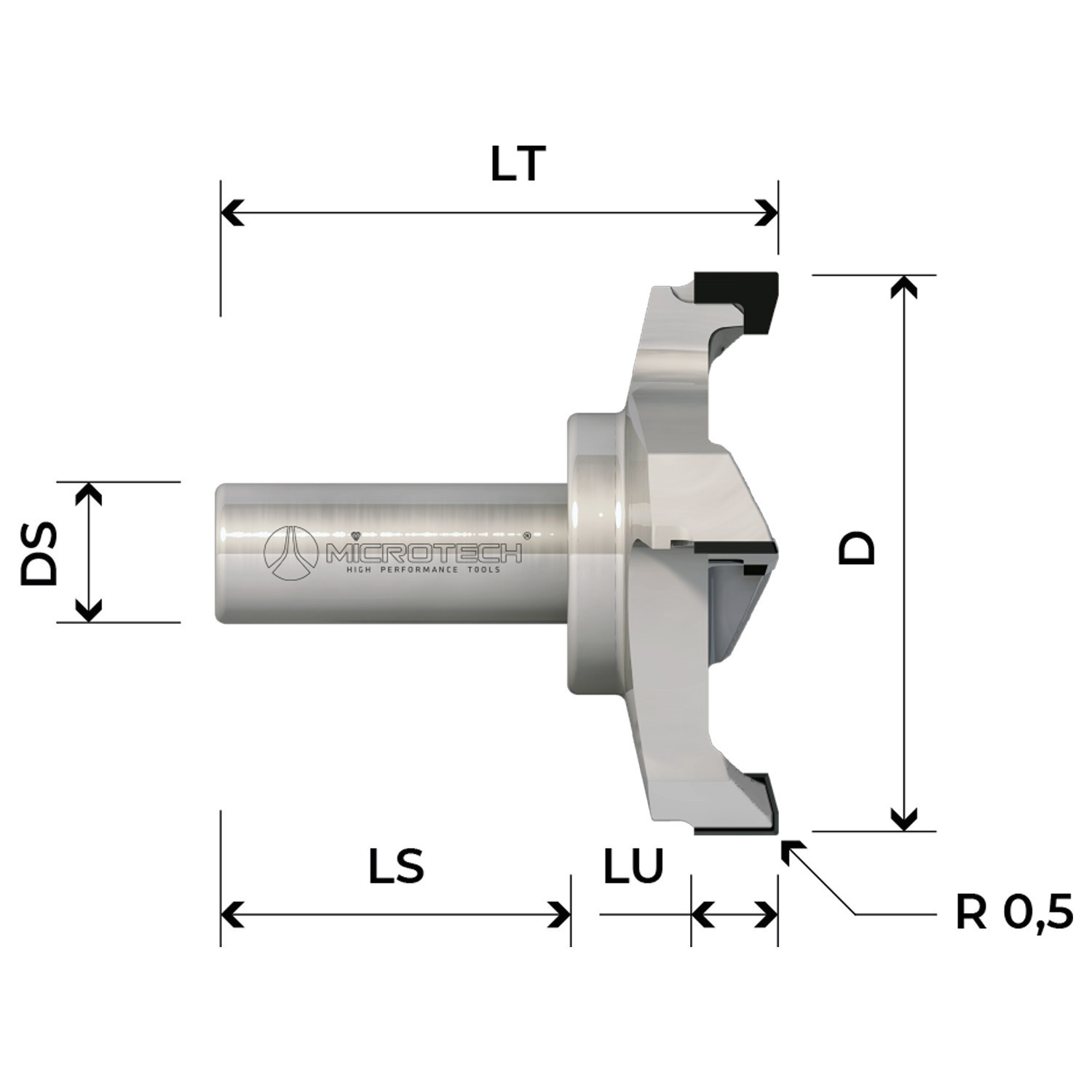

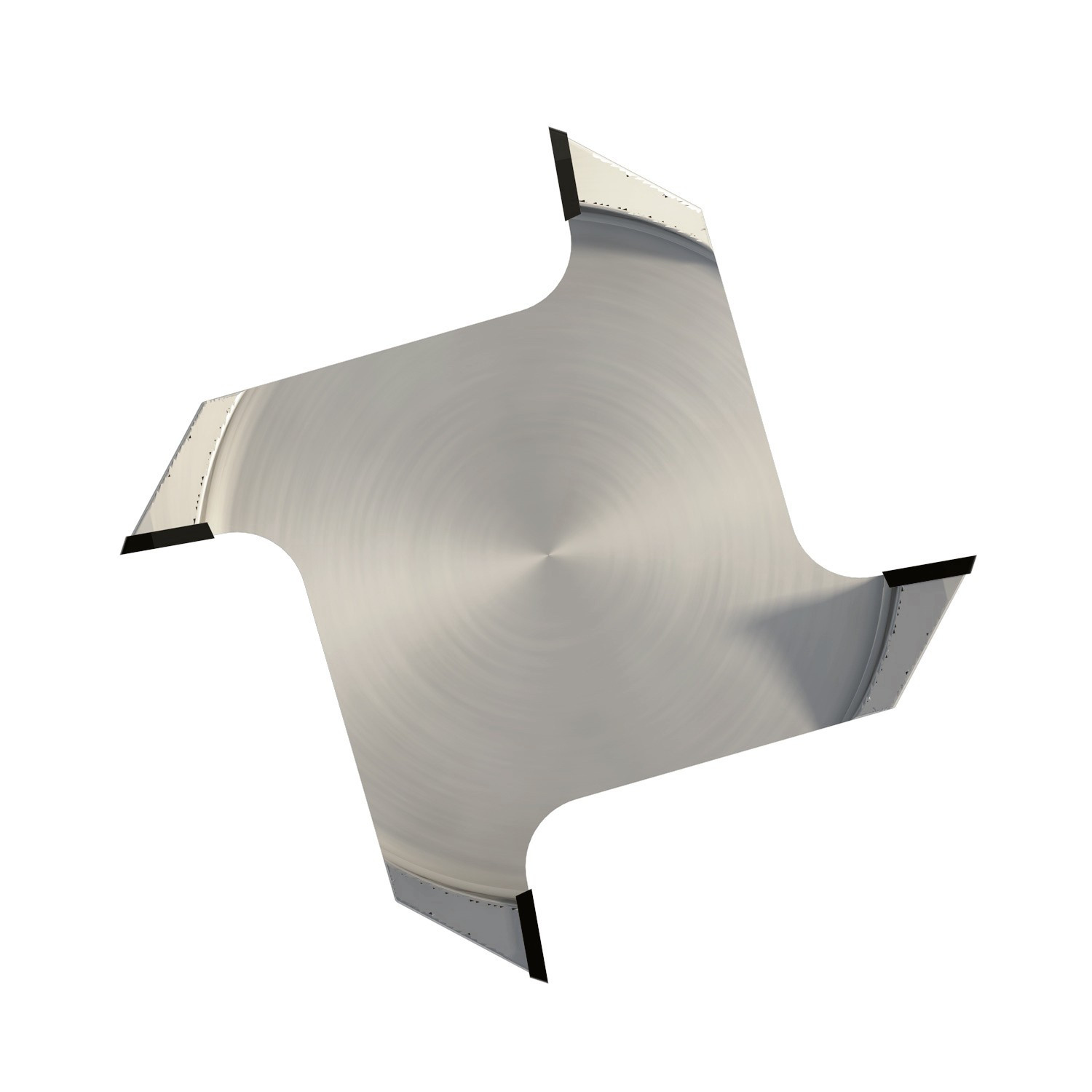

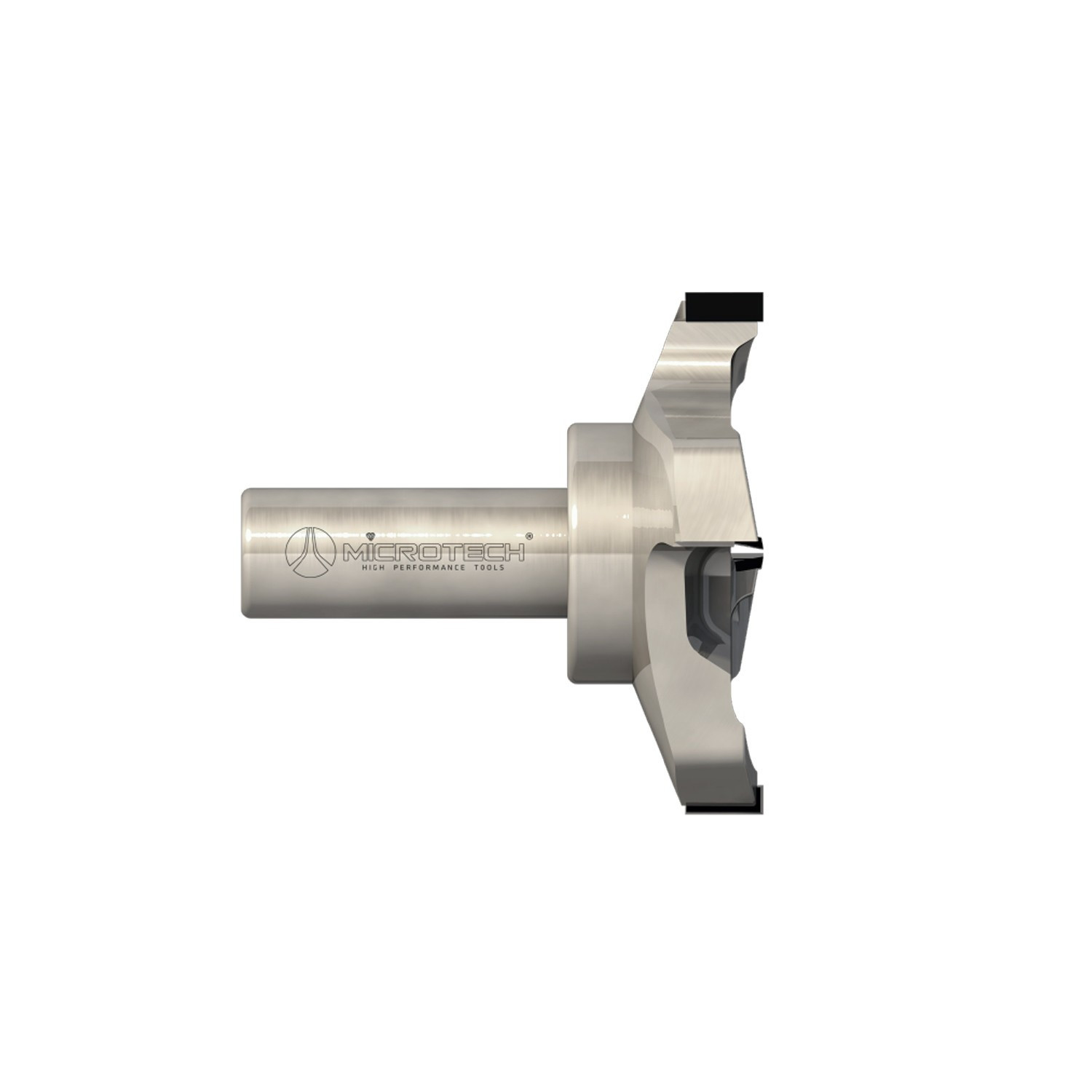

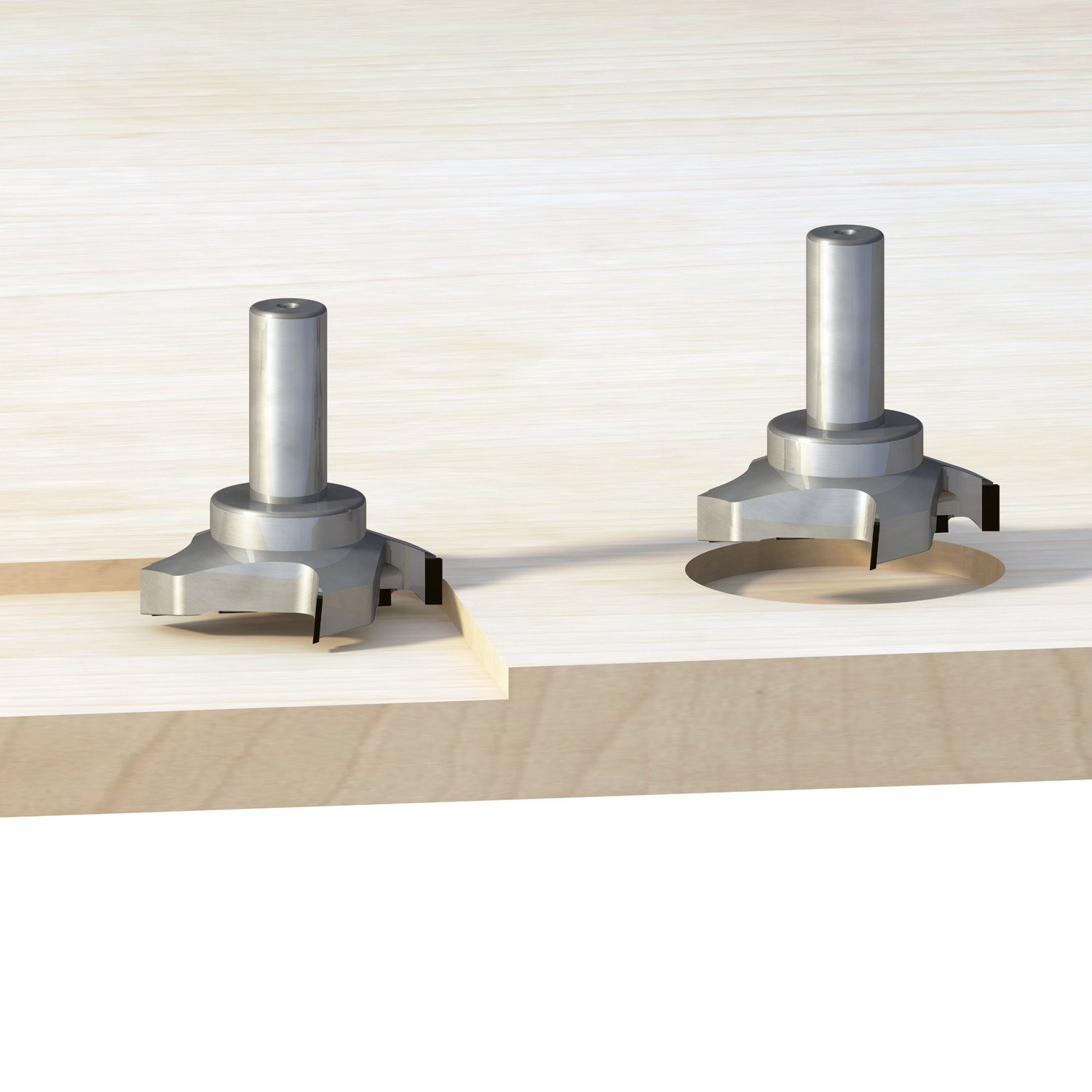

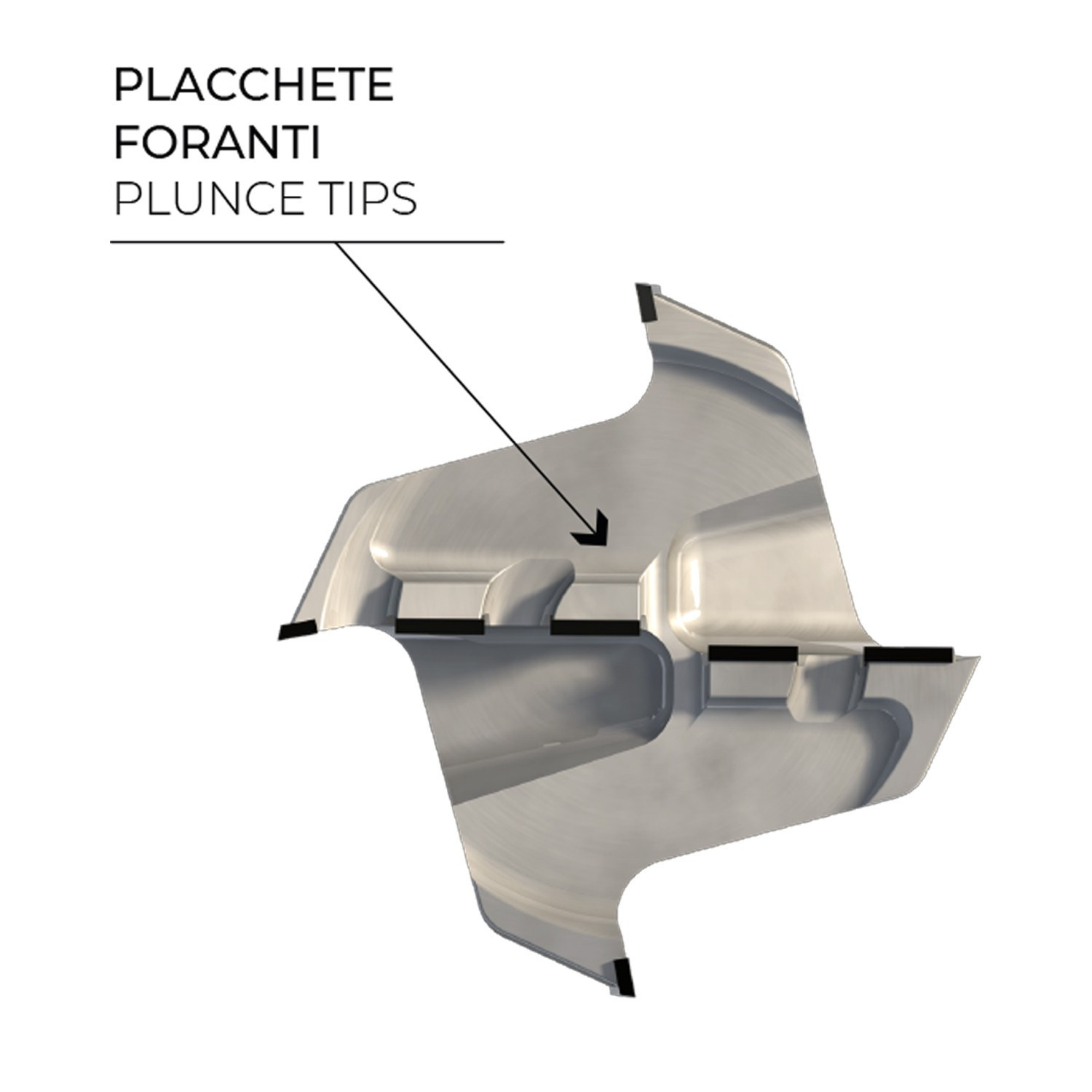

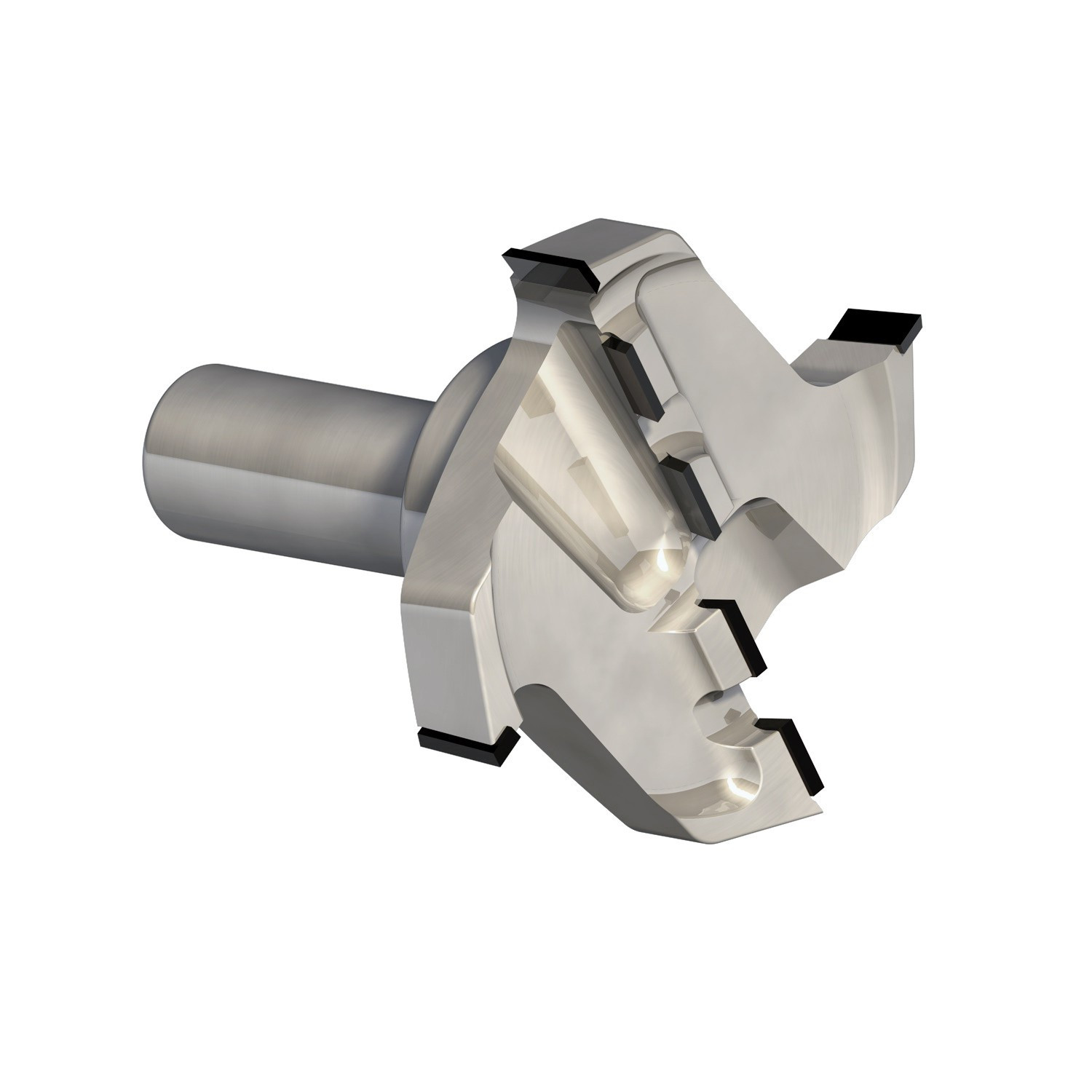

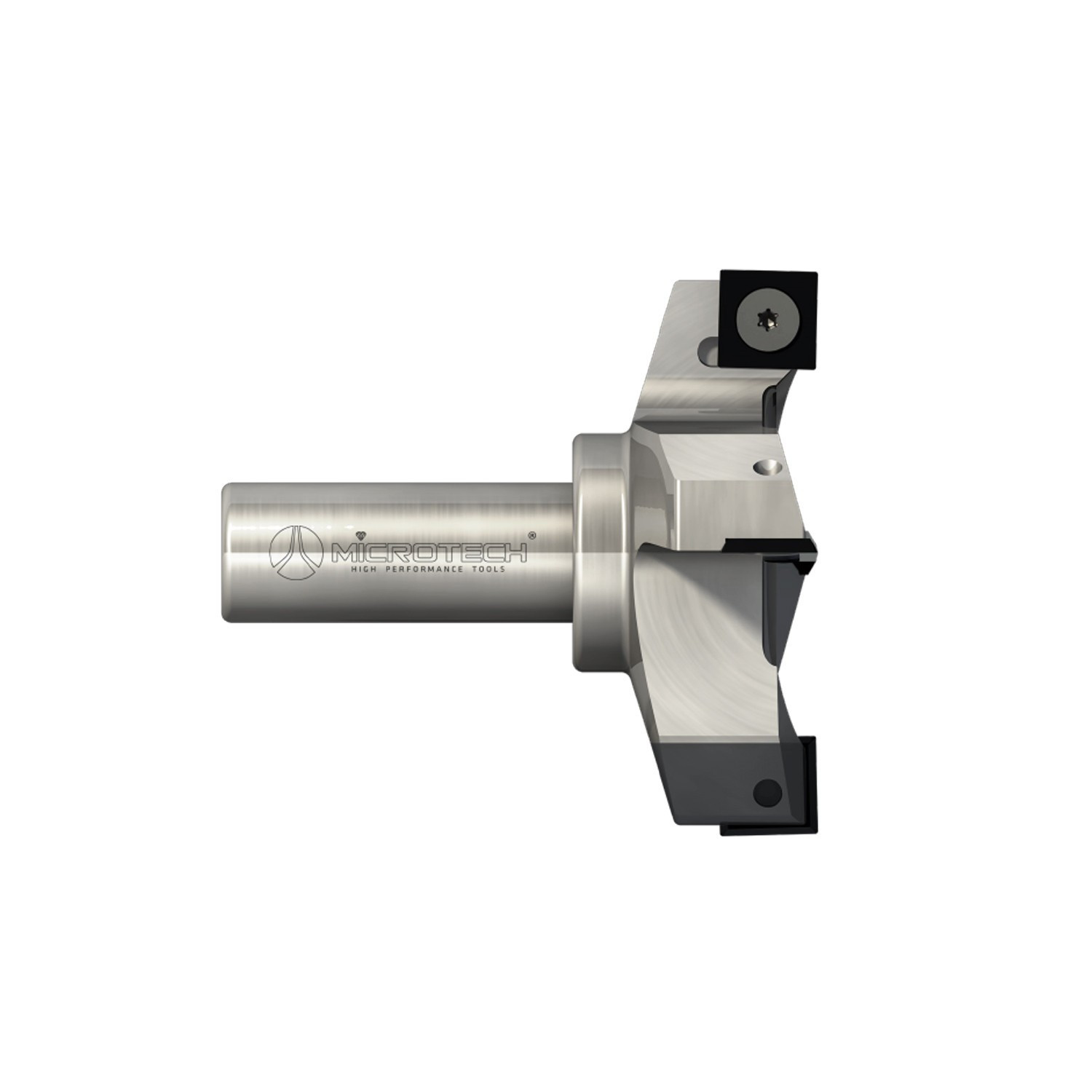

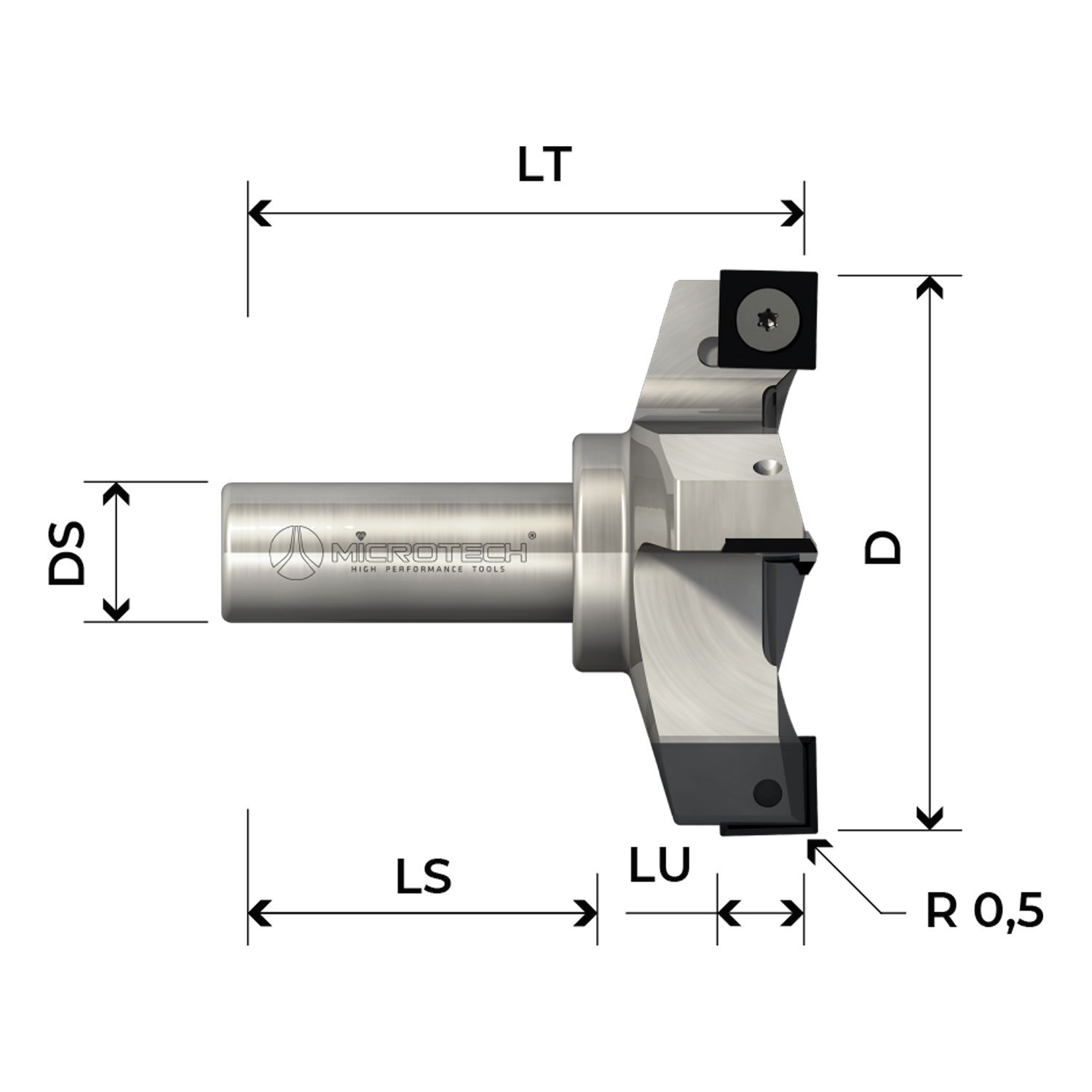

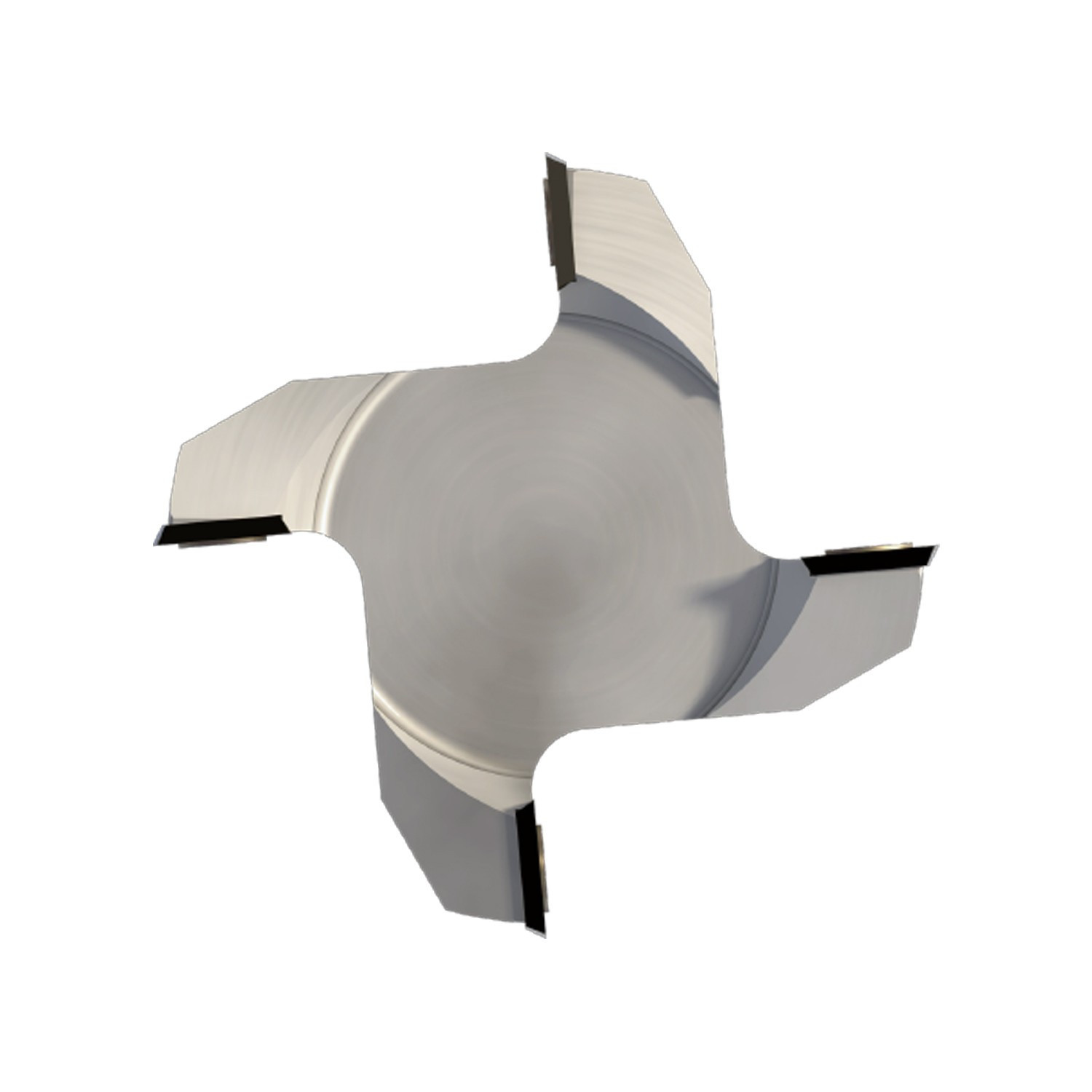

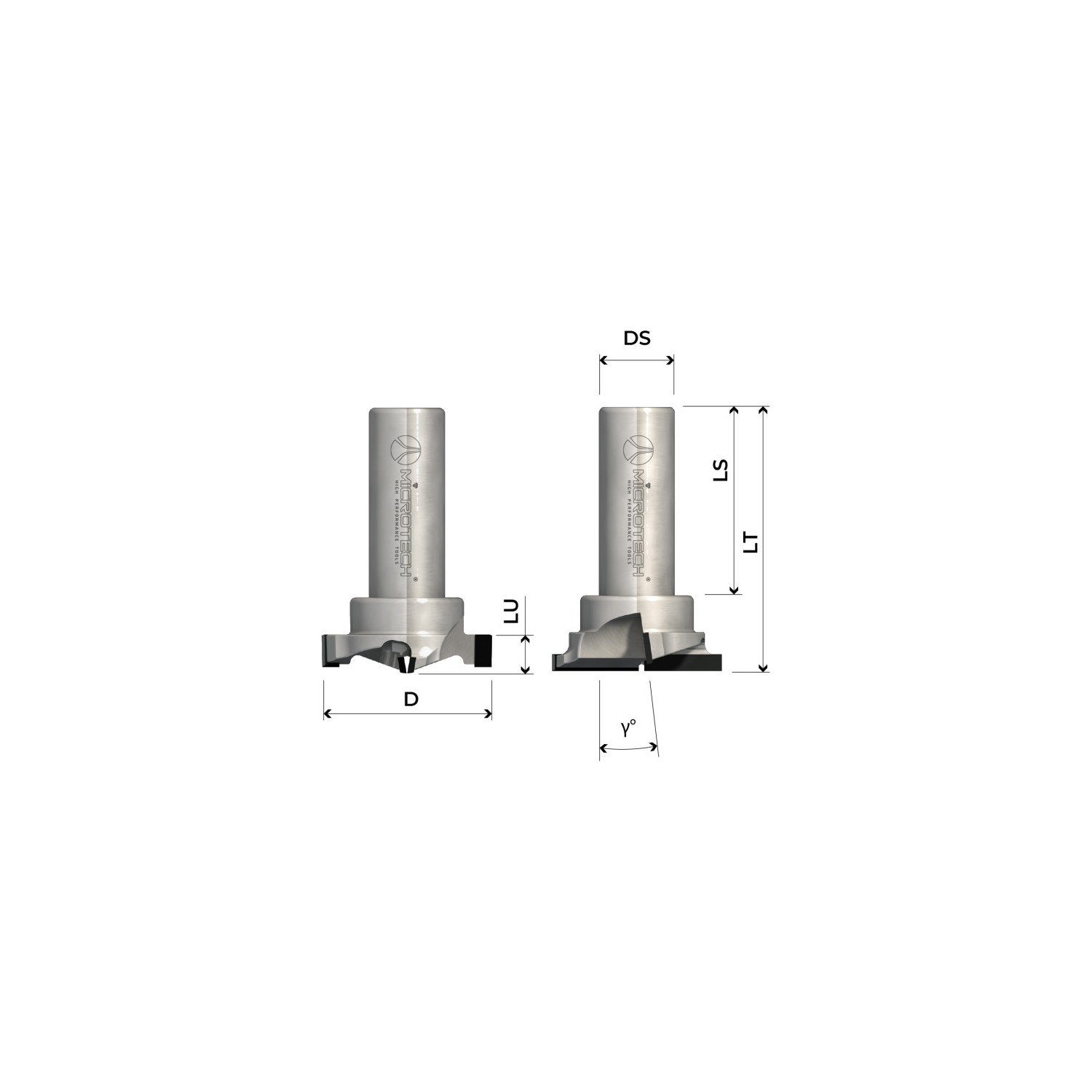

PCD diamond router bit designed for surfacing, drilling and rebate operations on panels and wood based materials. The 4 flute Z4 geometry with 0° axial angle and center cutting edge delivers flat surfaces and precise machining.

• 4.5 mm PCD inserts for long service life

• Center cutting edge for combined drilling and surfacing

• 0.5 mm corner radius to avoid surfacing marks

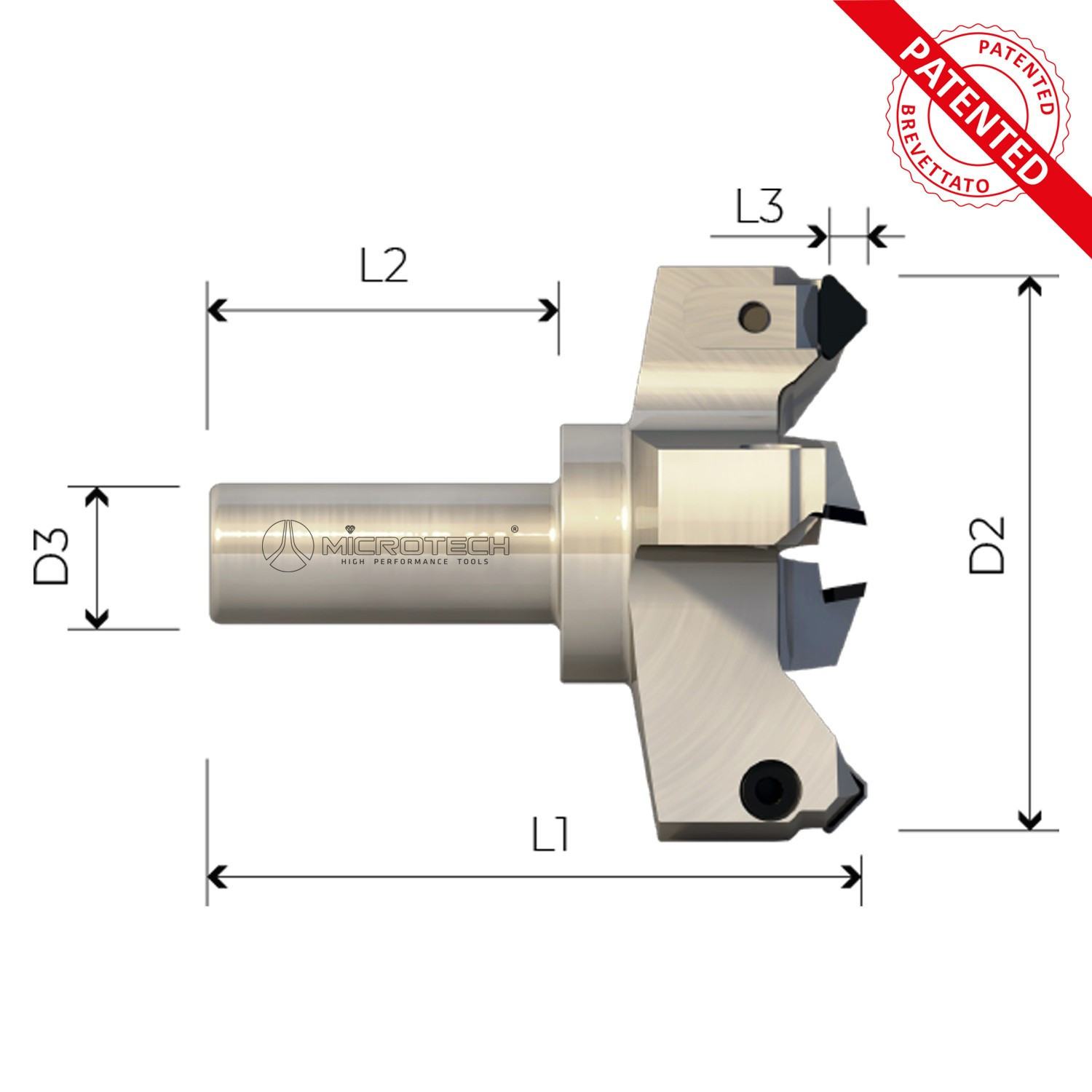

Surfacing cutter with carbide inserts designed for leveling large surfaces and machining rebates on MDF, wood and non-ferrous materials. Ensures constant flatness, stable cutting and high surface quality.

• Carbide inserts for long tool life and consistent cutting

• Ideal for spoilboard leveling and deep rebates

• Suitable for CNC routers and machining centers

High-precision PCD insert cutter designed for surfacing and leveling operations on routers and CNC machining centers. Clean cutting, stable feed and uniform finish on abrasive boards, composites and non-ferrous materials.

• Replaceable PCD inserts for consistent performance

• Fast surfacing and accurate leveling in fewer passes

• Ideal for panels, composites and non-ferrous materials

CNC surfacing cutter designed for professional surfacing and leveling operations on CNC machine tables and large panels. The indexable PCD insert design ensures stable cutting, low noise and consistent surface finish on technical materials.

• Indexable PCD inserts for extended tool life

• Accurate CNC surfacing and table leveling

• Low noise and excellent surface quality

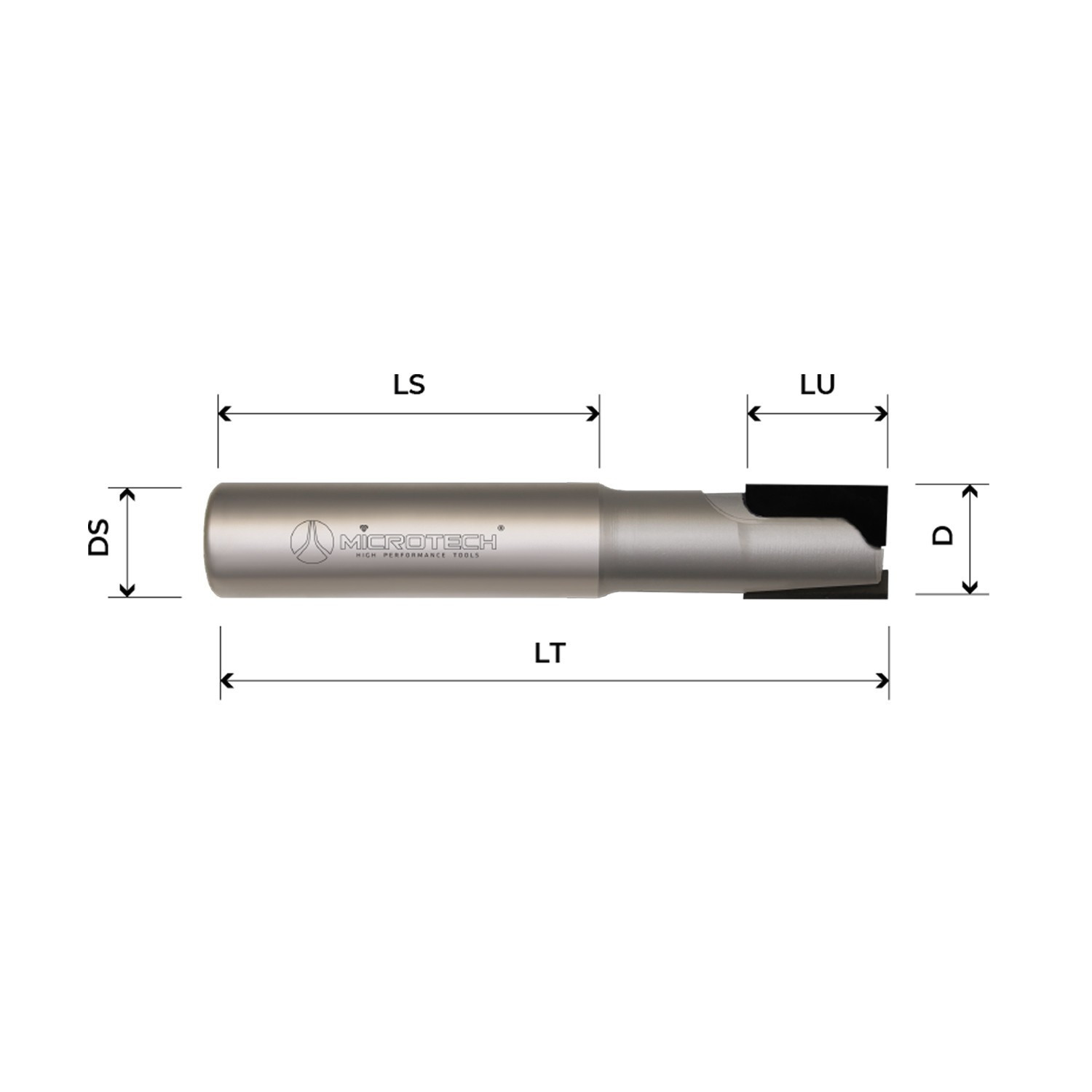

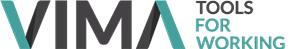

PCD diamond router bit designed for grooving, contouring and surfacing operations on CNC machines with manual or mechanical feed. The two straight Z2 cutting edges and the steel body ensure cutting stability, controlled material removal and consistent surface finish.

• PCD cutting edges H 4 mm for long tool life

• Z2 configuration for balanced and productive cutting

• Steel body for robustness and reliability

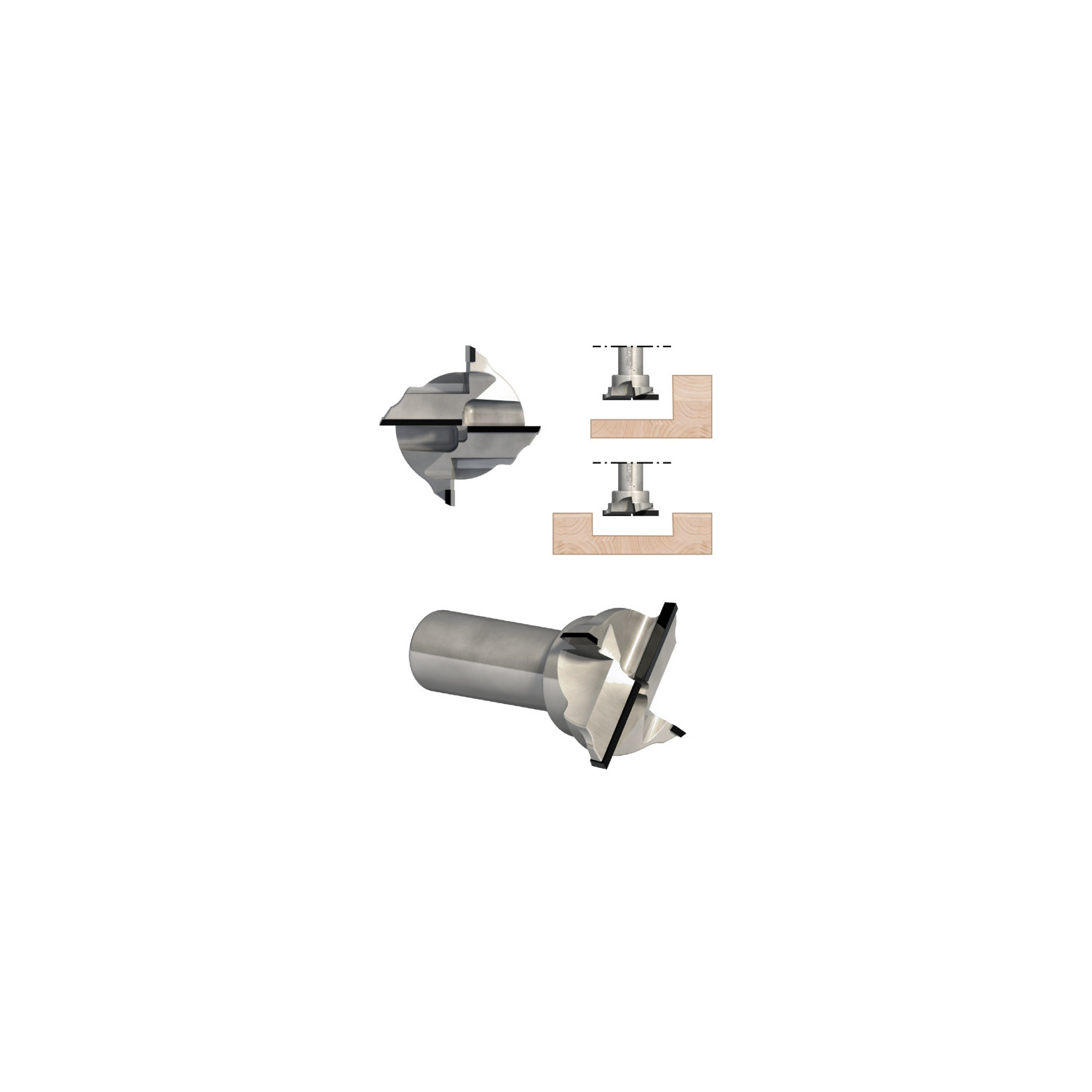

PCD diamond router bit designed for surfacing, drilling and rebate operations on coated panels and technical materials. The negative axial cutting concept and center cutting geometry improve chip control and deliver a cleaner side finish, even during continuous CNC runs.

• 4.5 mm PCD cutting edge for long tool life and high output

• Negative cutting edge for clean and stable side surfaces

• Center cutting geometry to surface and drill with accurate results

.jpg)