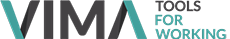

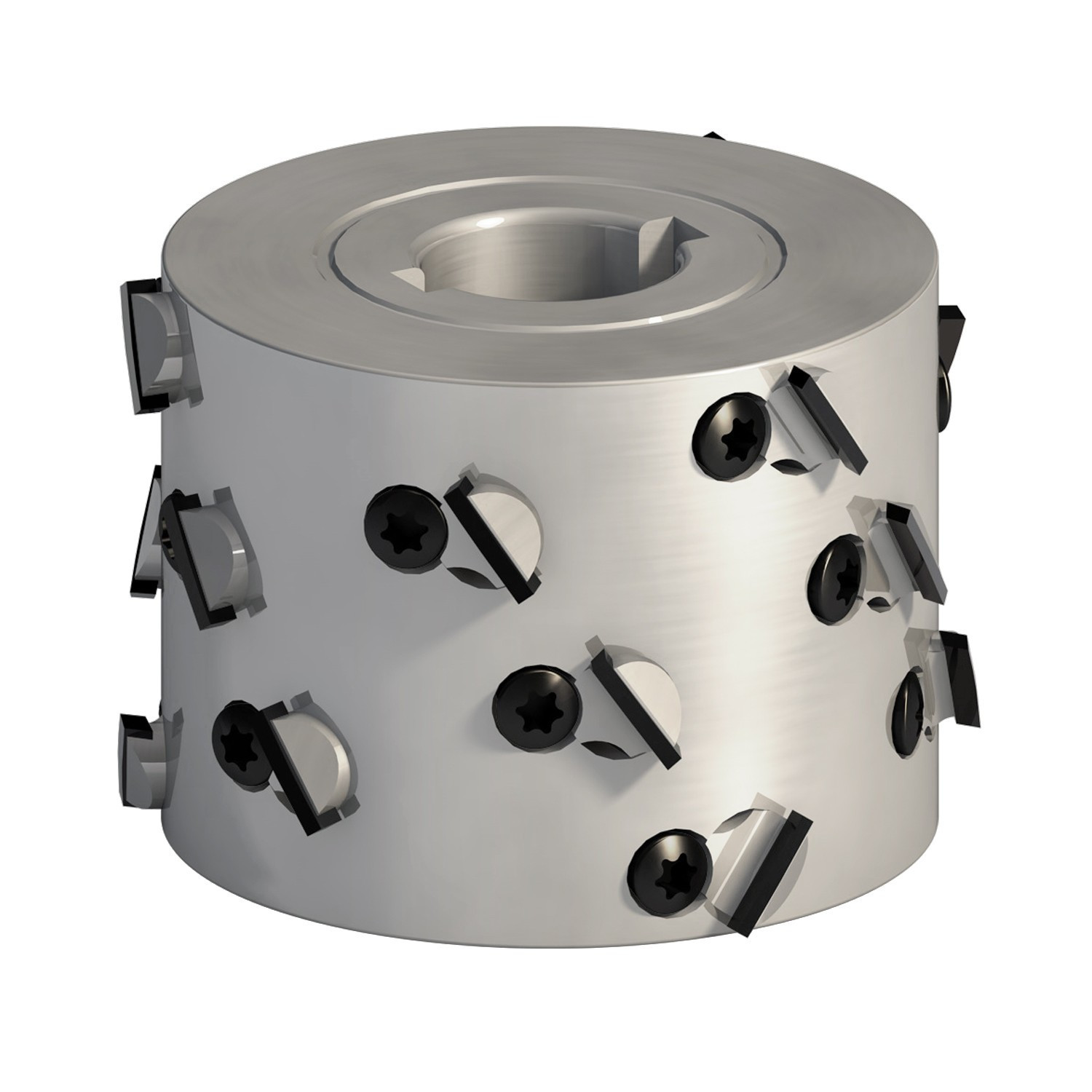

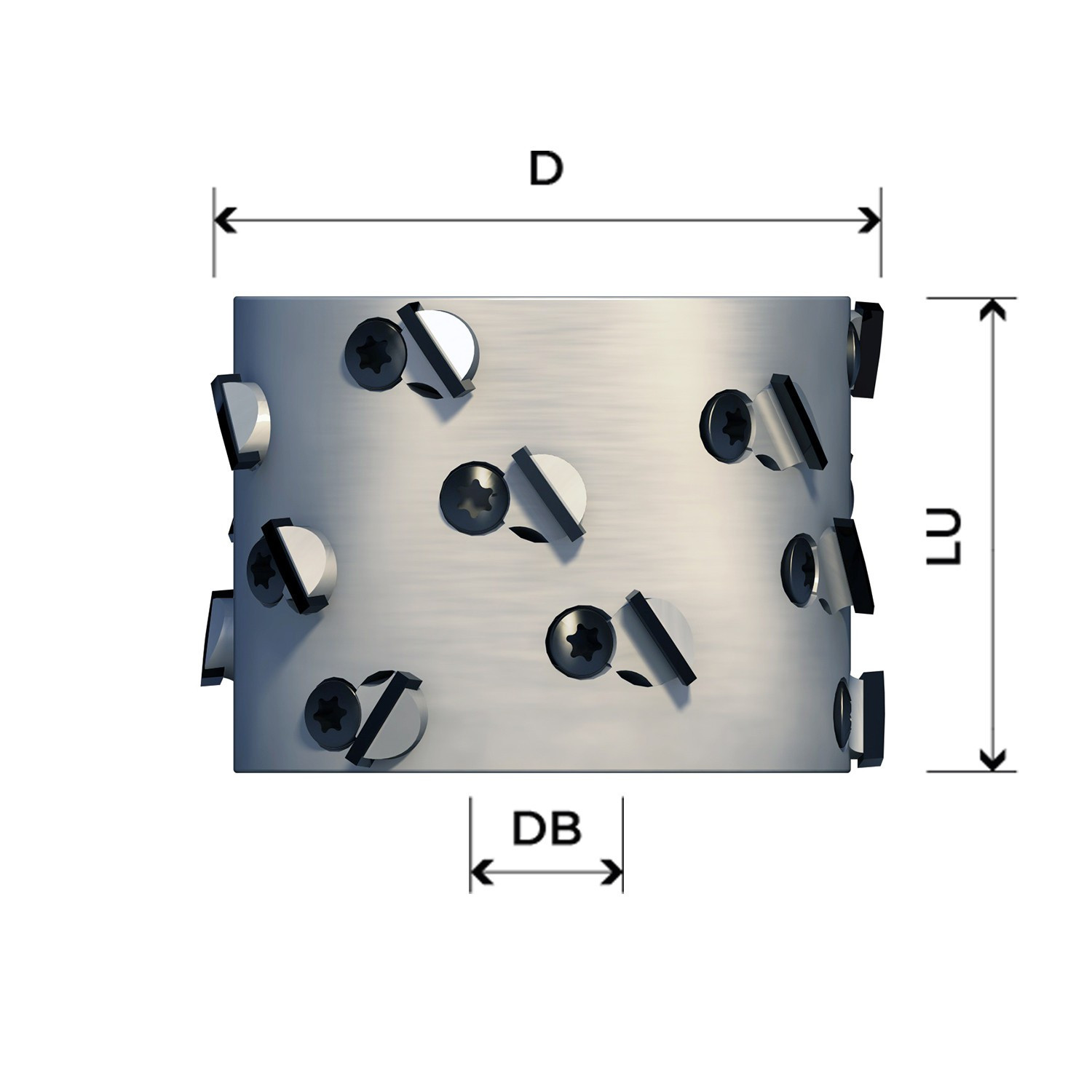

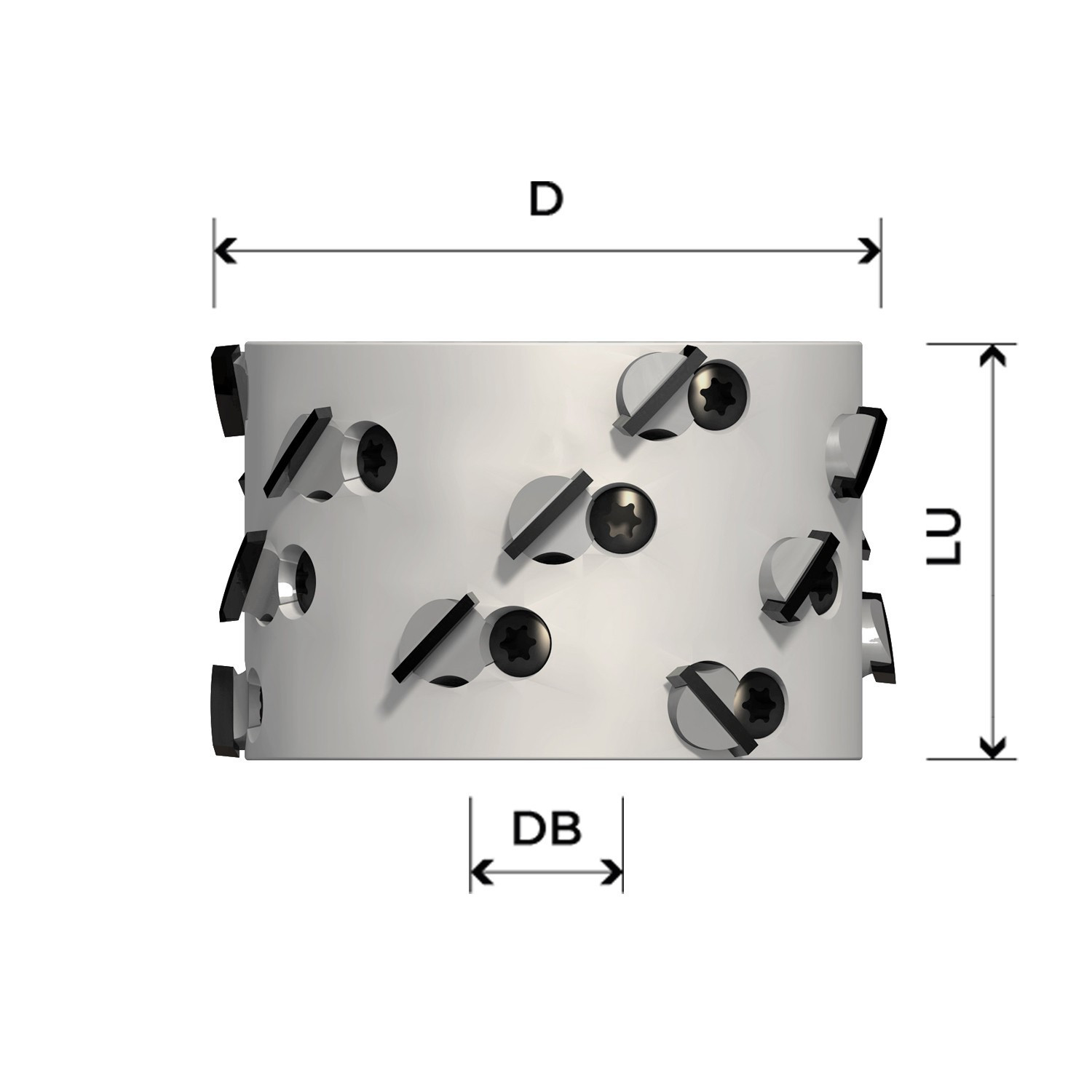

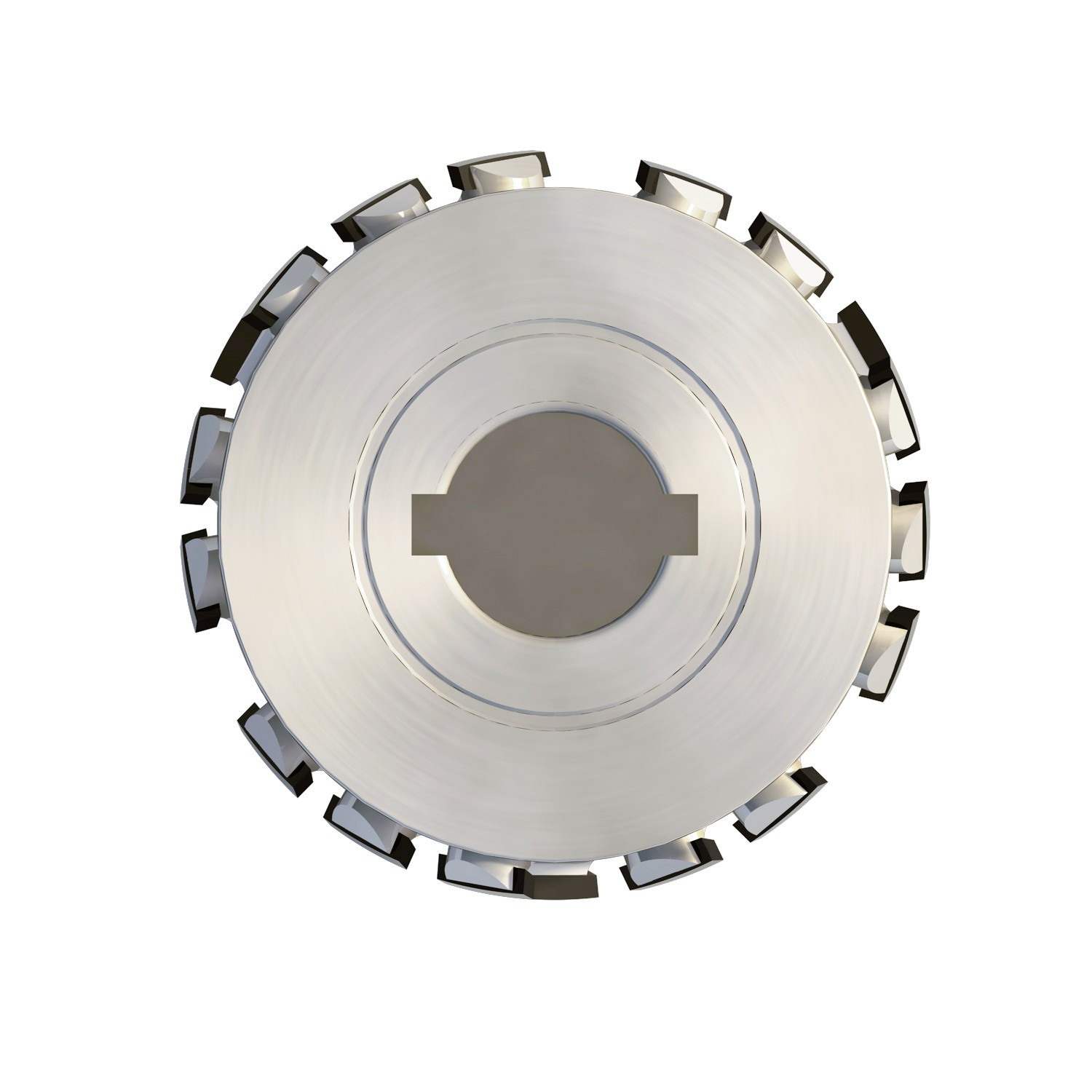

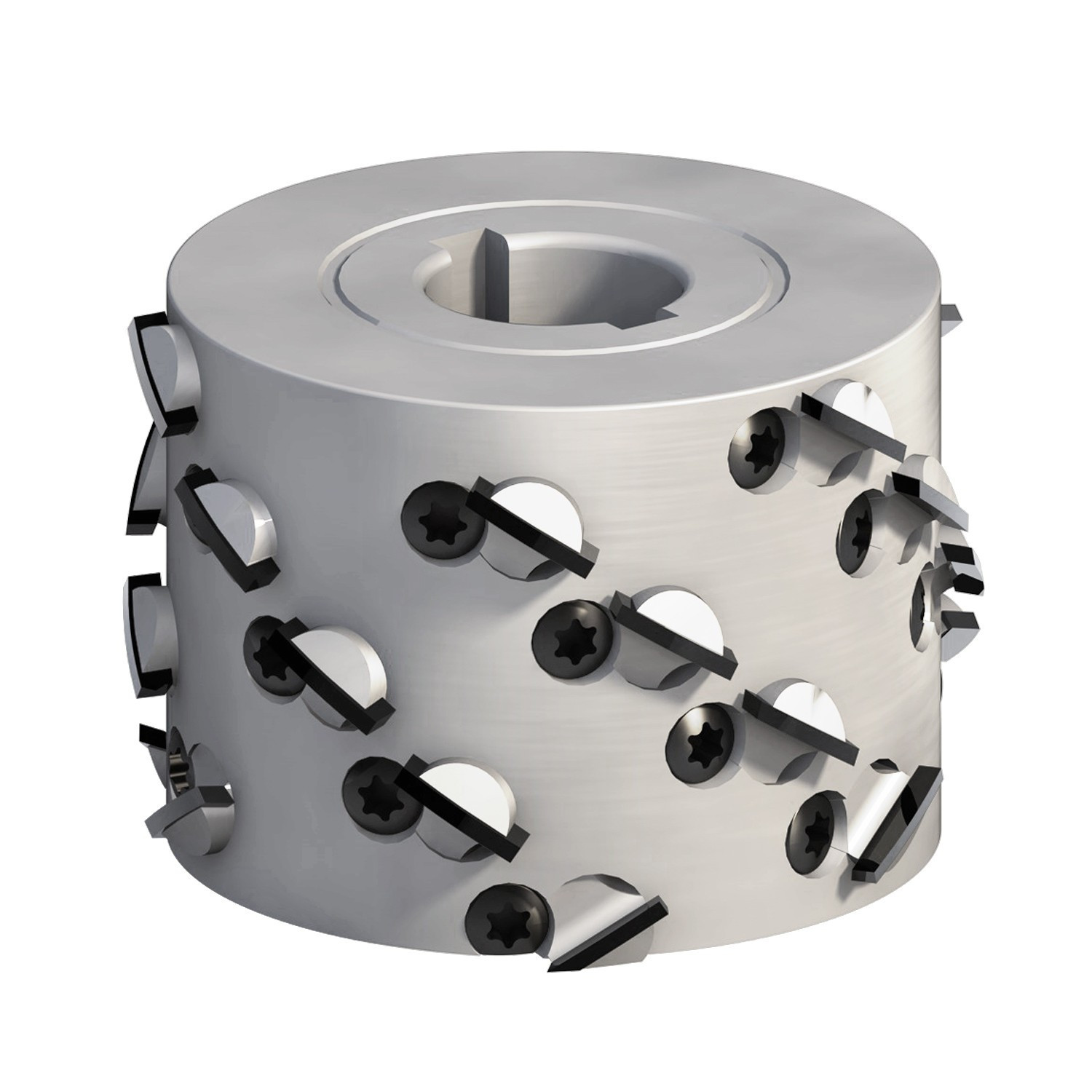

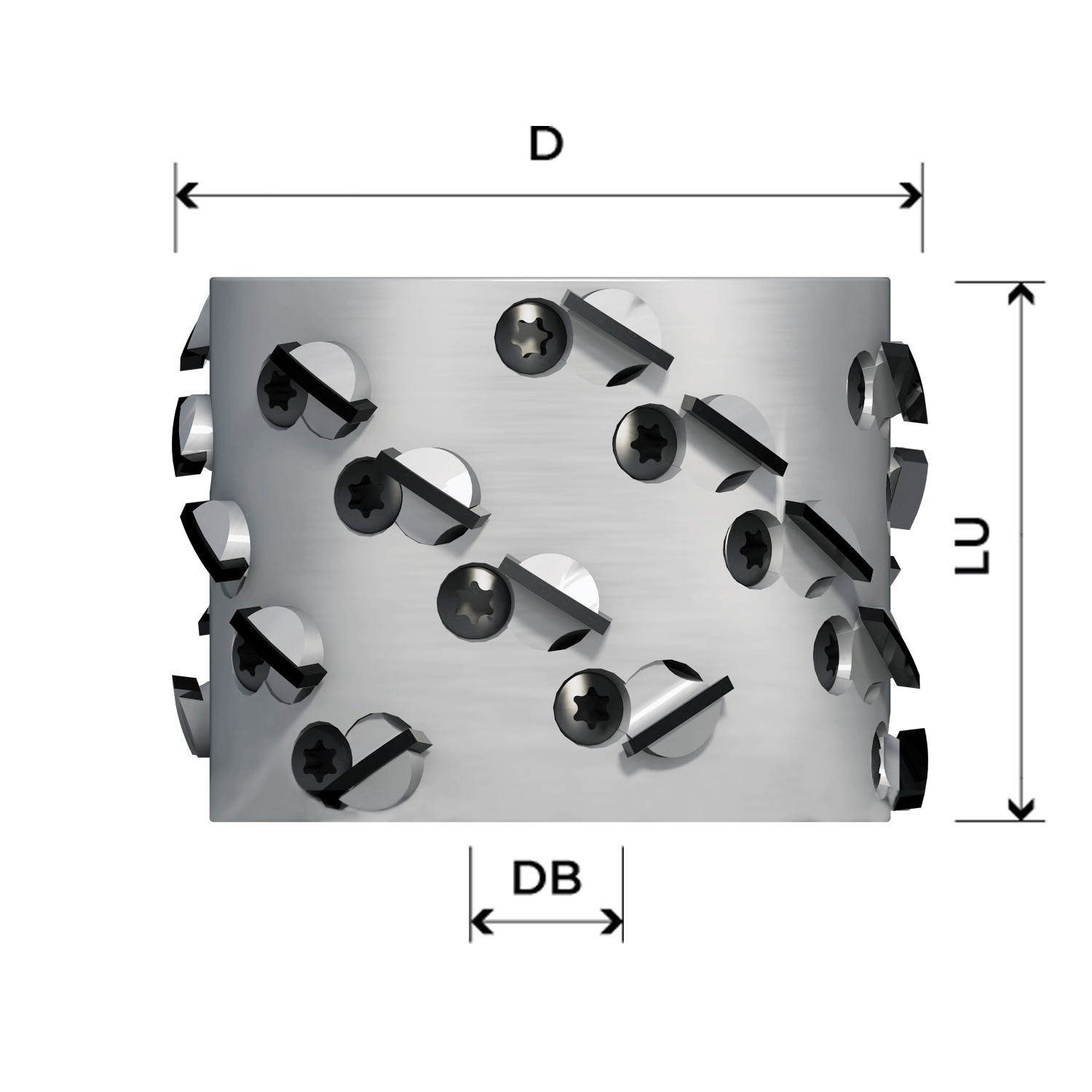

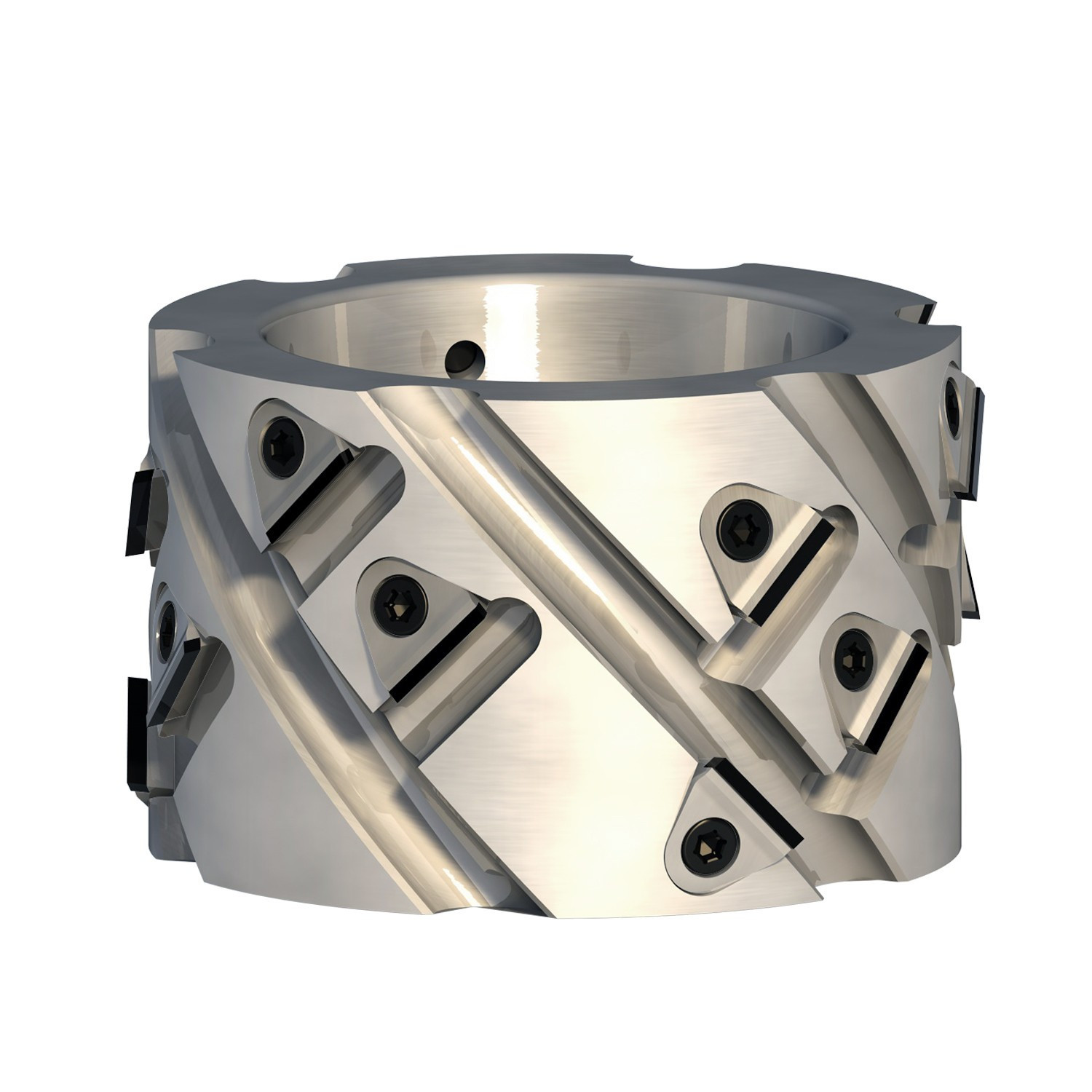

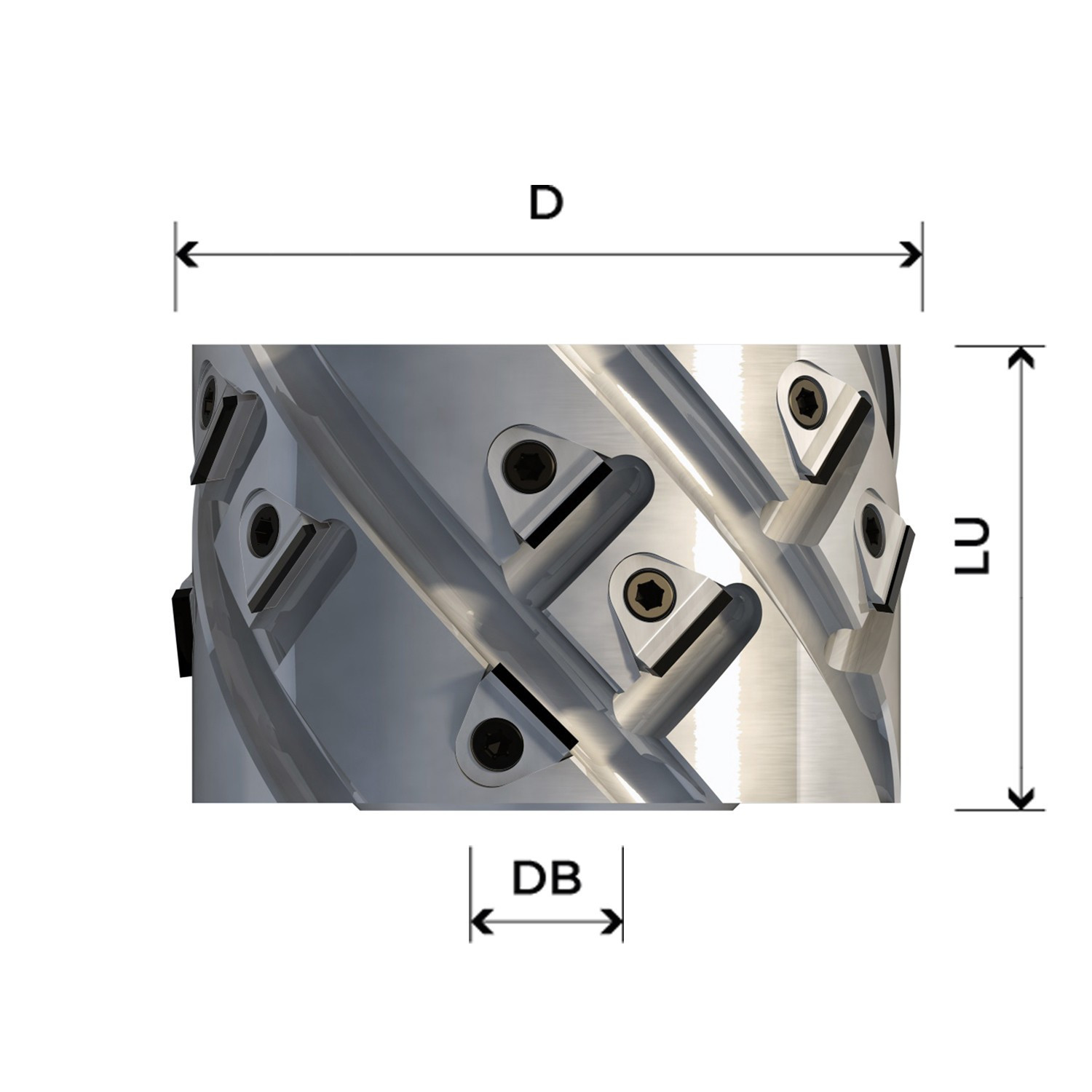

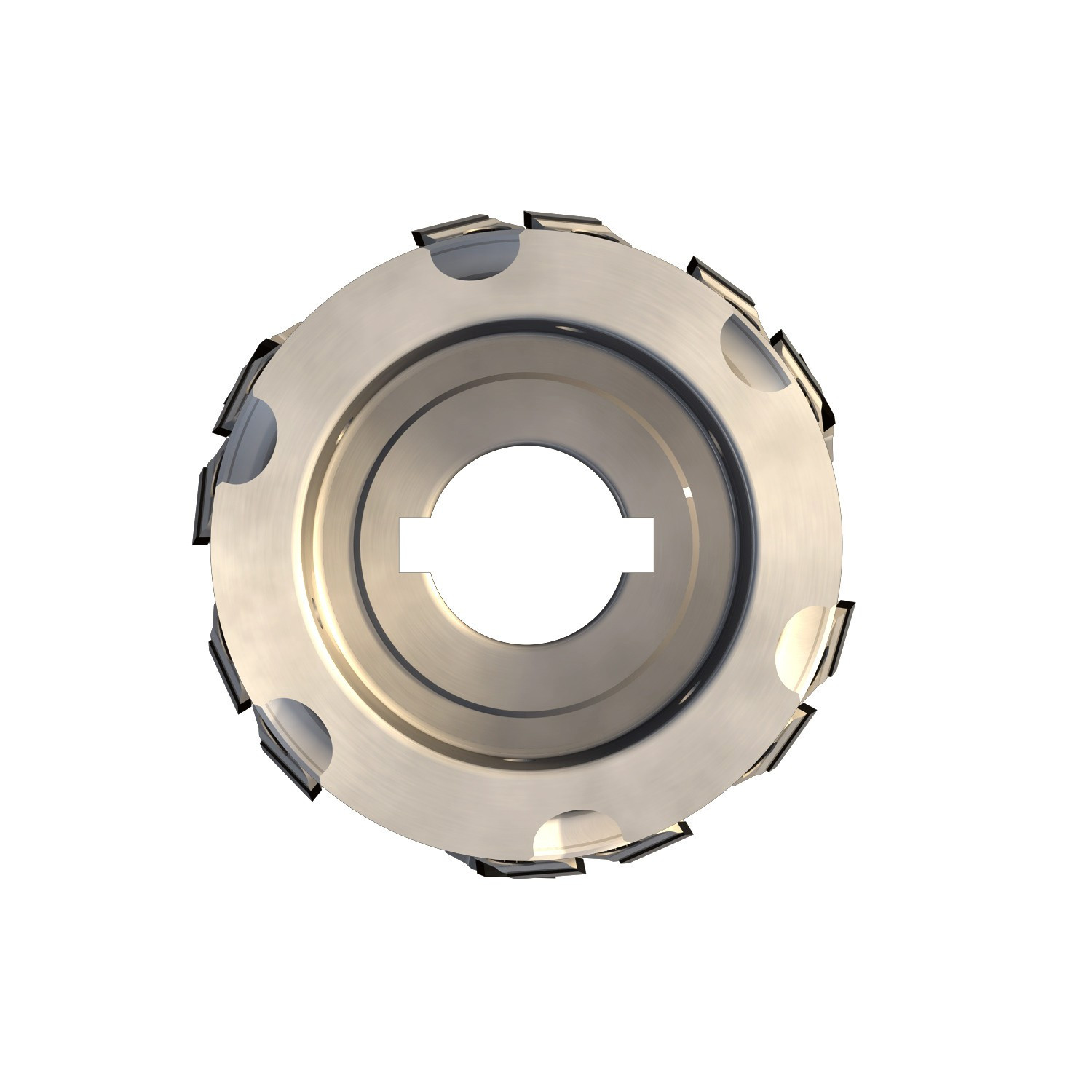

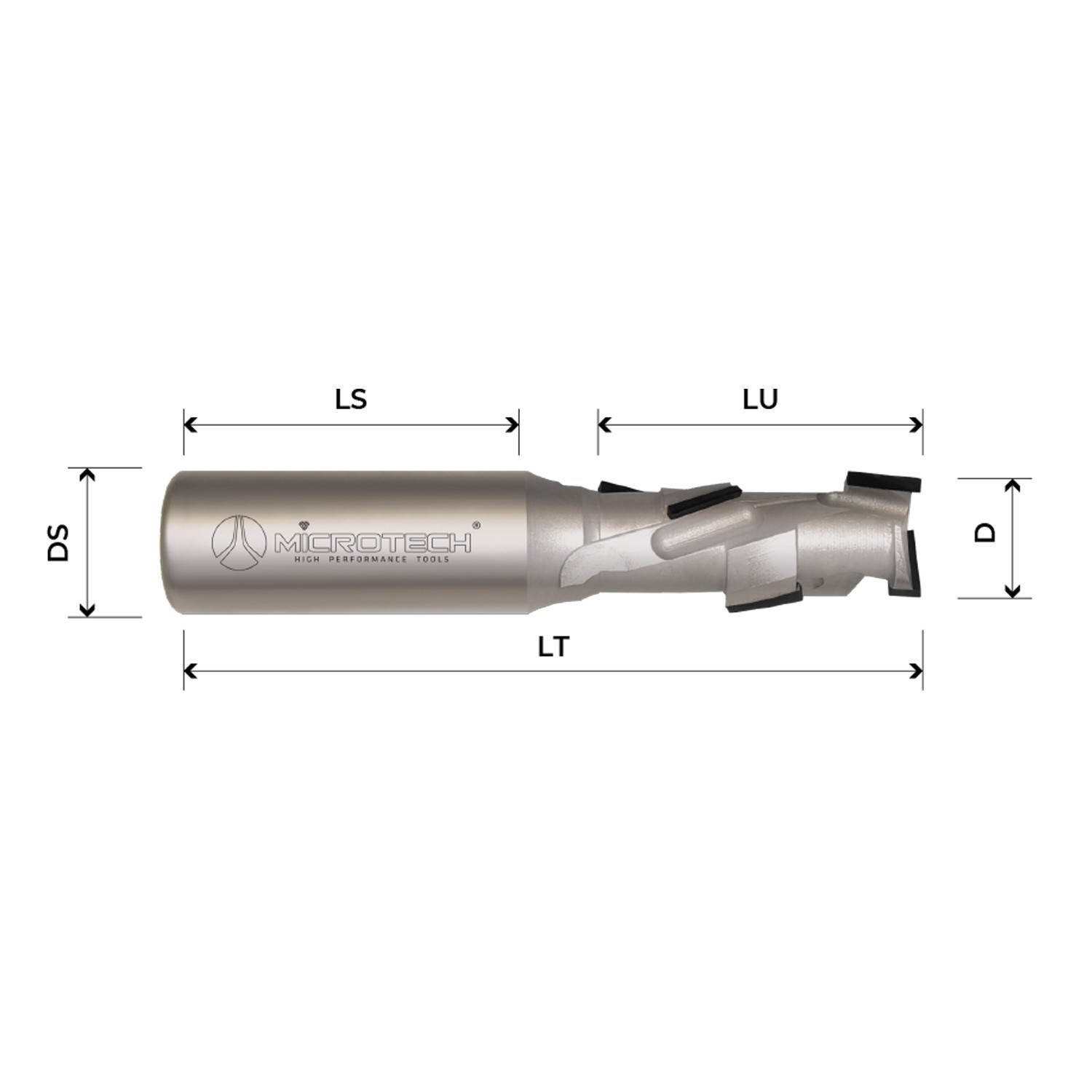

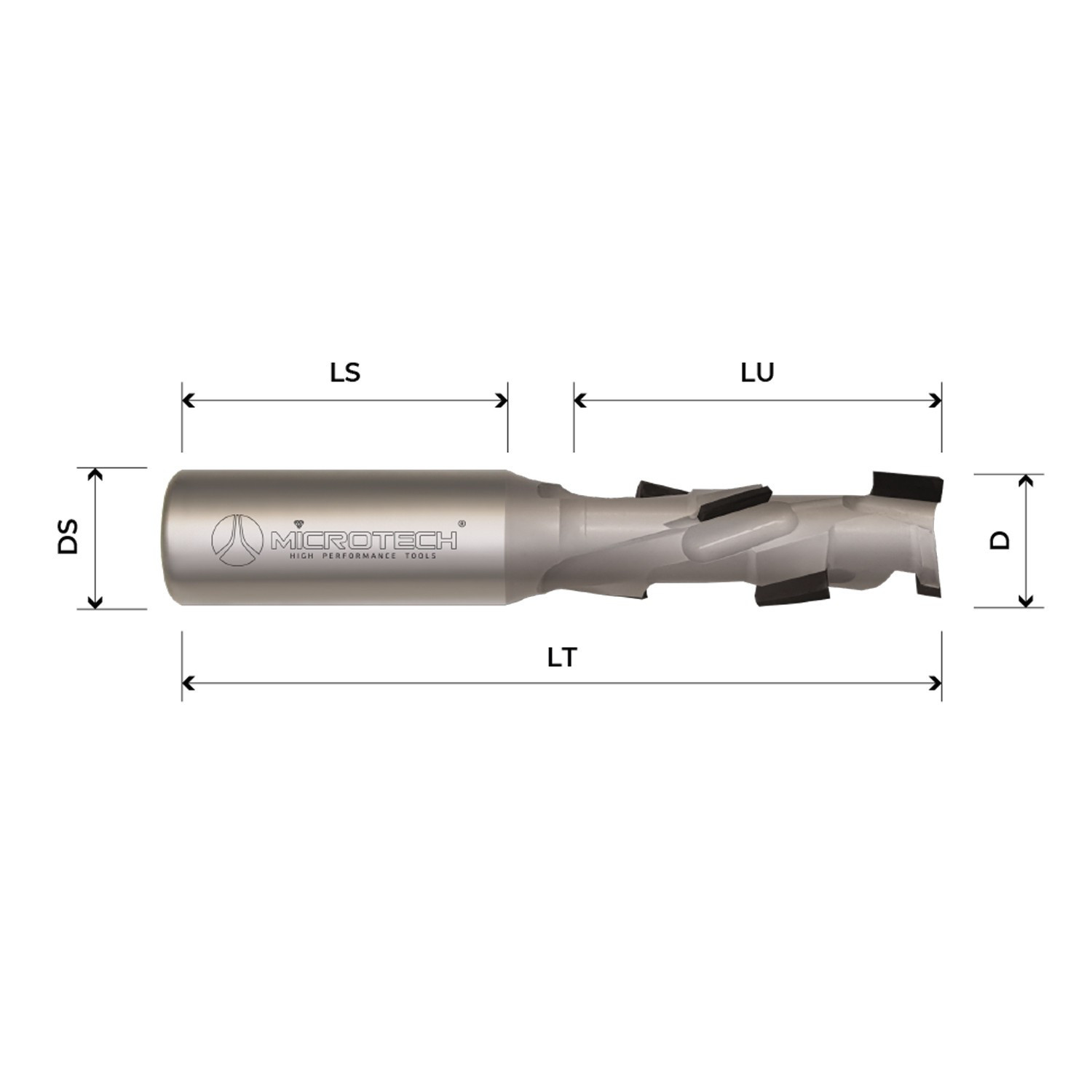

Jointing cutter with pcd inserts, PCD H3, axial 35°. It’s possible to change the inserts position to have symmetrical and asymmetrical cutter.

Jointing cutter with pcd inserts, PCD H3, axial 45°. It’s possible to change the inserts position to have symmetrical and asymmetrical cutter.

Jointing cutter with pcd inserts, PCD H3 mm, axial 54.9°. It’s possible to change the inserts position to have symmetrical and asymmetrical cutter.

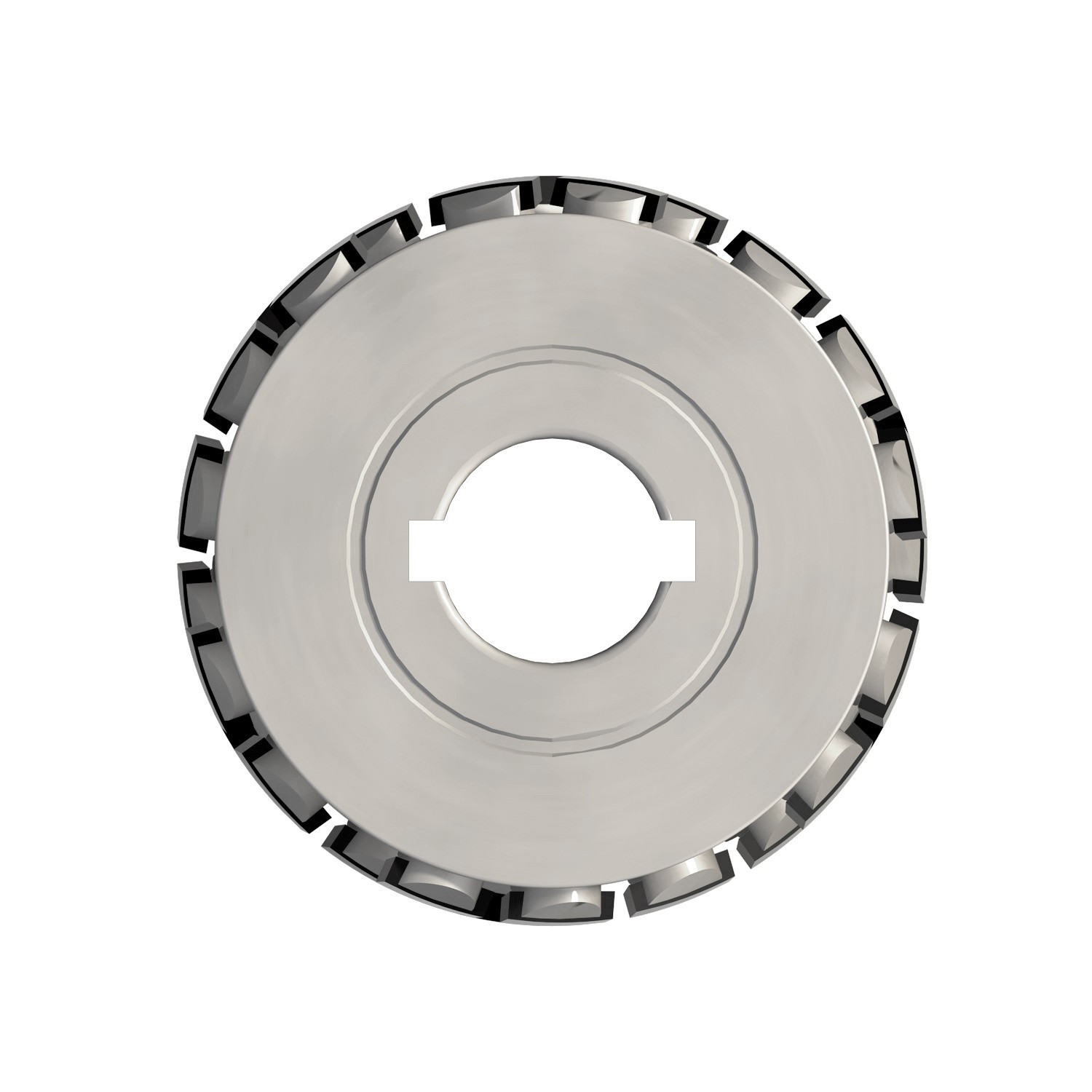

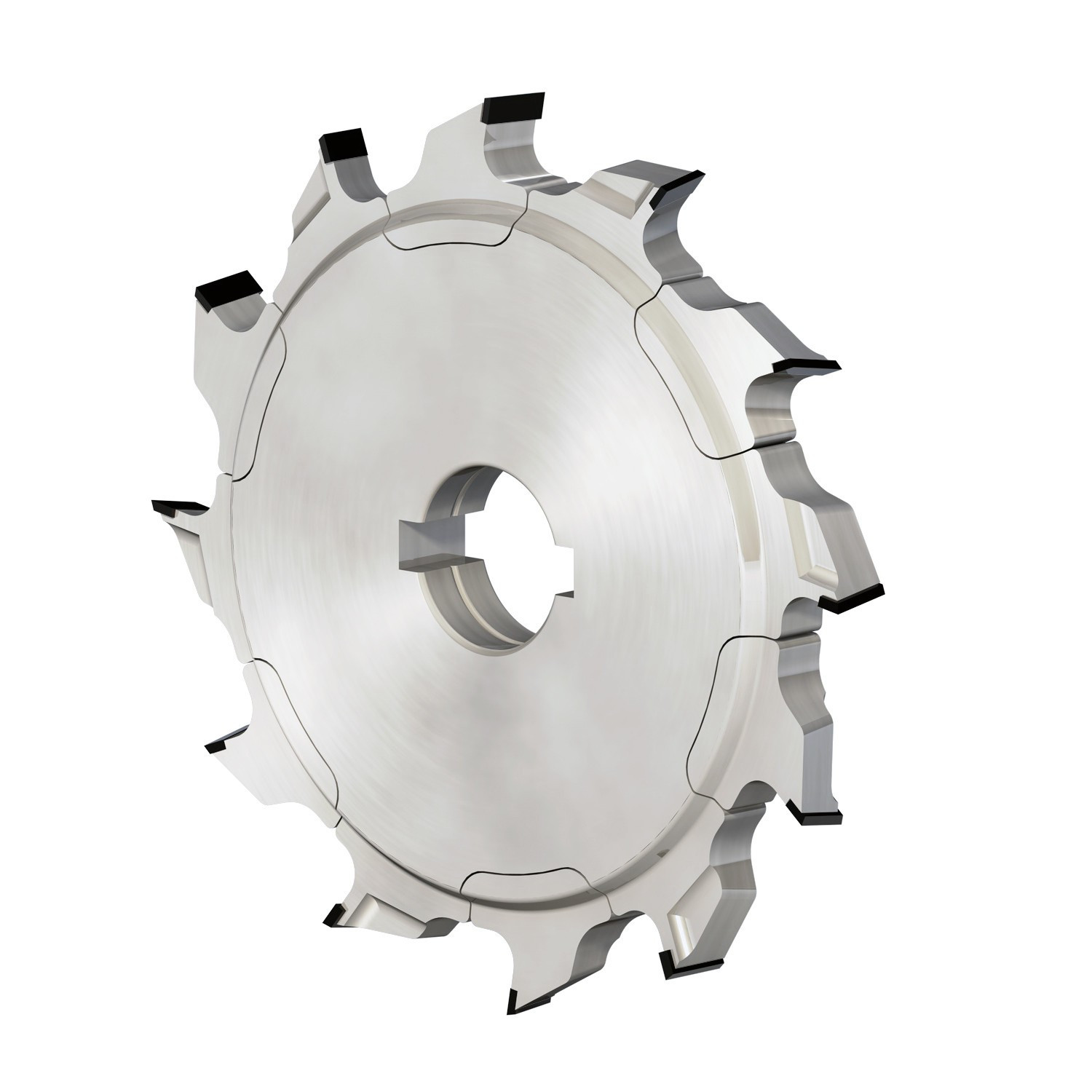

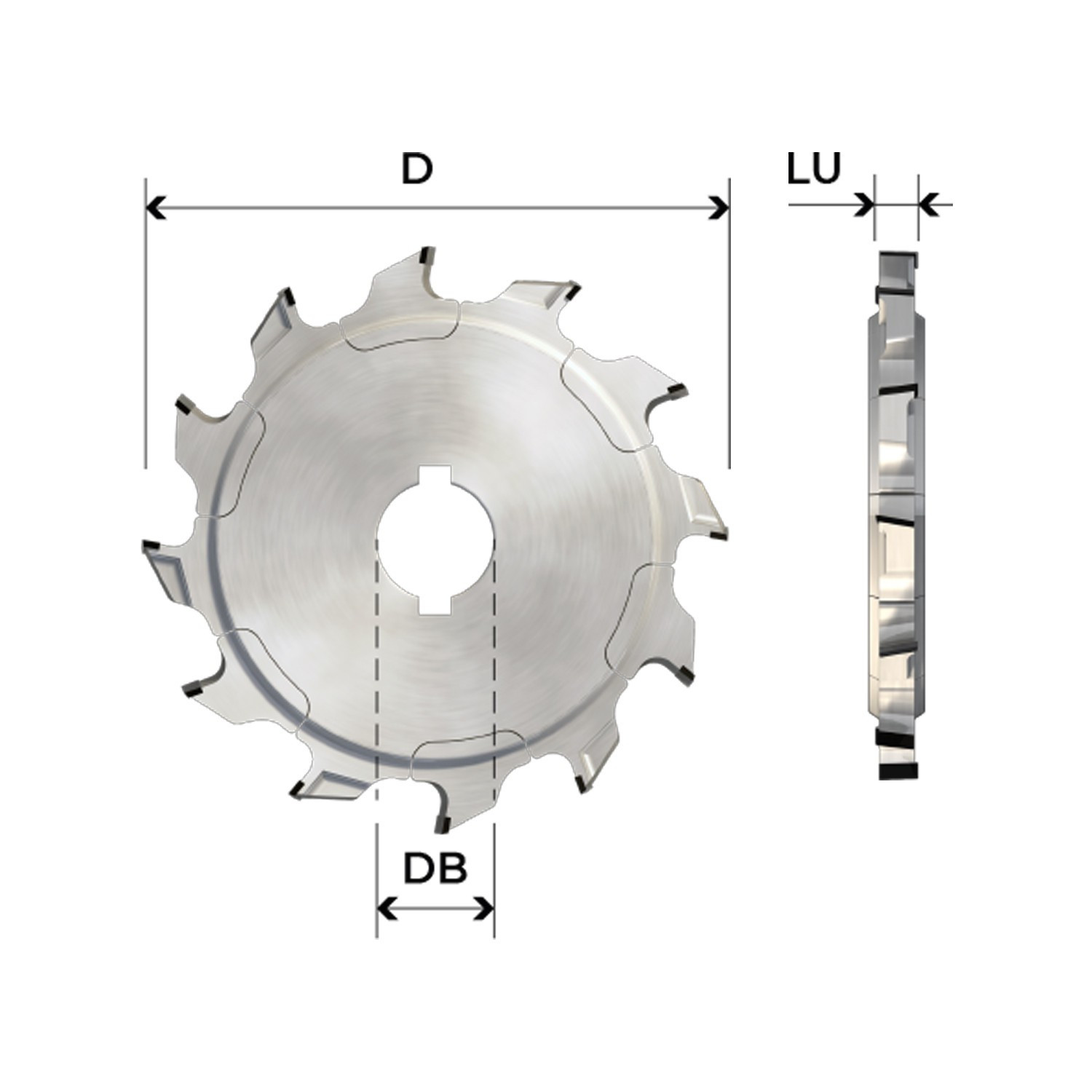

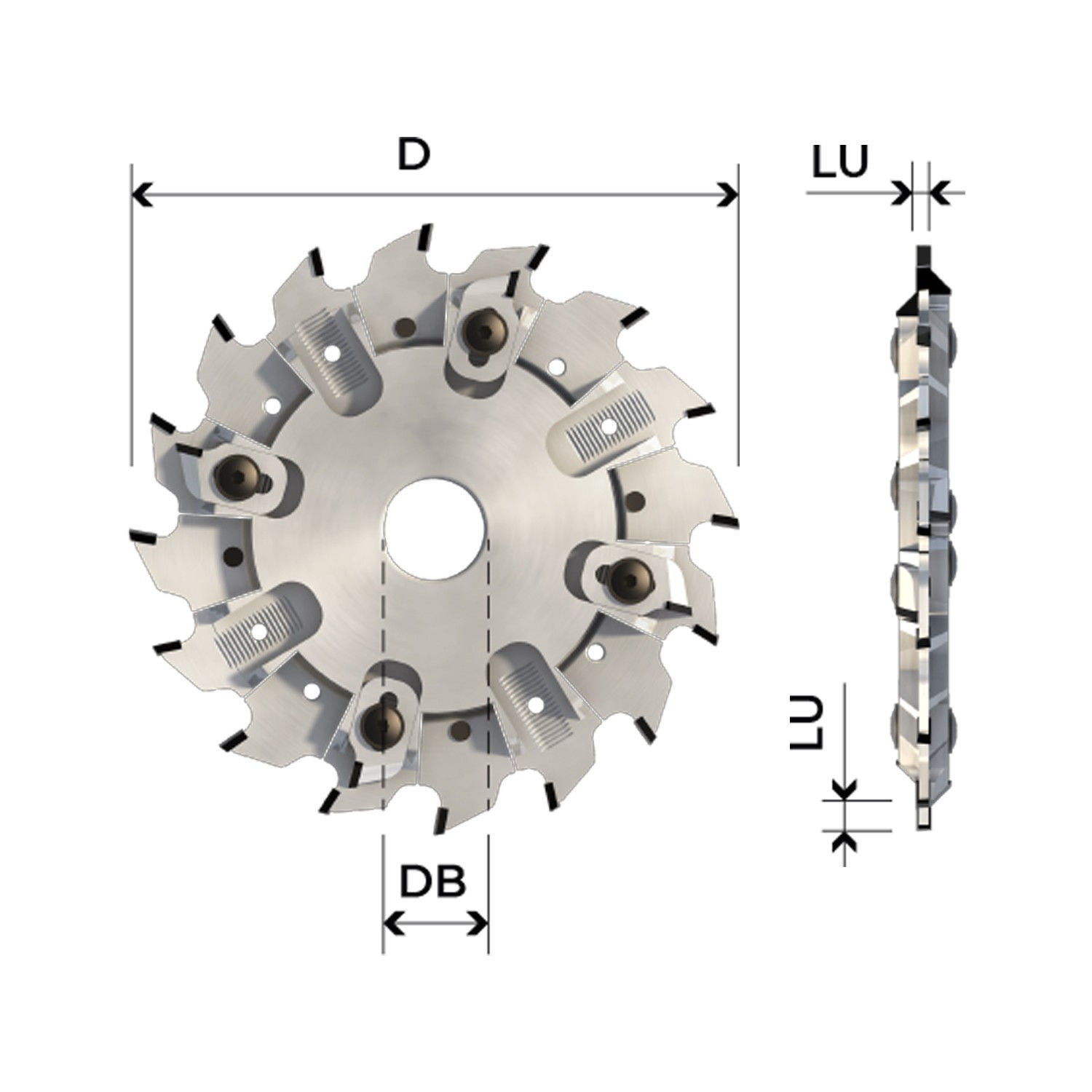

Re-sharpening adjustable grooving cutter in diamond with adjustable chanfering knife, suitable for grooving on chipboard panels, used on edgebanding machines.

Re-sharpening adjustable grooving cutter in diamond with adjustable chanfering knife, suitable for grooving on chipboard panels, used on edgebanding machines.

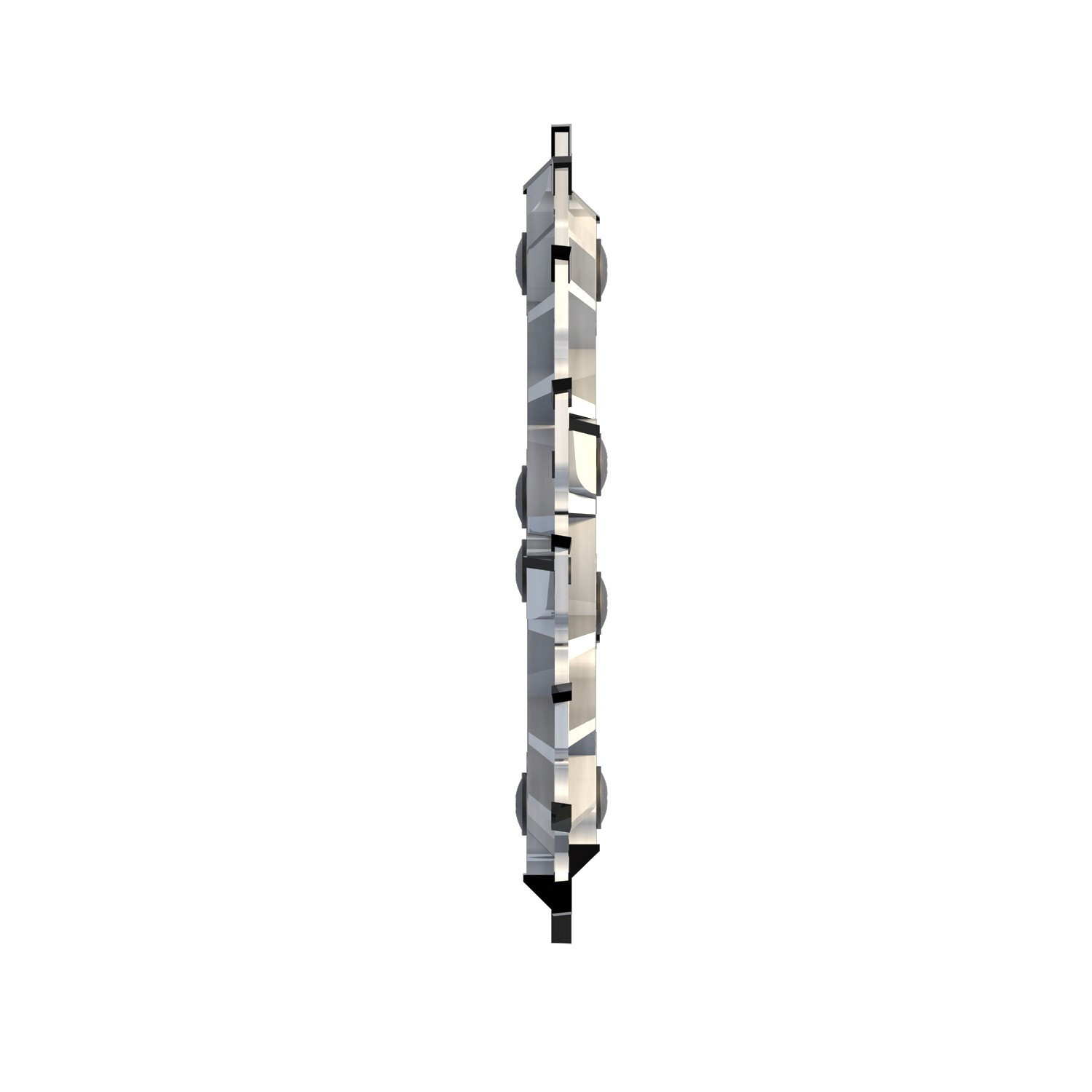

To trim edgebandings on horizontal spindles or for bevelling with inclinated spindles, for jointing and flush -cutting of solid wood, veneer and plastic edge bands for machines HOMAG - IMA.

Jointing cutter with pcd inserts, PCD H2,5 mm, axial 30°.

Jointing cutter with pcd inserts, PCD H2,5 mm, axial 45°.

For rounding solid wood, veneer and plastic edge bands for HOLZHER FR201 with AIR SYSTEM.

For rounding solid wood, veneer and plastic edge bands for SCM - STEFANI ROUNDK AIR SYSTEM Z3.

For rounding solid wood, veneer and plastic edge bands for SCM - IDM C1/C2 CON AIR SYSTEM.

For rounding solid wood, veneer and plastic edge bands for BIESSE ERGHO AKRON.

For rounding solid wood, veneer and plastic edge bands for HOMAG FF - IMA.

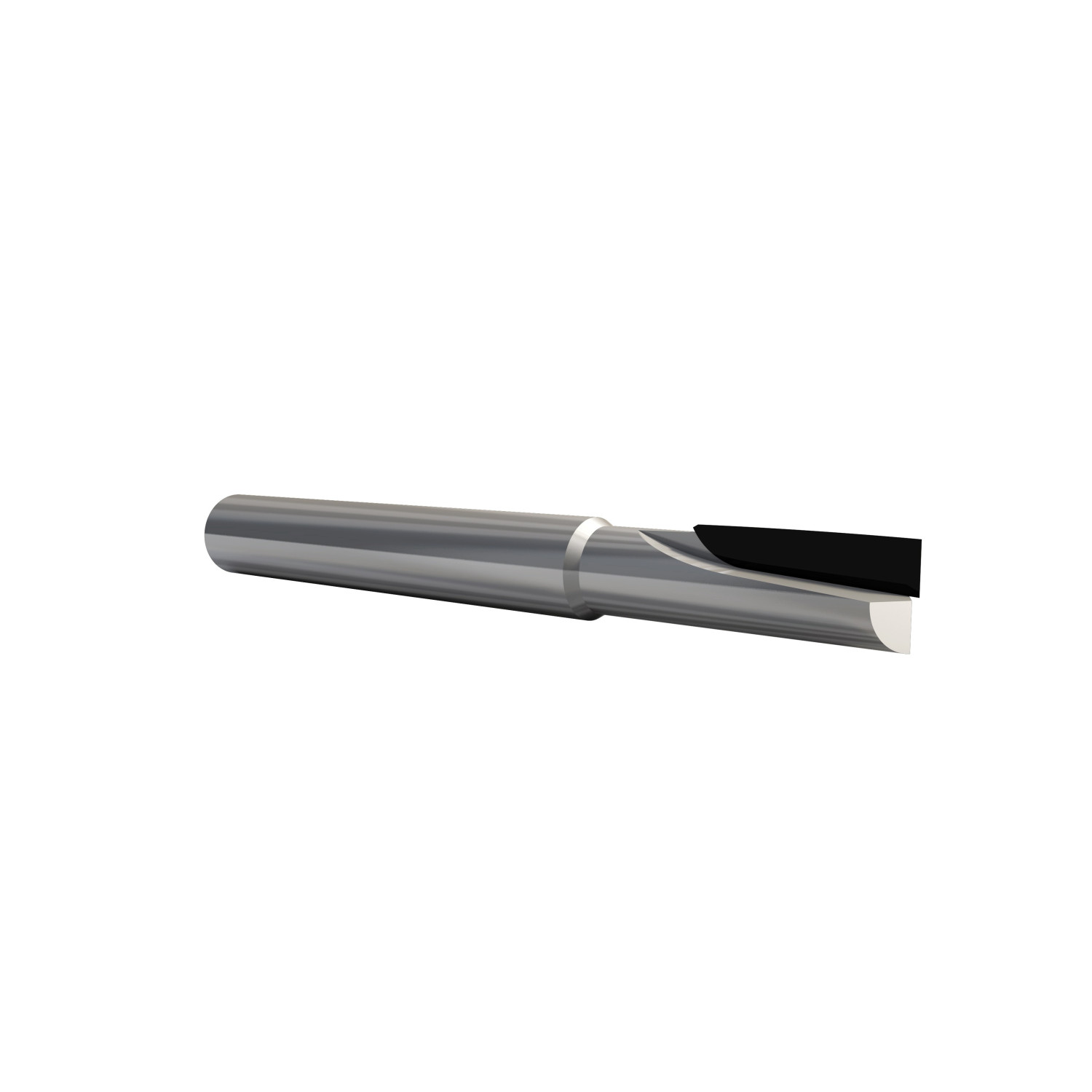

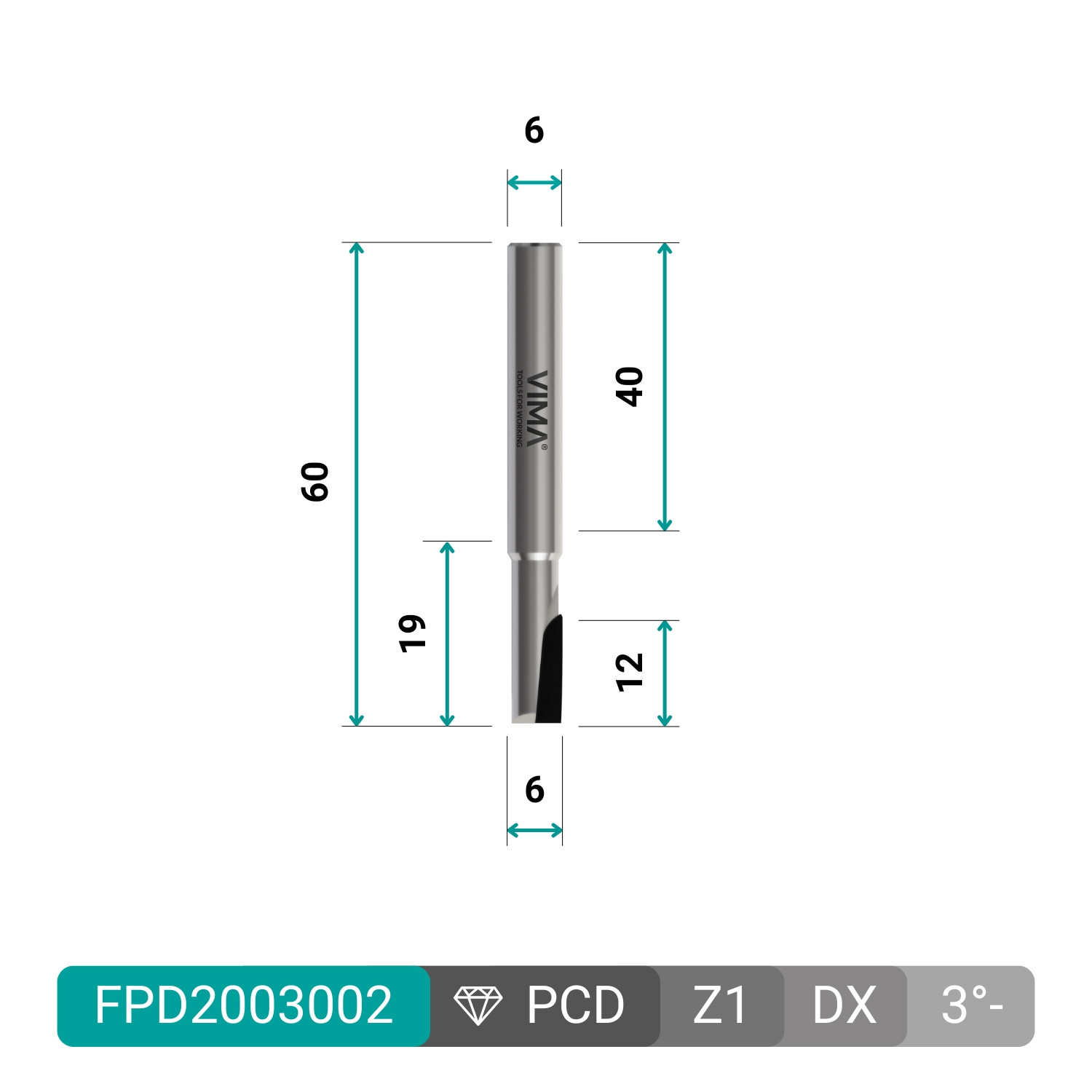

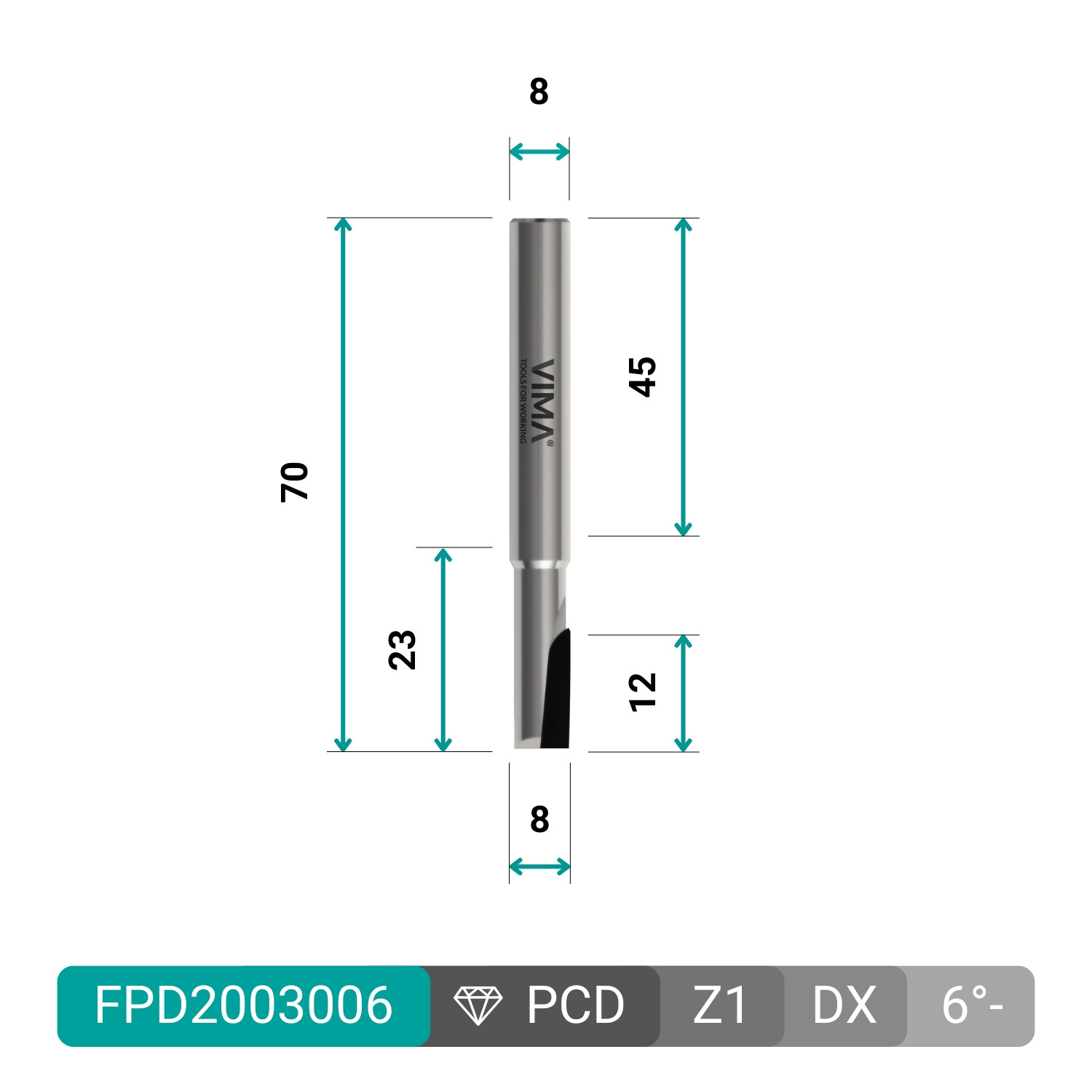

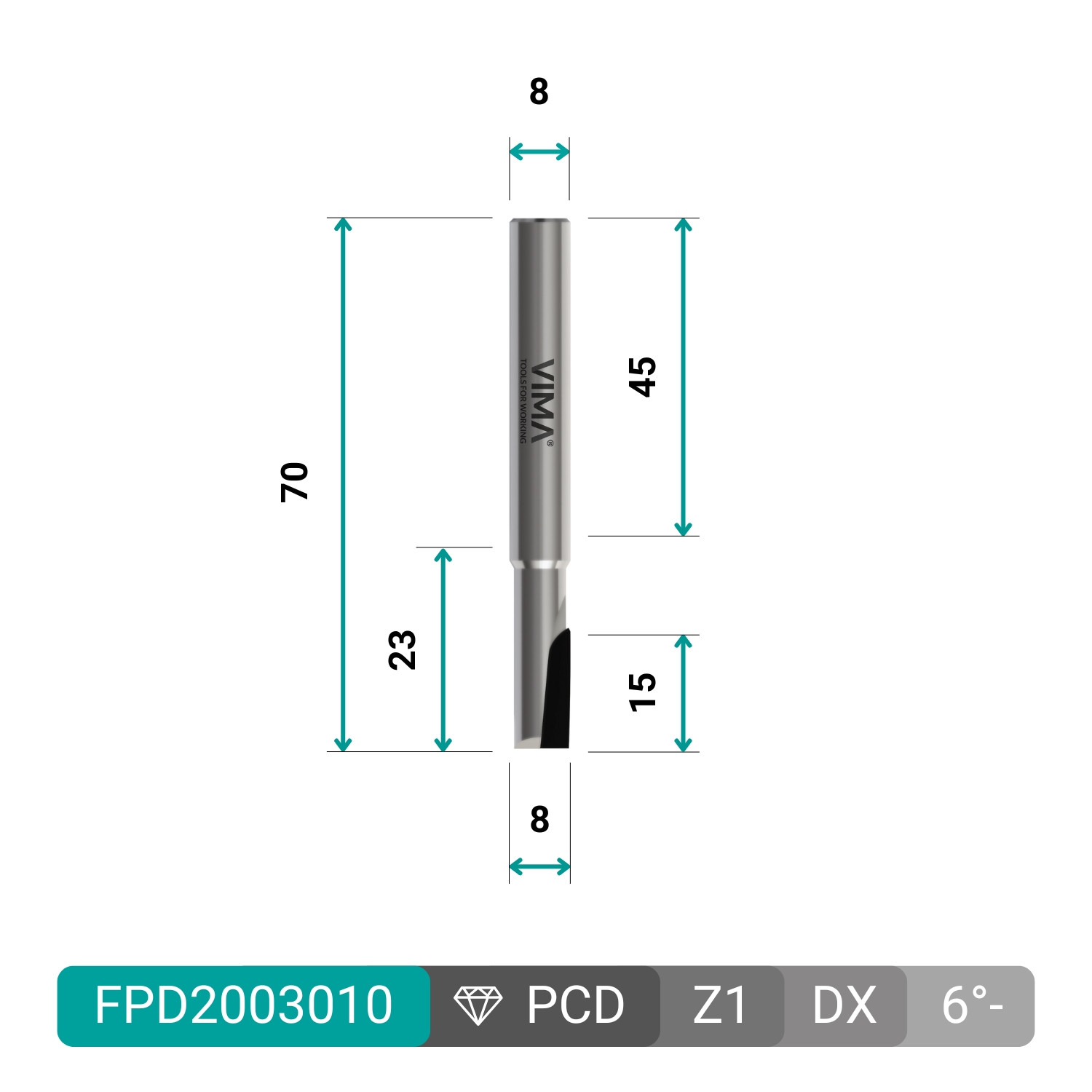

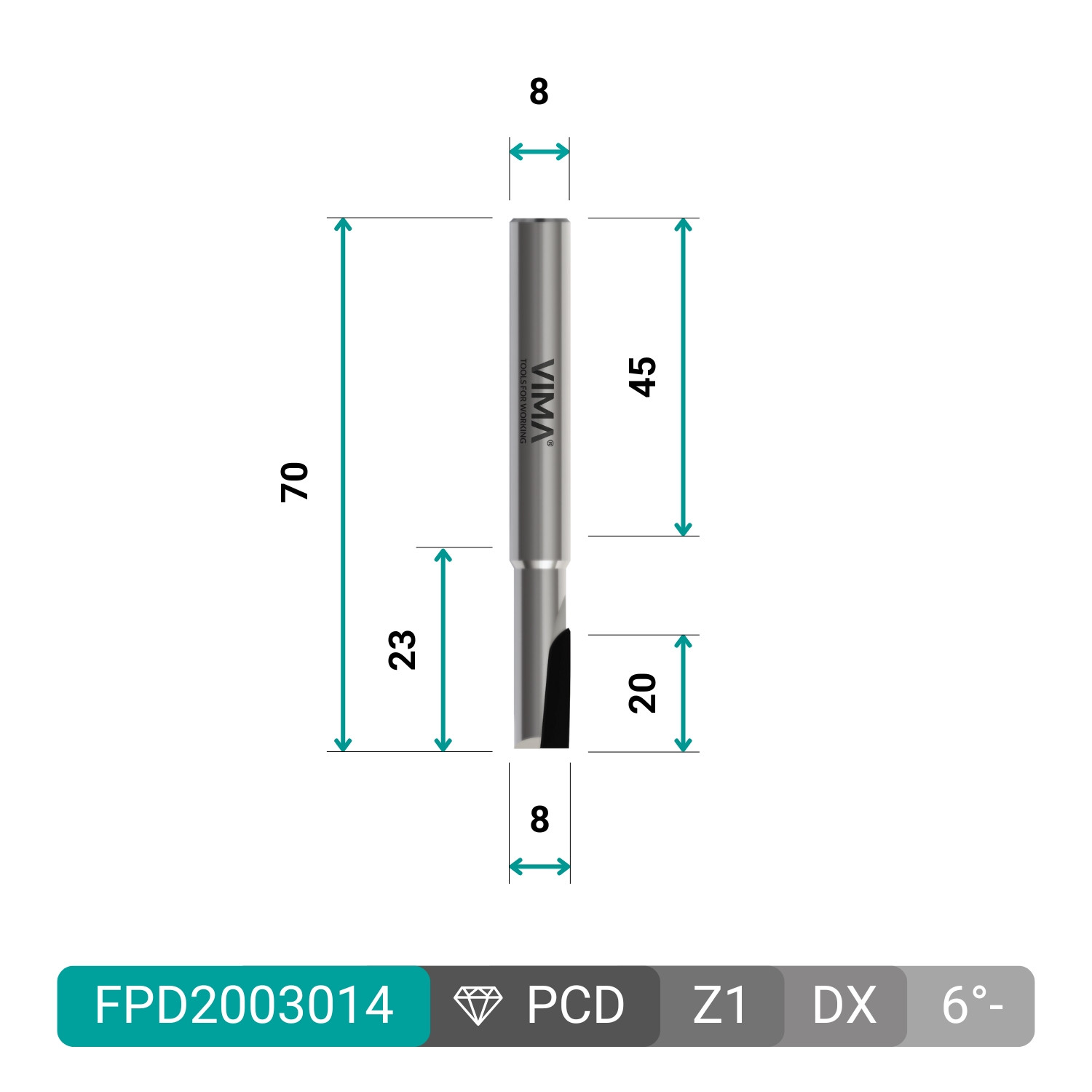

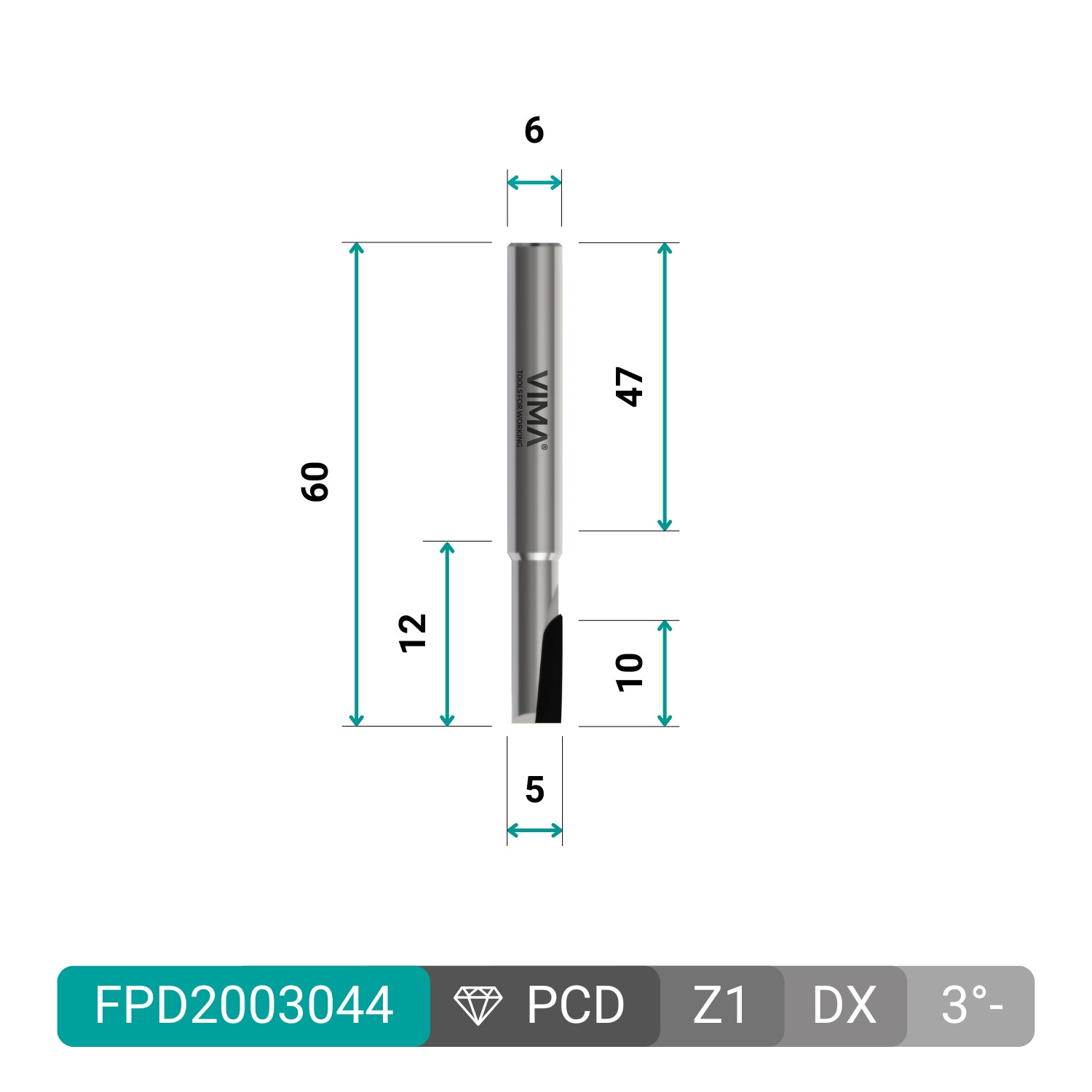

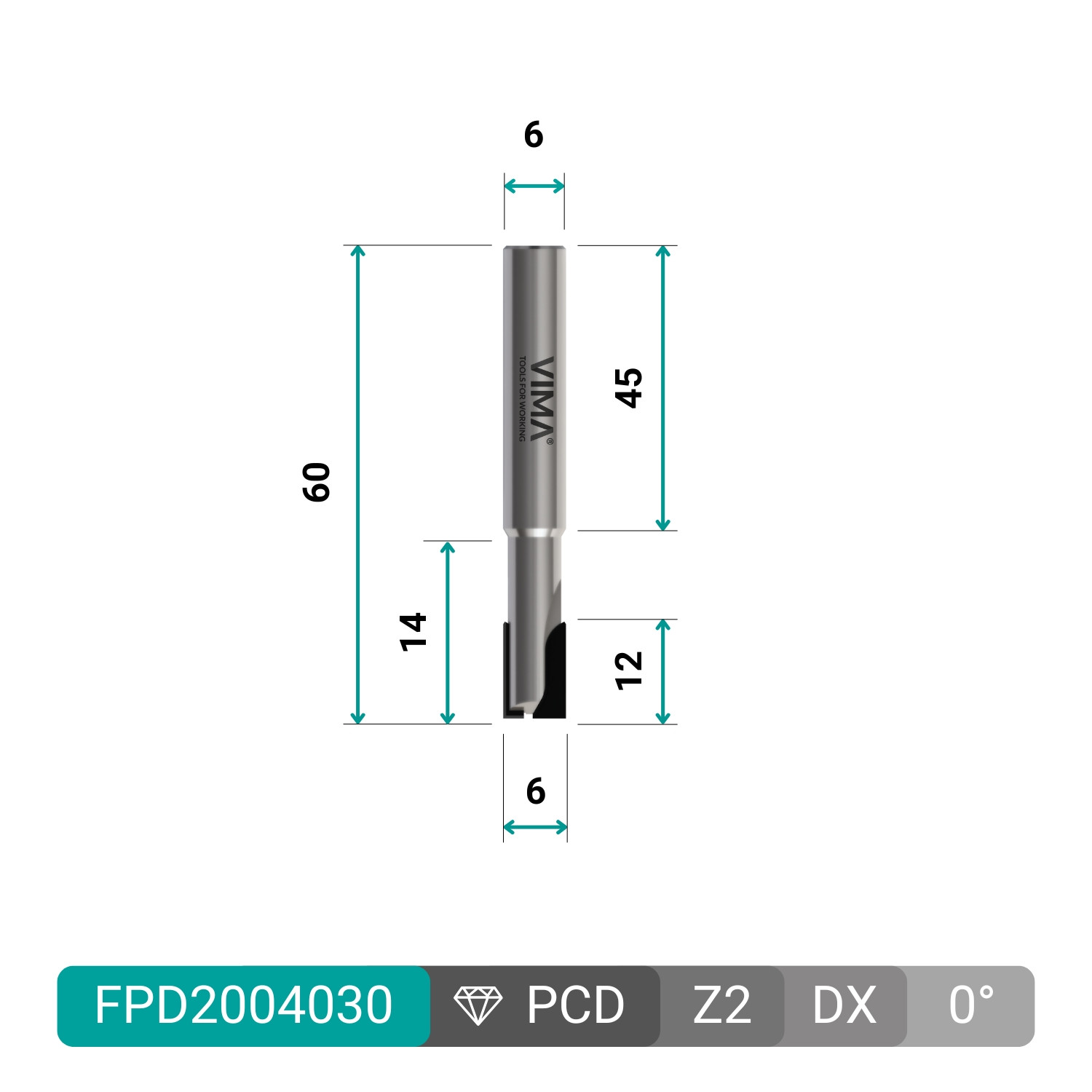

PCD diamond router bit designed for groove cutting with high surface quality on coated panels. The negative Z1 cutting edge and solid carbide body ensure maximum stability, controlled material removal and clean finishes even on delicate surfaces.

• PCD cutting edge H 3.5 mm for long tool life

• Negative Z1 cutting edge for superior panel finish

• Solid carbide body for high rigidity and stability

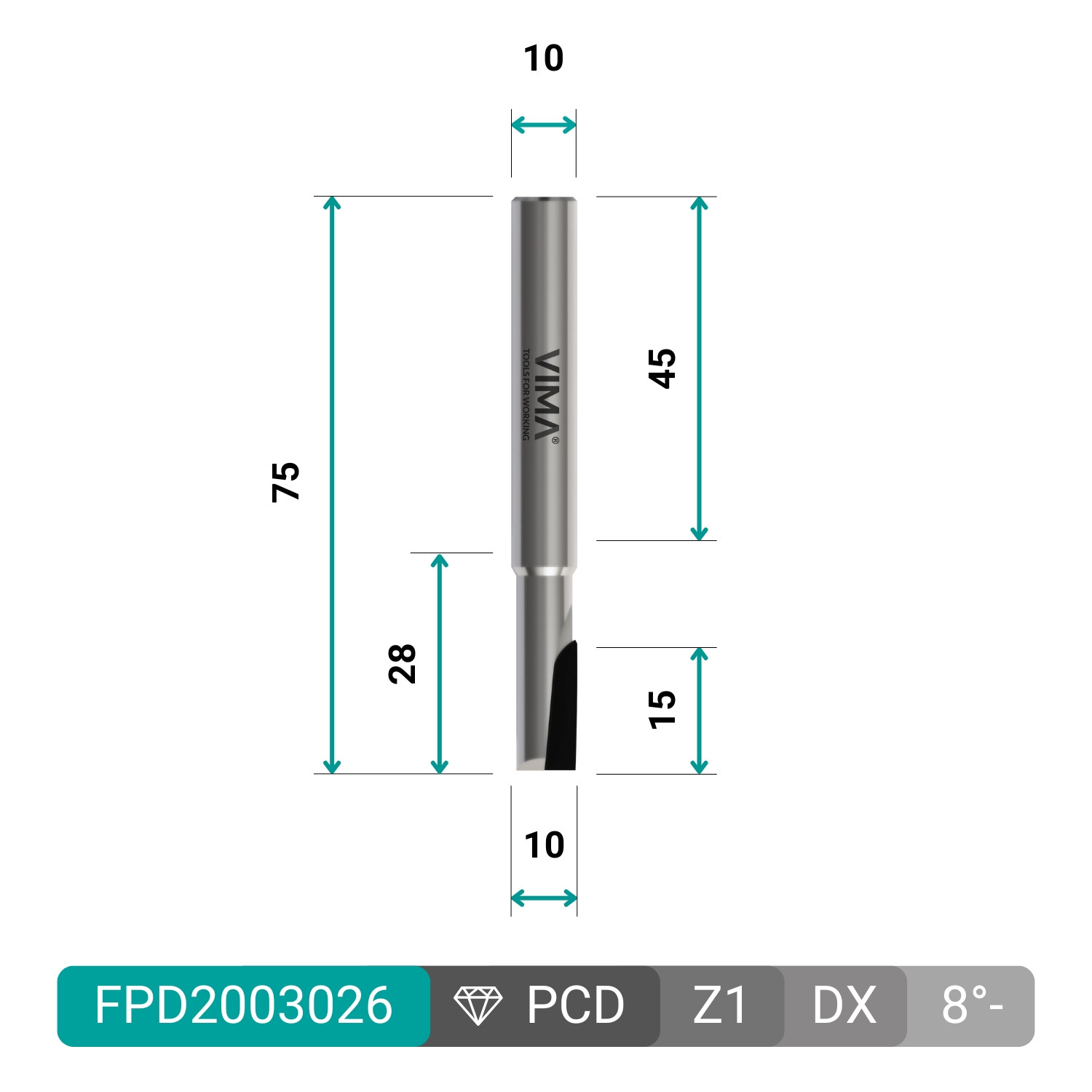

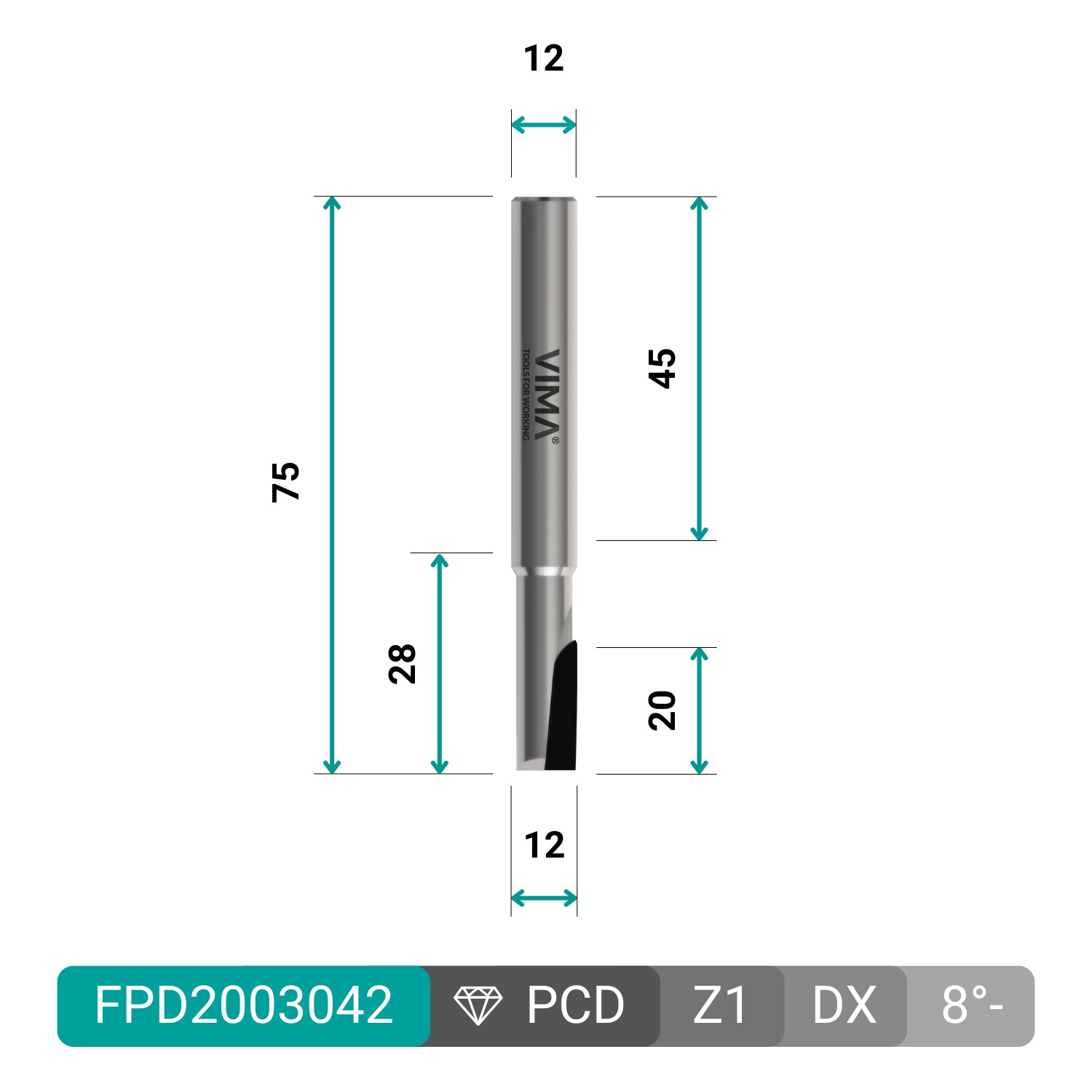

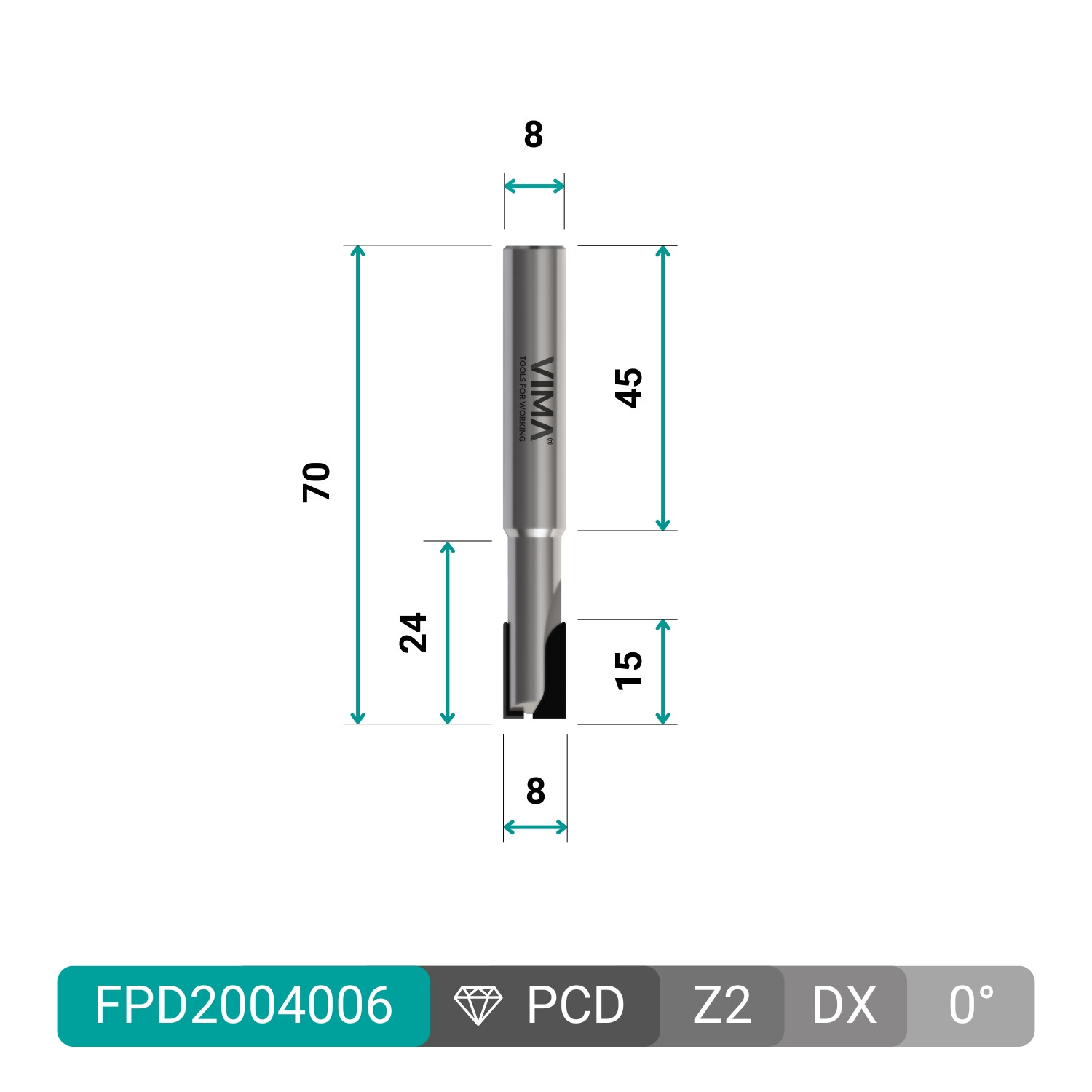

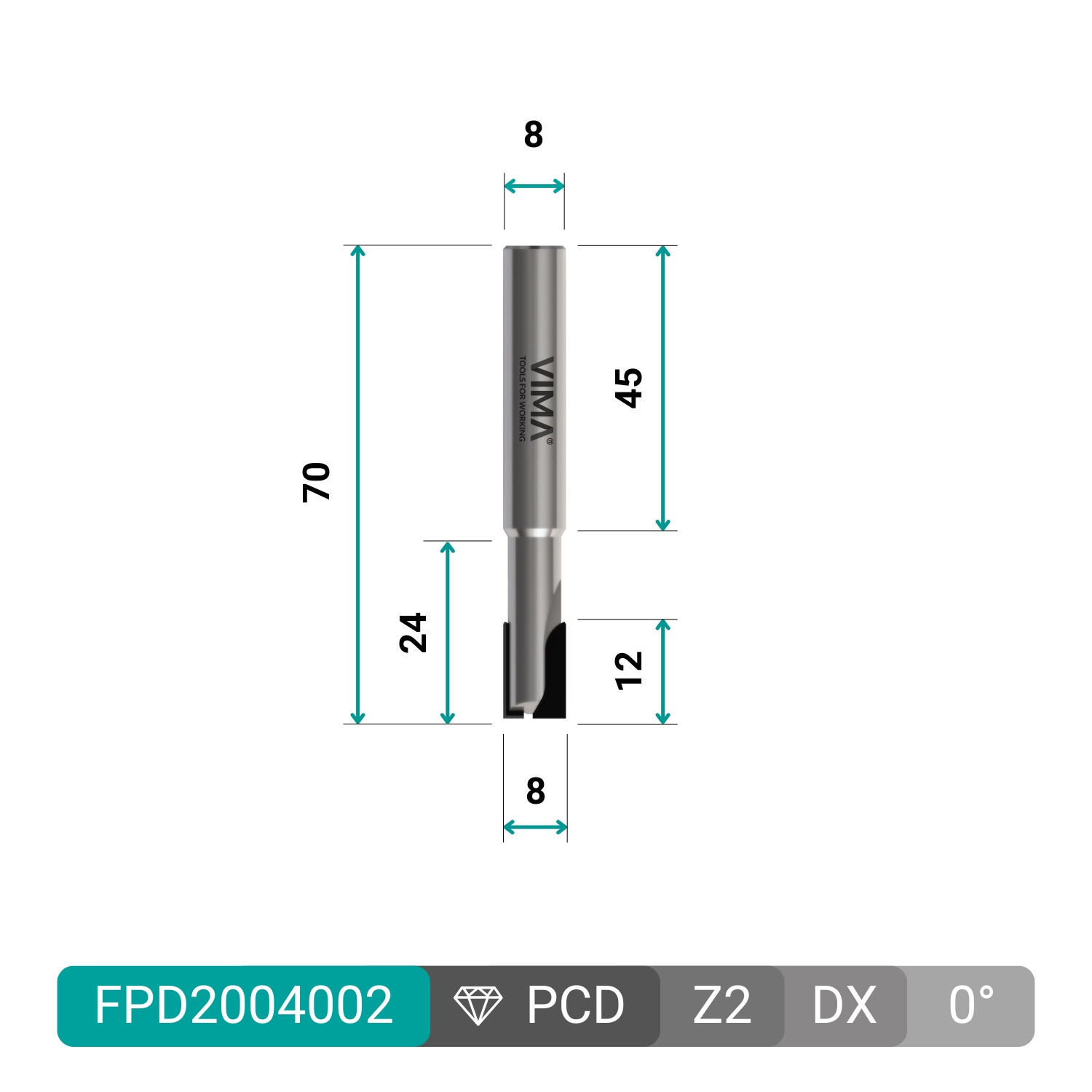

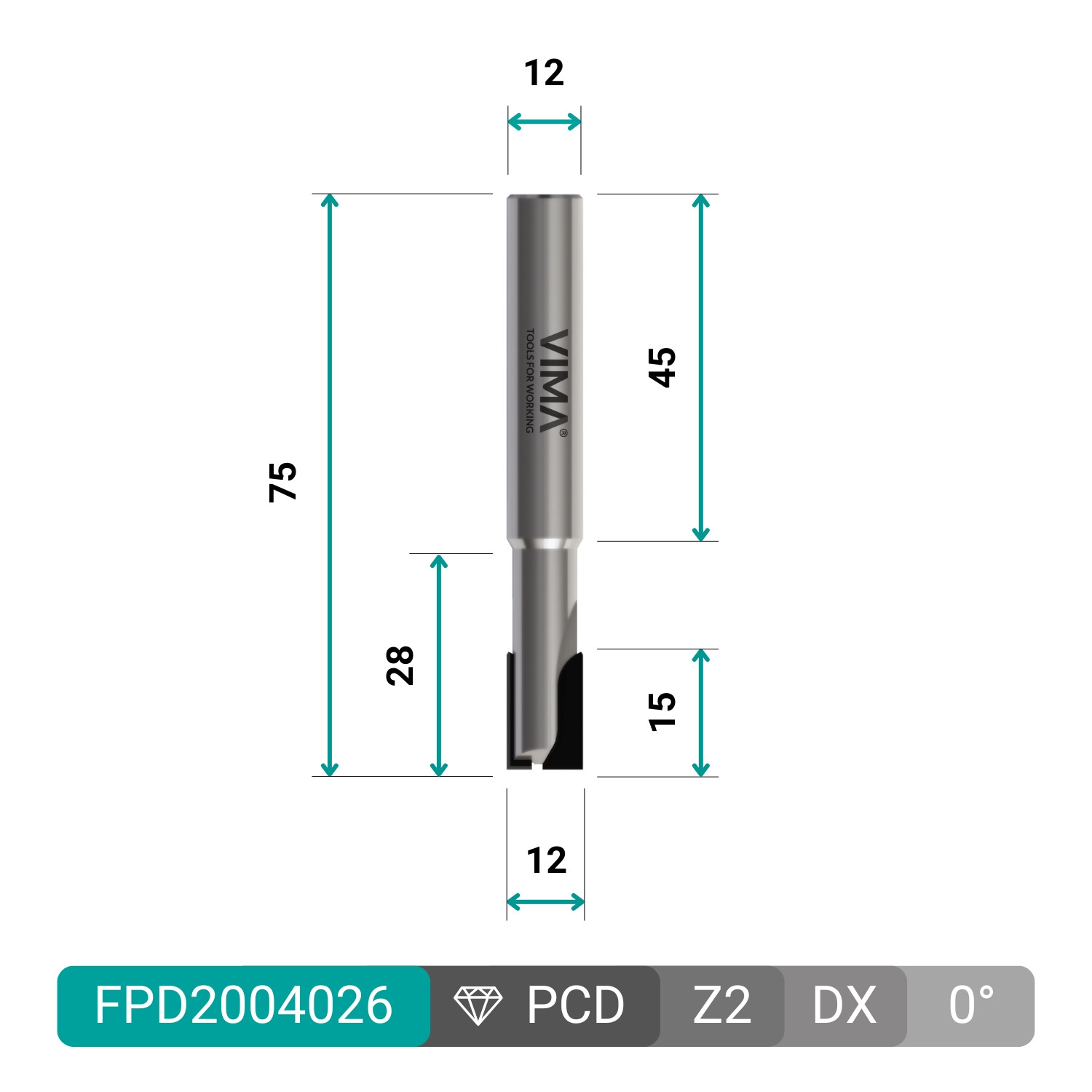

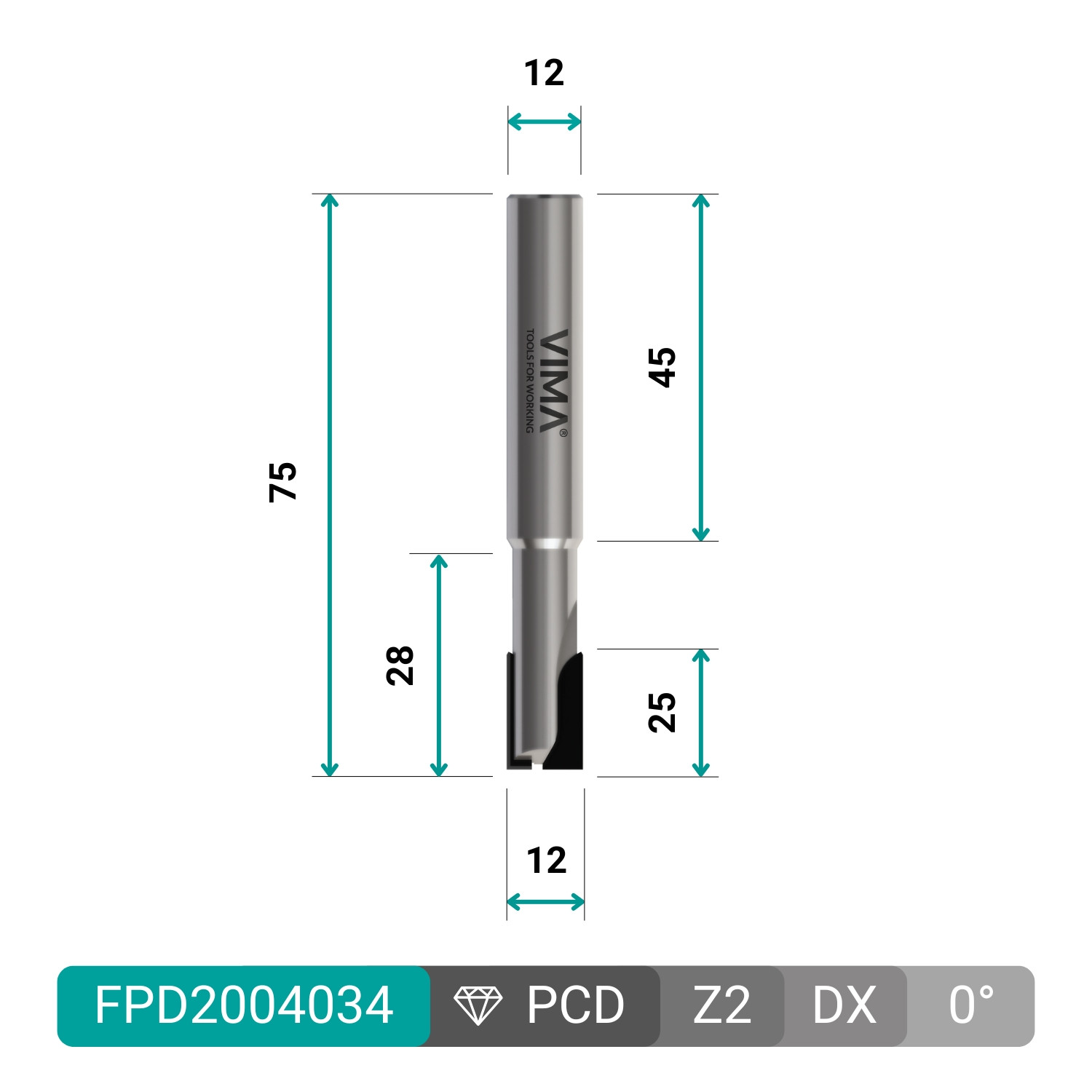

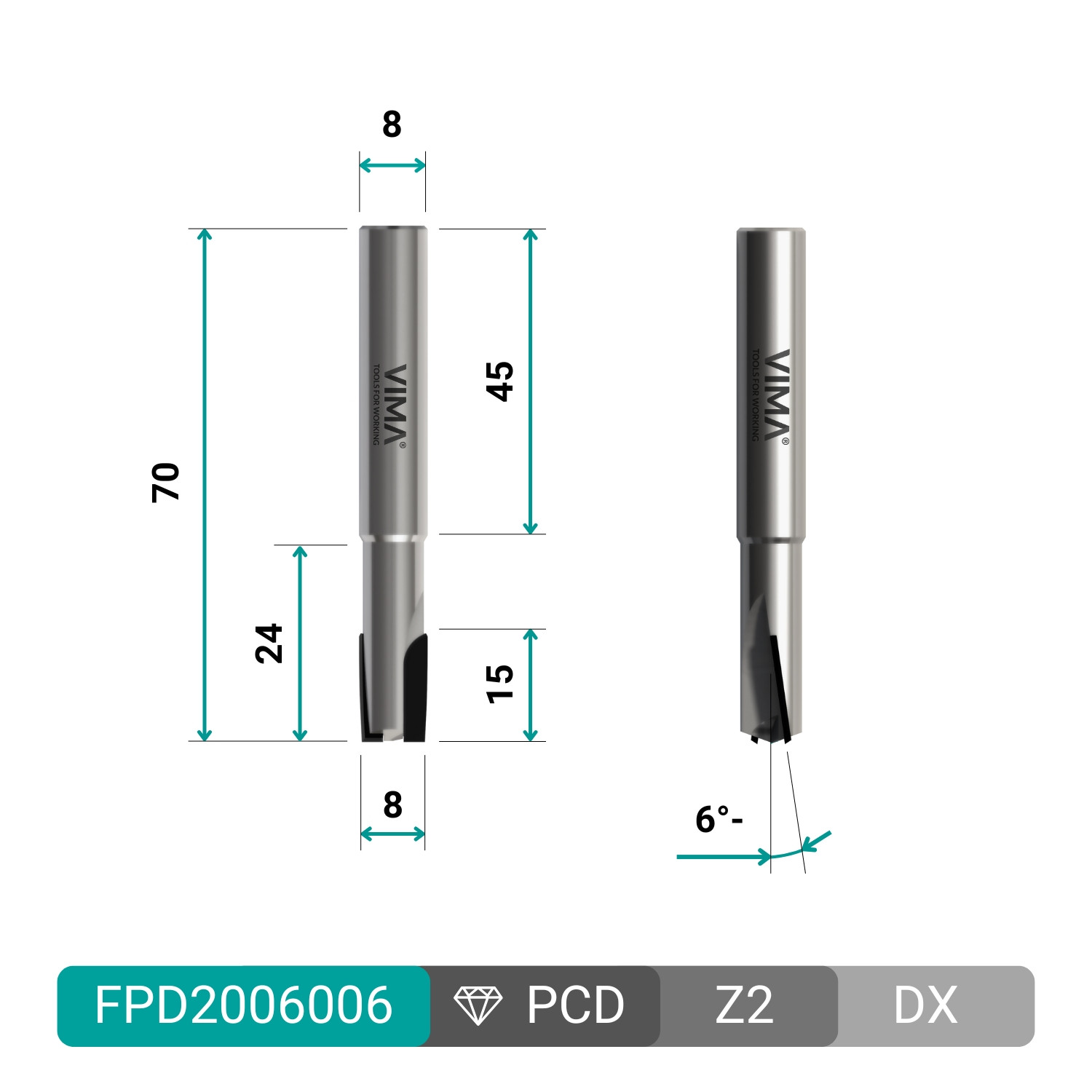

PCD diamond router bit designed for groove cutting and contouring on CNC machines with mechanical feed. The two straight Z2 cutting edges and solid carbide body provide balanced cutting action, improved stability and consistently high finish quality.

• PCD cutting edges H 3.5 mm for high durability

• Z2 configuration for higher stability and productivity

• Solid carbide body for rigidity and operational precision

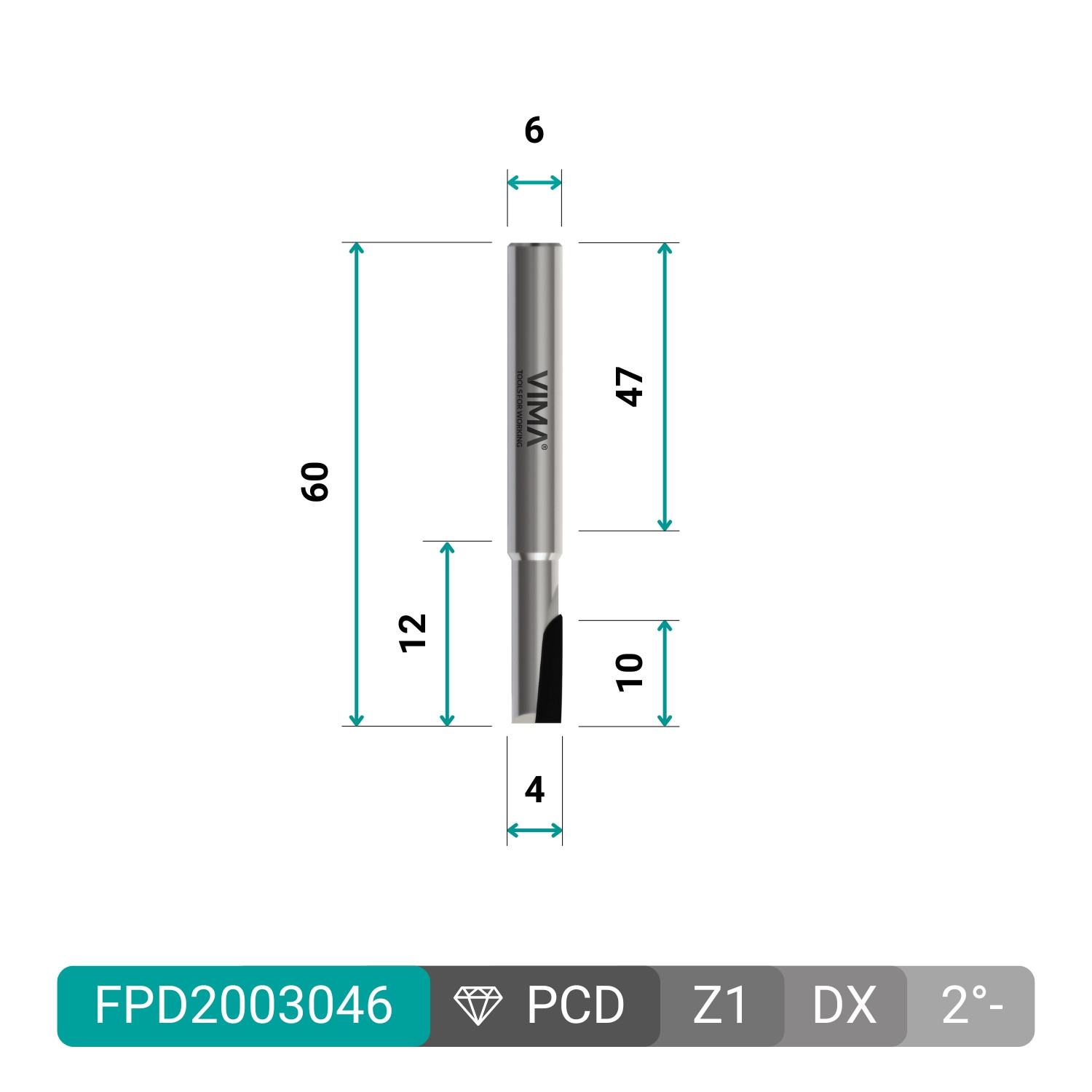

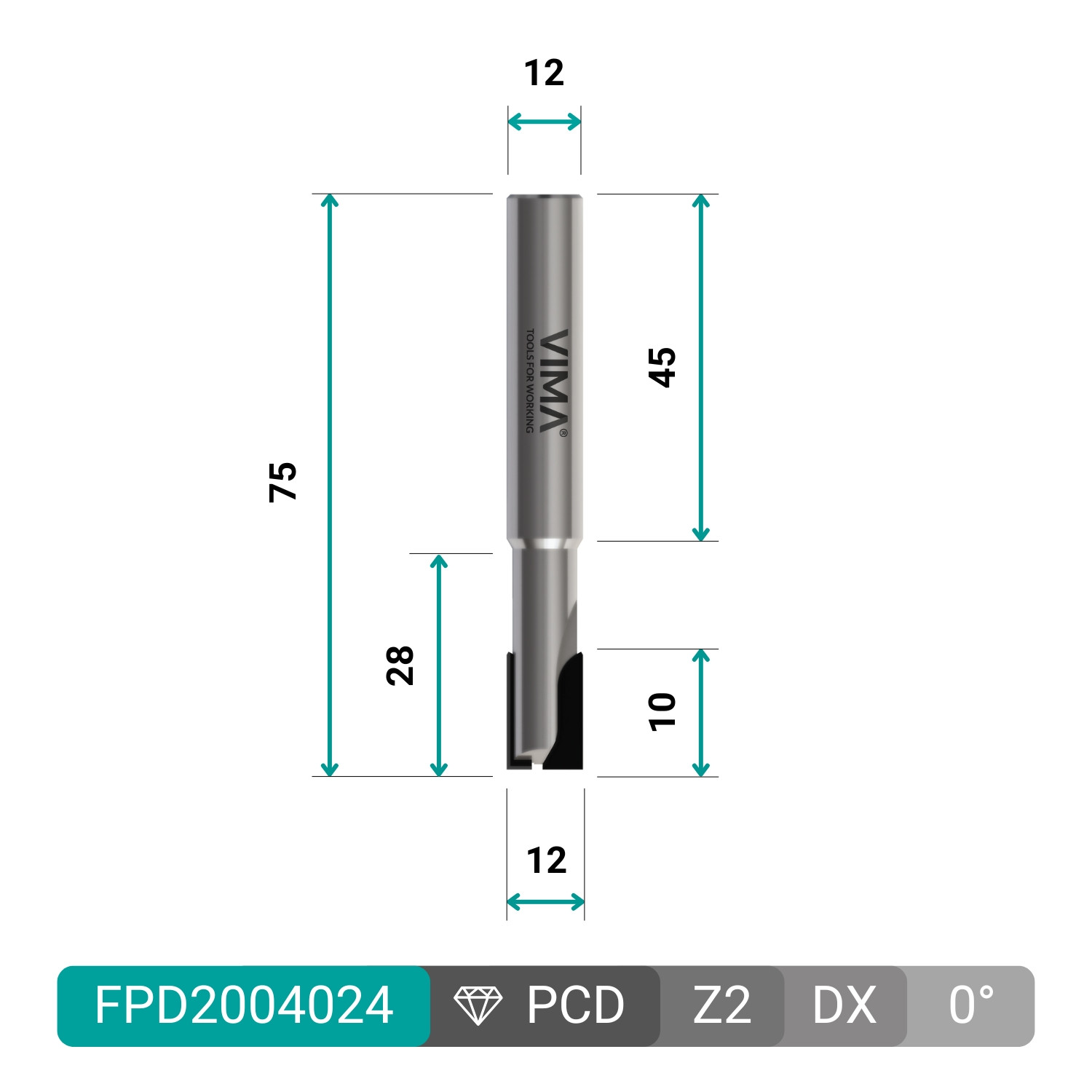

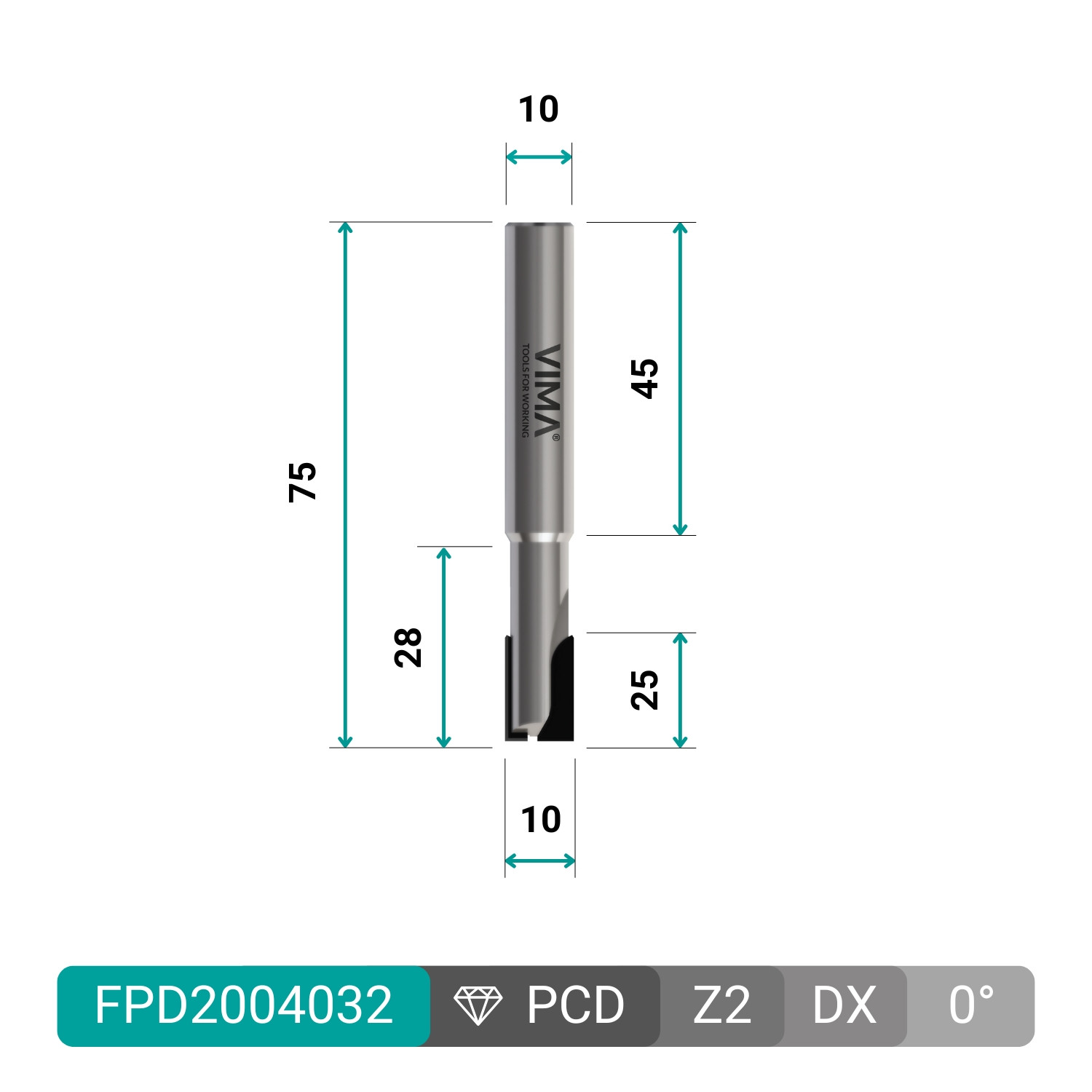

PCD diamond router bit designed for grooving coated panels where the highest surface quality is required. The negative Z2 cutting edges and solid carbide body ensure stability, controlled material removal and clean finishing even on delicate surfaces.

• PCD cutting edges H 3.5 mm for long tool life

• Negative Z2 cutting edges for superior surface finish

• Solid carbide body for rigidity and operational stability

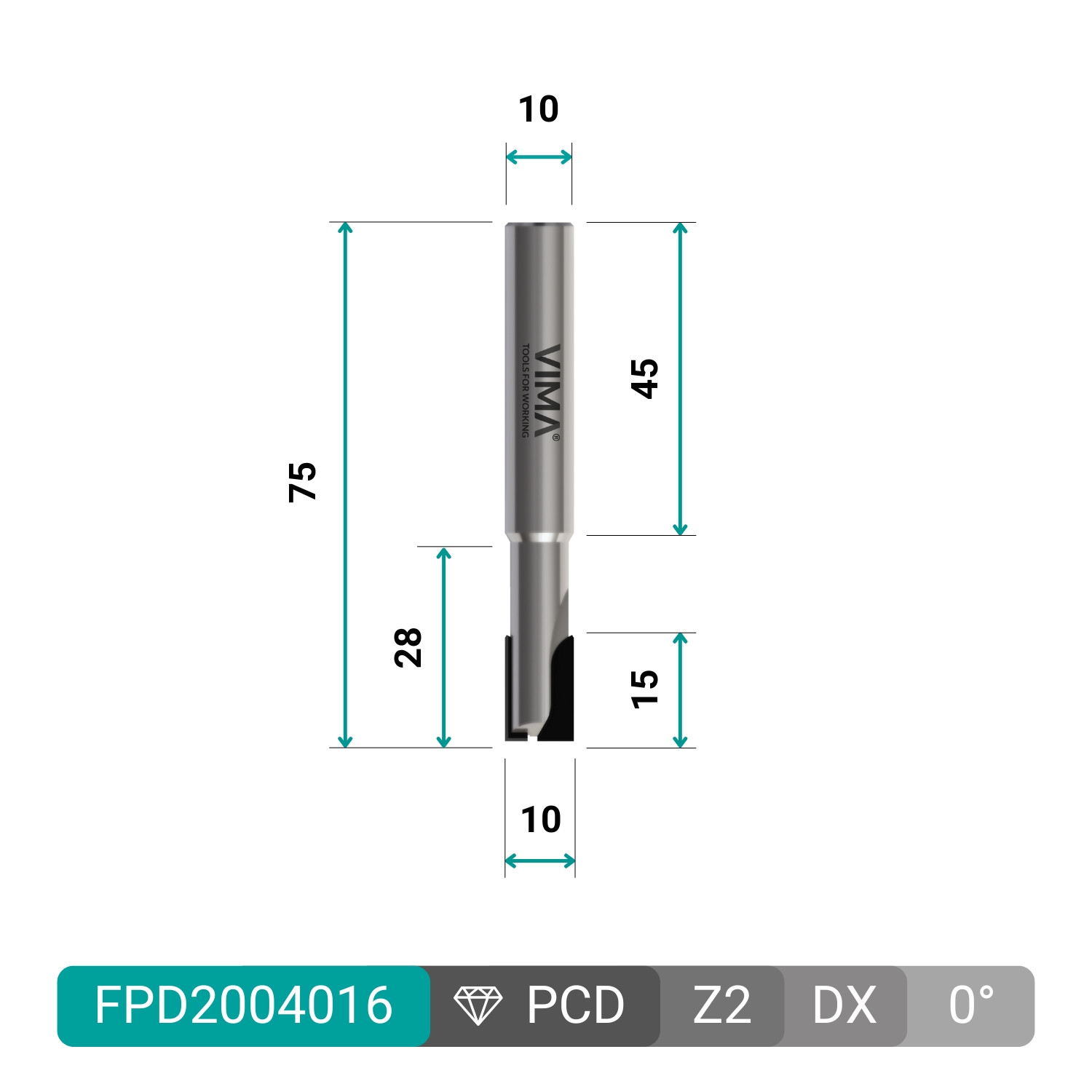

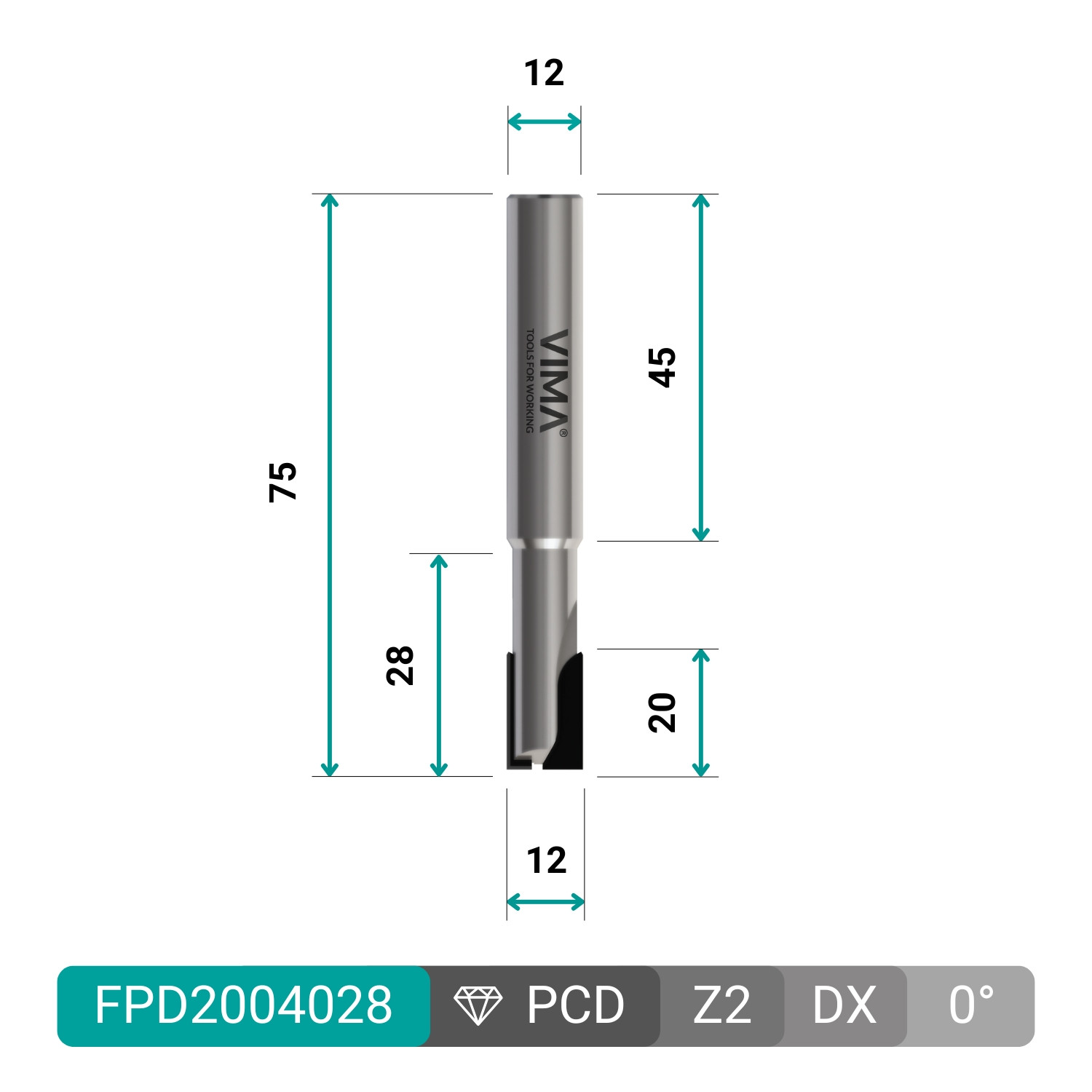

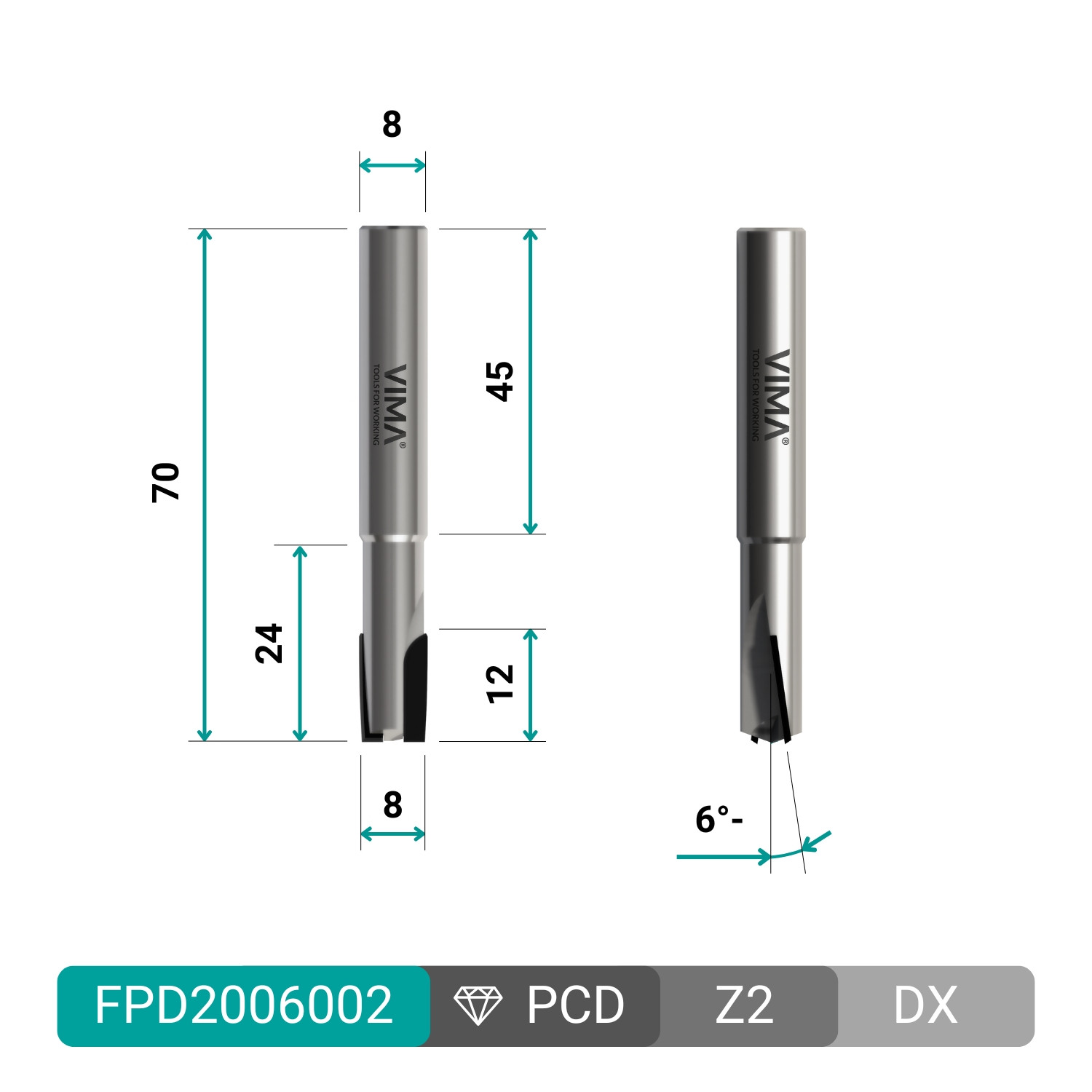

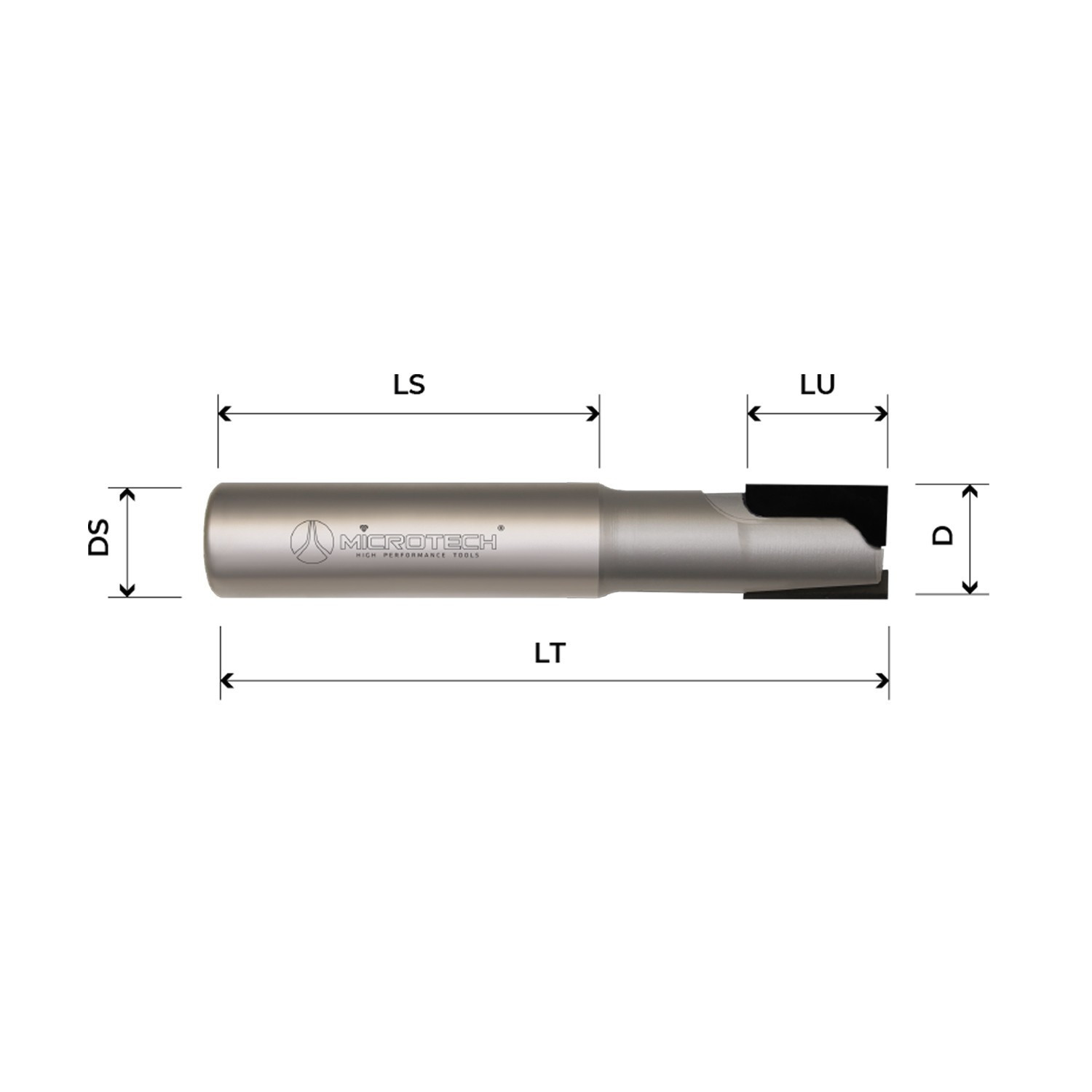

PCD diamond router bit designed for grooving, contouring and surfacing operations on CNC machines with manual or mechanical feed. The two straight Z2 cutting edges and the steel body ensure cutting stability, controlled material removal and consistent surface finish.

• PCD cutting edges H 4 mm for long tool life

• Z2 configuration for balanced and productive cutting

• Steel body for robustness and reliability

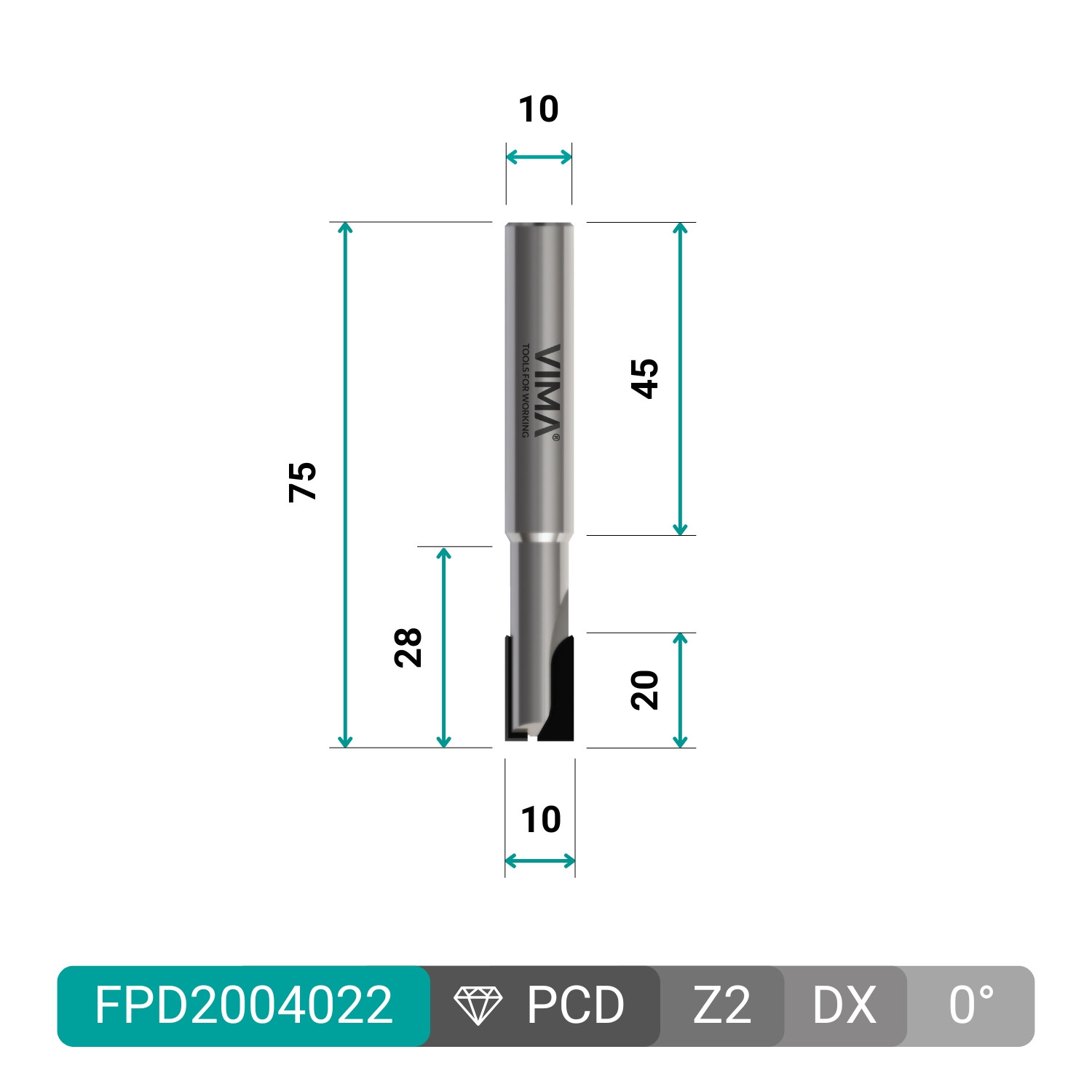

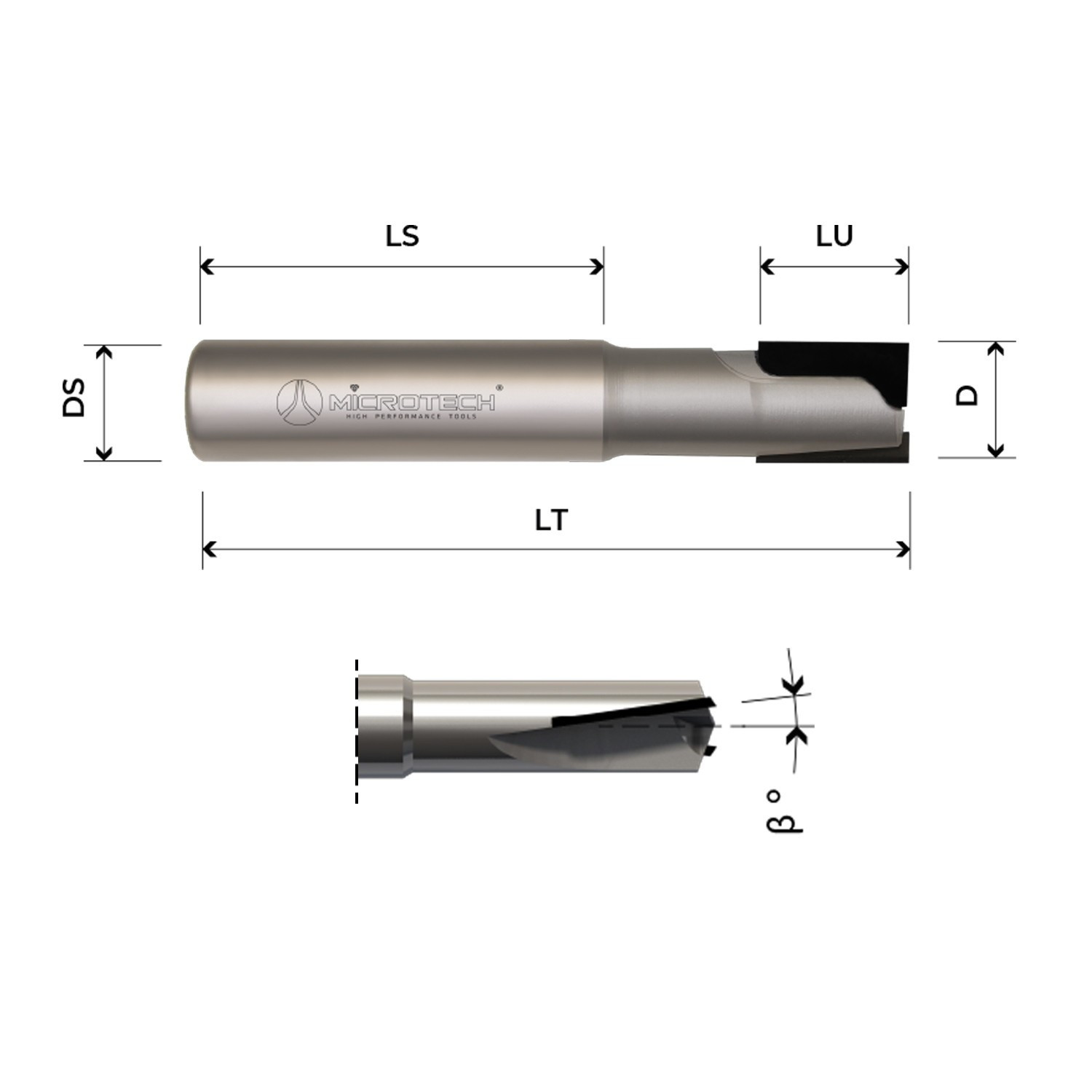

PCD diamond router bit engineered for grooving operations on coated panels and wood-based materials when an excellent surface finish is required. The negative Z2 cutting geometry together with the steel body provides high stability, controlled chip removal and a clean, tear-free result.

• PCD cutting edges H 4 mm for extended tool life

• Negative Z2 geometry for chip-free surfaces and clean edges

• Steel body for robustness and machining accuracy

PCD helical router bit designed for contouring and grooving on both CNC and manual machines. The Z1+1 layout with two helical sections offers a solid balance between material removal, cutting stability and surface finish, especially on coated panels.

• Z1+1 configuration with positive and negative helix

• PCD diamond insert H 2.5 mm, regrindable

• Ideal for laminated panels and coated MDF

PCD Z1+1 helical router bit designed for CNC grooving and contouring on panels and wood-based materials. The cost-effective PCD insert H 2.5 mm, regrindable up to three times, combined with the steel body, offers a balanced solution in terms of performance, durability and cost.

• PCD insert H 2.5 mm, regrindable

• Z1+1 geometry with positive and negative helix

• Steel body for stability and reliability

PCD Z1+1 helical router bit designed for CNC contouring applications with shank. The PCD diamond insert H 4.5 mm, regrindable up to eight times, combined with the steel body ensures long tool life, cutting stability and consistent quality even on coated panels.

• PCD insert H 4.5 mm, regrindable up to 8 times

• Z1+1 geometry with positive and negative helix

• Steel body for rigidity and reliability

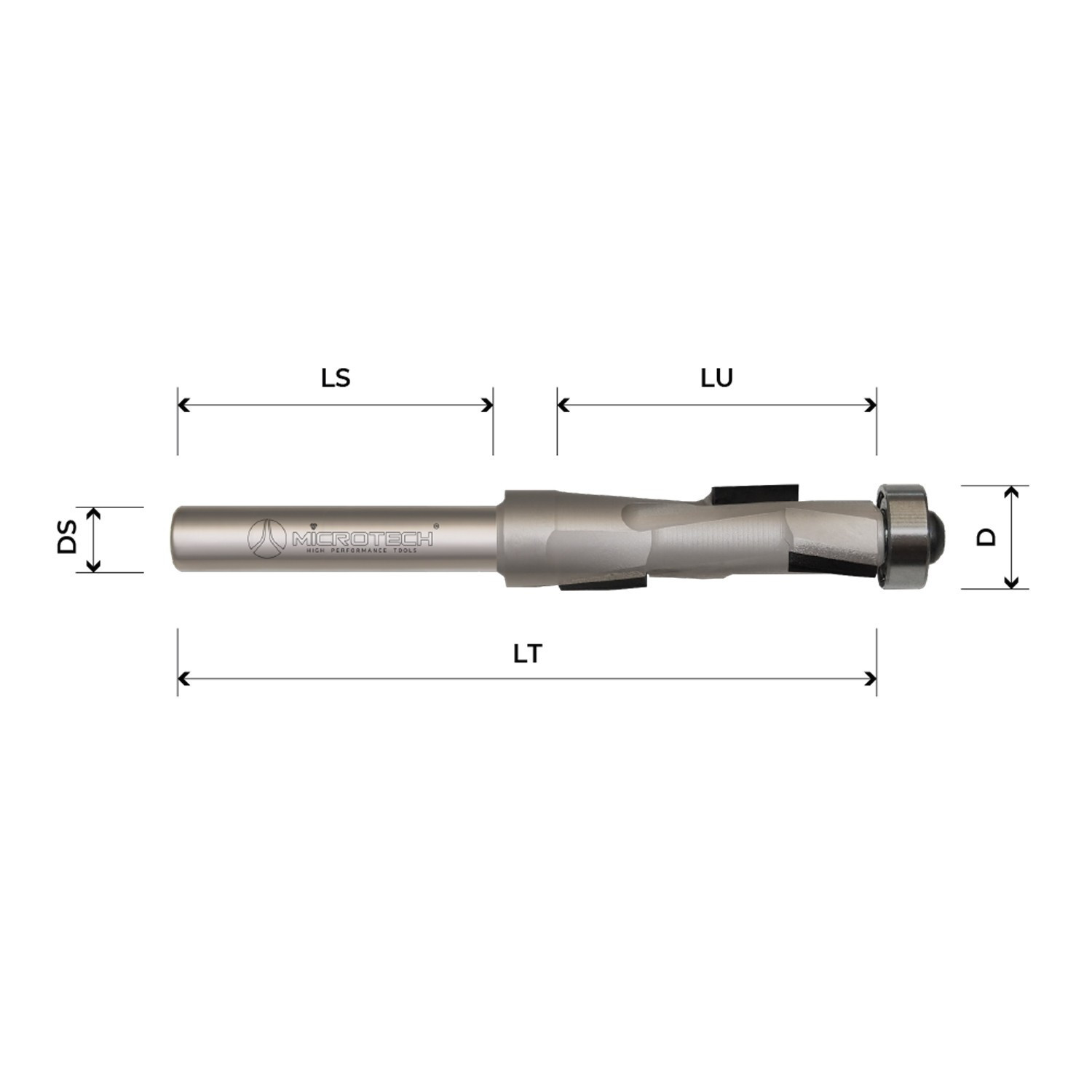

PCD Z1+1 router bit with guide bearing designed for trimming and contouring on CNC machines with manual or mechanical feed. The cost-effective PCD insert H 2.5 mm, regrindable up to three times, ensures cutting stability and a clean finish on coated panels.

• Guide bearing for precise trimming operations

• PCD insert H 2.5 mm, regrindable up to 3 times

• 3 helical divisions with positive/negative geometry

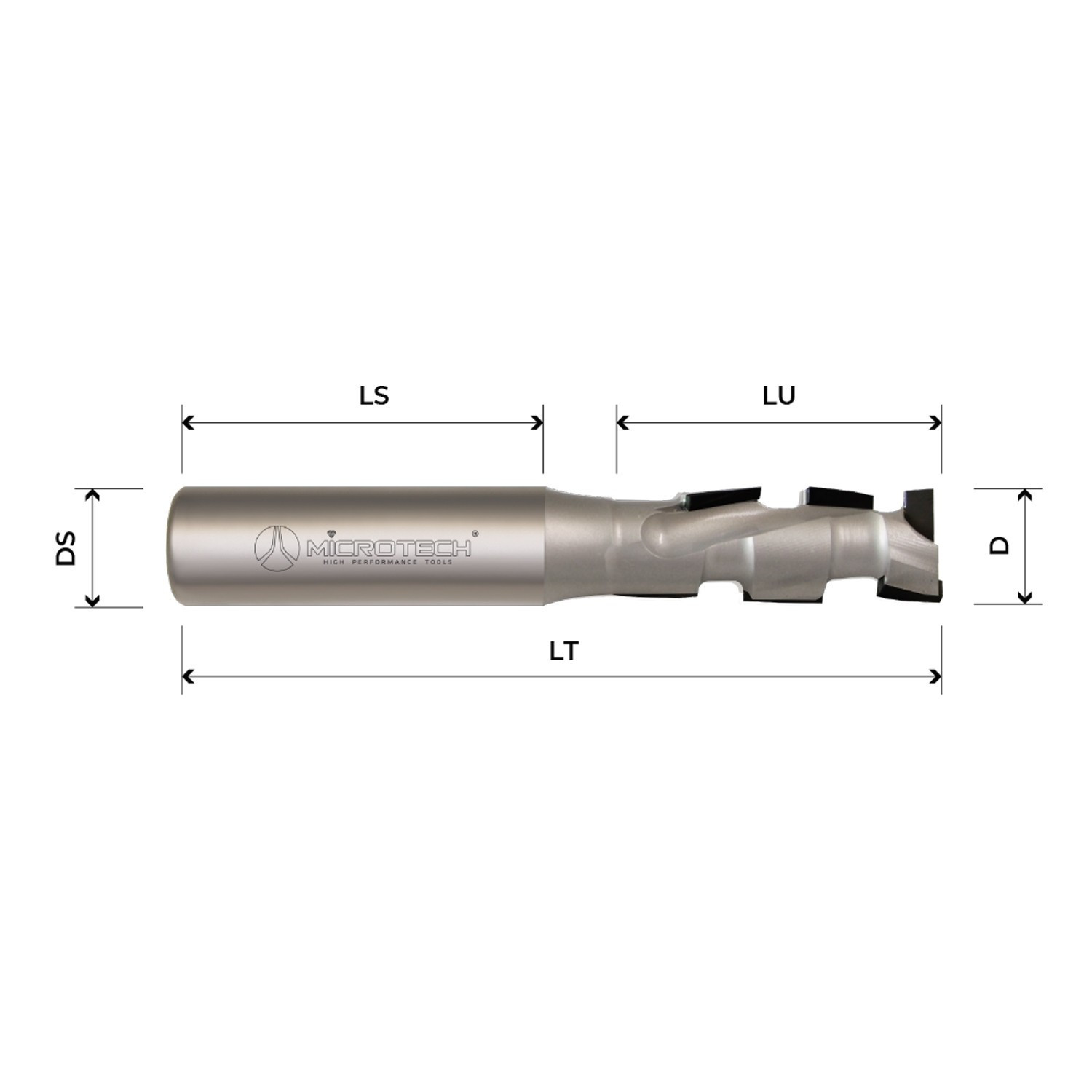

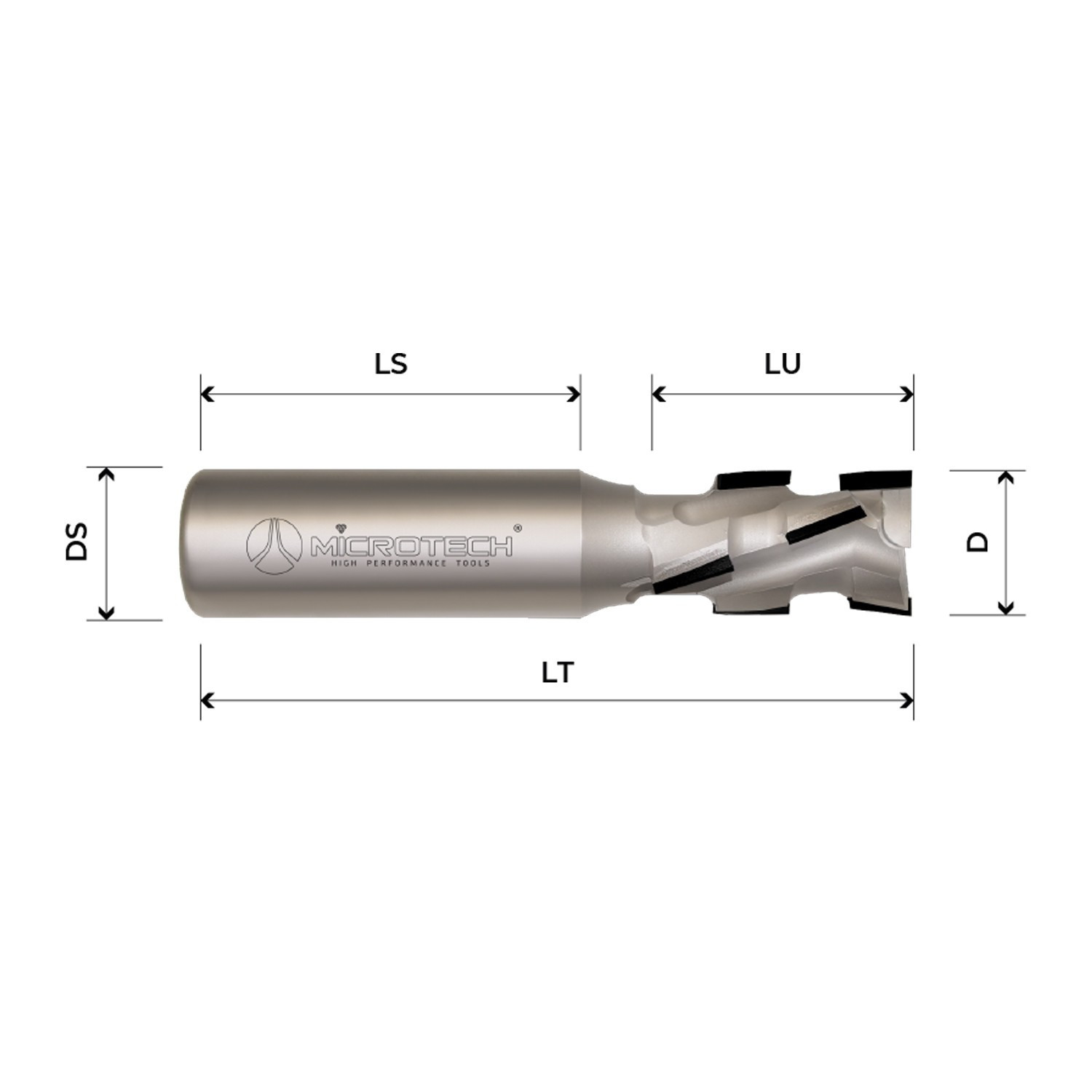

PCD Z2+2 helical router bit designed for shank contouring on CNC machines with mechanical feed. The 4 helical divisions and the pulling geometry with a first positive insert ensure efficient chip evacuation, cutting stability and consistent quality on panels and wood-based materials.

• Z2+2 with 4 helices for productive, stable machining

• PCD insert H 2.5 mm for good tool life and a clean finish

• Special steel body with HW drilling tip

PCD Z2+2 CNC/router bit for shank contouring with mechanical feed, designed for CNC routers and pantographs. The 4 helical divisions and pulling geometry deliver efficient chip evacuation, cutting stability and a clean finish on coated panels and plywood.

• PCD H 4.5 mm with up to 8 regrinds for extended service life

• Z2+2 and 4 helices for productive, stable CNC contouring

• Special steel body with HW drilling tip

.jpg)