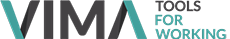

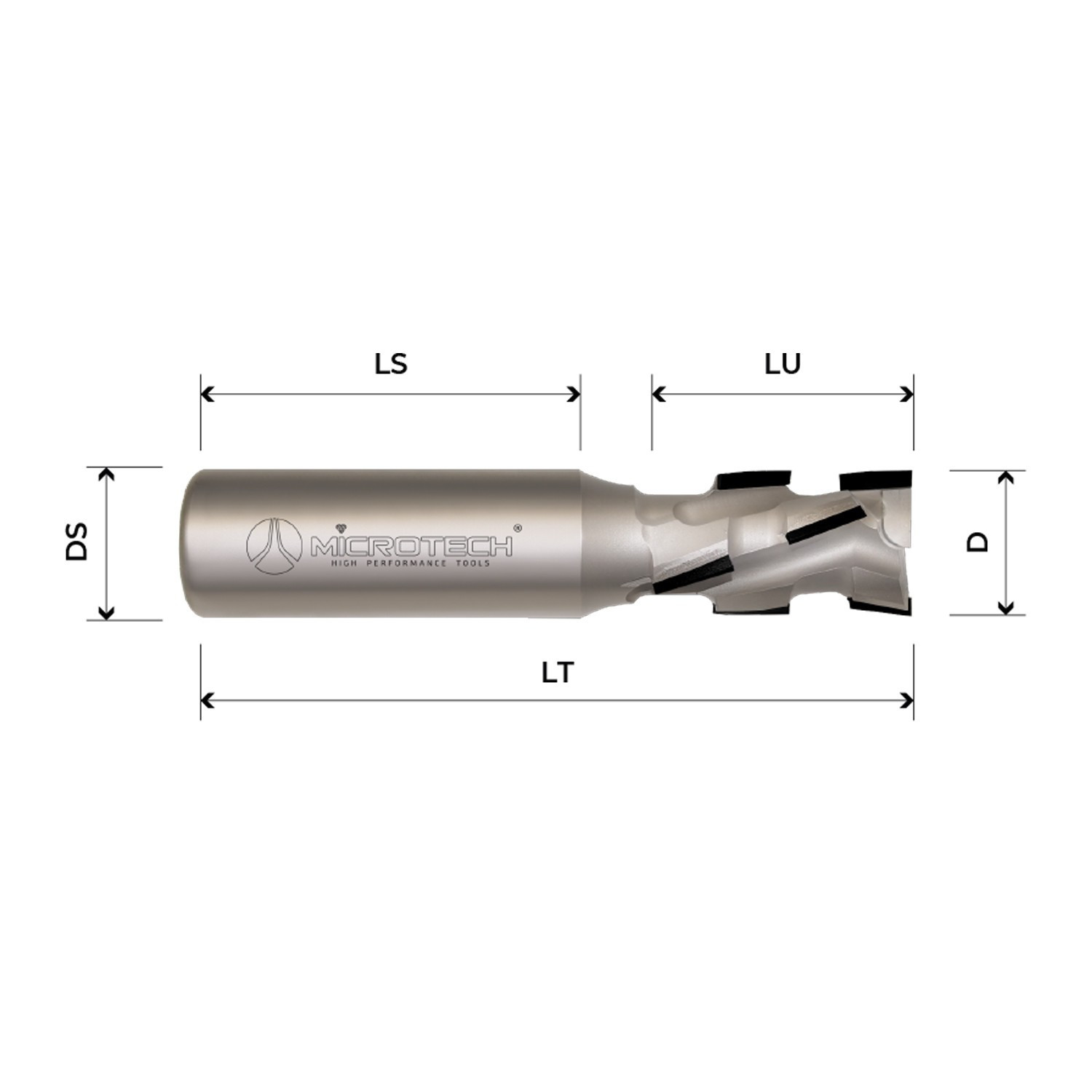

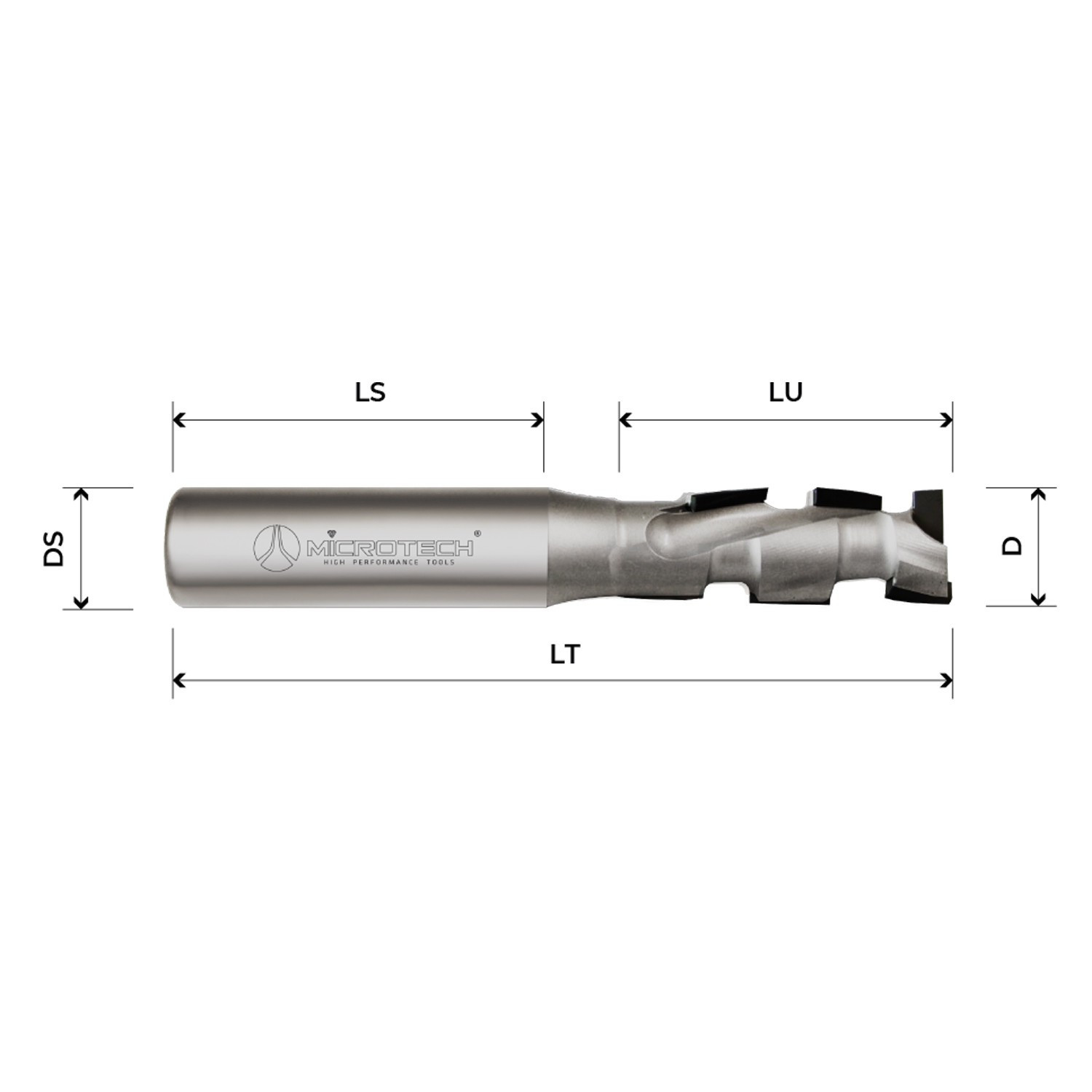

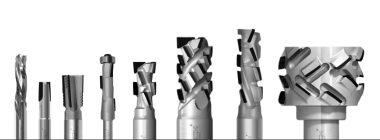

PCD helical router bit designed for contouring and grooving on both CNC and manual machines. The Z1+1 layout with two helical sections offers a solid balance between material removal, cutting stability and surface finish, especially on coated panels.

• Z1+1 configuration with positive and negative helix

• PCD diamond insert H 2.5 mm, regrindable

• Ideal for laminated panels and coated MDF

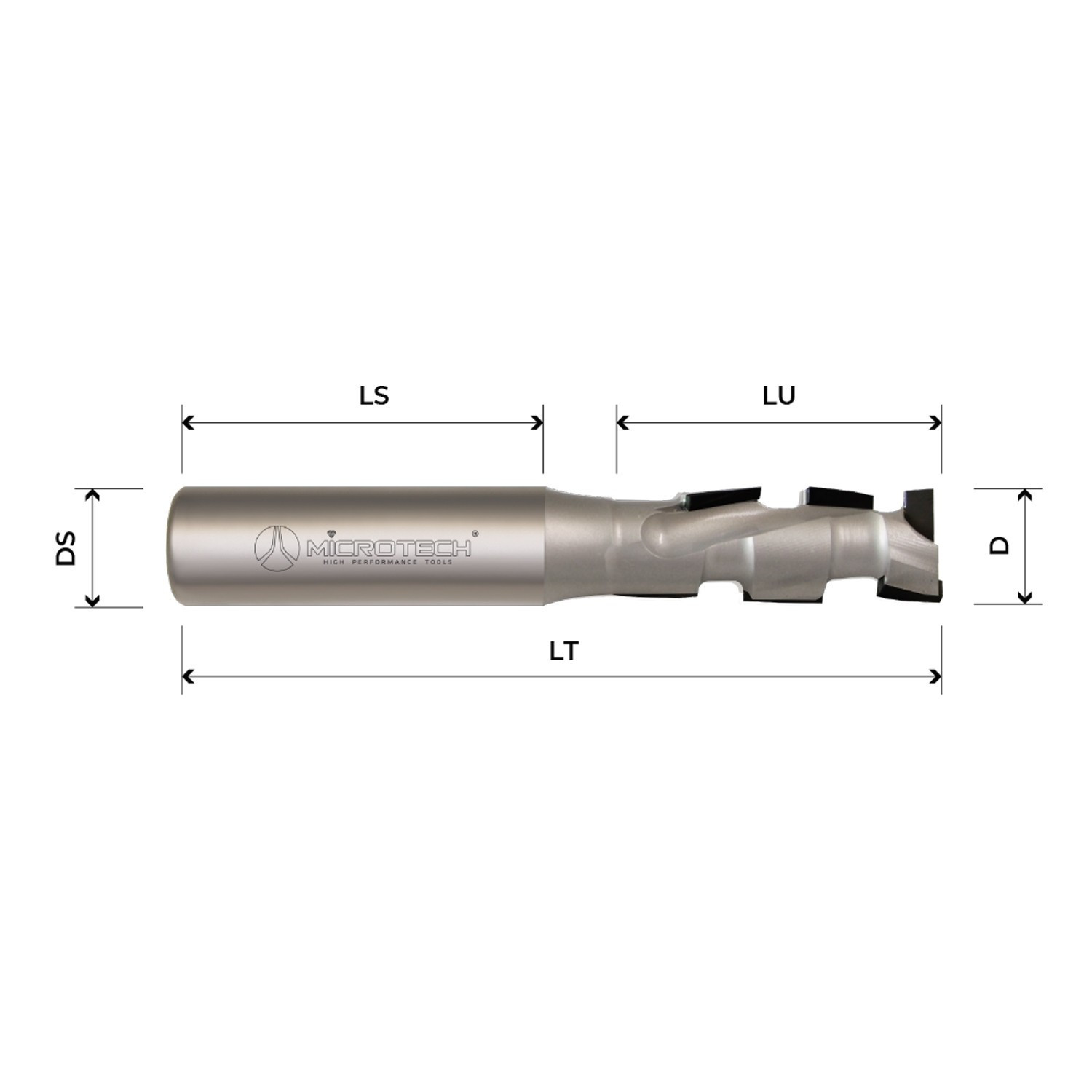

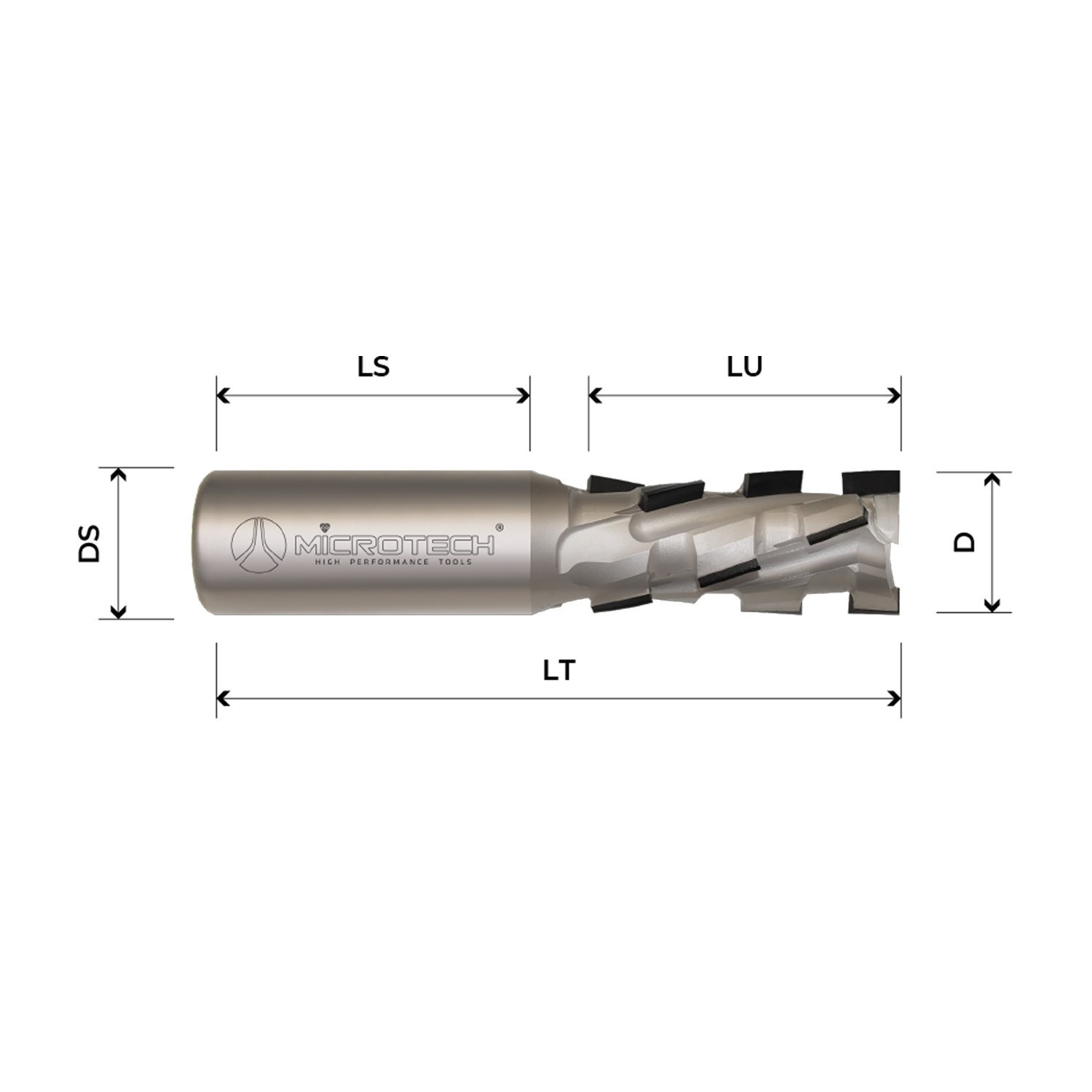

PCD Z1+1 helical router bit designed for CNC grooving and contouring on panels and wood-based materials. The cost-effective PCD insert H 2.5 mm, regrindable up to three times, combined with the steel body, offers a balanced solution in terms of performance, durability and cost.

• PCD insert H 2.5 mm, regrindable

• Z1+1 geometry with positive and negative helix

• Steel body for stability and reliability

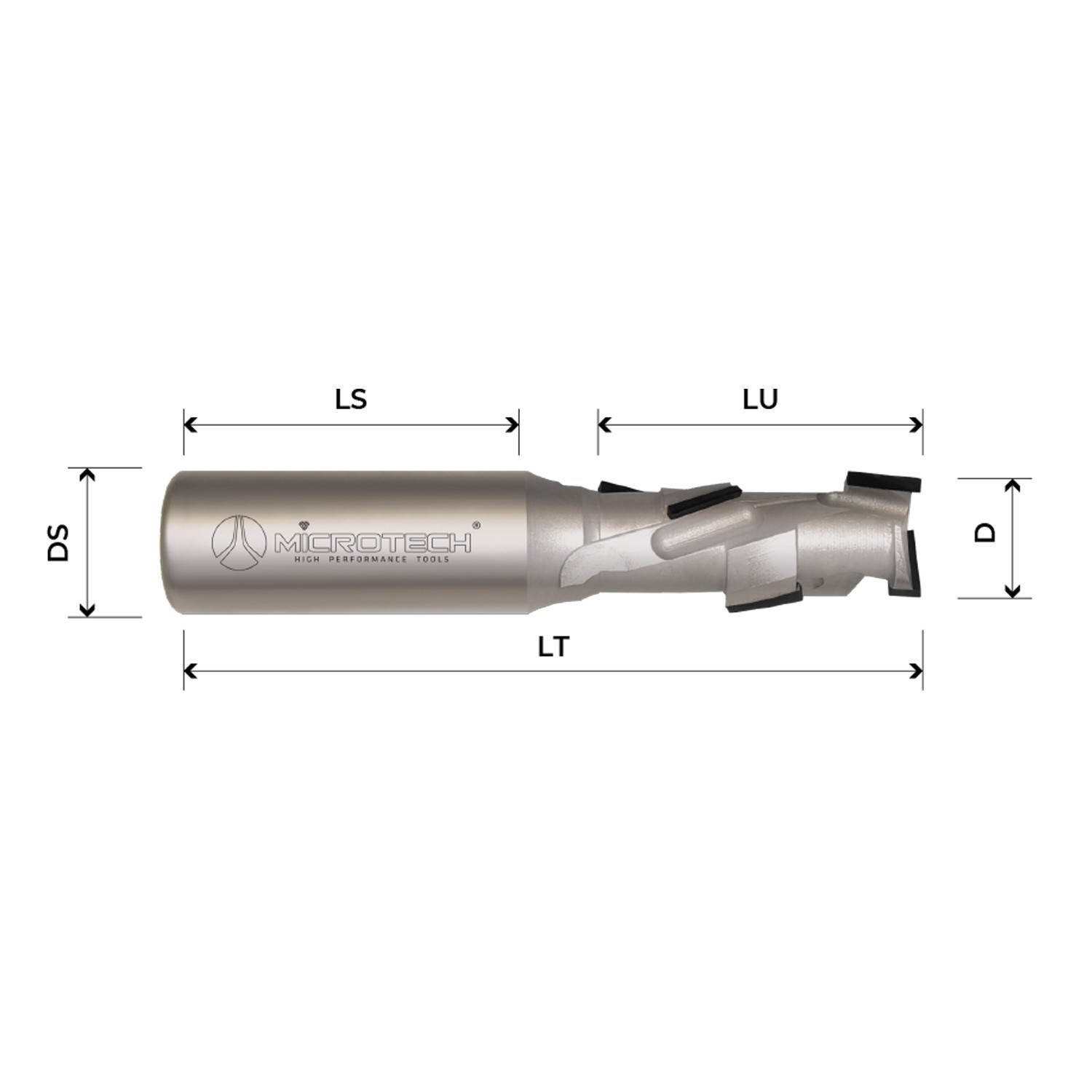

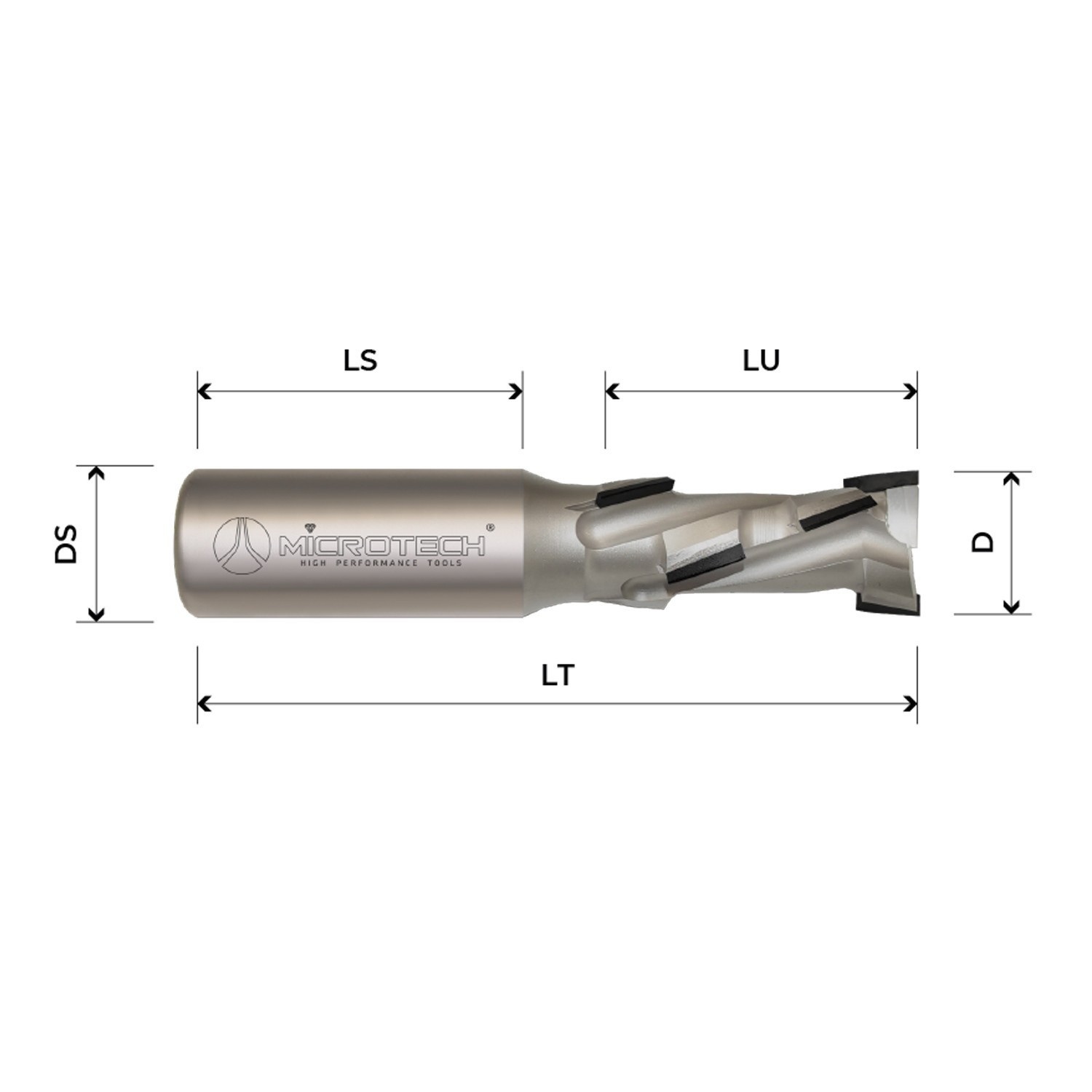

PCD Z1+1 helical router bit designed for CNC contouring applications with shank. The PCD diamond insert H 4.5 mm, regrindable up to eight times, combined with the steel body ensures long tool life, cutting stability and consistent quality even on coated panels.

• PCD insert H 4.5 mm, regrindable up to 8 times

• Z1+1 geometry with positive and negative helix

• Steel body for rigidity and reliability

PCD Z2+2 helical router bit designed for shank contouring on CNC machines with mechanical feed. The 4 helical divisions and the pulling geometry with a first positive insert ensure efficient chip evacuation, cutting stability and consistent quality on panels and wood-based materials.

• Z2+2 with 4 helices for productive, stable machining

• PCD insert H 2.5 mm for good tool life and a clean finish

• Special steel body with HW drilling tip

PCD Z2+2 CNC/router bit for shank contouring with mechanical feed, designed for CNC routers and pantographs. The 4 helical divisions and pulling geometry deliver efficient chip evacuation, cutting stability and a clean finish on coated panels and plywood.

• PCD H 4.5 mm with up to 8 regrinds for extended service life

• Z2+2 and 4 helices for productive, stable CNC contouring

• Special steel body with HW drilling tip

Helical PCD CNC router bit developed for contouring and finishing on coated panels and technical materials. The cutting layout combines Z2+2 on the top and bottom with Z1+1 in the central section, ensuring stable cutting, controlled material removal and a clean finish even on abrasive substrates.

• PCD insert H 2.5 mm, regrindable up to 3 times

• Combined Z1+1 / Z2+2 geometry for a stable cut

• Special steel body for rigidity and precision

Helical PCD diamond cutter Z1+1 with 2.5 mm insert regrindable up to three times, designed for shank contouring on CNC machining centres. The three-helix geometry, with a first positive cutting edge followed by negative edges, ensures chip control, cutting stability and good surface quality.

• PCD insert H2.5 mm regrindable up to 3 times

• Z1+1 geometry for controlled contouring

• HW body for rigidity and accuracy

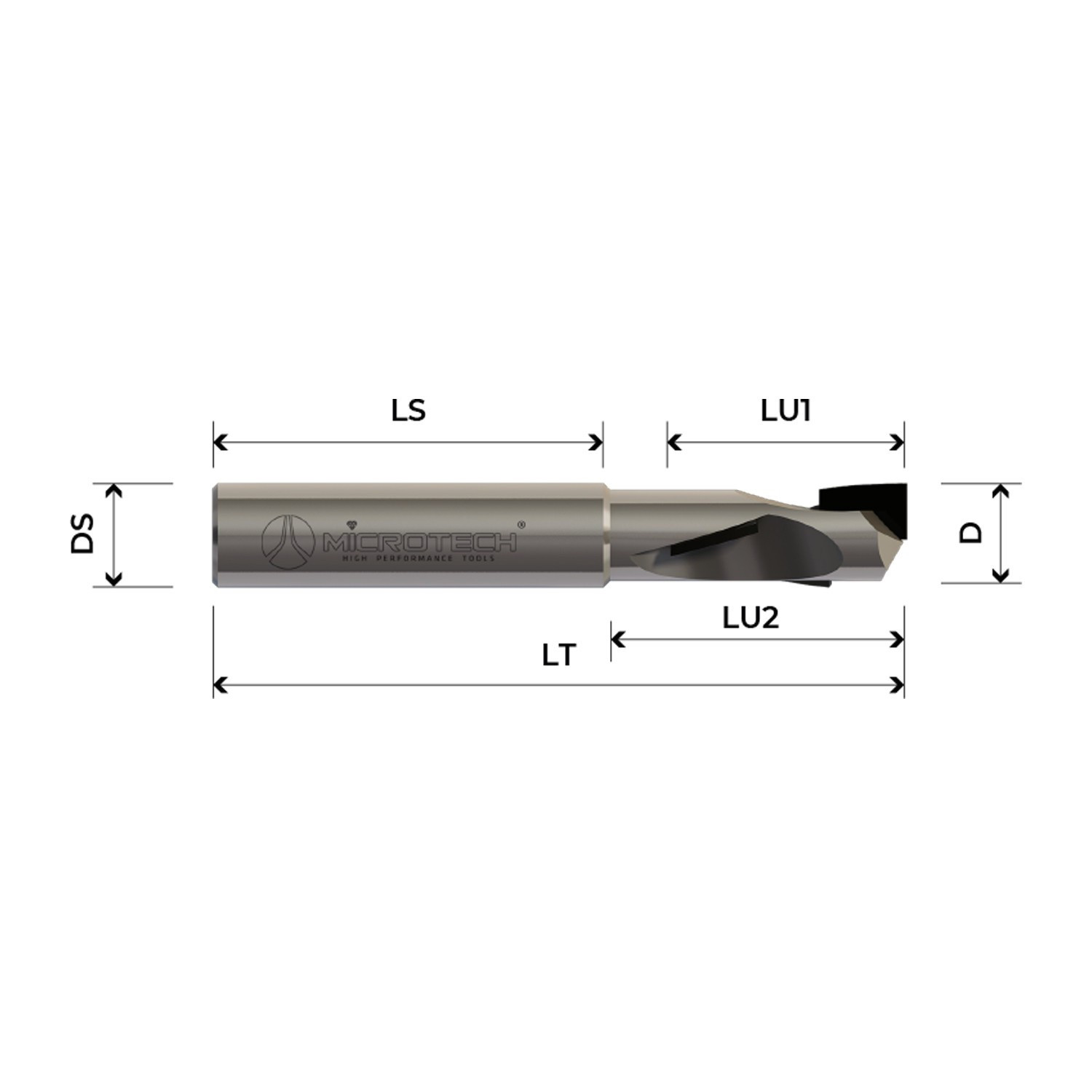

PCD diamond Z1+1 router bit designed for cutting channels and profiling on panels and wood-based materials with high accuracy. The cost-effective H2.5 mm PCD tip and the heavy DENSIMET body deliver stability on small diameters and consistent finish. Made in Italy.

• PCD H2.5 mm tip resharpenable up to 3 times

• Z1+1 geometry for clean channels and profiling

• Heavy DENSIMET body for rigidity and low vibration

.jpg)