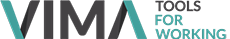

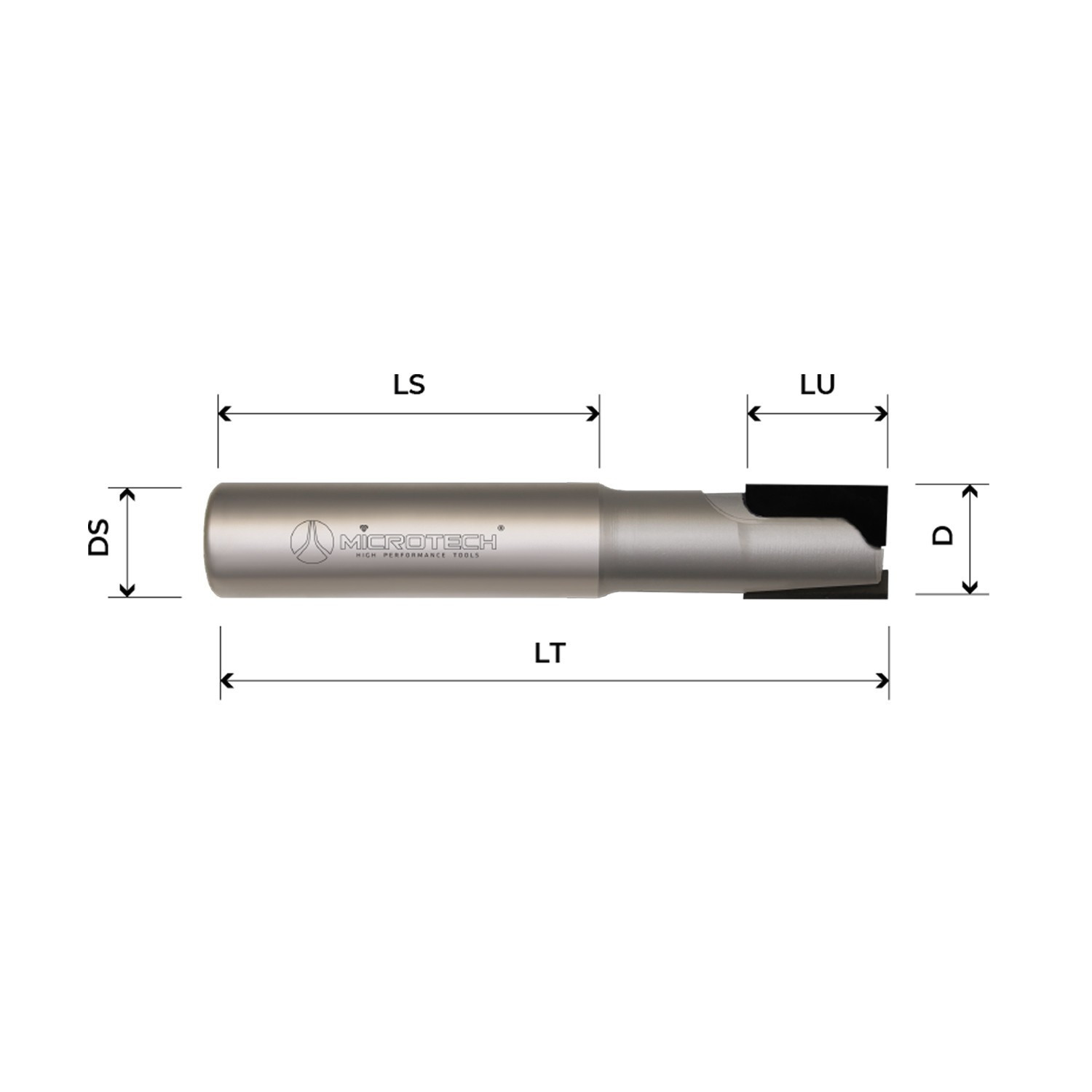

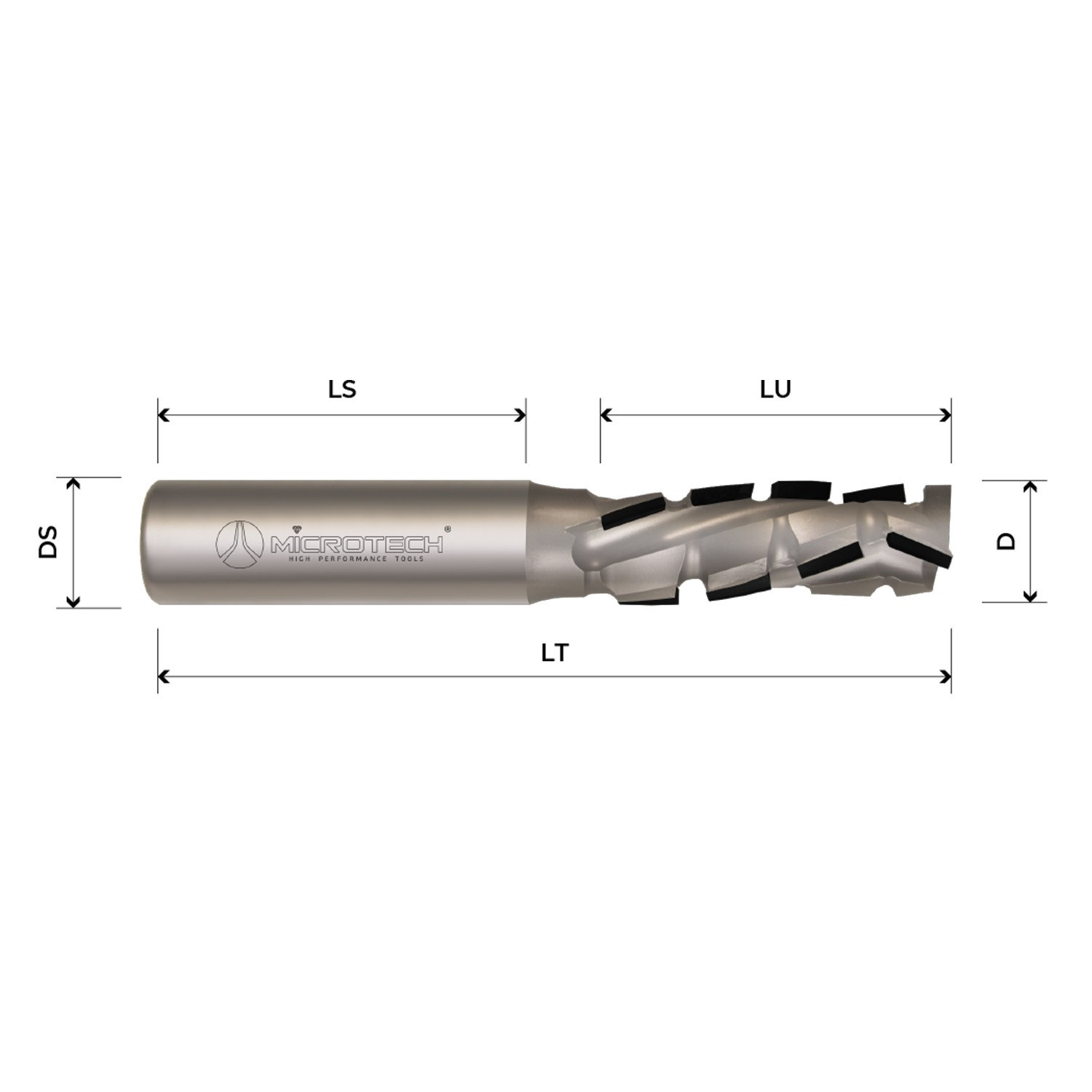

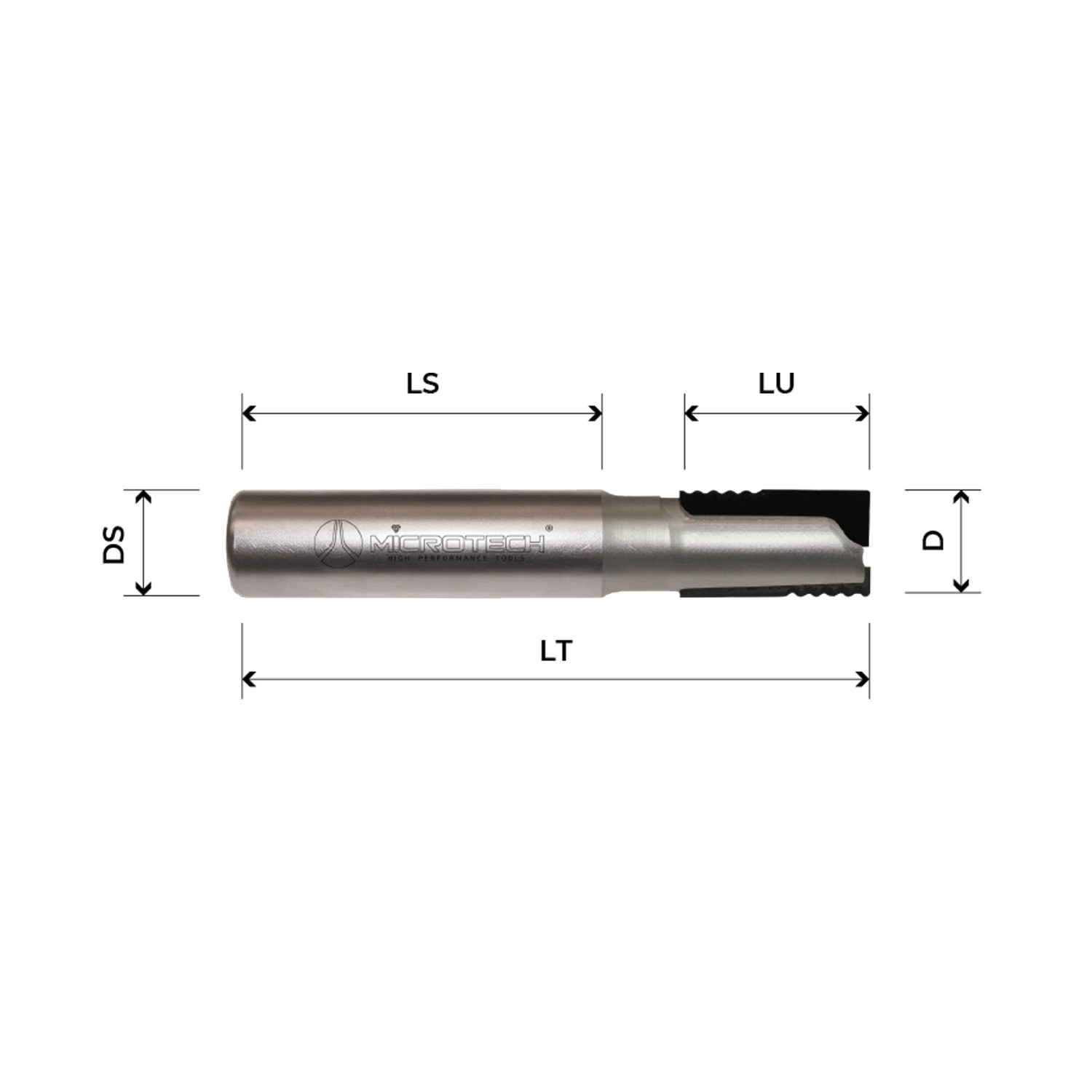

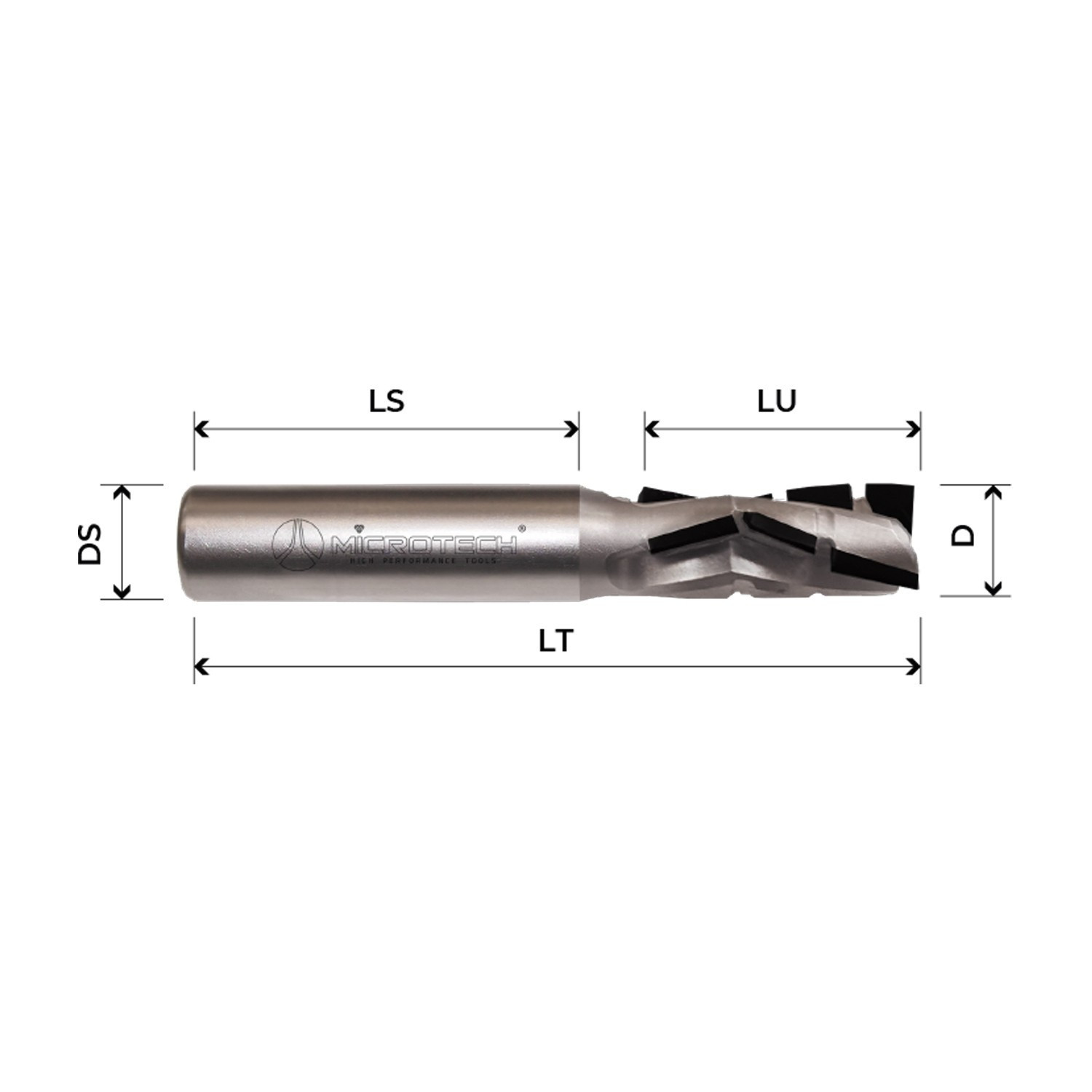

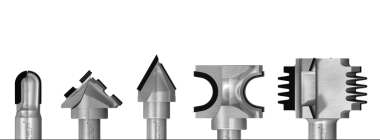

PCD diamond router bit designed for grooving operations requiring excellent surface quality on coated panels. The negative Z1 cutting edge and solid HW body ensure cutting stability, controlled material removal and clean surface finishing.

• PCD cutting edge H 3.5 mm for long service life

• Negative Z1 geometry for superior surface finish

• Solid HW body for rigidity and stability

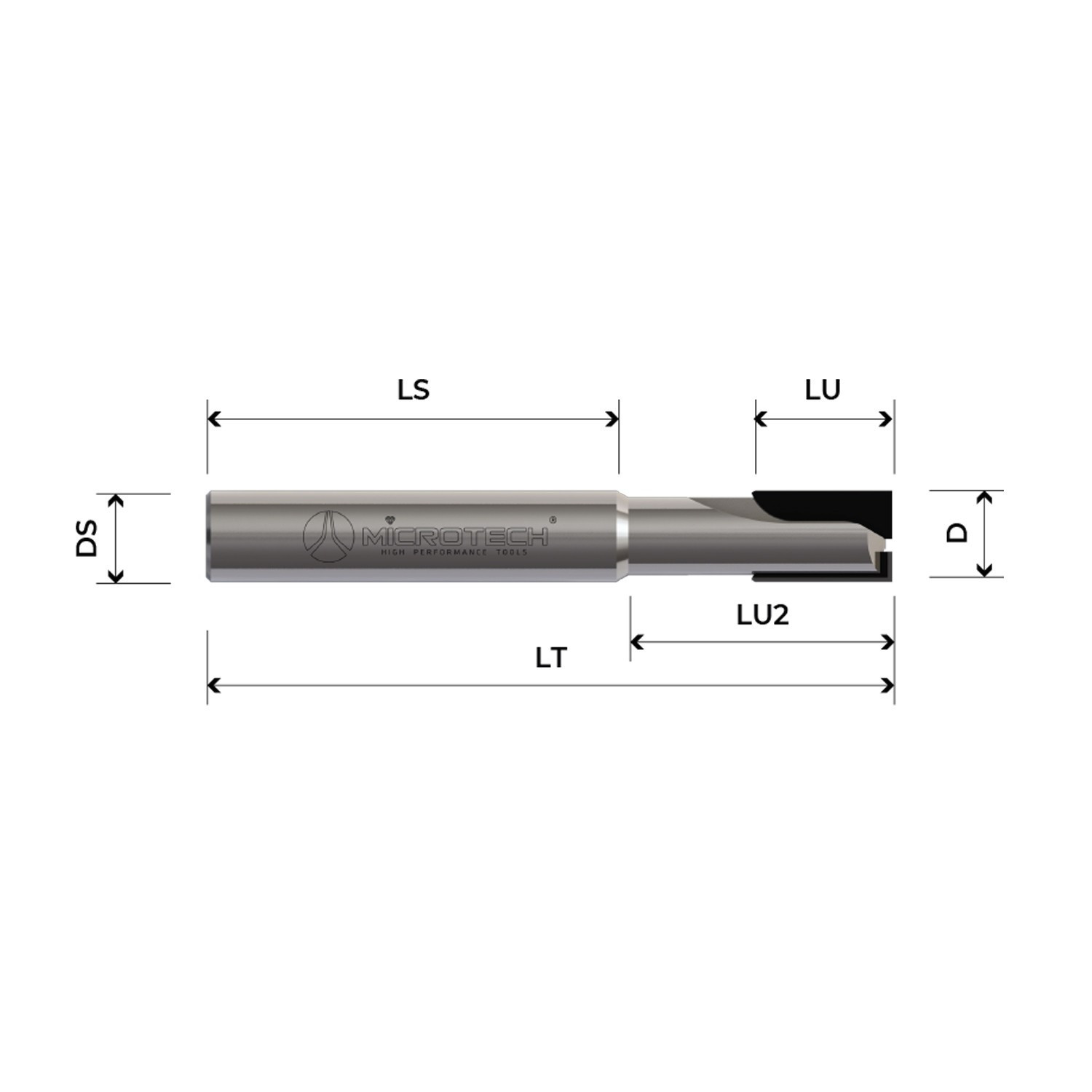

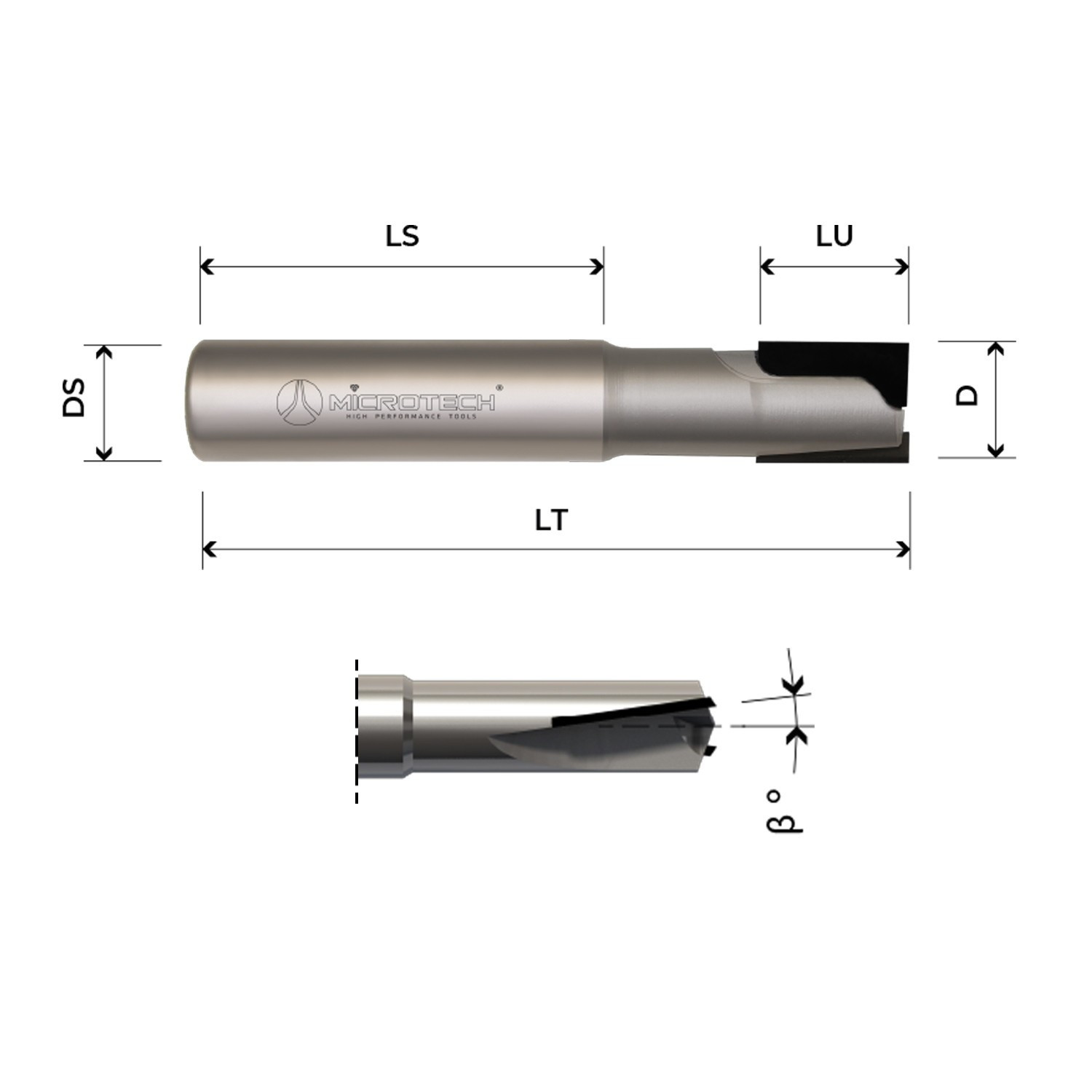

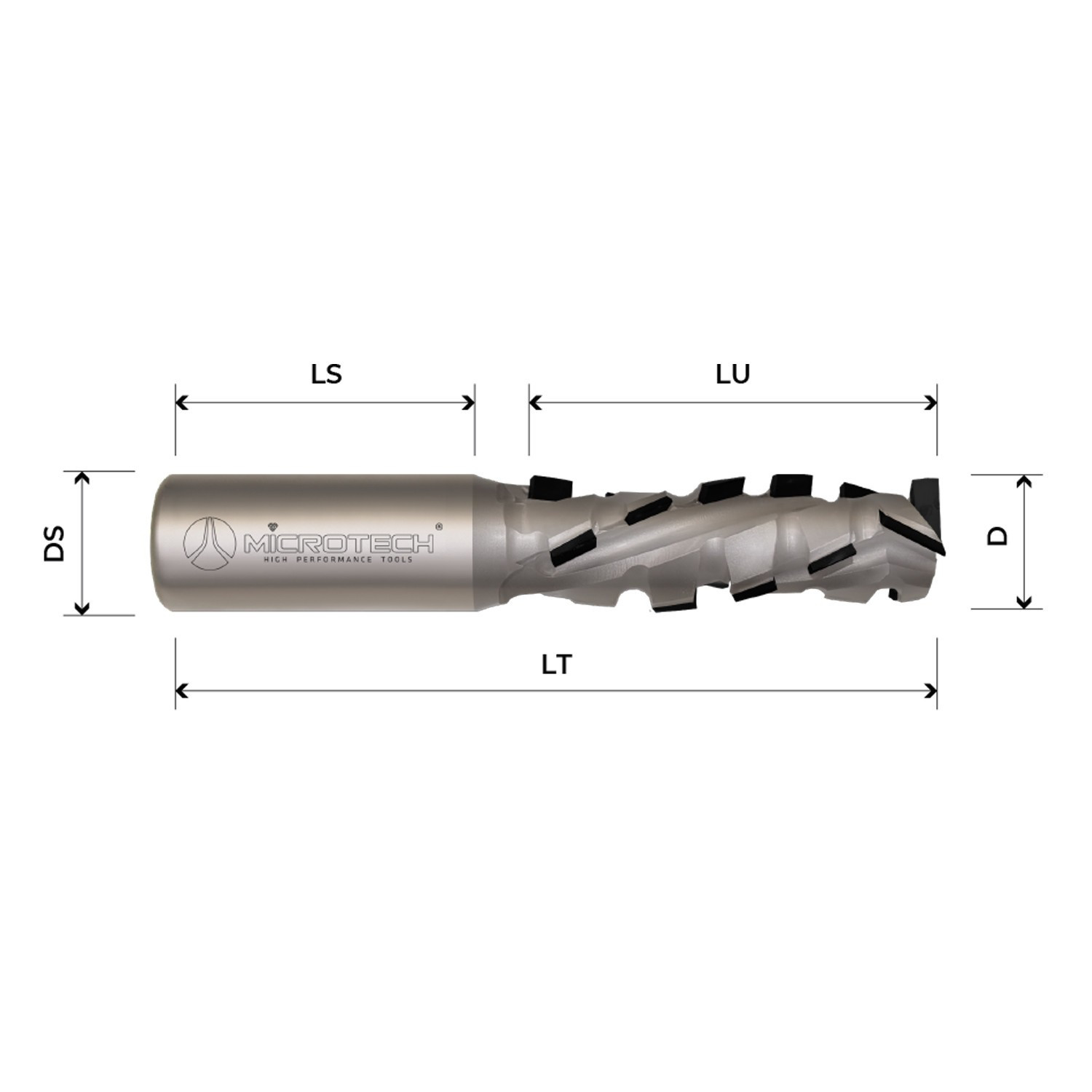

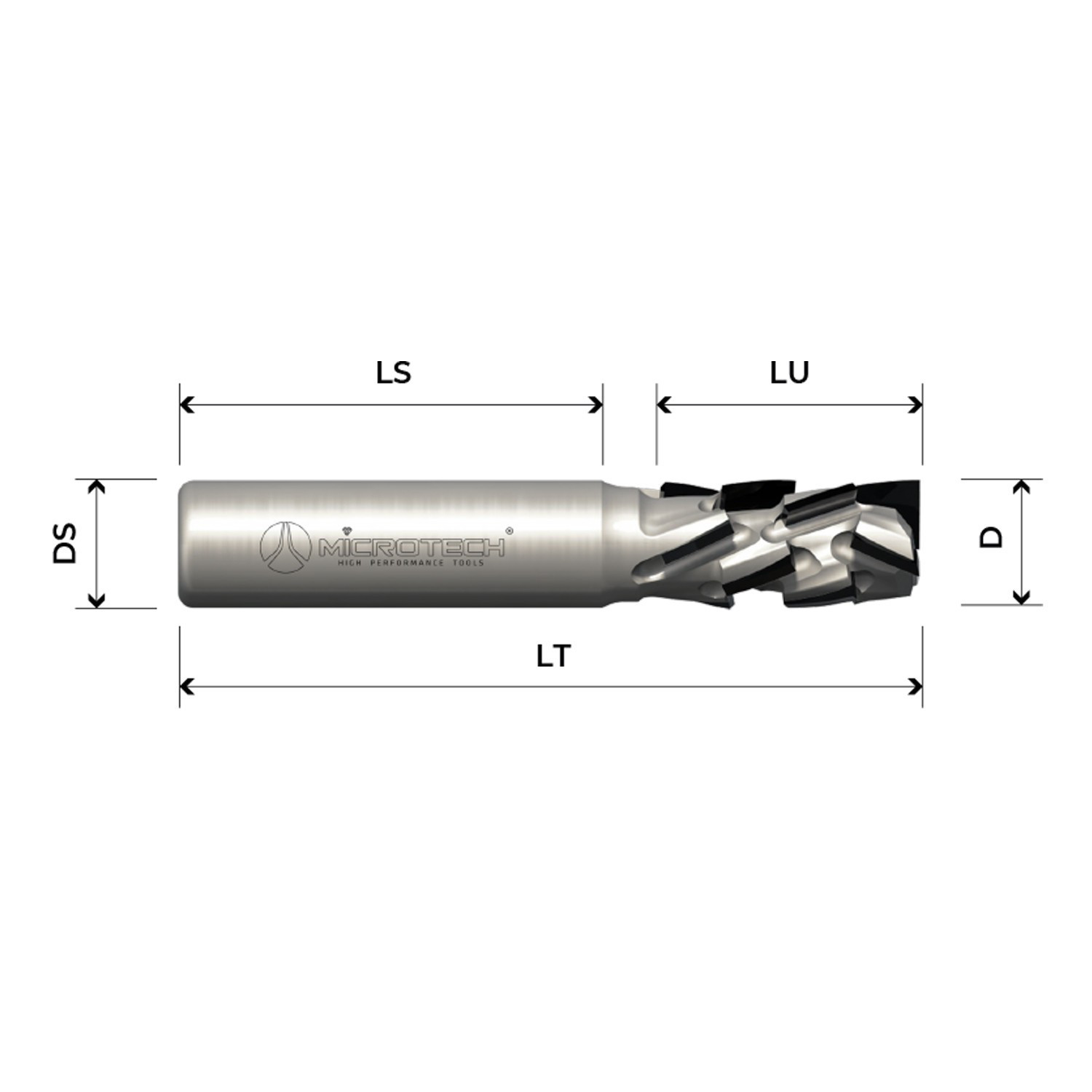

PCD diamond router bit designed for grooving and contouring operations on CNC machines with mechanical feed. The dual straight Z2 cutting edges and solid HW body ensure balanced cutting action and consistent surface quality.

• PCD cutting edges H 3.5 mm for extended durability

• Z2 configuration for higher stability and productivity

• Solid HW body for rigidity and precision

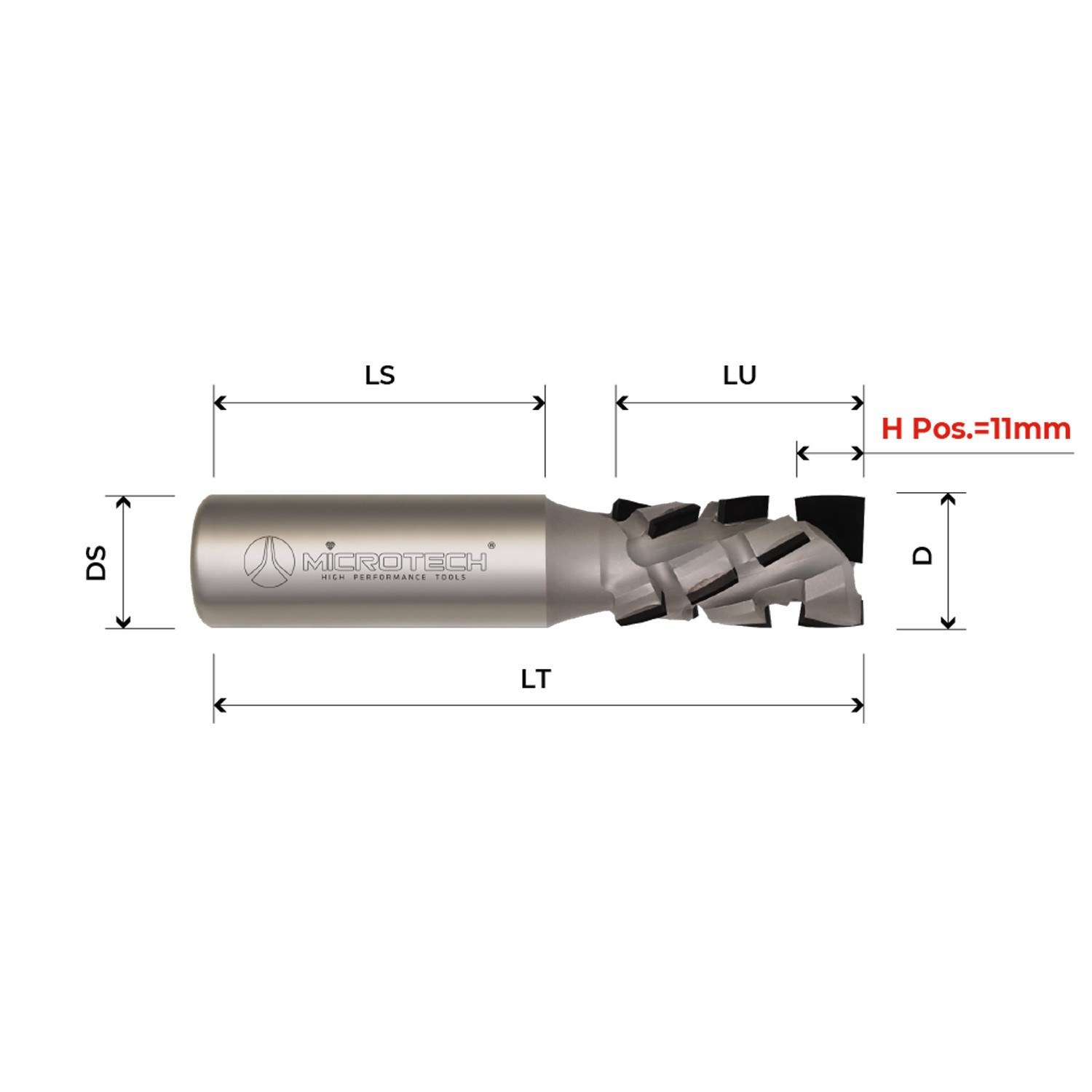

PCD diamond router bit designed for grooving operations requiring excellent surface quality on coated panels. The negative Z2 cutting edges and solid HW body ensure controlled cutting action and clean surface finishing.

• PCD cutting edges H 3.5 mm for long service life

• Negative Z2 geometry for superior surface quality

• Solid HW body for rigidity and stability

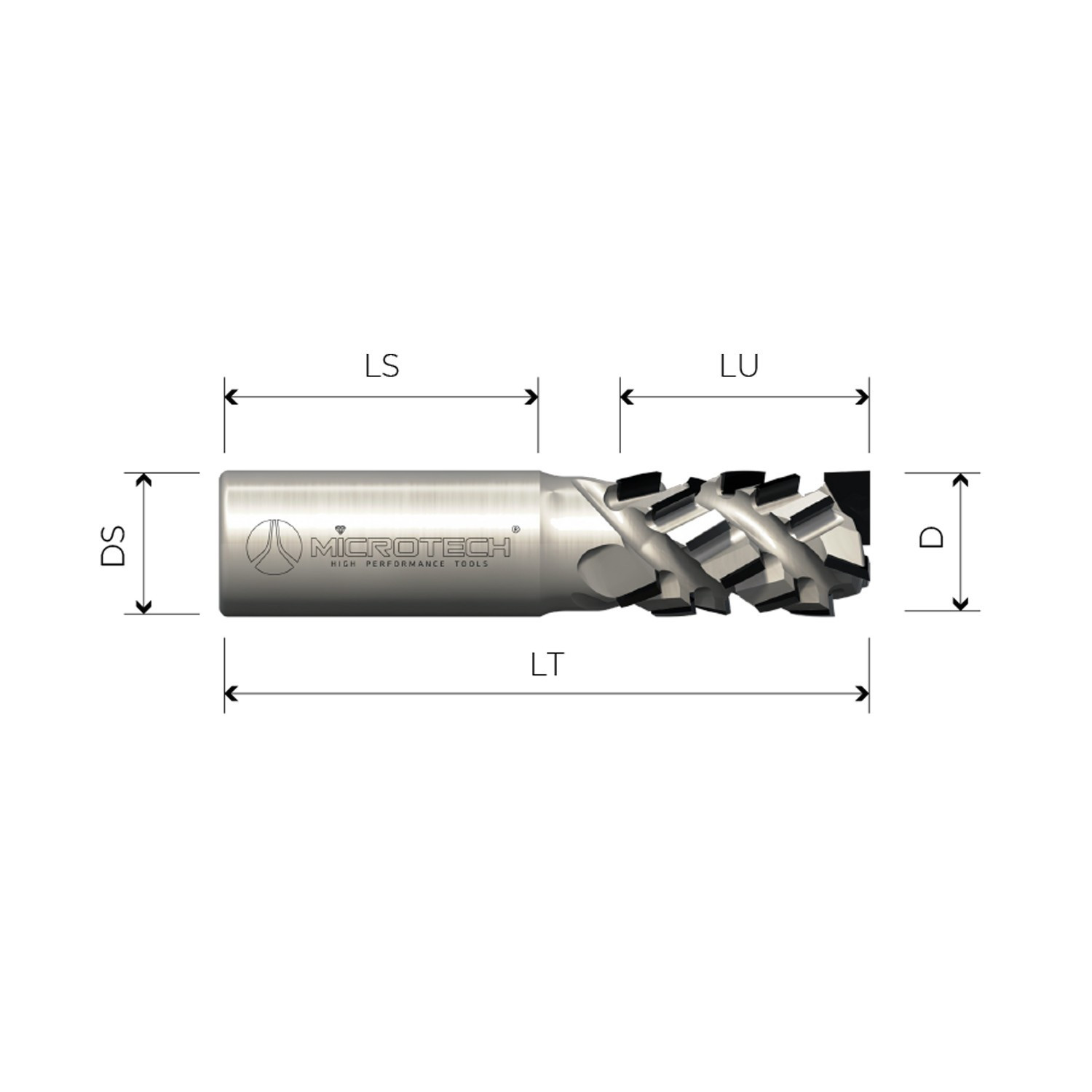

PCD diamond router bit designed for grooving, contouring and surfacing operations on CNC machines with manual or mechanical feed. The dual straight Z2 cutting edges and steel body ensure cutting stability and consistent finishing.

• PCD cutting edges H 4 mm for extended tool life

• Z2 configuration for balanced and productive cutting

• Steel body for strength and reliability

PCD diamond router bit designed for grooving operations requiring excellent surface quality on coated and laminated panels. The negative Z2 cutting edges and steel body ensure controlled cutting action and clean surface finishing.

• PCD cutting edges H 4 mm for long service life

• Negative Z2 geometry for superior surface quality

• Steel body for robustness and stability

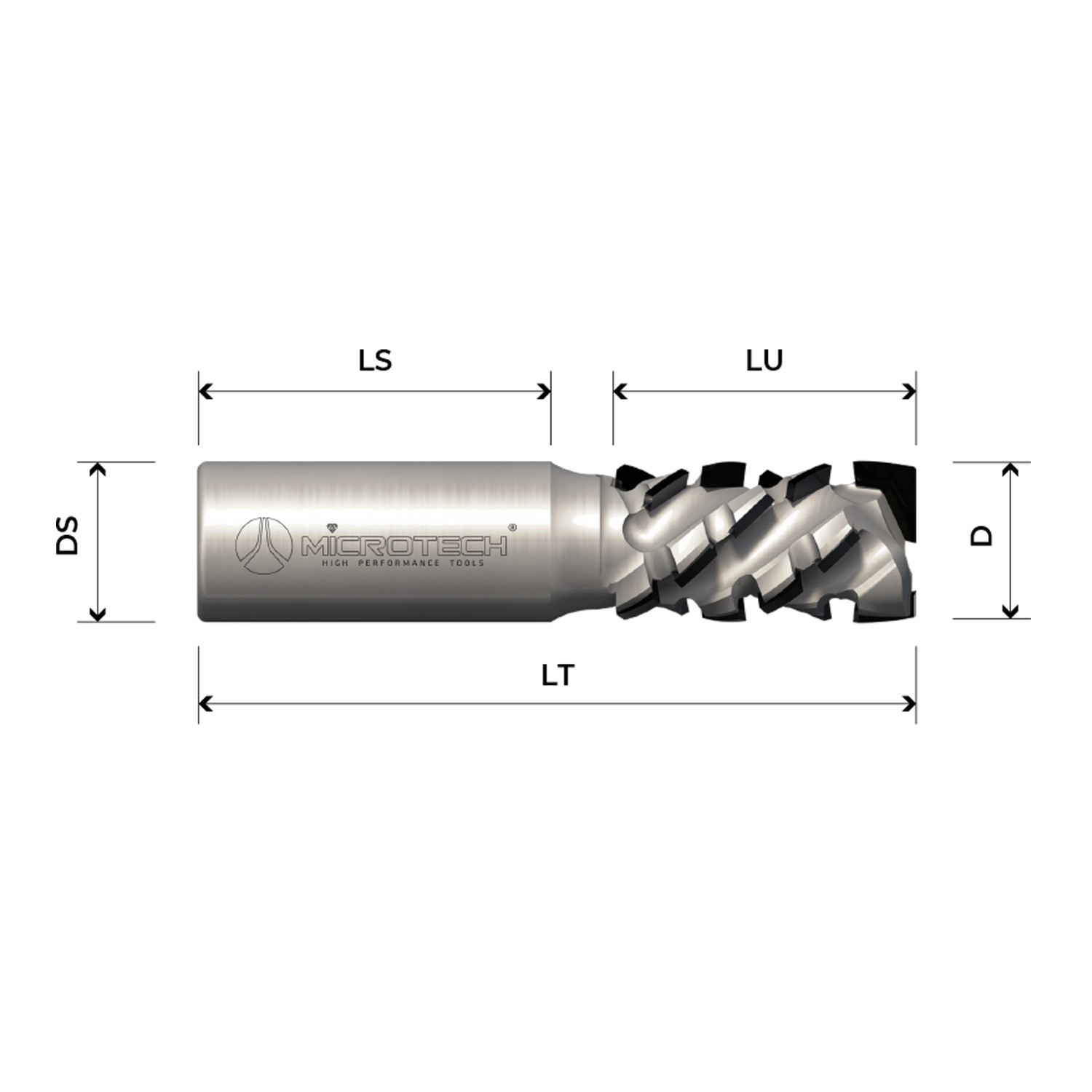

PCD helical router bit designed for contouring and grooving operations on CNC and manual machines. The Z1+1 configuration with dual helix geometry provides balanced cutting action and consistent surface finish on coated panels.

• Z1+1 helical geometry with positive and negative edges

• PCD insert H 2.5 mm, regrindable

• Suitable for laminated panels and coated MDF

PCD shank cutter Z1+1 with eco PCD tips H2,5 mm resharpened up to 3 times three helicoidal wing, firt tip positive all the others negative, plunge tip in HW, steel body.

PCD shank cutter Z1+1 with eco PCD tips H4,5 mm resharpened up to 8 times three helicoidal wing, firt tip positive all the others negative, plunge tip in HW steel body. Suitable for working on chipboard panels, playwood, laminated, solid wood and MDF.

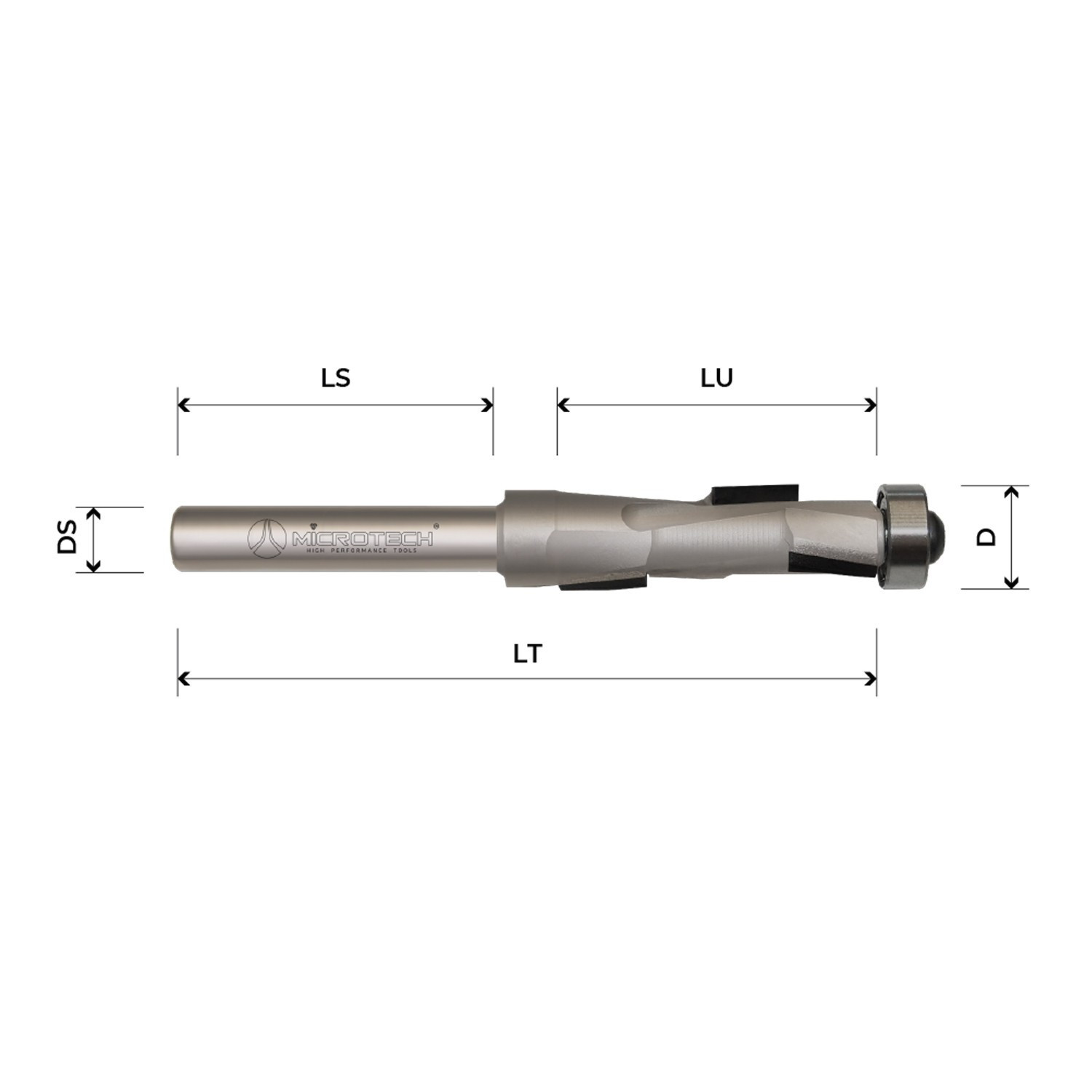

PCD shank cutter Z1+1 with copy bearing, eco PCD tips H2,5 mm resharpened up to 3 times three helicoidal wing, firt tip positive all the others negative. Suitable for working on chipboard panels, playwood, laminated, solid wood and MDF.

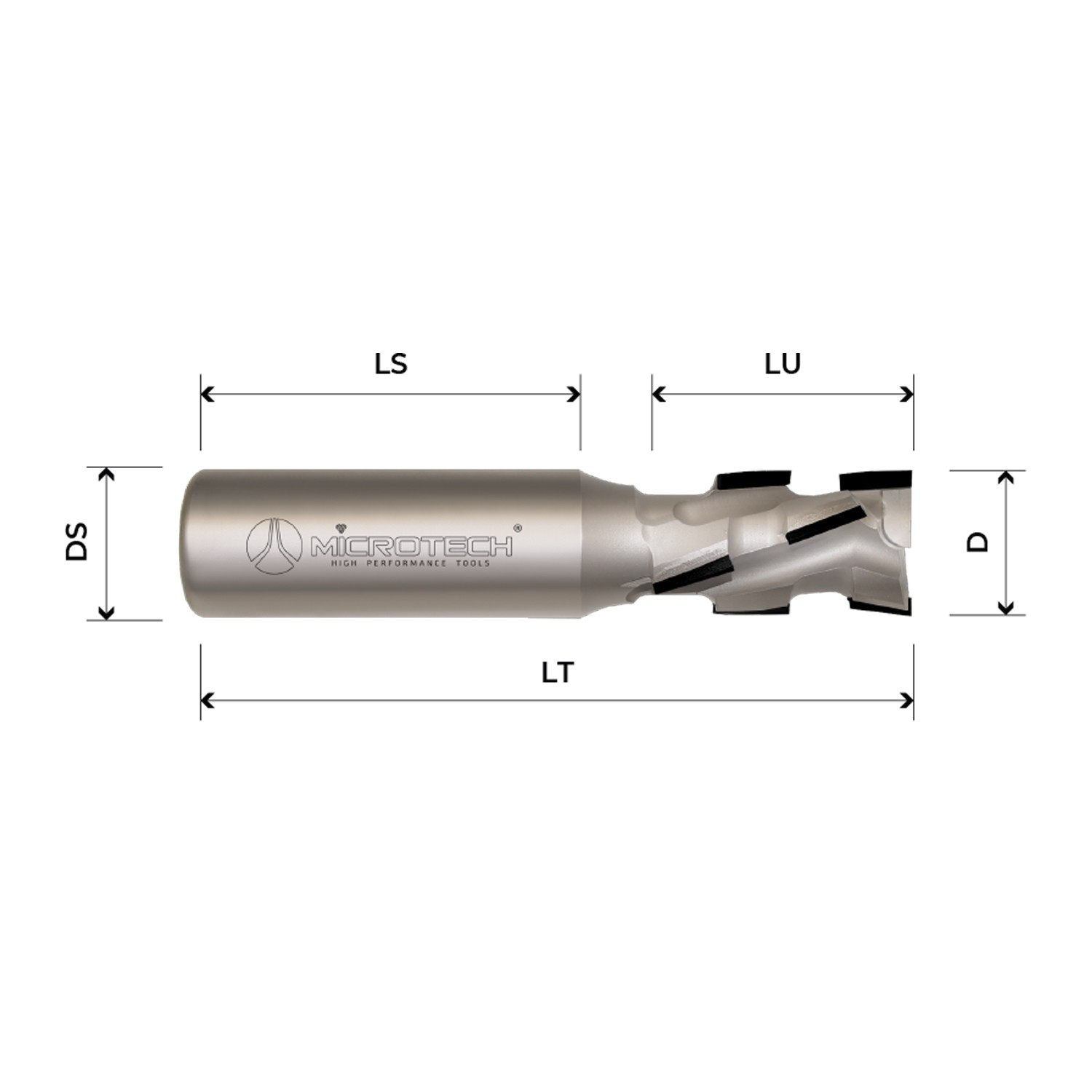

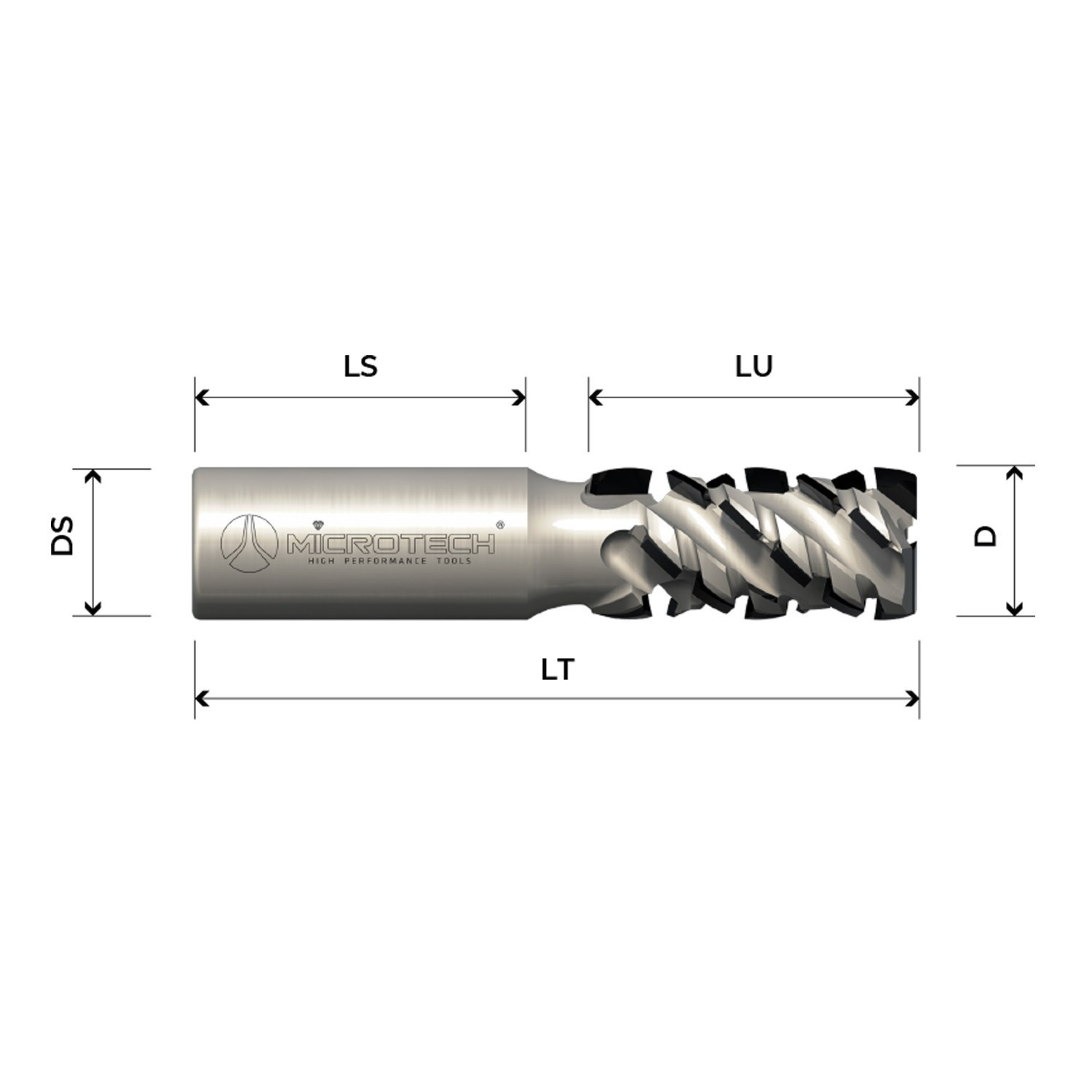

PCD shank cutter Z2+2 with PCD tips H2,5 mm, 4 helicoidal wing, firt tip positive all the others negative, plunge tip in HW steel body cutting angle 20°. Suitable for working on chipboard panels, playwood, laminated, solid wood and MDF.

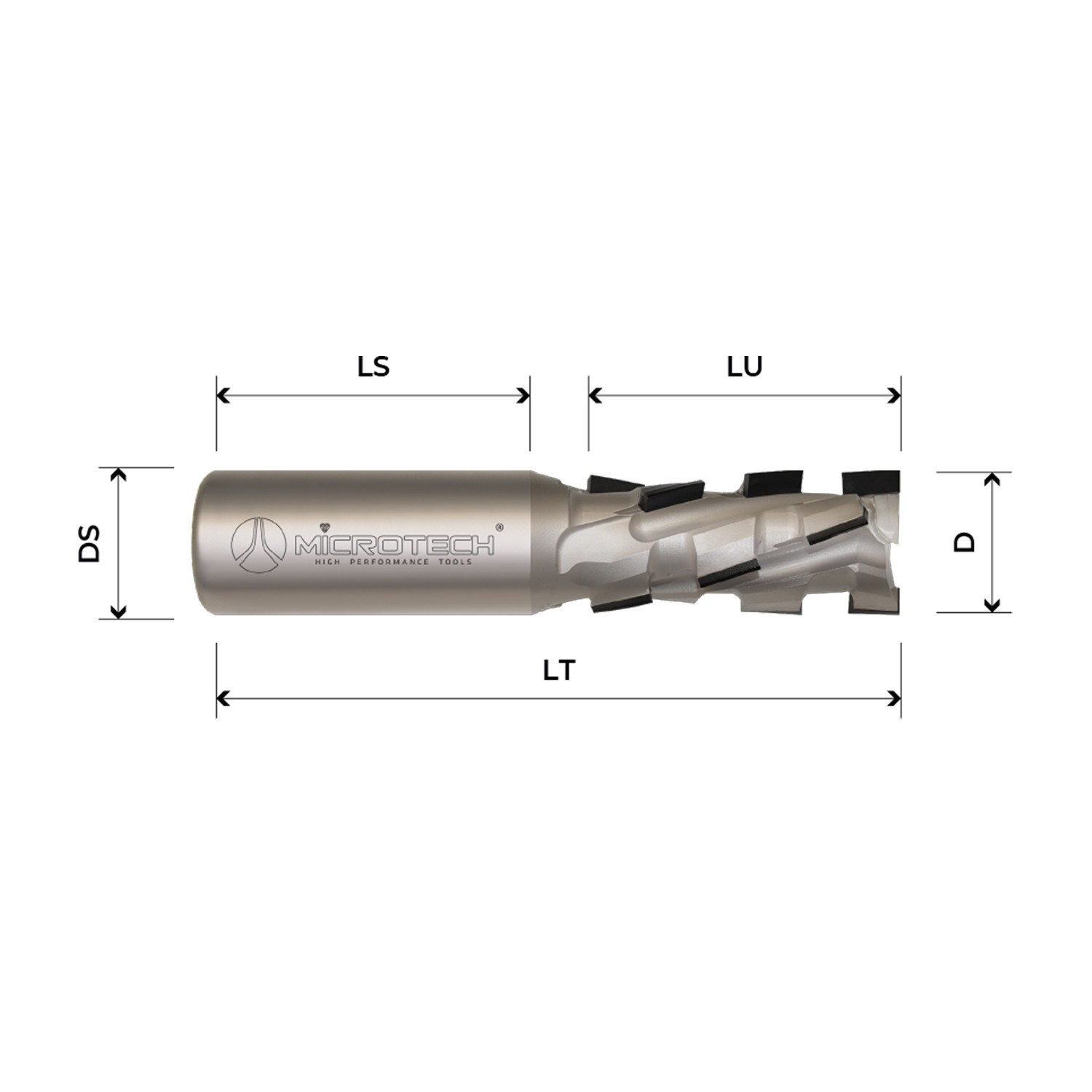

PCD shank cutter Z2+2 with PCD tips H4,5 mm resharpened up to 8 times four helicoidal wing, firt tip positive all the others negative, plunge tip in HW steel body cutting angle 20°. Suitable for working on chipboard panels, playwood, laminated, solid wood, MDF and polymers.

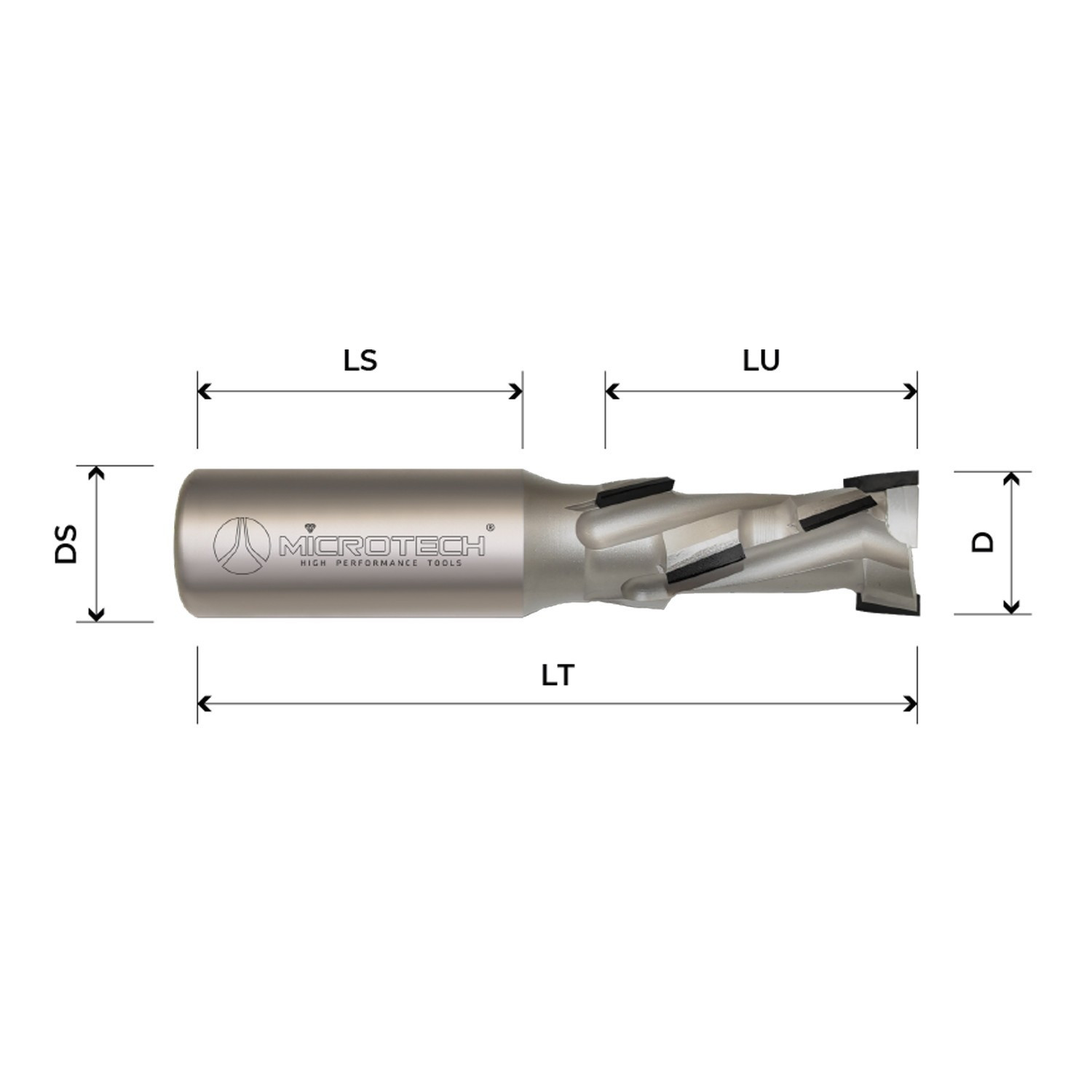

PCD shank cutter Z2+2 on top and bottom part Z1+1 in the midle part with PCD tips H2,5 mm resharpened up to 3 times four helicoidal wing, firt tip positive all the others negative, plunge tip in HW, steel body cutting angle 20°. Suitable for working on chipboard panels, playwood, laminated, solid wood, MDF and polymers.

PCD shank cutter Z2+2 with eco PCD tips H2,5 mm resharpened up to 3 times three helicoidal wing , firt tip positive all the others negative, plunge tip in HW,cutting angle 20° steel body. Suitable for working on chipboard panels, laminated, solid wood, MDF and polymers.

PCD shank cutter Z2+2 with PCD tips H4,5 mm resharpened up to 8 times three helicoidal wing, firt tip positive all the others negative, plunge tip in PCD, cutting angle 20° steel body. Suitable for working on chipboard panels, laminated, solid wood, MDF and polymers.

PCD shank cutter Z3+3 with PCD tips H4,5 mm resharpened up to 8 times three helicoidal wing, firt tip positive all the others negative, plunge tip in PCD, cutting angle 20° steel body. Suitable for working on chipboard panels, laminated, solid wood and MDF.

PCD shank cutter Z2+2 with PCD tips H4,5 mm resharpened up to 8 times four helicoidal wing, firt tip positive all the others negative, plunge tip in PCD, cutting angle 30° steel body. Suitable for working on chipboard panels, playwood, laminated, solid wood and MDF.

PCD shank cutter Z3+3 with PCD tips H4,5 mm resharpened up to 8 times four helicoidal wing, firt tip positive all the others negative, plunge tip in PCD, cutting angle 30° steel body. Suitable for working on chipboard panels, playwood, laminated, solid wood and MDF.

PCD shank cutter Z2+2 with PCD tips H4,5 mm resharpened up to 8 times four helicoidal wing, firt tip positive all the others negative, plunge tip in PCD, cutting angle 45° steel body. Suitable for working on chipboard panels, playwood, laminated, solid wood and MDF.

PCD shank cutter Z2+2 with PCD tips H4,5 mm resharpened up to 8 times four helicoidal wing, tip mainly positive for better evaquaton of wooden chips, plunge tip in PCD, cutting angle 30° steel body. Suitable for working on chipboard panels, playwood, laminated, solid wood and MDF.

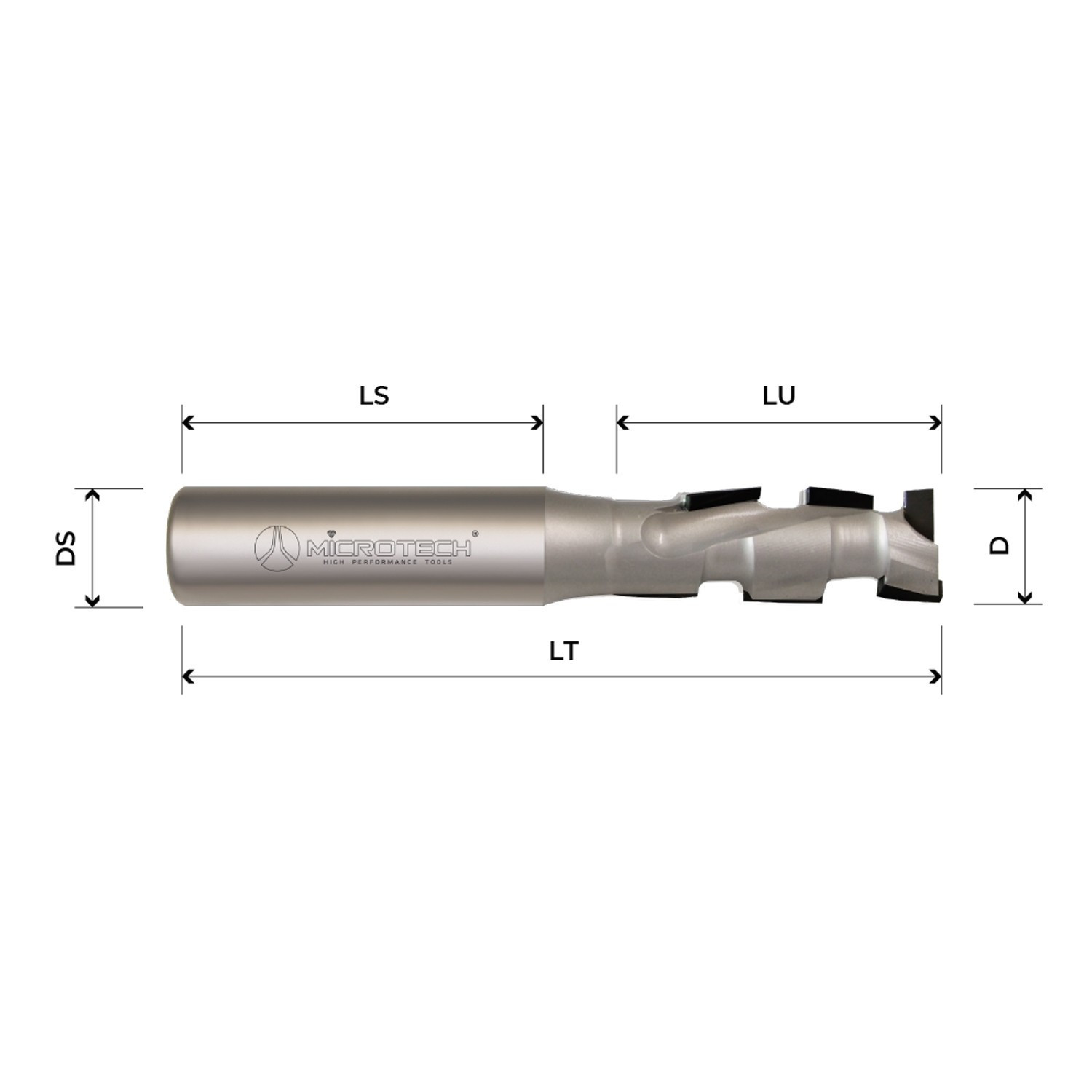

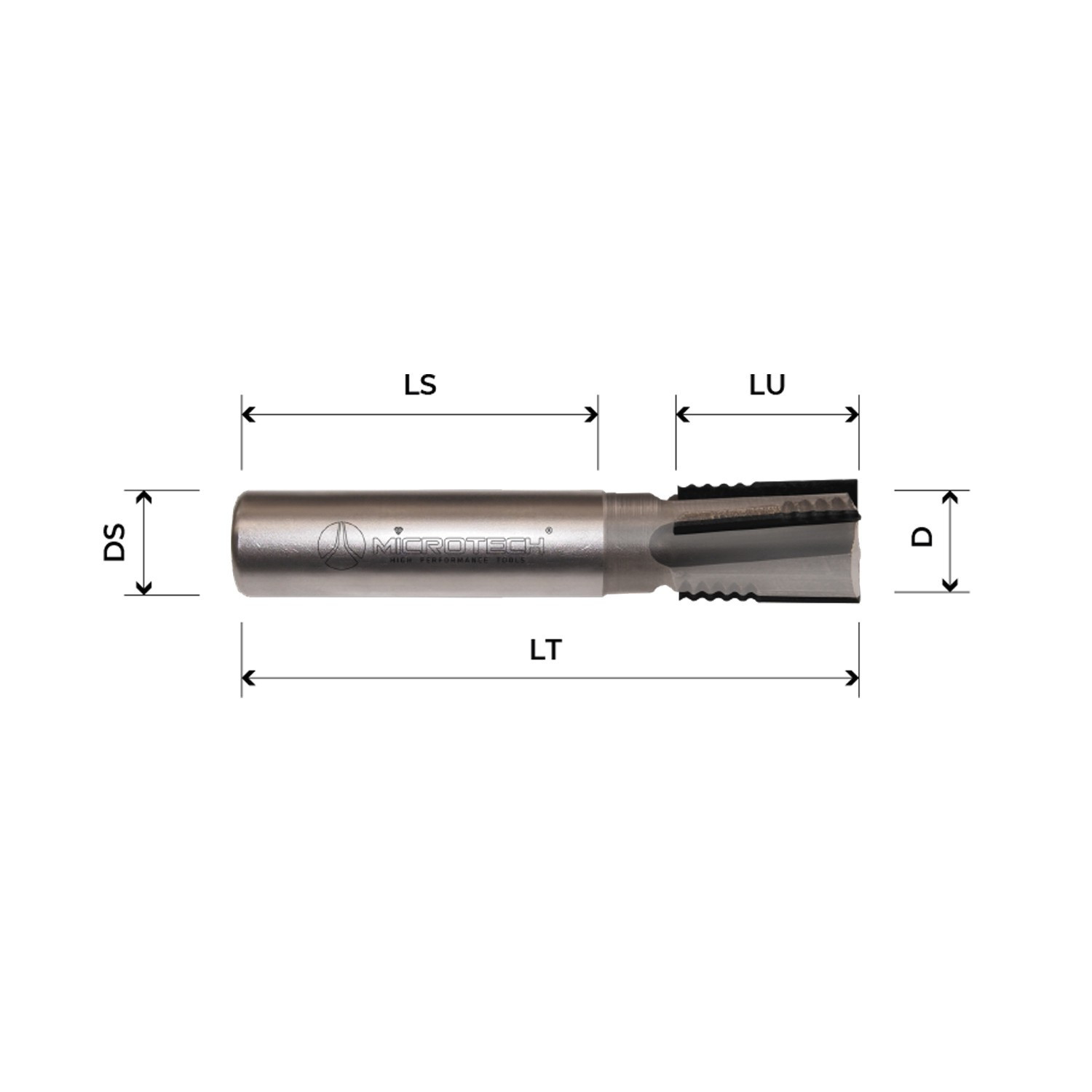

PCD diamond router bit designed for nesting and contouring operations on compact and abrasive materials. The alternating positive and negative cutting edges with chipbreaker provide combined roughing and finishing in a single pass.

• PCD cutting edges H 3.5 mm with alternating Z2 geometry

• Chipbreaker design for roughing and finishing

• Heavy HDM body for maximum stability

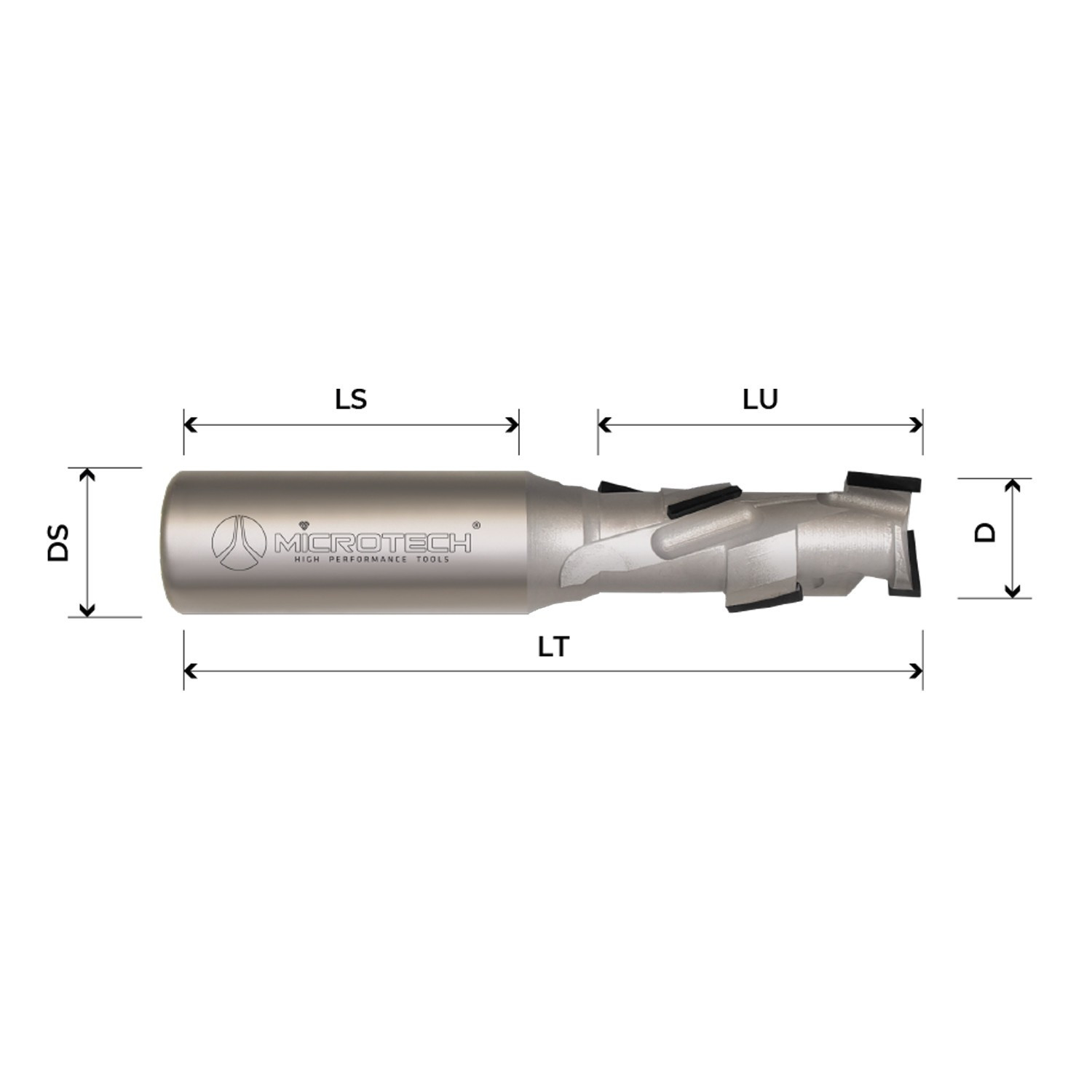

PCD router bit designed for high-speed nesting and contouring on CNC machines. The Z4 chipbreaker configuration with alternating positive and negative cutting edges ensures excellent chip evacuation, cutting stability and superior surface finish on technical materials.

• Z4 PCD chipbreaker cutting edges for high productivity

• Heavy-duty HDM body for maximum rigidity

• Ideal for CNC nesting and precision contouring

PCD shank cutter Z2+2 for nesting, with PCD tips H3,5 mm resharpened up to 3 times, two helicoidal wing, firt tip positive all the others negative, plunge tip in PCD, cutting angle 25°, HDM (High density metal) and steel body.

Re-sharpening shank cutter with split tips on three helicoidal wings, three engaged cutters on top and bottom parts, mainly negative helix, HDM body, PCD H3,5 mm. Tool suitable for nesting operation, cutters positive/negative, high working speed, good evaquation of chips, excellent finishing and low noise.

Re-sharpening shank cutter with split tips on three helicoidal wings, three engaged cutters on top and bottom parts, mainly positive helix, HDM (High density metal) body, PCD H3,5 mm. Tool suitable for nesting, cutters positive/negative, high working speed, good evaquation of chips, excellent finishing and low noise.

Re-sharpening shank cutter with split tips on six helicoidal wings, three engaged cutters on top and bottom parts, mainly negative helix, HDM (High density metal) body, PCD 3,5 mm. Tool suitable for nesting operation on chipboard panels laminate, coated or on MDF, OSB, cutters positive/negative, high working speed, good evaquation of chips, excellent finishing and low noise.

.jpg)