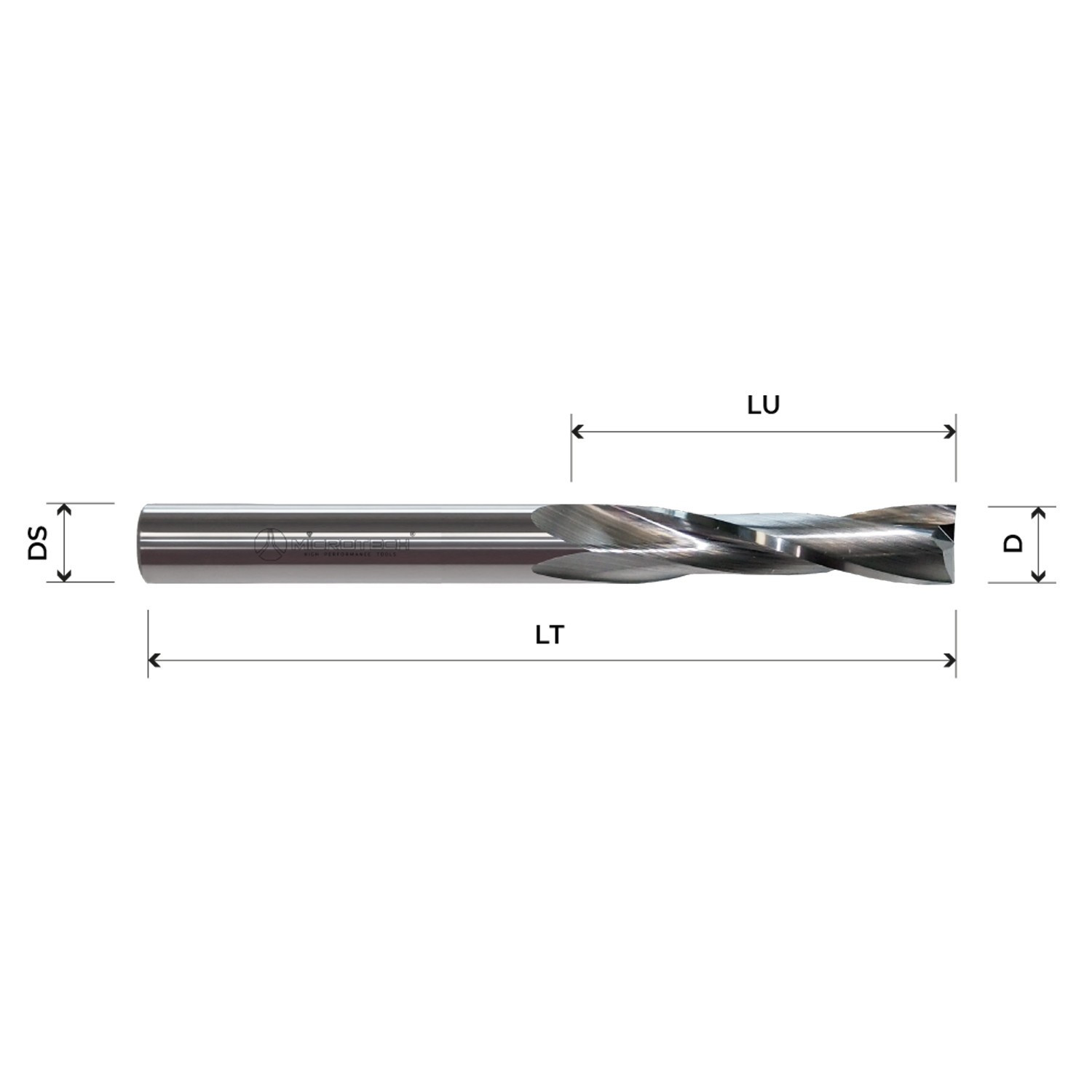

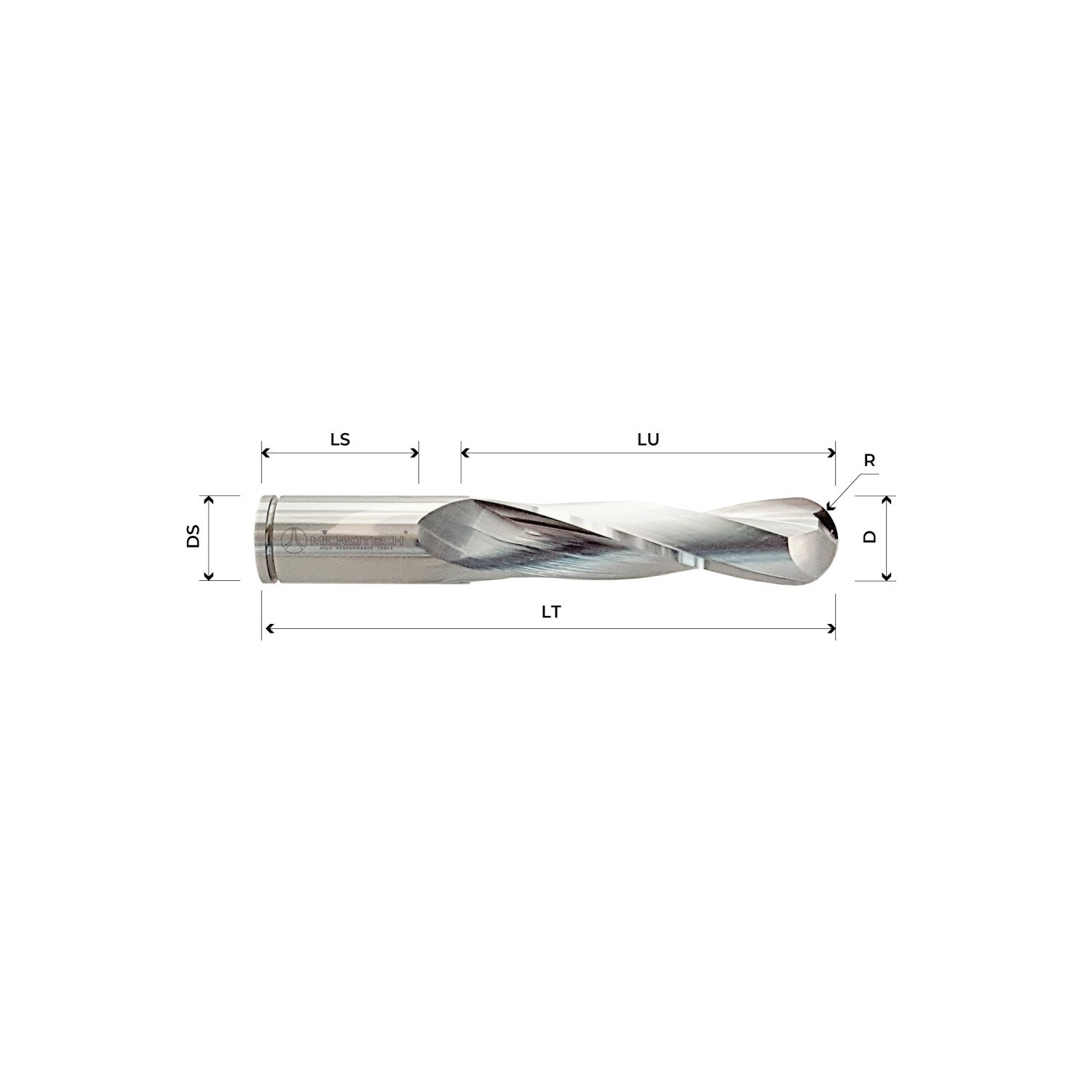

HW helical end mill with 1 flute and a positive Z1 cutting geometry, designed for grooving and shank profiling on CNC routers with mechanical feed. The positive helix promotes smooth chip evacuation and helps deliver a consistent surface finish while reducing vibration and material build-up on non-ferrous jobs.

• Single-flute HW Z1 edge for smooth cutting and clean sidewalls

• Positive helix for steady chip evacuation and less material welding

• Ideal for grooving and profiling on CNC machines with mechanical feed

HW helical end mill with a single flute and negative Z1 cutting geometry, designed for profiling and grooving with shank on CNC routers. The negative helix improves cutting control and helps prevent material lifting, delivering cleaner edges on coated and laminated panels.

• HW negative Z1 edge for controlled cutting and clean finishes

• Negative helix to reduce chipping on laminated materials

• Ideal for profiling and grooving on CNC routers

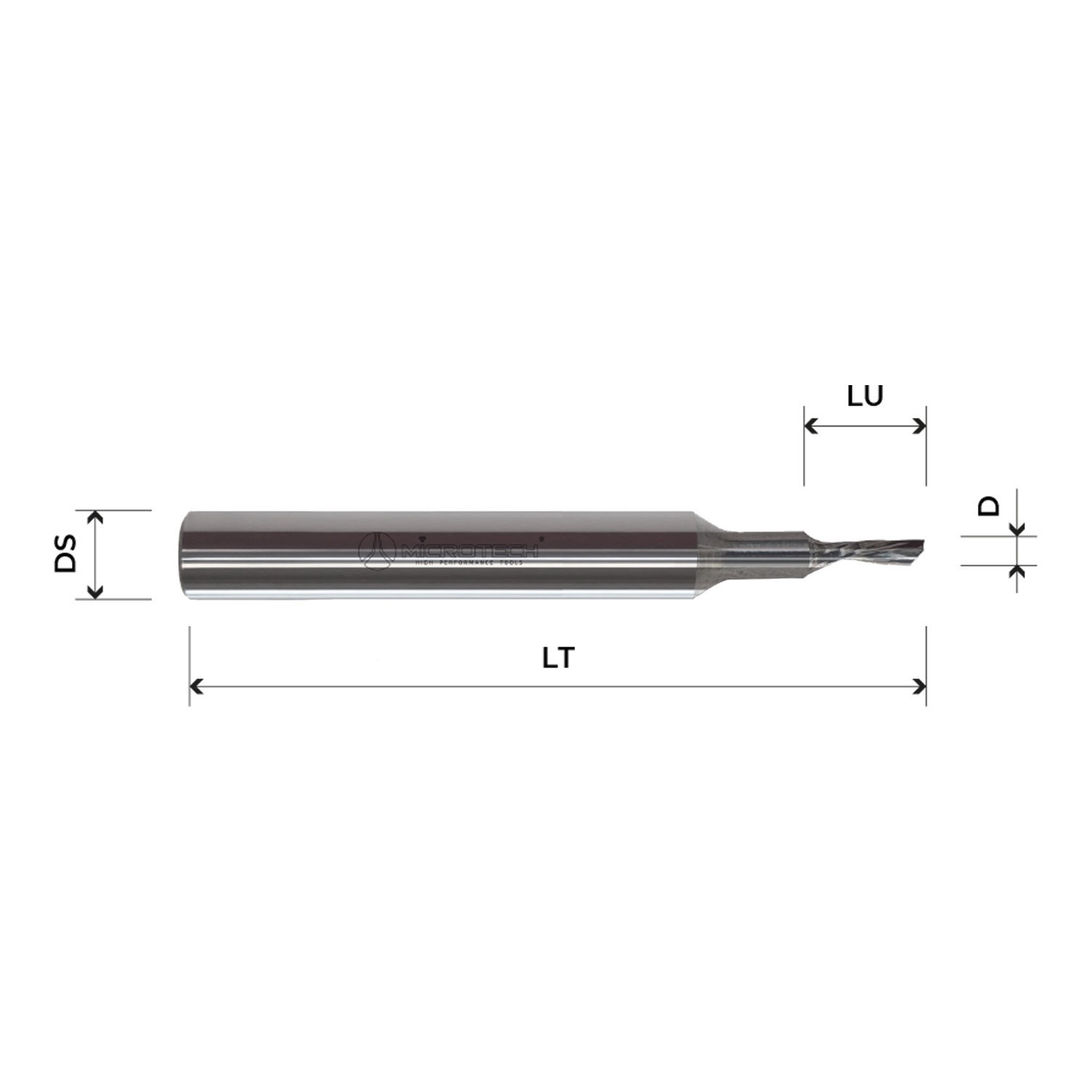

HW helical end mill with 2 flutes and a positive Z2 cutting geometry, designed for profiling, cutting and shaping with shank on CNC routers. The positive helix promotes smooth chip flow and stable cutting behaviour, ensuring consistent surface quality across a wide range of materials.

• Positive Z2 HW cutting edge for smooth and accurate cutting

• Two flutes for improved stability and controlled material removal

• Ideal for profiling, cutting and shaping on CNC machines

HW helical end mill with 2 flutes and a negative Z2 cutting geometry, designed for profiling cutting and shaping with shank on CNC machines. The negative helix improves cutting control and surface quality, reducing fibre lifting on coated and composite panels.

• Negative Z2 HW cutting edge for clean surfaces

• Two flutes for improved stability and control

• Ideal for profiling cutting and shaping on CNC

HW helical cutter with positive Z3 cutting edges designed for contouring, cutting and shaping operations on solid wood, wood based panels and plastic materials. The positive helix geometry ensures smooth cutting action, reduced cutting forces and improved surface finish even during continuous machining.

• HW Z3 cutting edges for clean and consistent finish

• Positive helix for efficient chip evacuation

• Ideal for CNC routers and mechanical feed systems

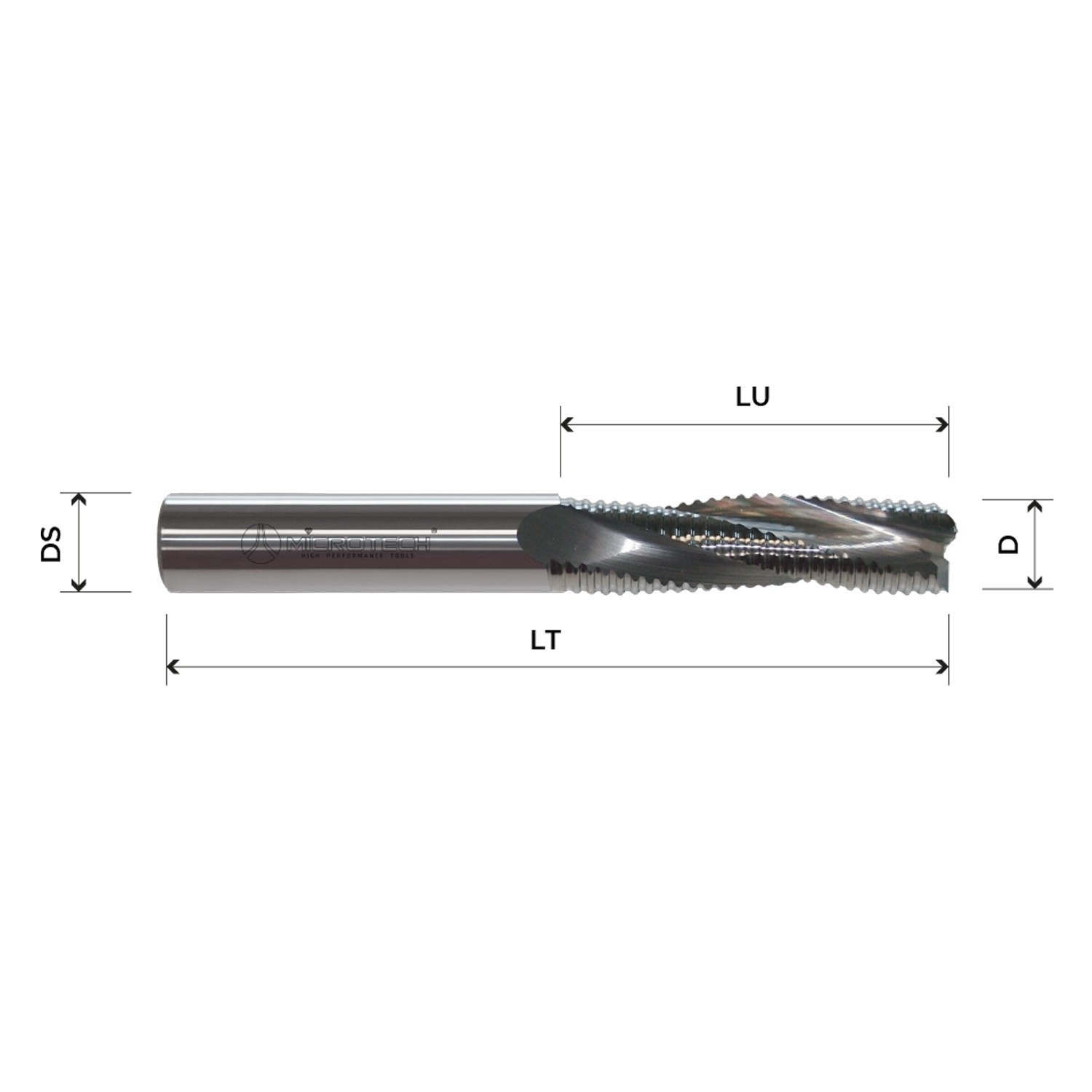

HW helical cutter with positive Z3 cutting edges and integrated chipbreaker designed for contouring, cutting and shaping operations on solid wood, wood based panels and plastic materials. The positive helix combined with the chipbreaker ensures controlled chip evacuation, smooth cutting action and consistent surface quality.

• HW Z3 cutting edges with chipbreaker for stable cutting

• Positive helix for efficient chip evacuation

• Ideal for CNC pantograph routers with mechanical feed

HW helical cutter with negative Z3 cutting edges designed for contouring, cutting and shaping operations on solid wood and wood based panels. The negative helix improves process control, helps reduce chipping on laminated surfaces and provides stable cutting performance with mechanical feed.

• HW Z3 cutting edges with negative helix for cleaner edges

• Better control and stability on laminated panels

• Ideal for CNC routers and pantographs up to 24,000 rpm

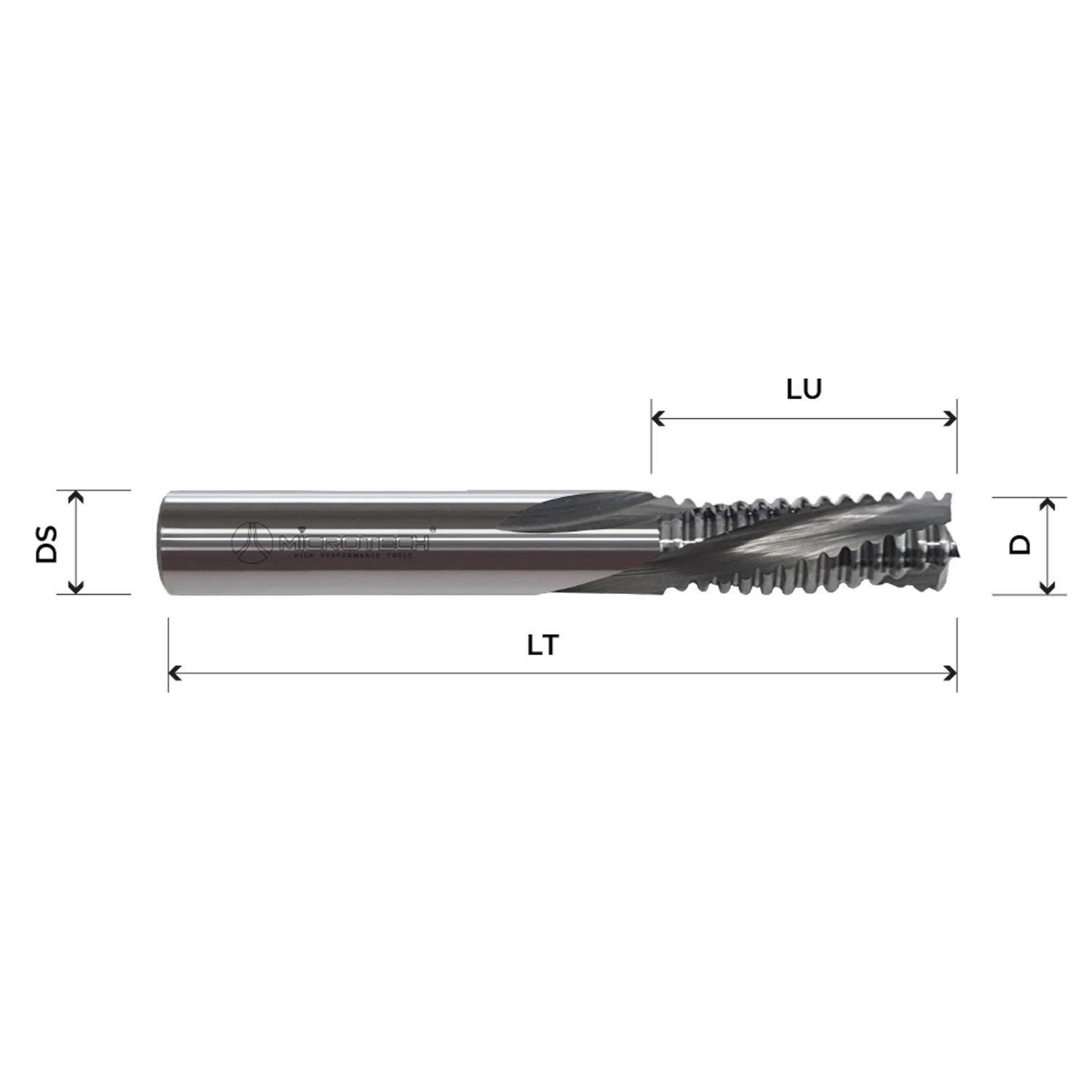

HW helical cutter with negative Z3 cutting edges and integrated chipbreaker designed for contouring, cutting and shaping on solid wood, wood based panels and plastic materials. The negative helix helps reduce chipping on laminated surfaces, while the chipbreaker improves chip control and cutting stability.

• HW Z3 cutting edges with negative helix for cleaner edges

• Integrated chipbreaker for chip control and stable cutting

• Ideal for CNC pantographs with mechanical feed

HW helical cutter with positive Z3 cutting edges designed for machining lock mortises on doors and windows on CNC machines. The positive geometry provides smooth cutting and effective chip evacuation, delivering clean mortise walls even on laminated boards and sized wood components.

• Positive HW Z3 cutting edges for accurate mortises

• Ideal for door and window lock pockets

• Efficient chip evacuation with mechanical feed

HW helical cutter with positive Z3 cutting edges and integrated chipbreaker designed for lock mortises on doors and windows on CNC machines. The positive geometry provides smooth cutting and efficient chip evacuation, while the chipbreaker improves chip control and machining stability even on laminated boards.

• Positive HW Z3 cutting edges for accurate mortises

• Integrated chipbreaker for chip control and stable cutting

• Ideal for door and window lock pockets

HW helical cutter with negative Z3 cutting edges designed for lock mortises on doors and windows on CNC machines. The negative helix improves top edge quality, reducing chipping and ensuring cleaner finishes on laminated boards and coated panels.

• Negative HW Z3 cutting edges for clean top edges

• Ideal for door and window lock mortises

• Stable cutting performance in CNC machining

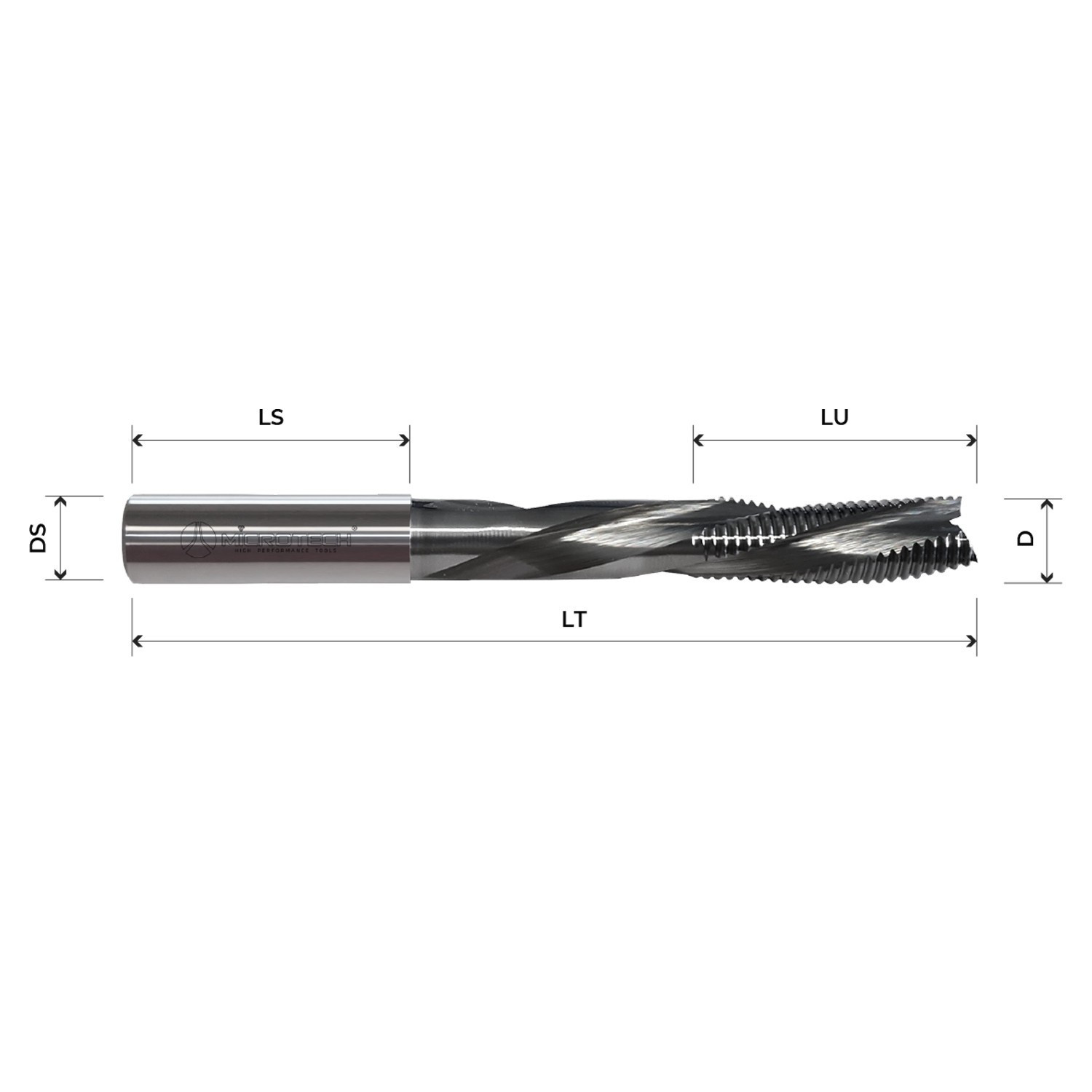

Carbide helical cutter with negative Z3 geometry and integrated chipbreaker, developed for precise lock mortising on doors and windows. The negative helix ensures clean surfaces, high stability and excellent chip control on laminated and wood based materials.

• Integrated chipbreaker for controlled chip evacuation

• Negative Z3 cutting geometry for stable finishing

• Ideal for door and window lock mortising

Coated carbide helical cutter with up down Z2+2 geometry, developed for high speed nesting applications on wood based panels and composite materials. Provides clean finishing on both top and bottom surfaces with long tool life.

• Up down Z2+2 geometry for double side finishing

• Coated carbide for extended durability

• Ideal for high speed nesting operations

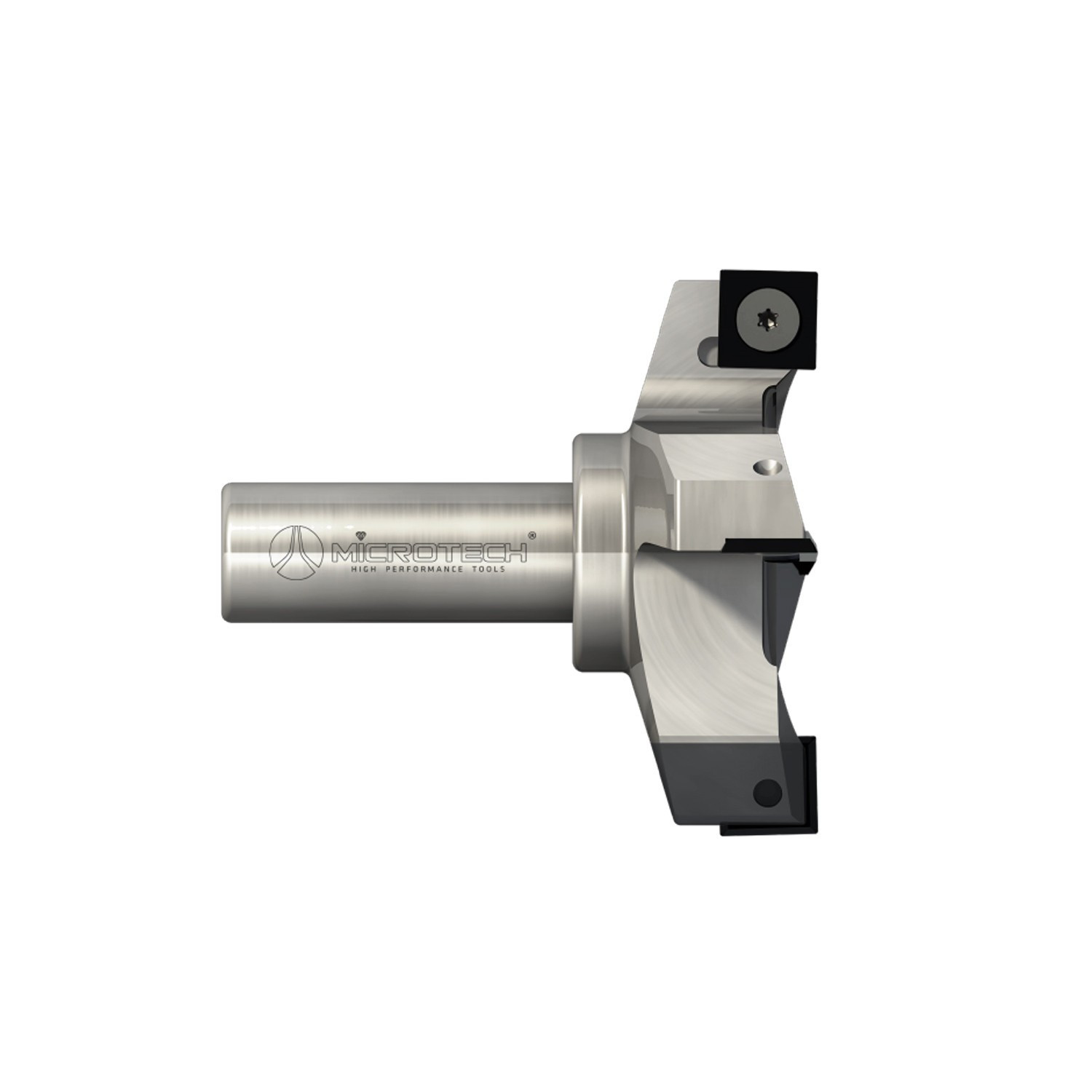

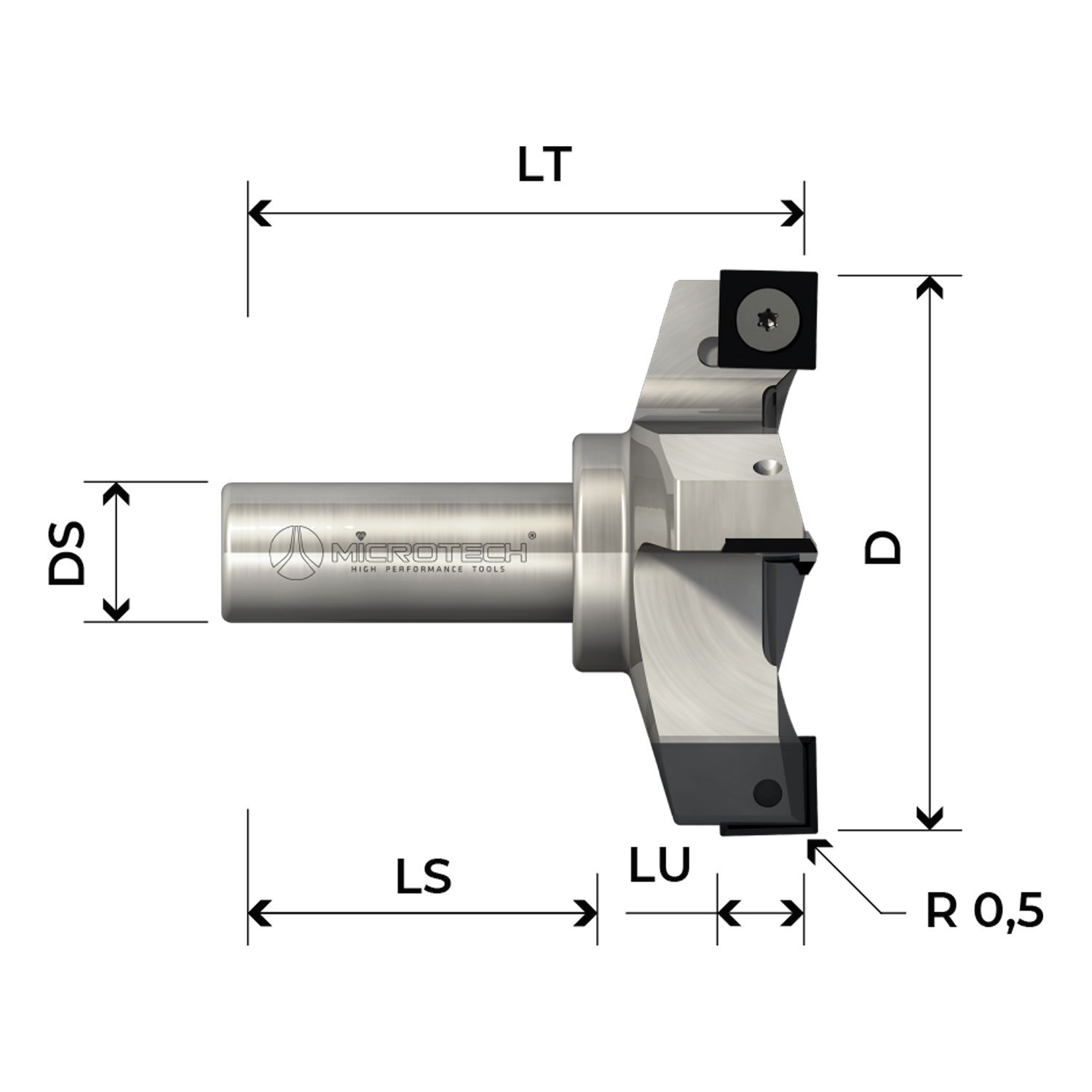

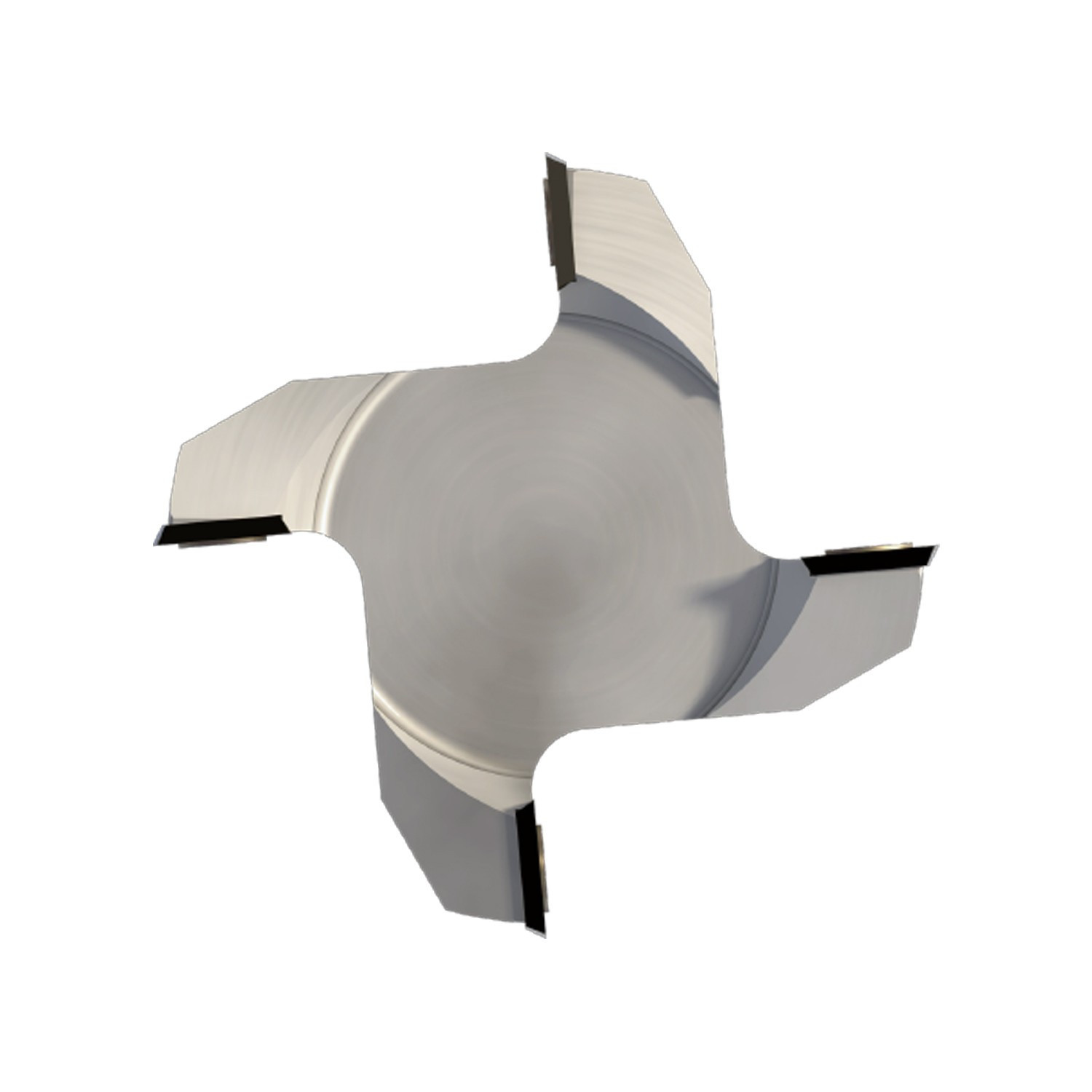

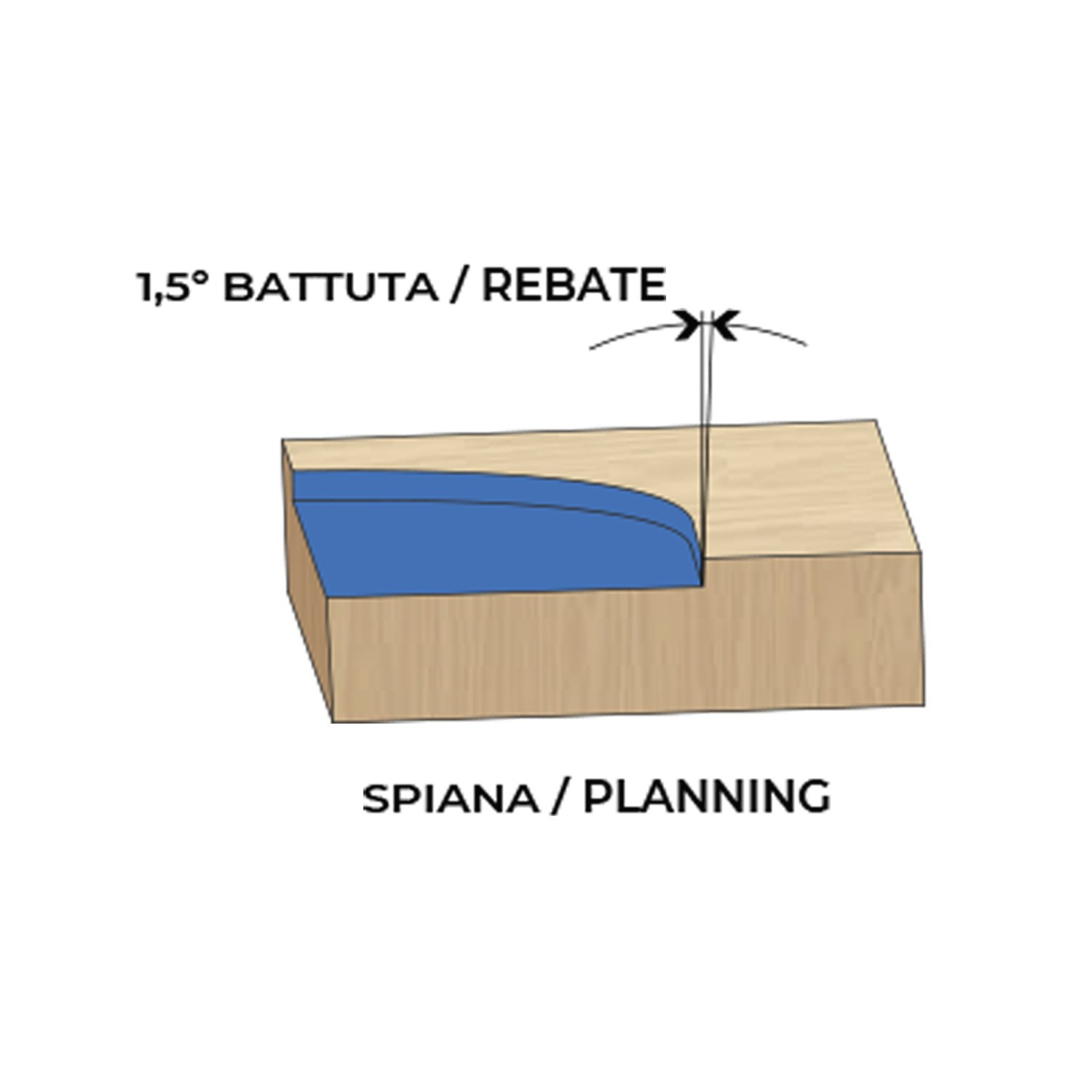

Surfacing cutter with carbide inserts designed for leveling large surfaces and machining rebates on MDF, wood and non-ferrous materials. Ensures constant flatness, stable cutting and high surface quality.

• Carbide inserts for long tool life and consistent cutting

• Ideal for spoilboard leveling and deep rebates

• Suitable for CNC routers and machining centers

Carbide helical cutter with up down Z2+2 geometry, designed to achieve clean finishes on both top and bottom surfaces of the workpiece. Ideal for contouring cutting and shaping operations on wood based materials and plastics.

• Up down Z2+2 geometry for double side finishing

• Solid carbide cutting edges for precision

• Suitable for contouring cutting and shaping

Positive helix carbide end mill Z3 with chipbreaker designed for finishing contouring, cutting and profiling on wood and composite materials. Provides high surface quality and controlled chip evacuation.

• Positive helix Z3 carbide cutting edges

• Integrated chipbreaker for smooth chip control

• Ideal for finishing contouring and profiling

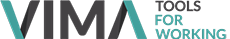

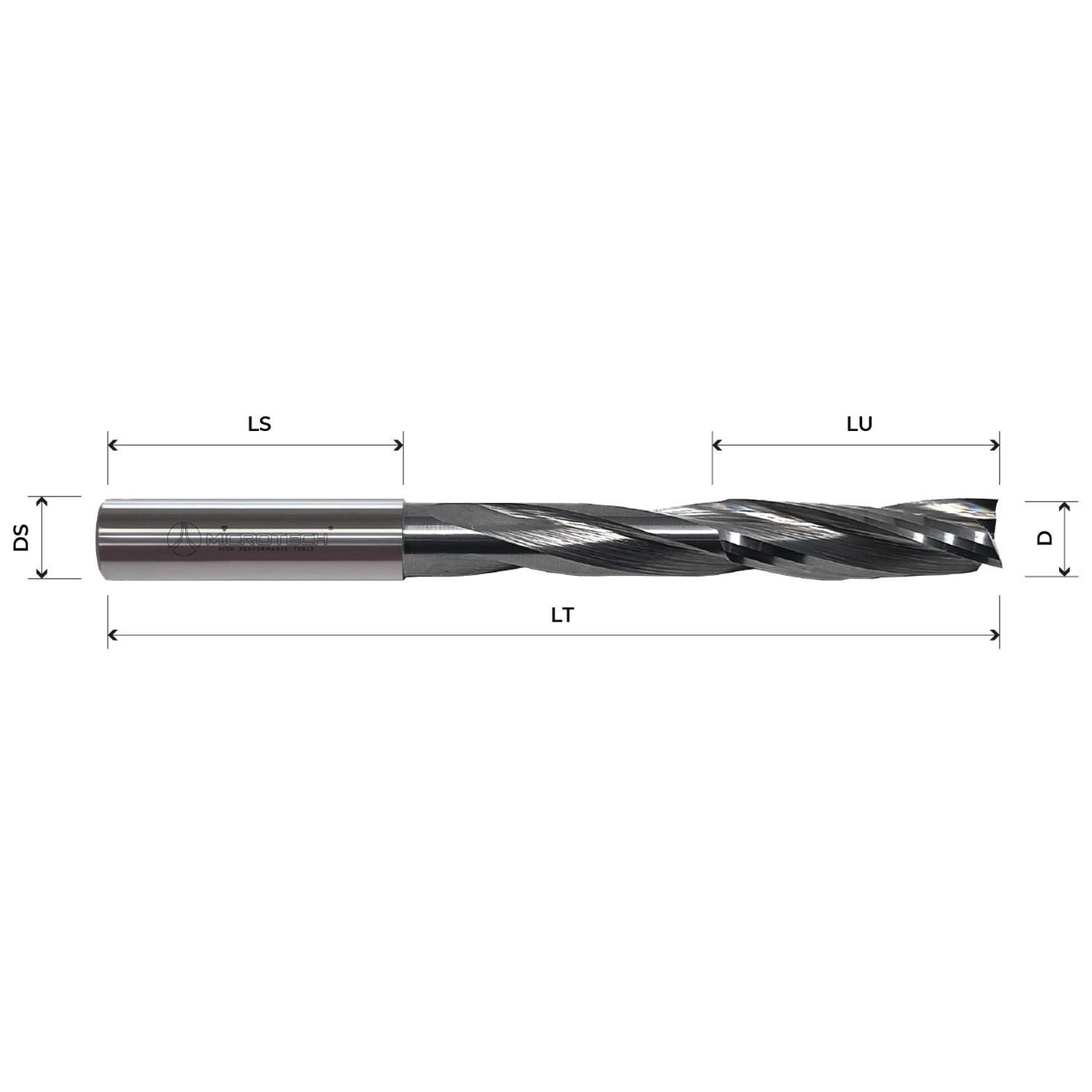

Solid hardmetal helical tool with Z1 positive geometry designed for aluminium machining on CNC routers and machining centres, delivering stable cutting action and a clean surface finish.

• Z1 geometry for efficient chip flow

• Polished inner and outer flutes to reduce built up edge

• Suitable for high speed CNC work up to 24000 rpm

.jpg)