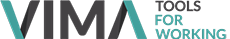

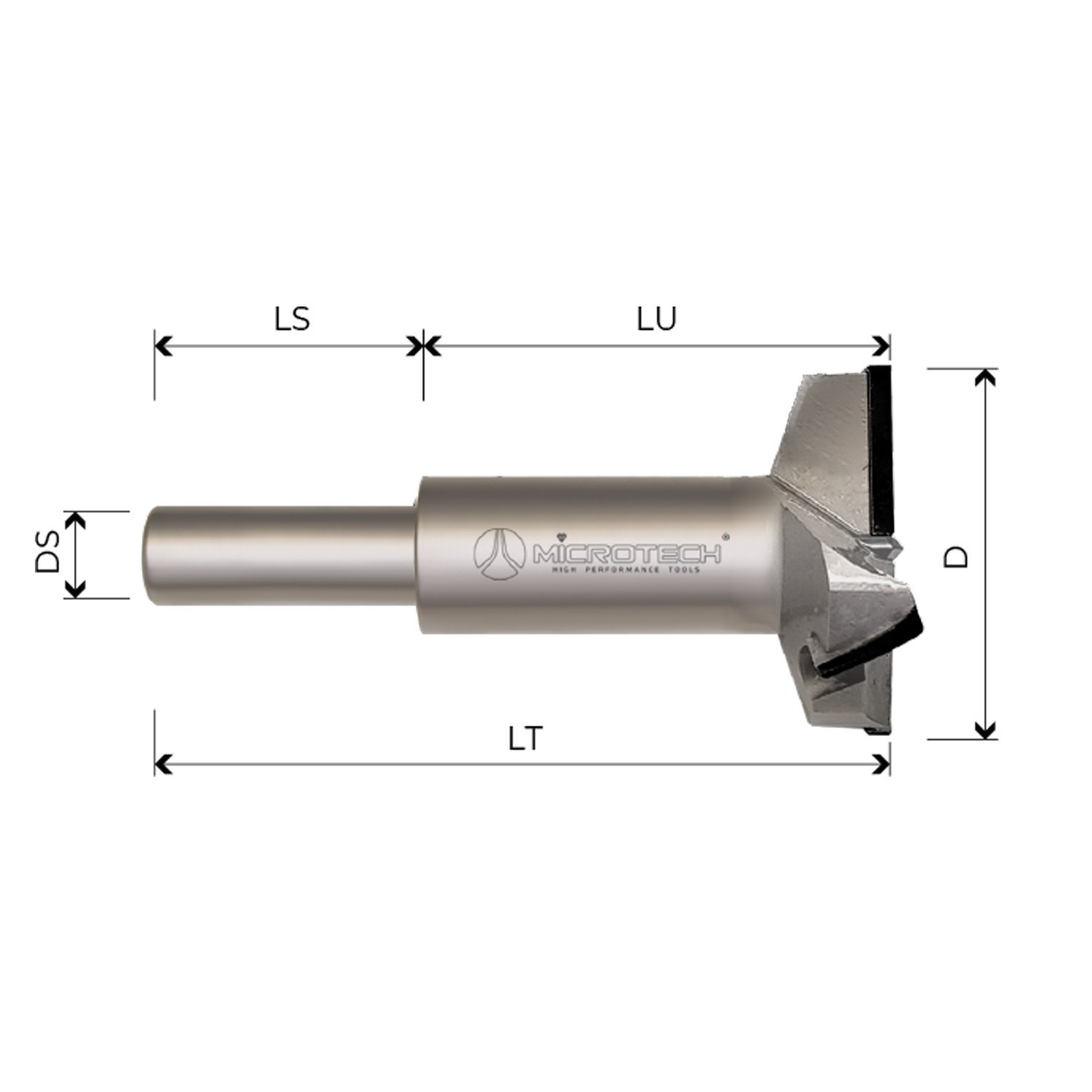

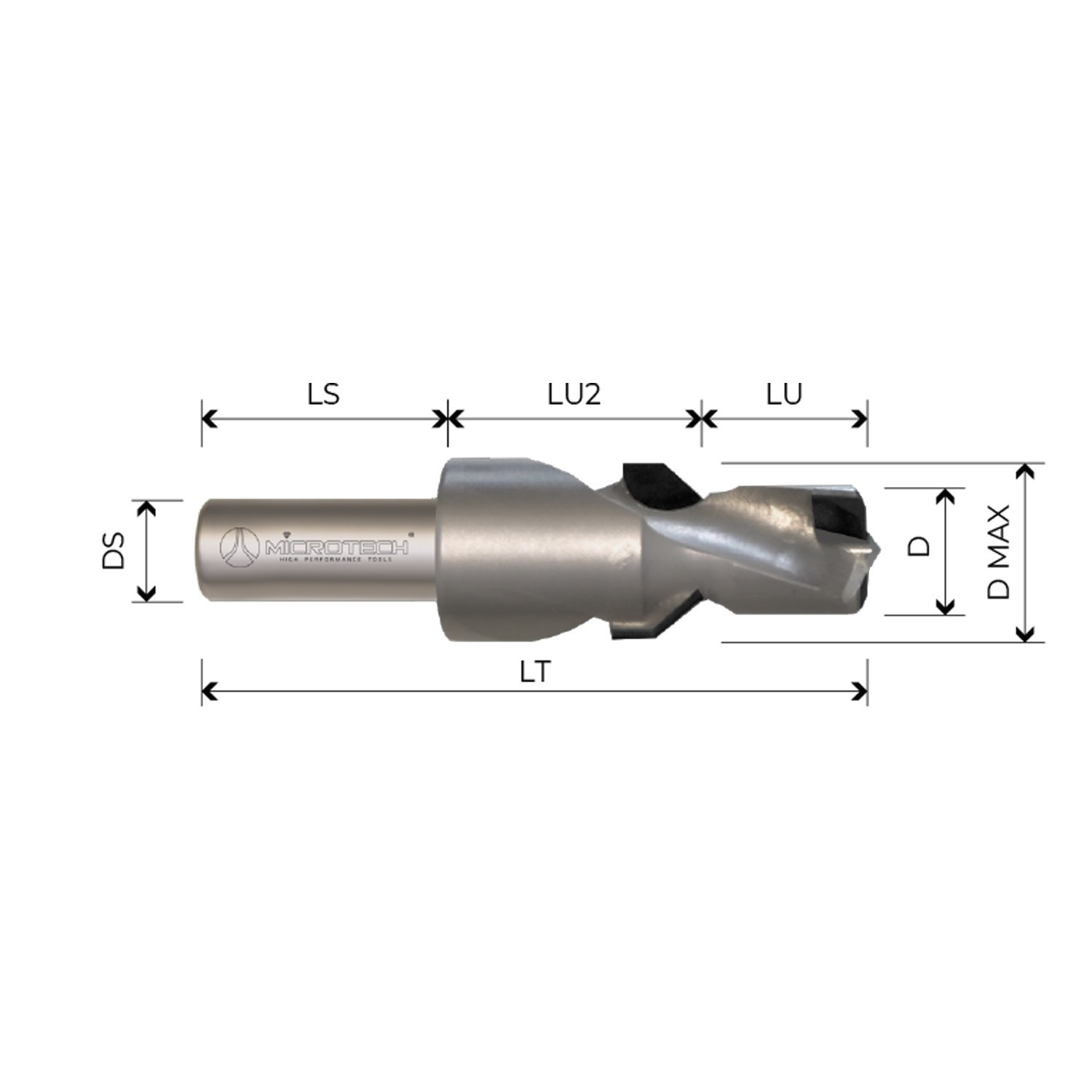

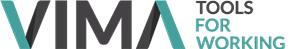

PCD high performance blind holes drilling bit Z2+2 with negative shaver tips.

PCD high performance blind holes drilling bit Z2+2 with negative shaver tips and chip breaker. Suitable for drilling on laminated chipboard panels MDF.

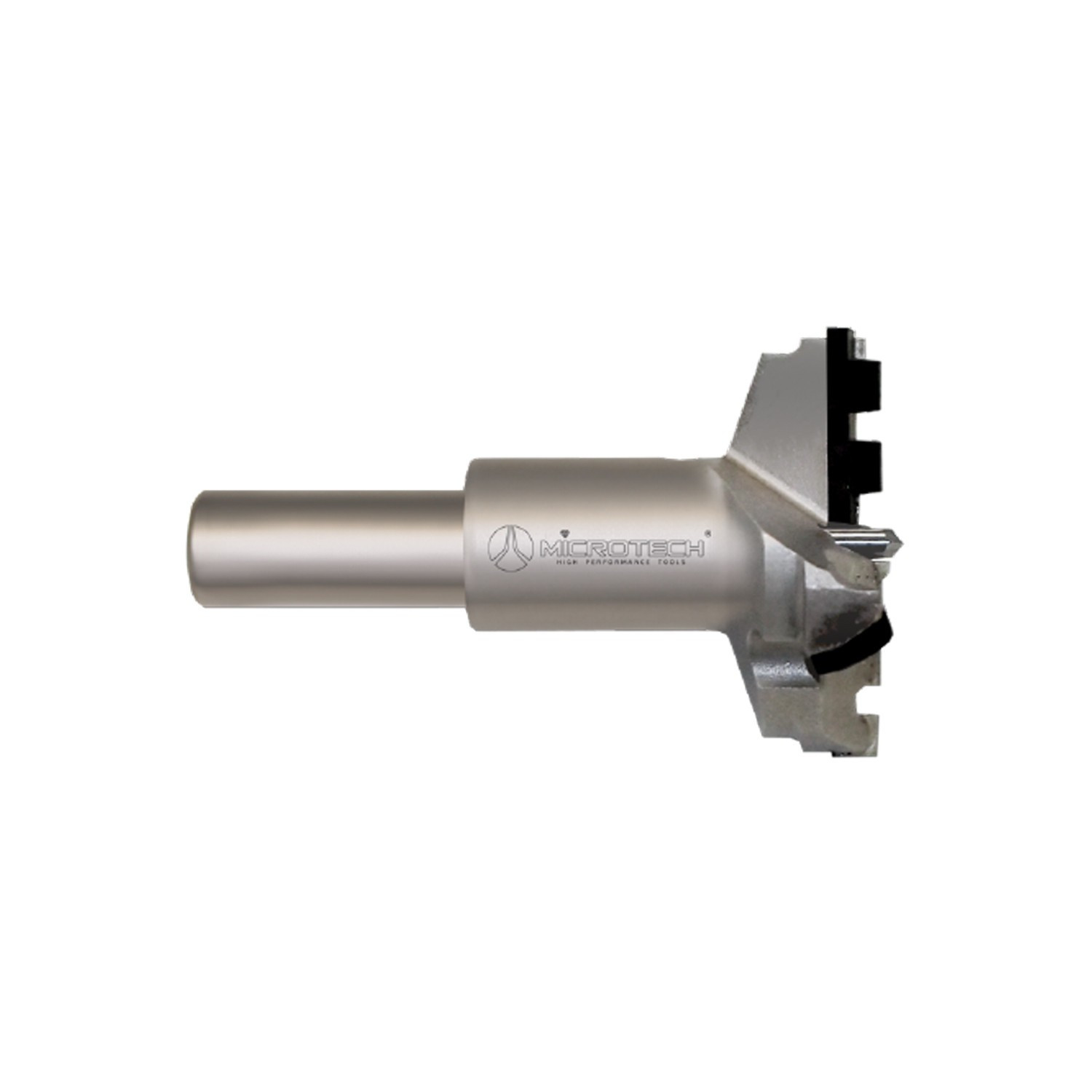

PCD high performance blind holes drilling bit Z2+2 with negative countersink tips and HW center tip. Suitable for drilling on laminated chipboard panels MDF

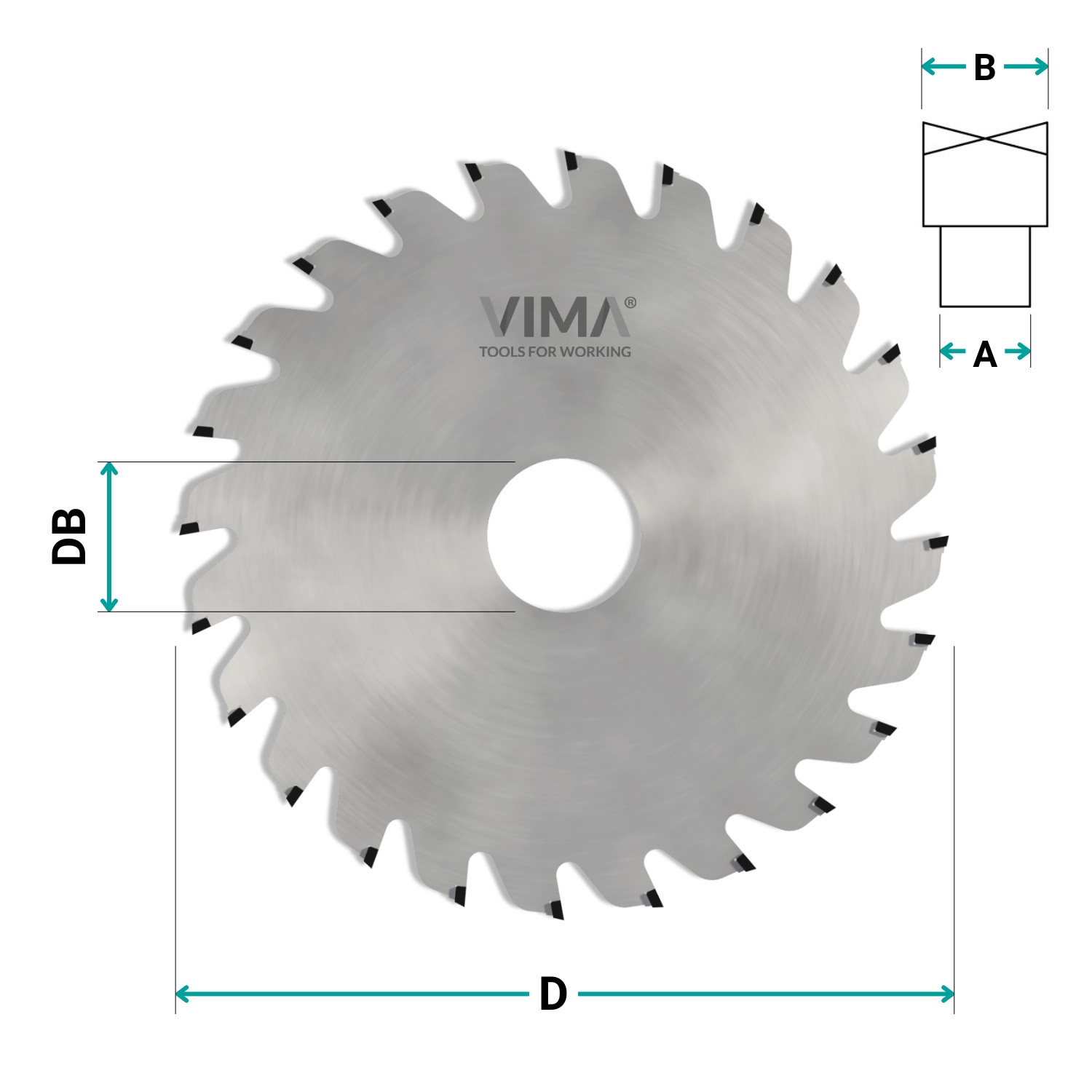

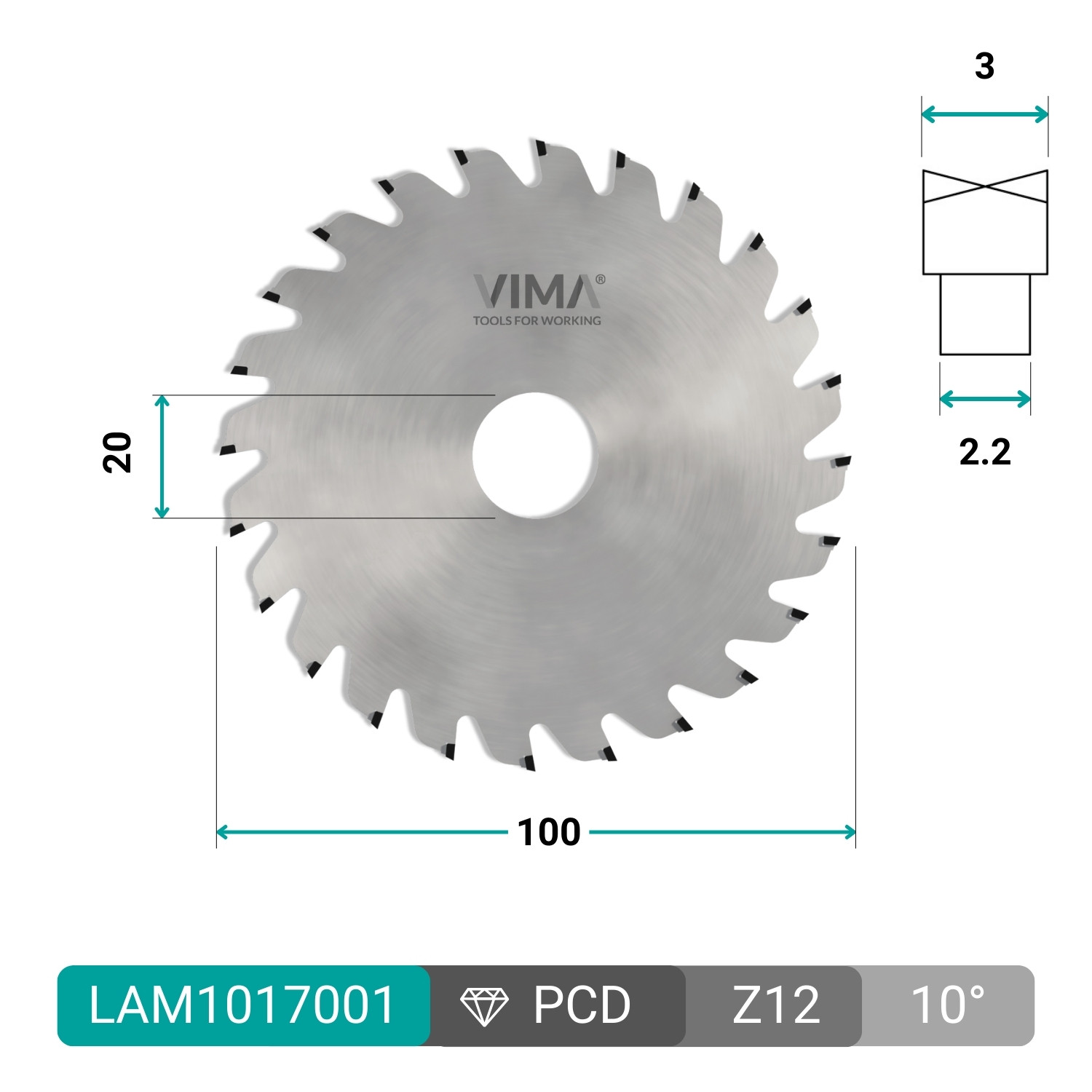

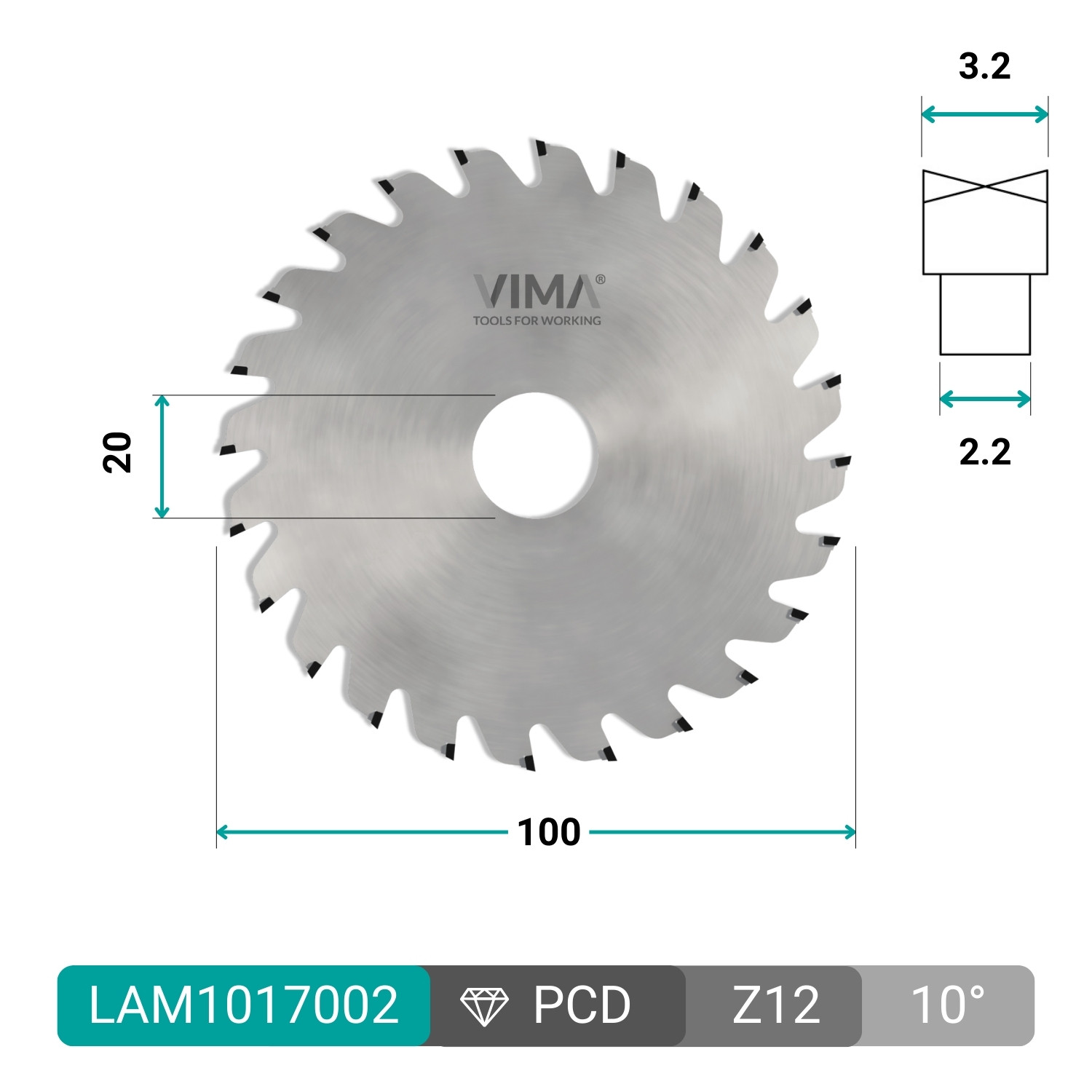

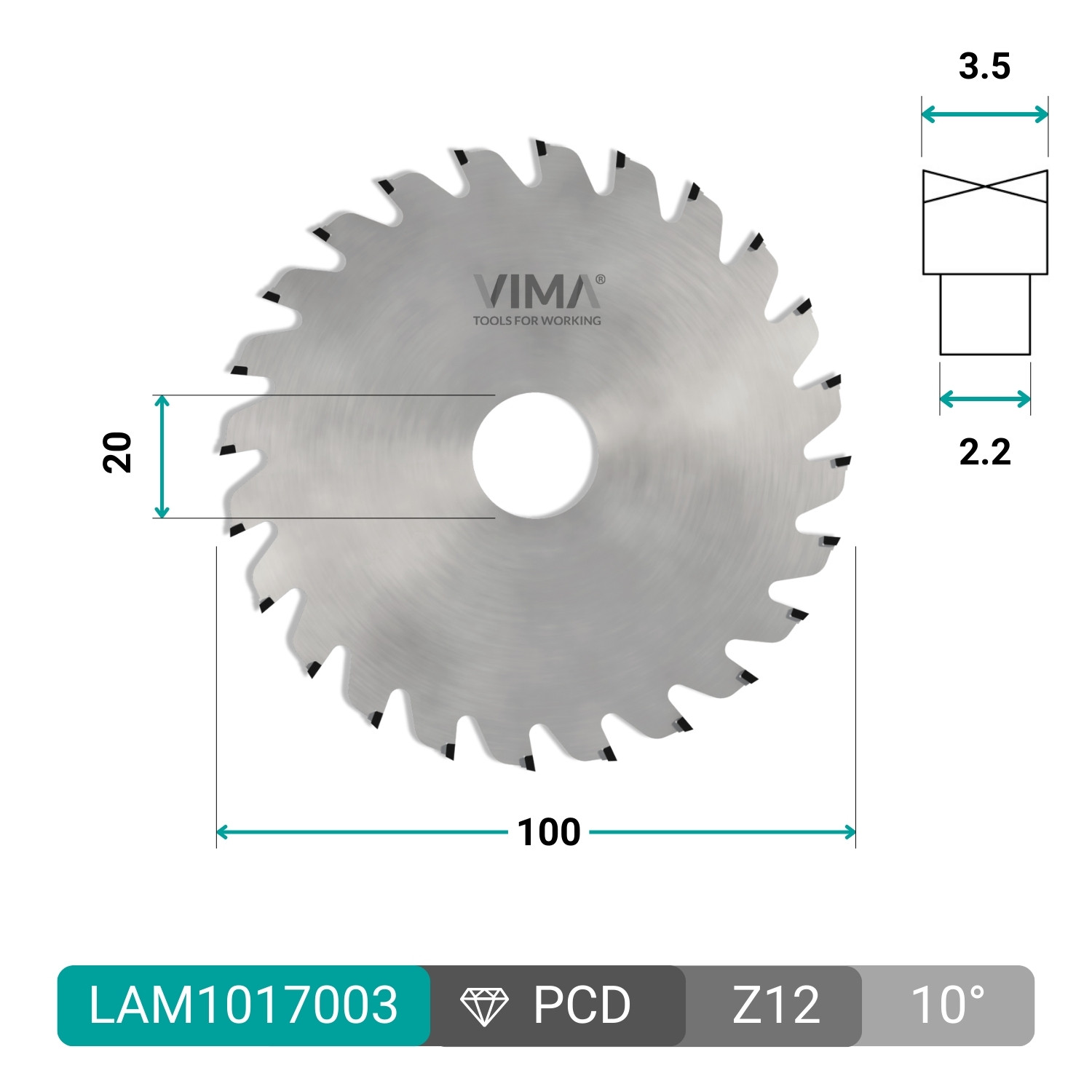

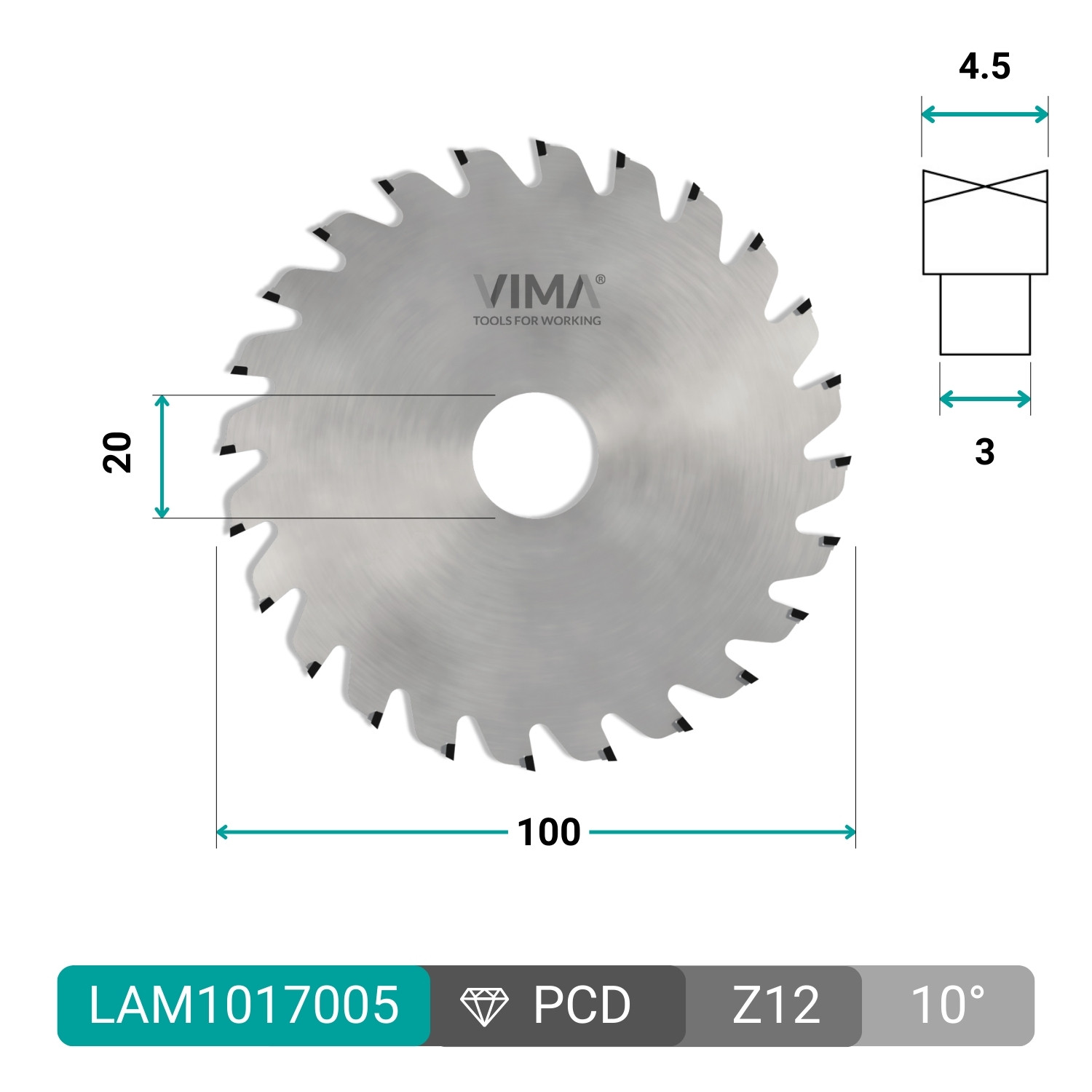

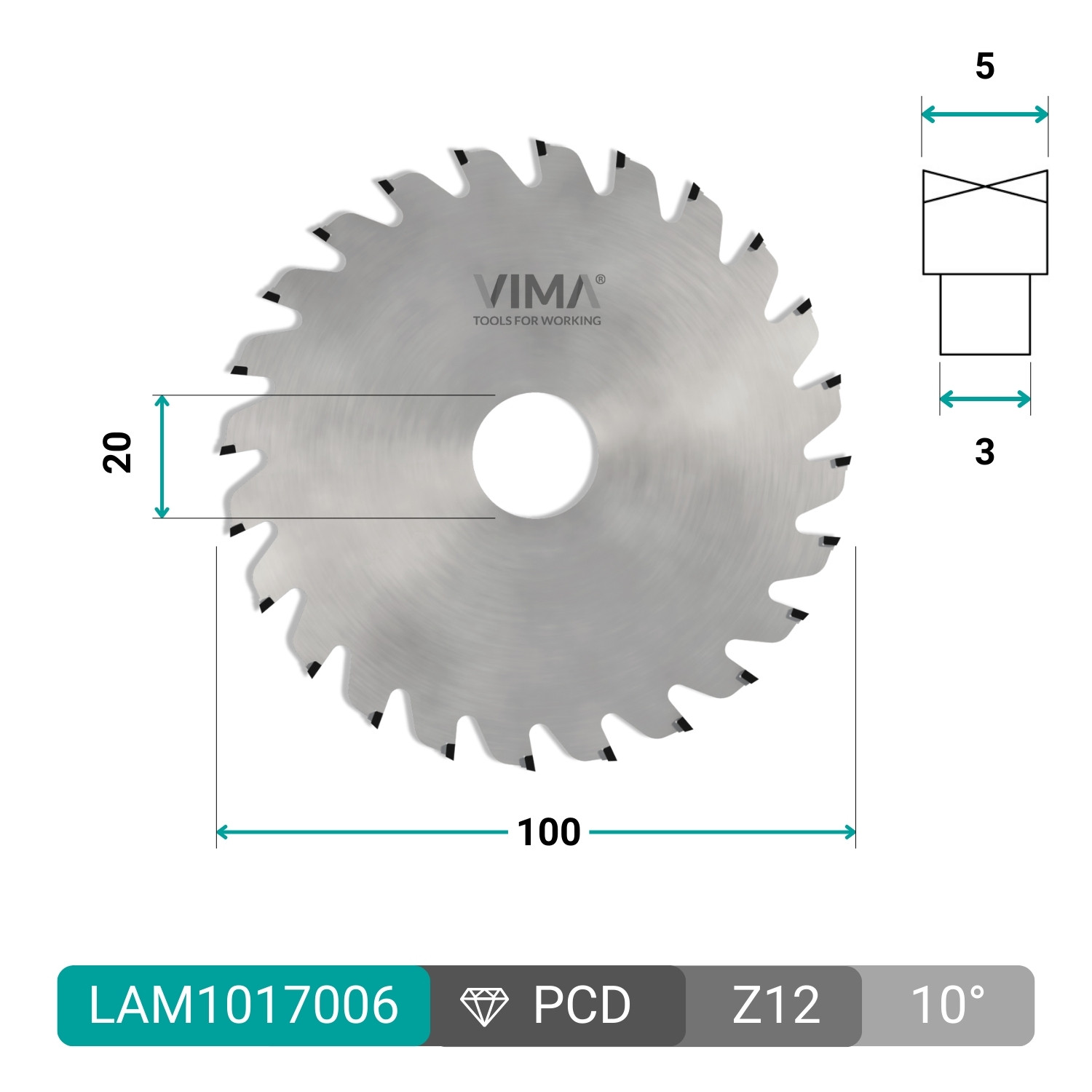

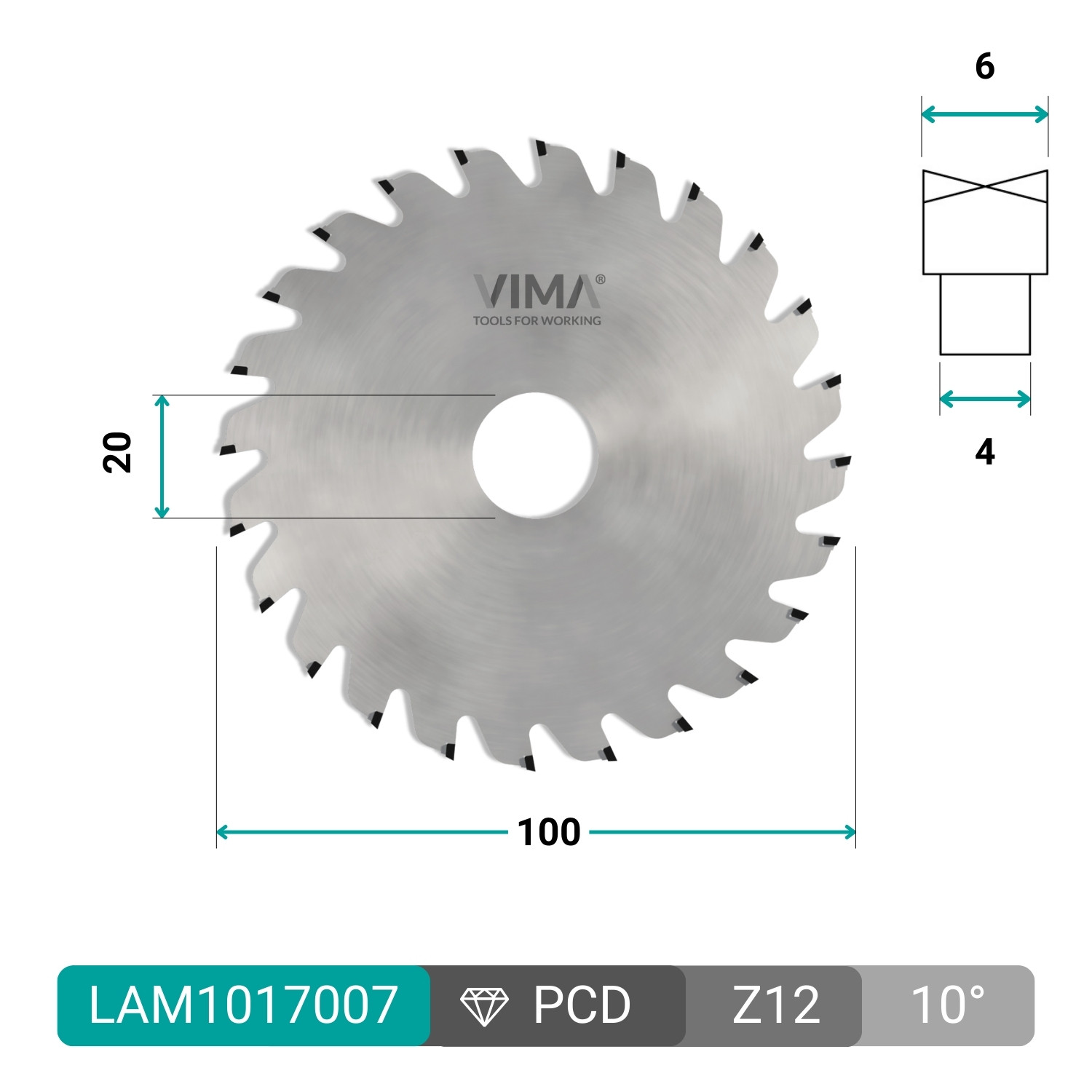

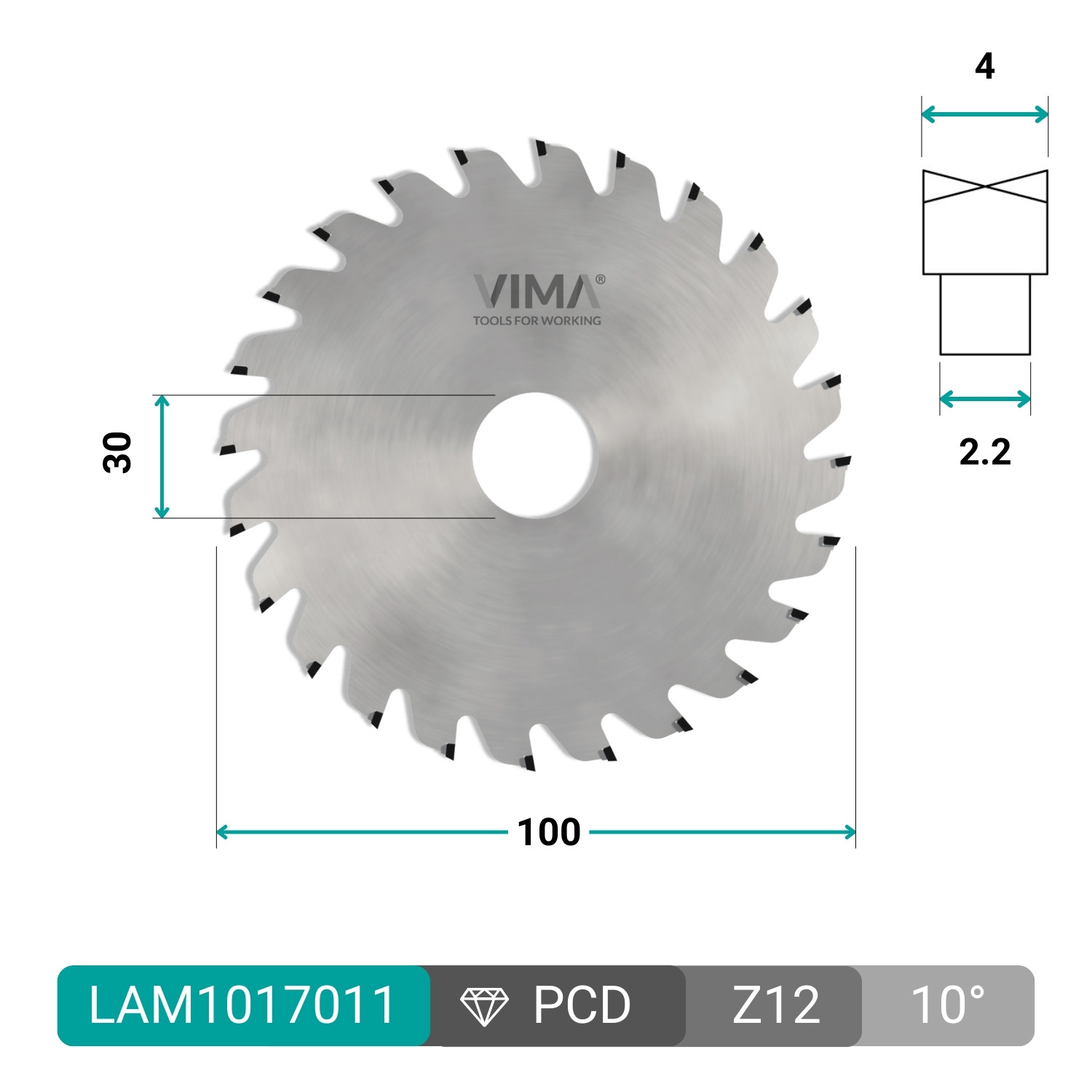

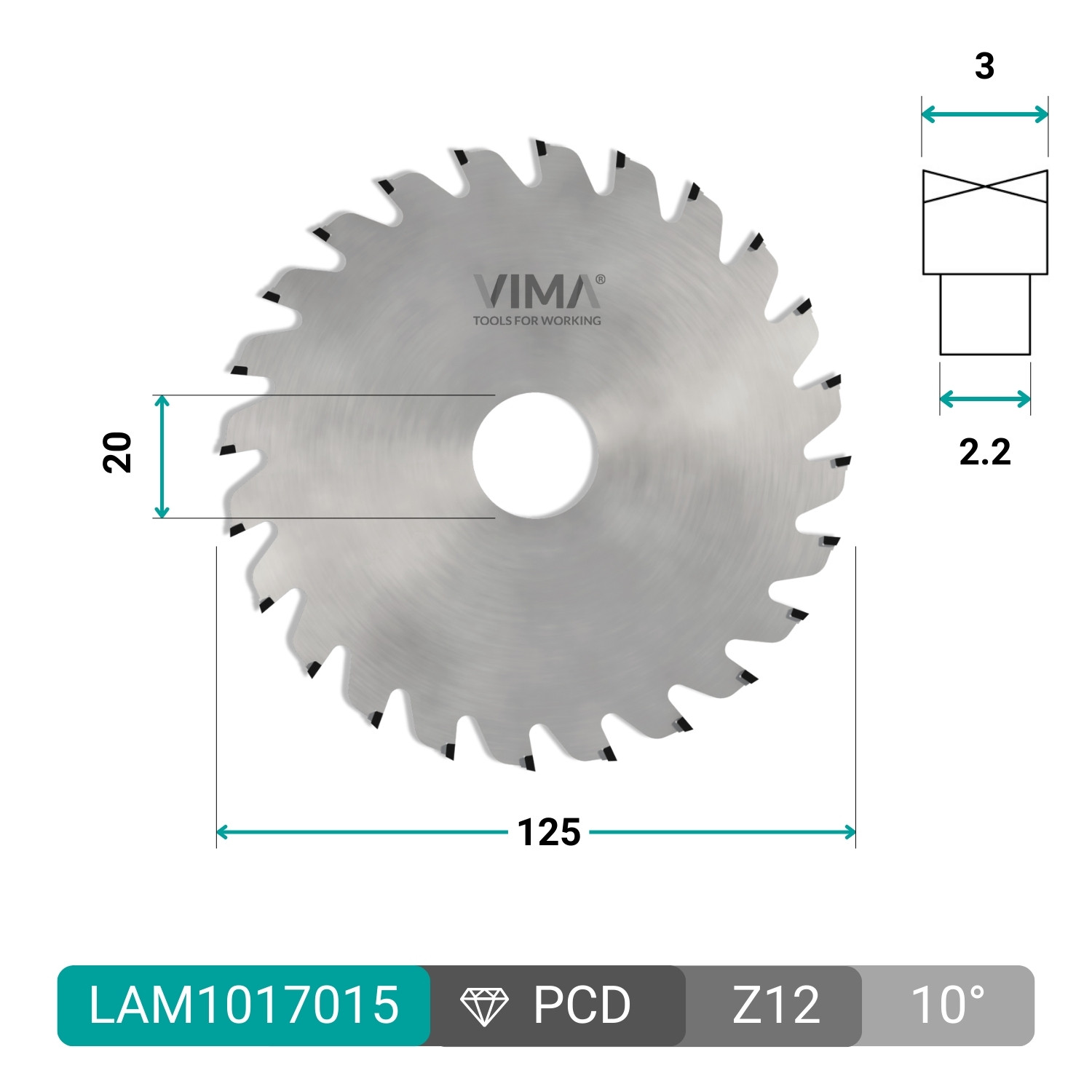

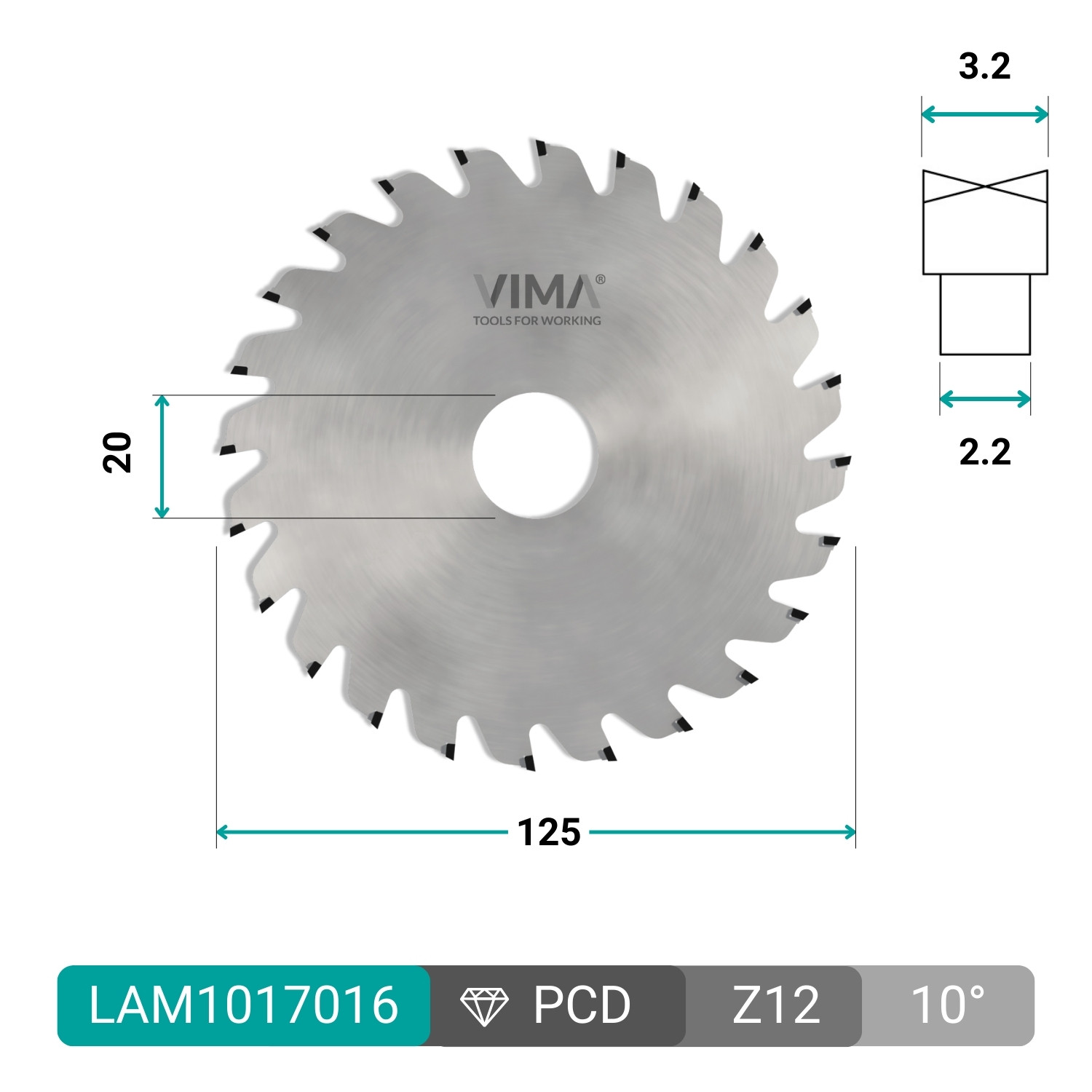

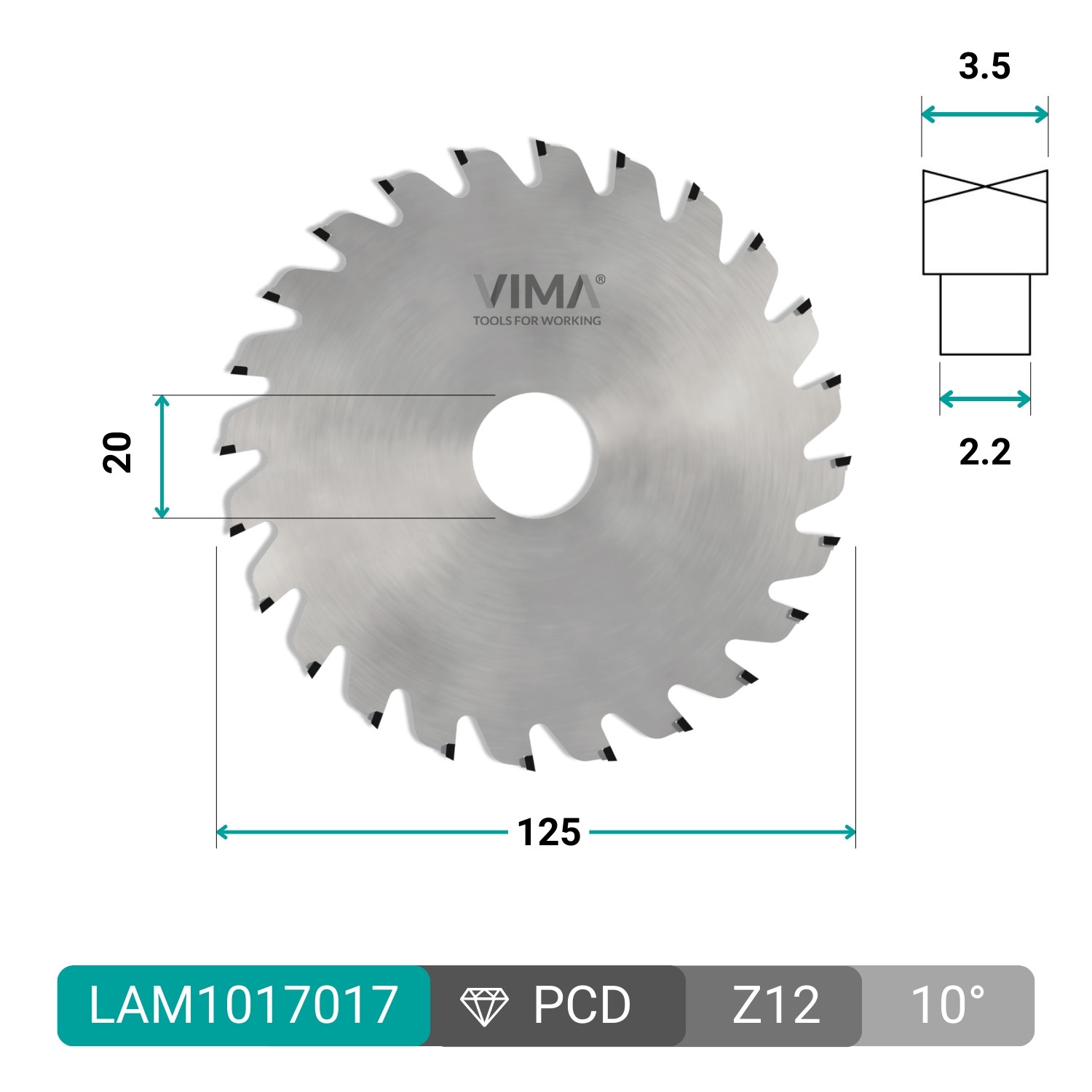

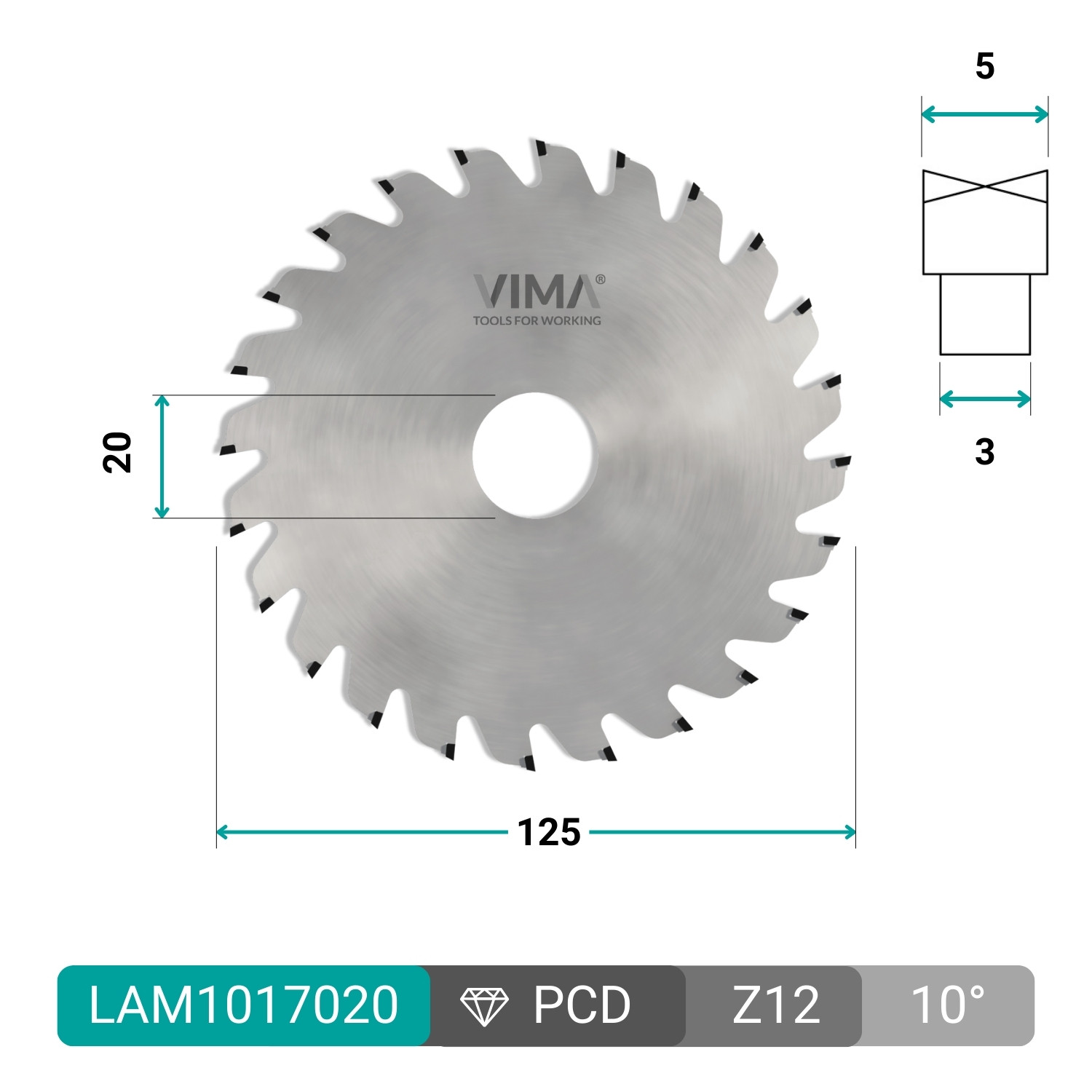

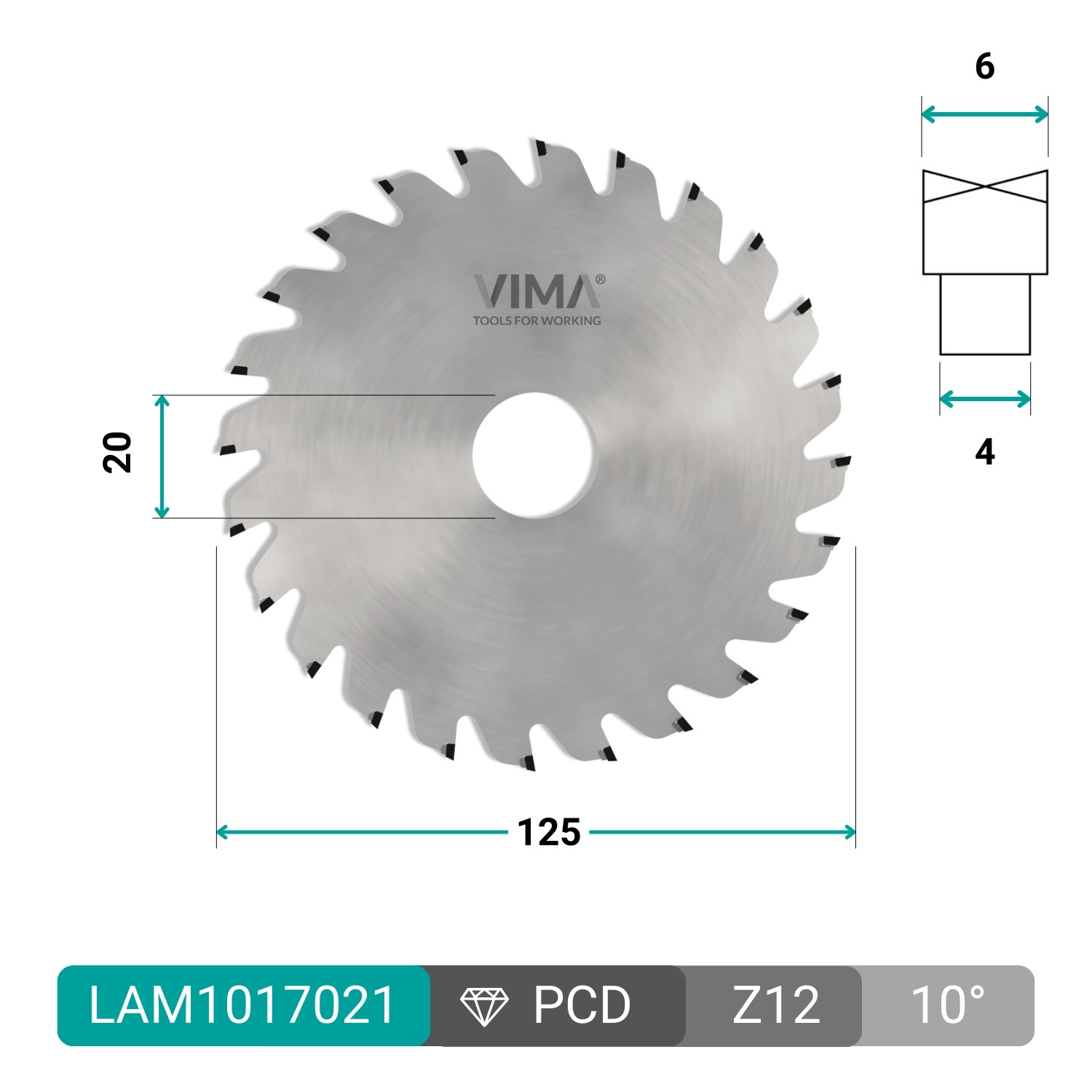

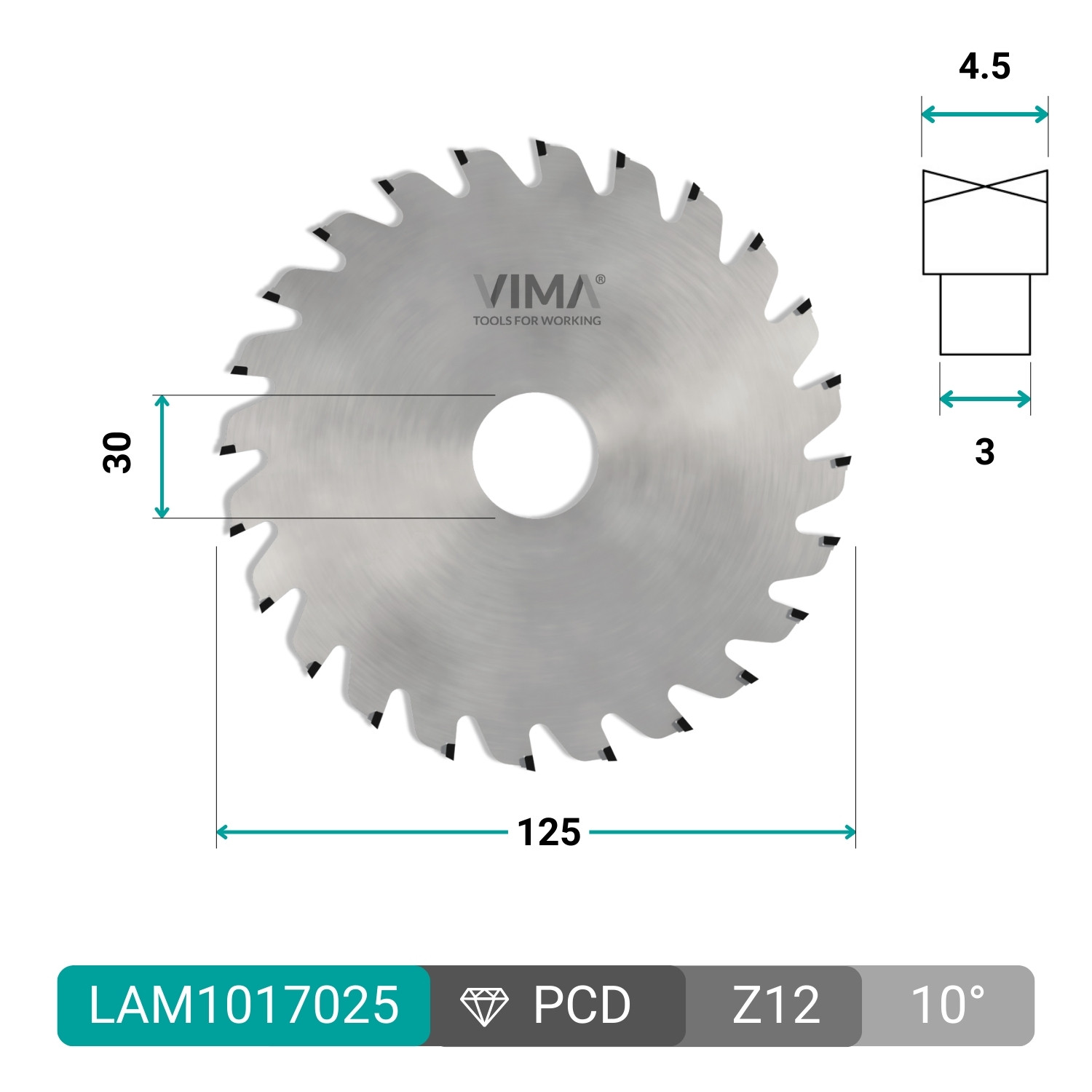

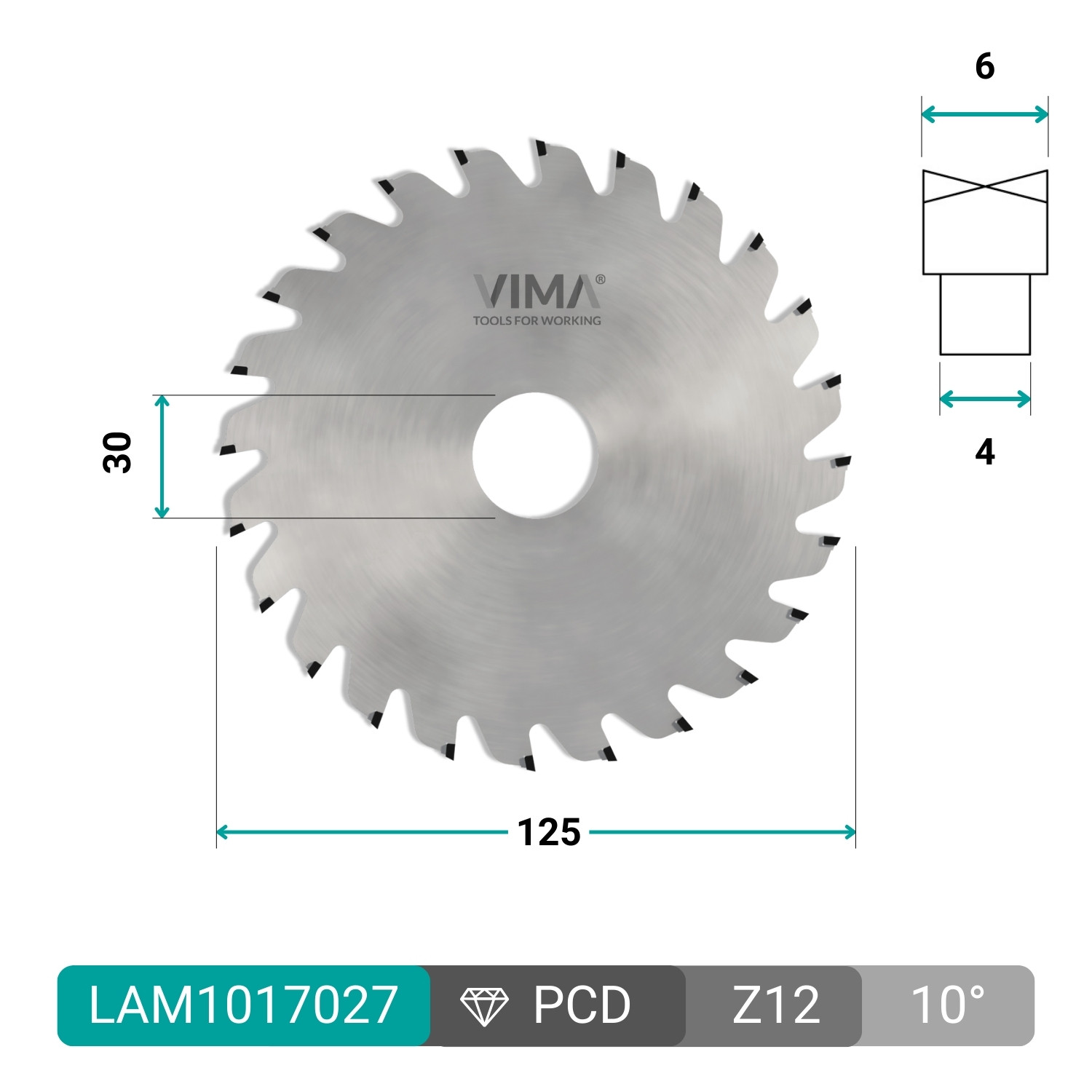

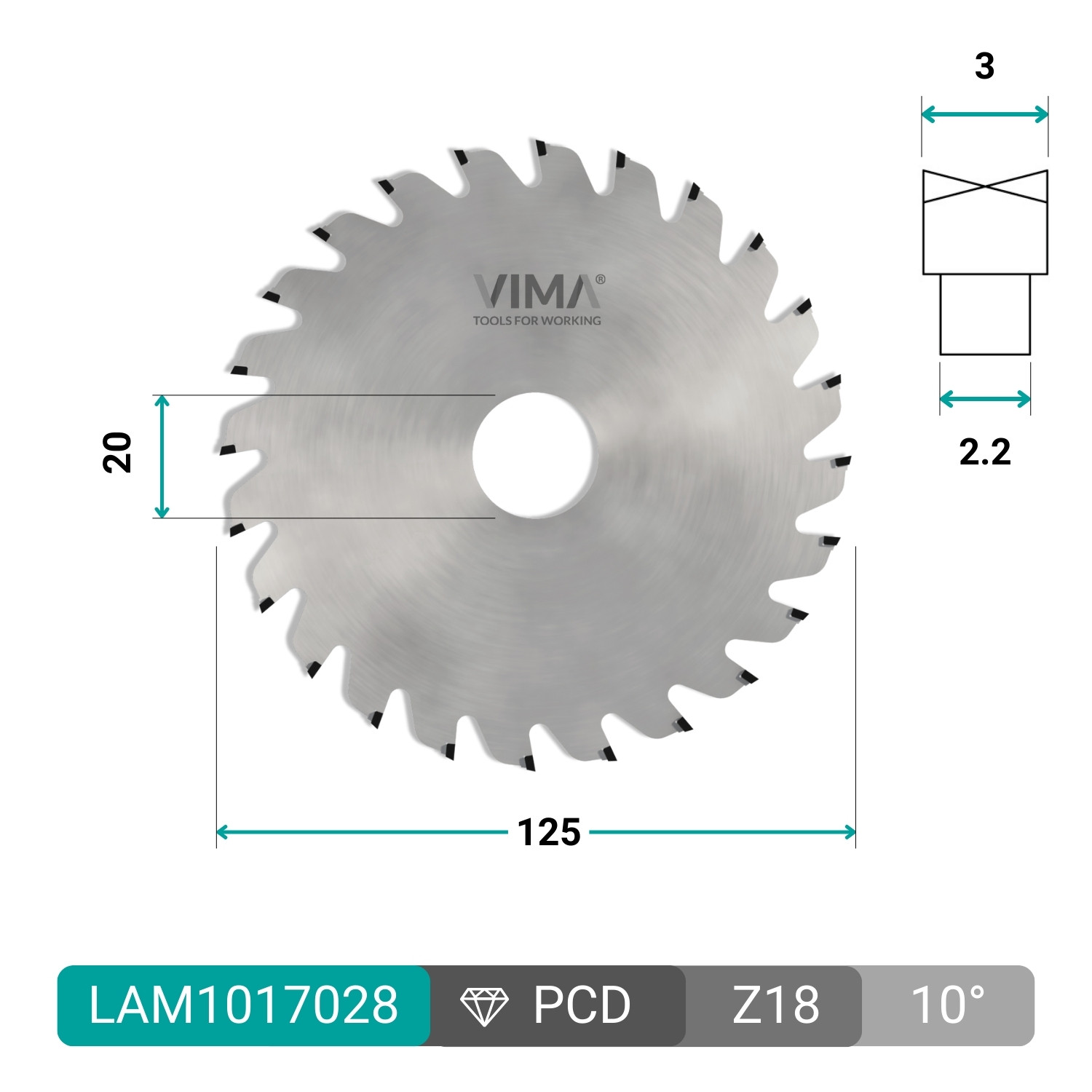

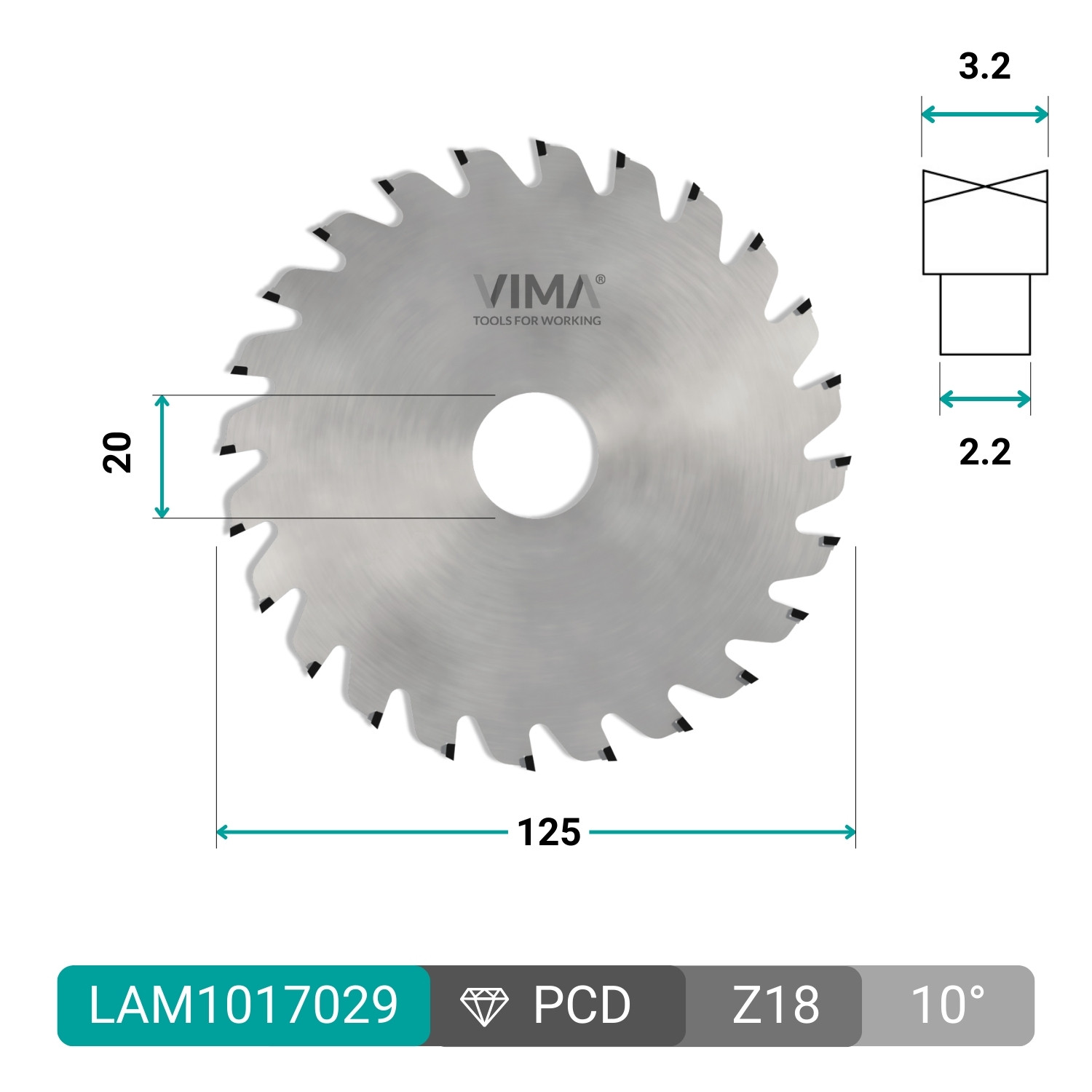

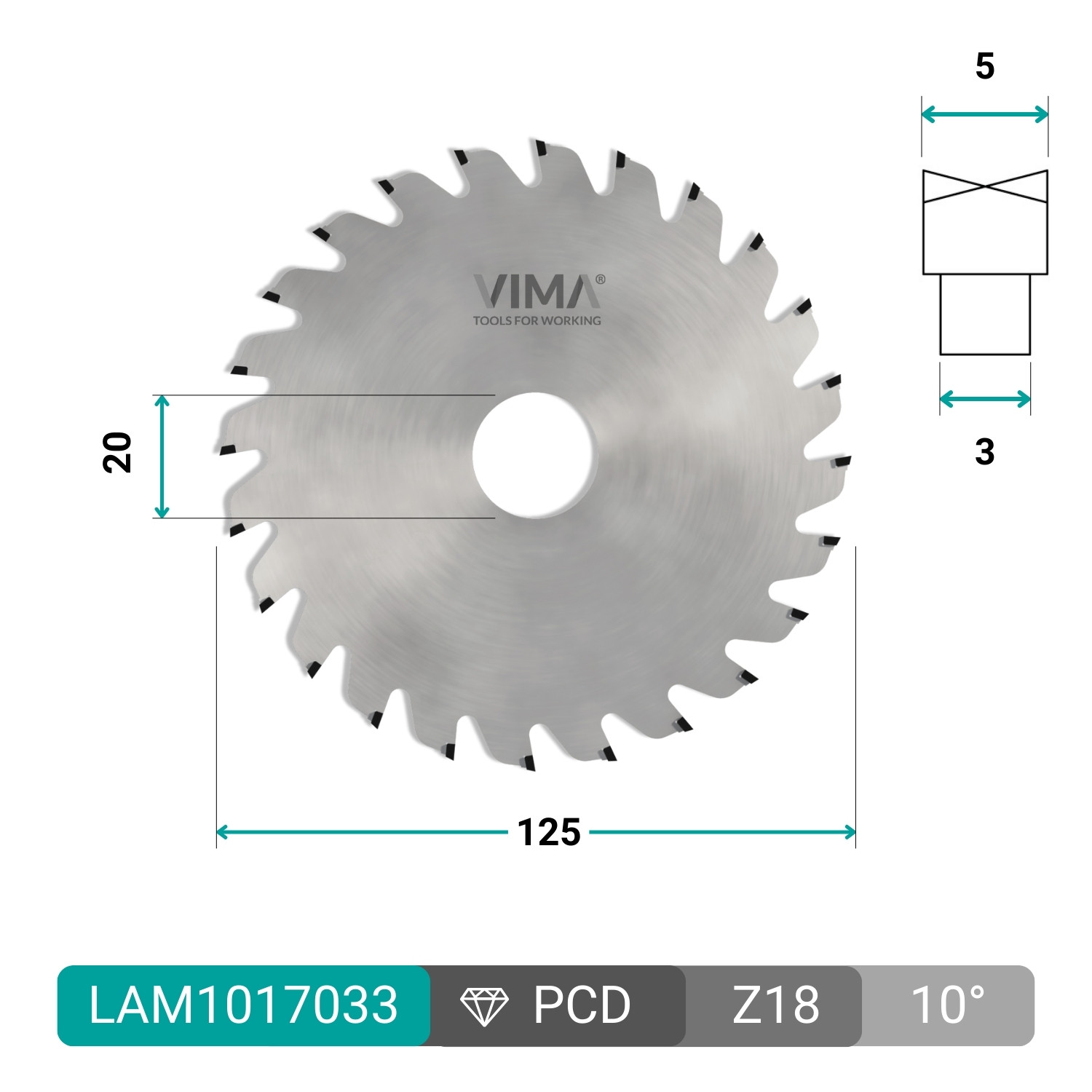

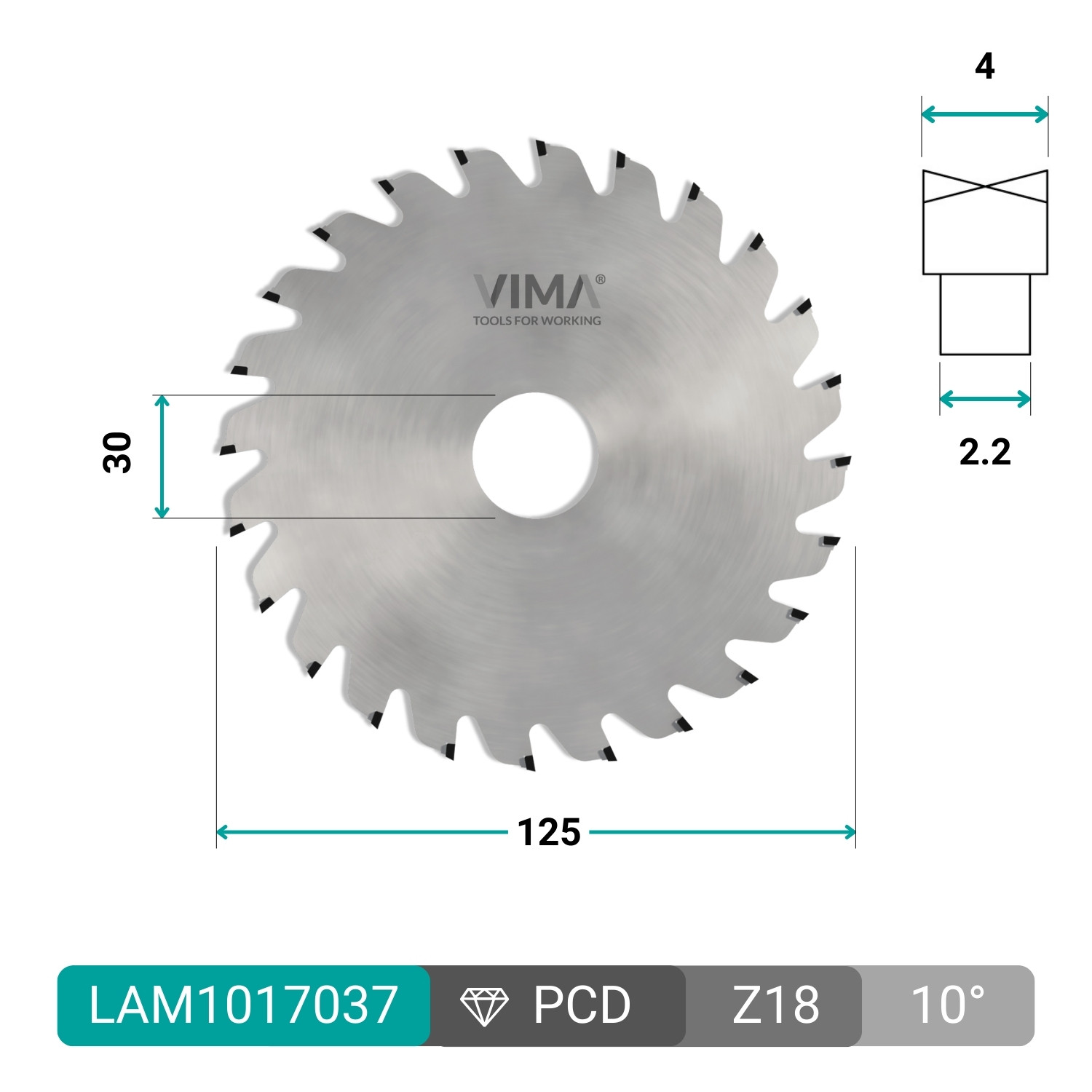

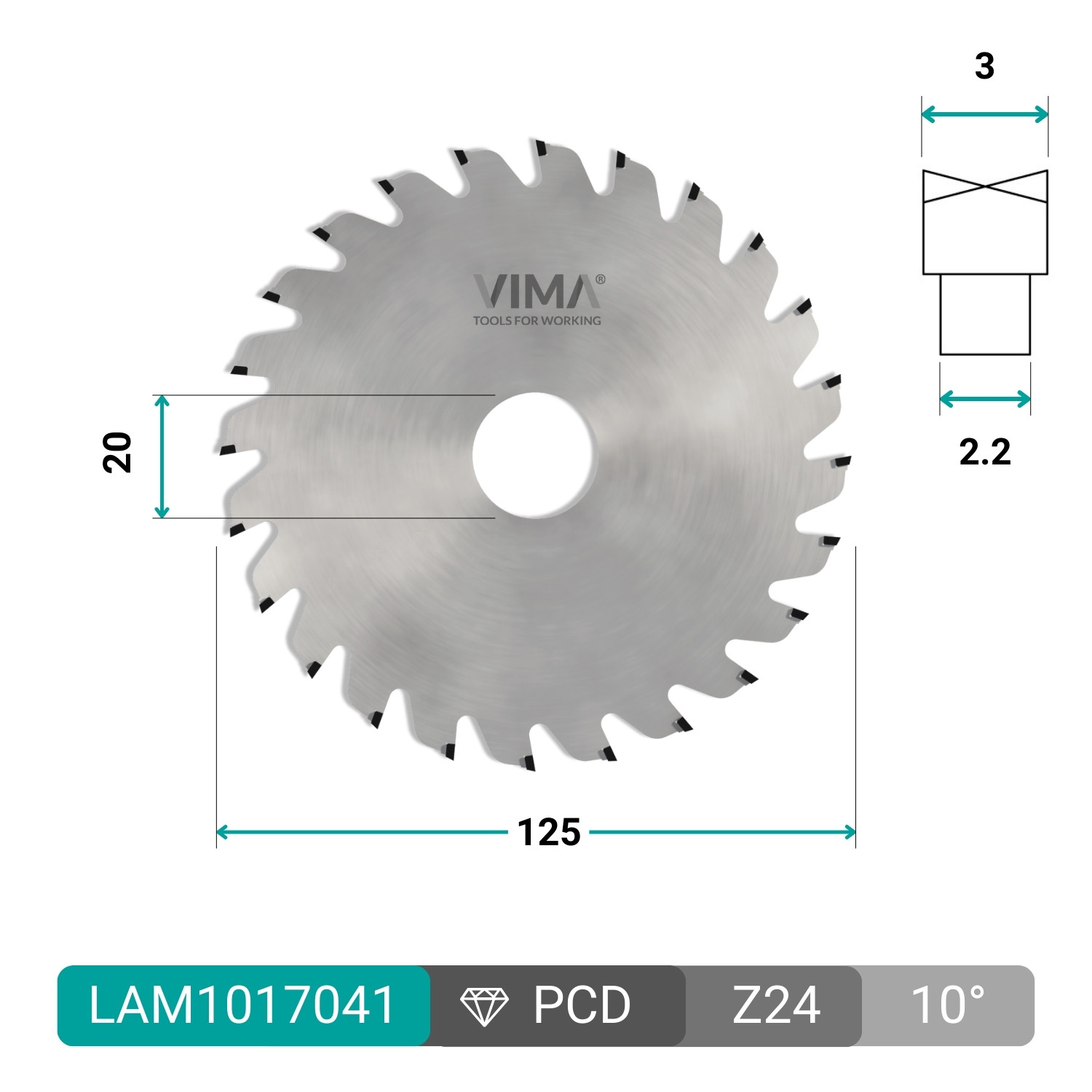

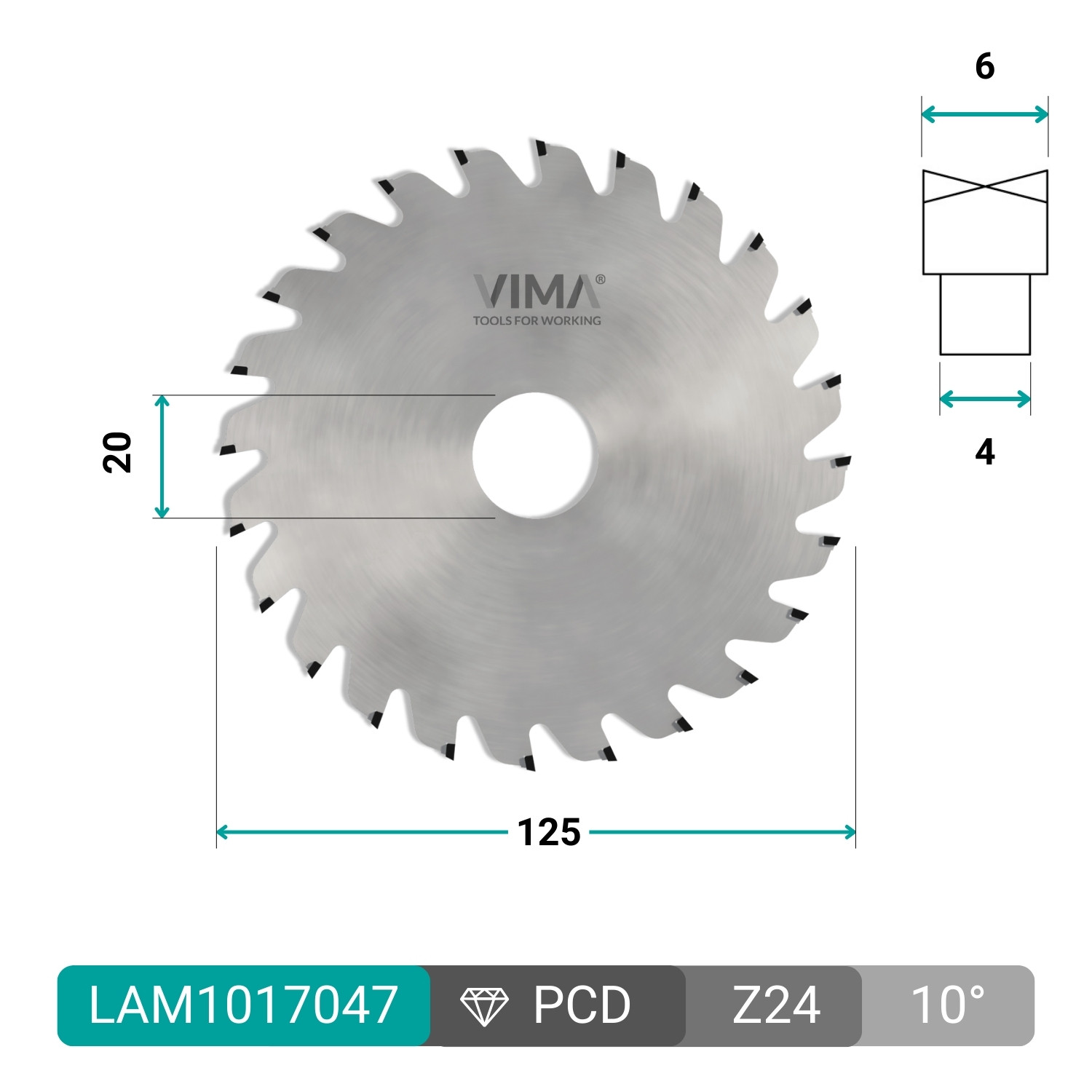

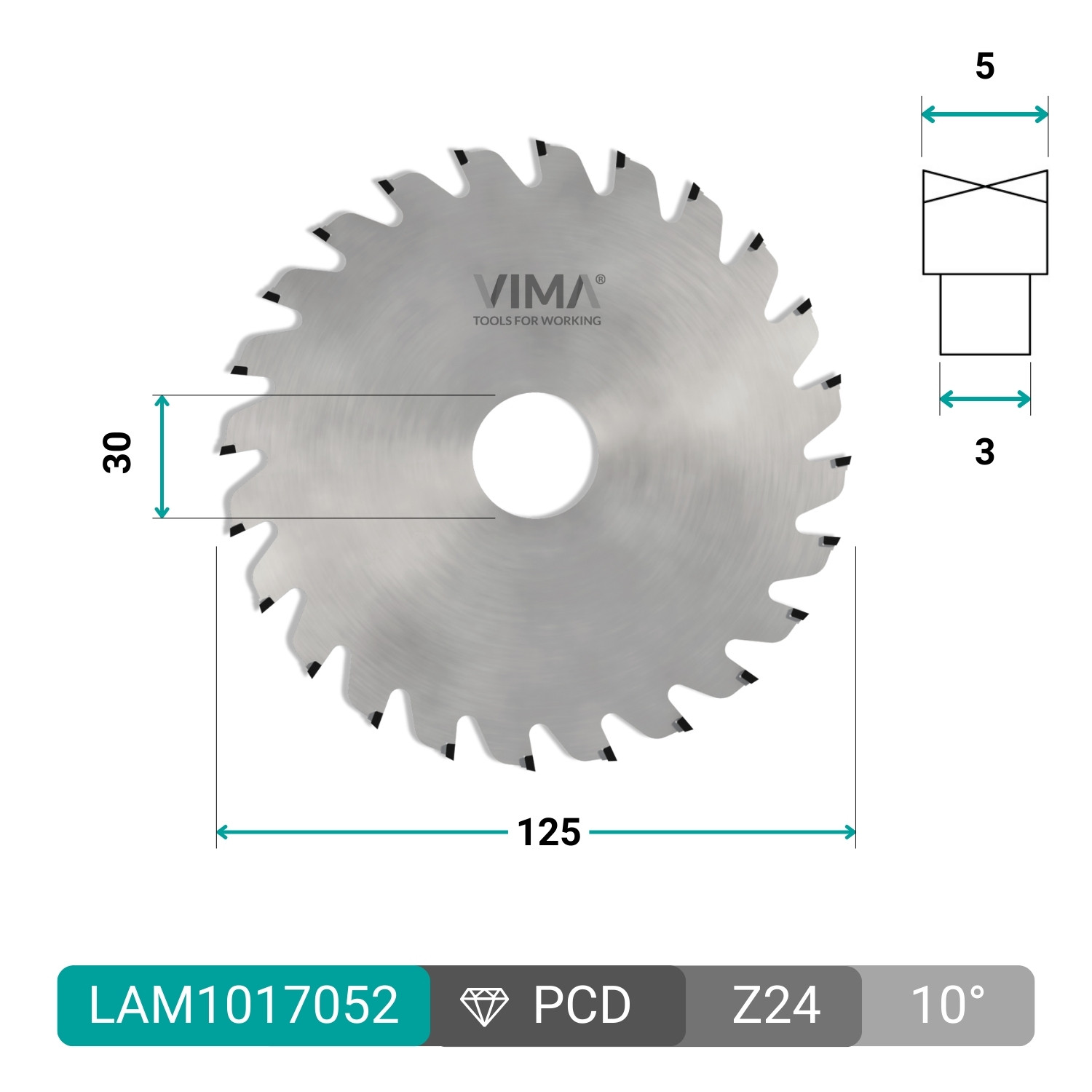

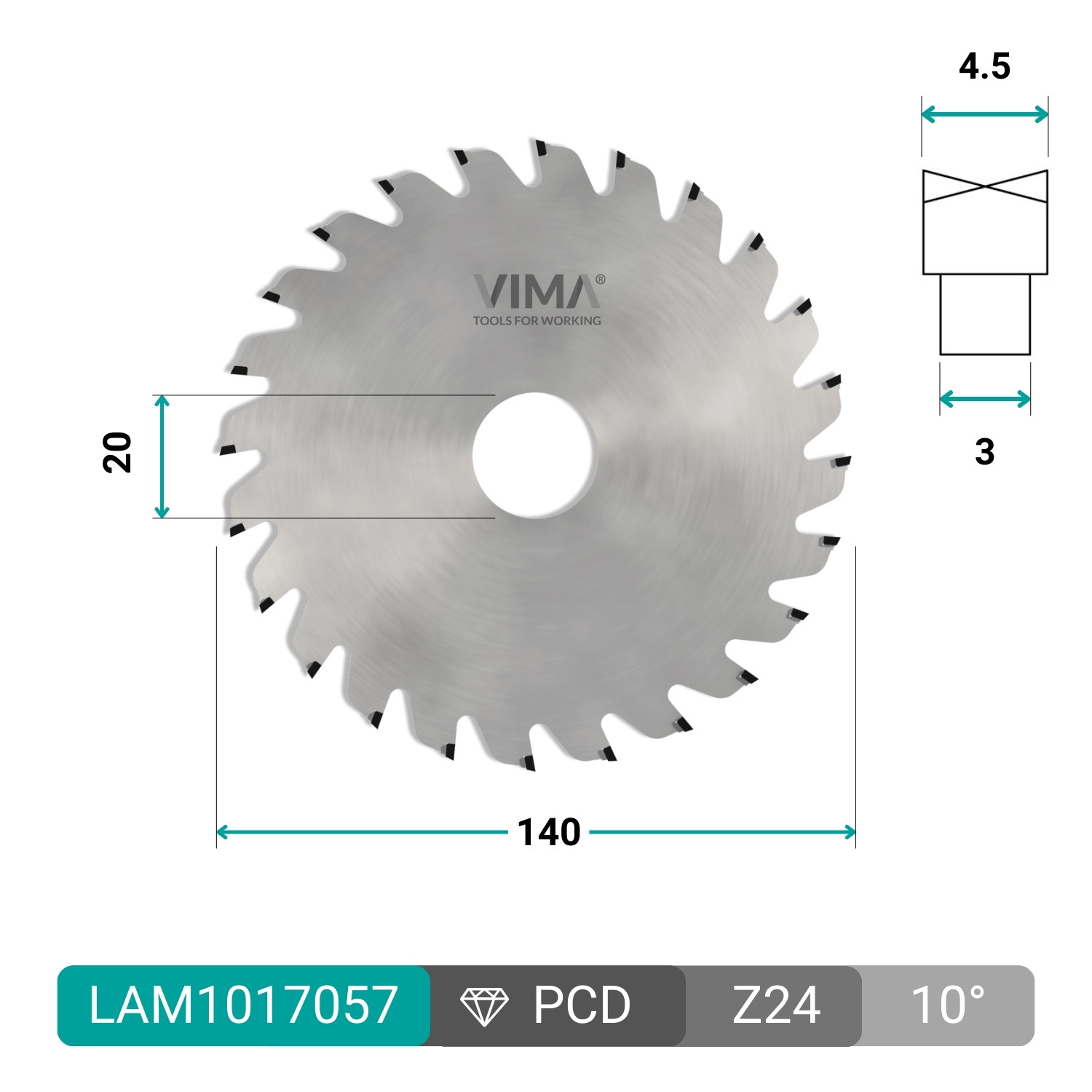

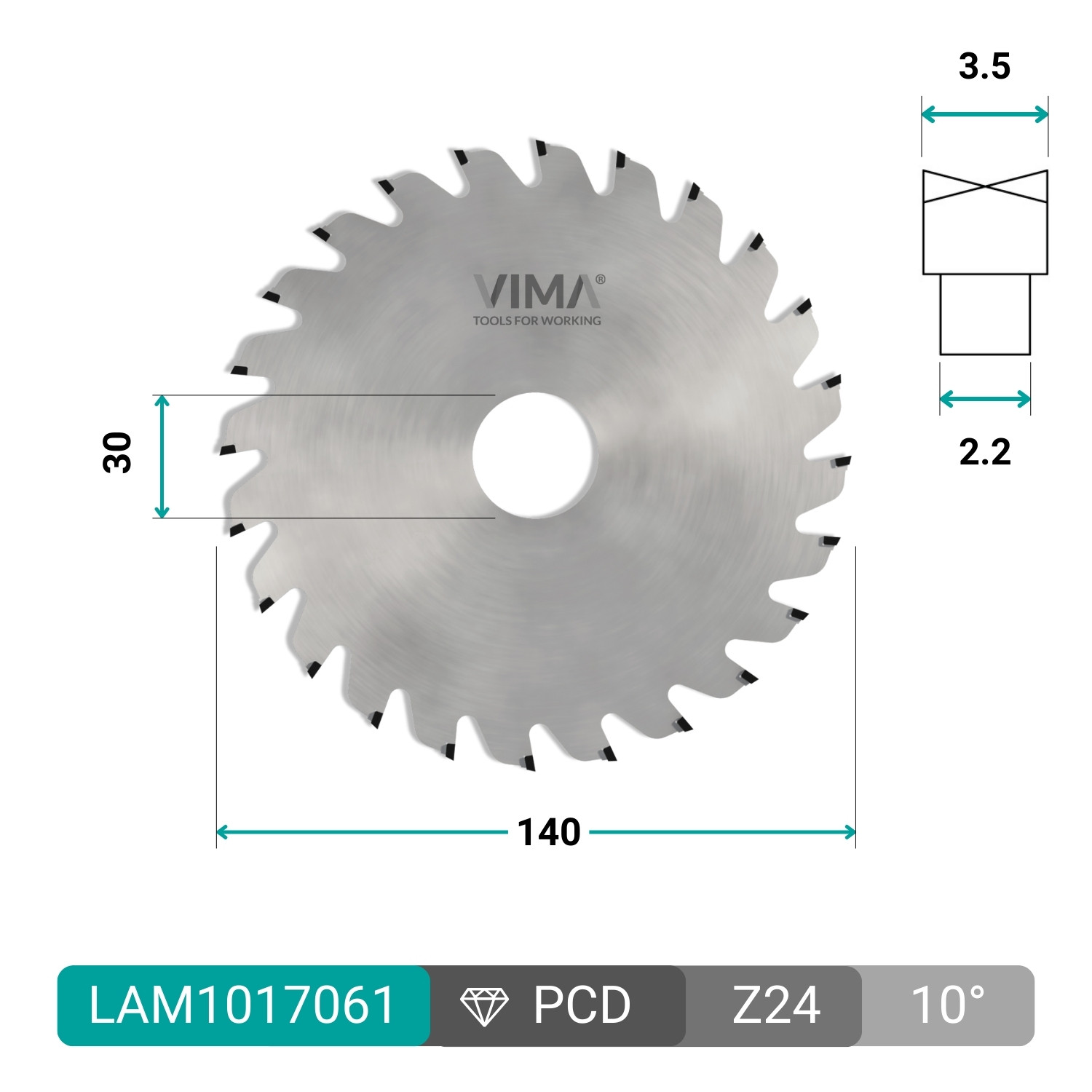

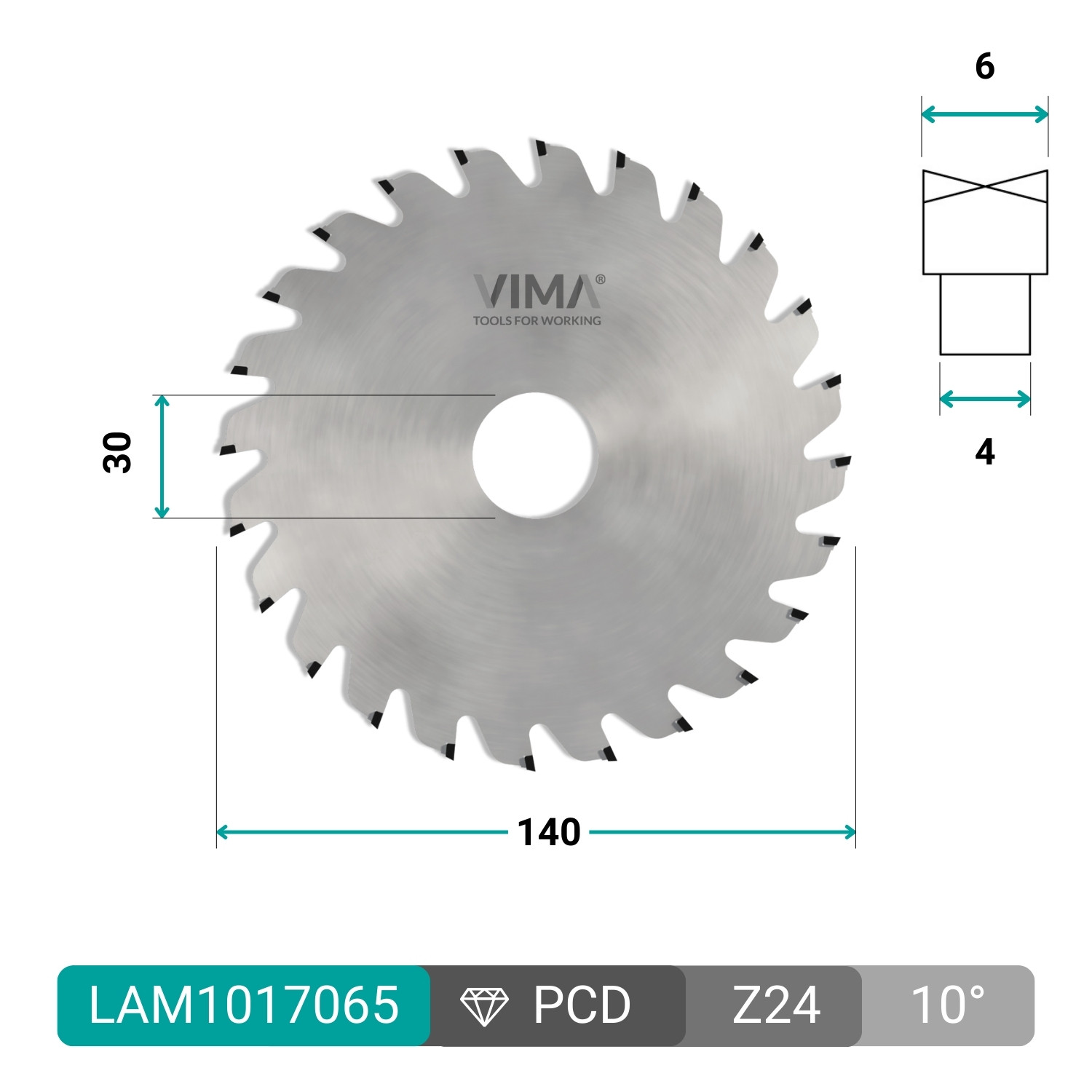

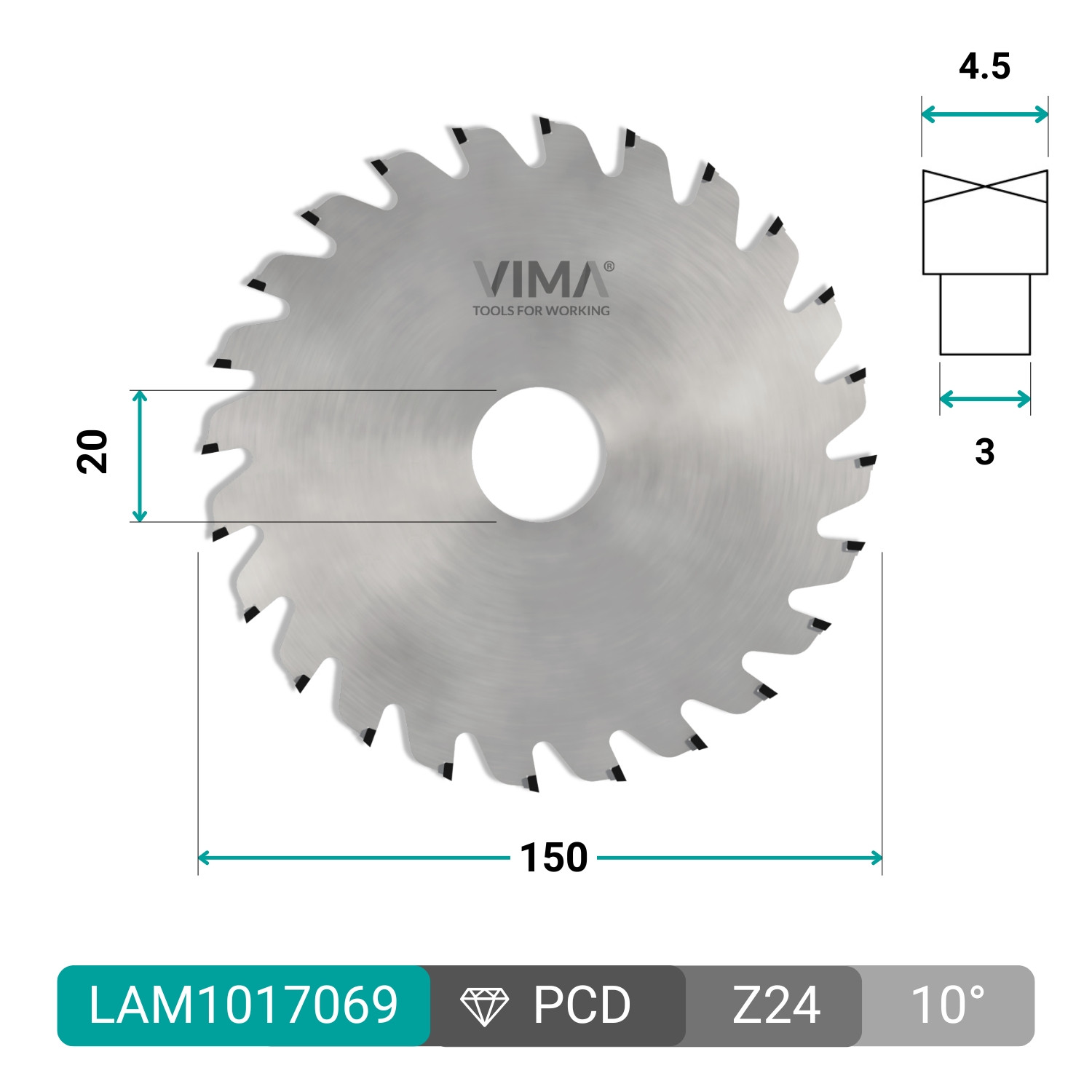

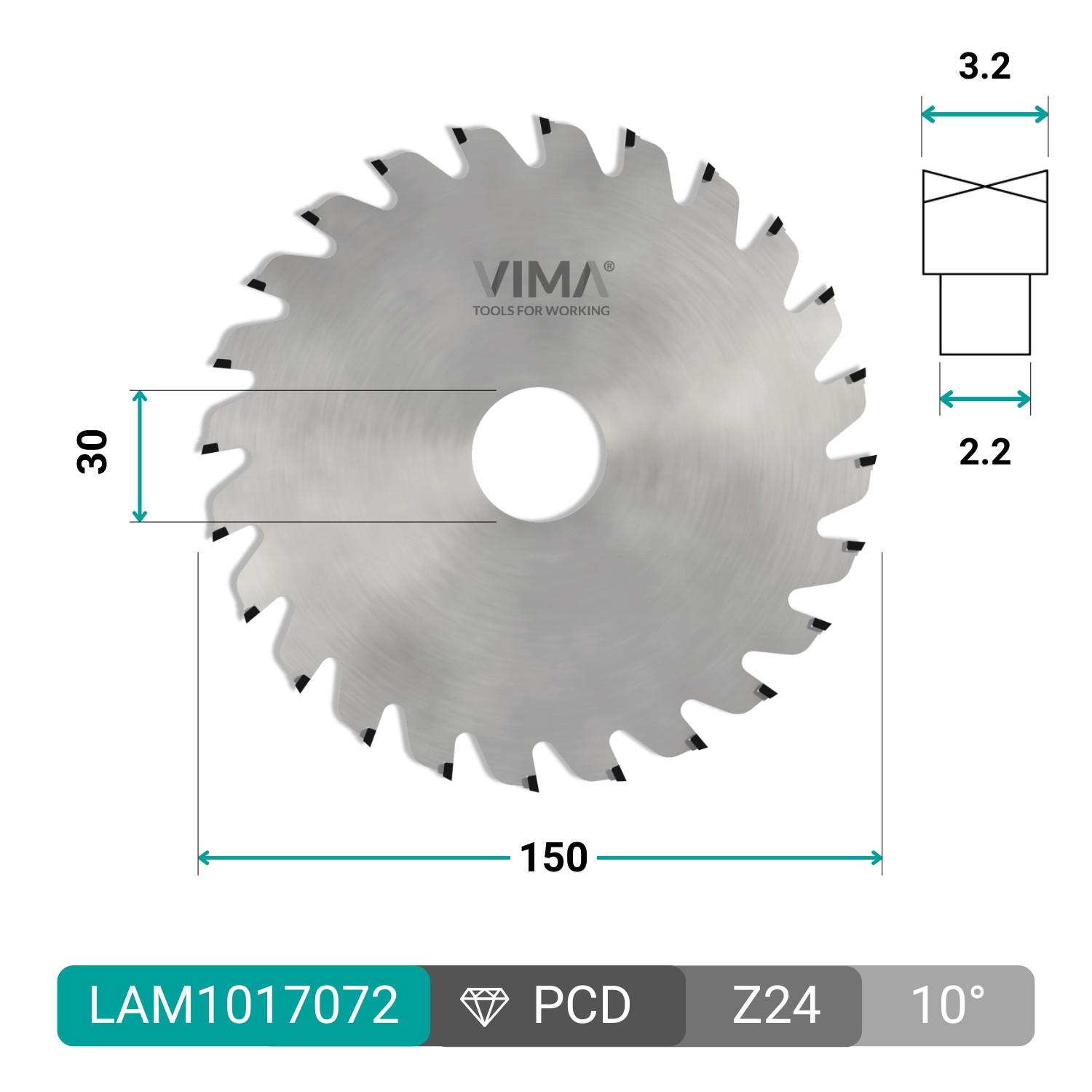

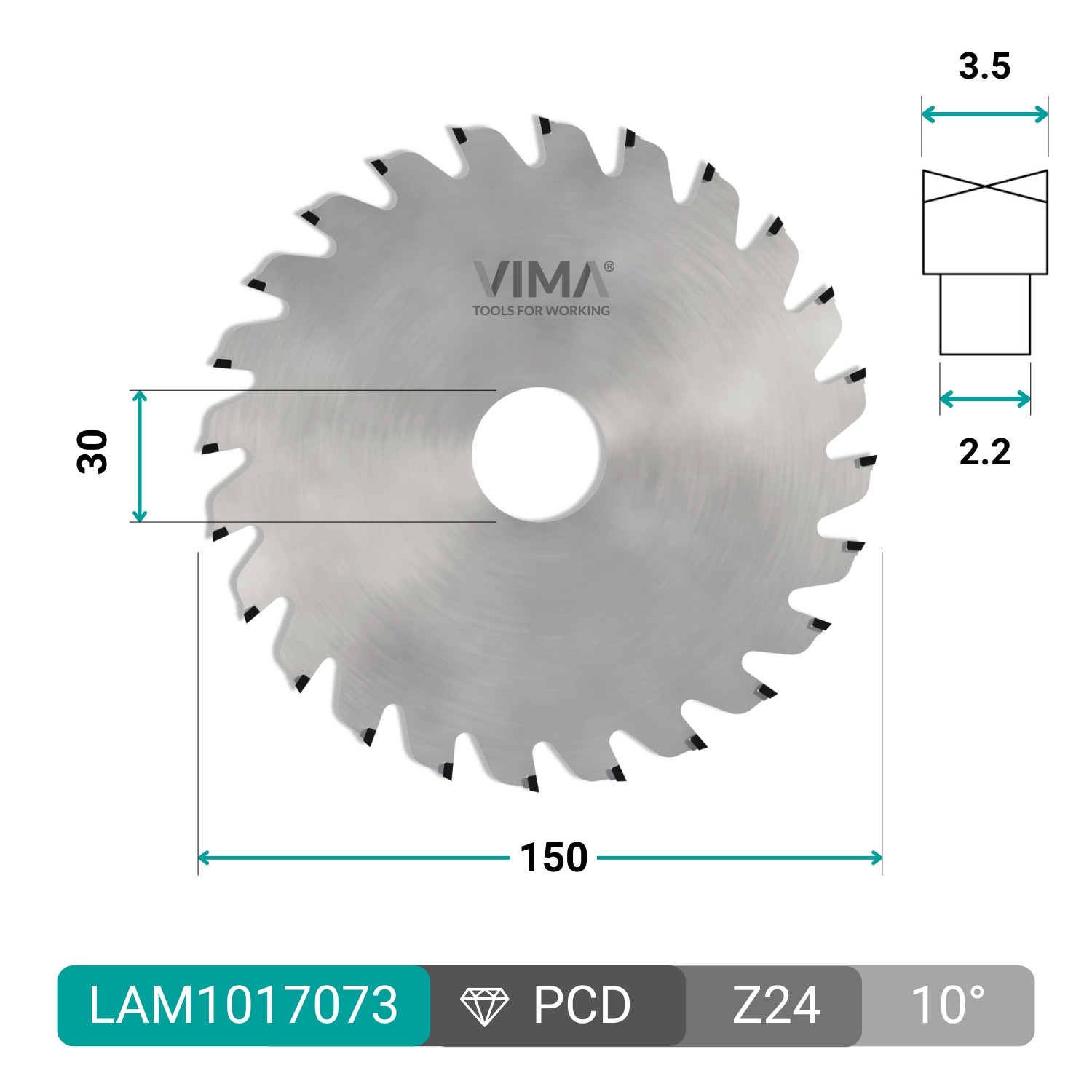

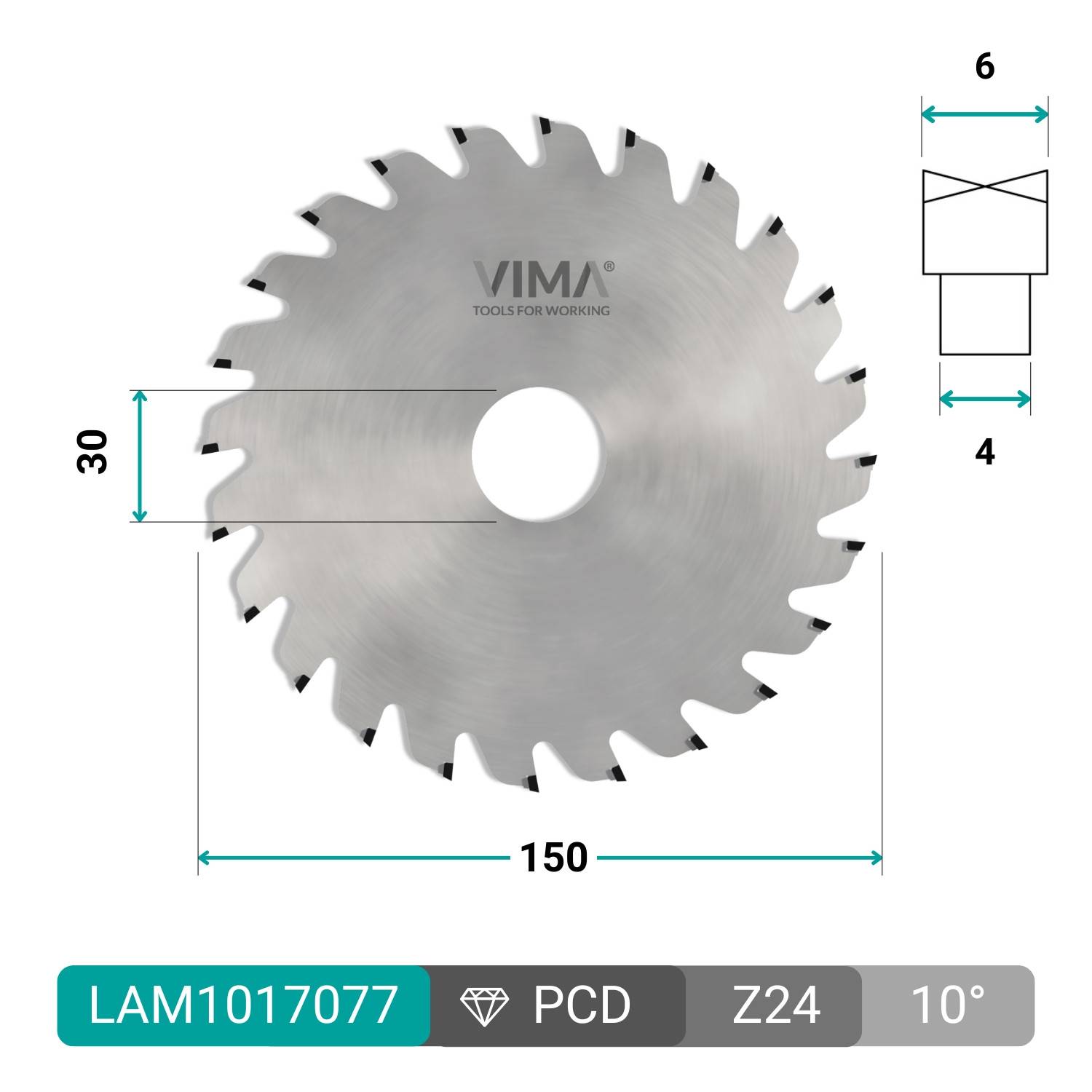

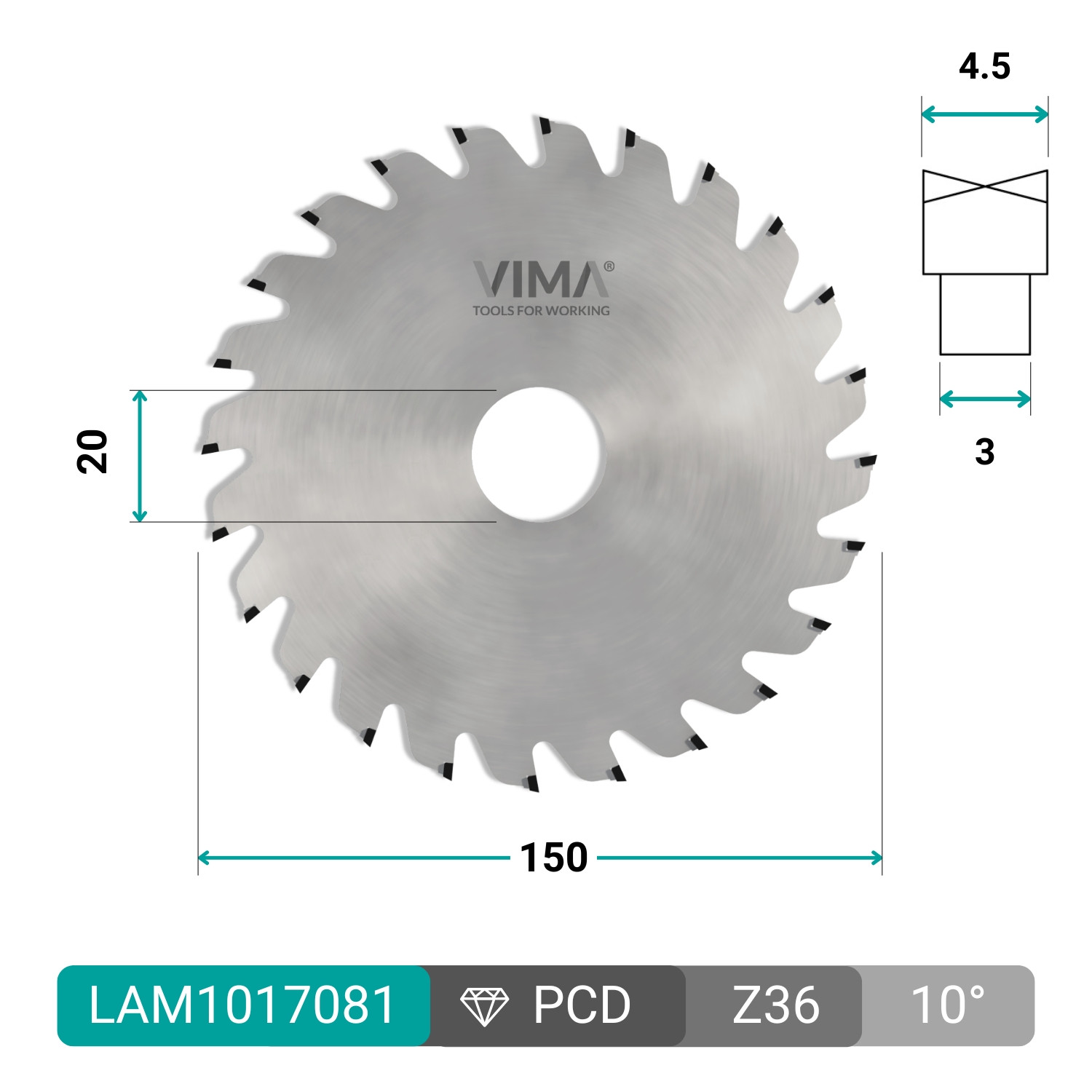

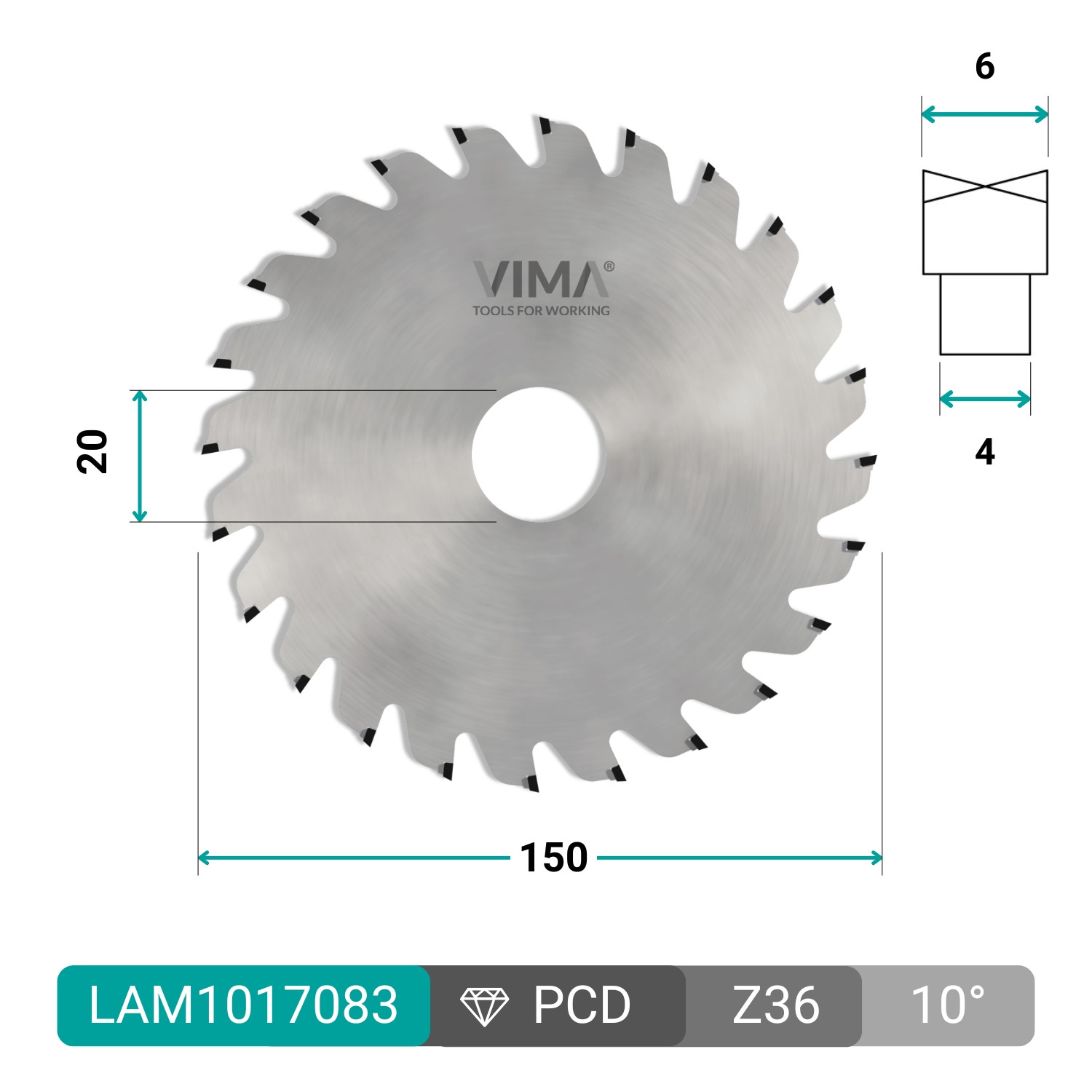

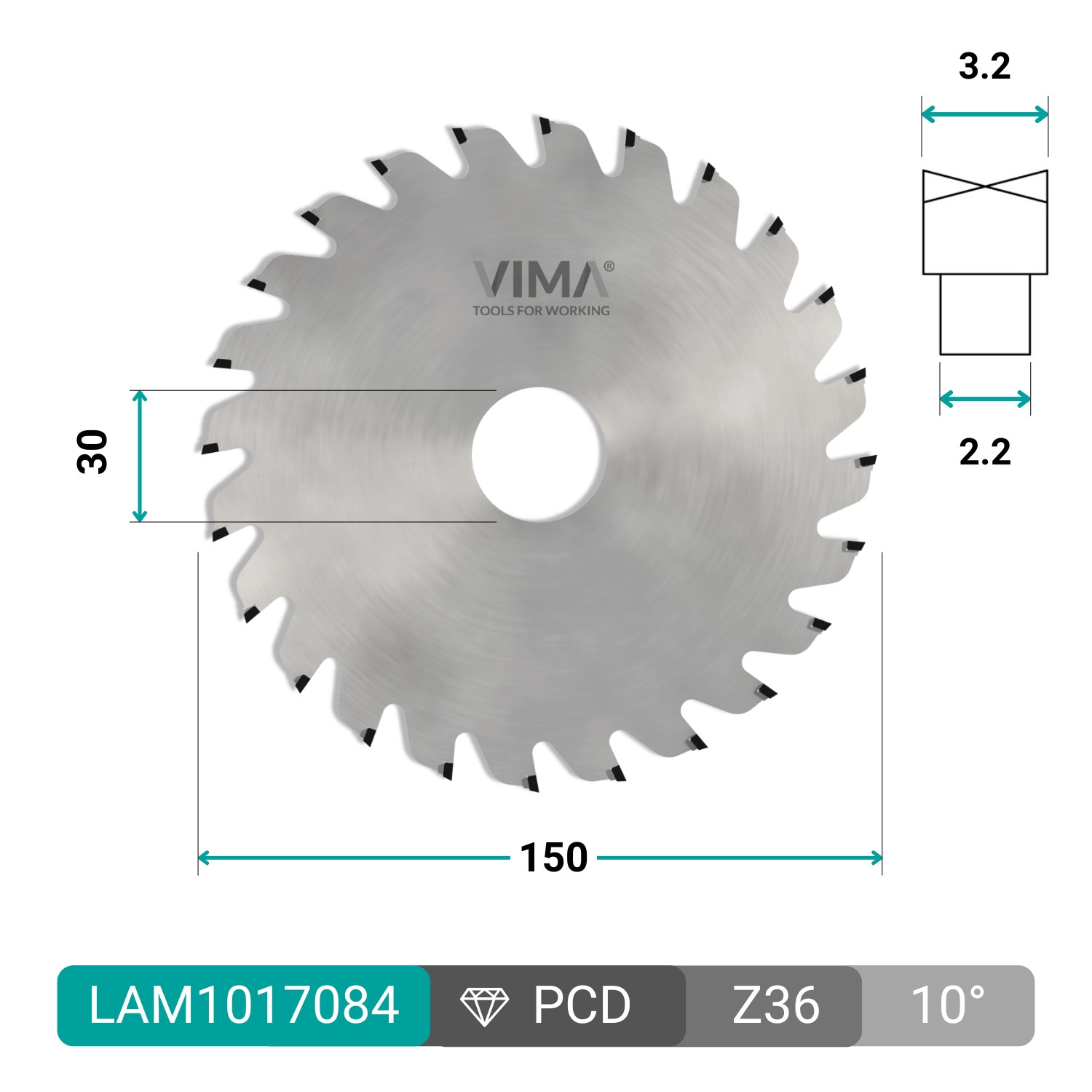

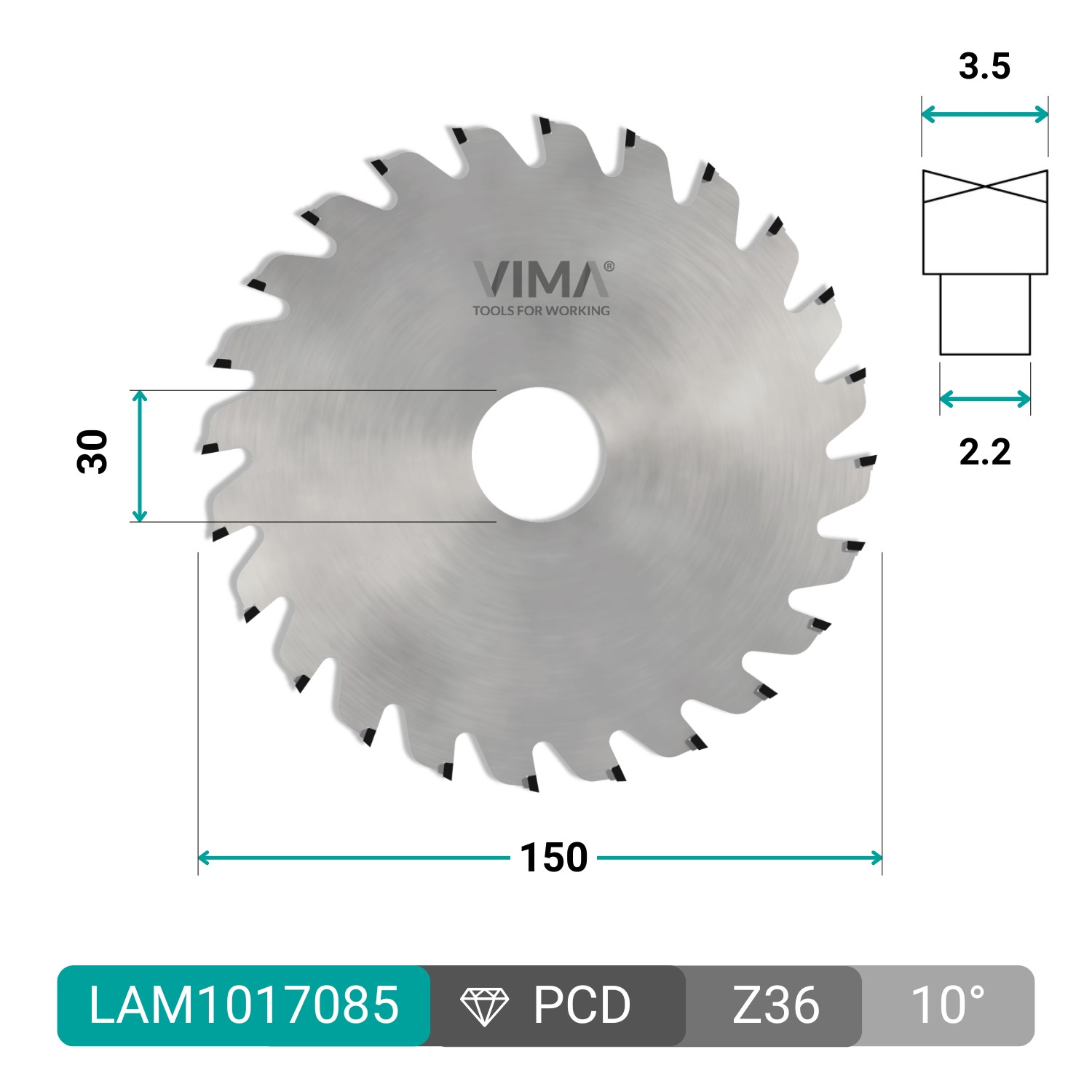

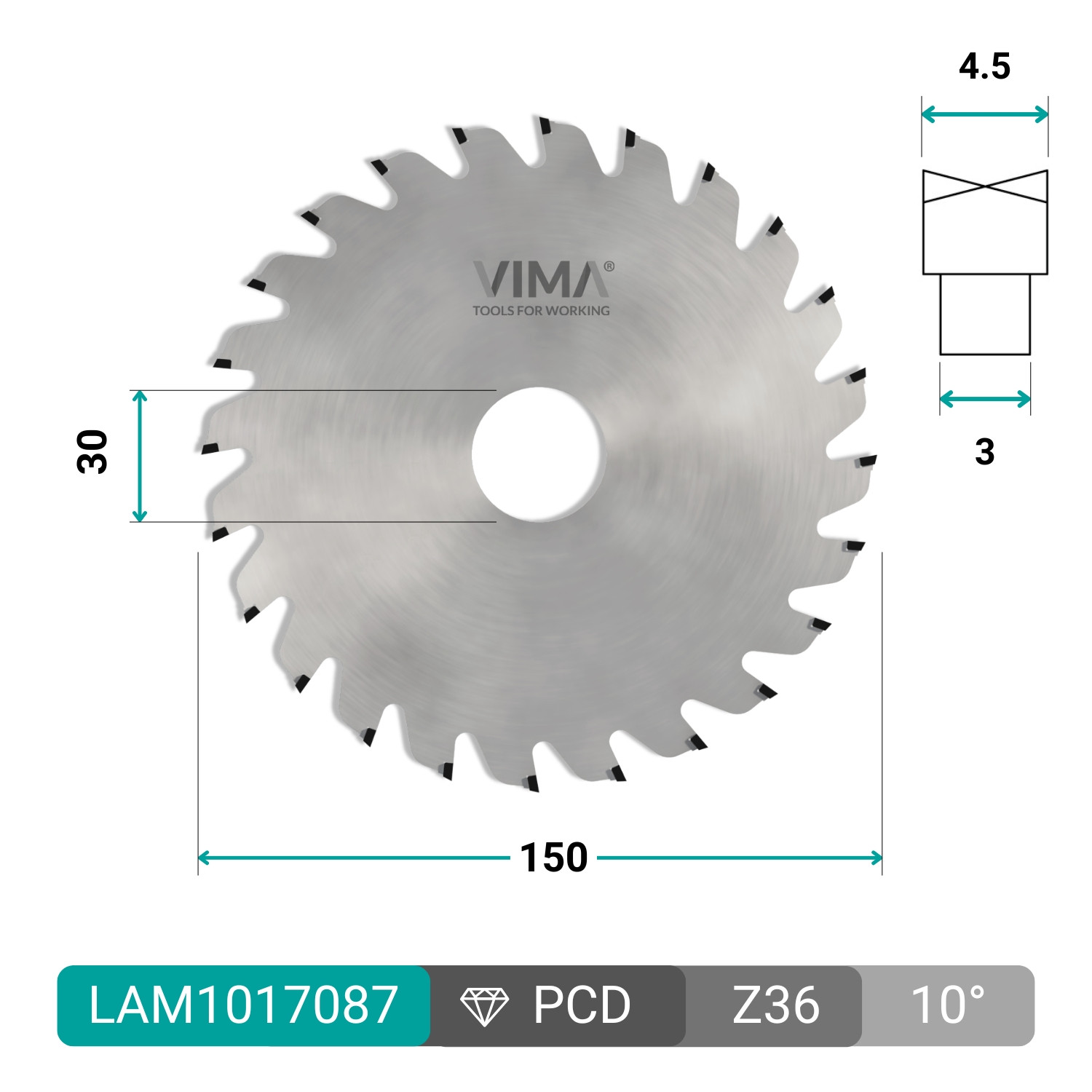

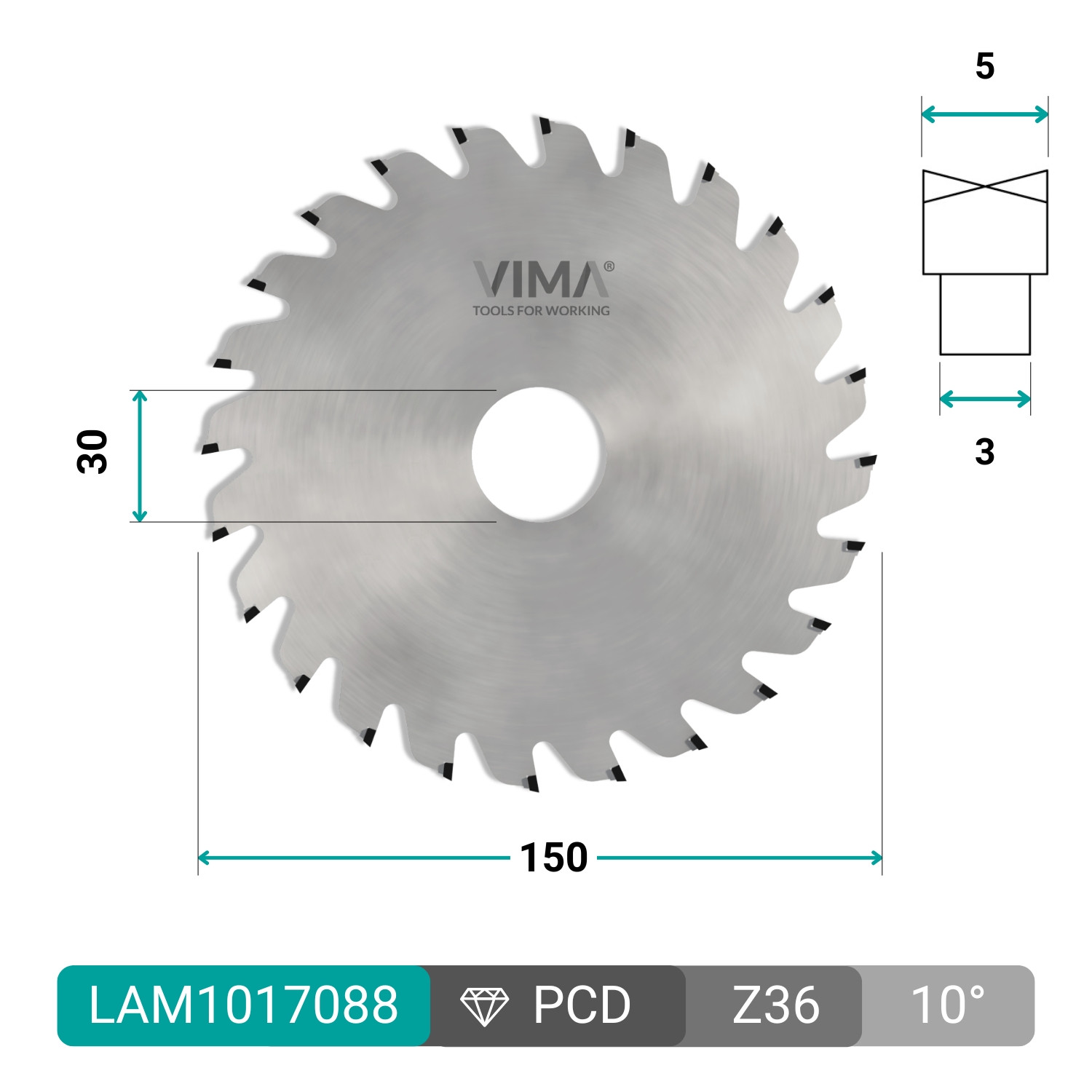

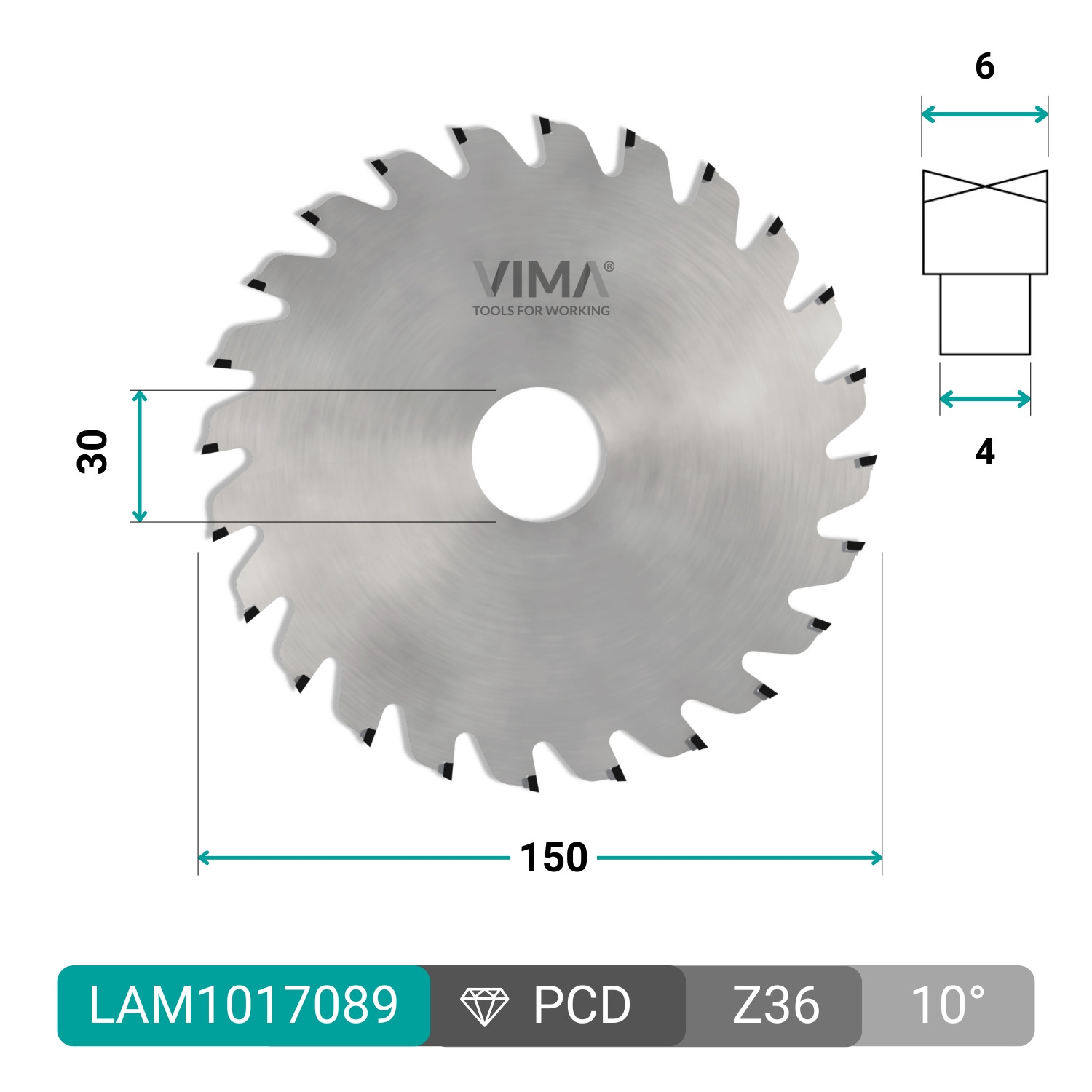

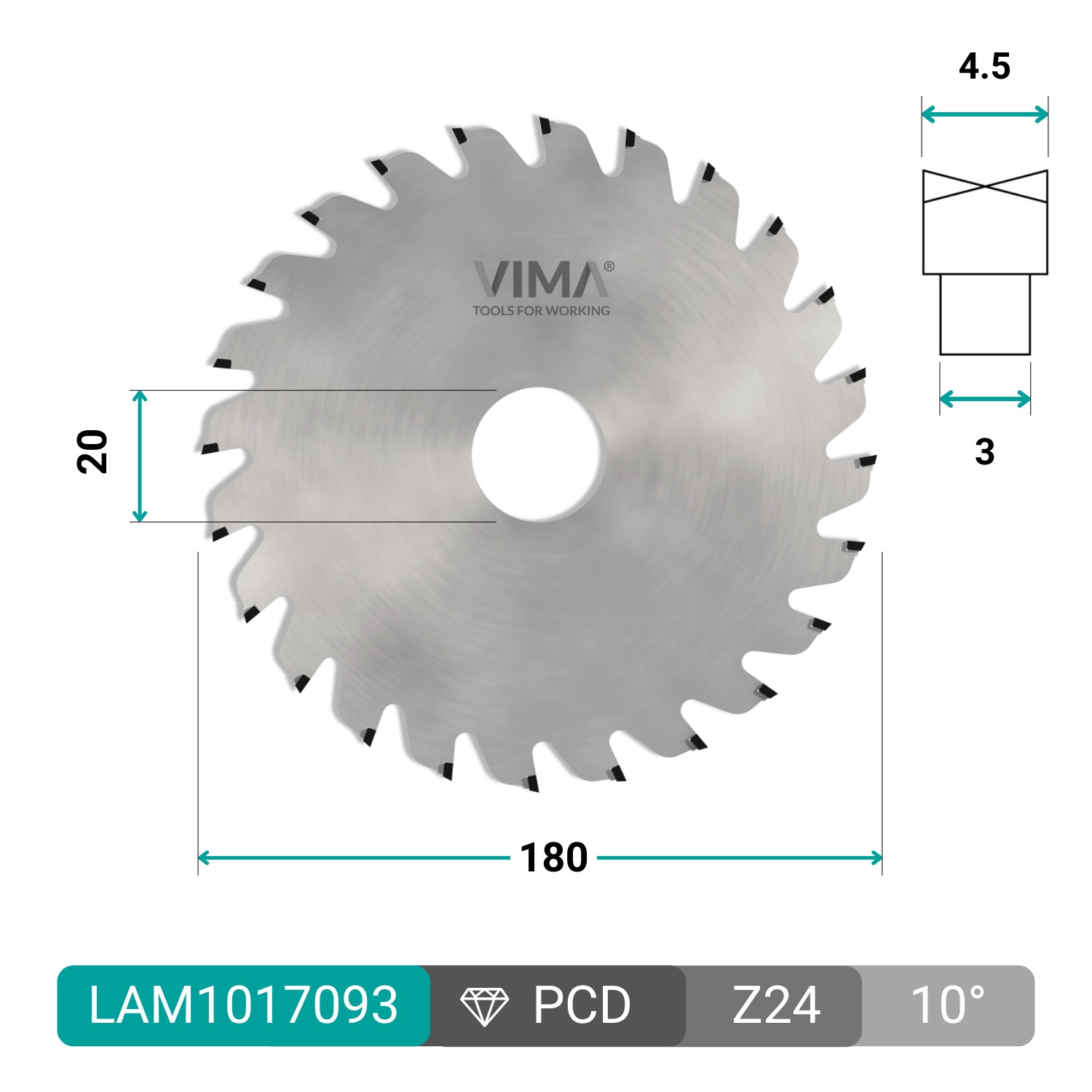

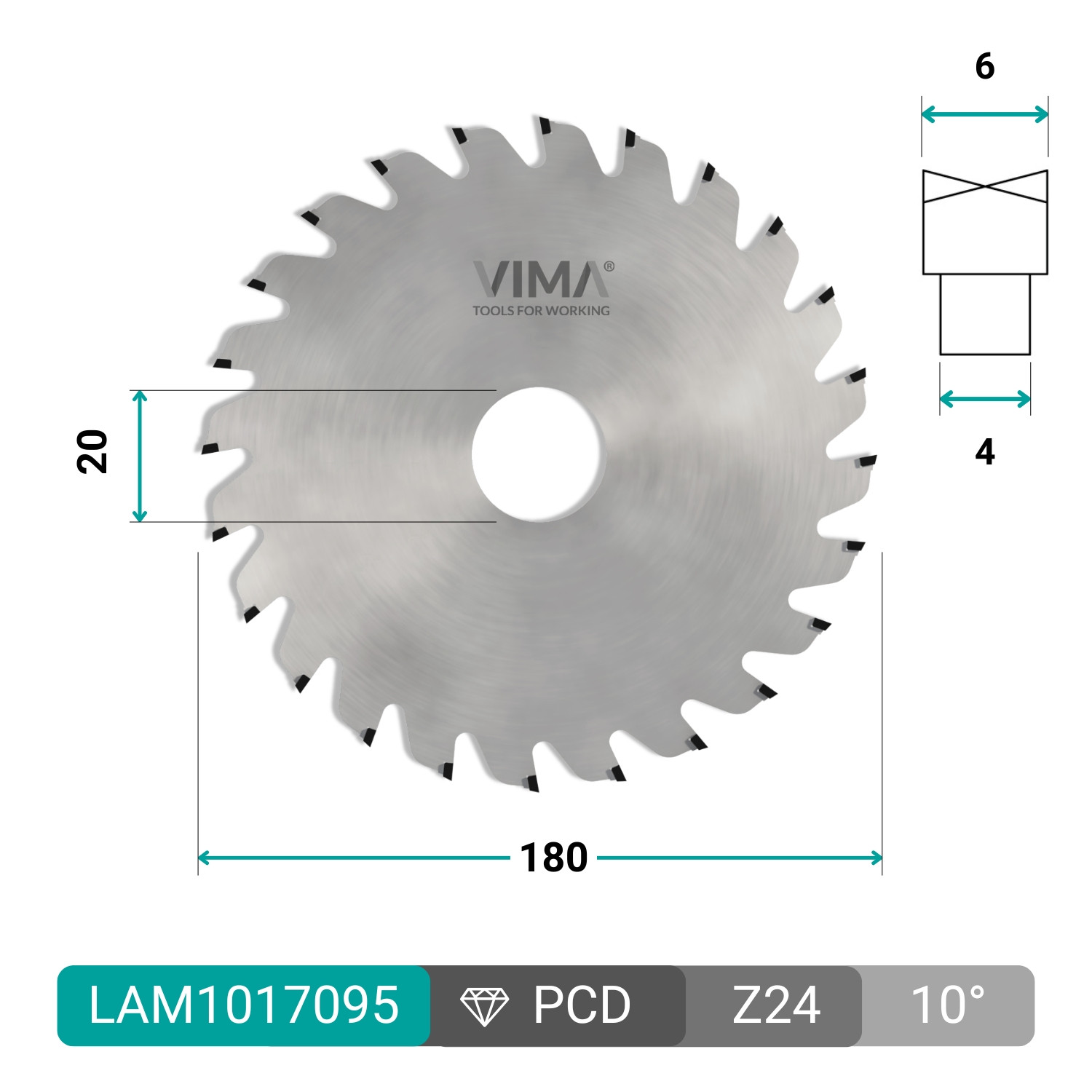

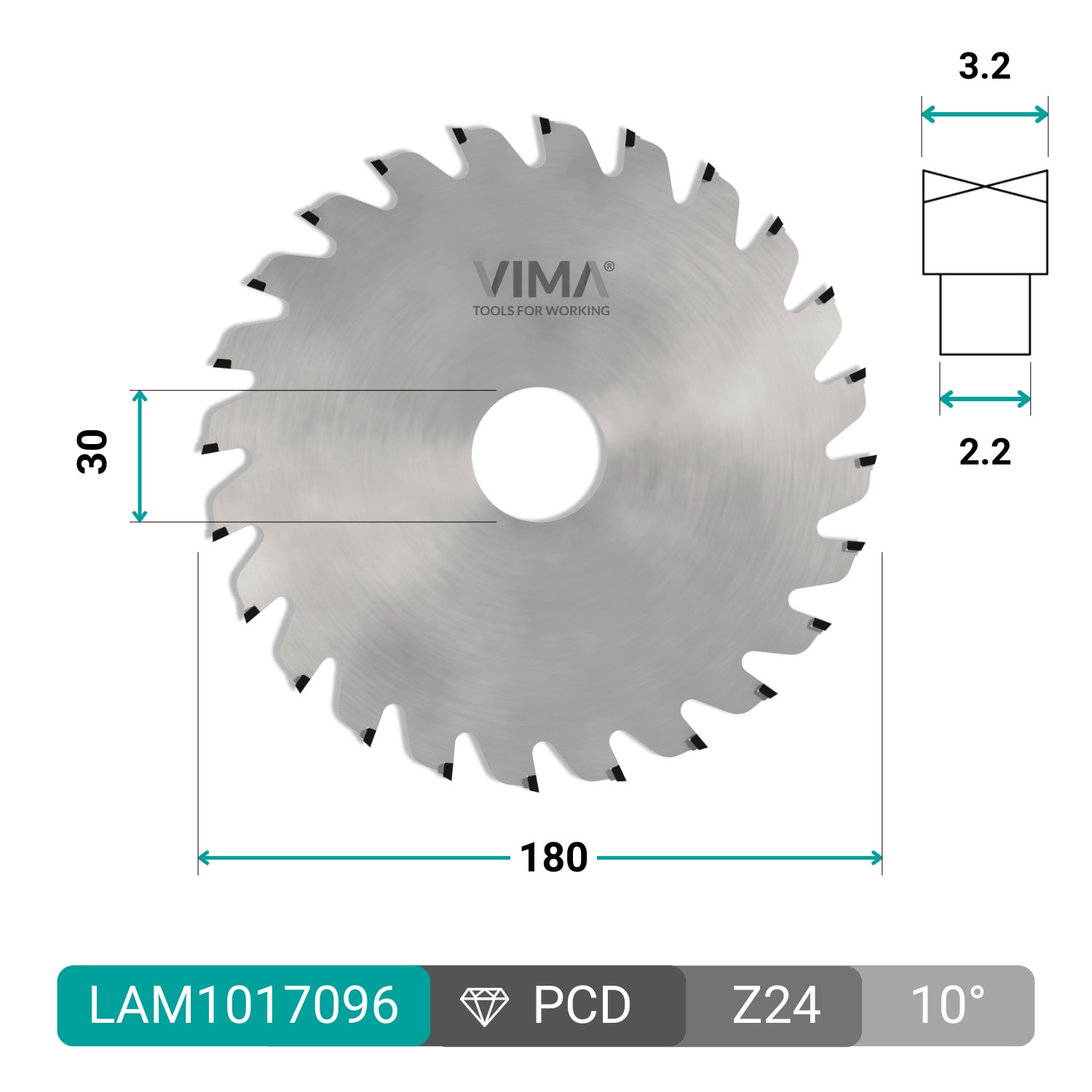

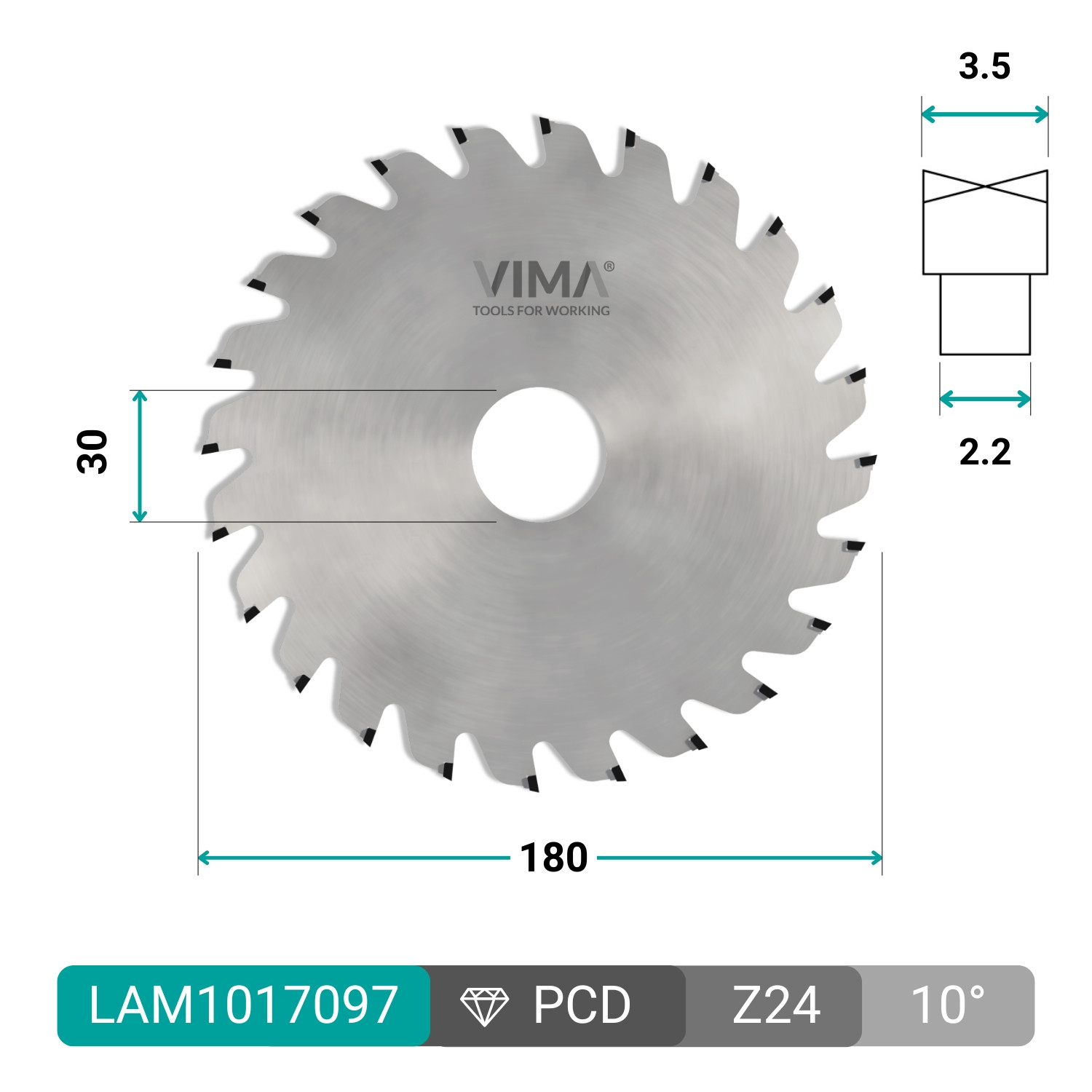

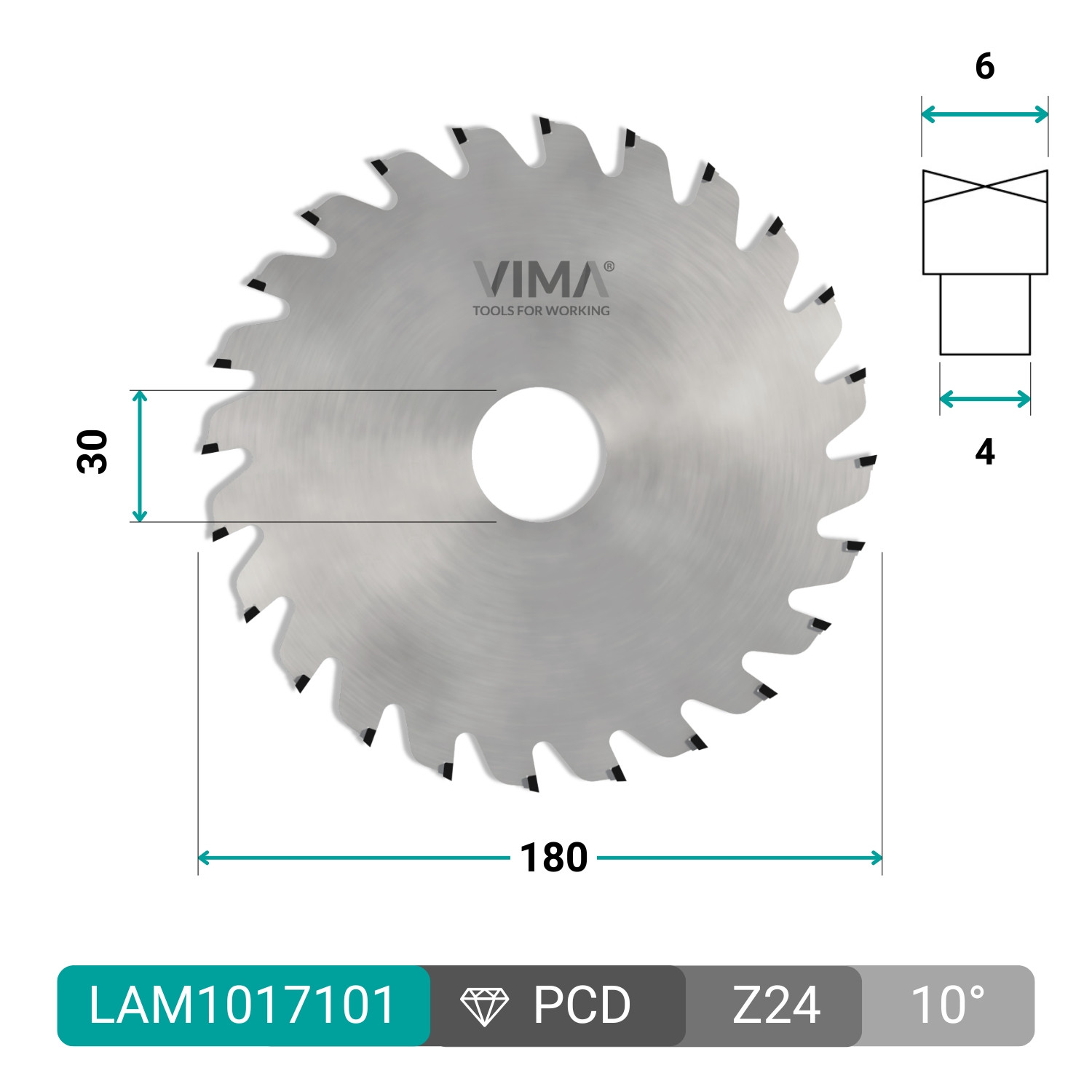

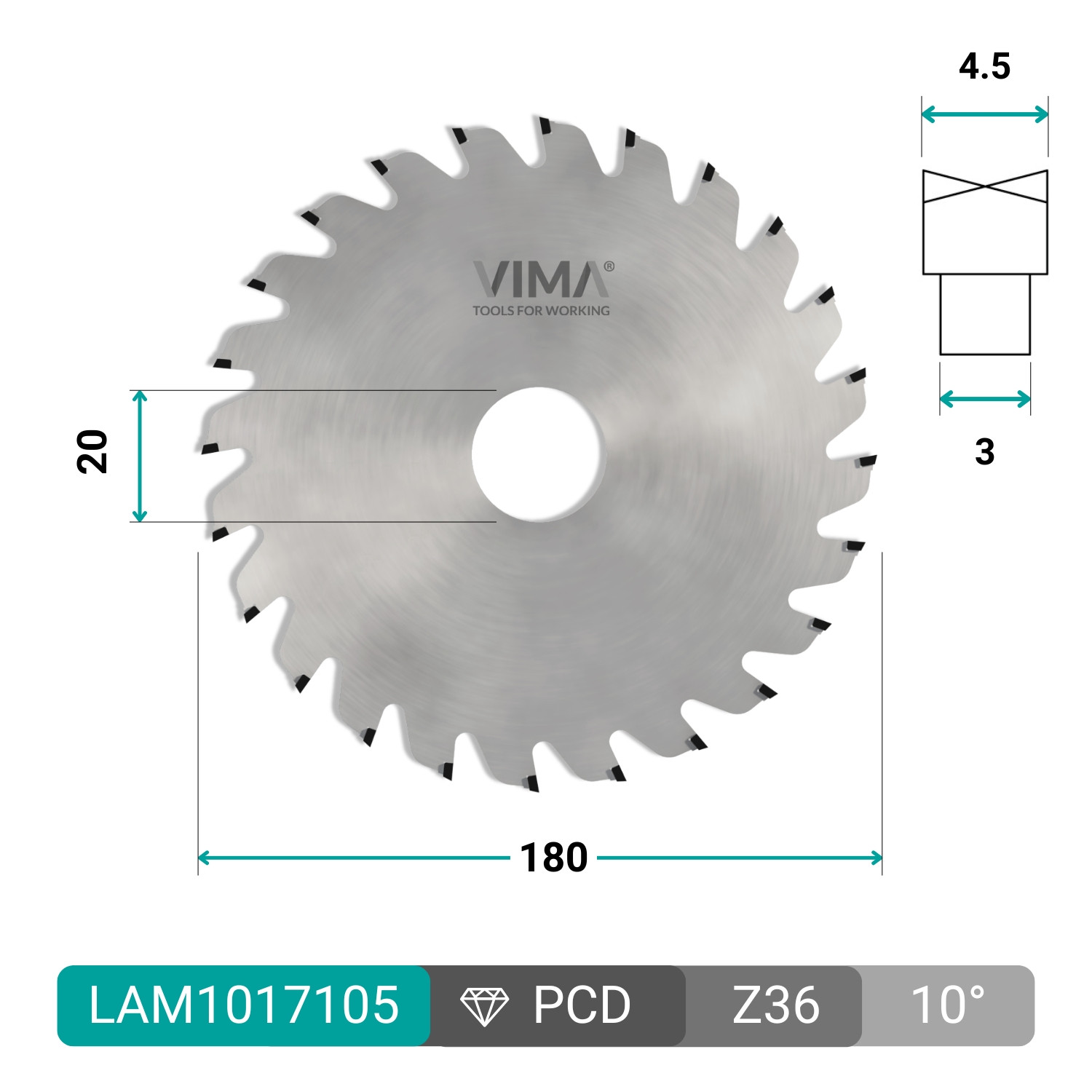

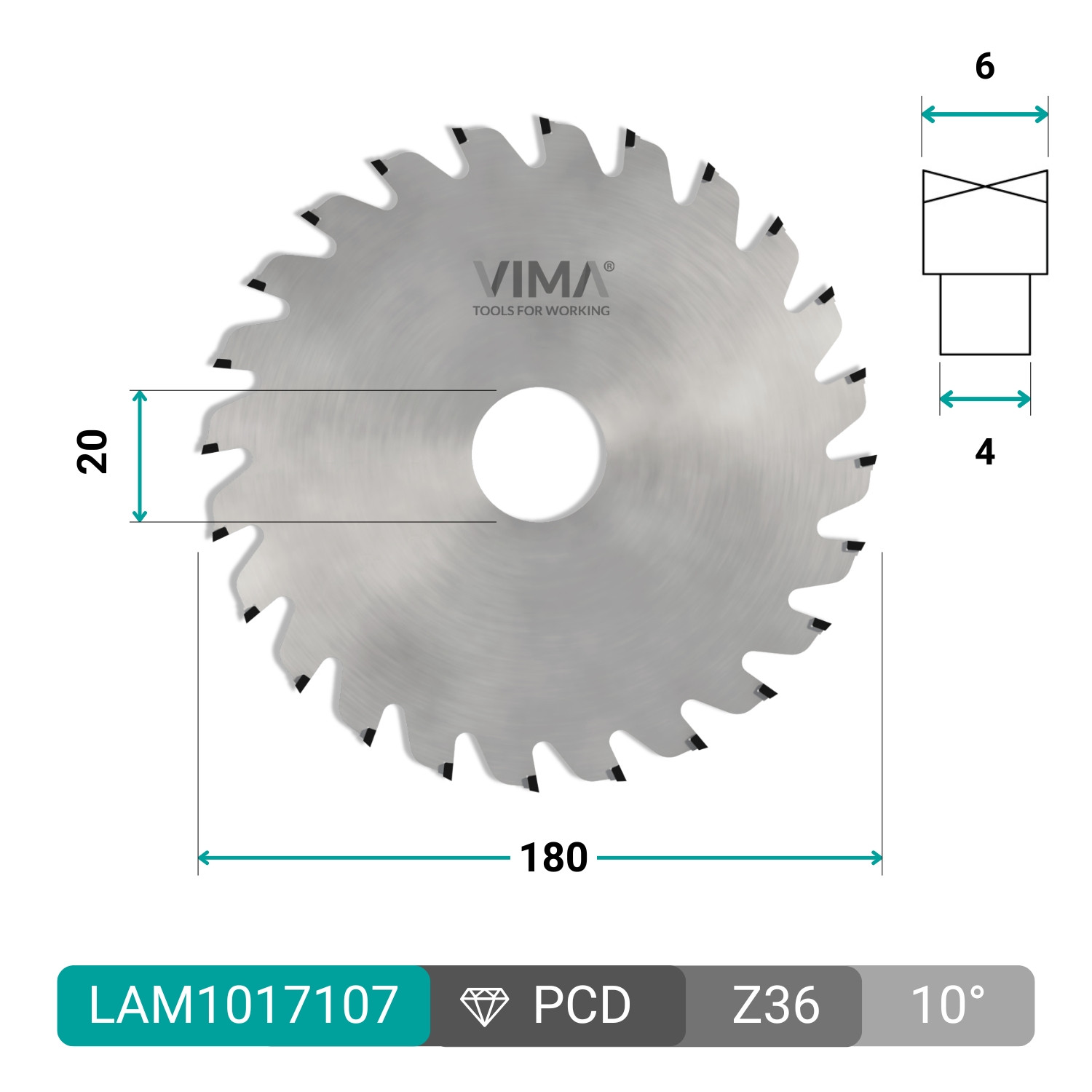

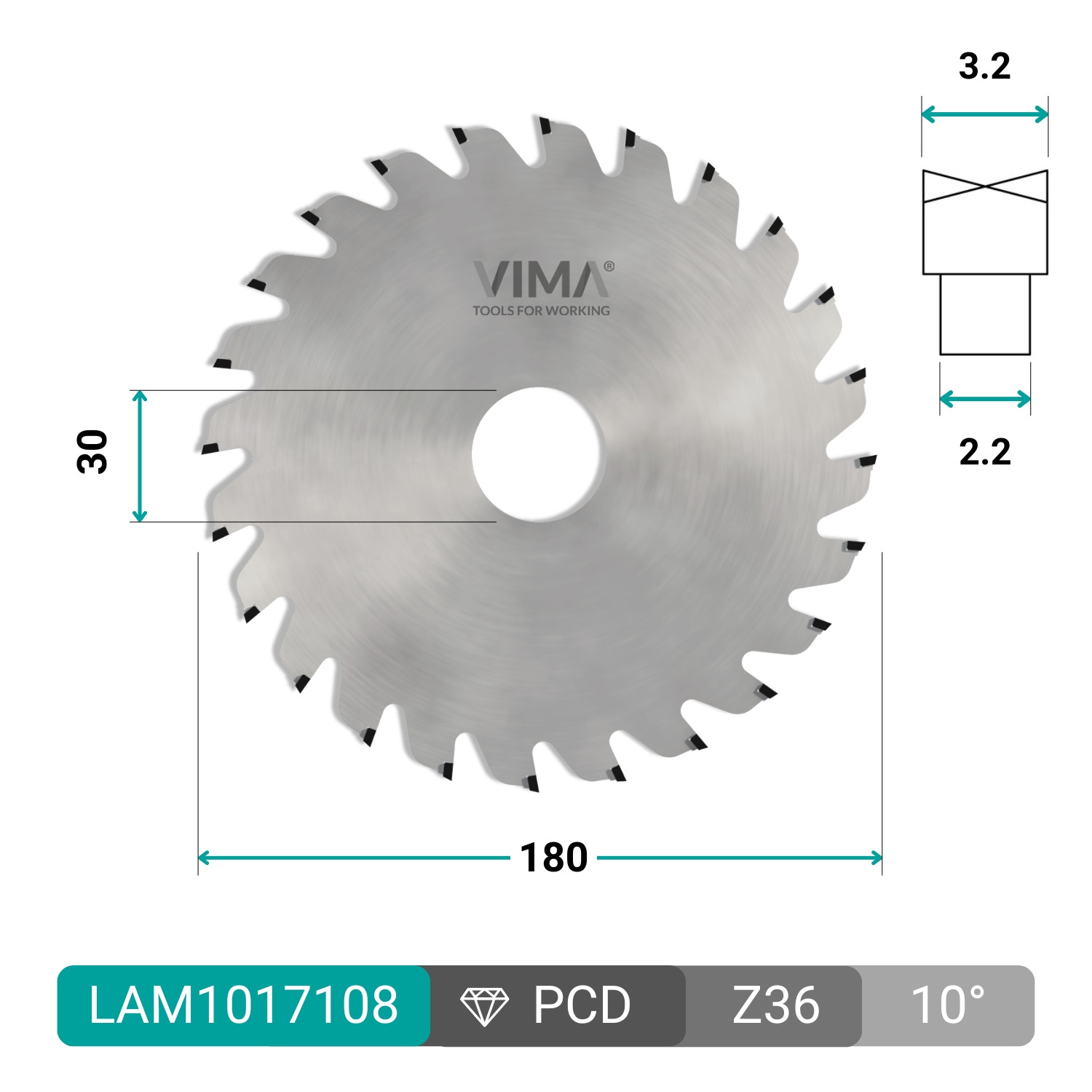

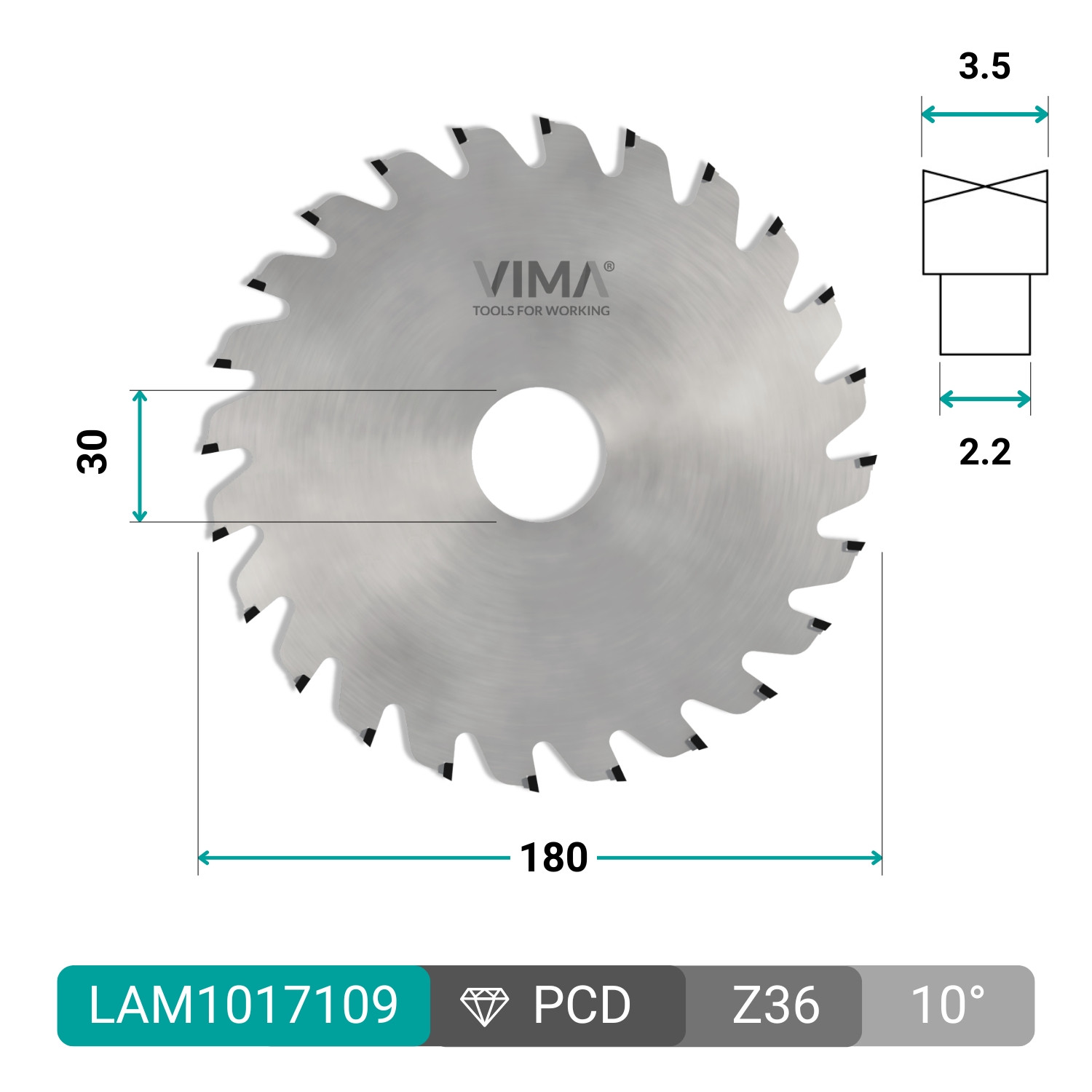

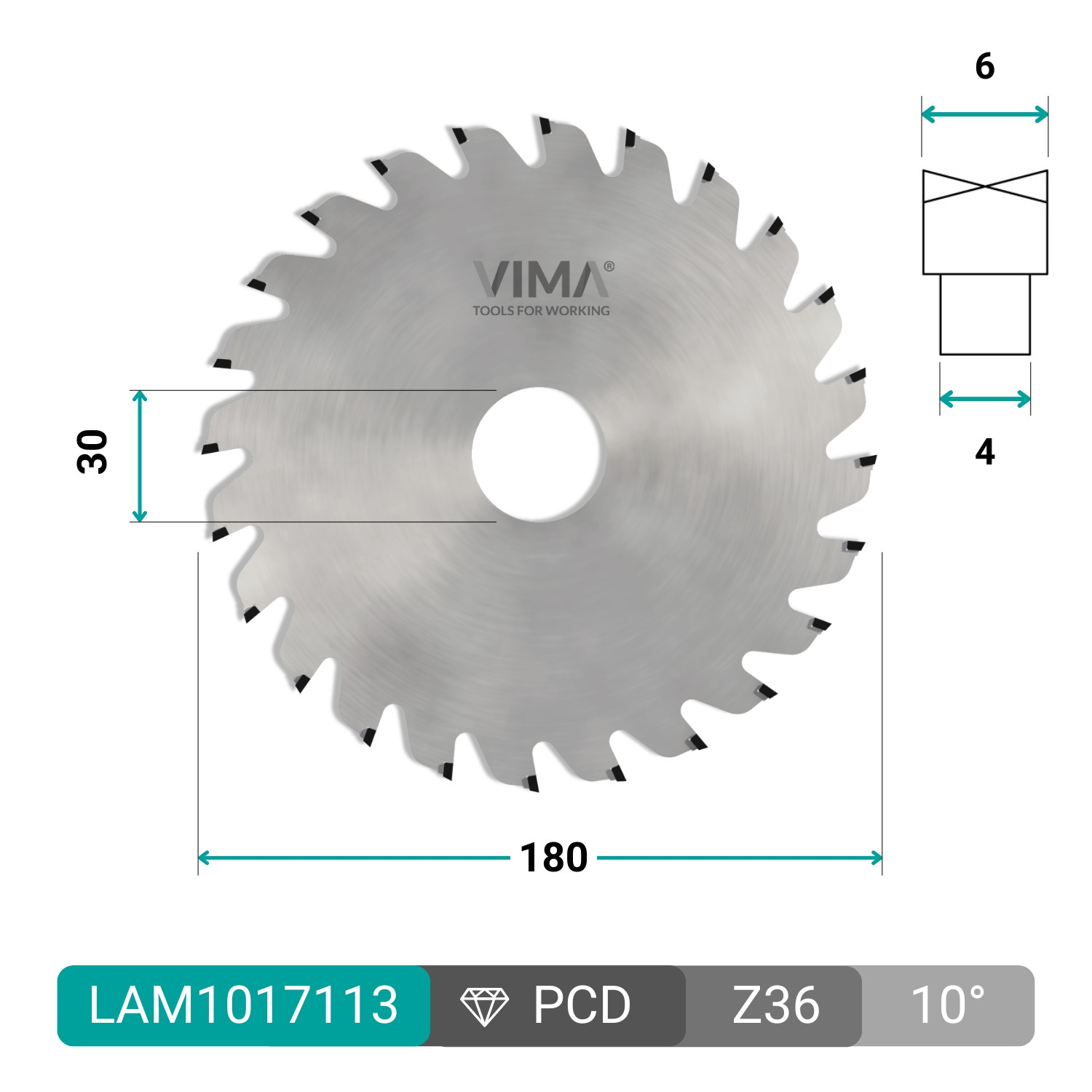

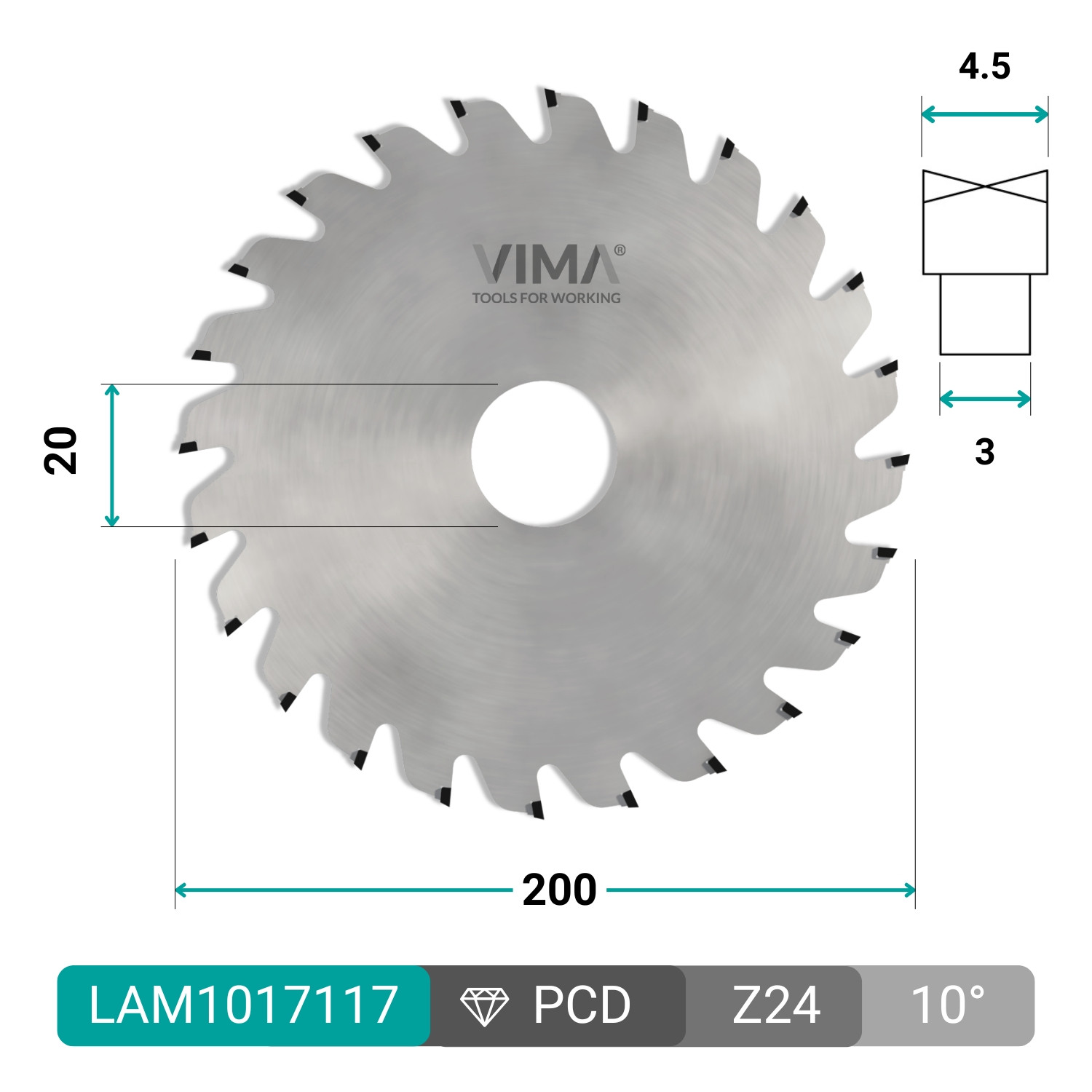

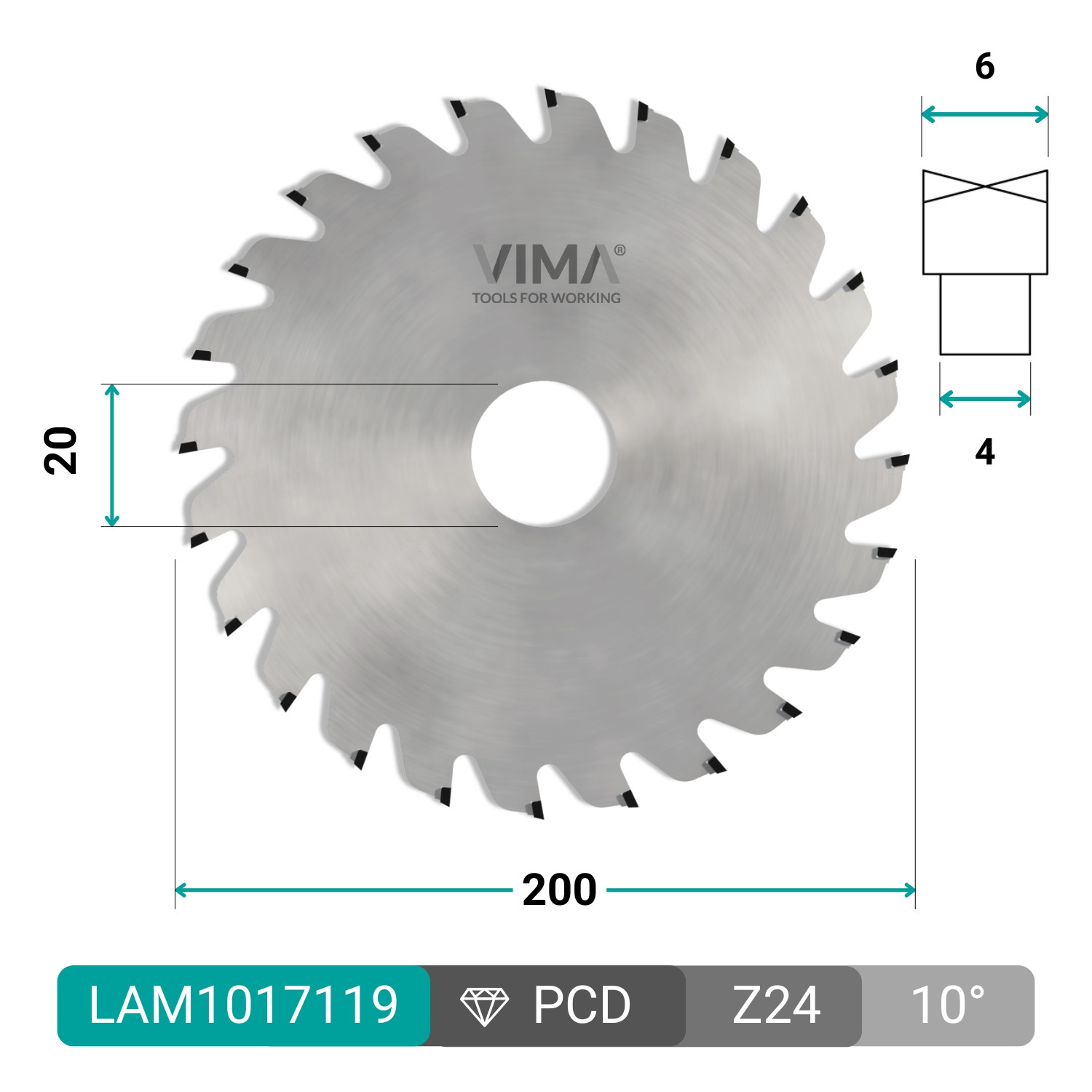

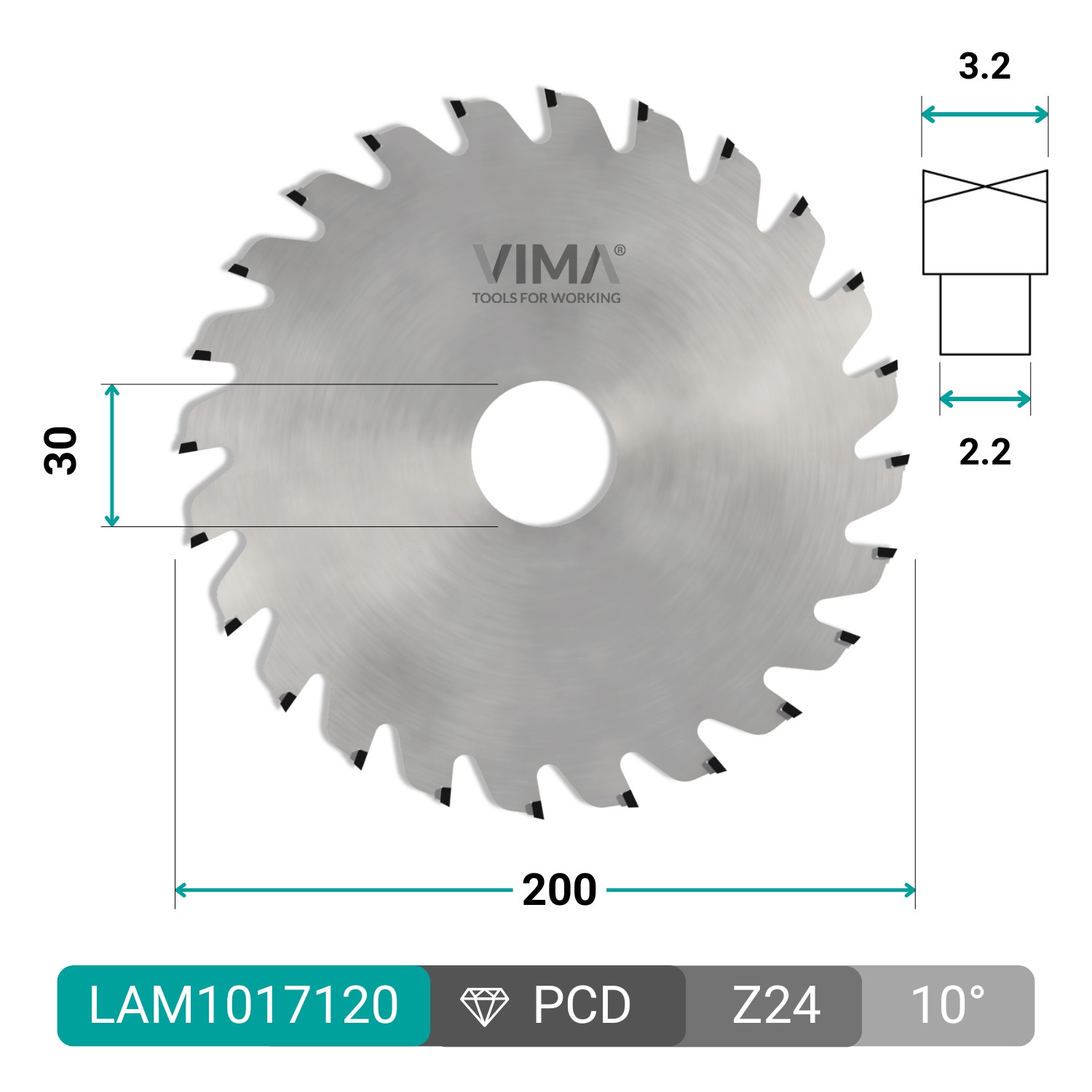

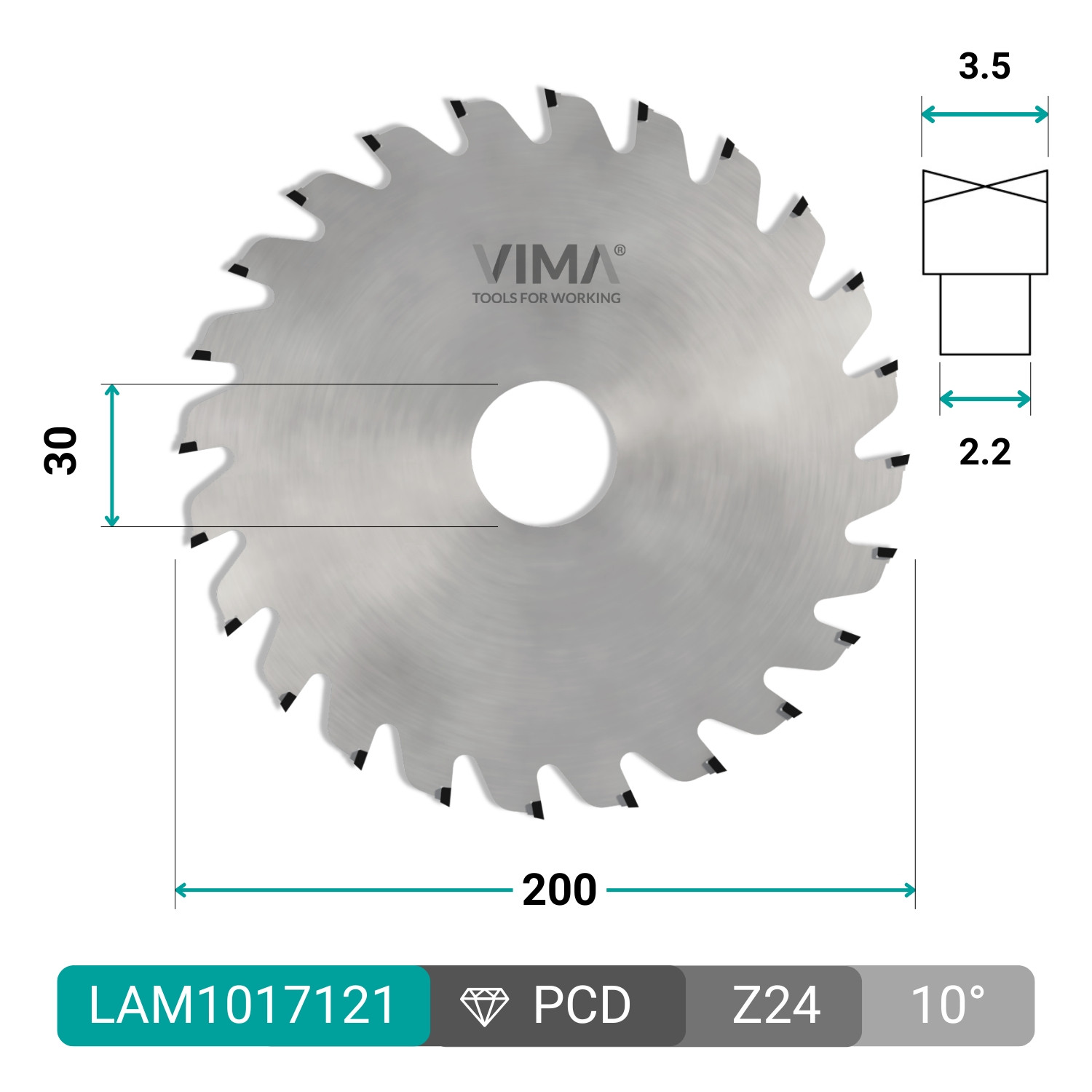

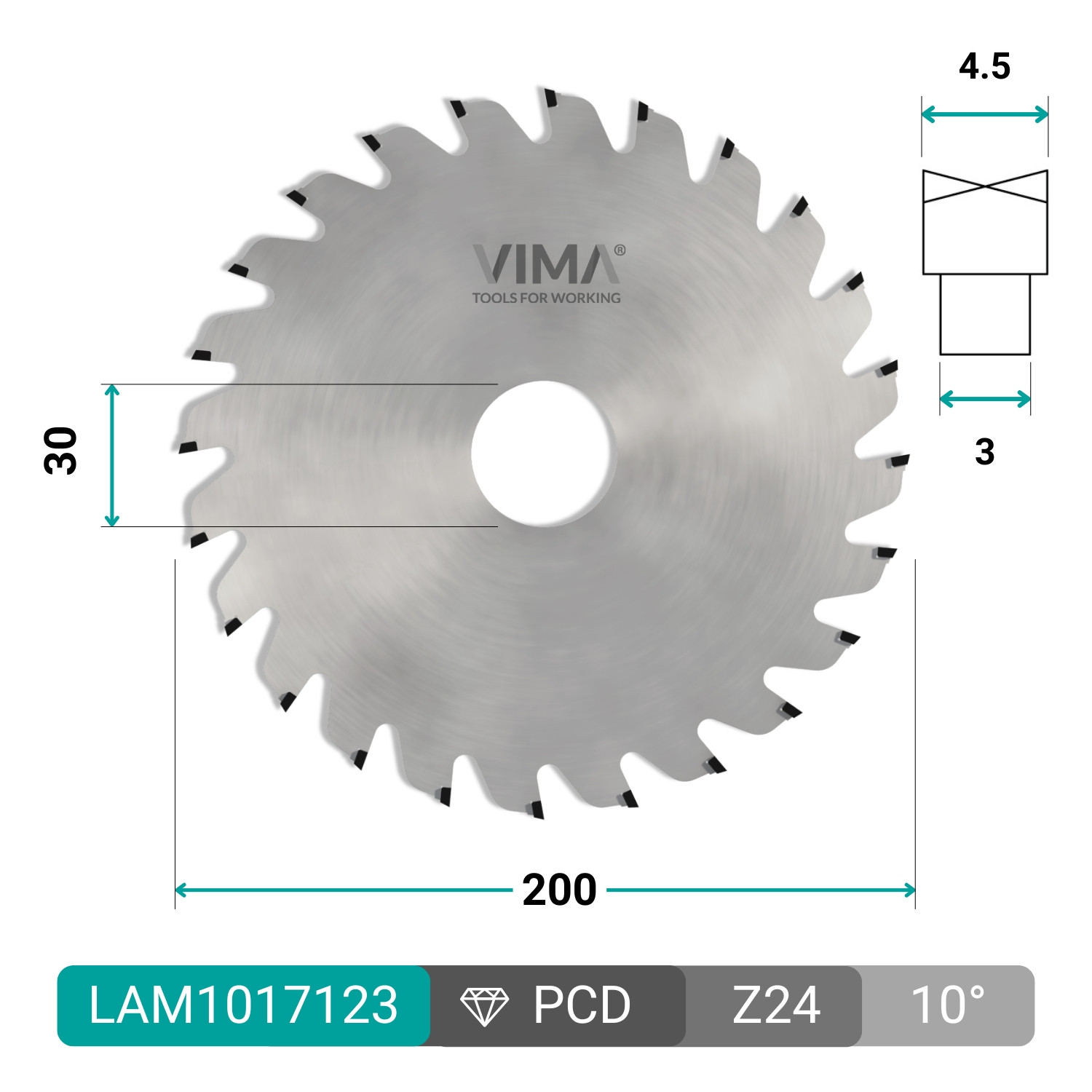

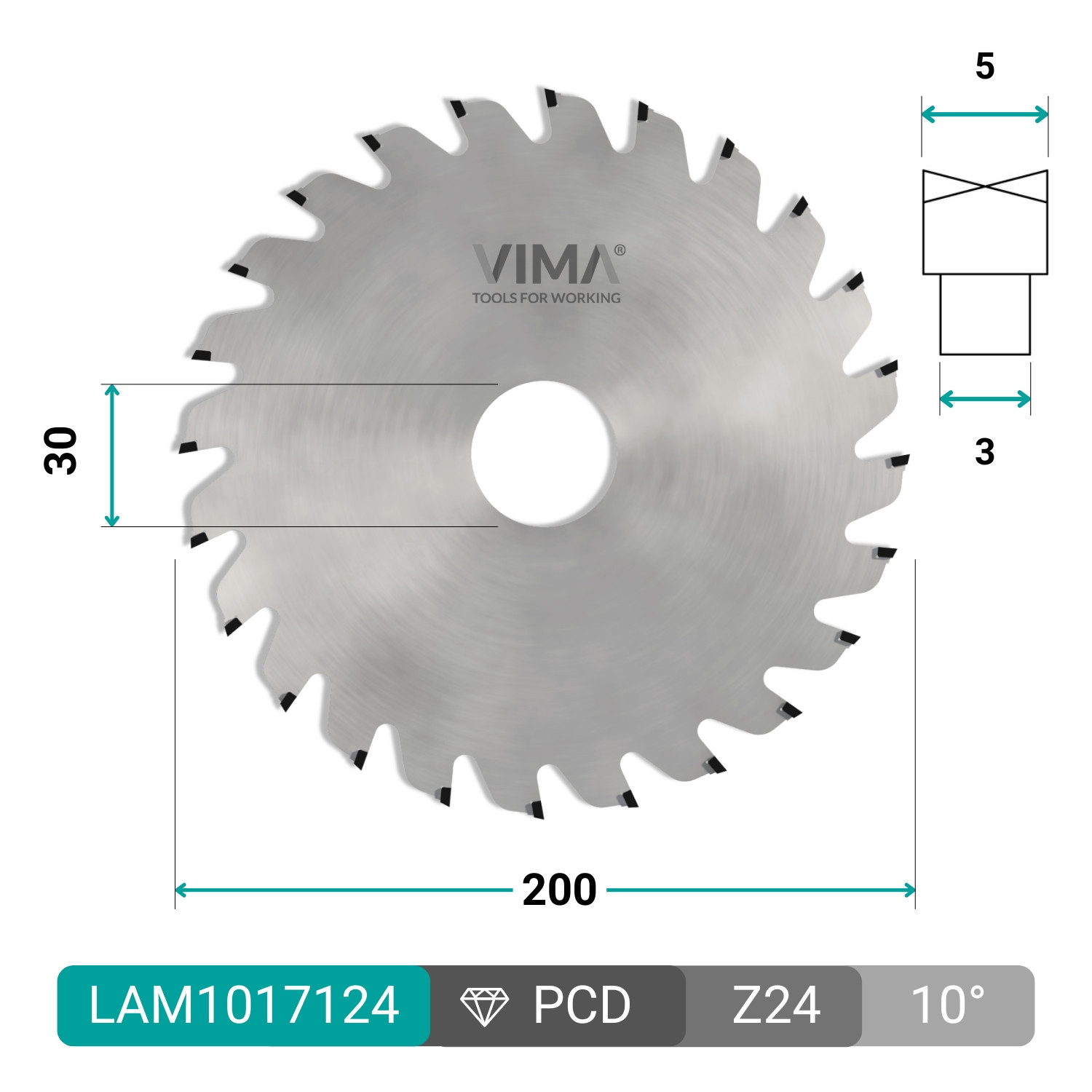

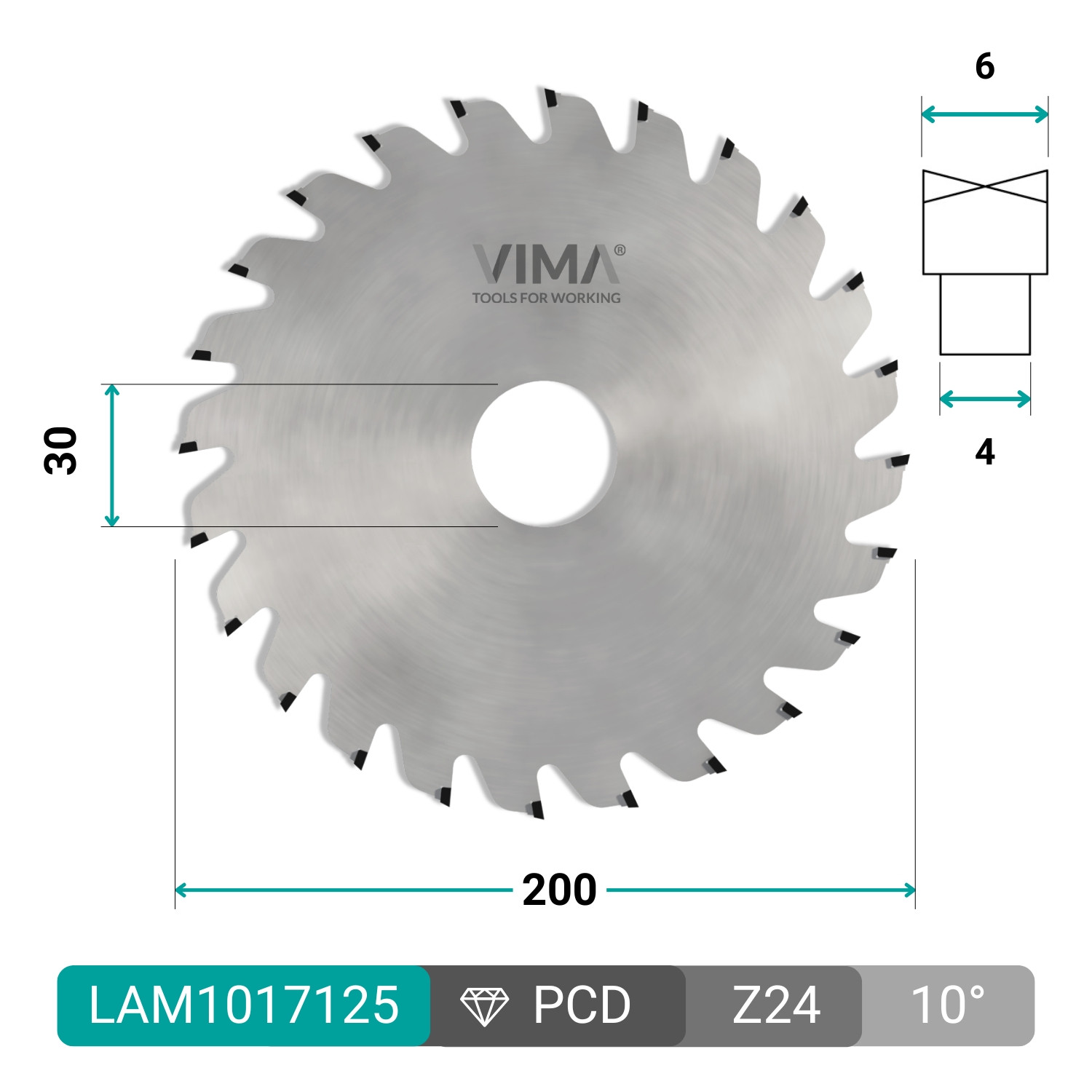

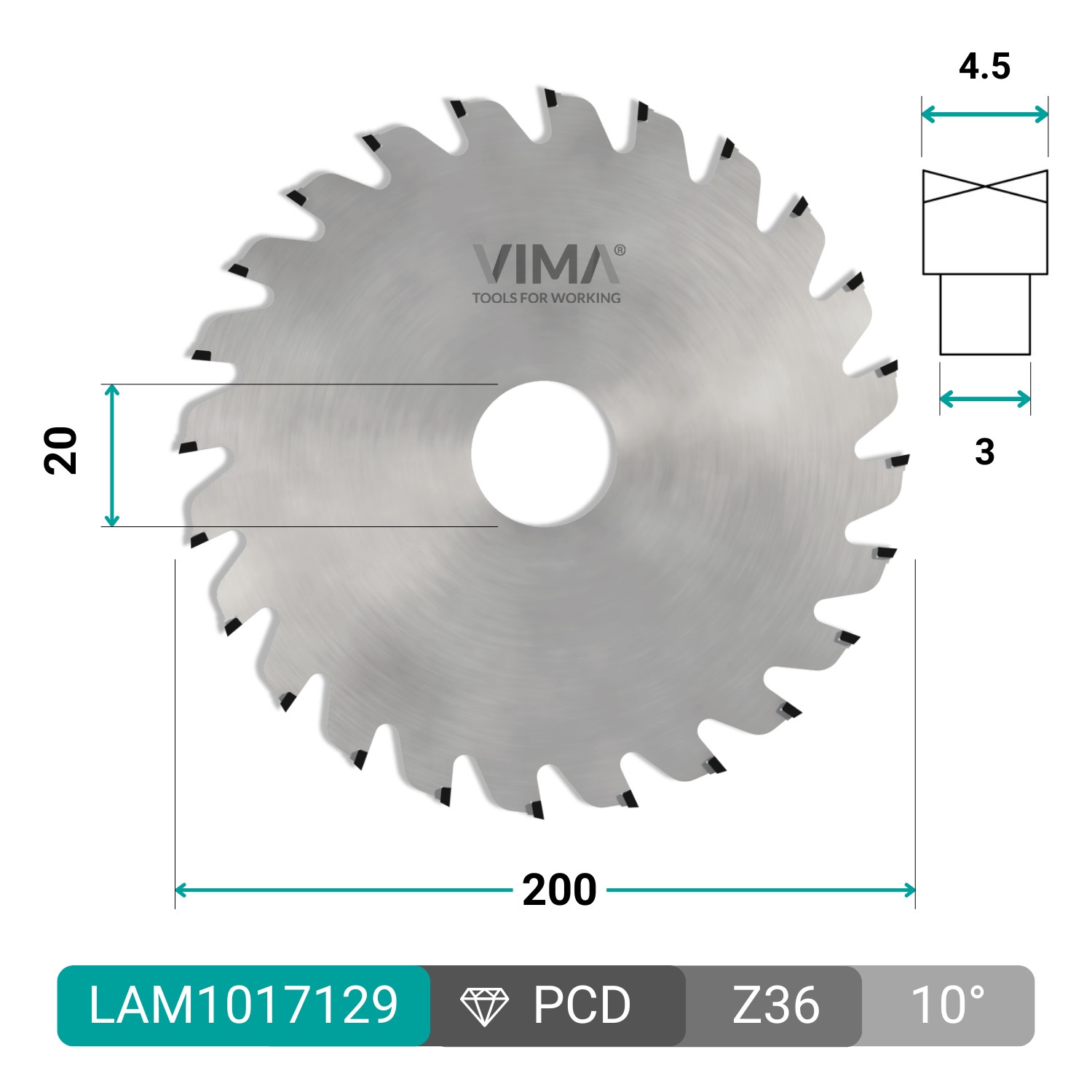

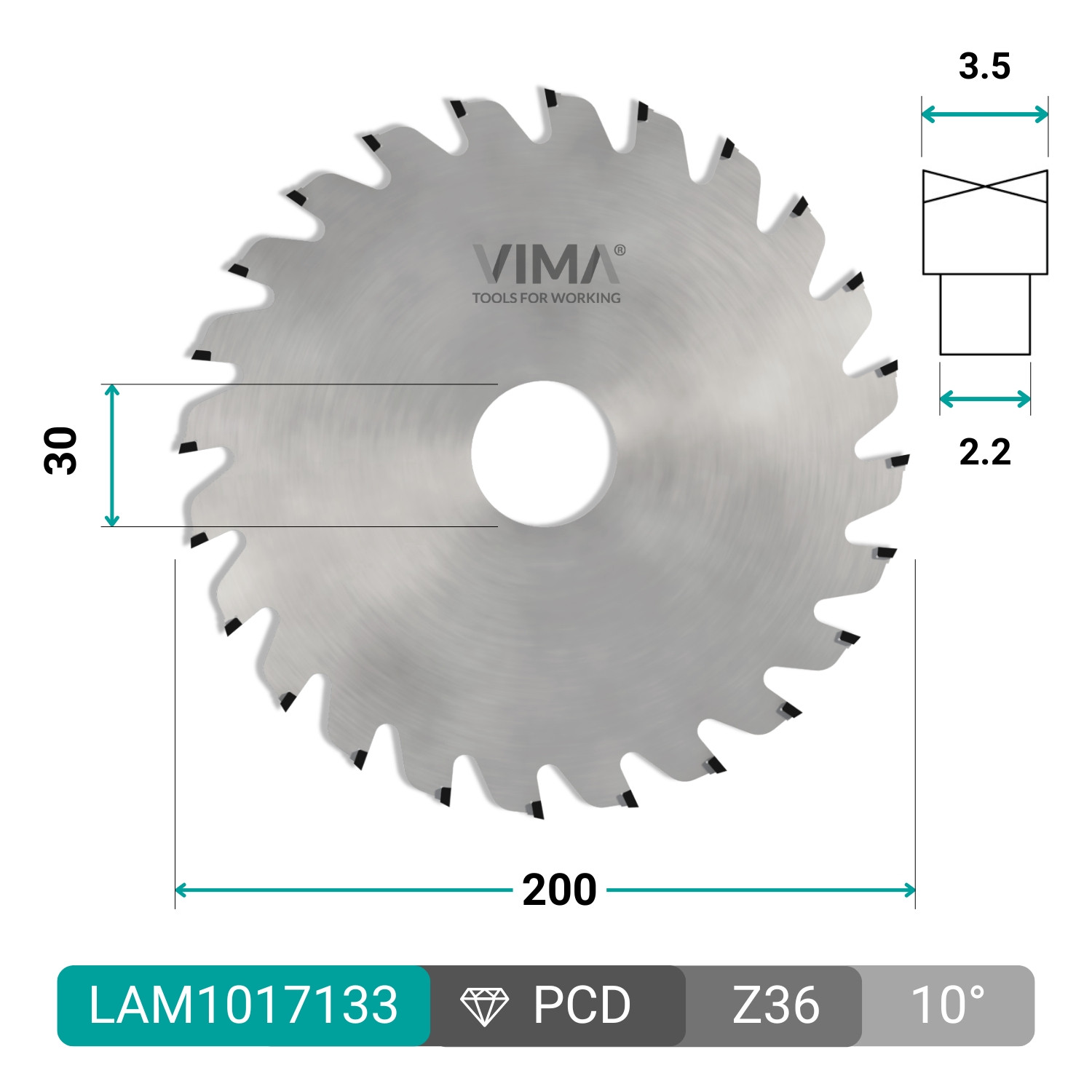

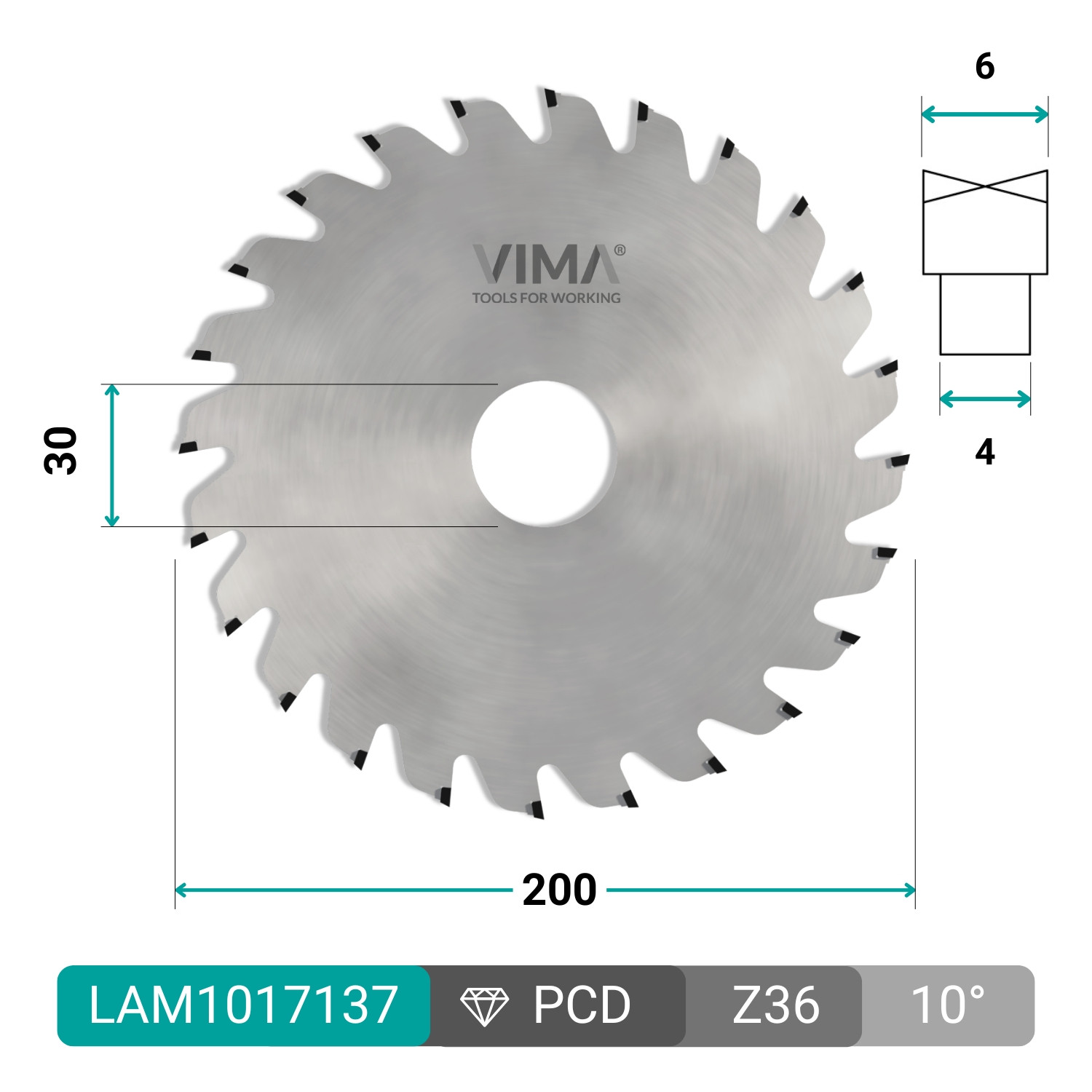

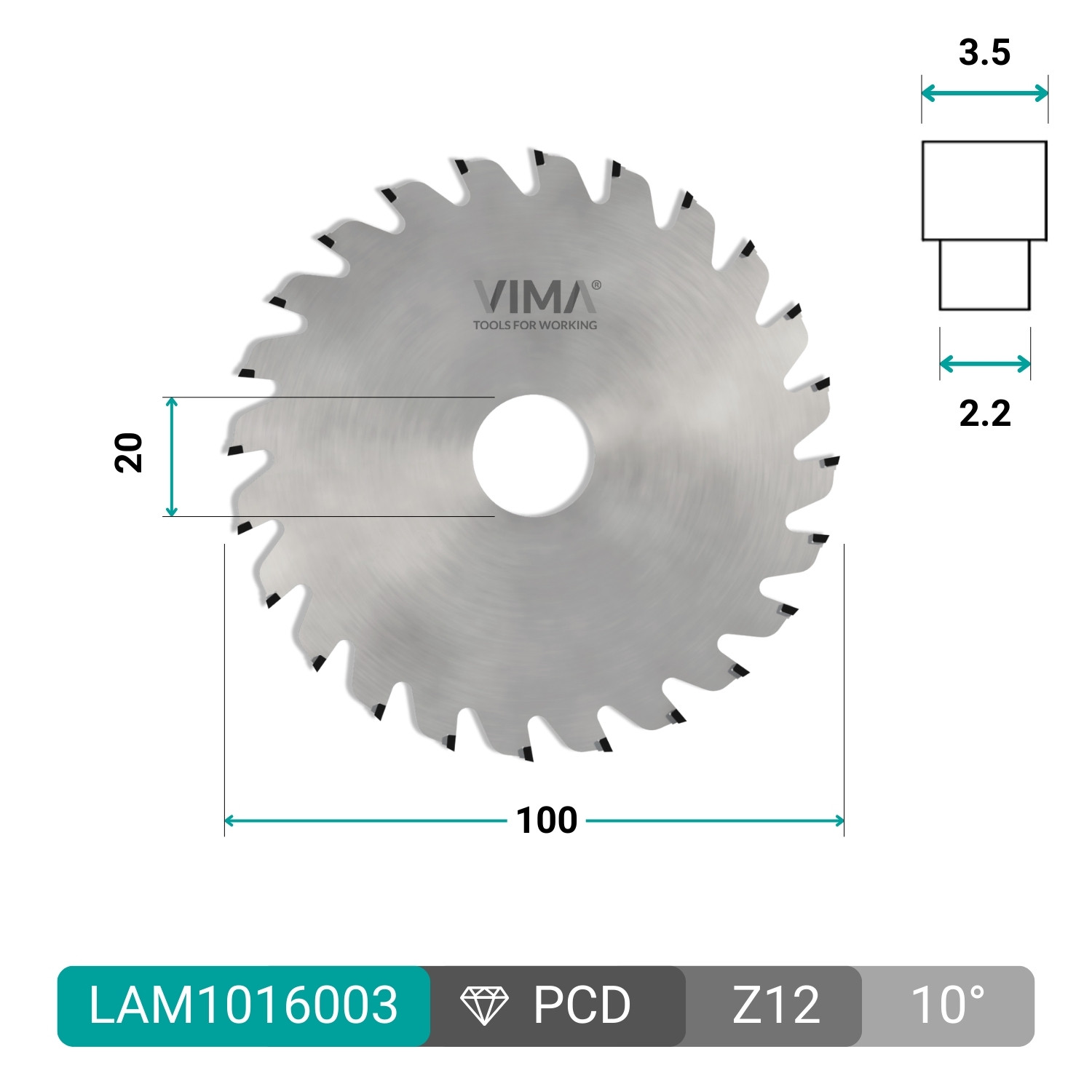

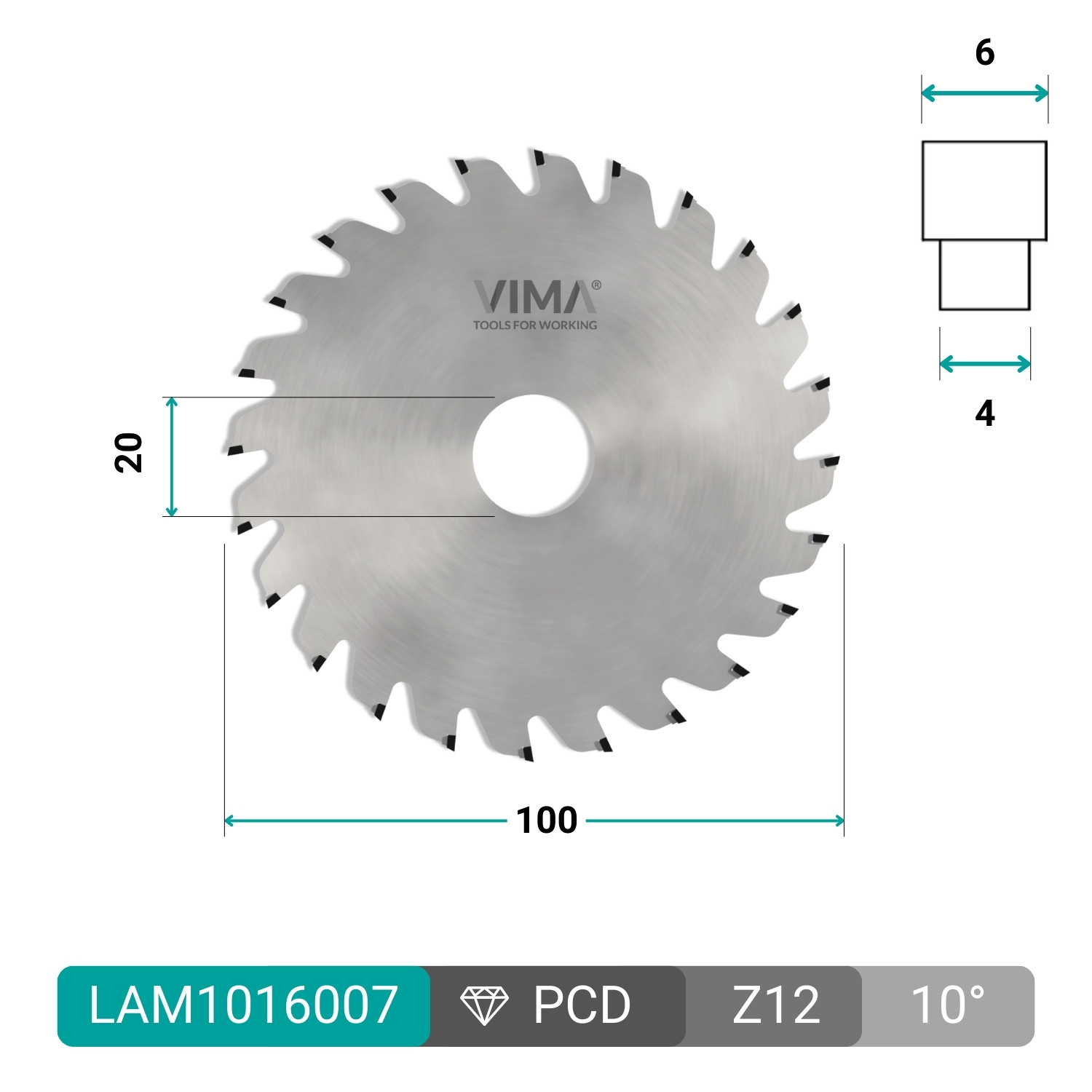

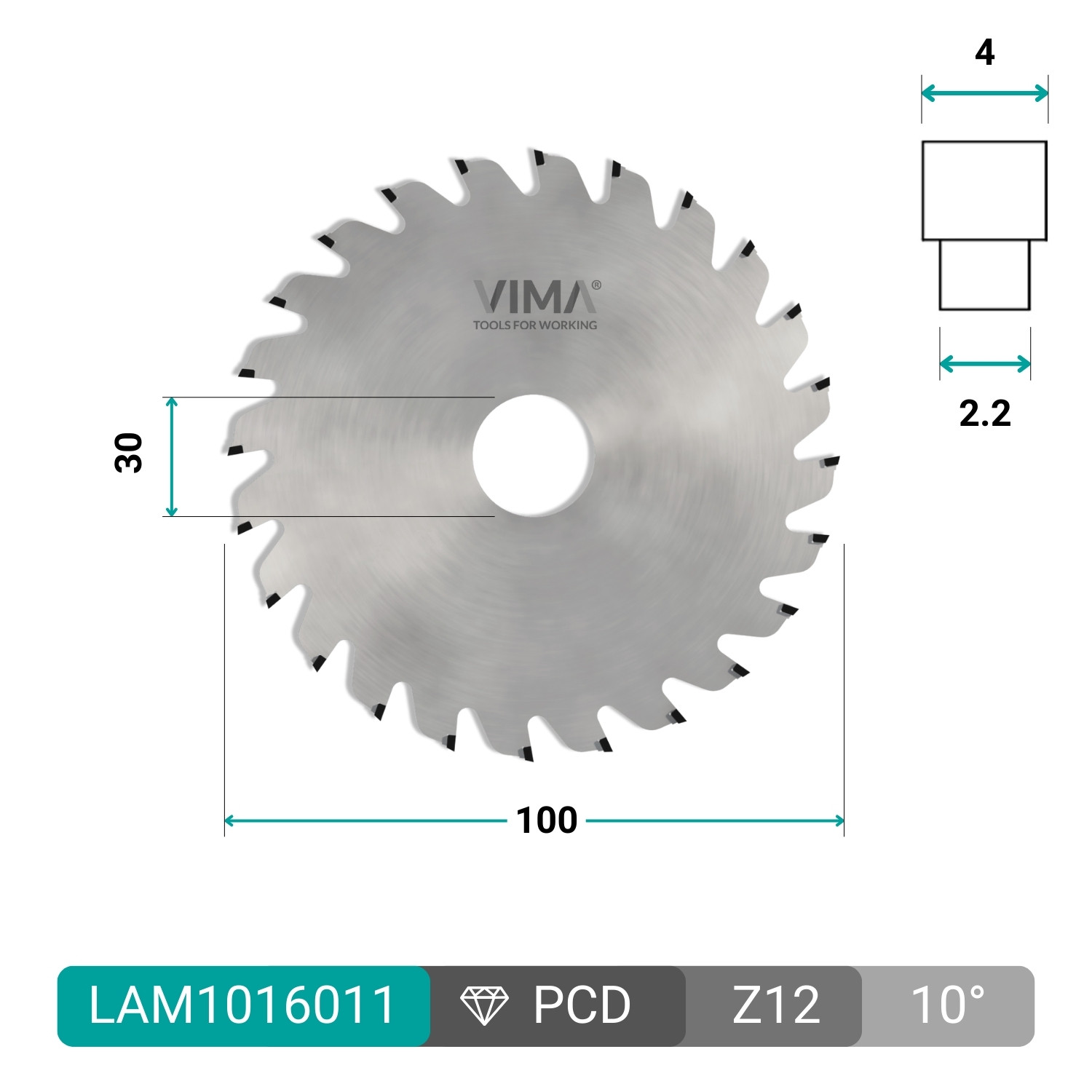

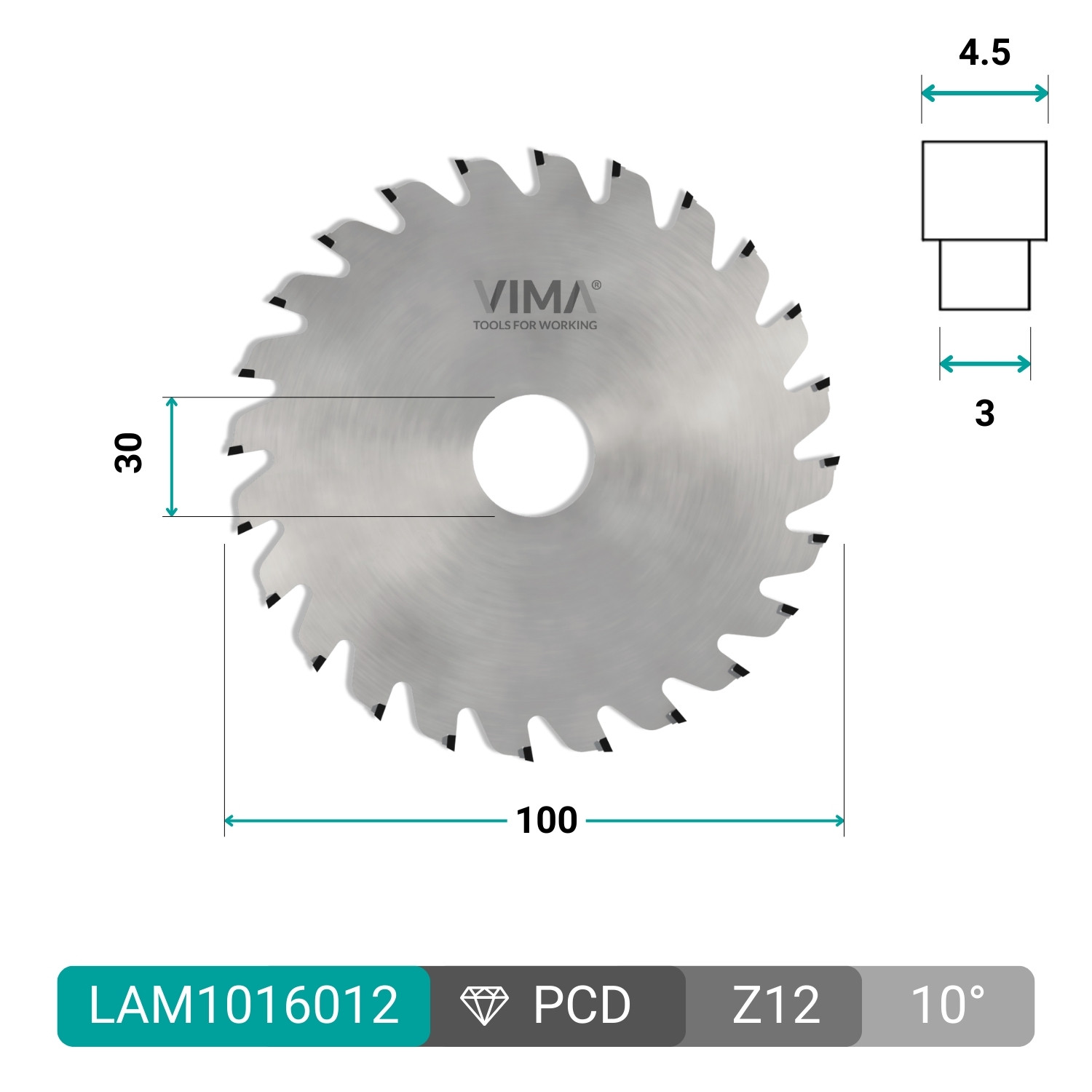

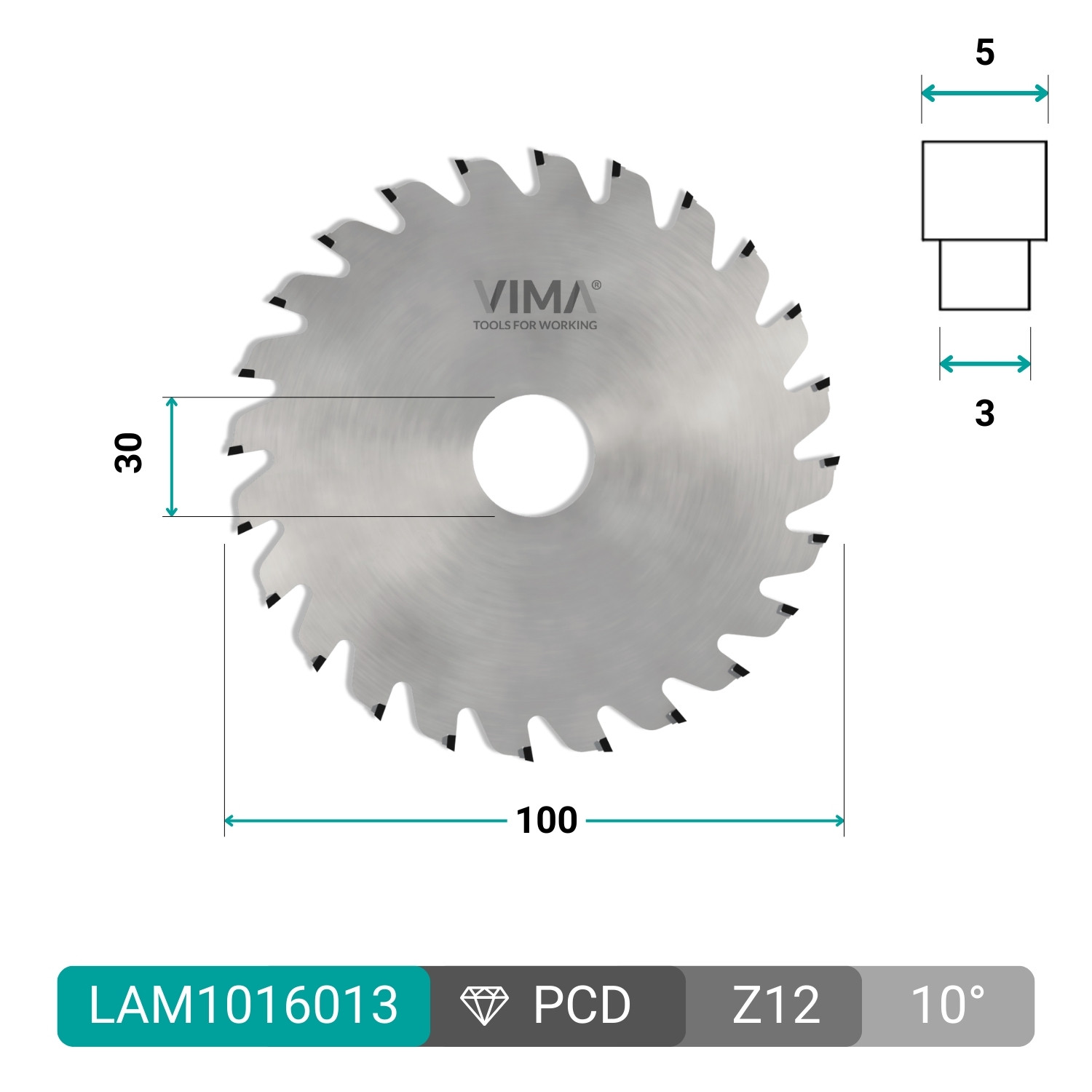

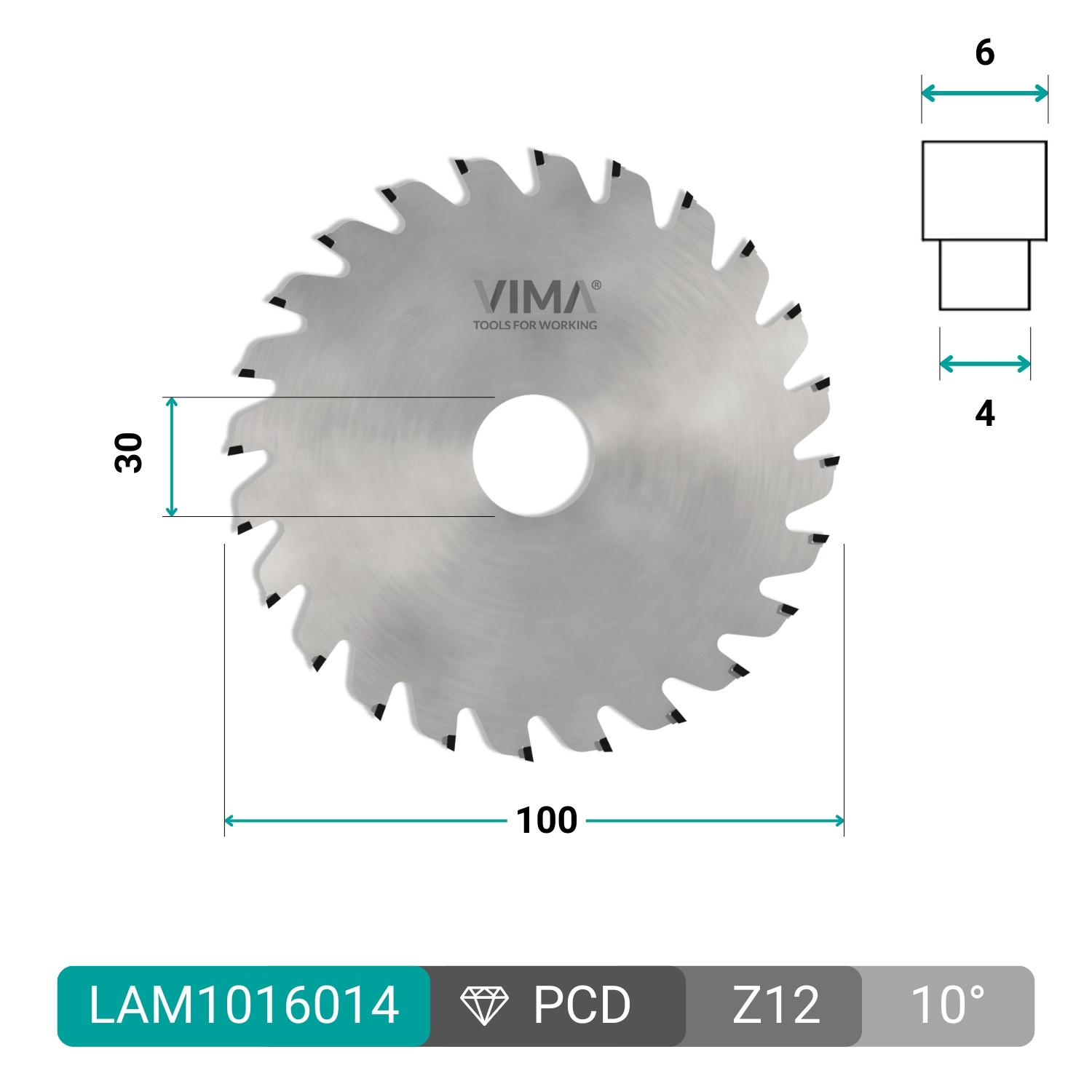

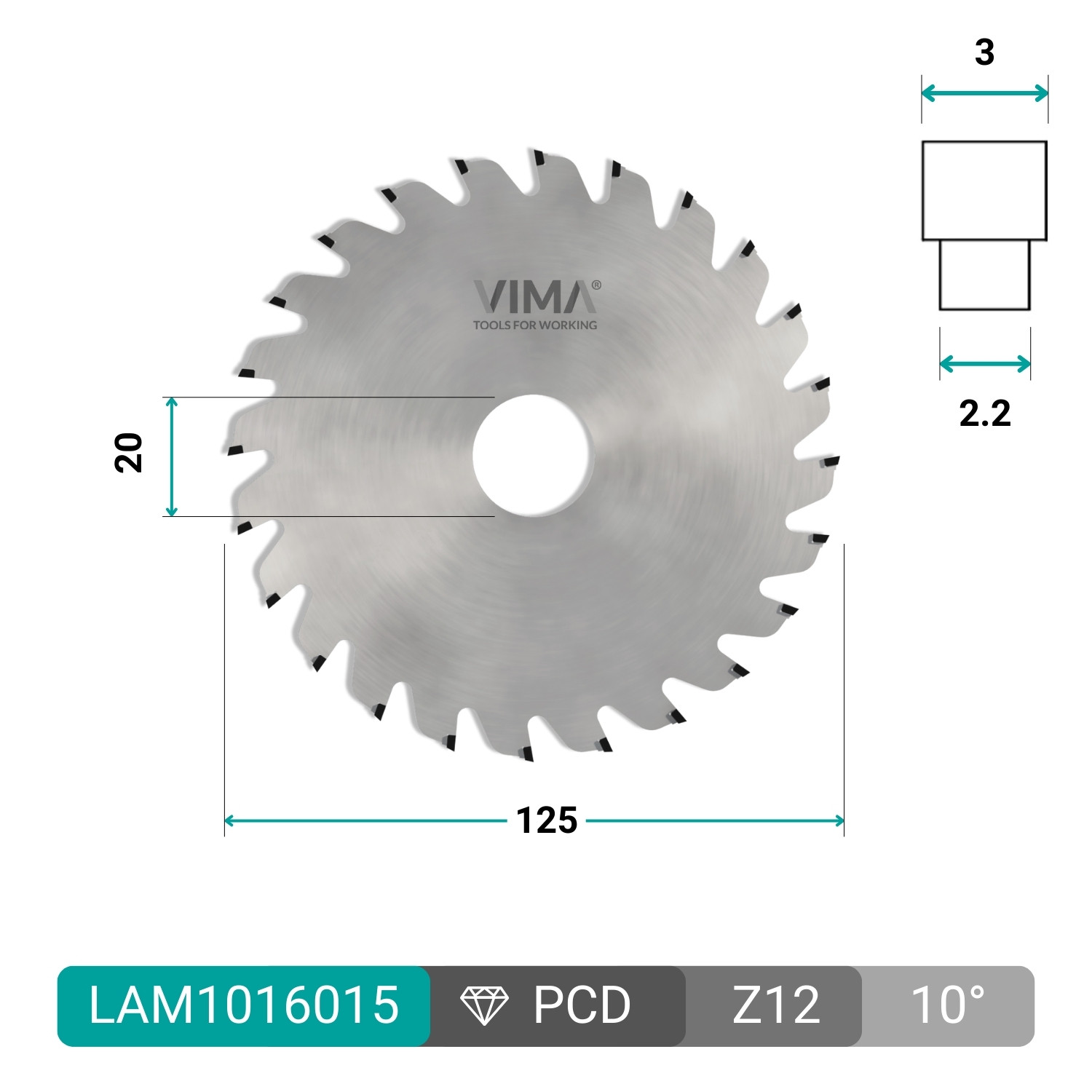

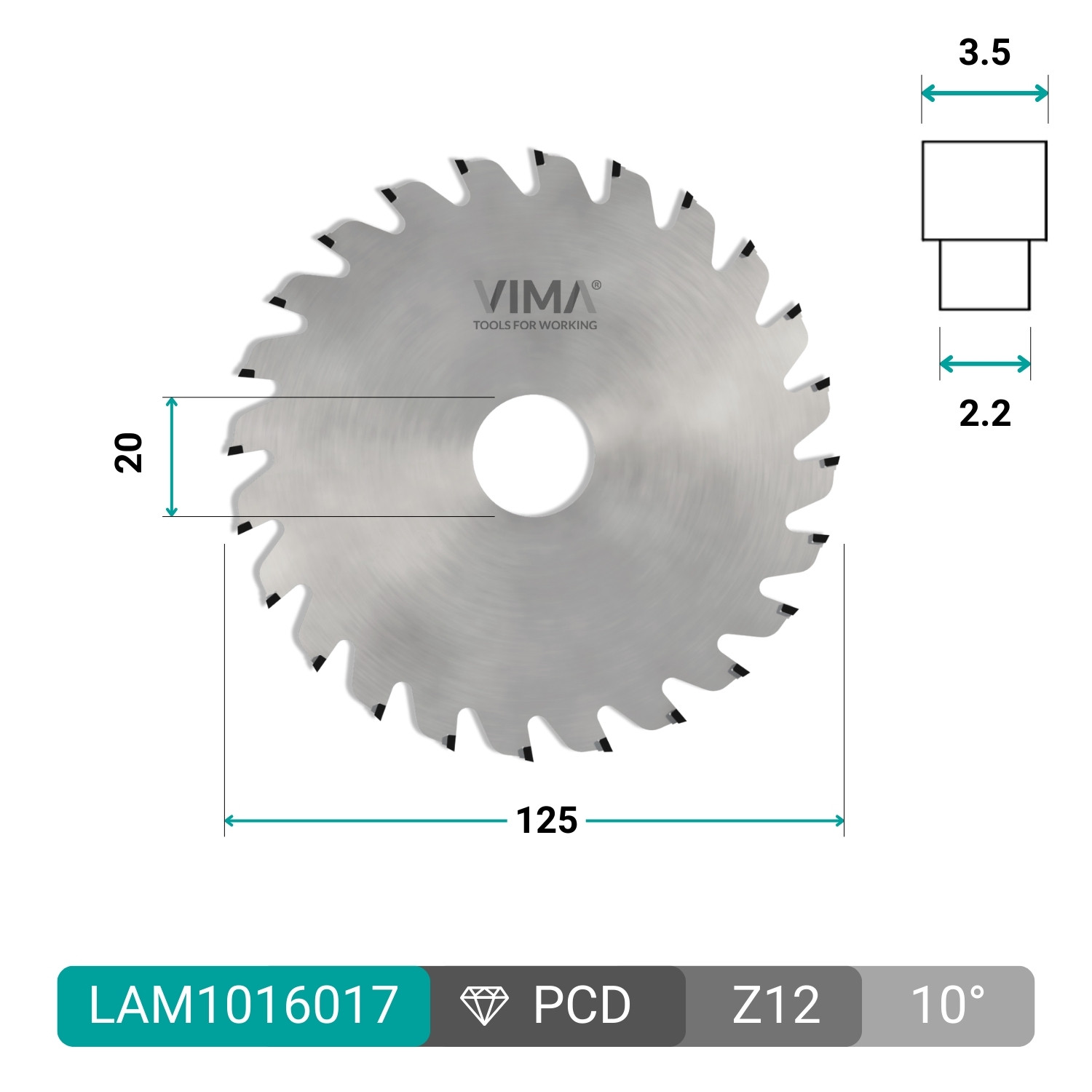

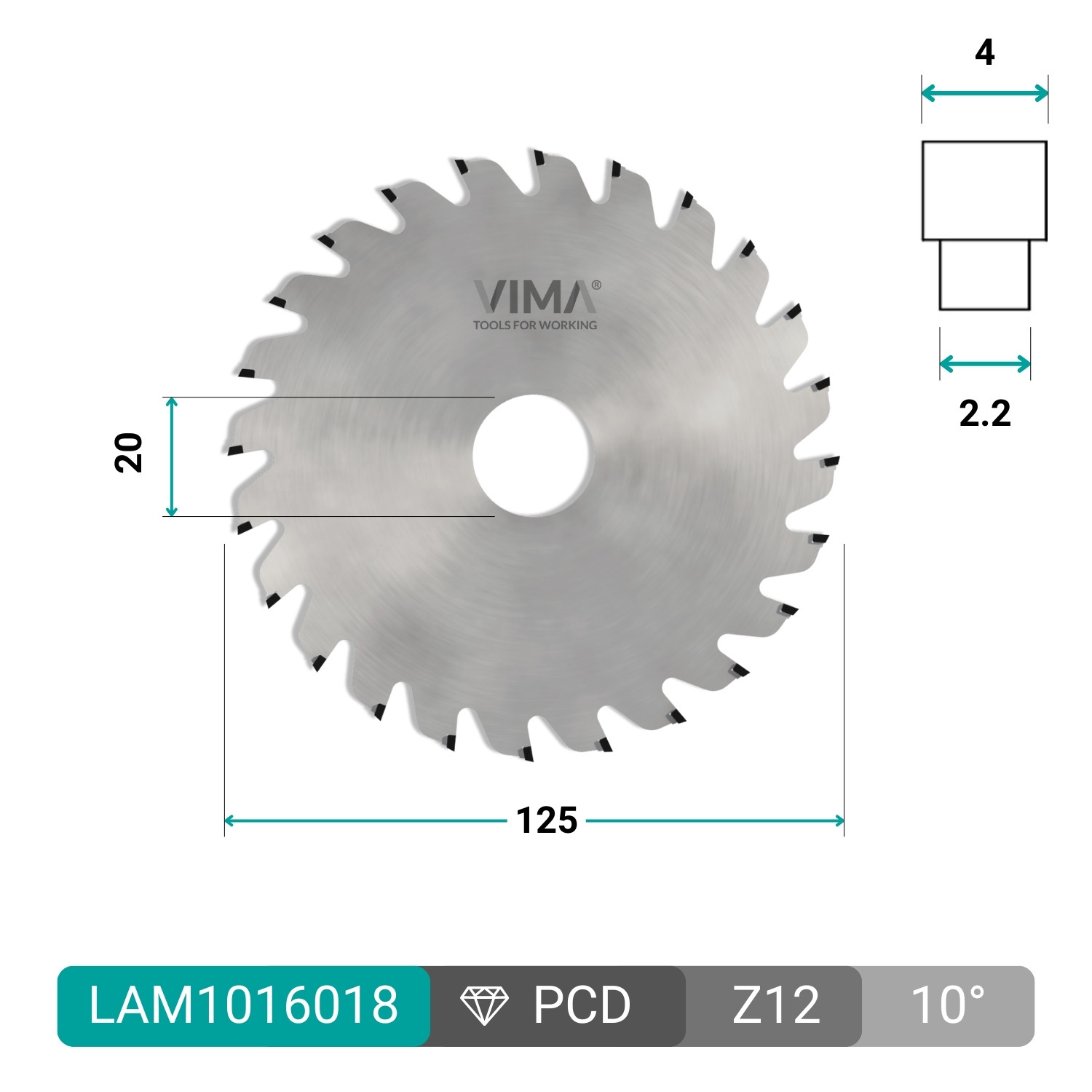

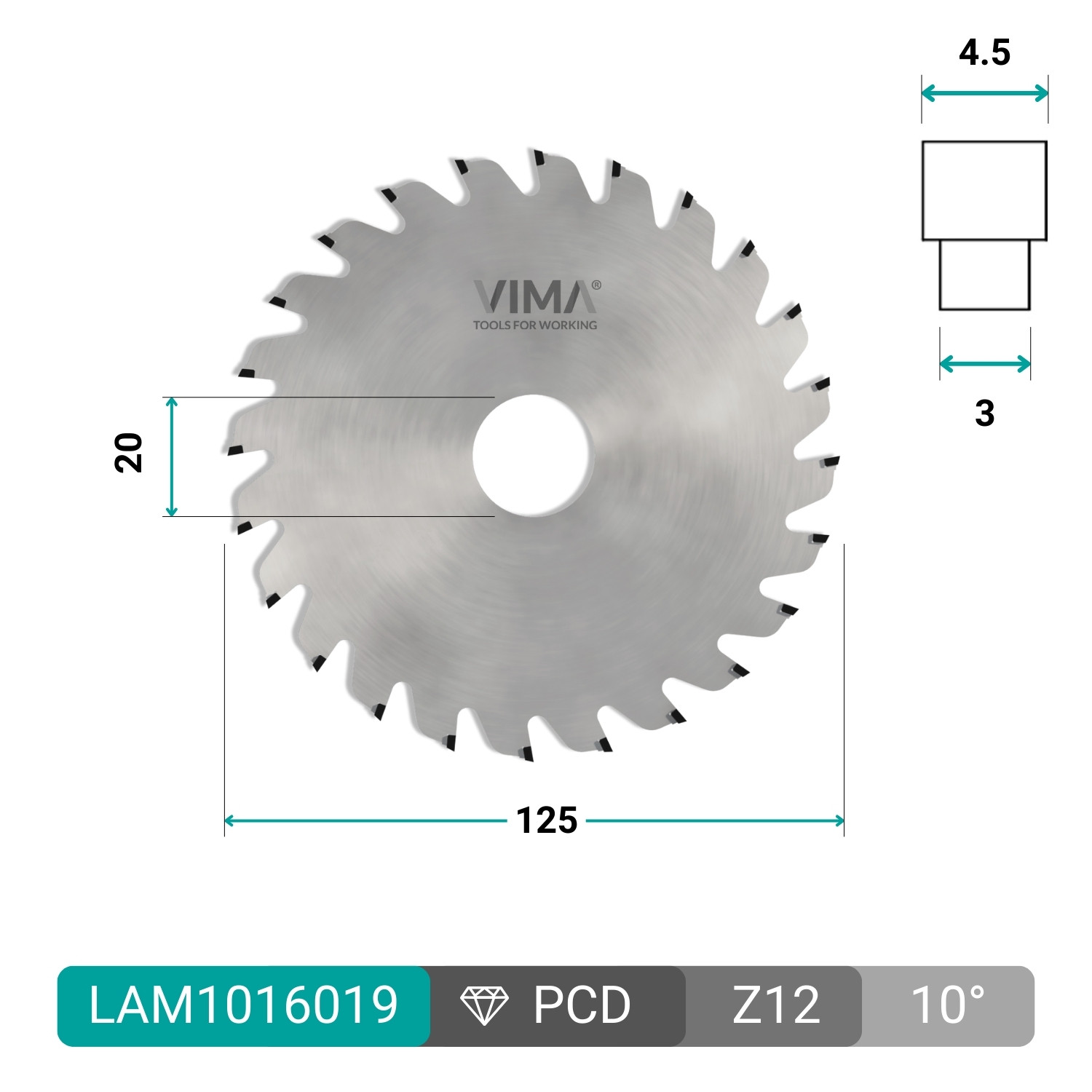

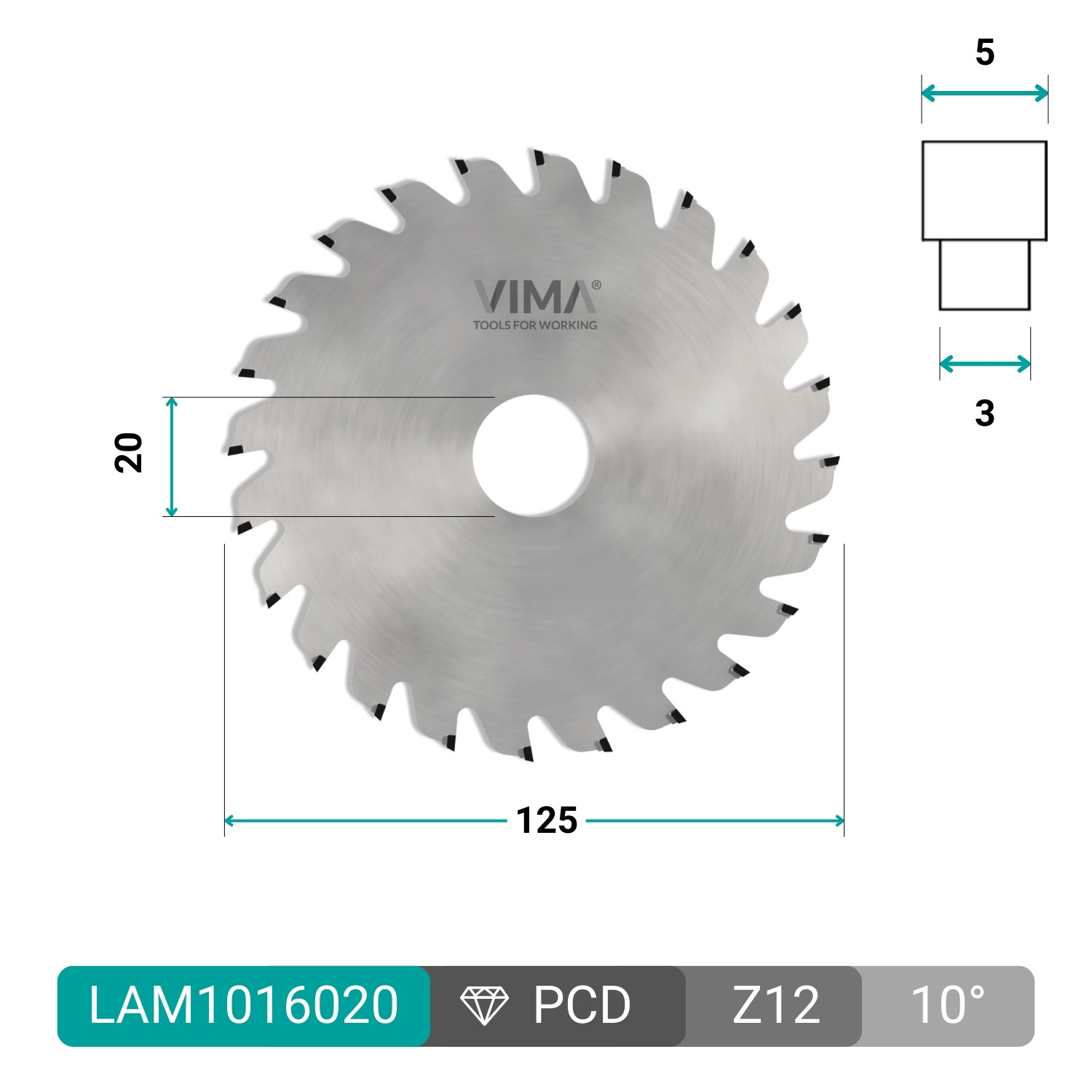

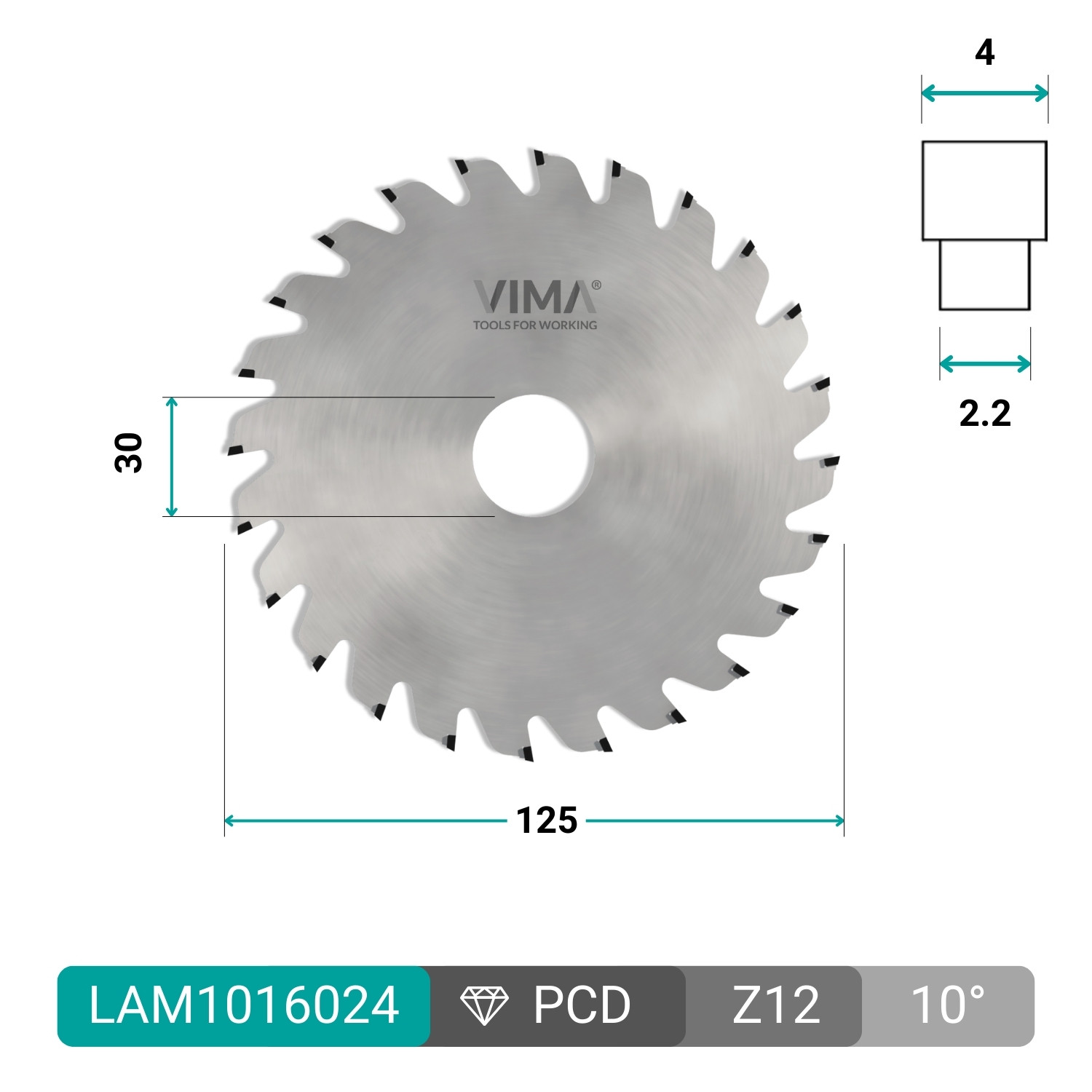

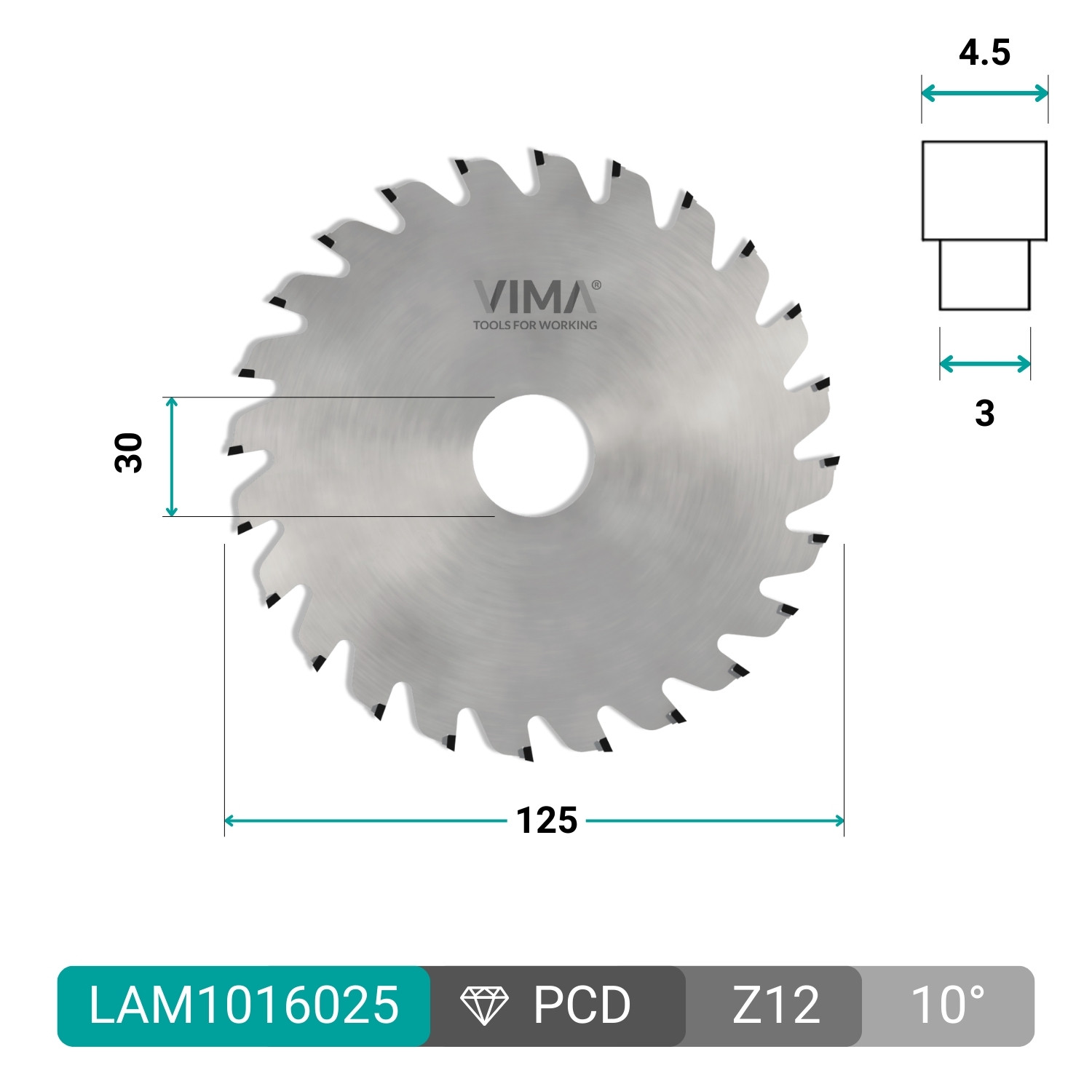

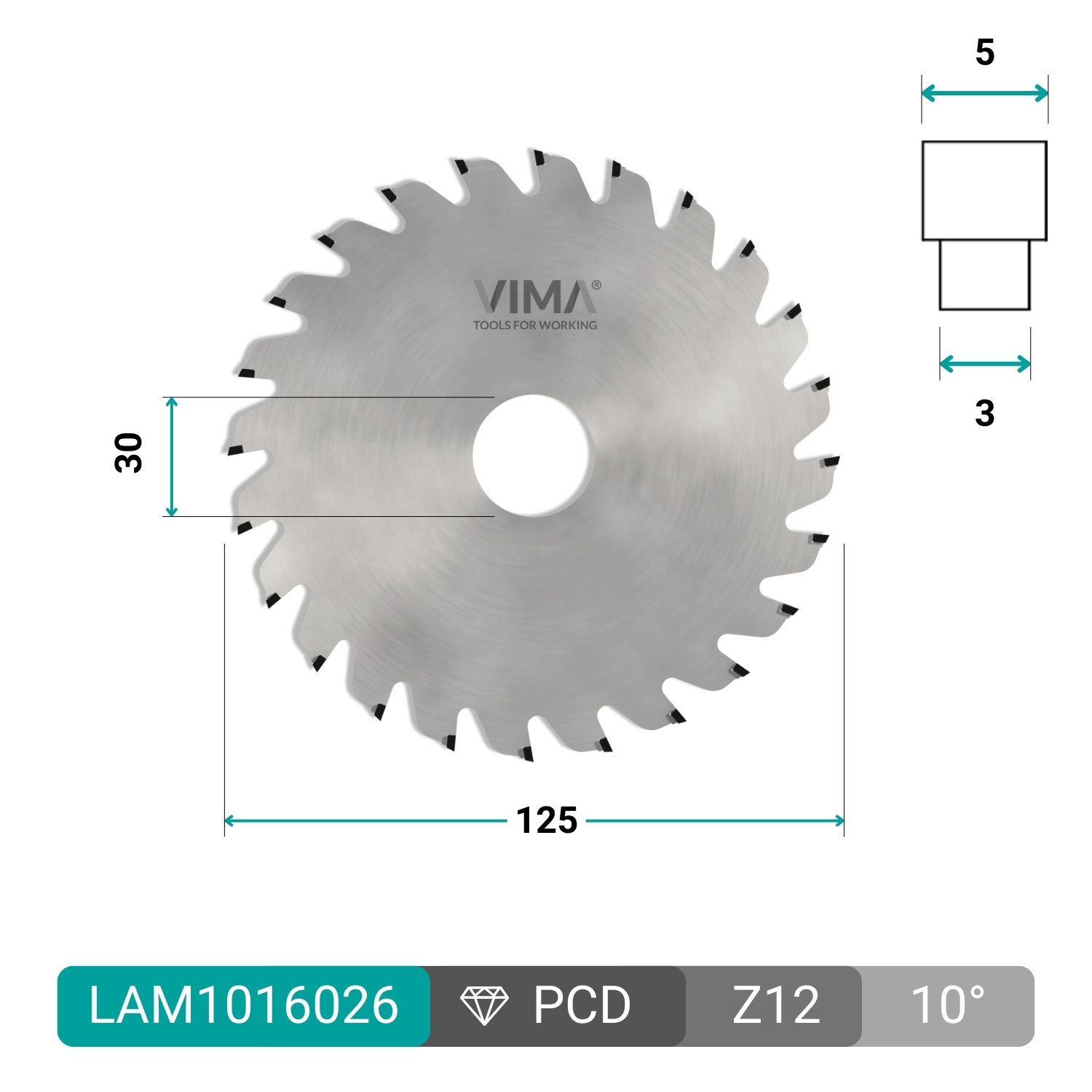

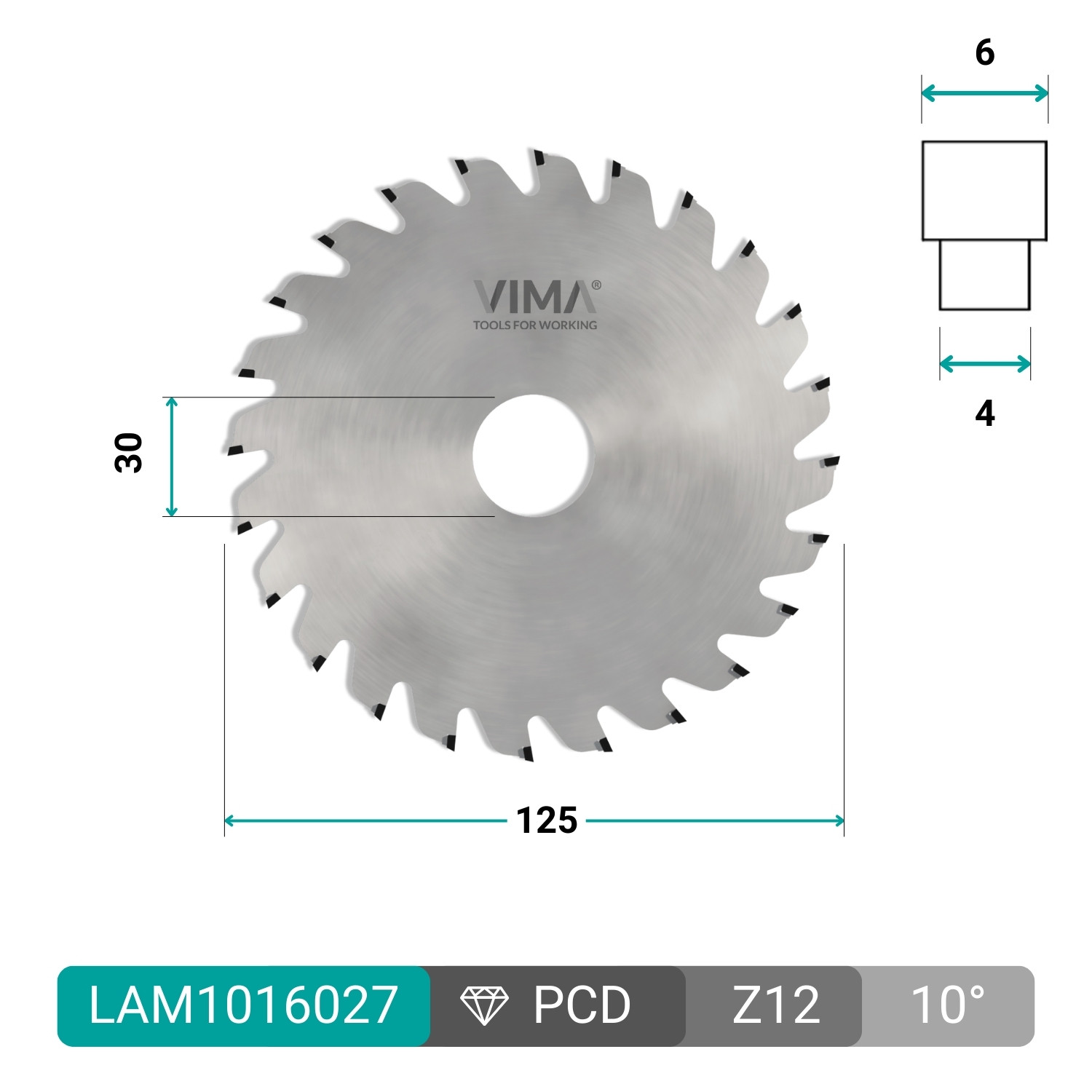

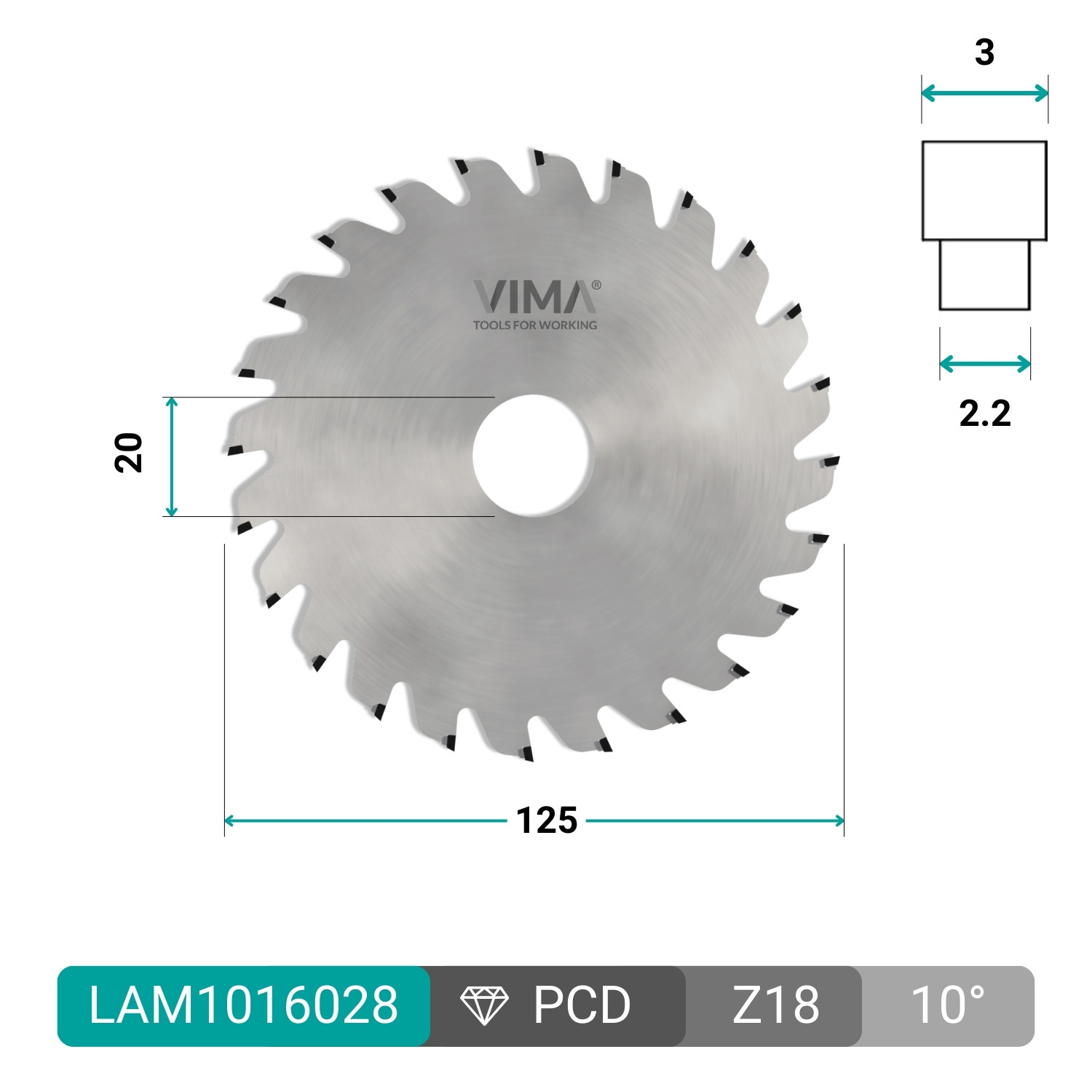

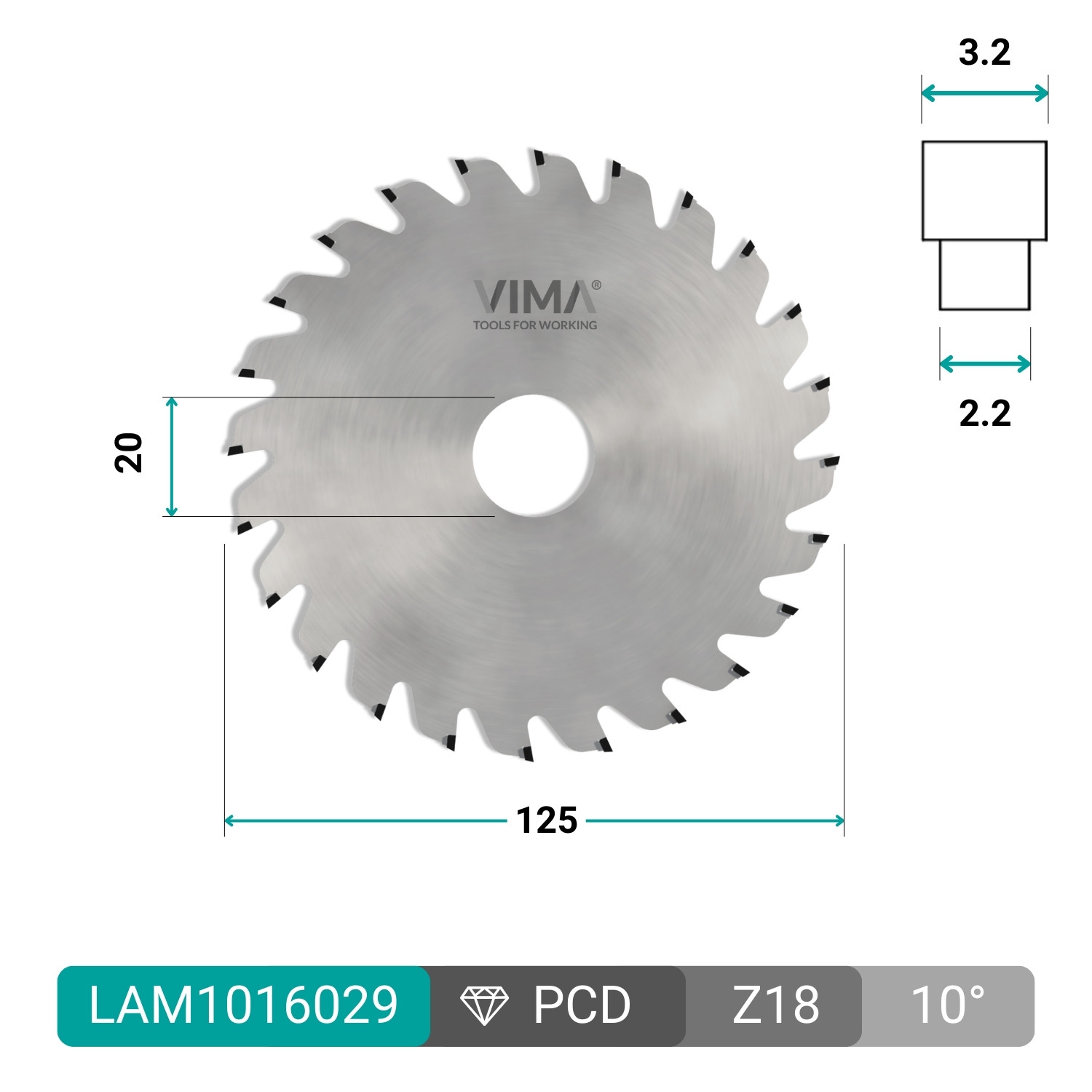

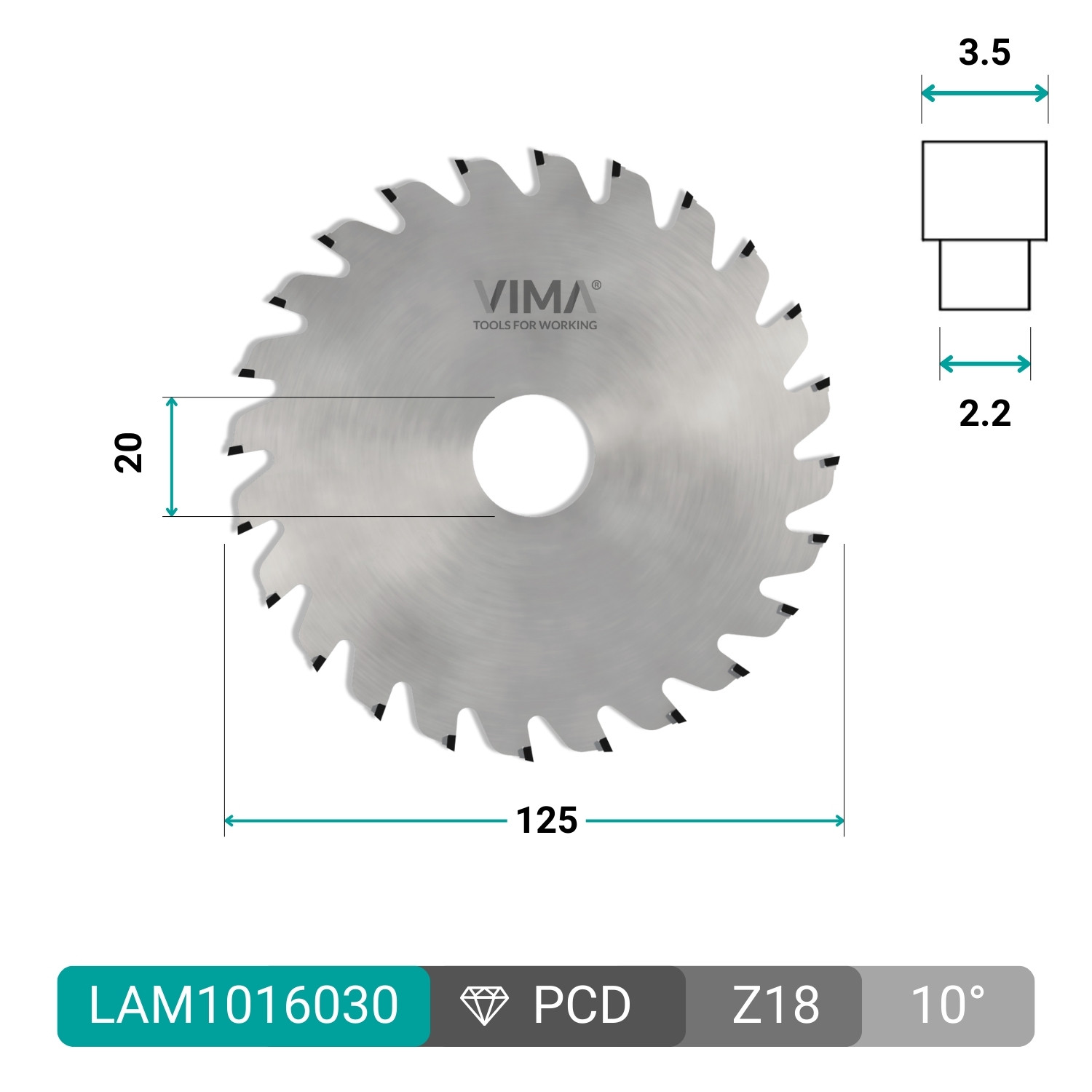

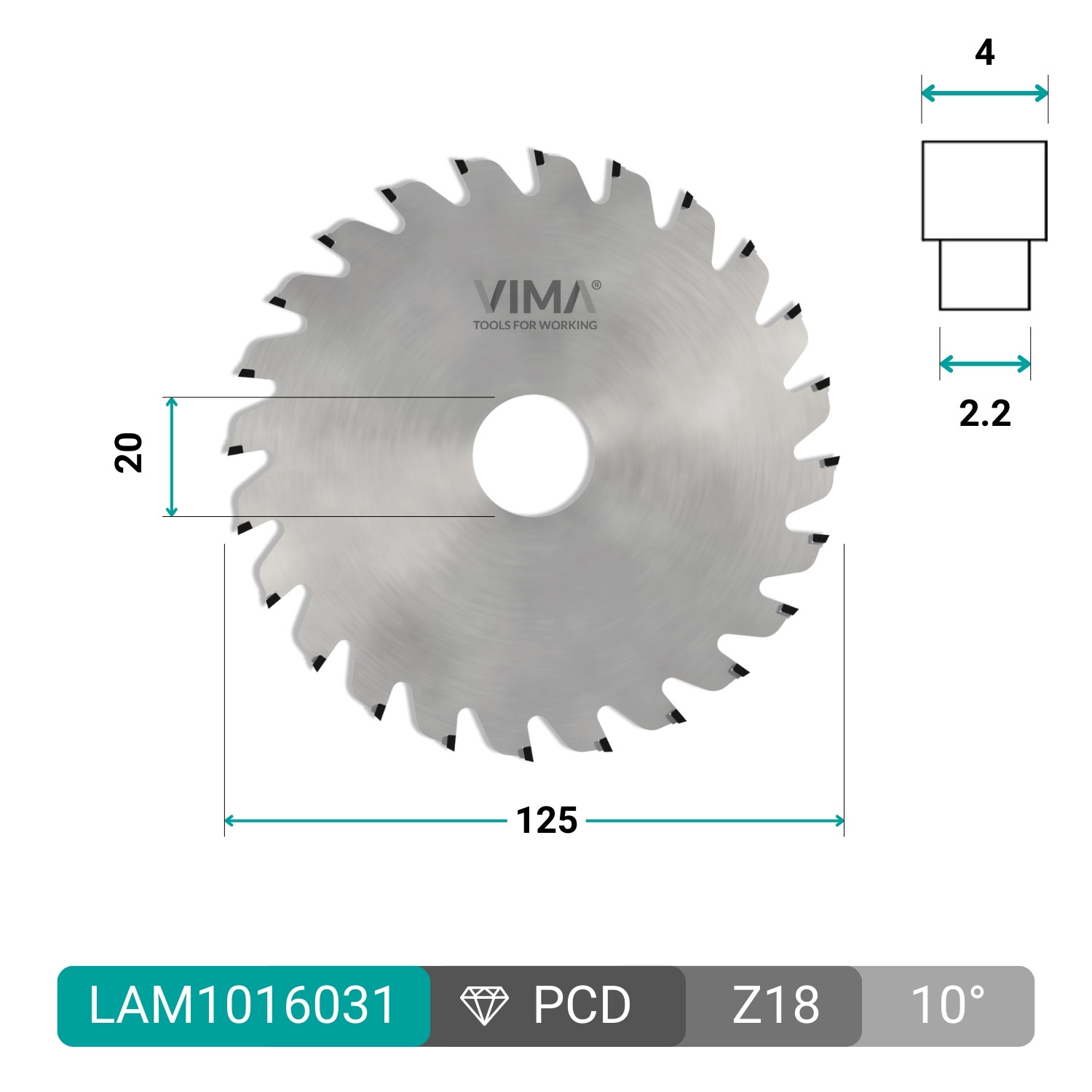

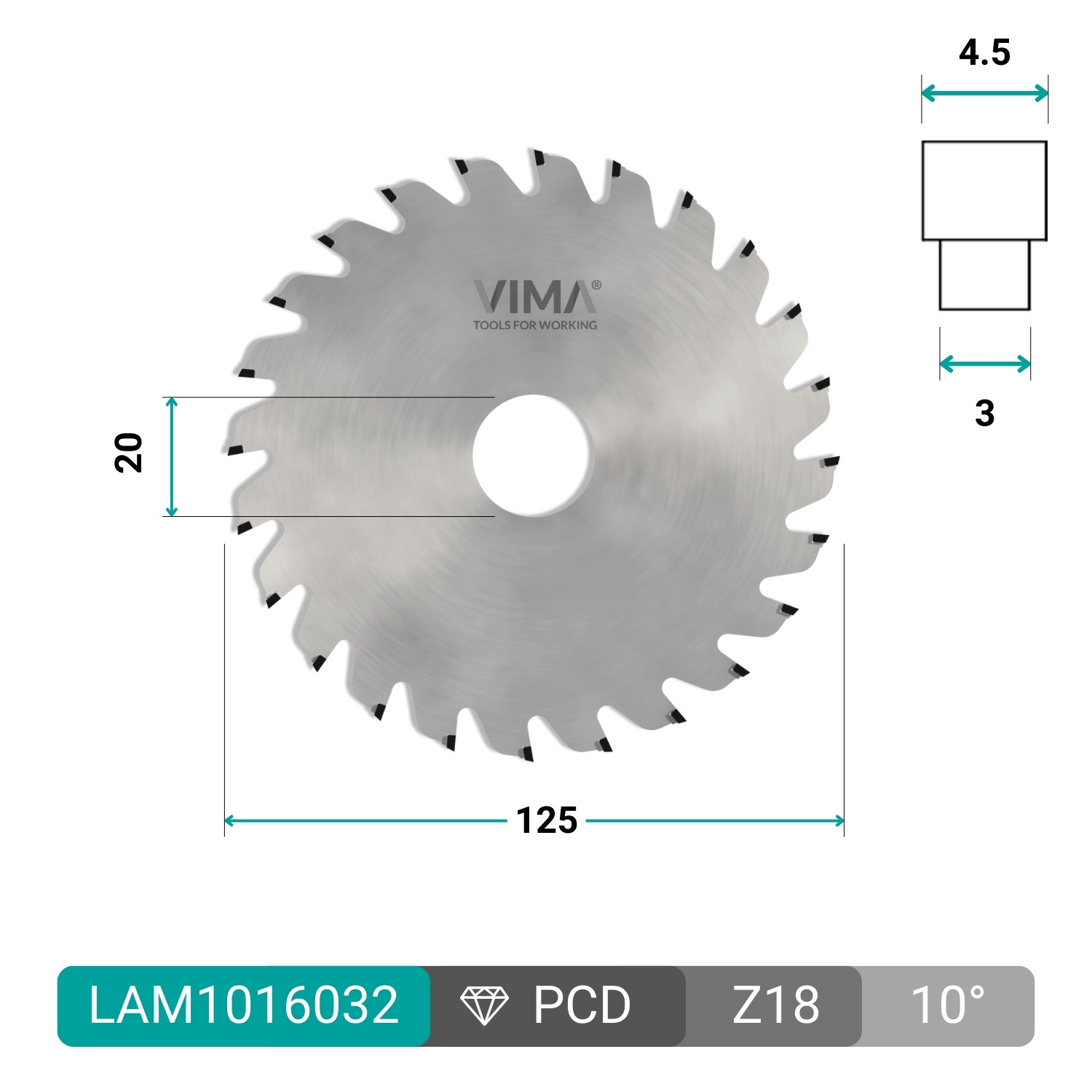

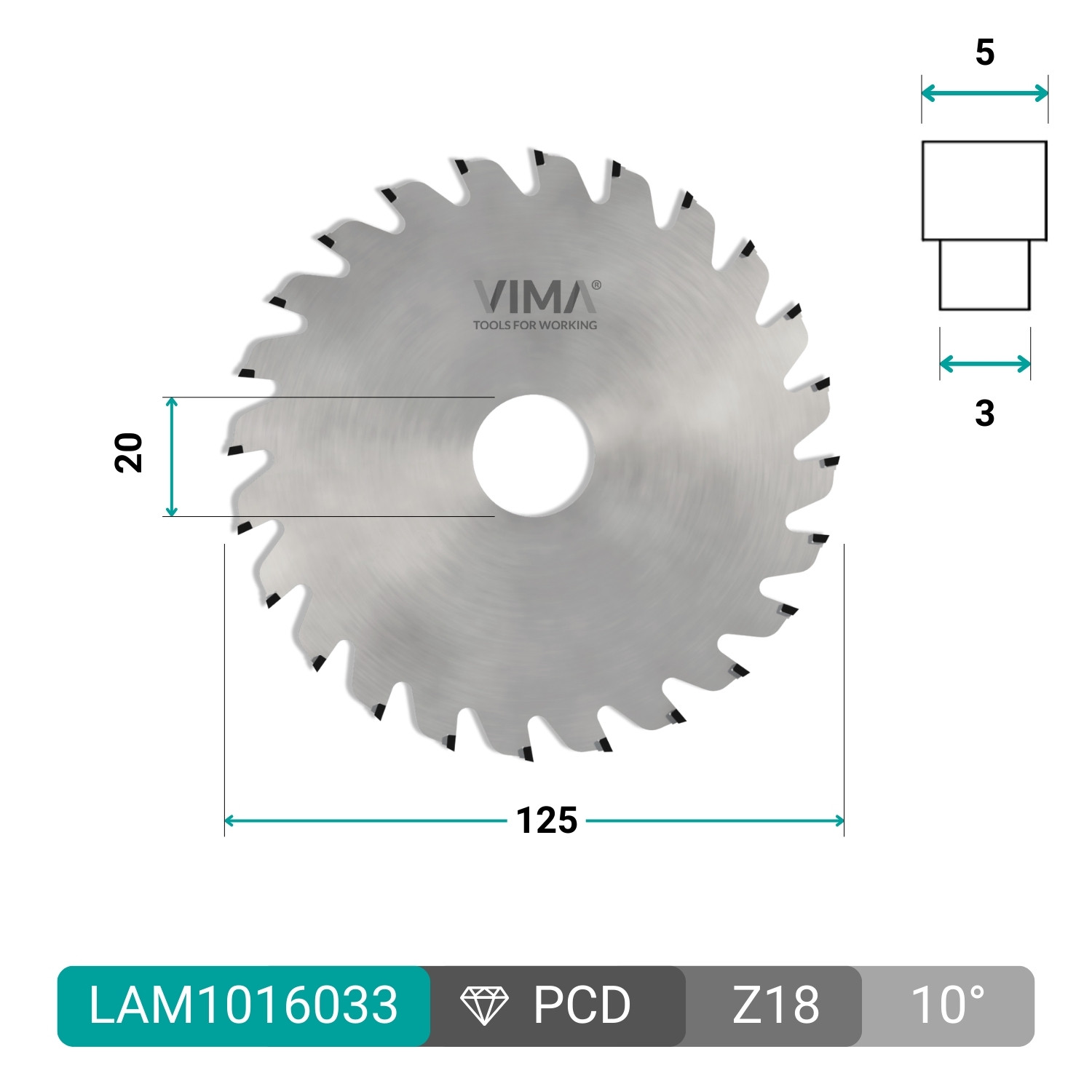

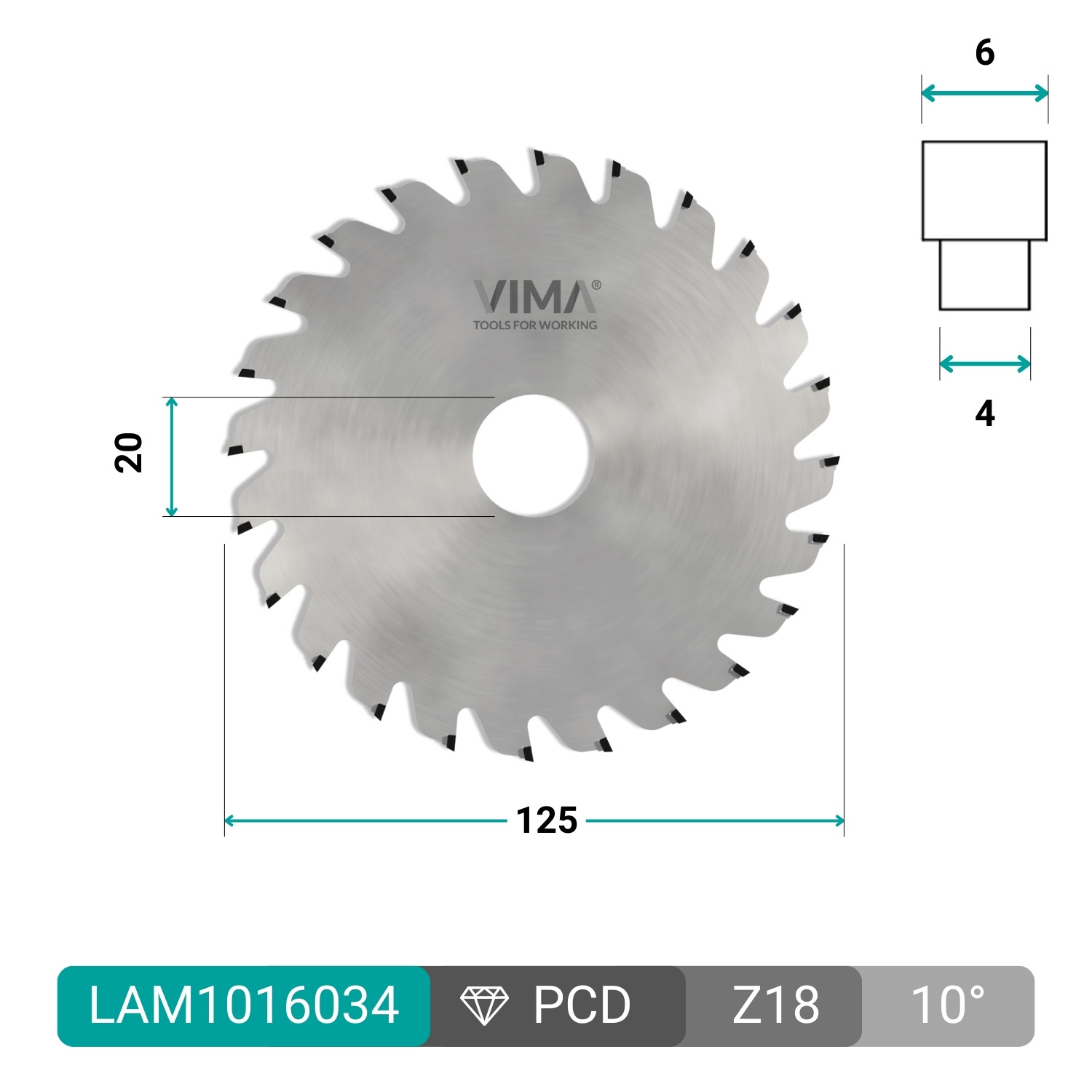

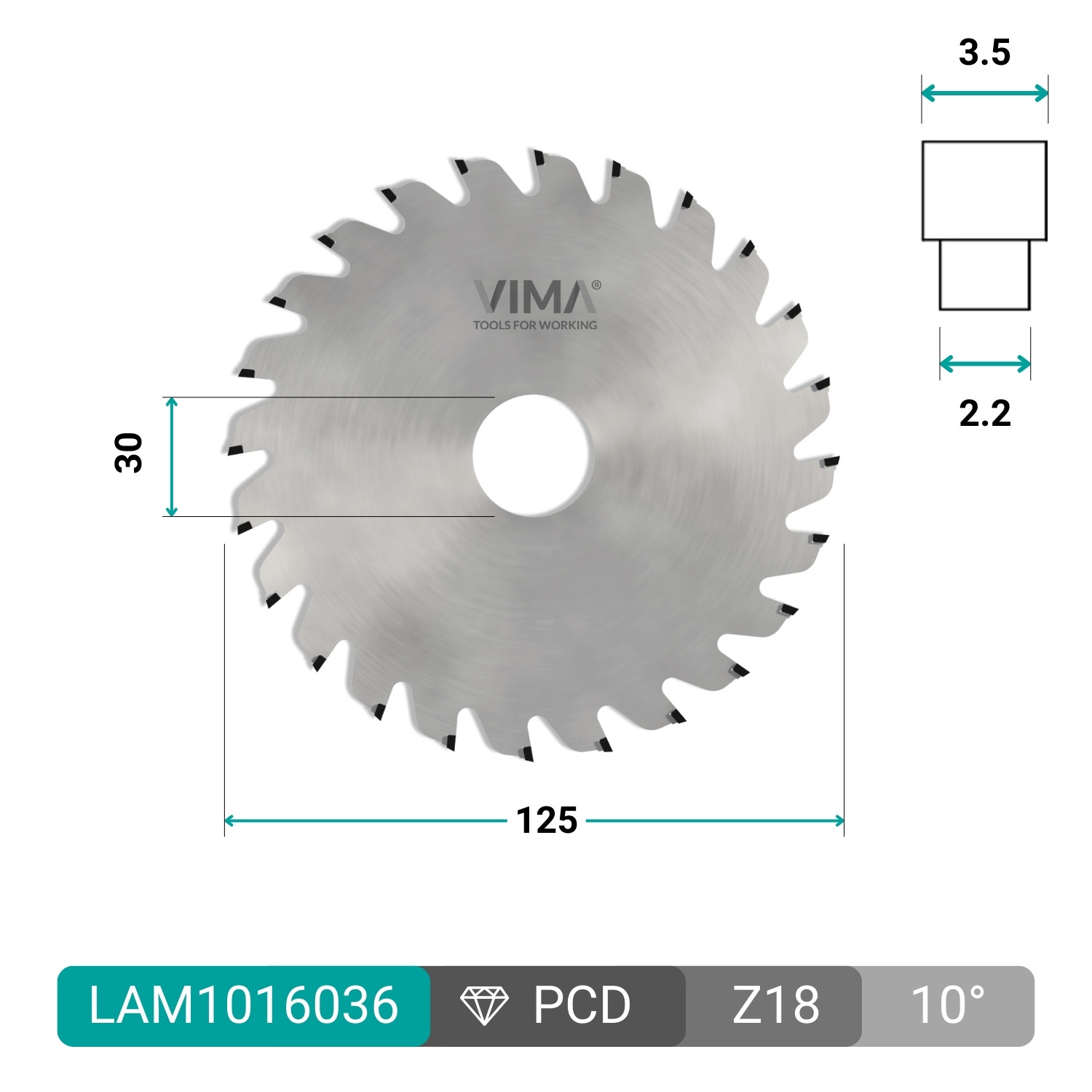

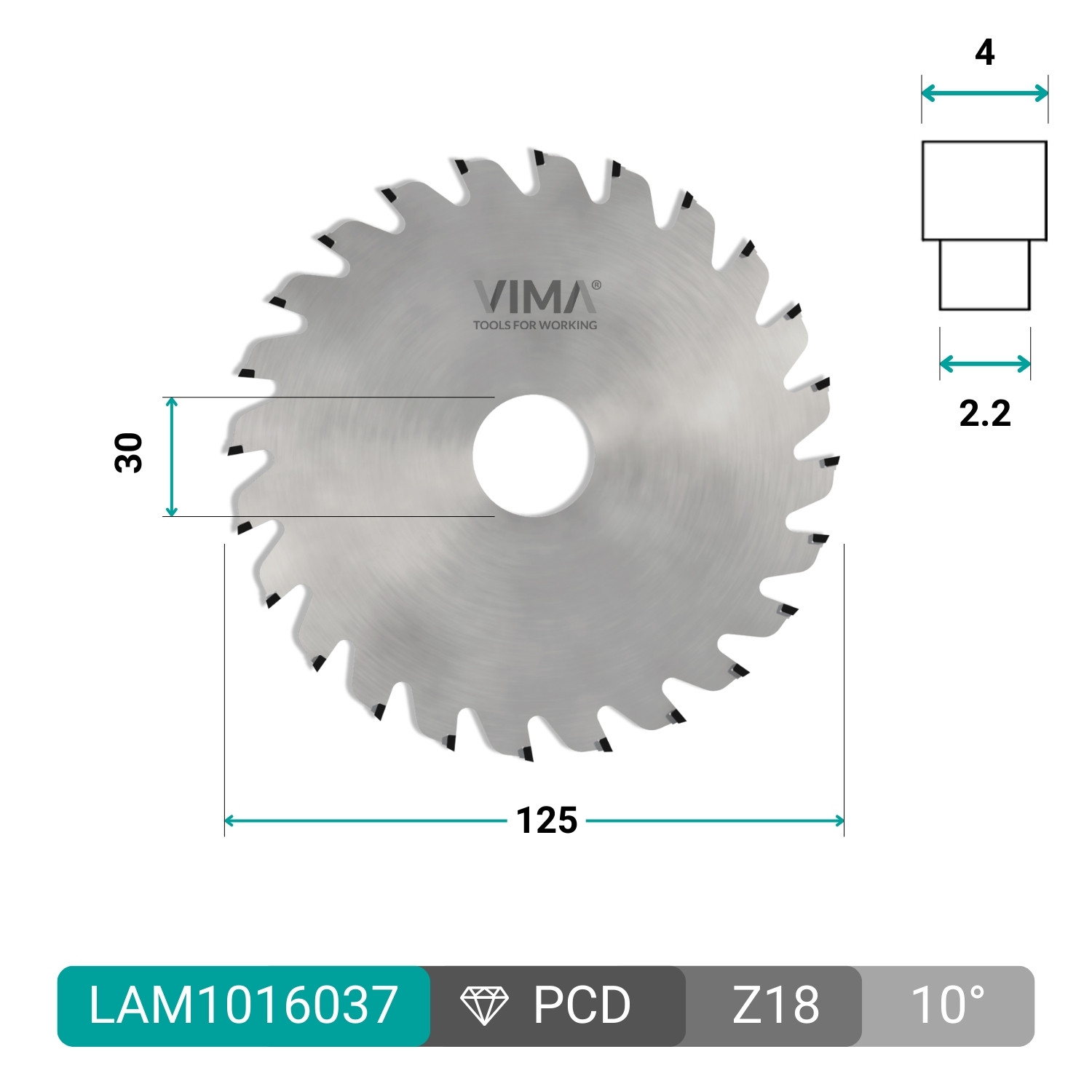

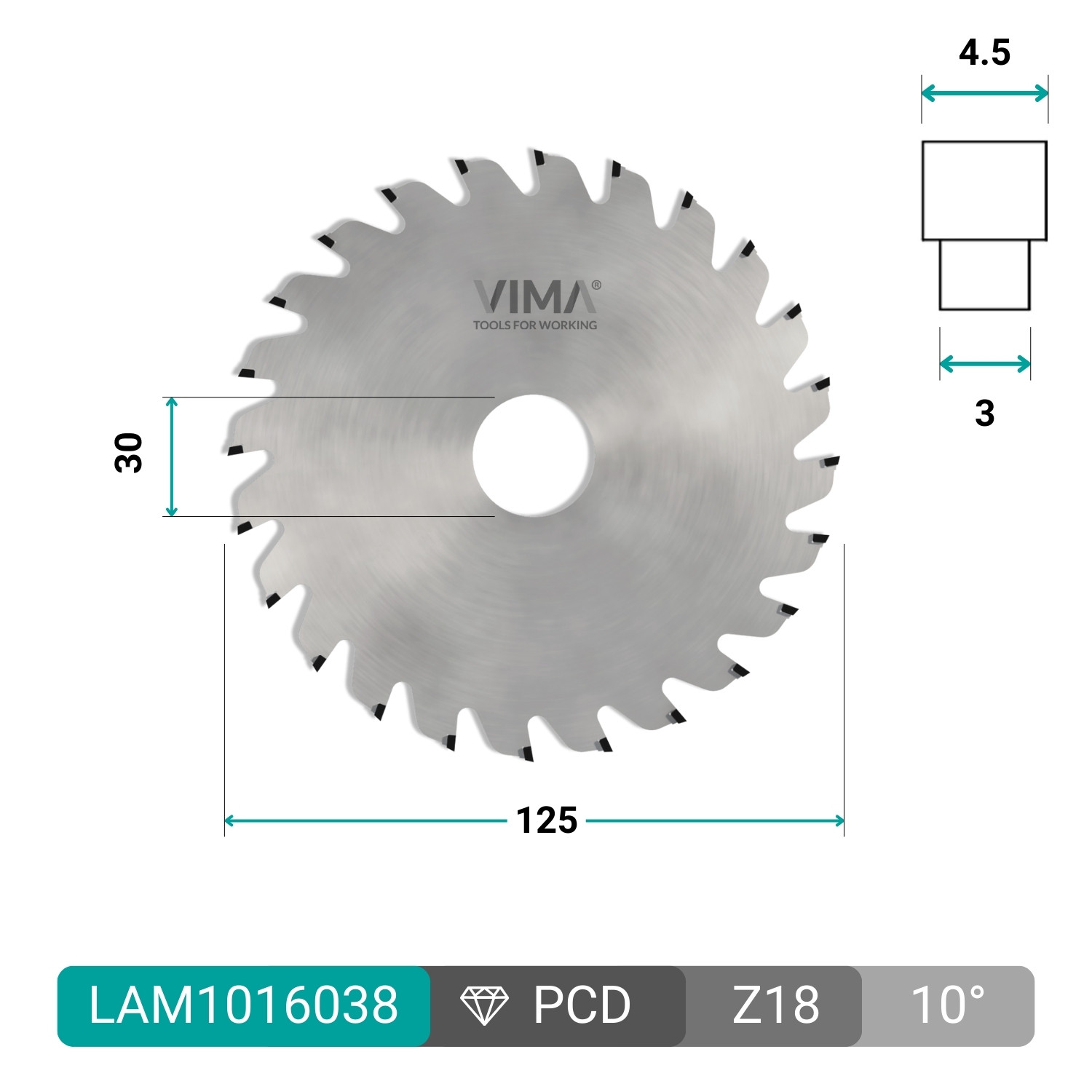

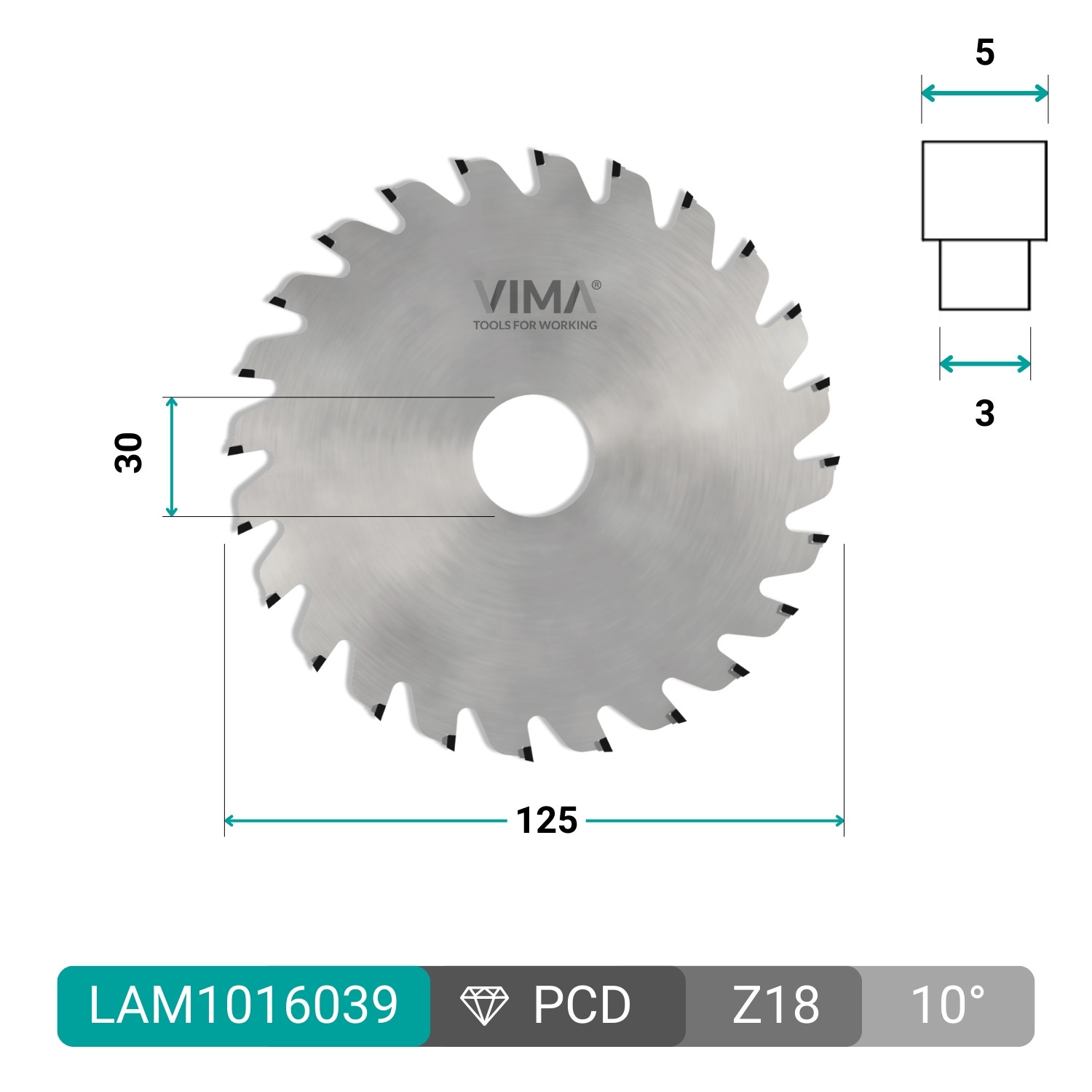

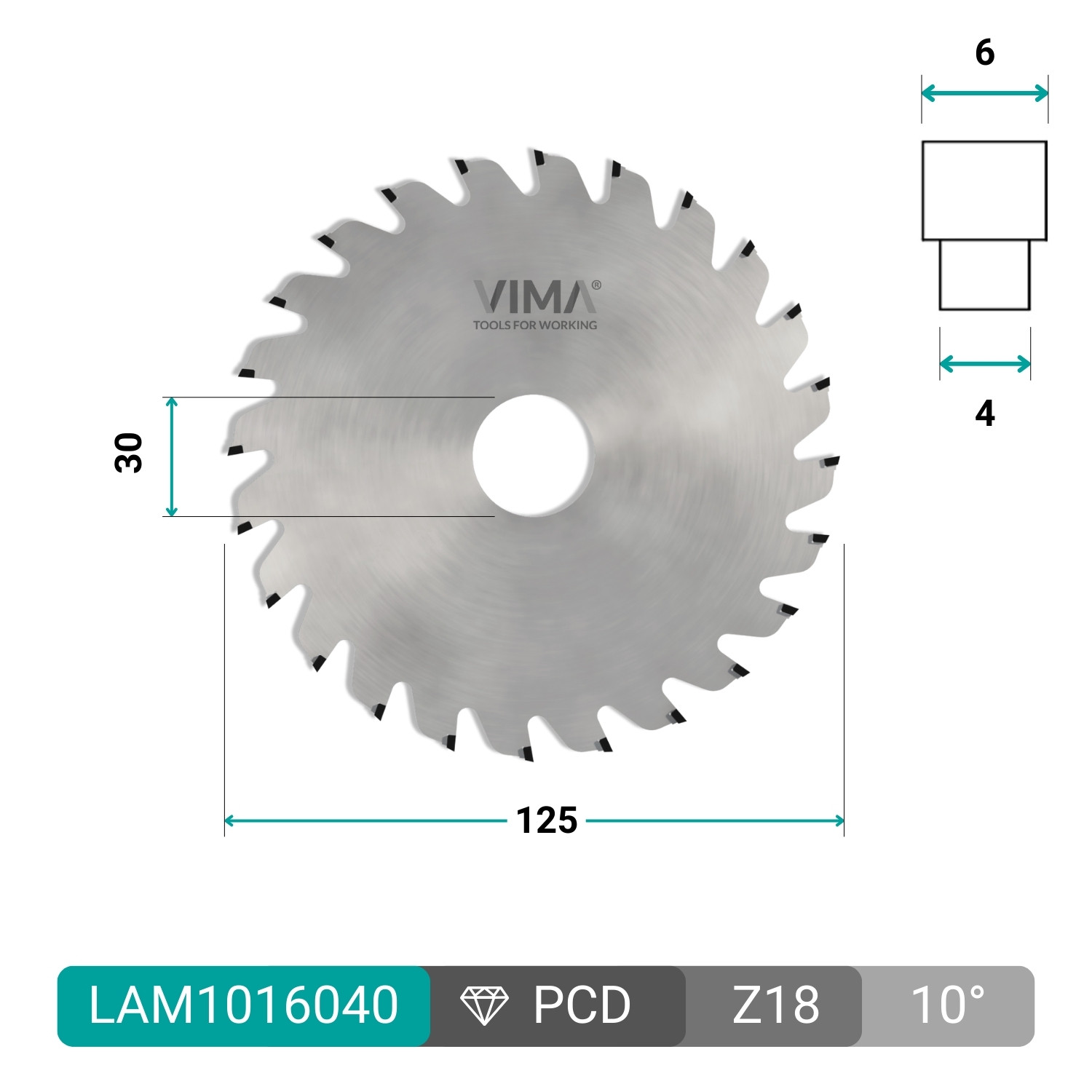

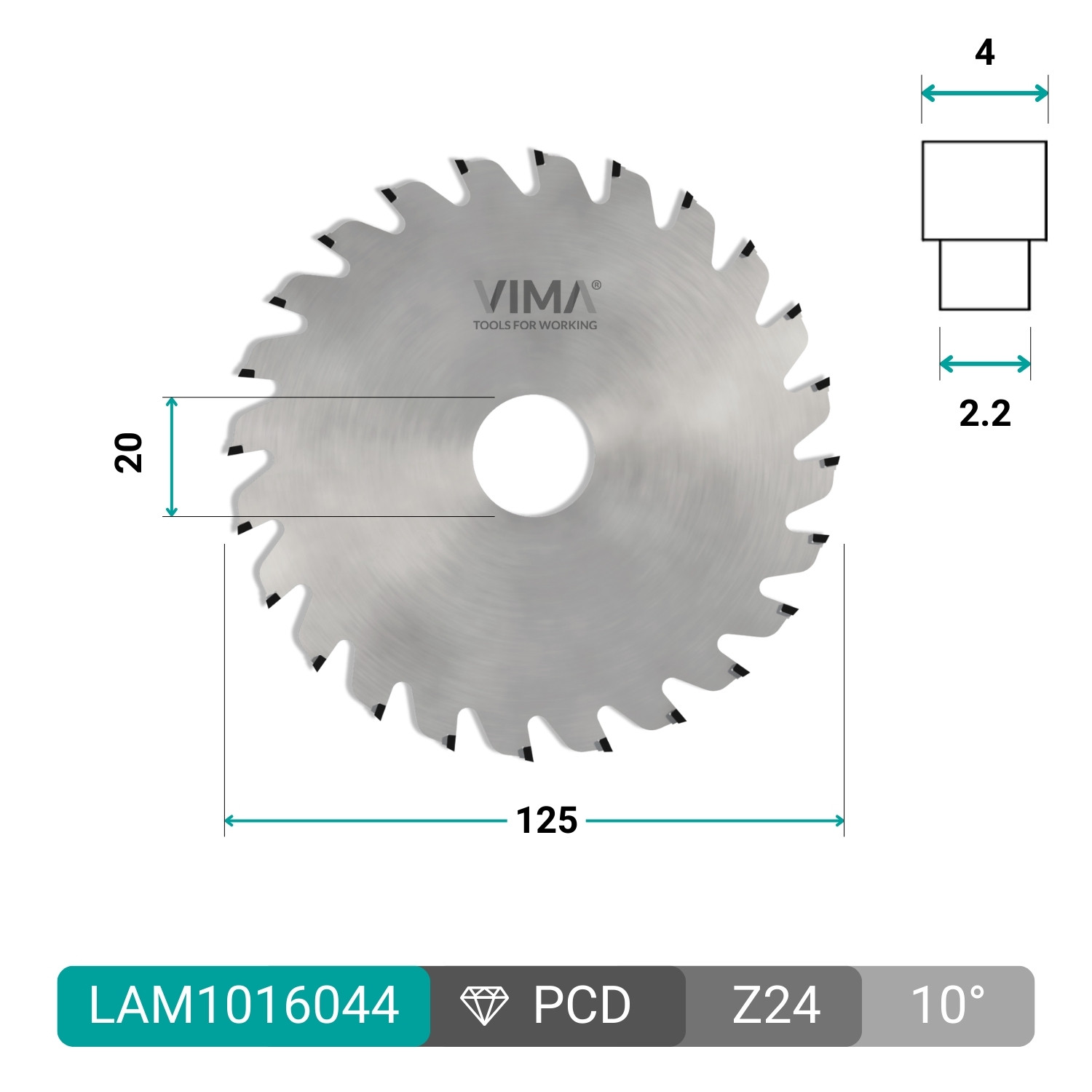

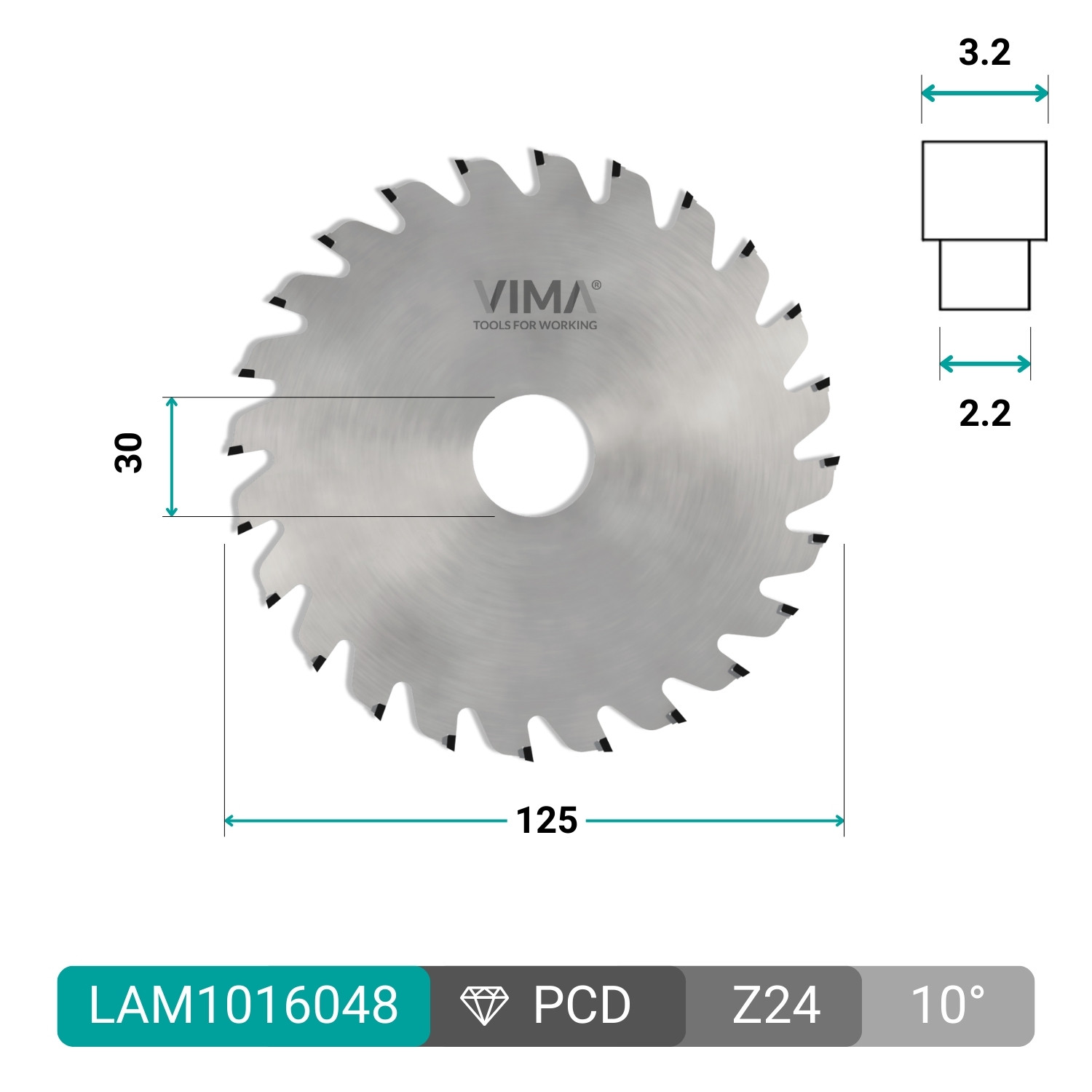

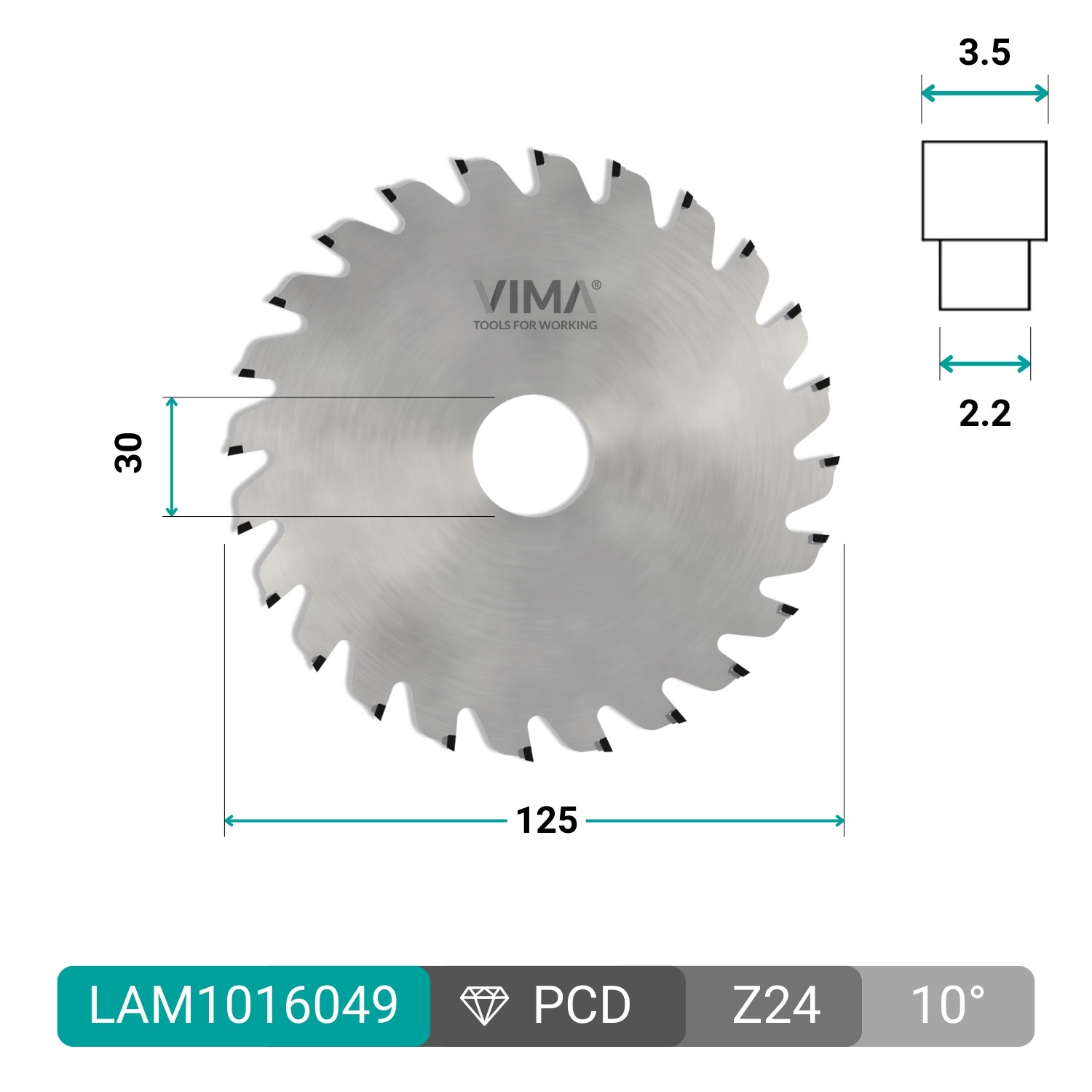

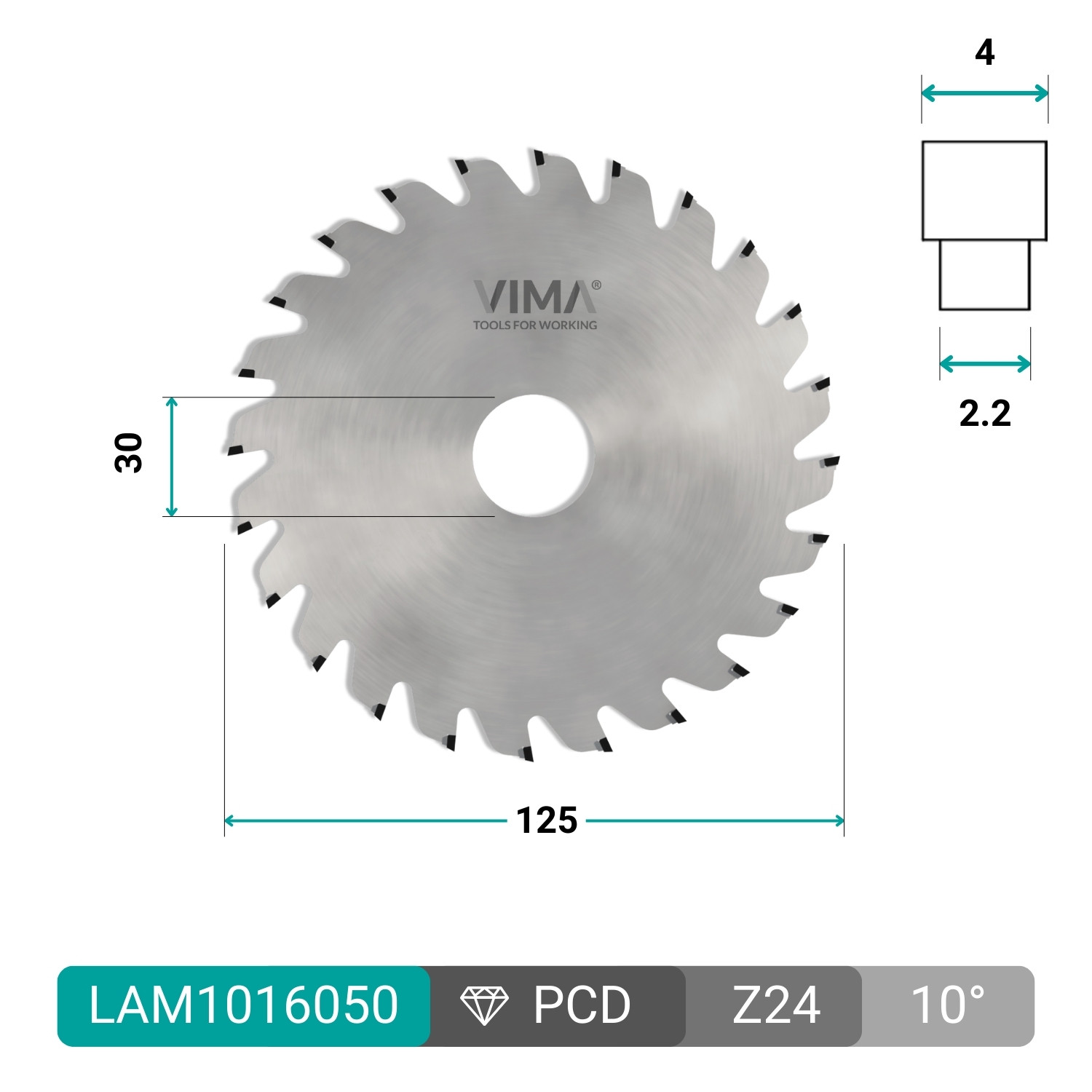

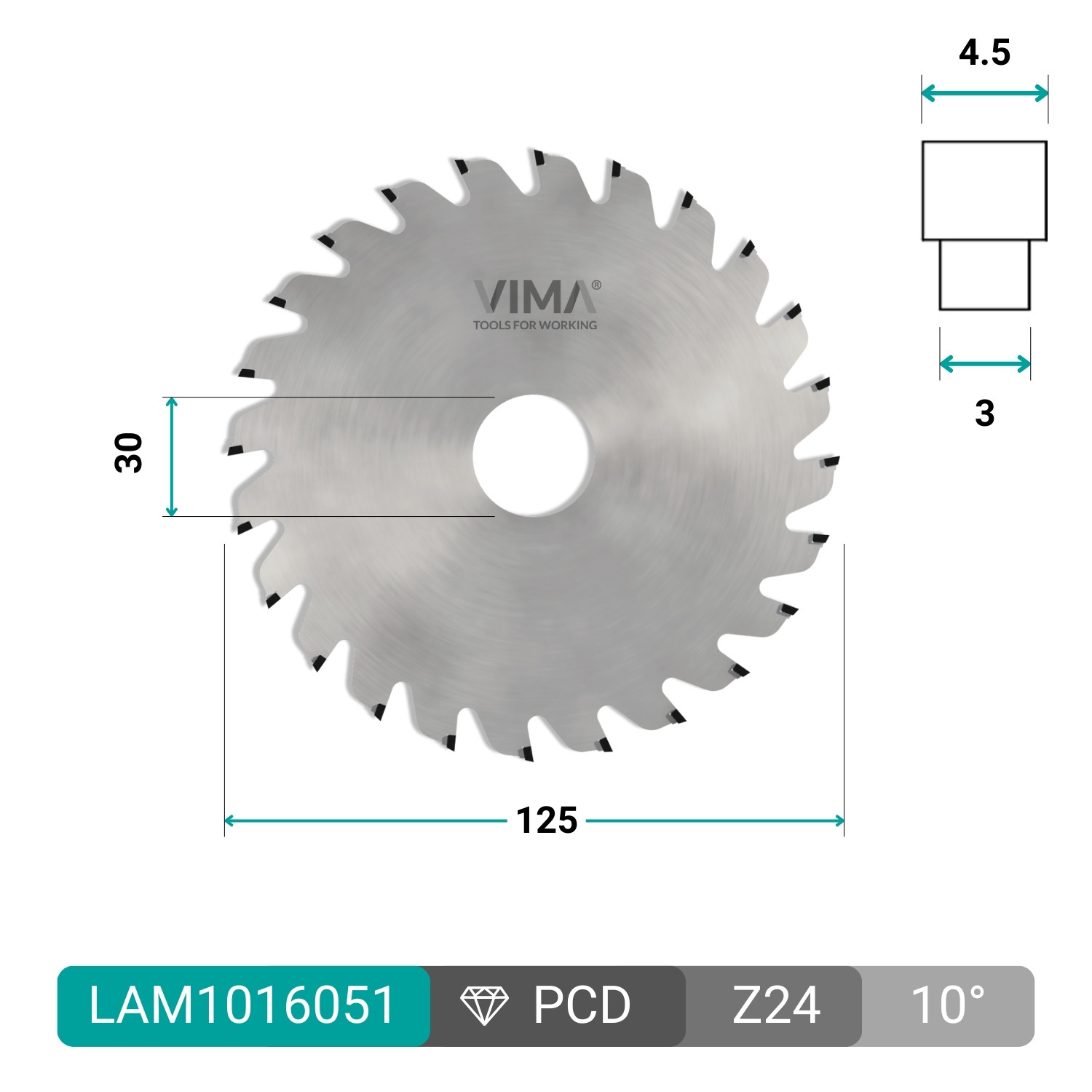

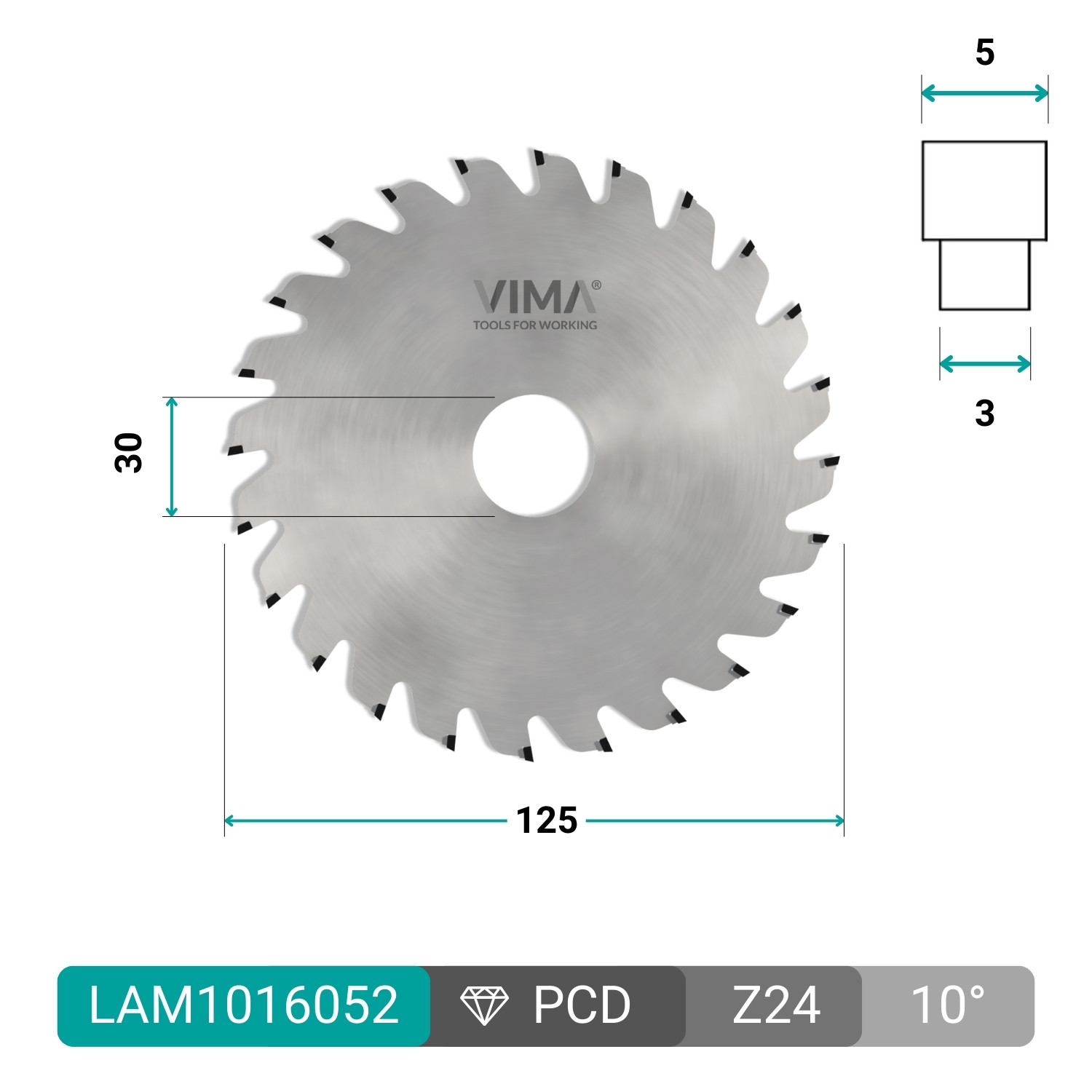

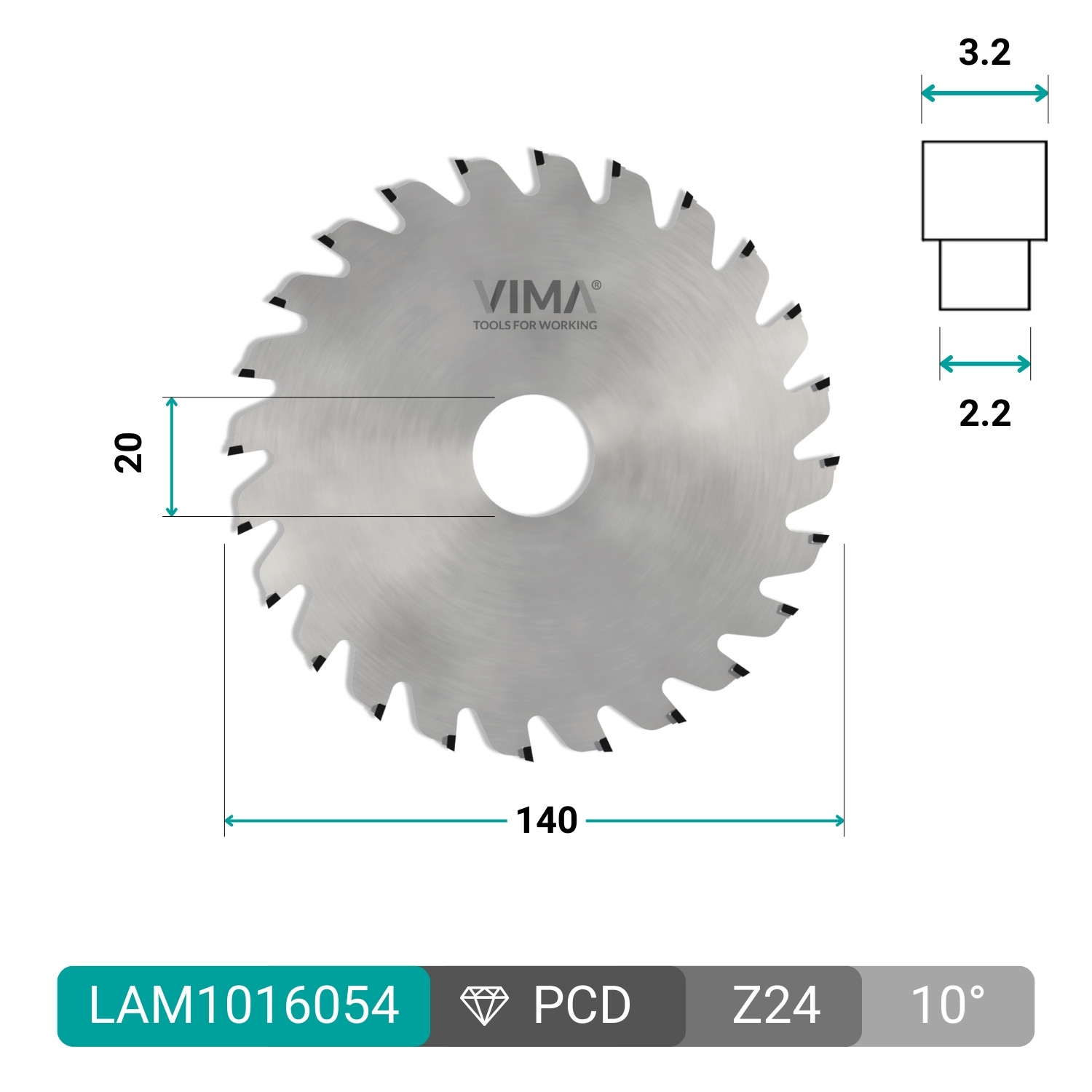

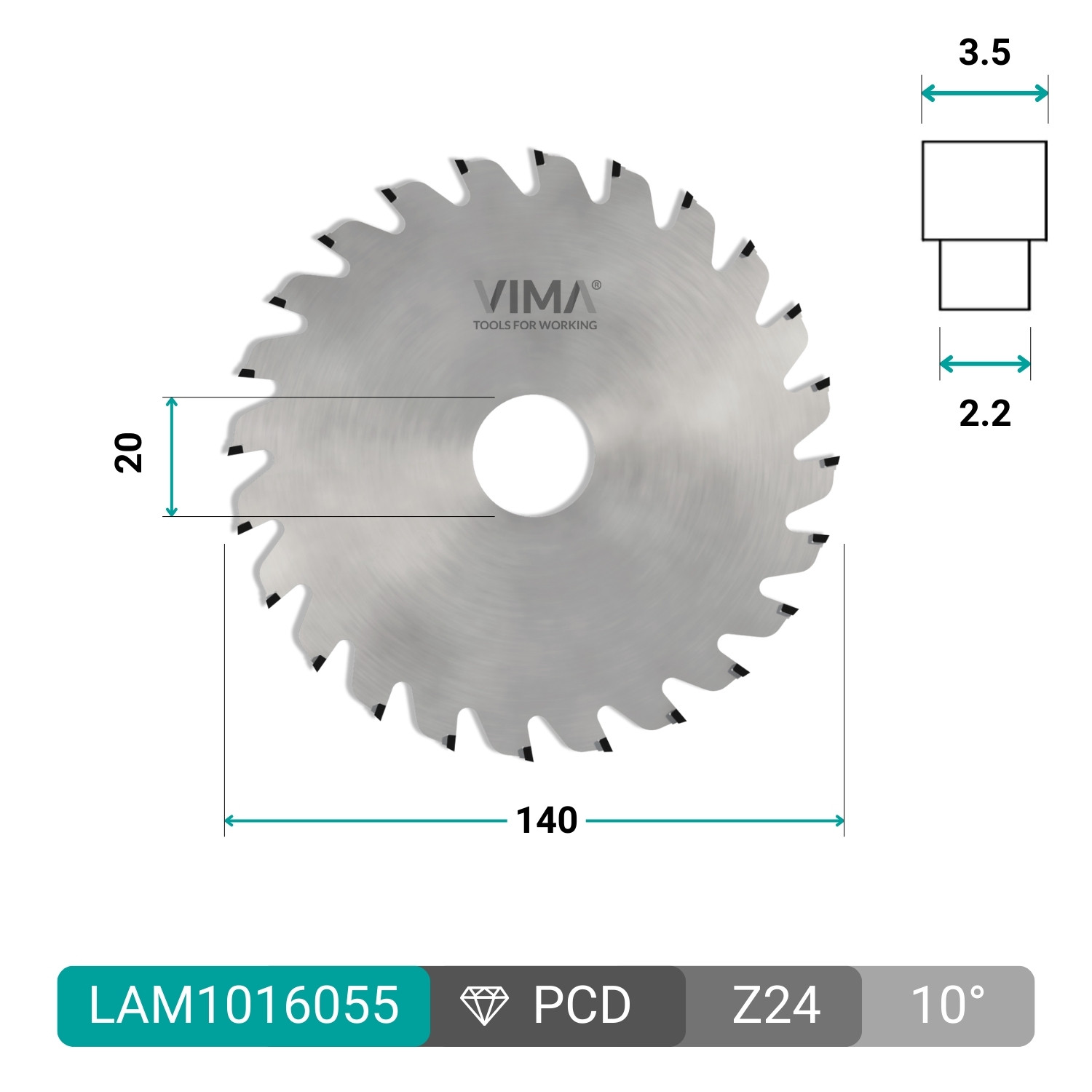

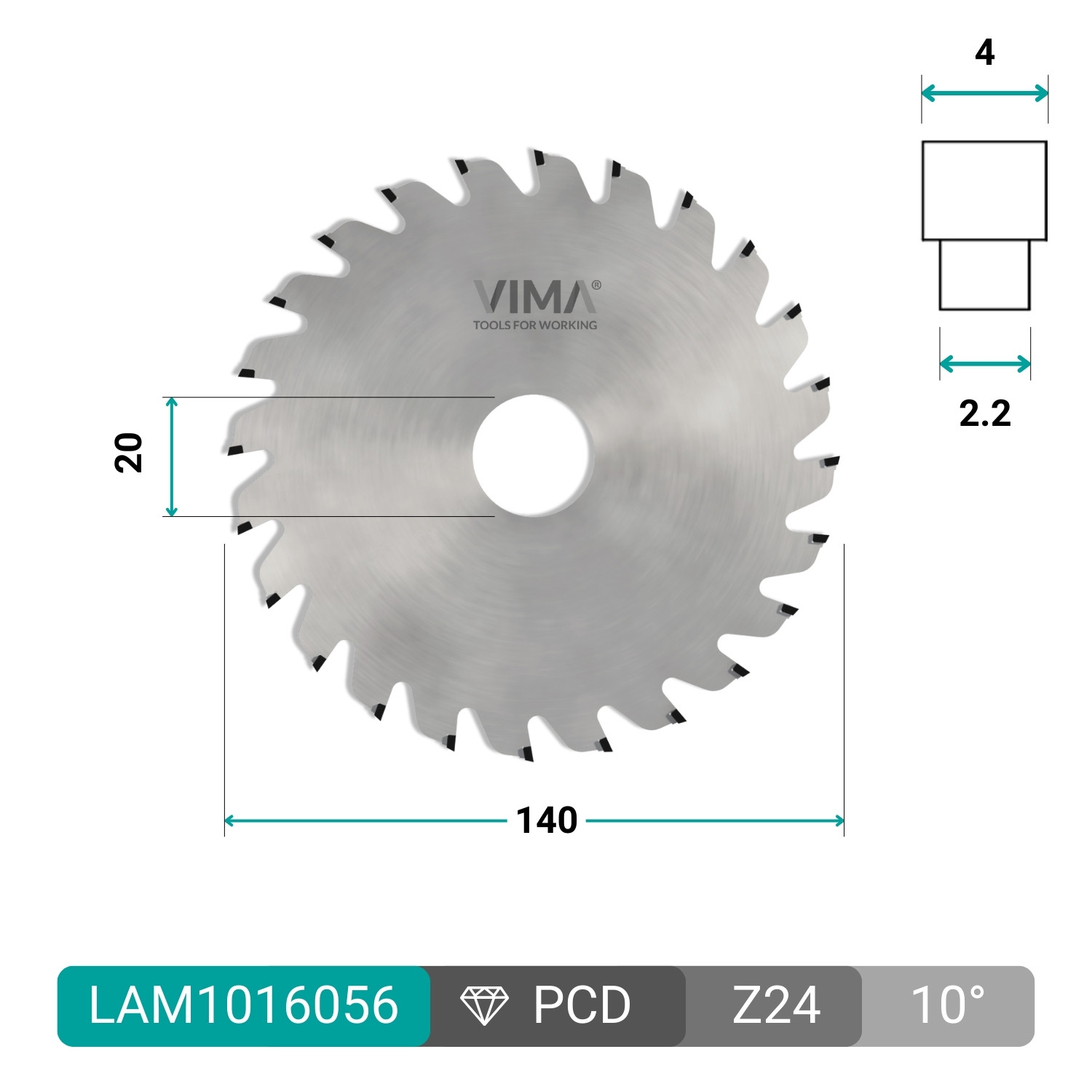

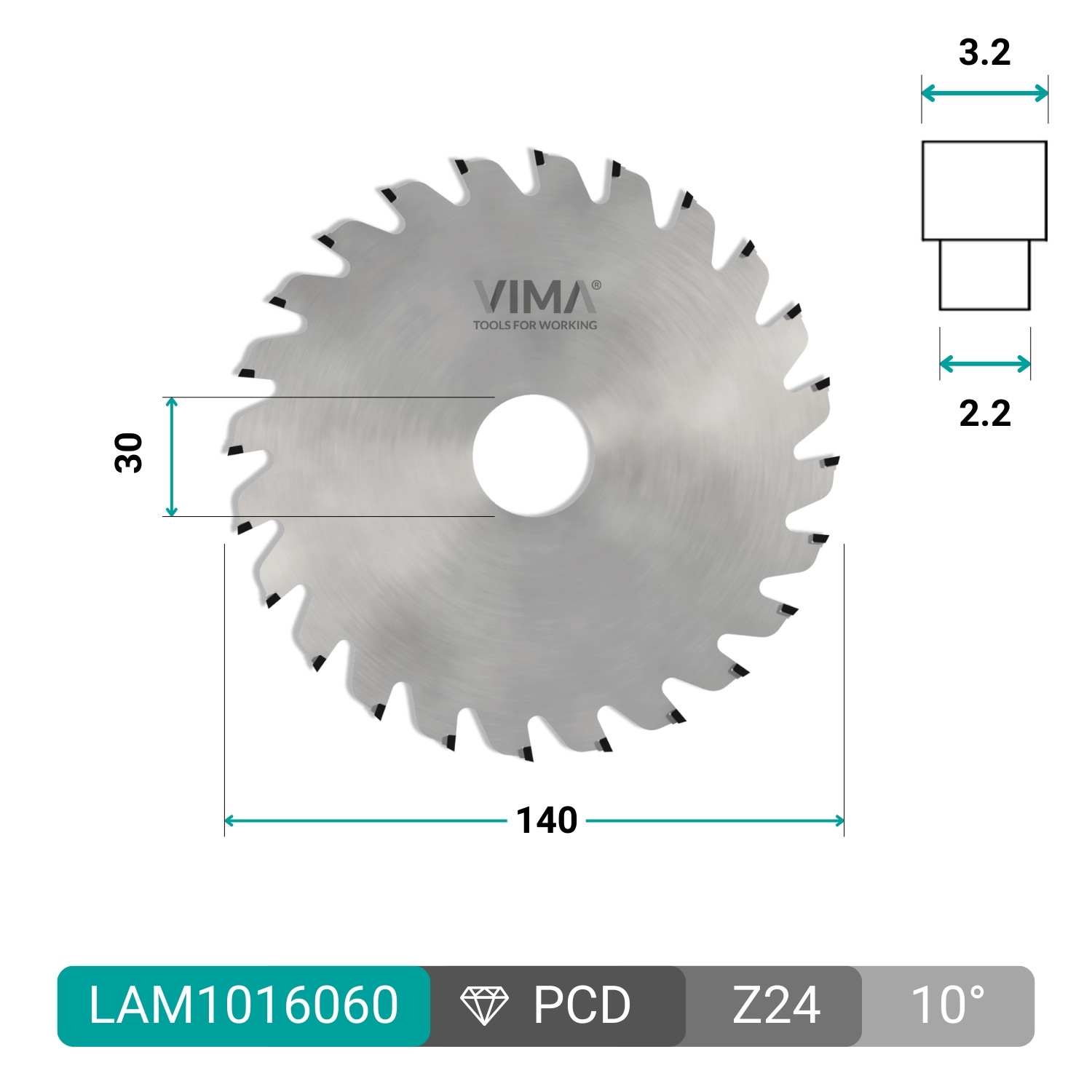

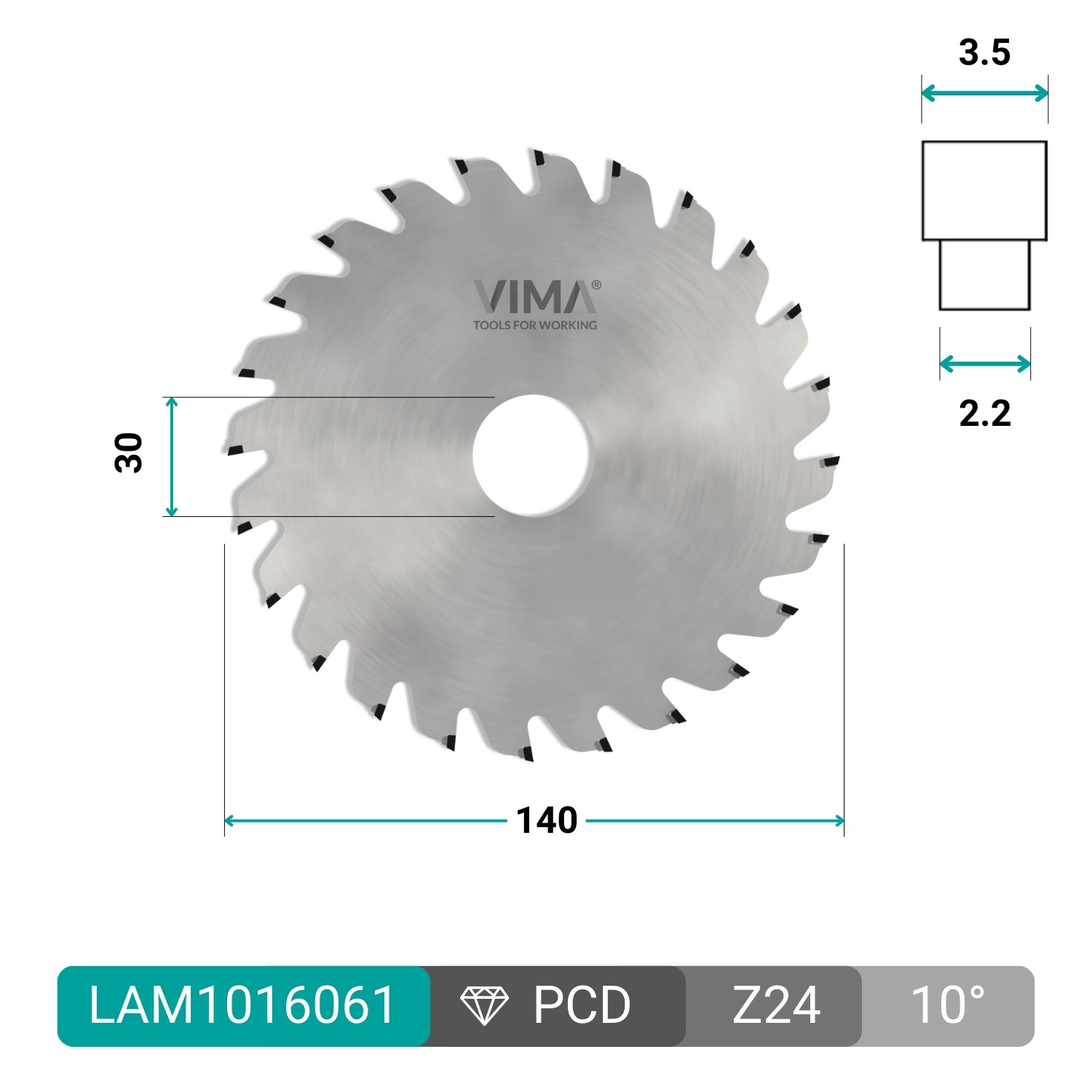

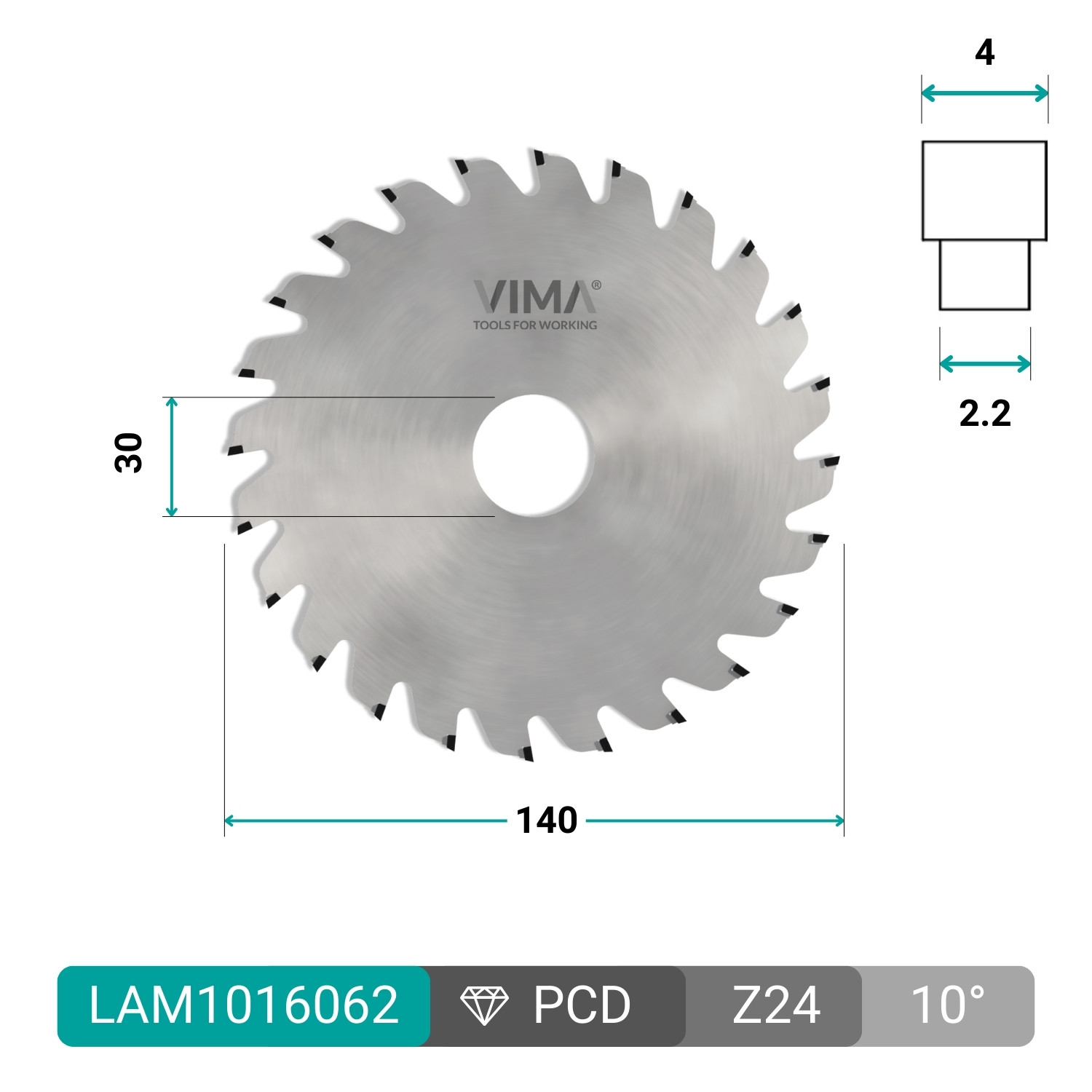

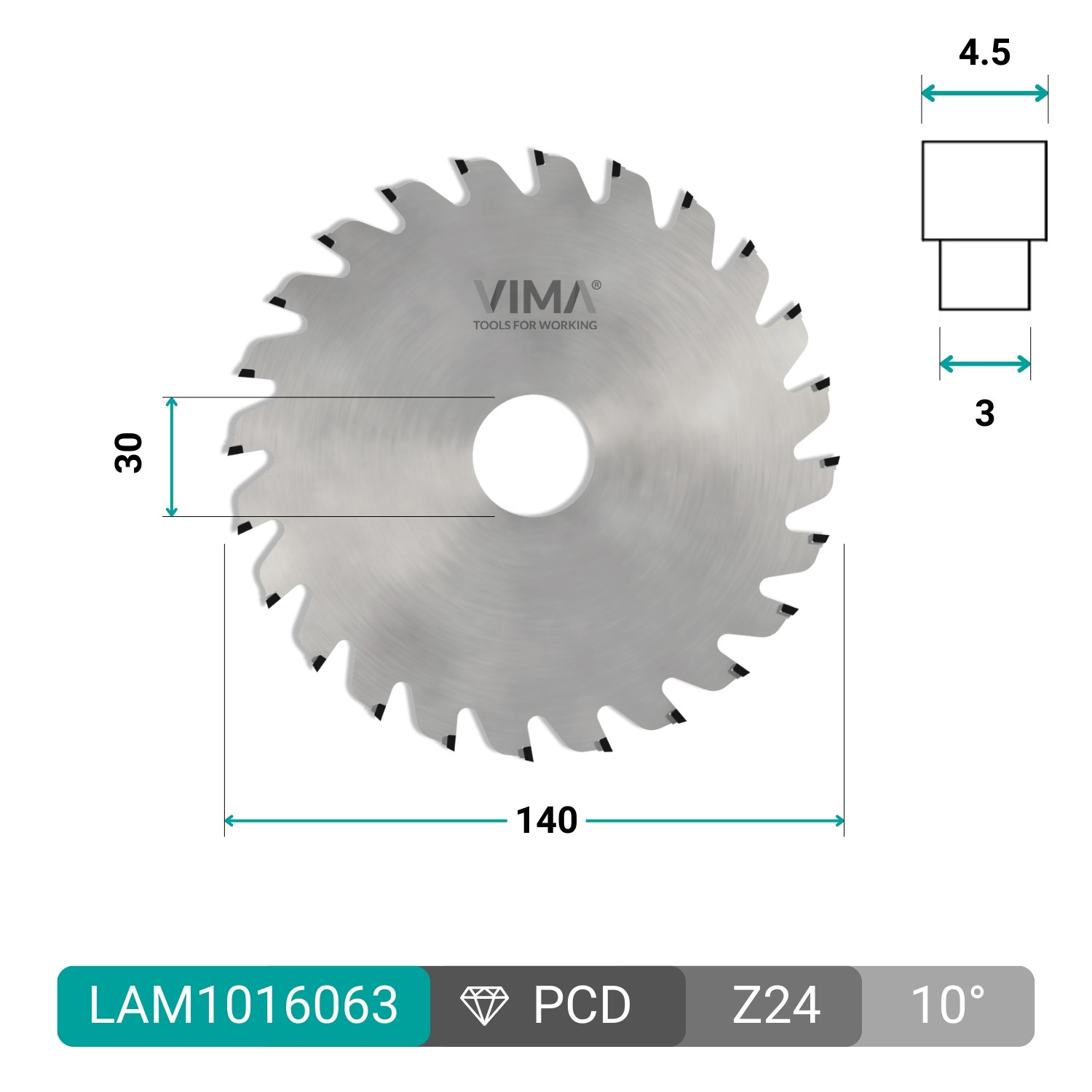

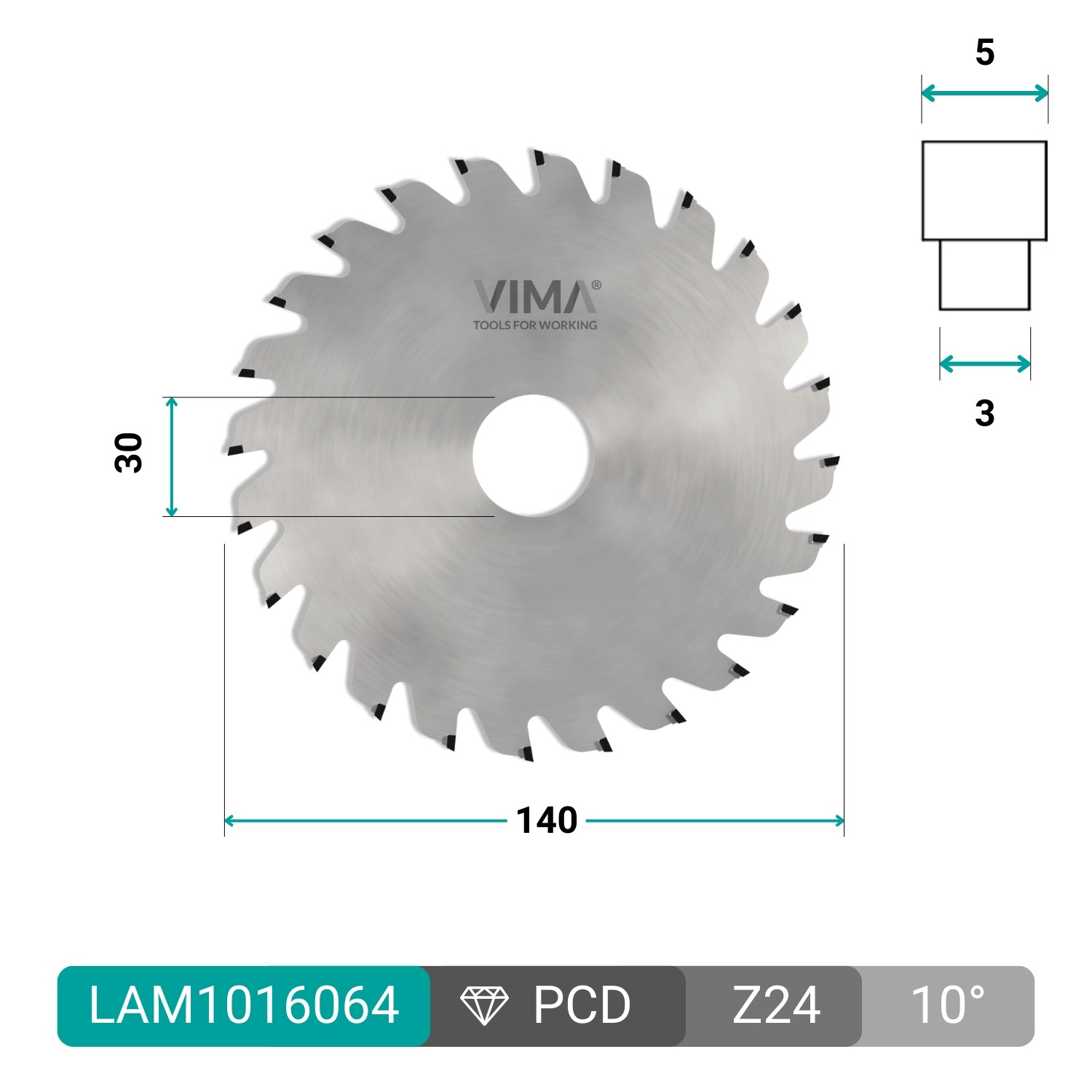

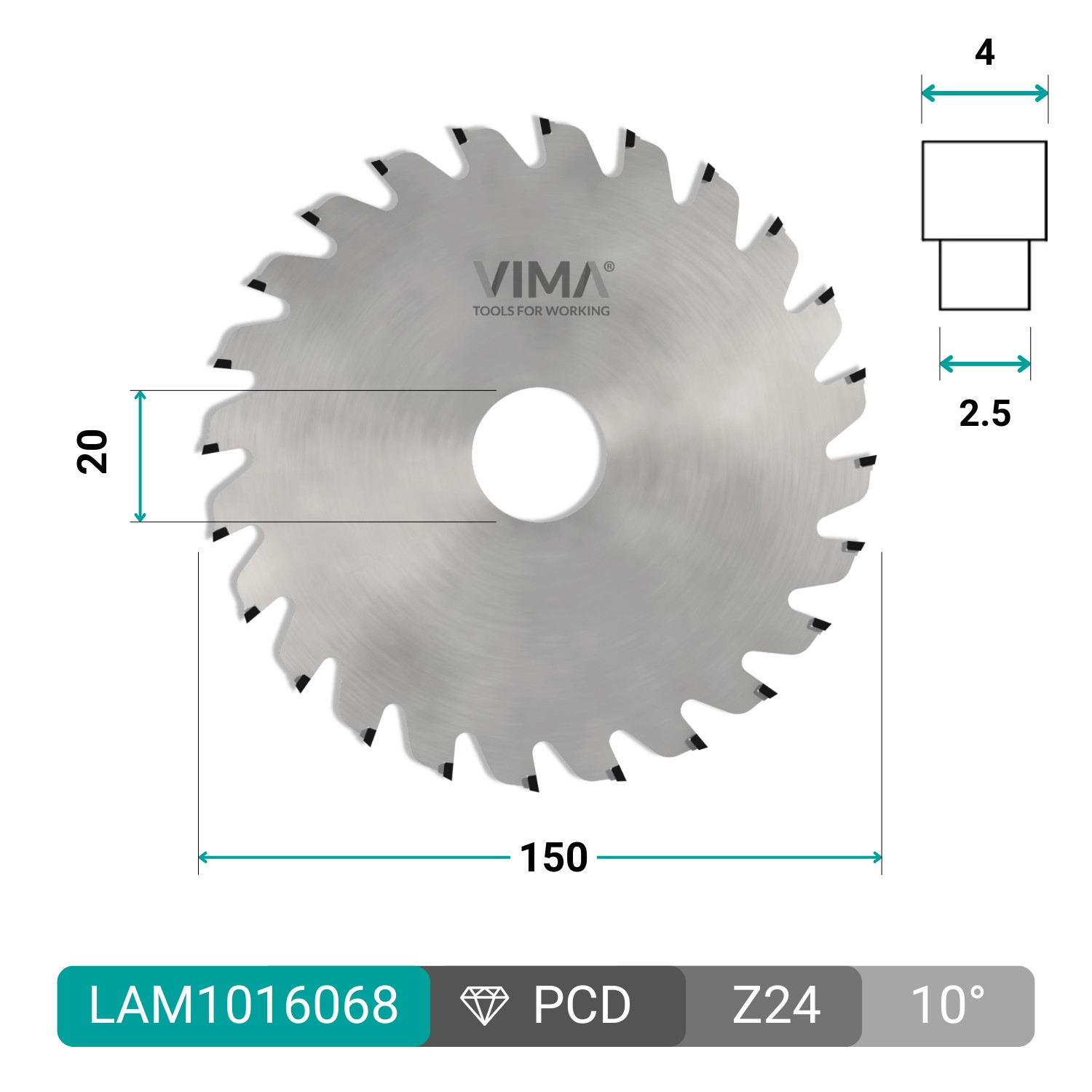

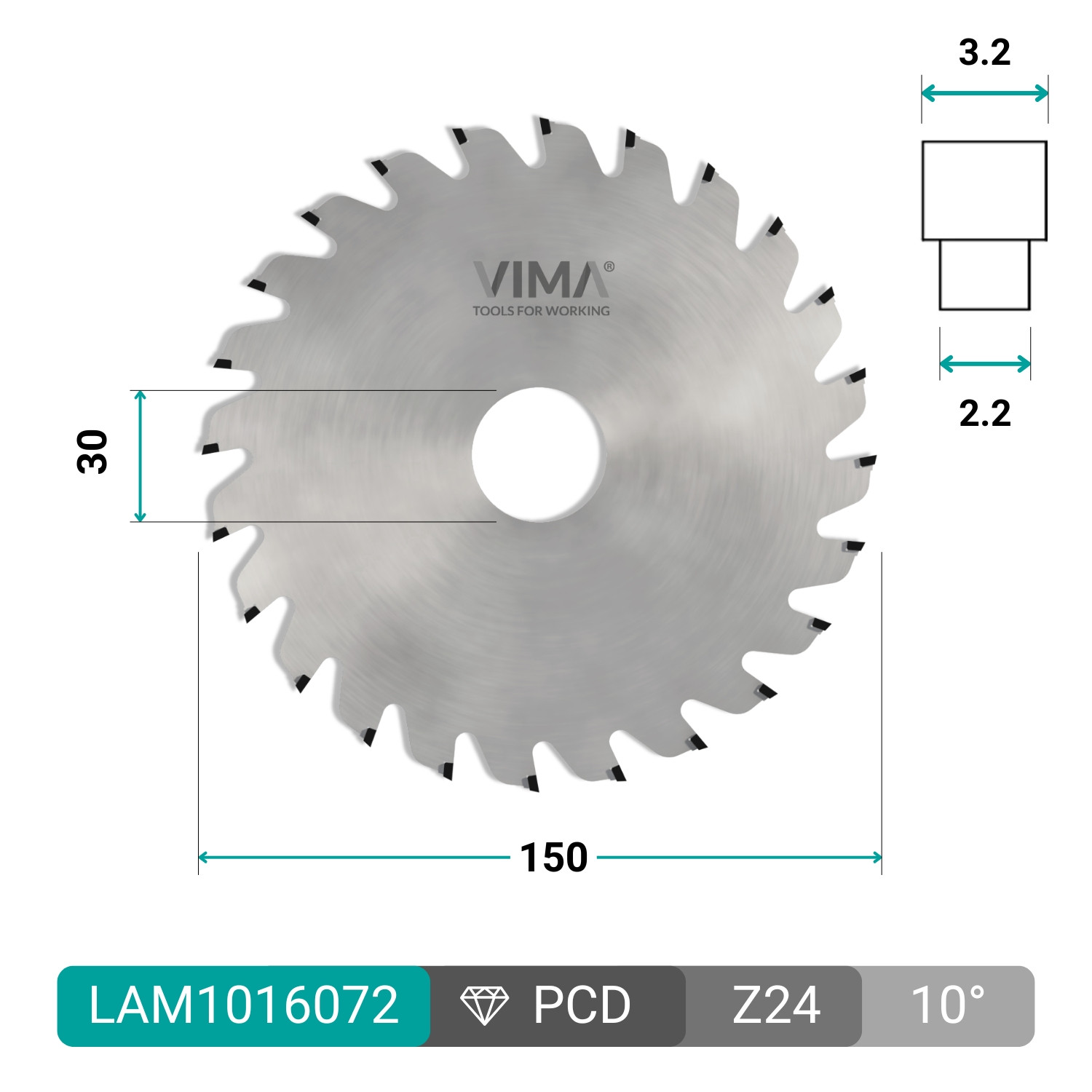

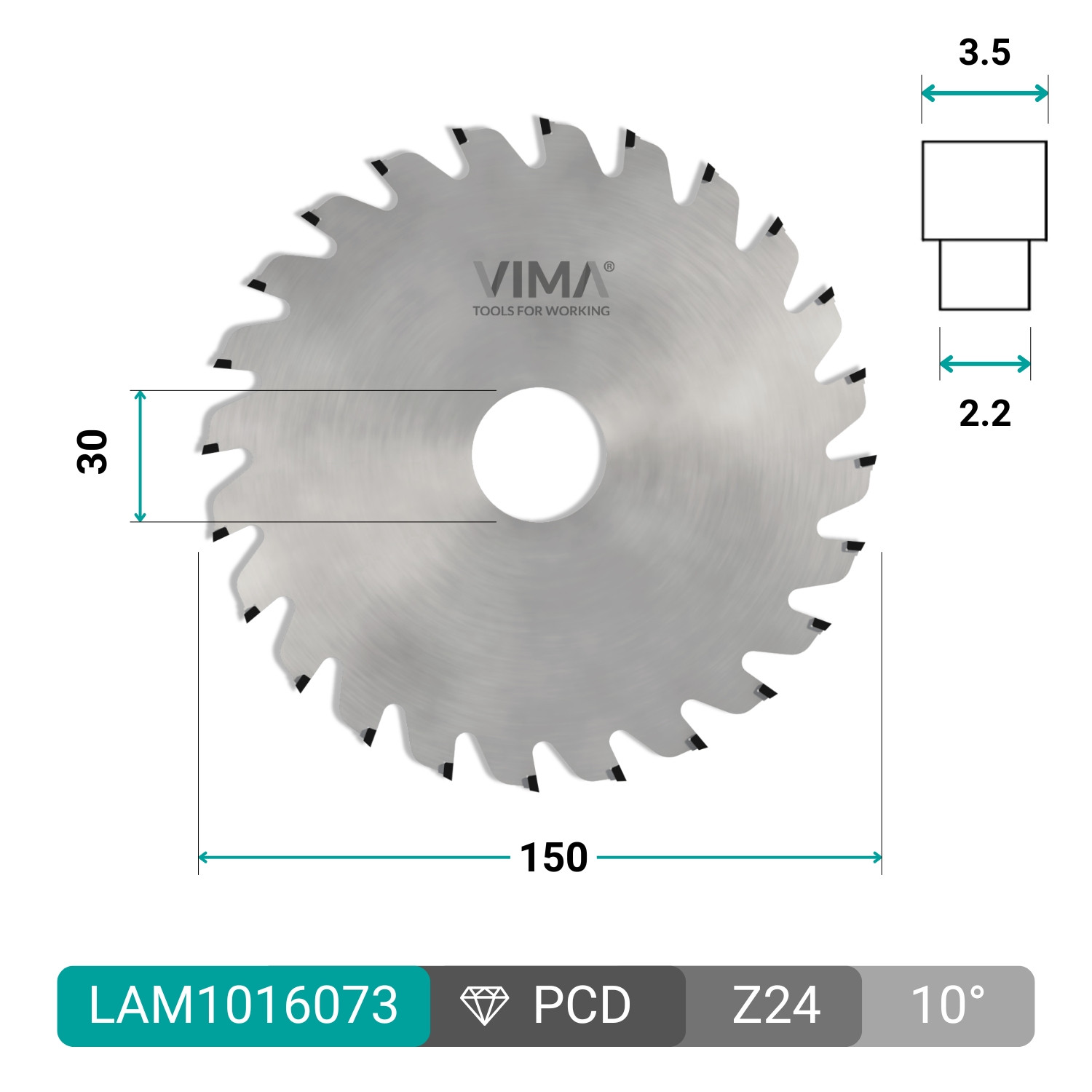

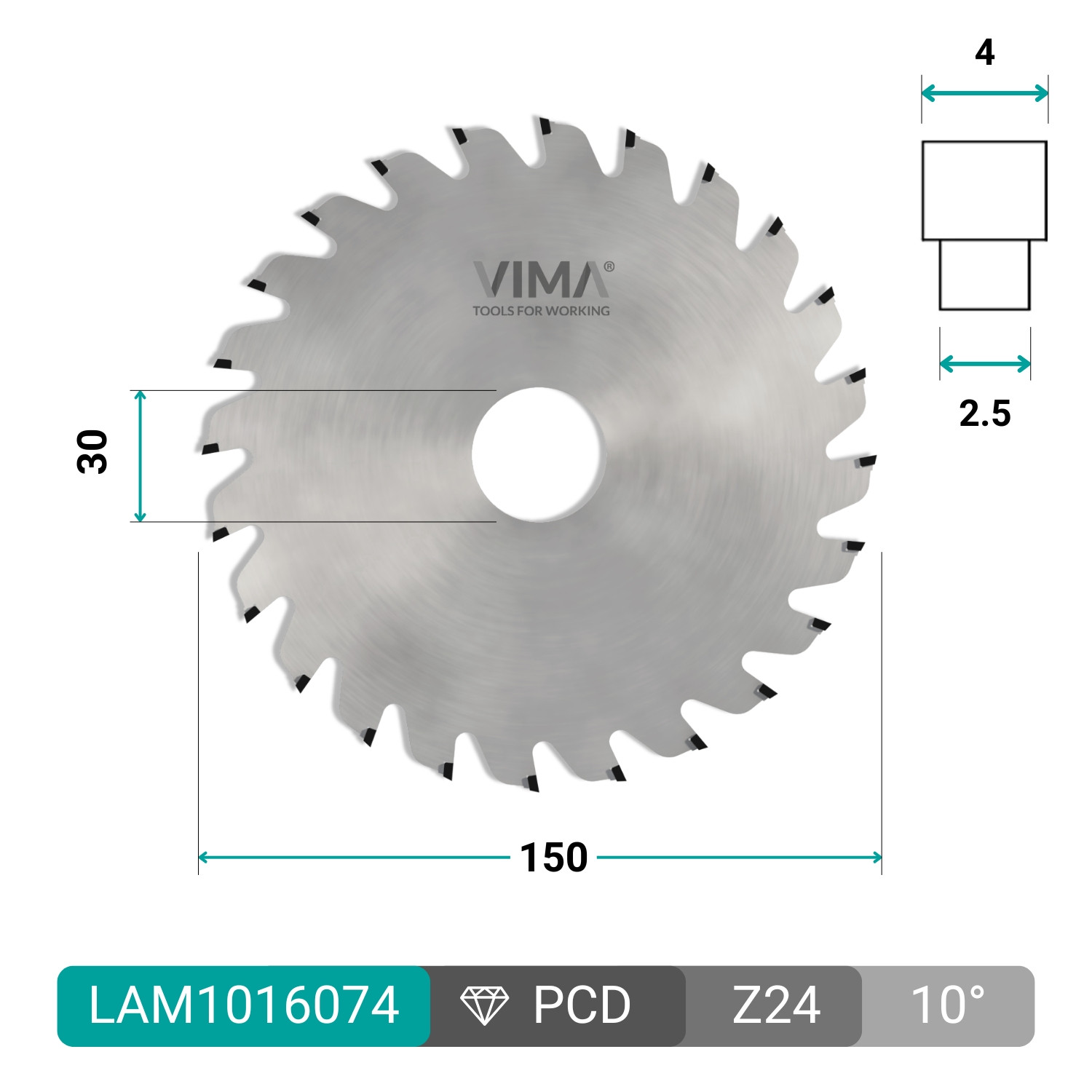

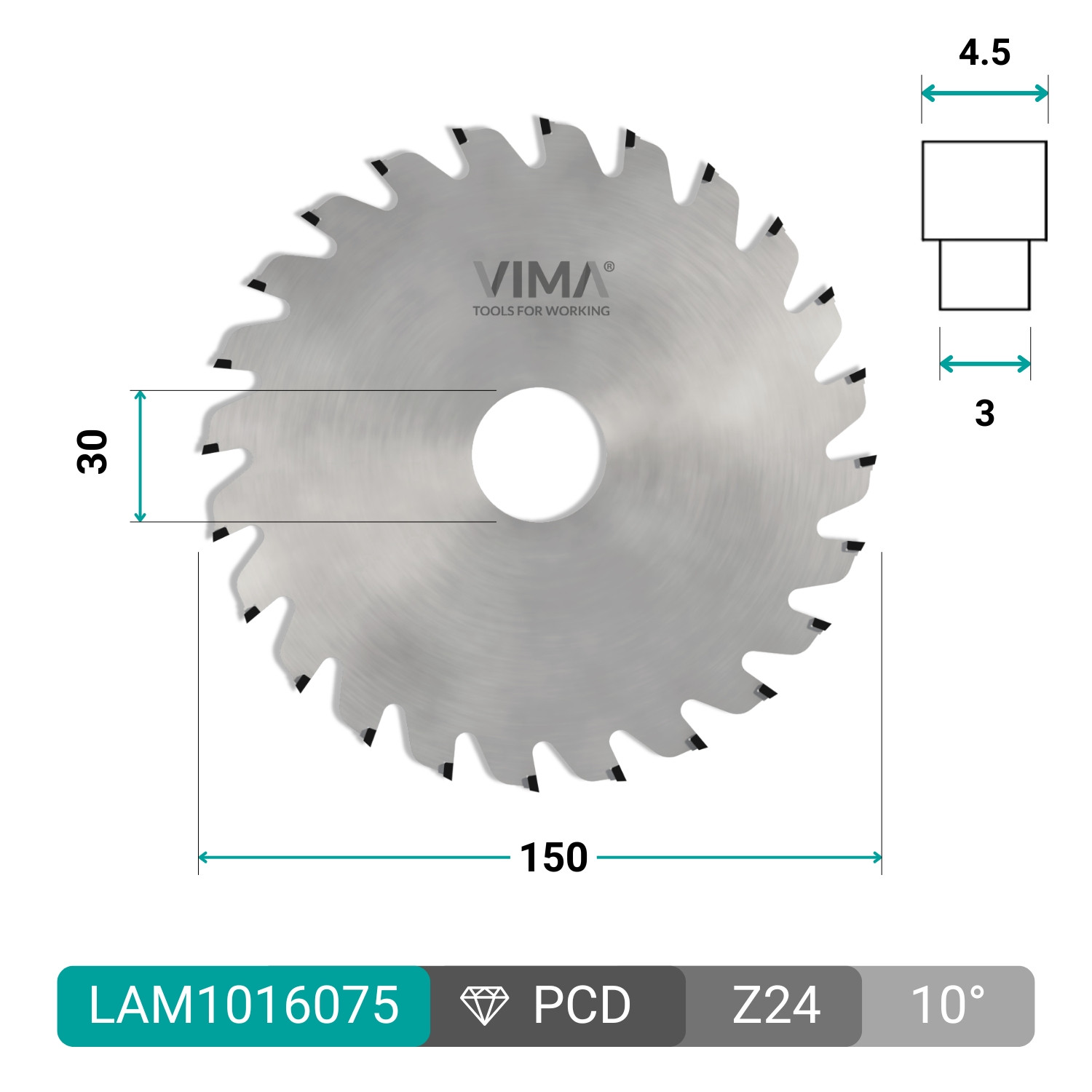

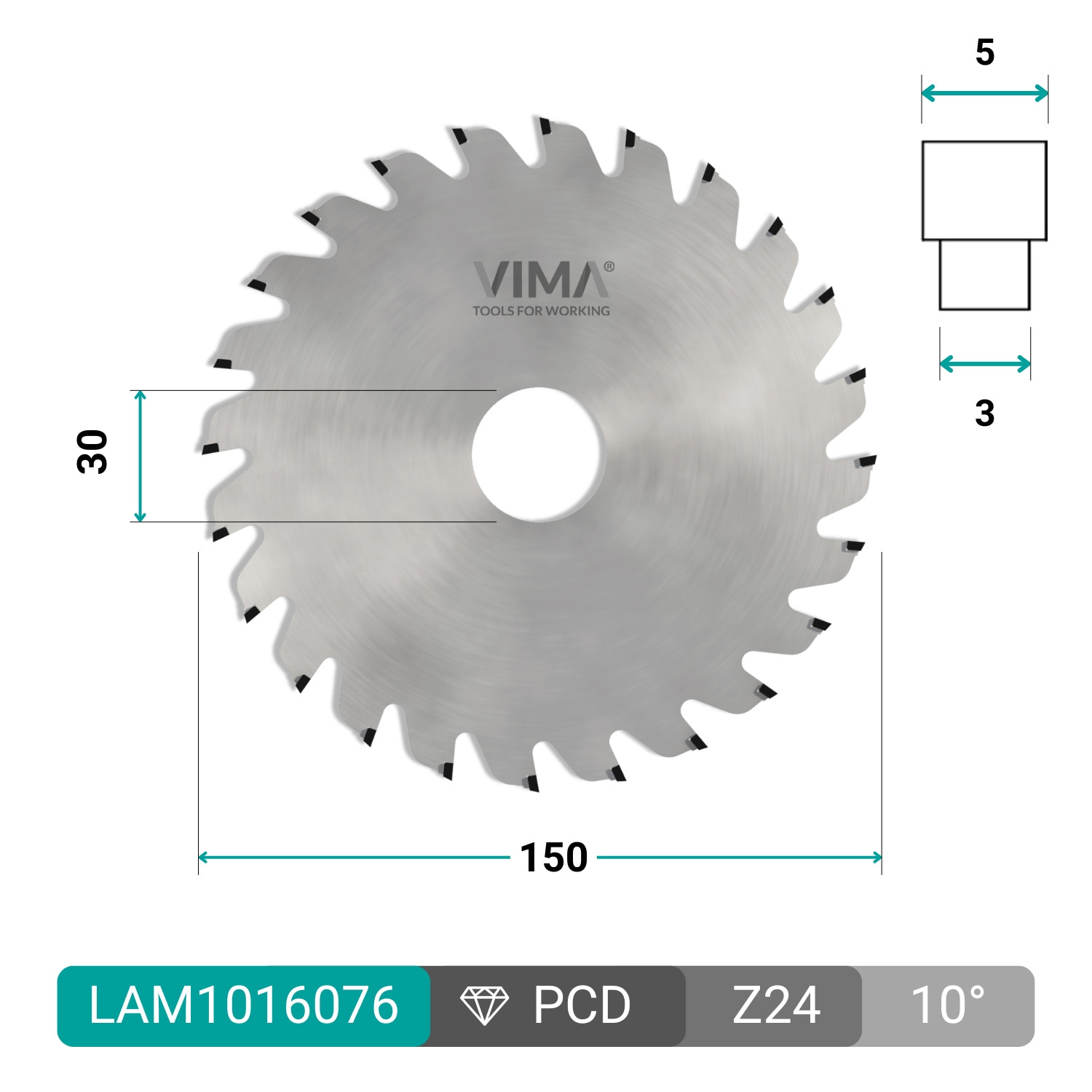

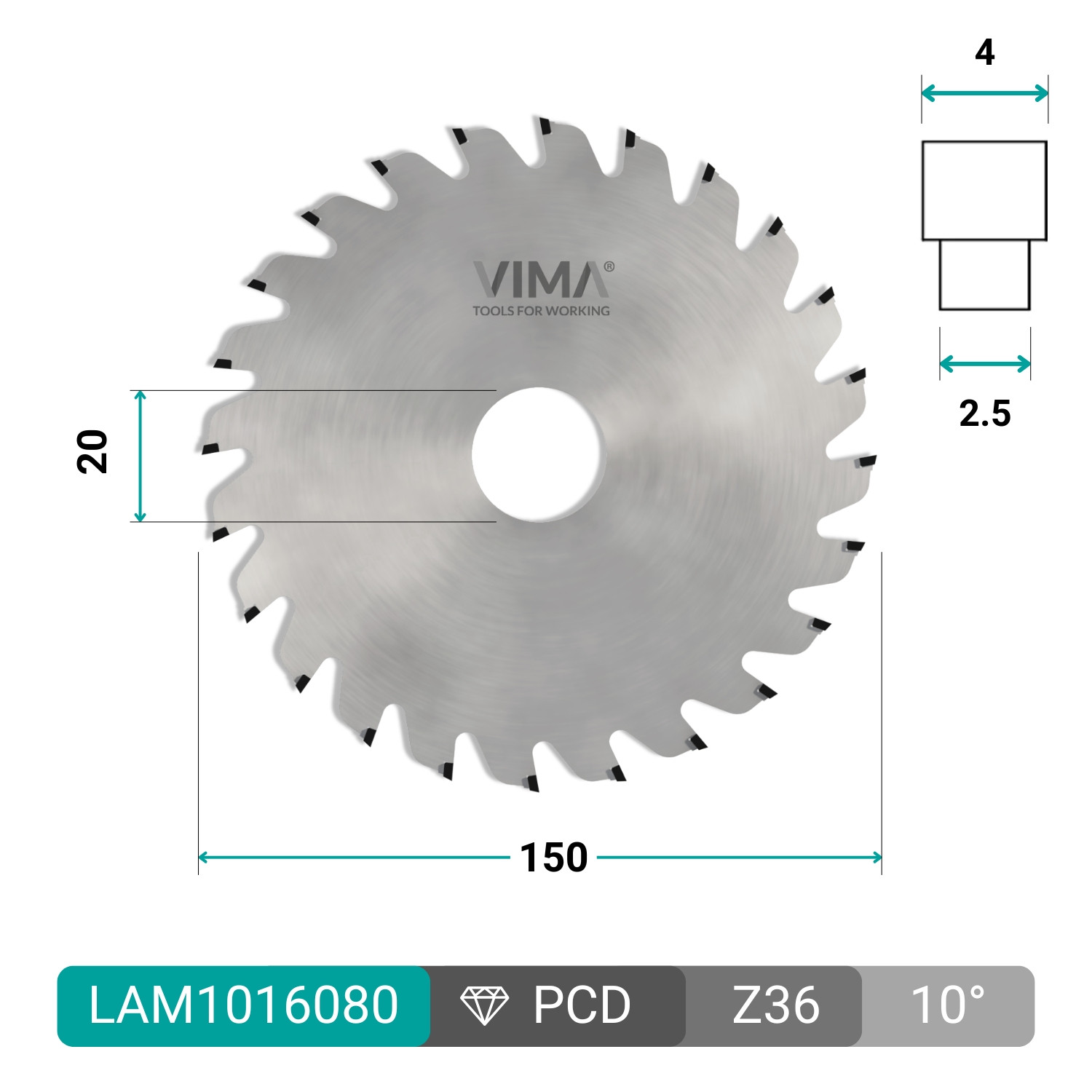

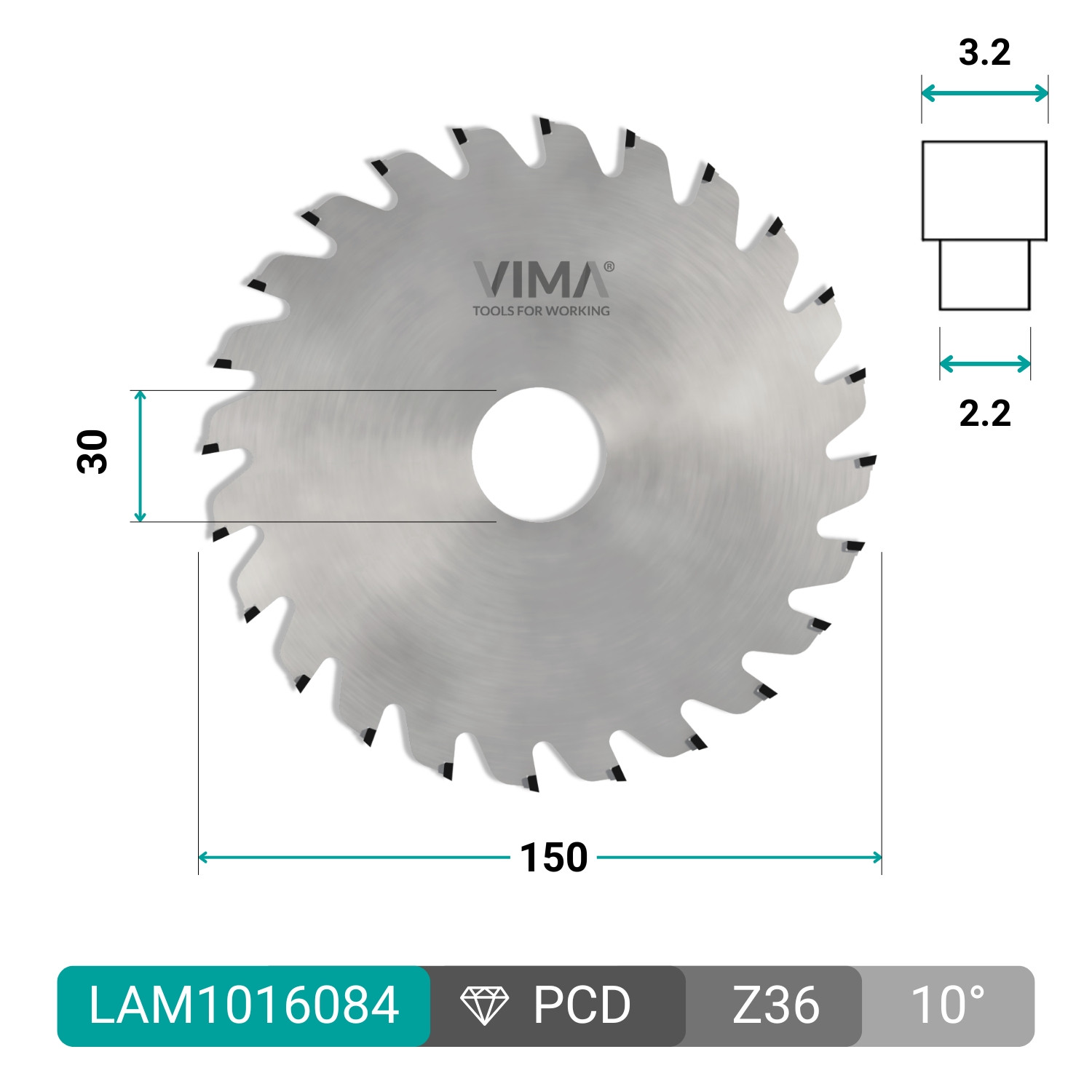

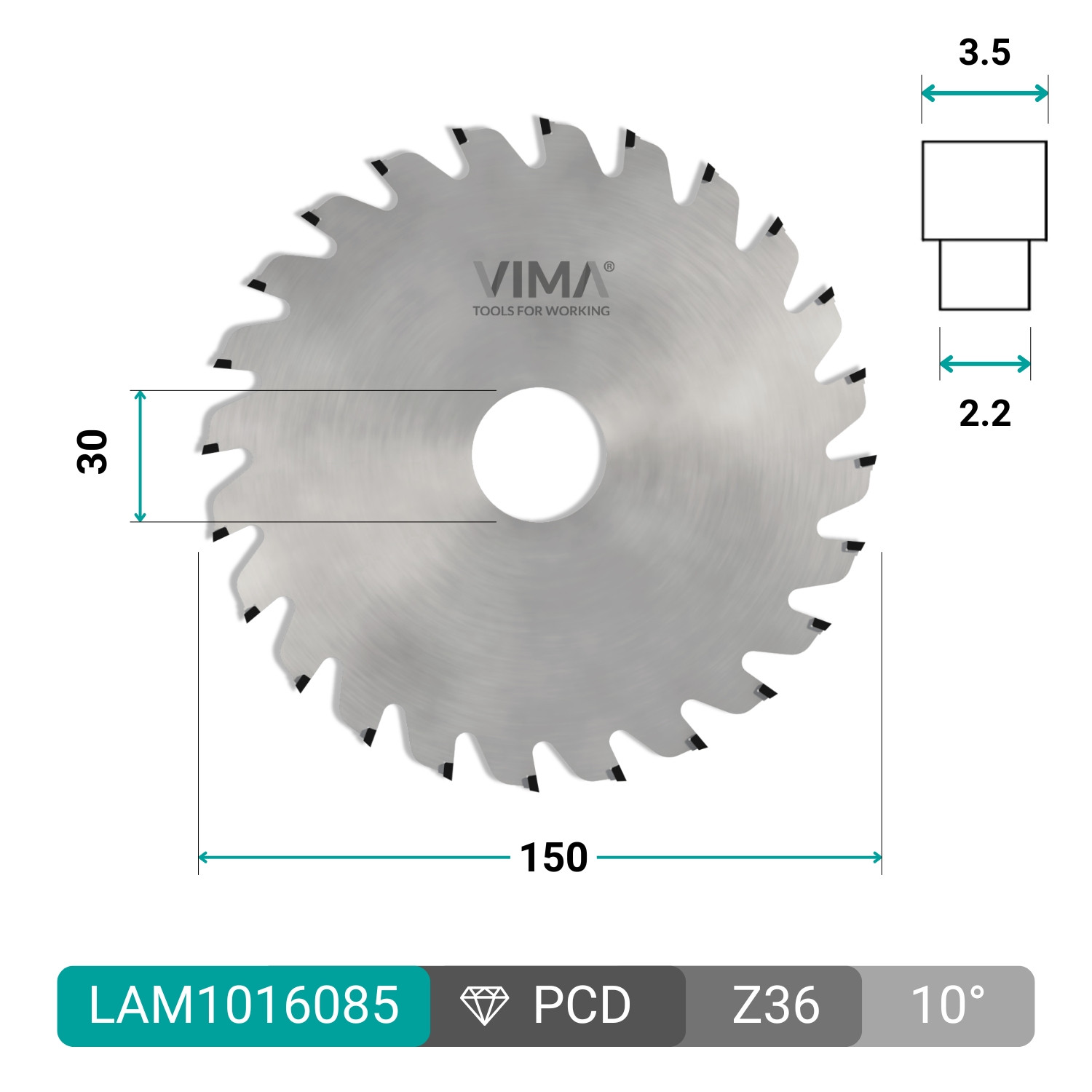

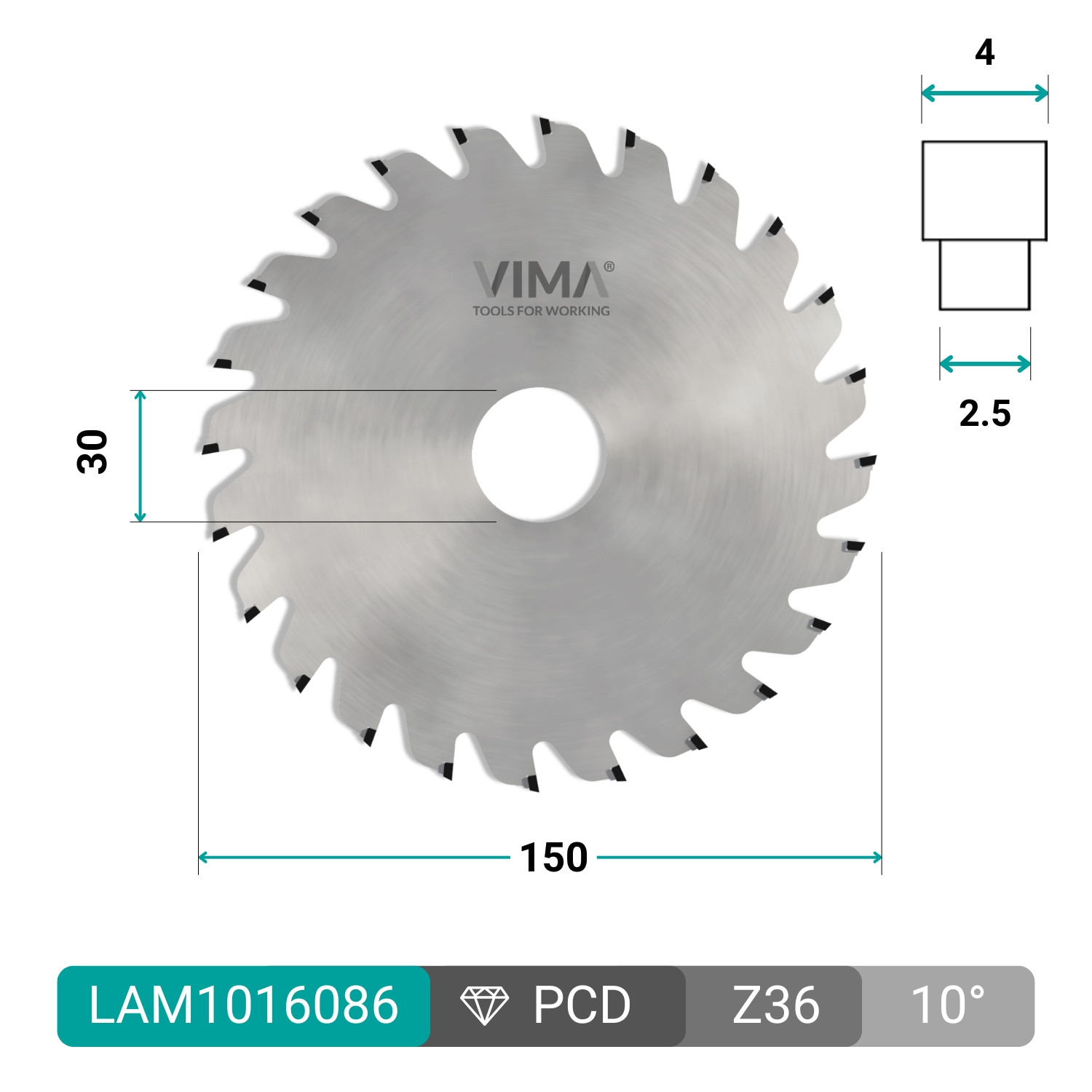

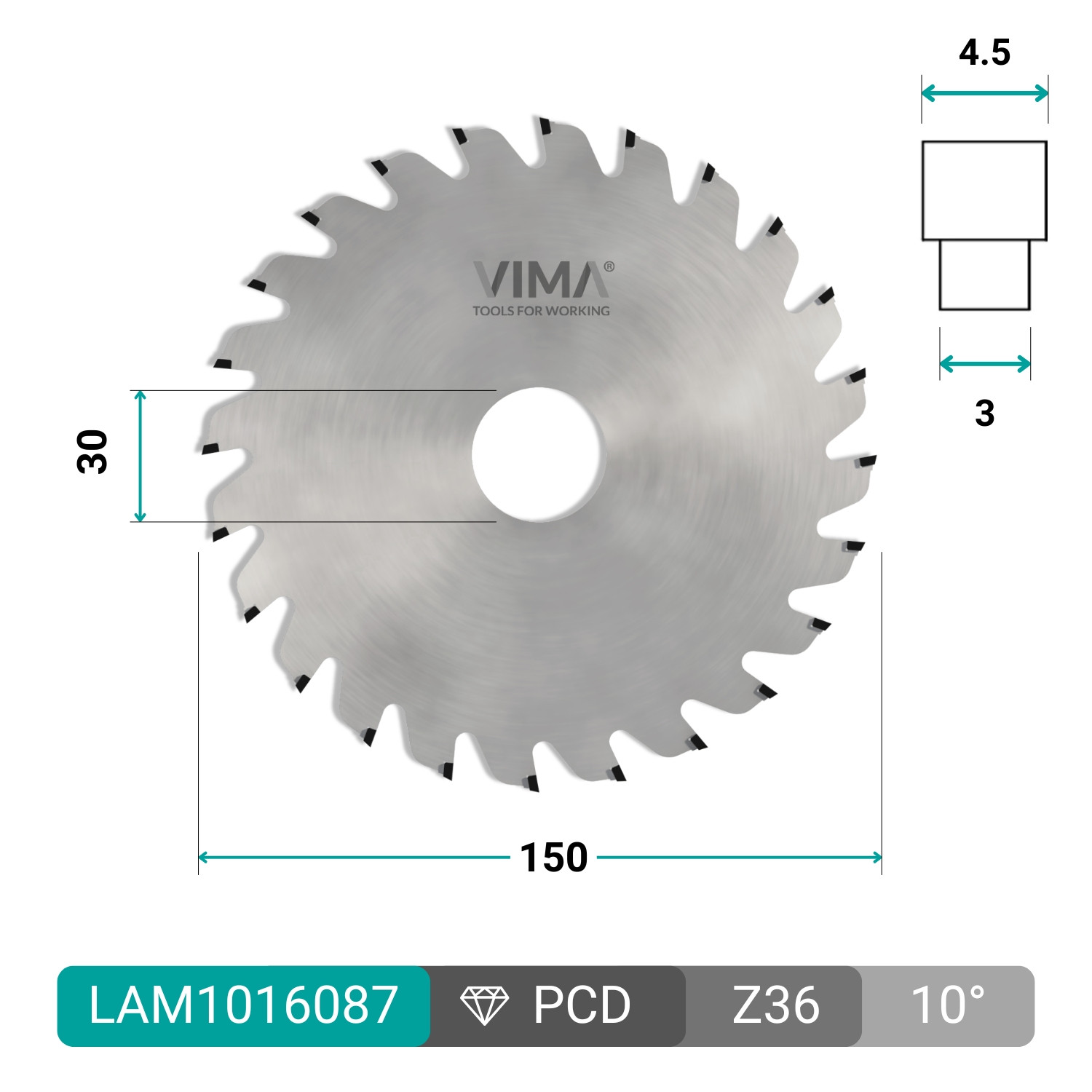

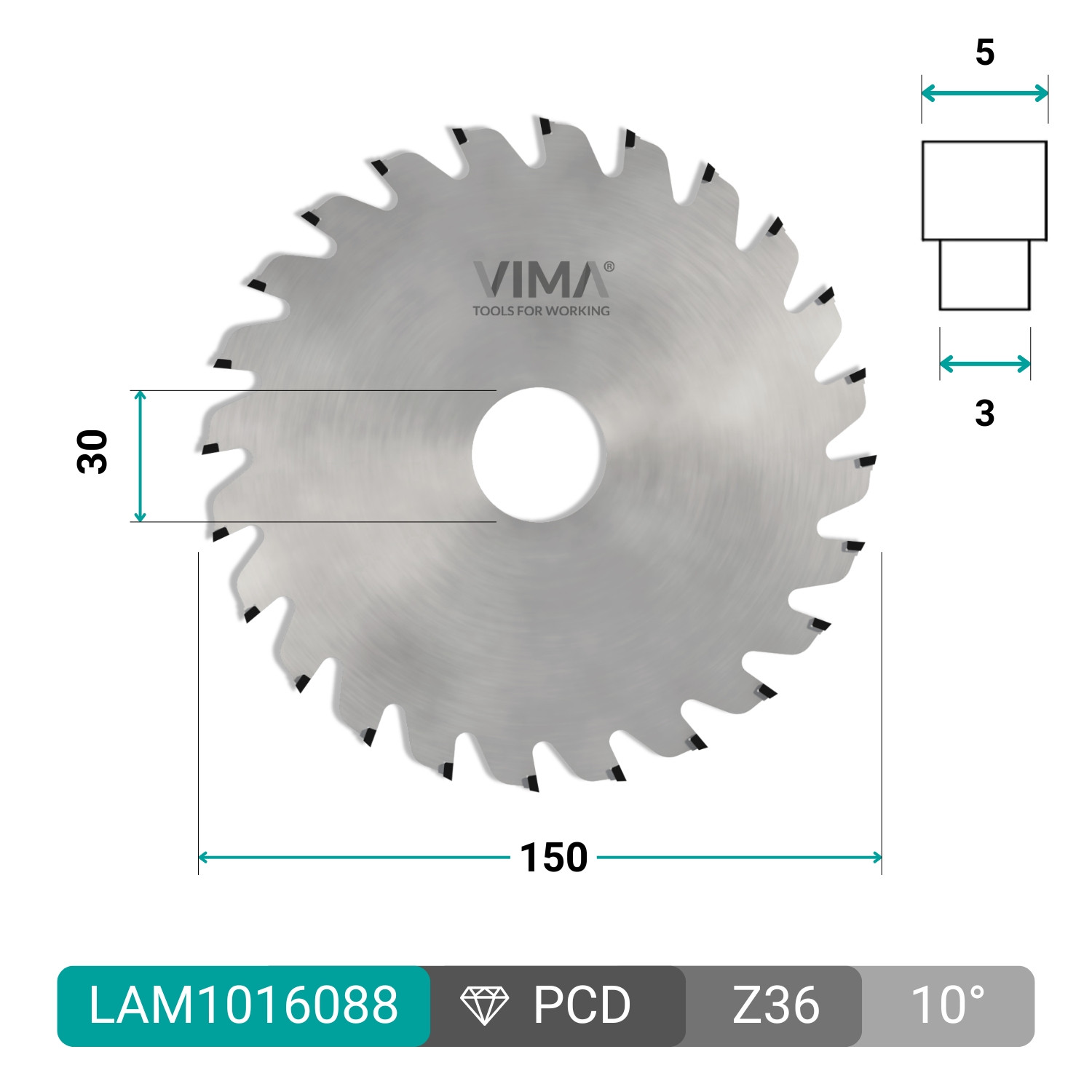

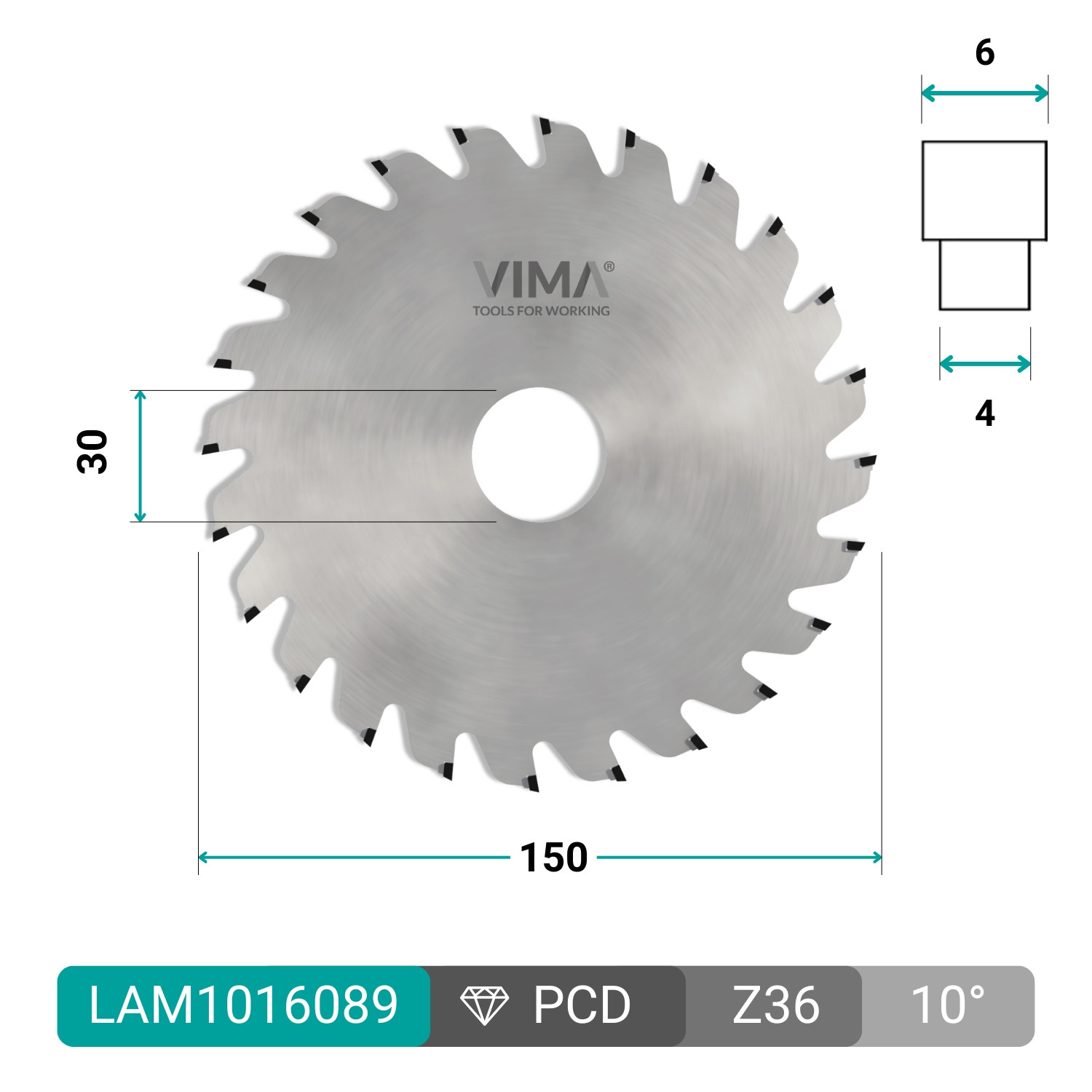

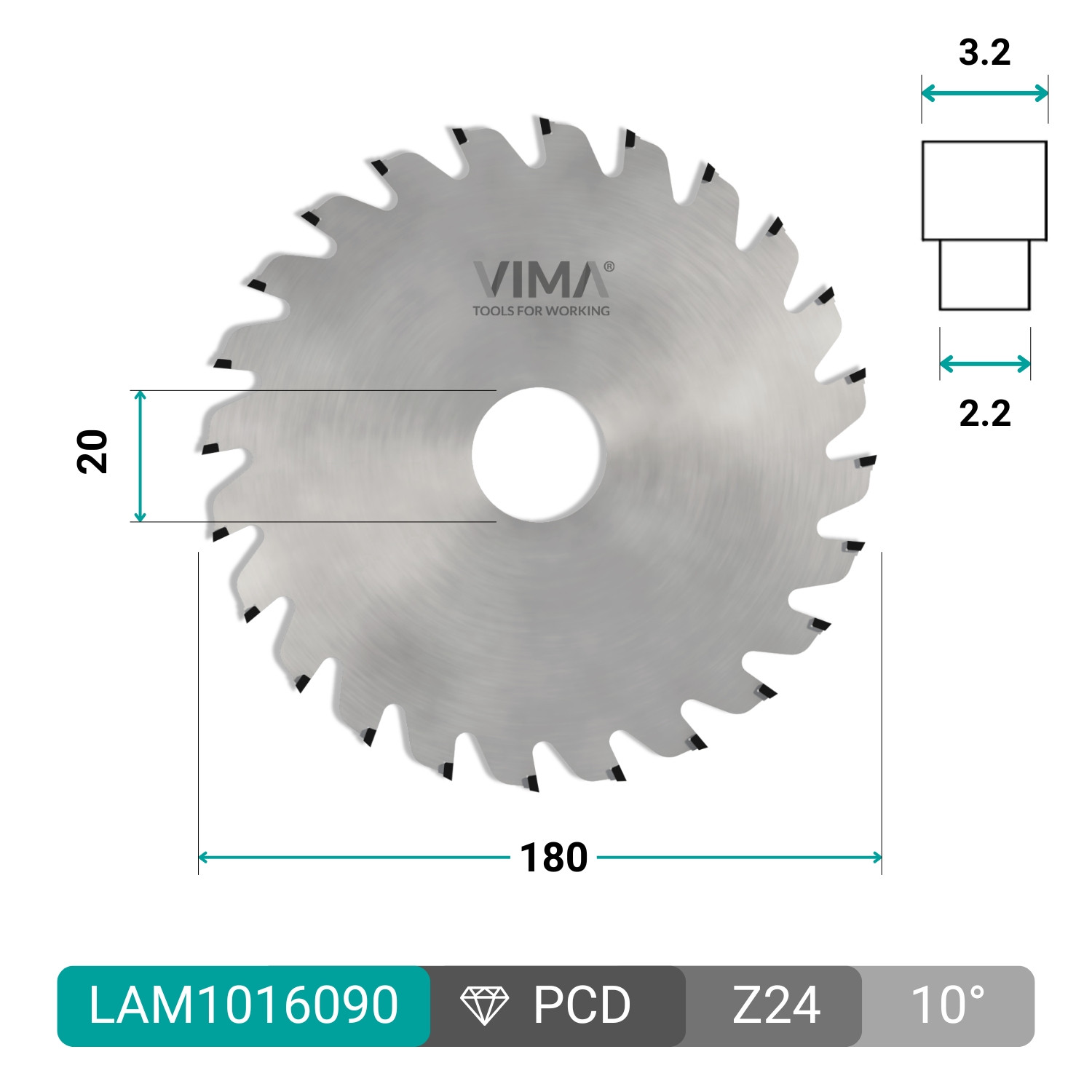

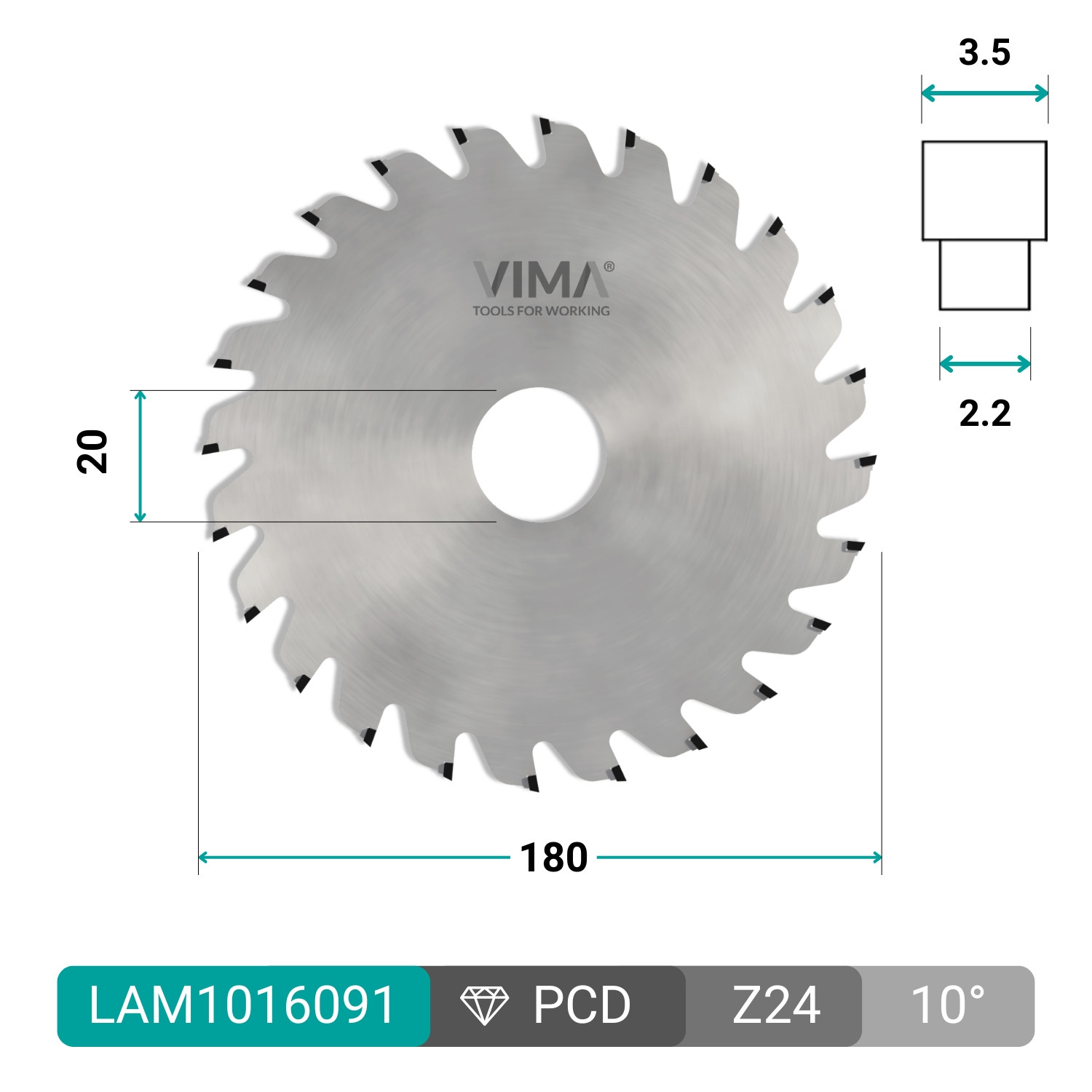

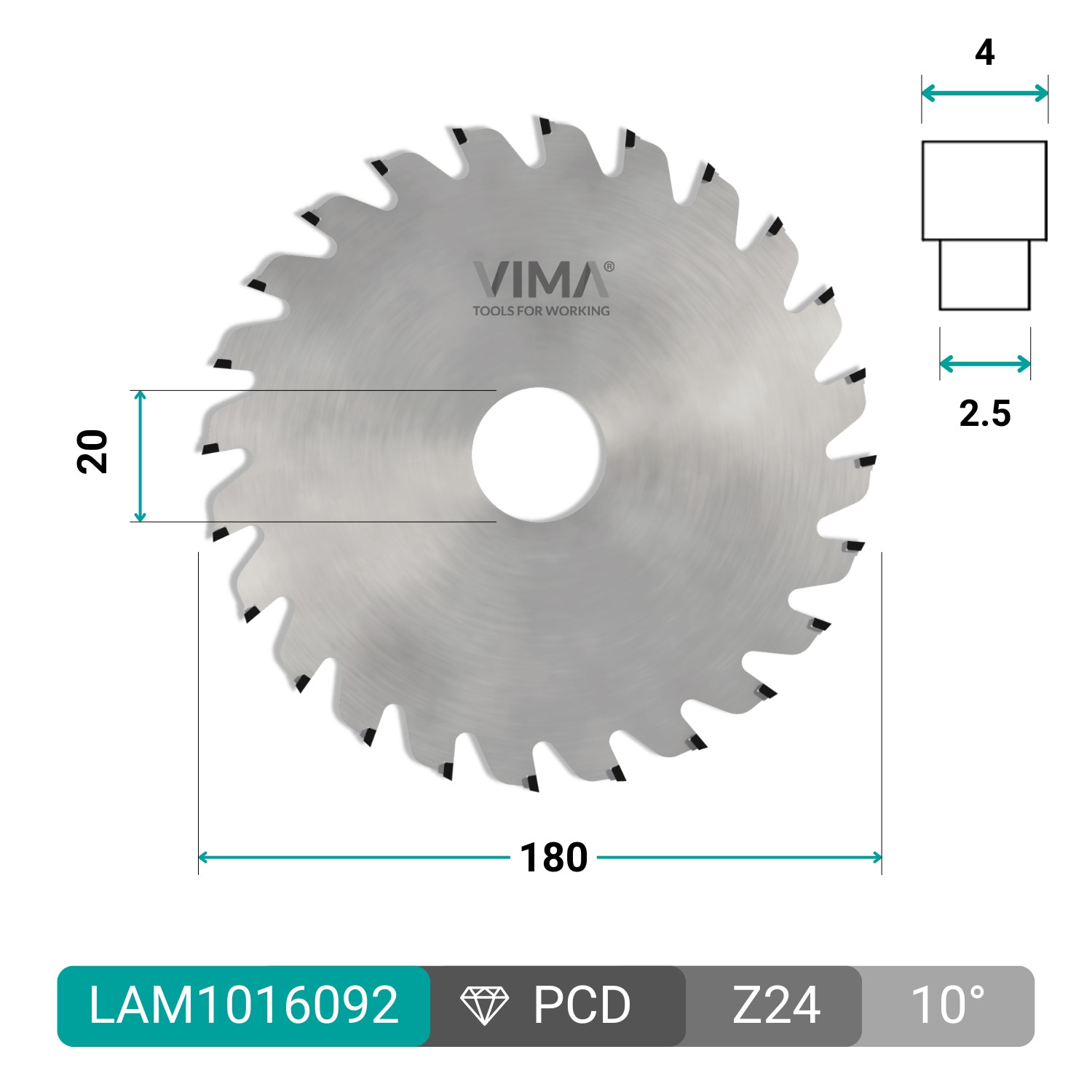

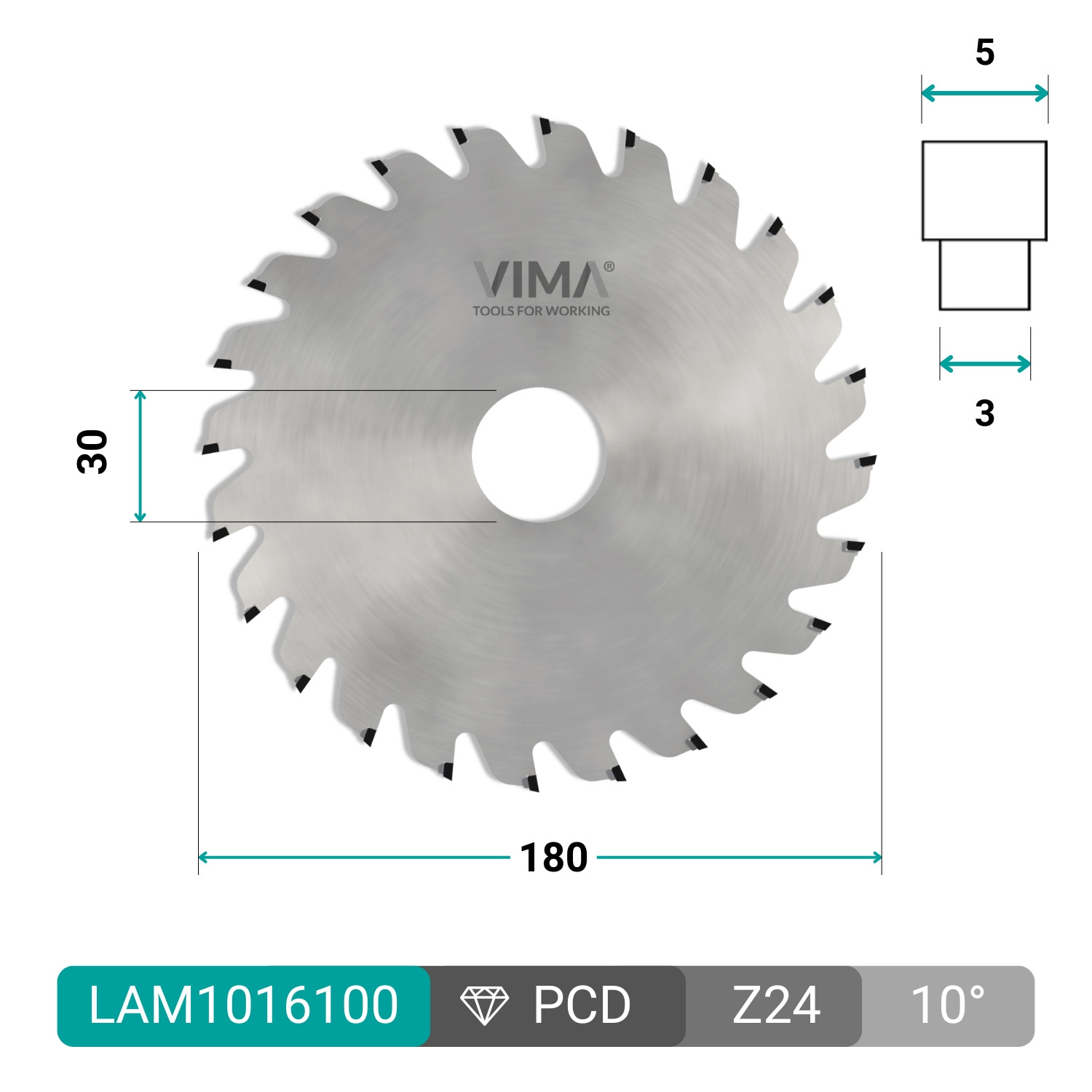

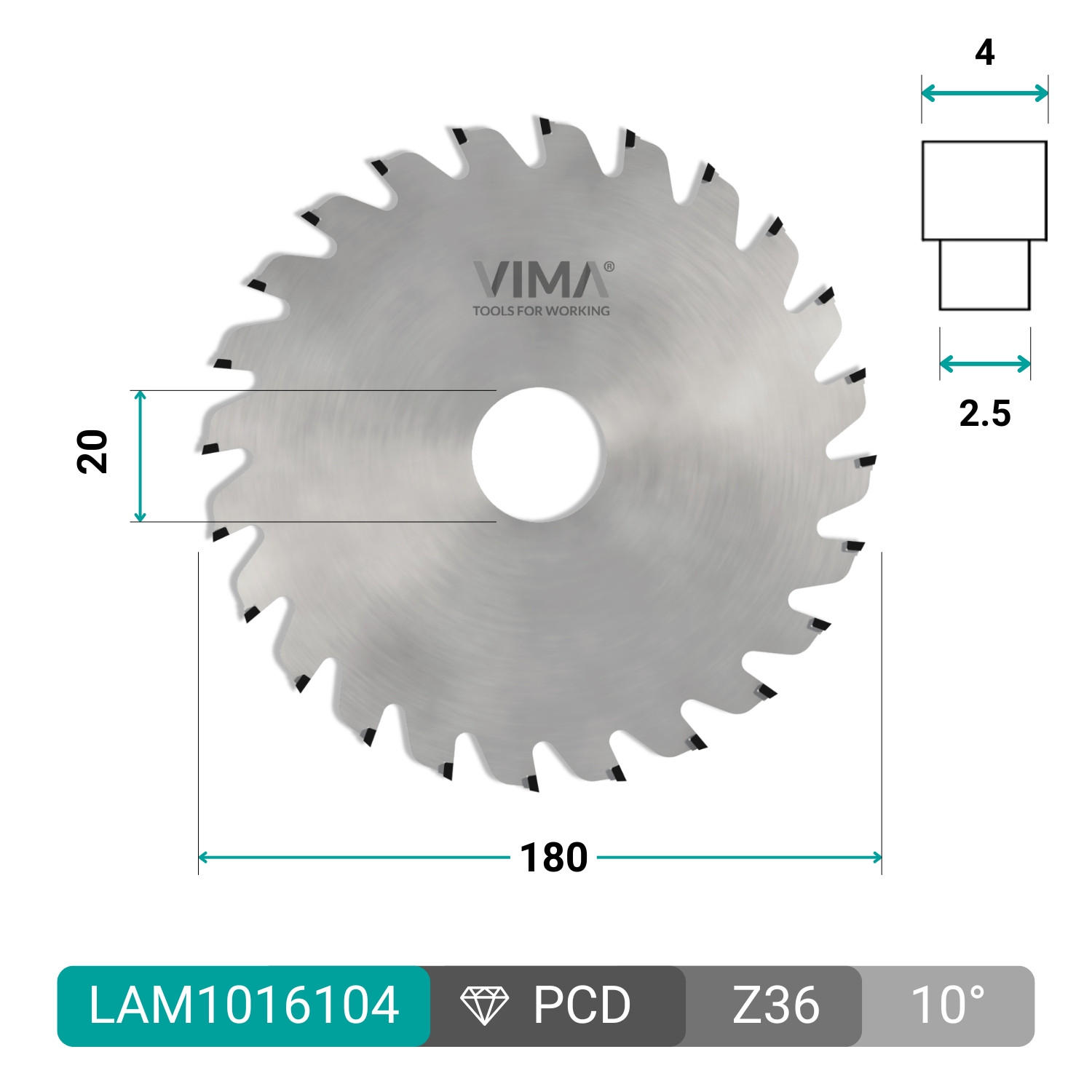

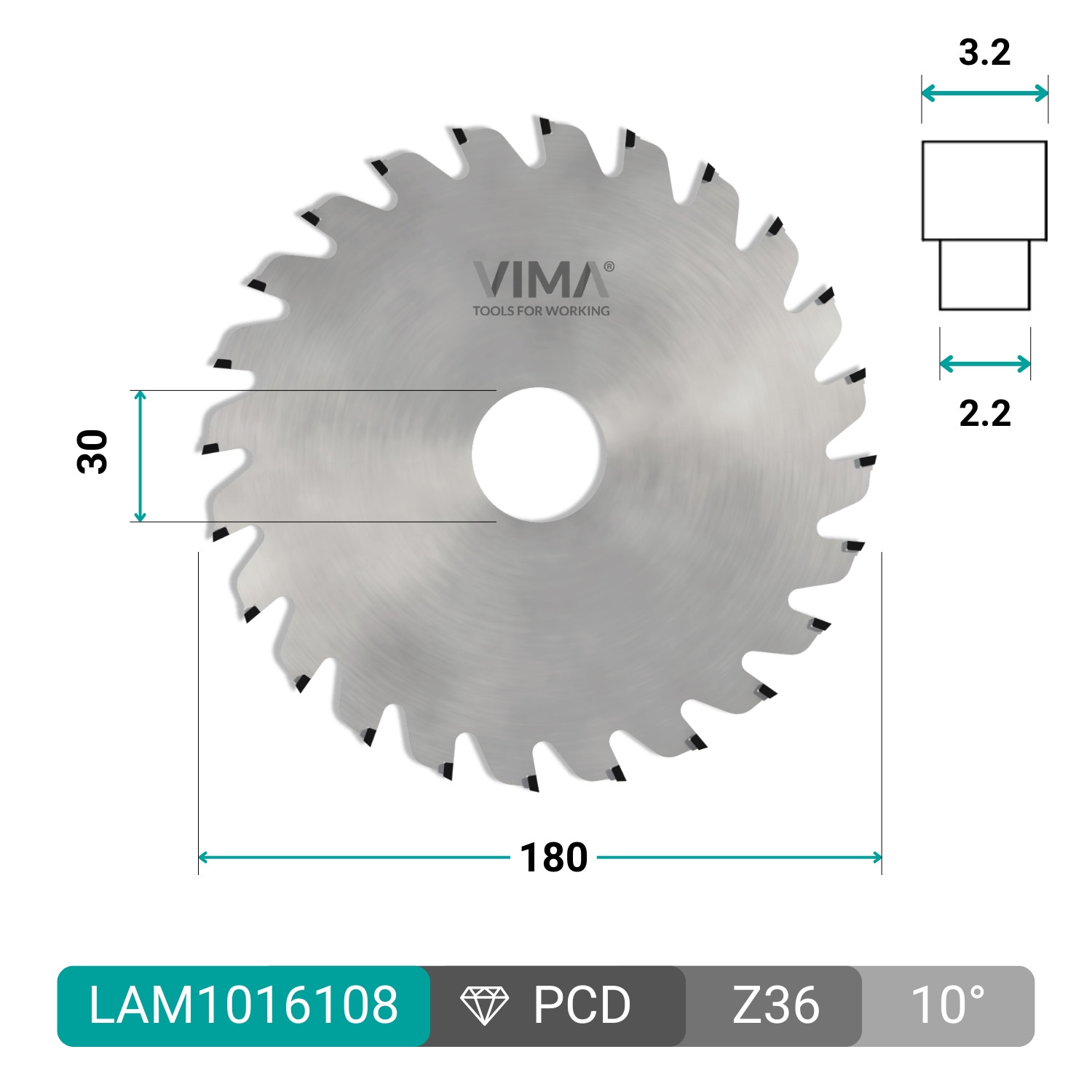

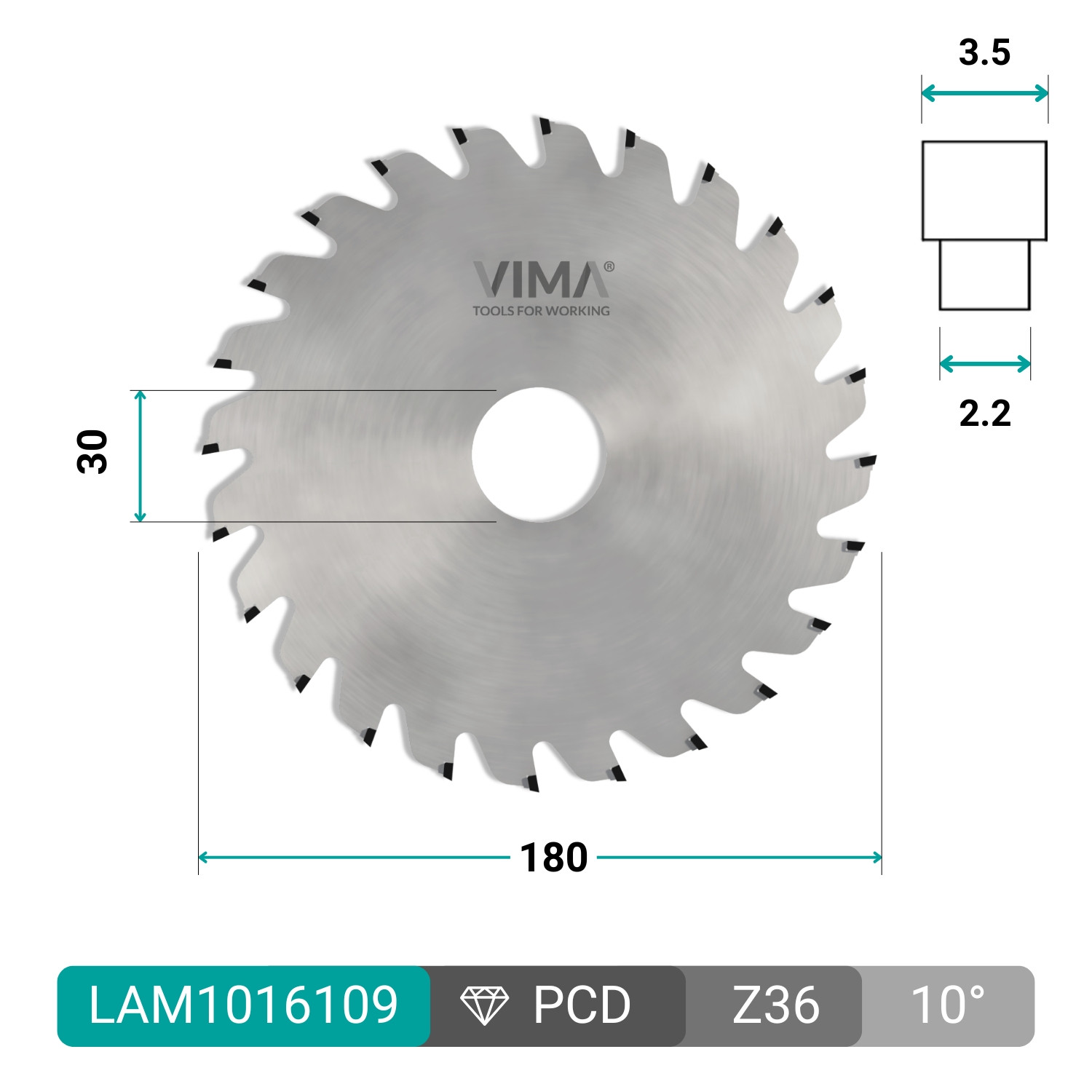

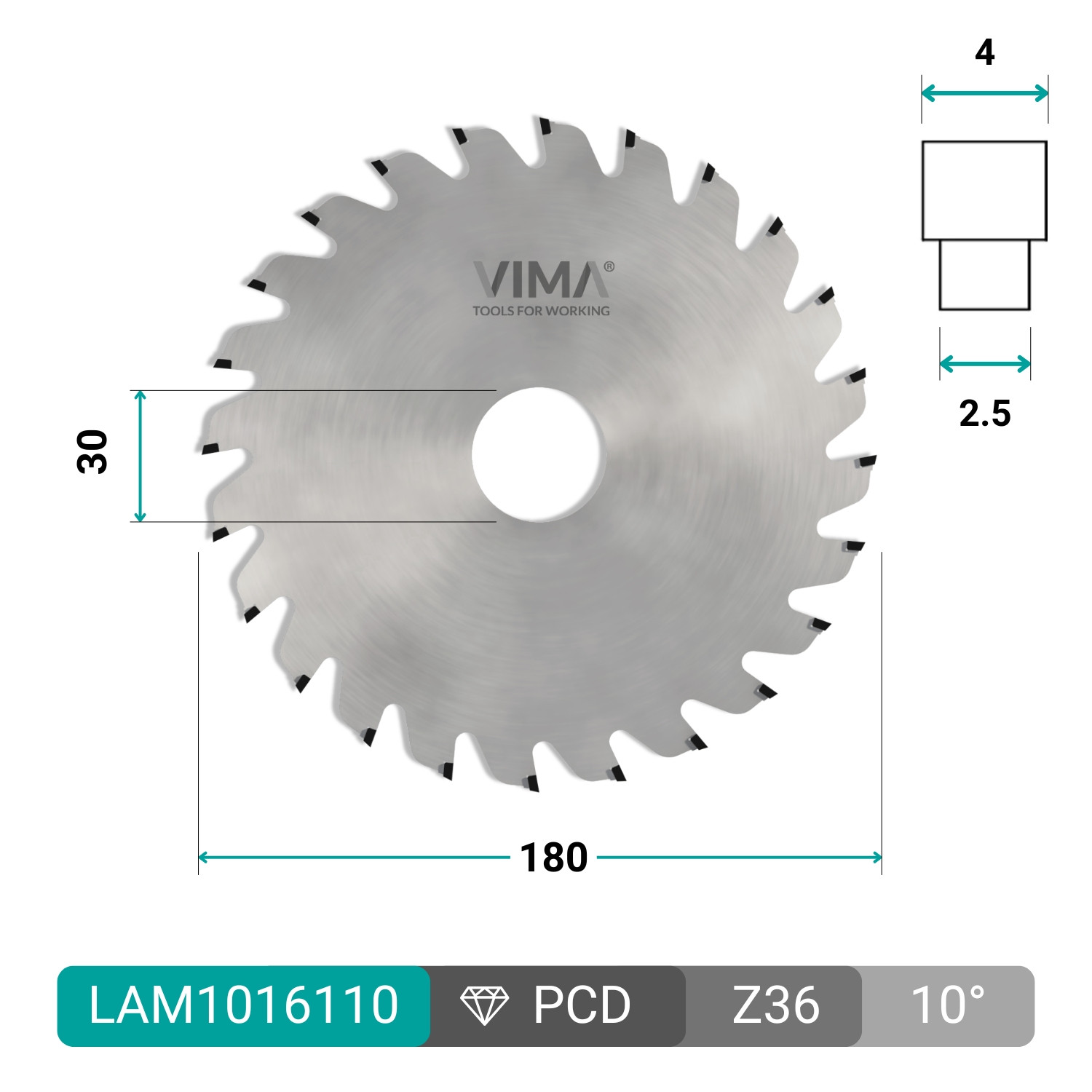

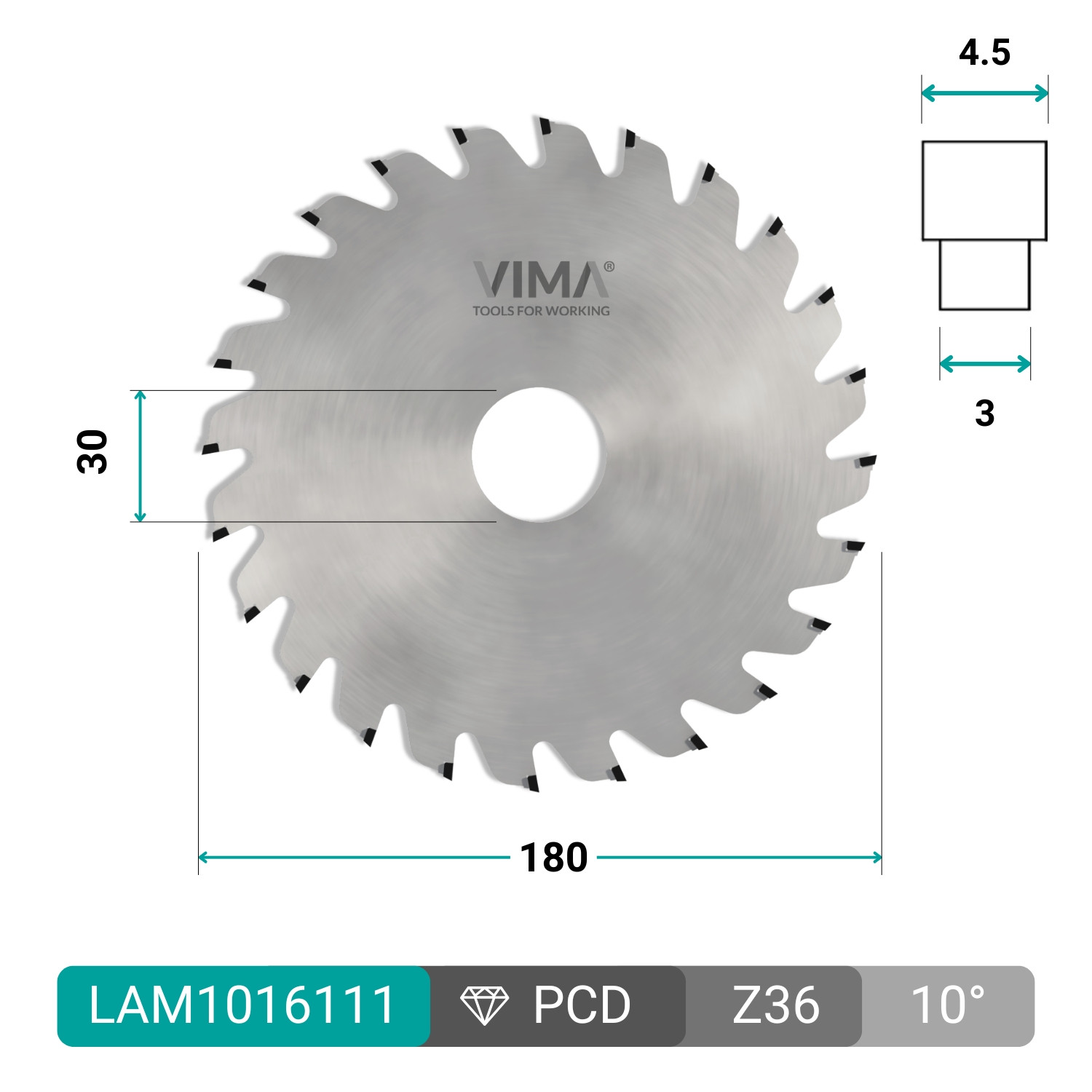

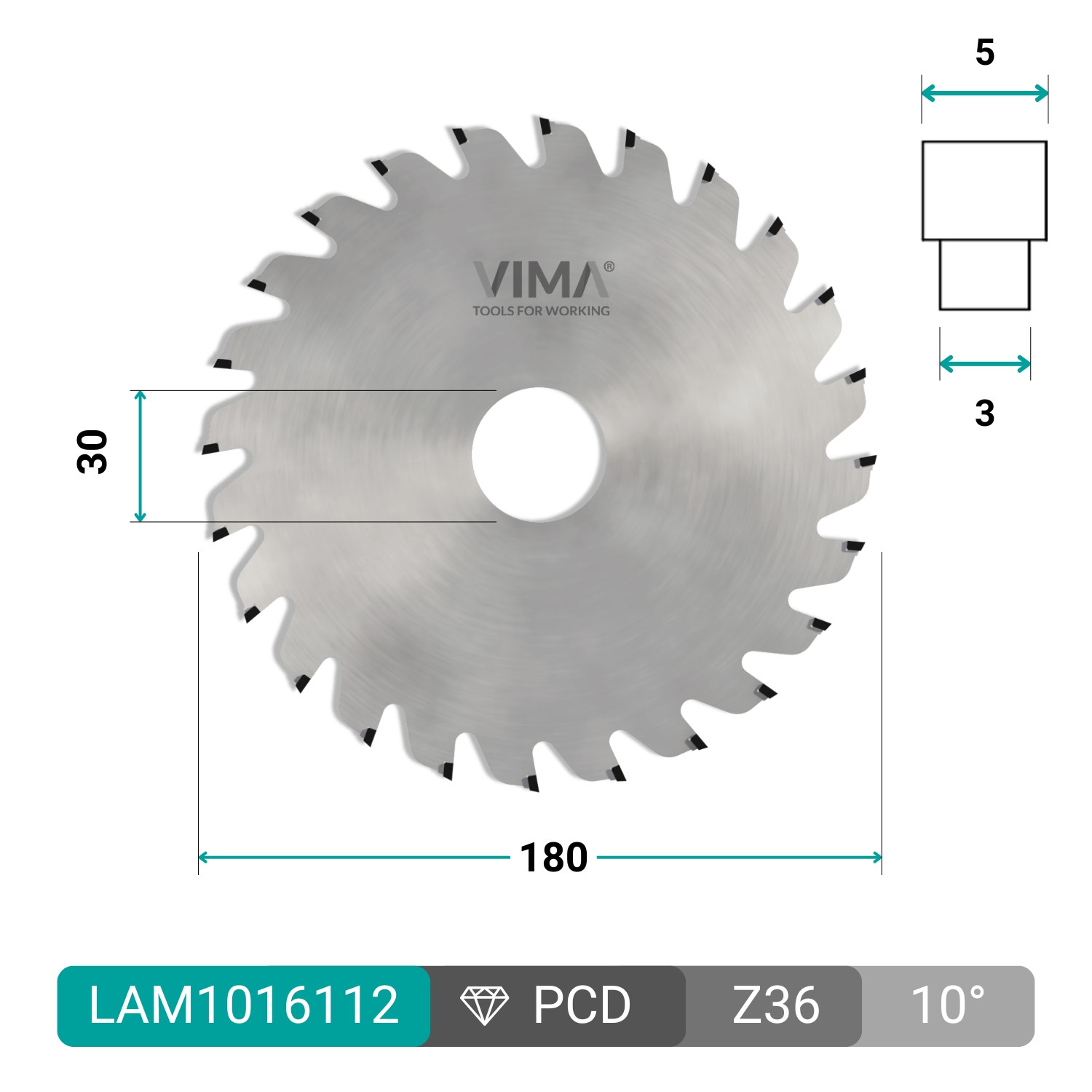

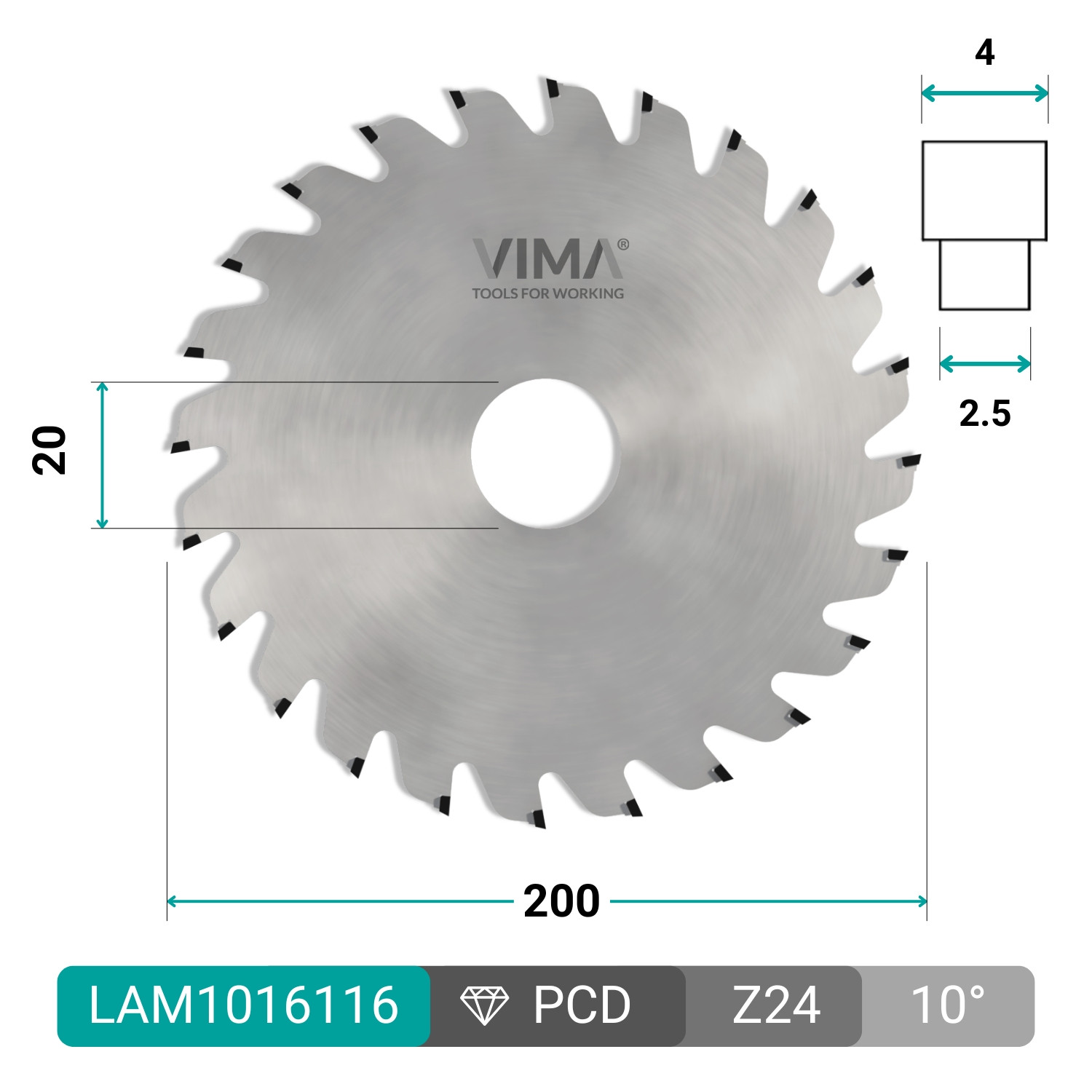

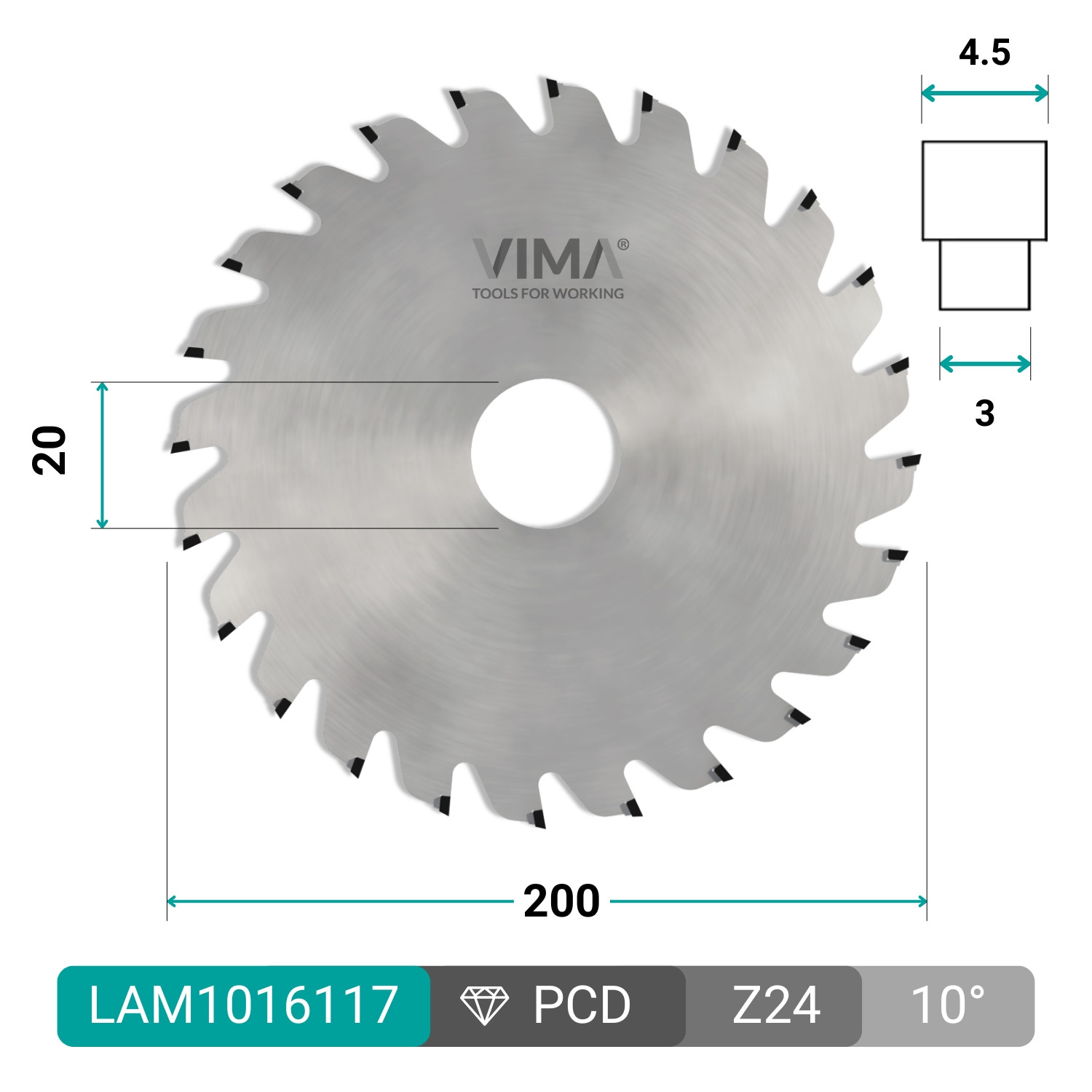

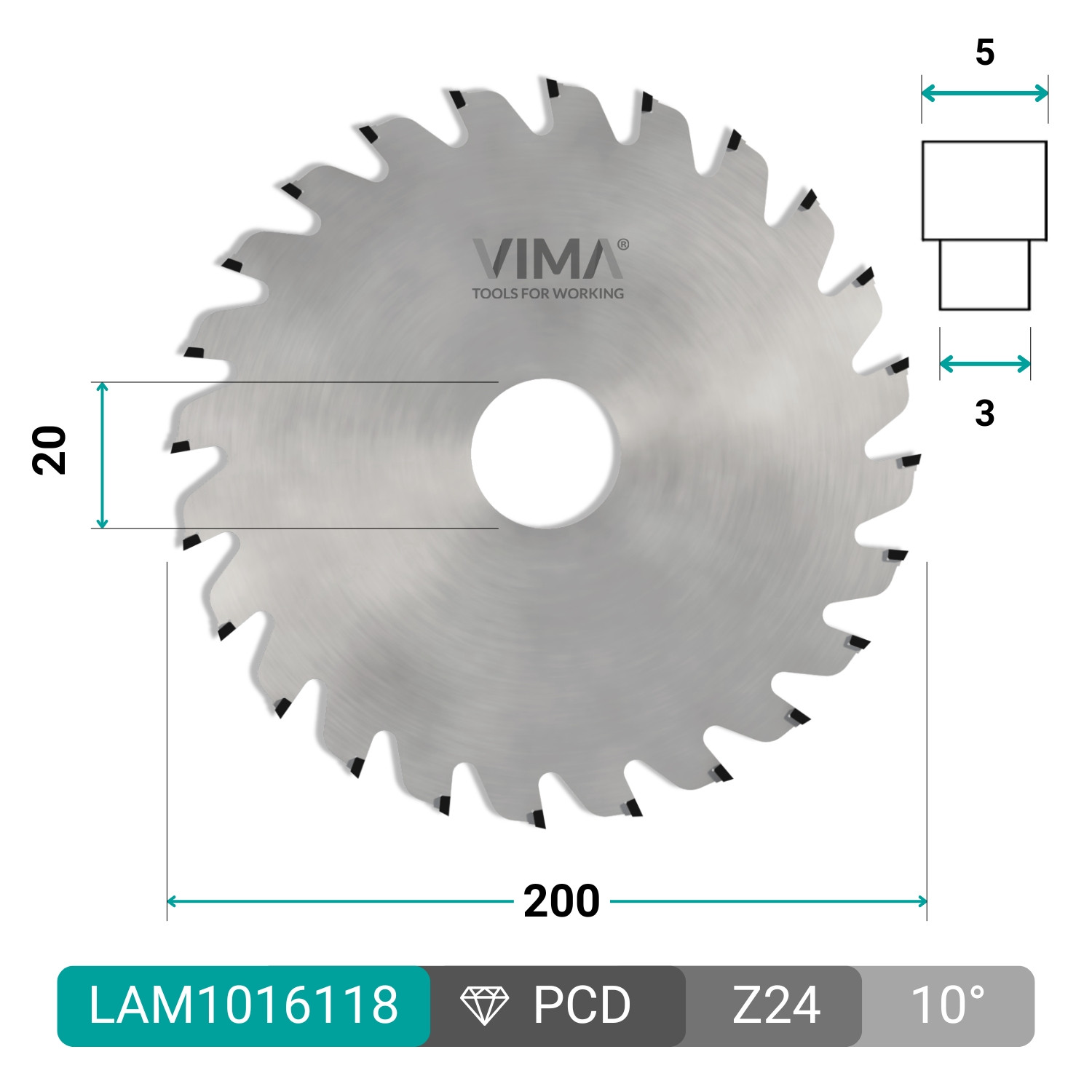

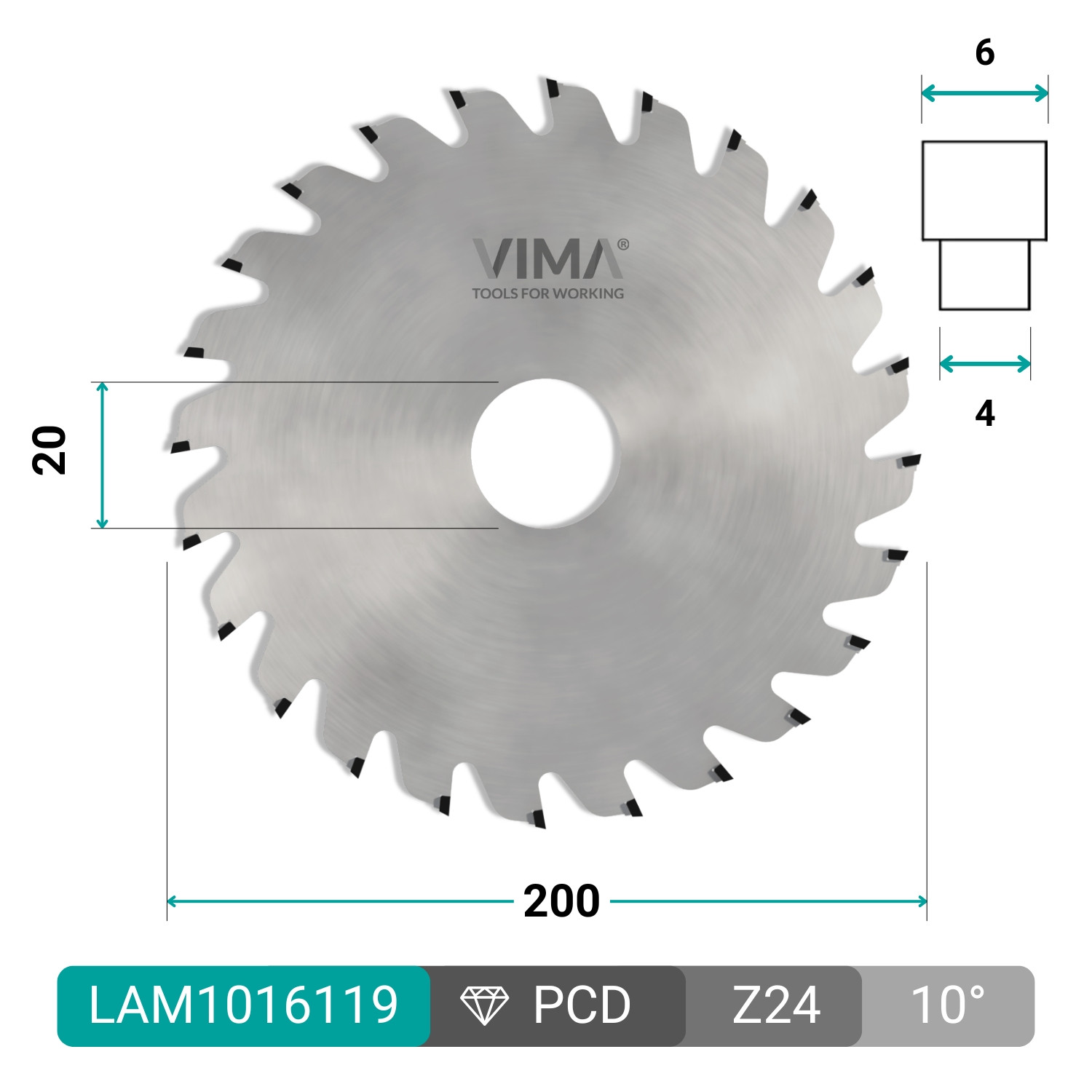

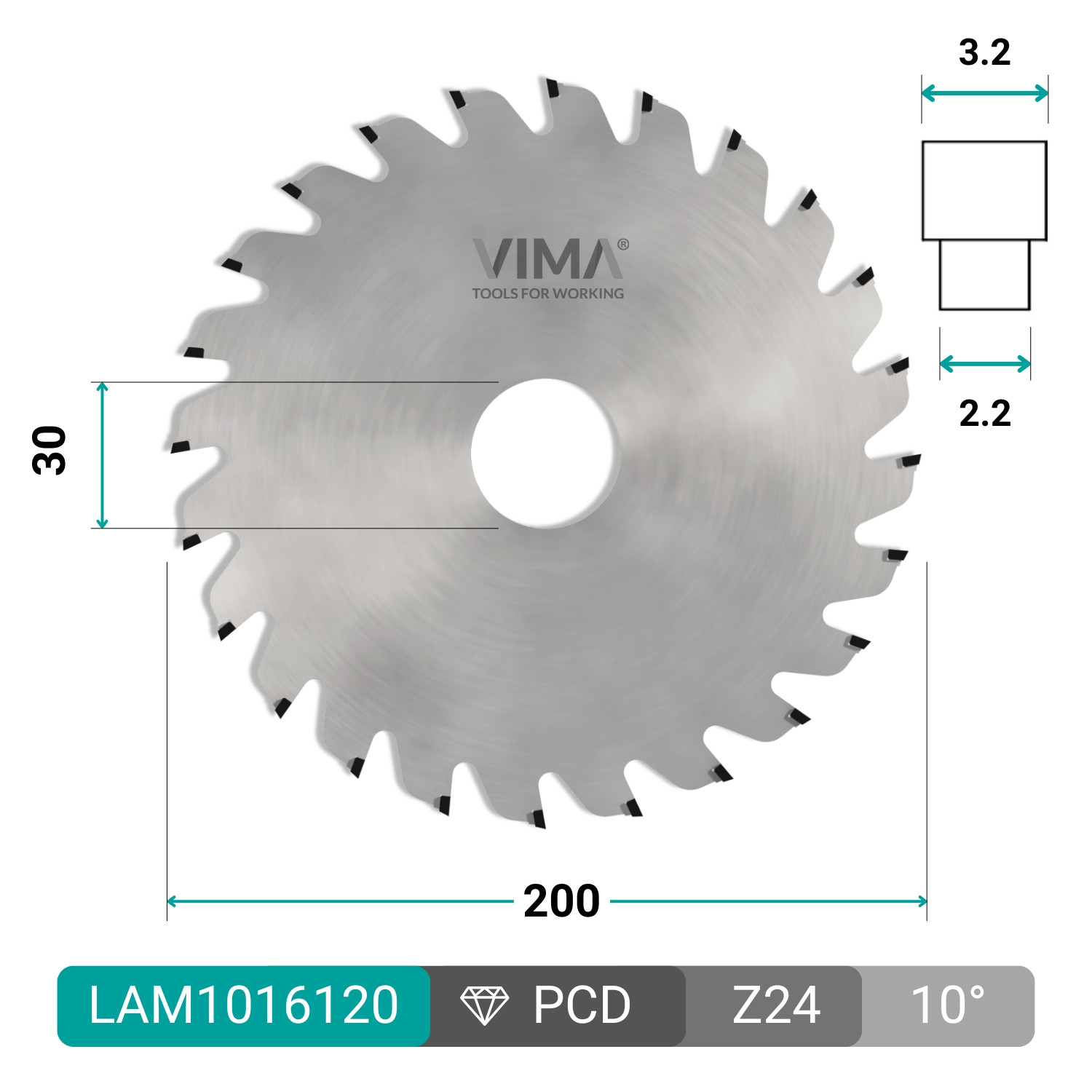

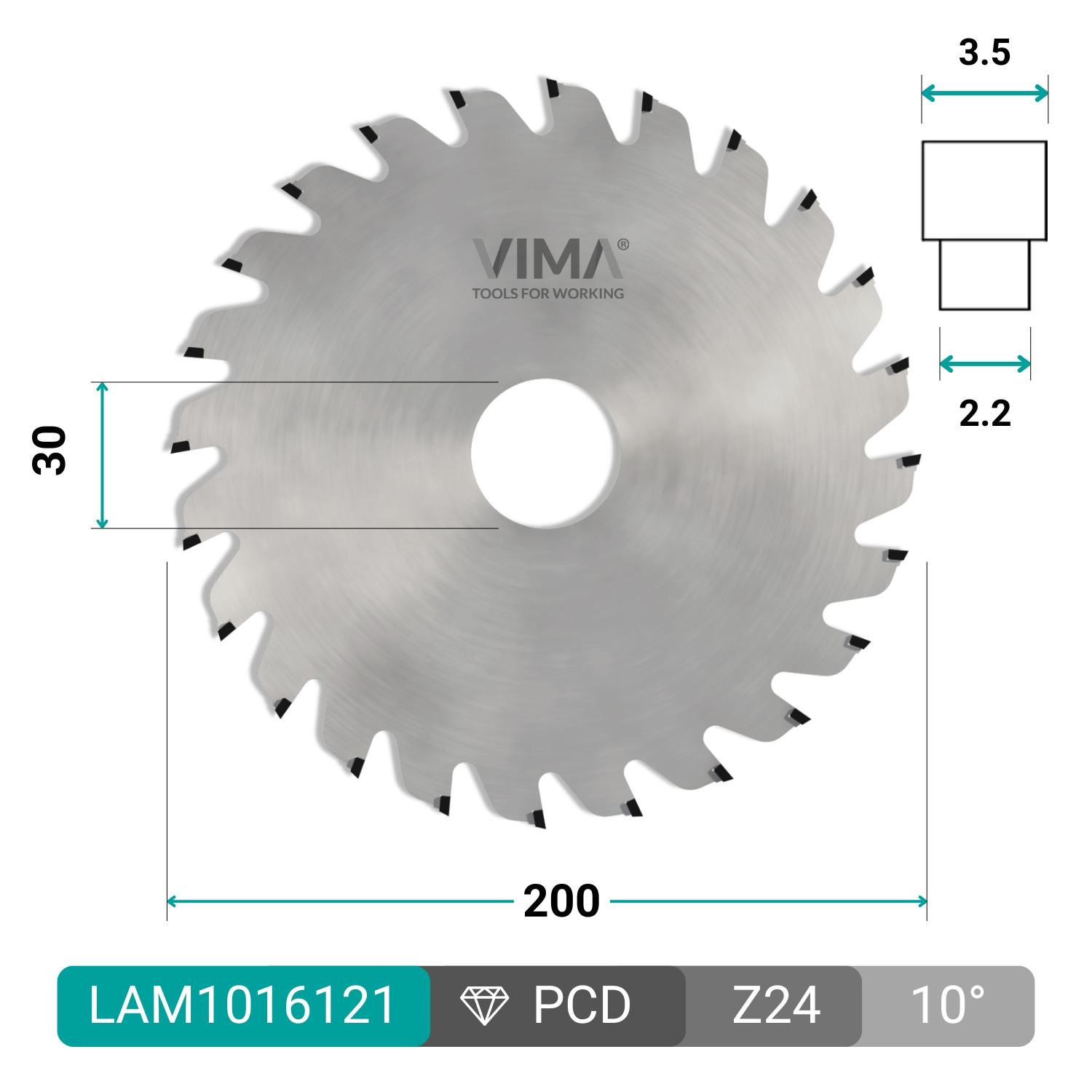

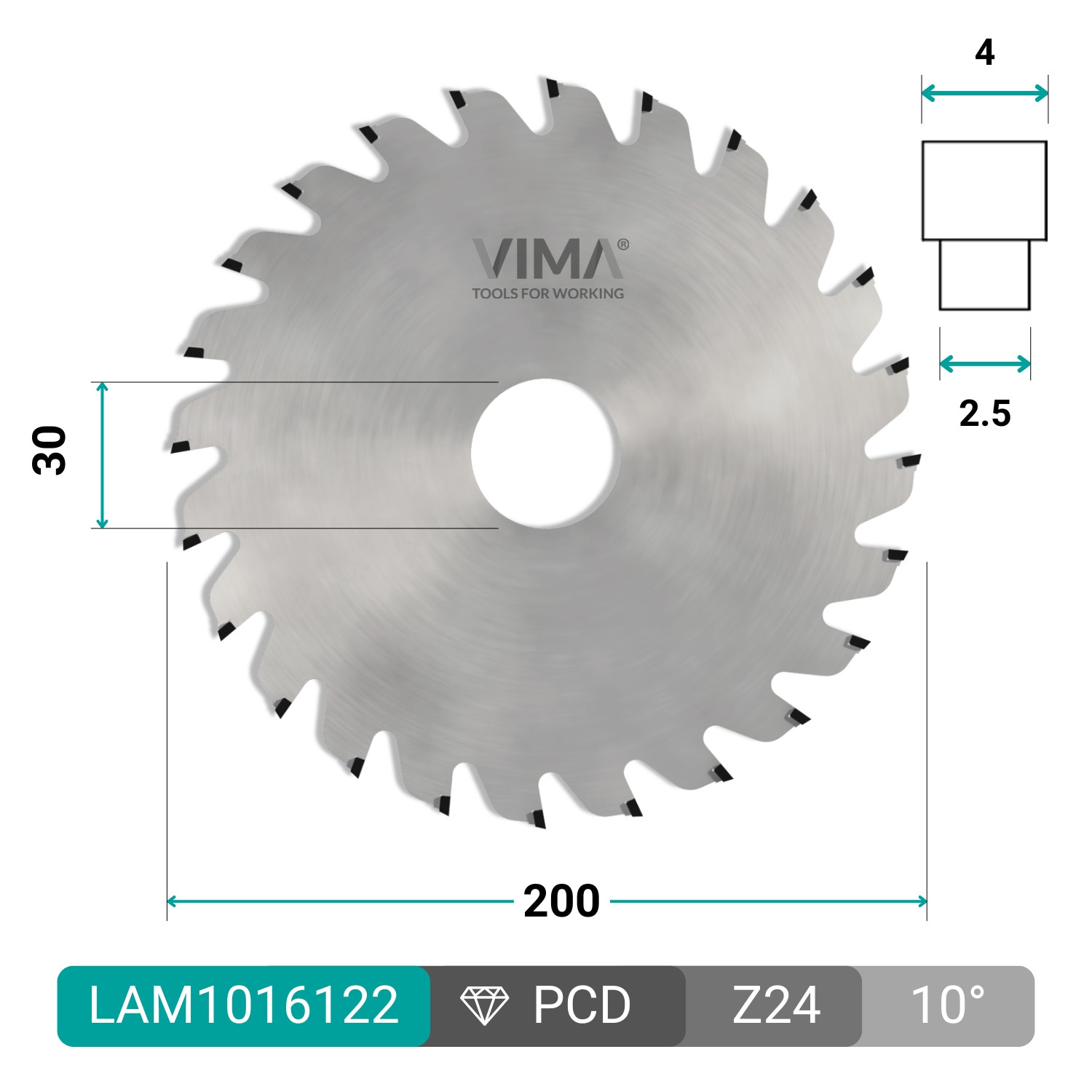

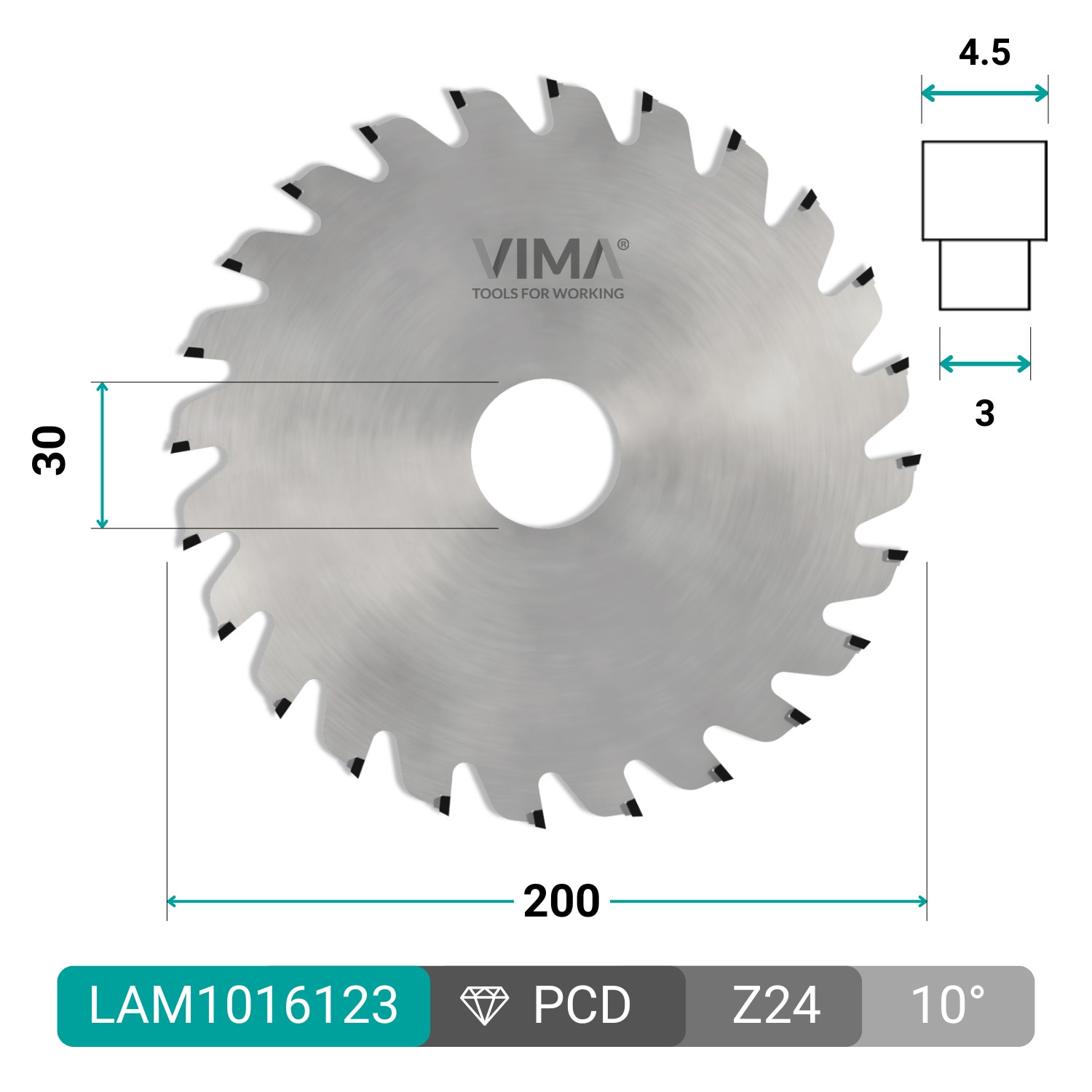

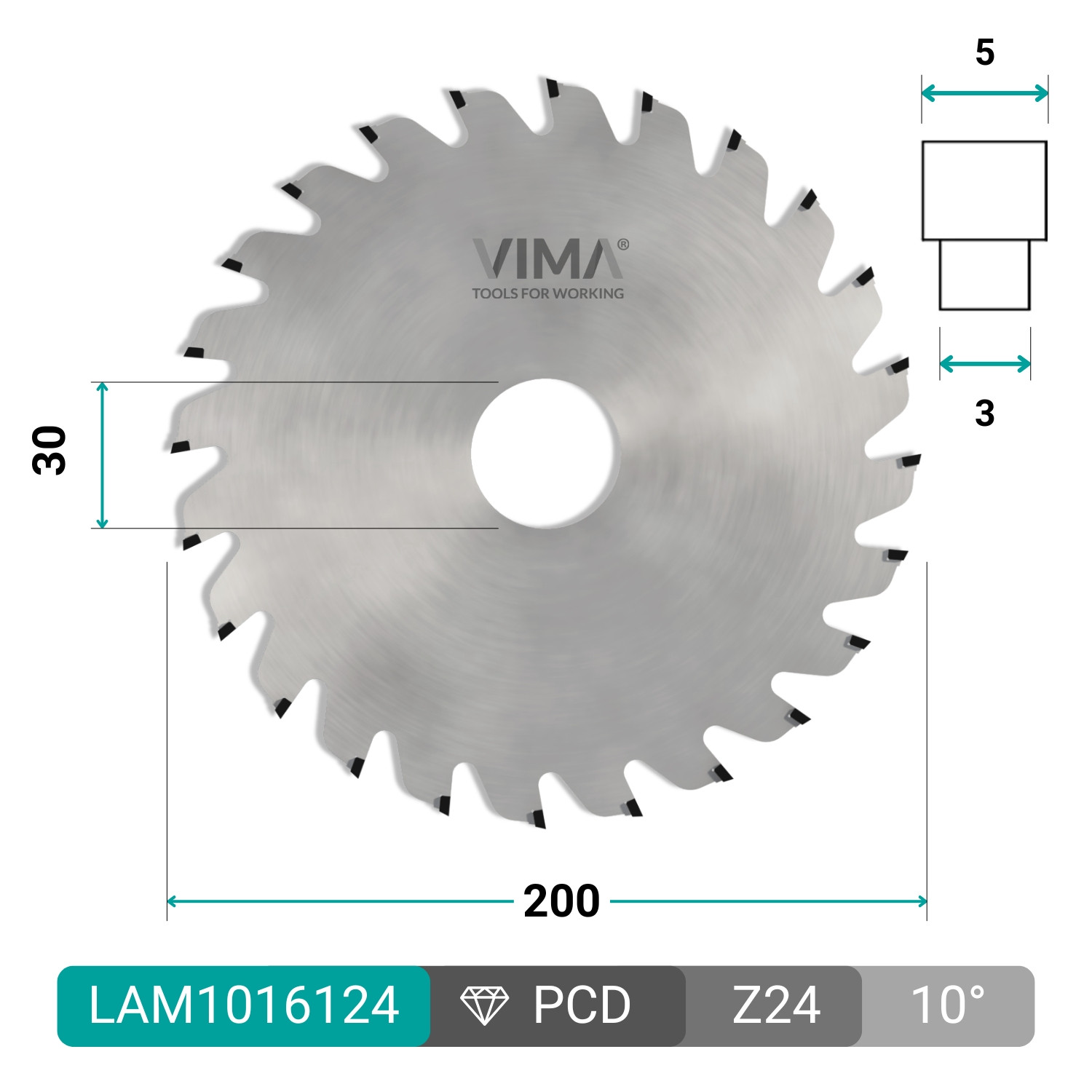

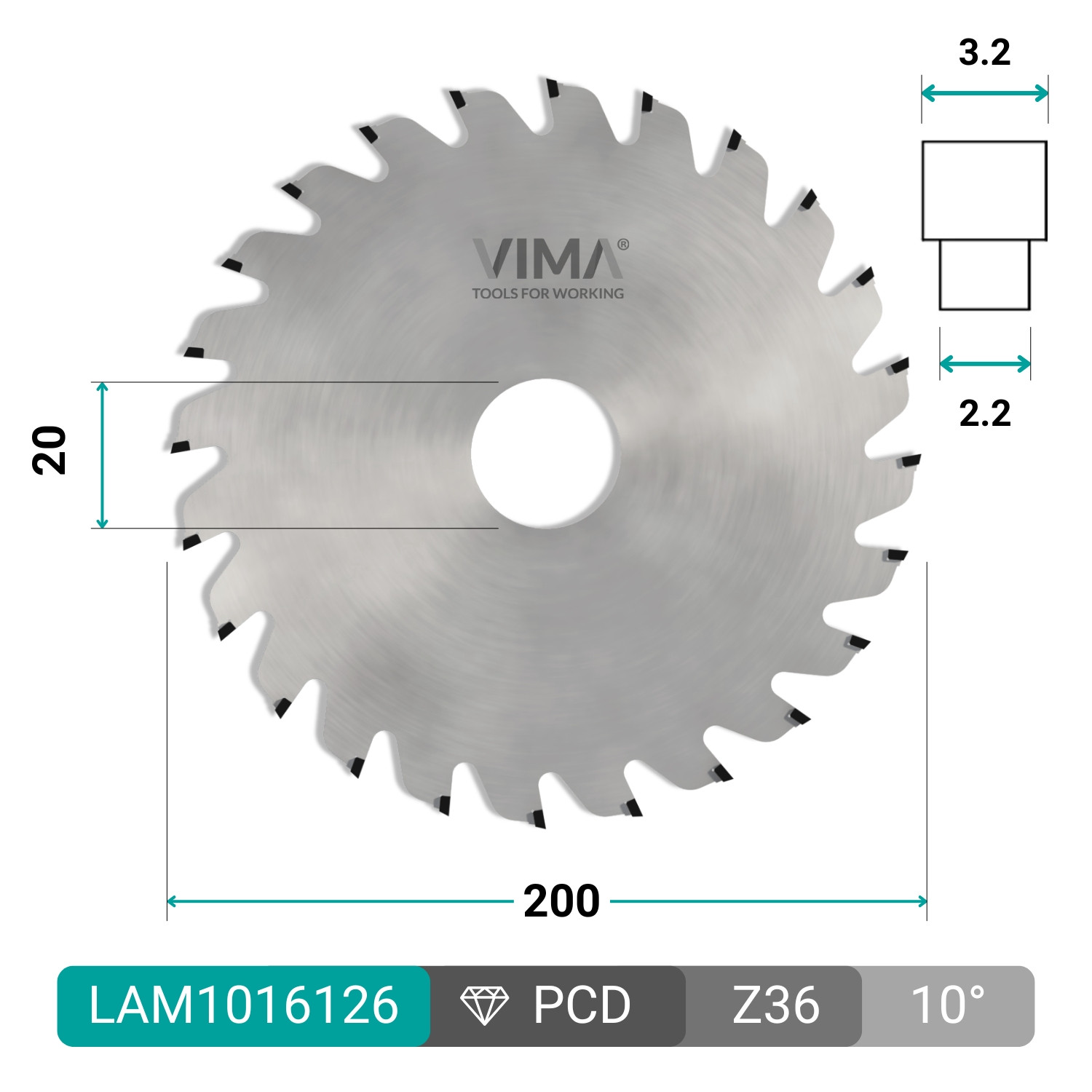

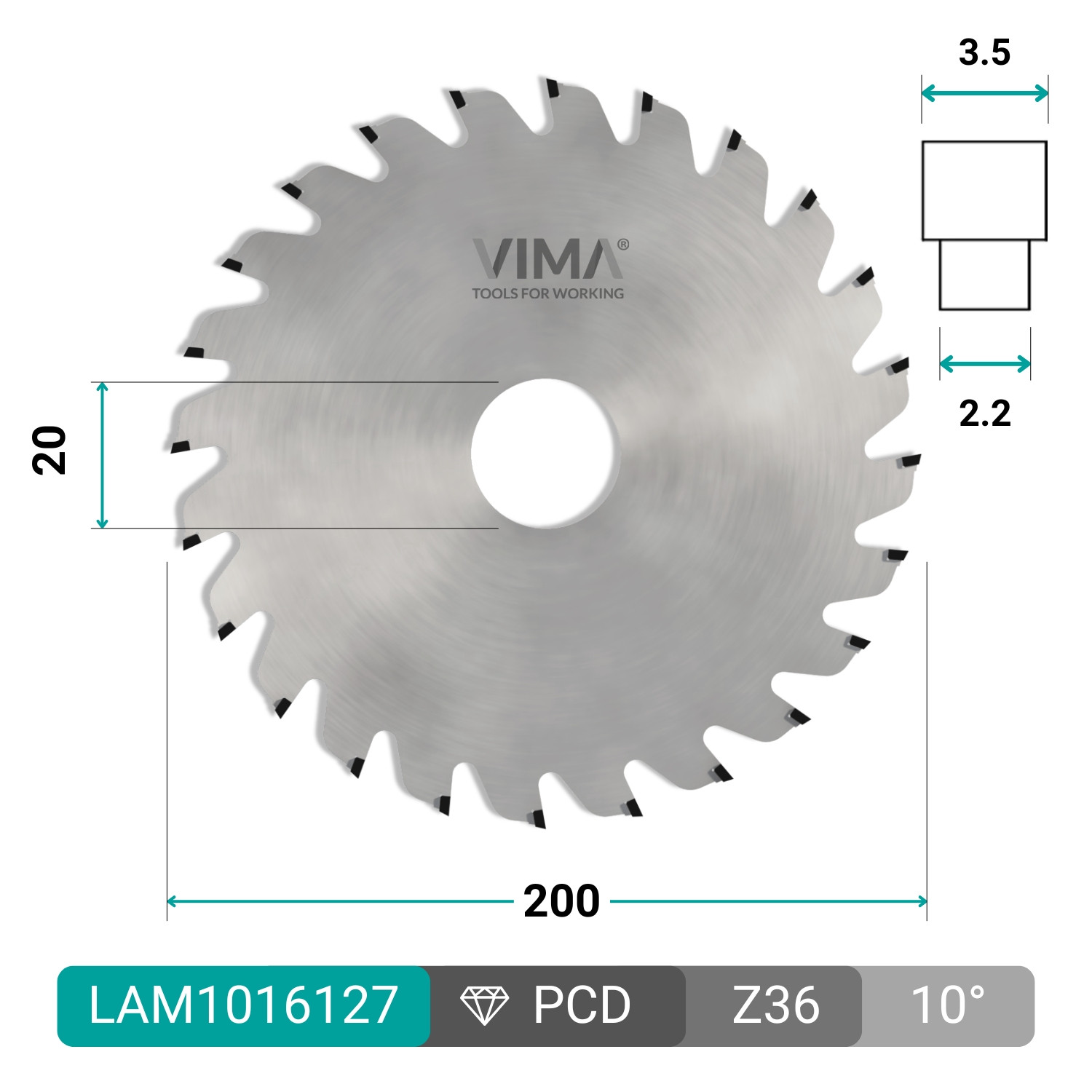

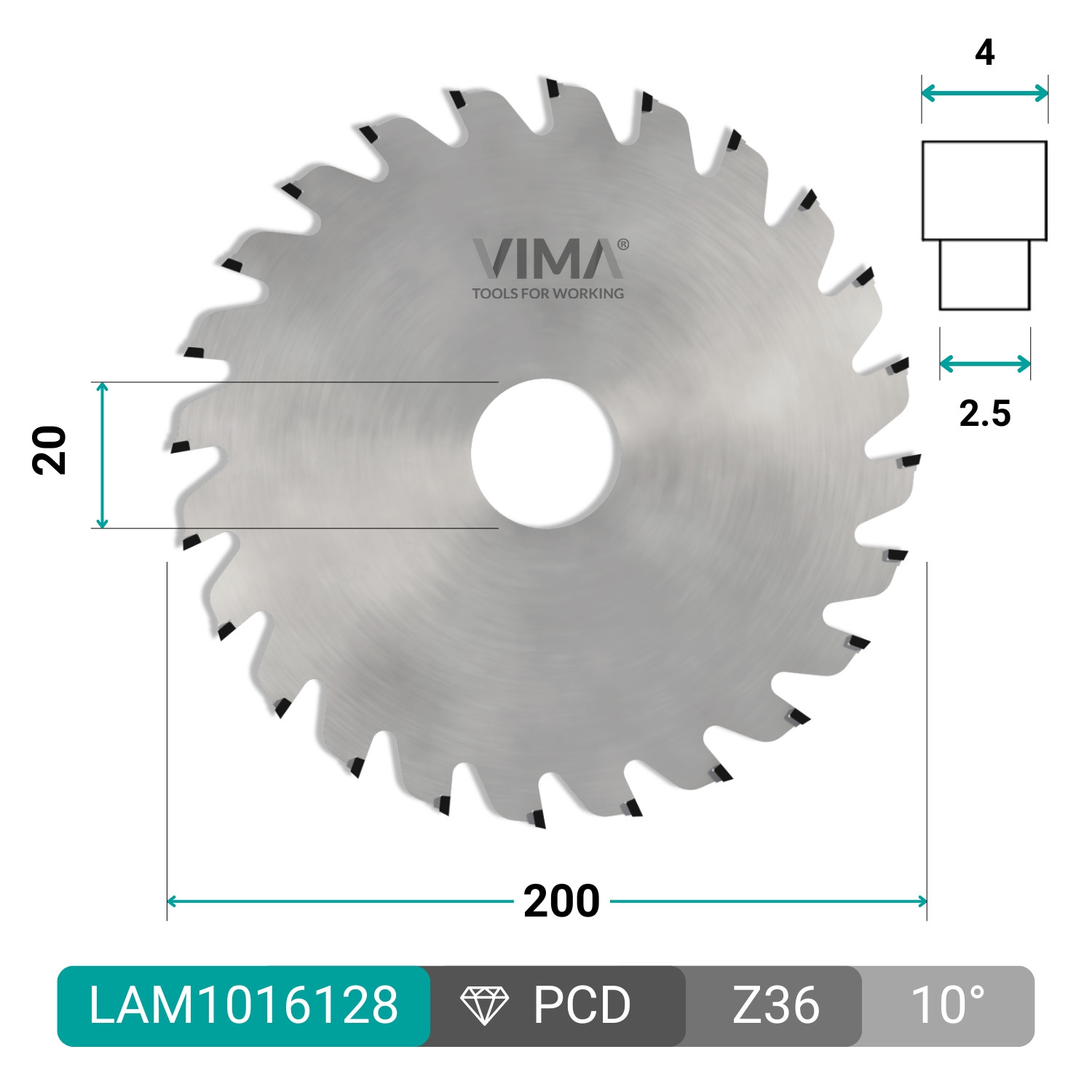

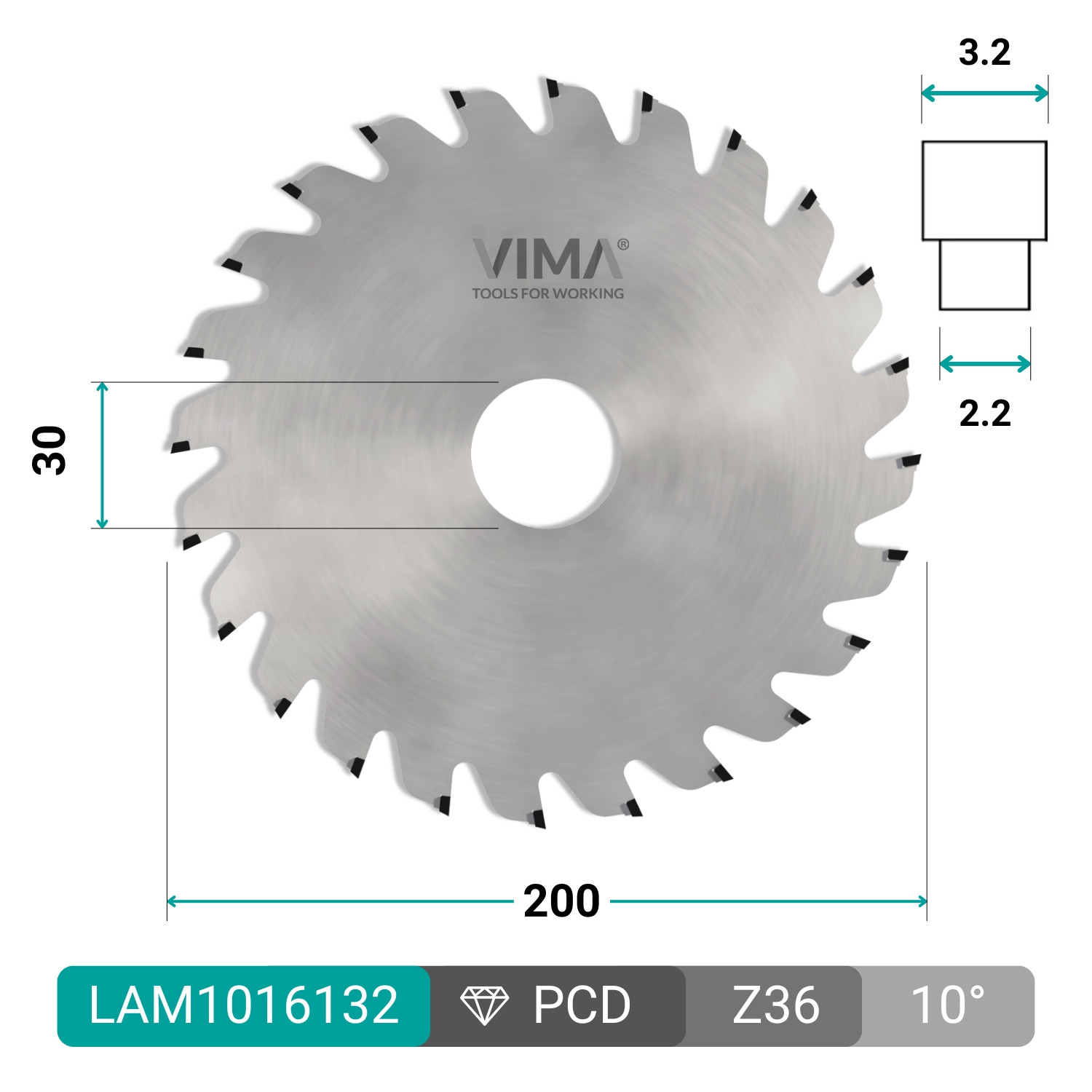

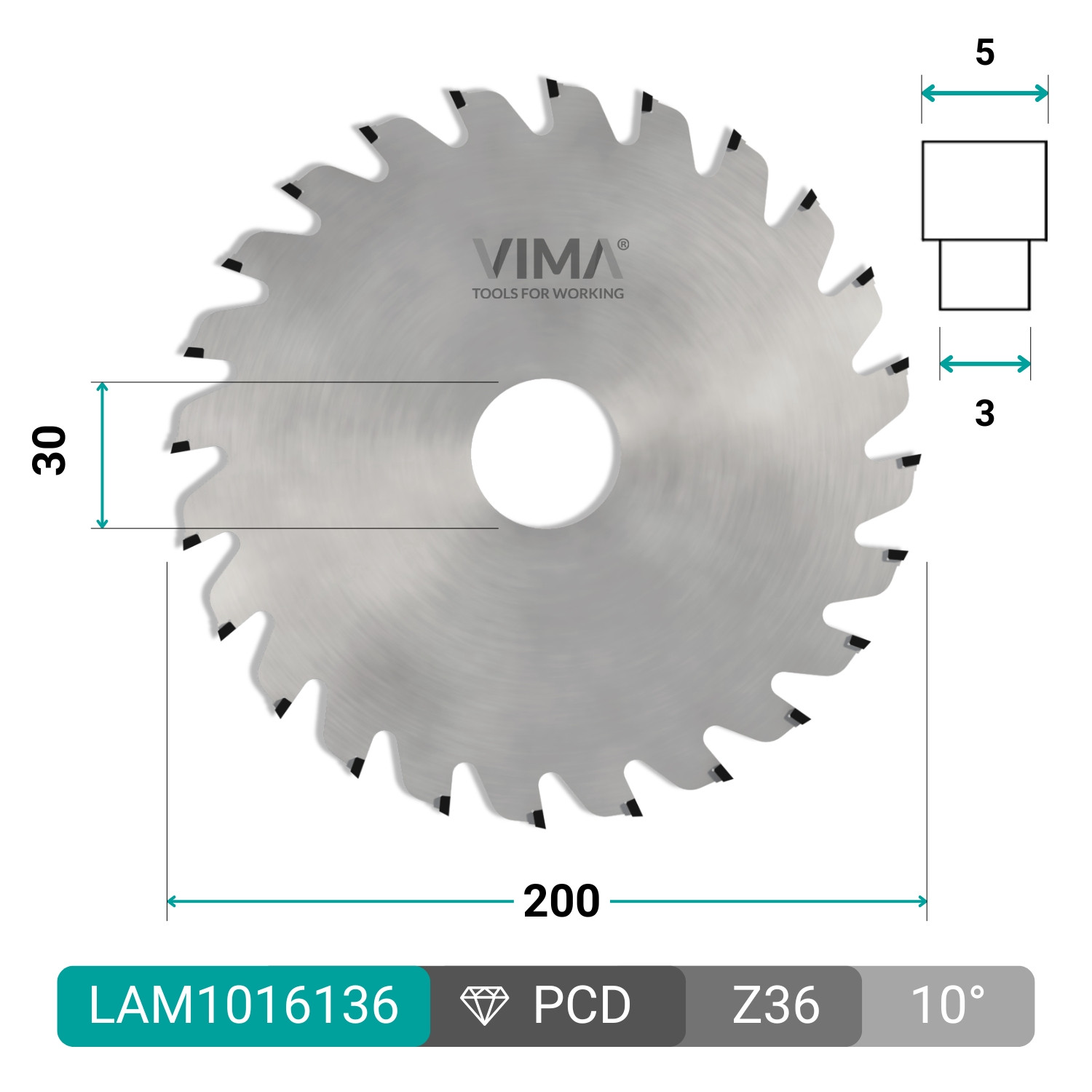

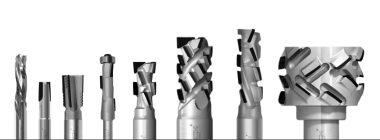

PCD circular blade engineered for grooving applications with alternate bevel sharpening (DX/SX). The H6 PCD tip delivers superior durability and clean cutting results on MDF/HDF, particle board and plywood.

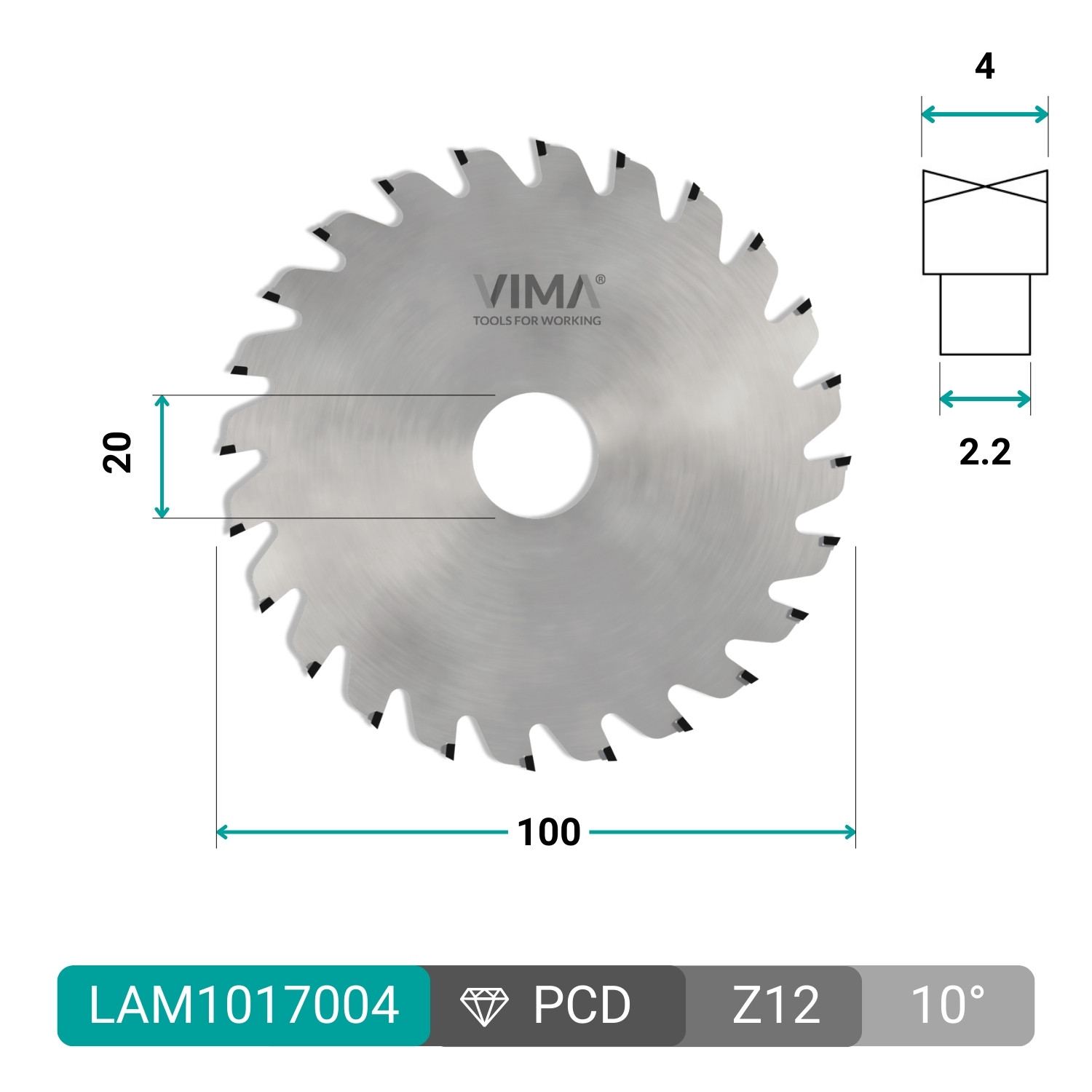

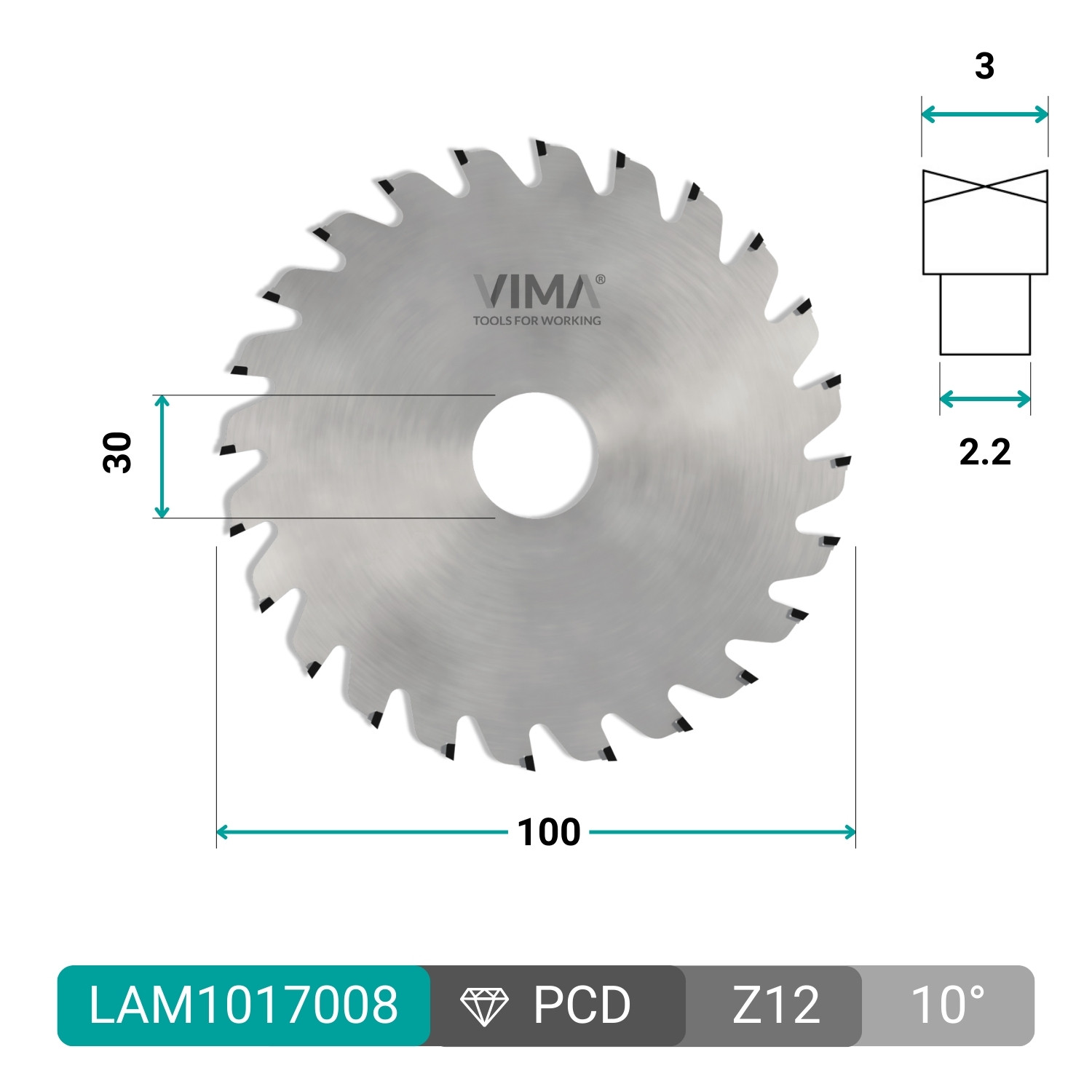

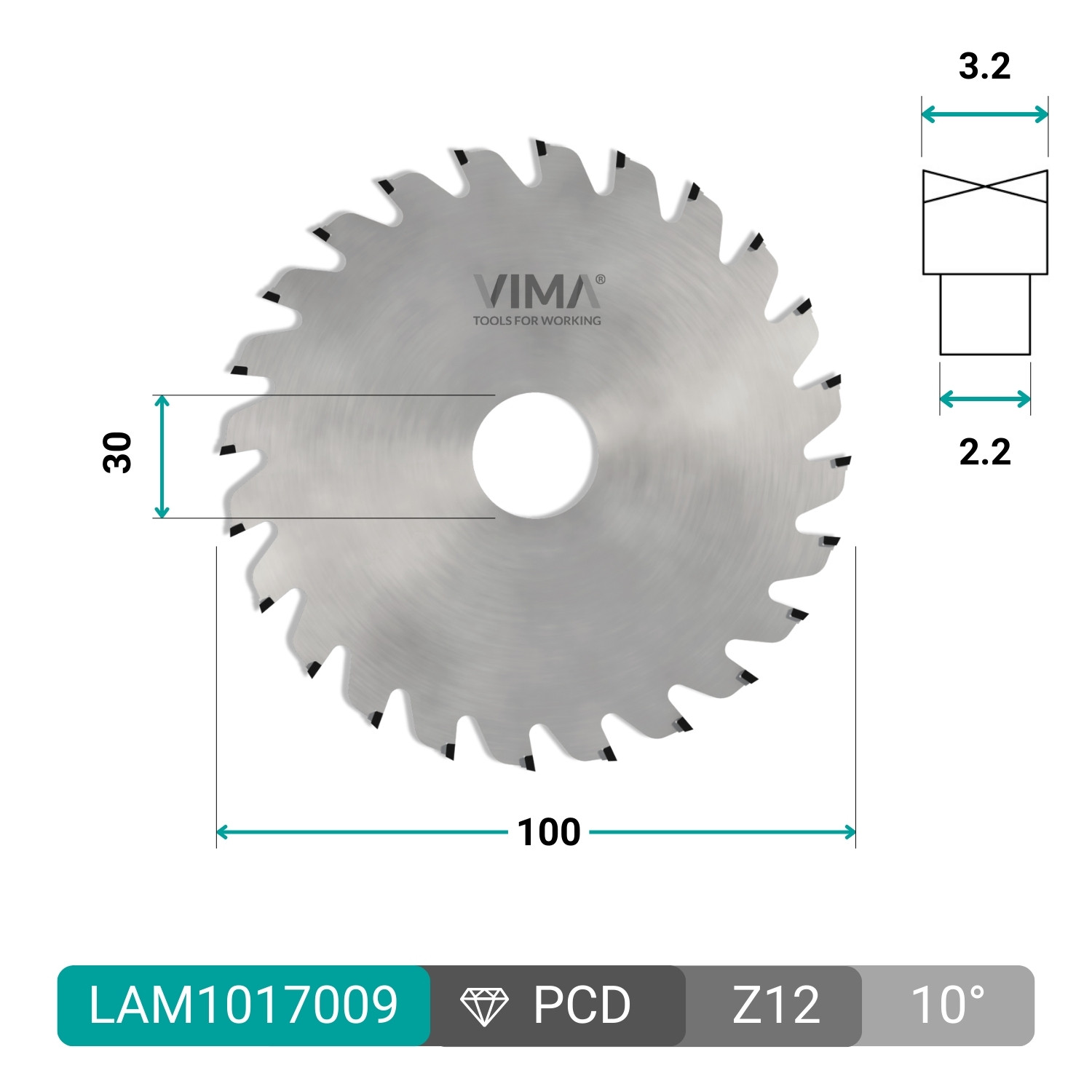

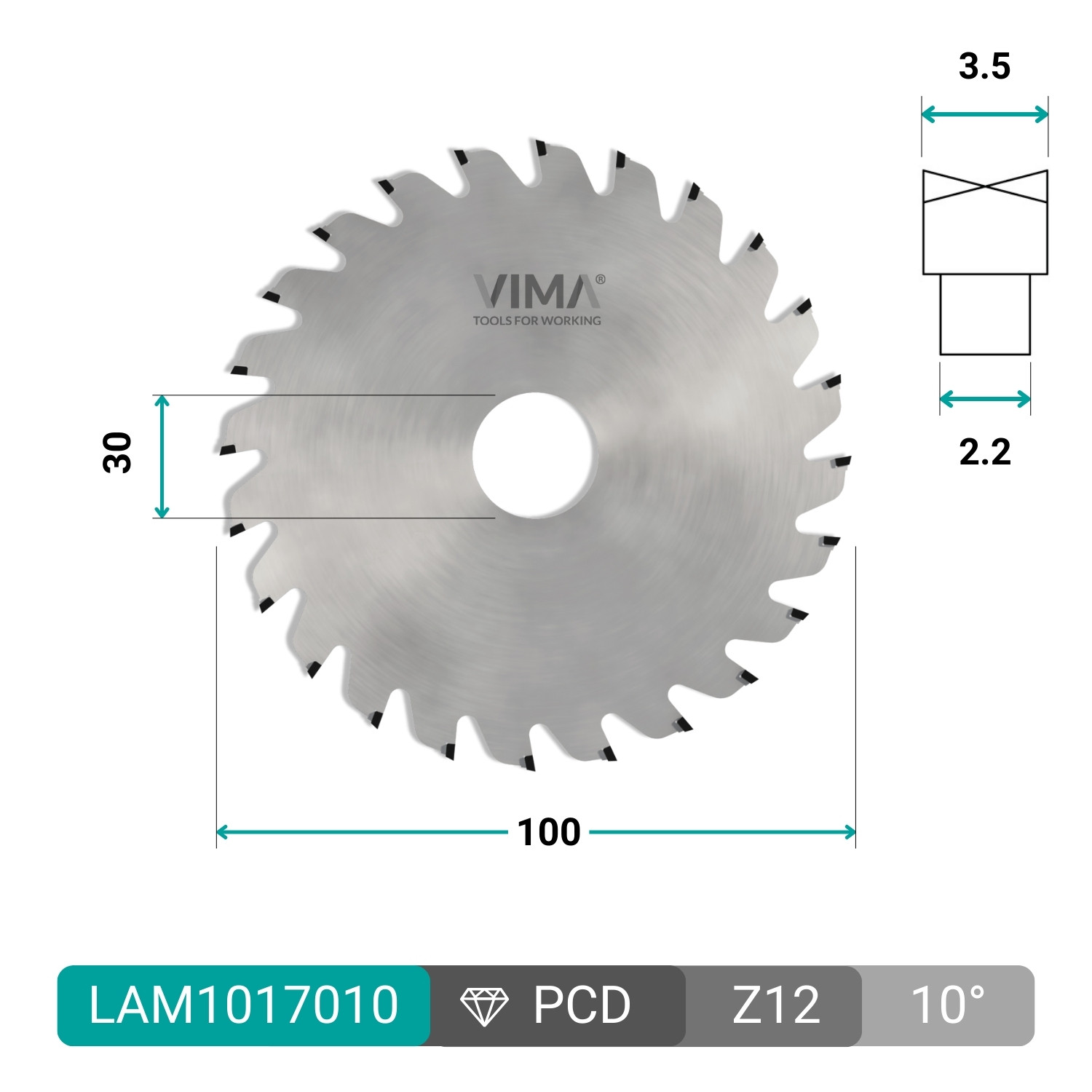

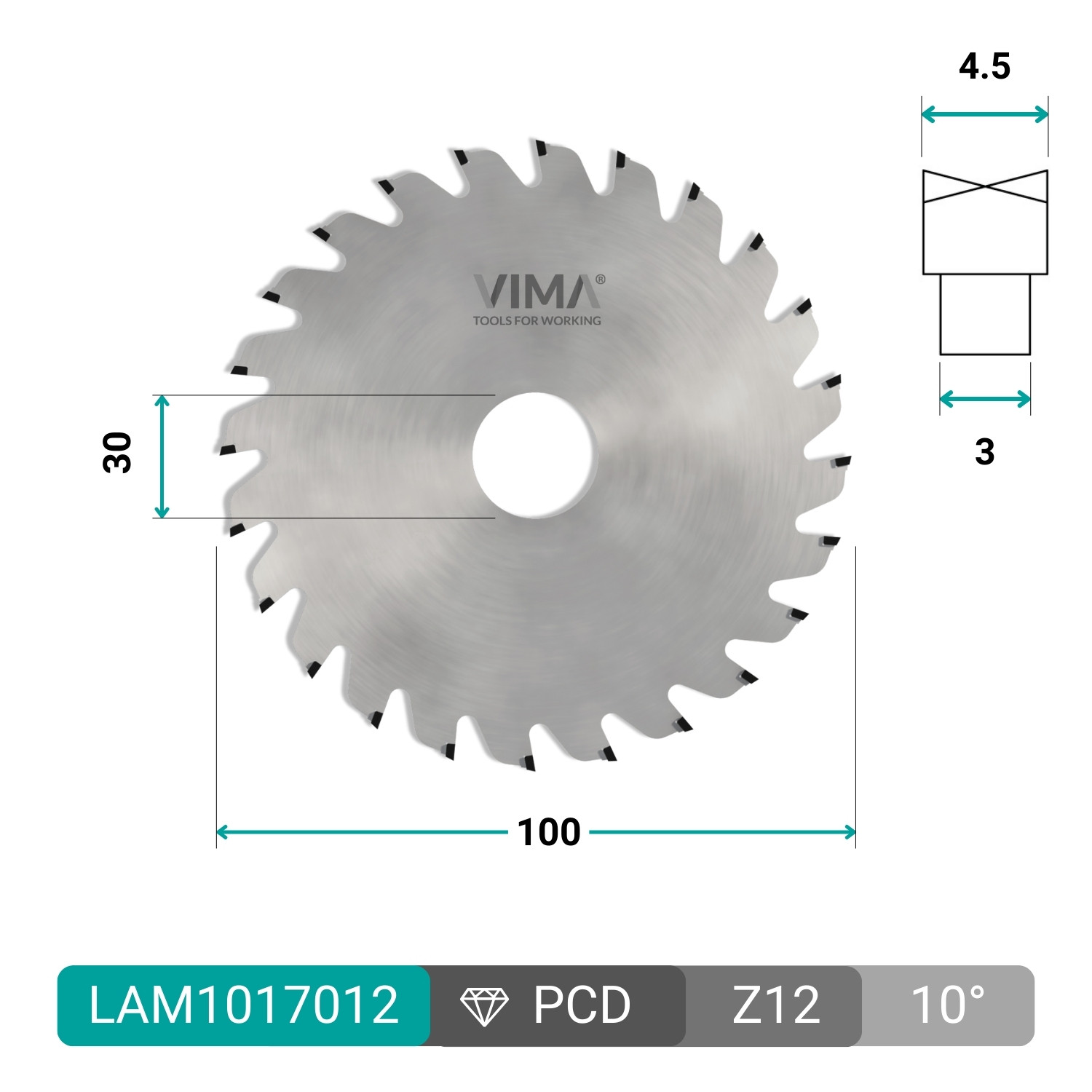

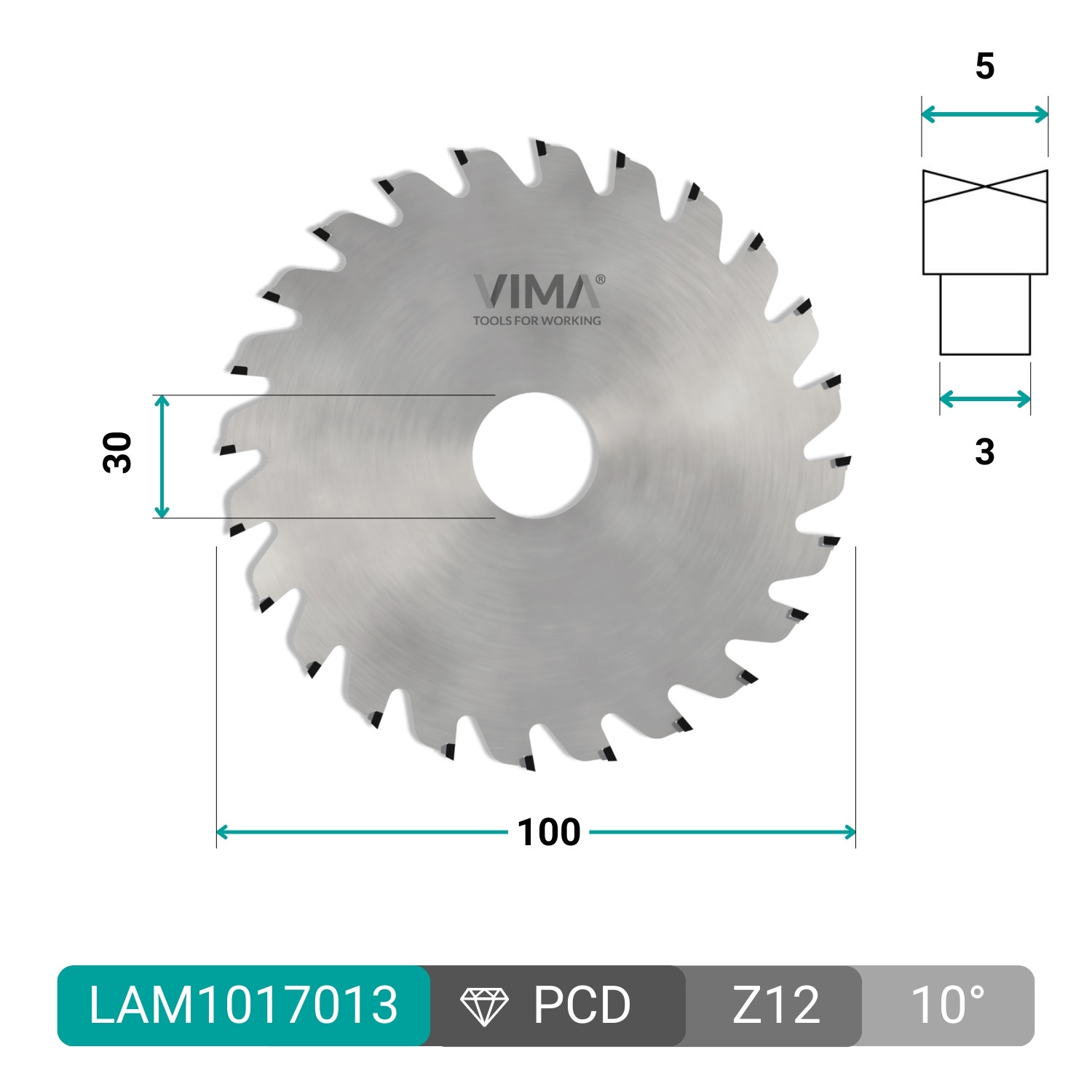

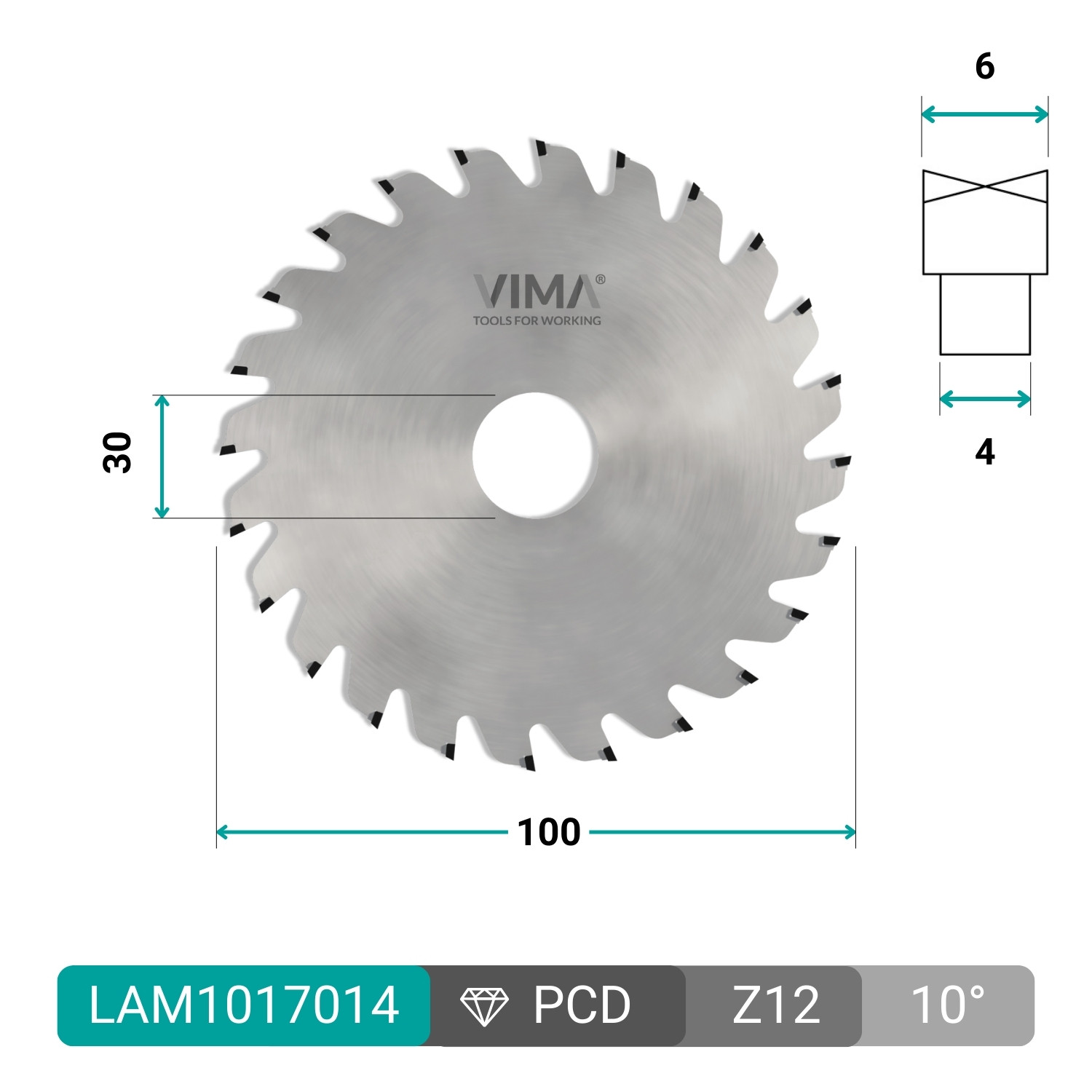

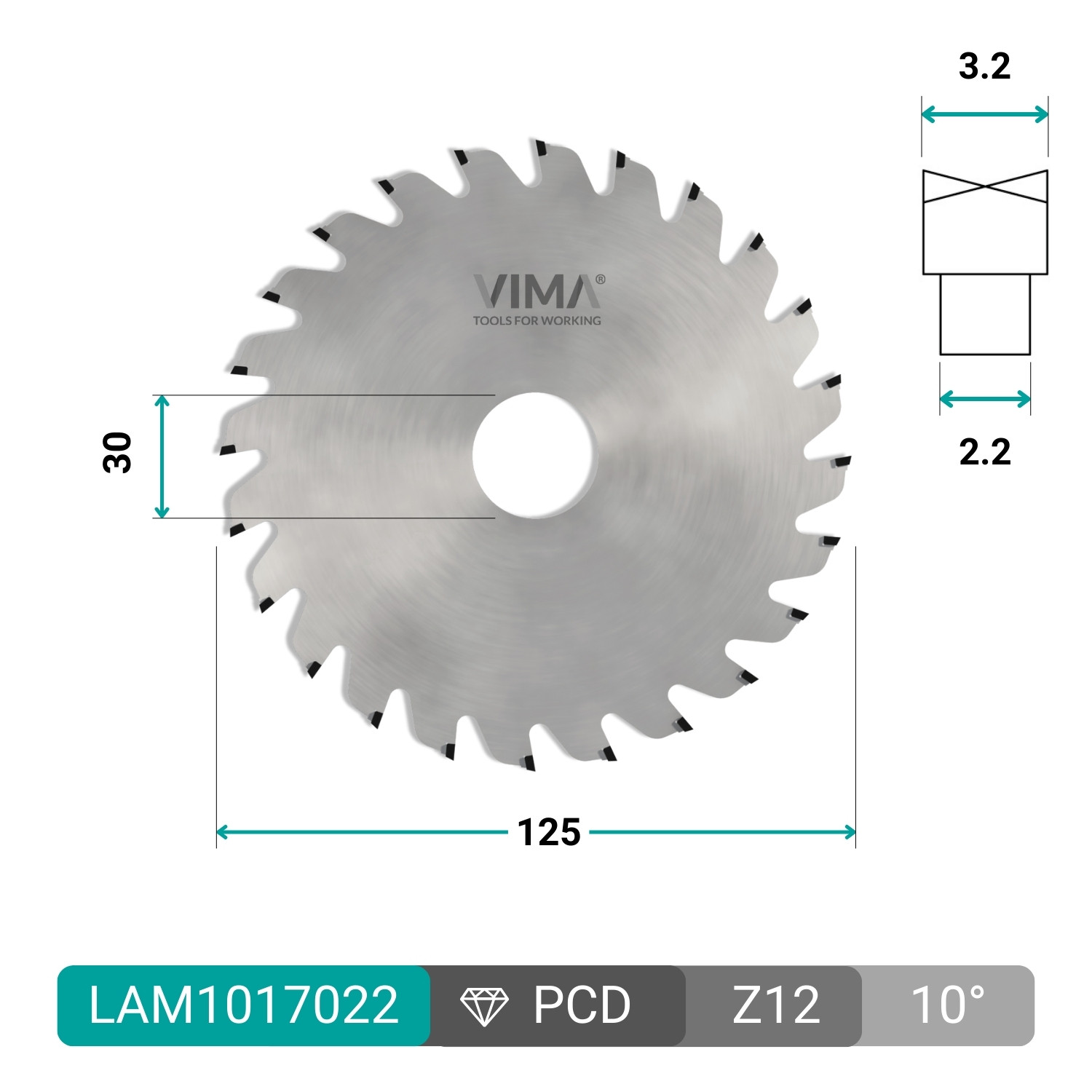

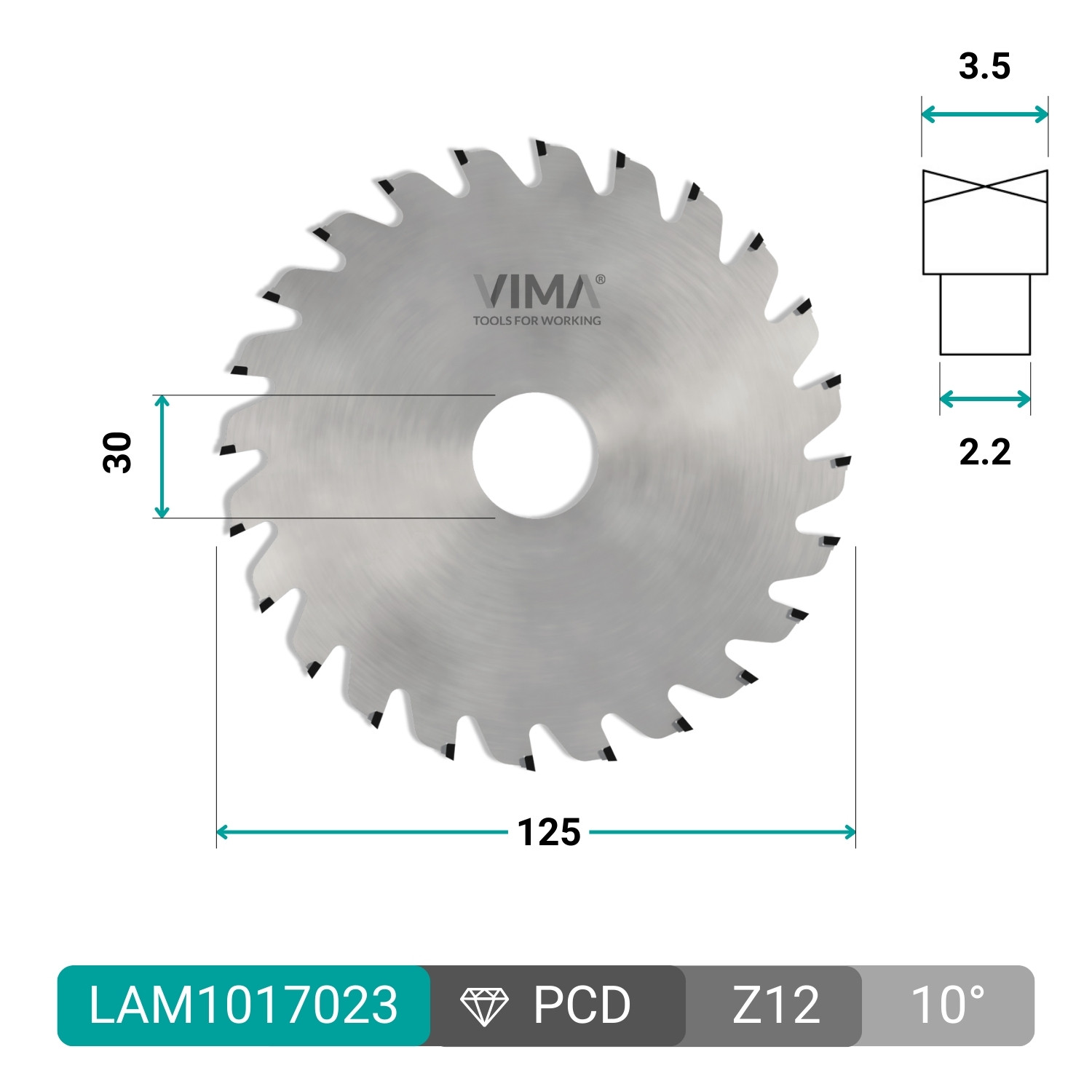

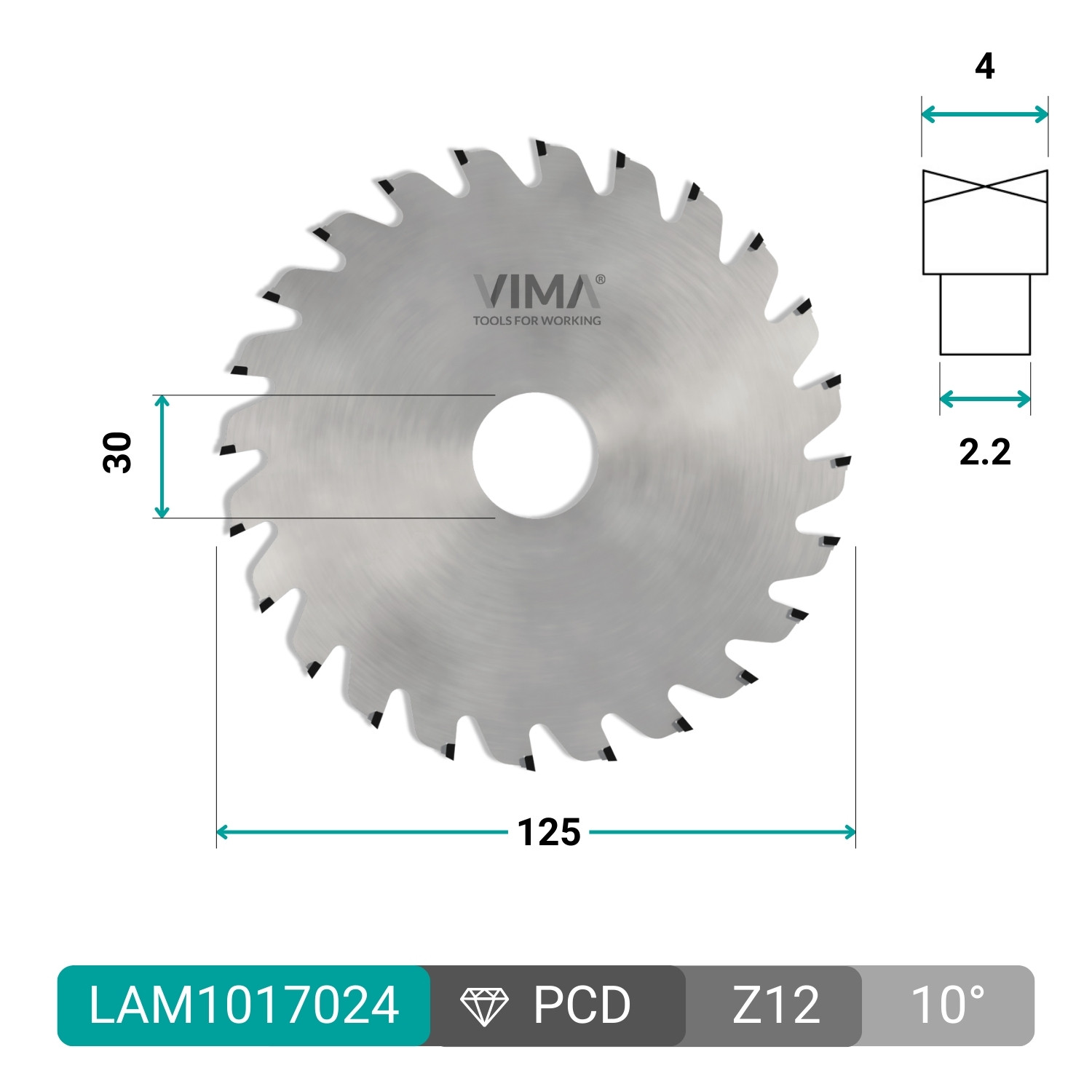

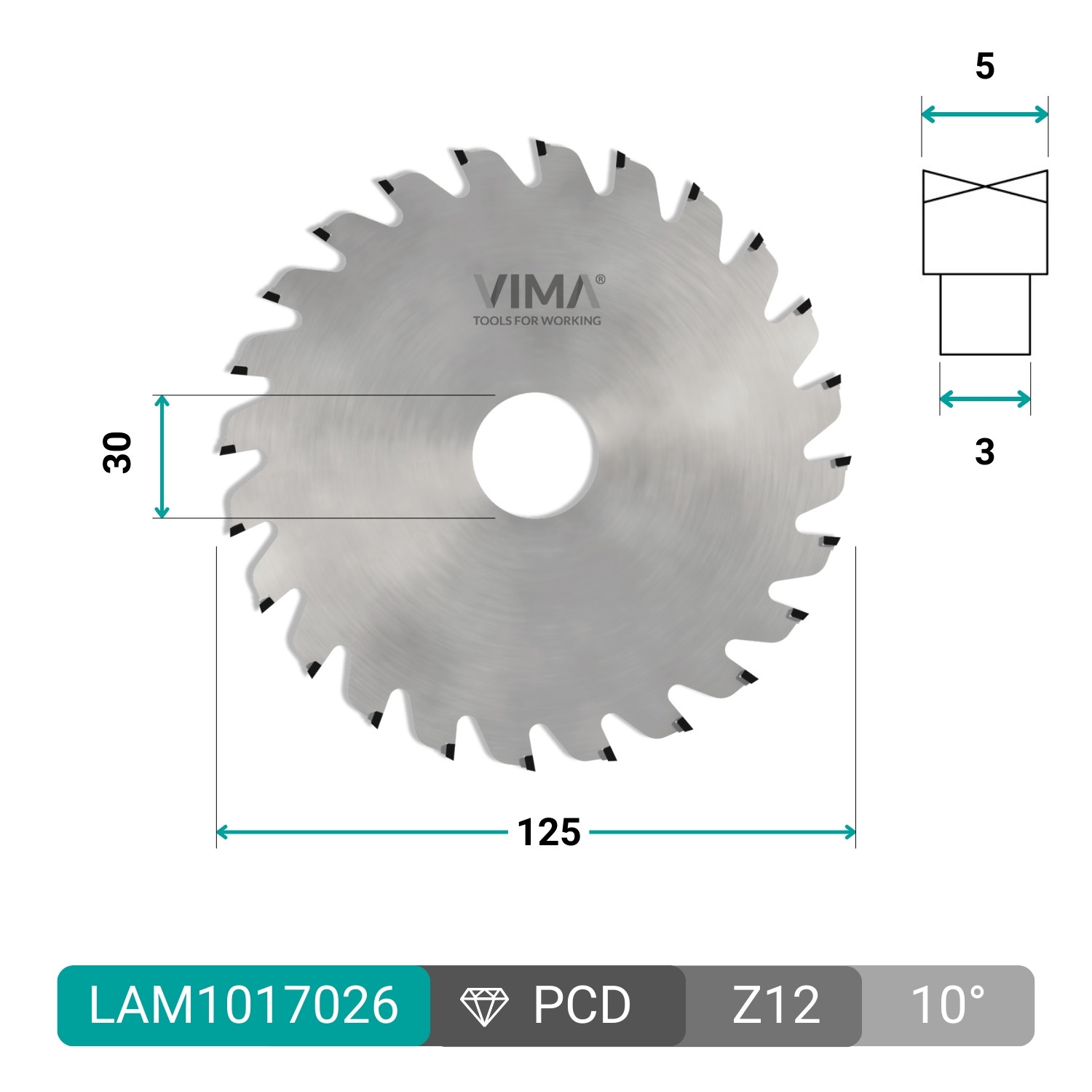

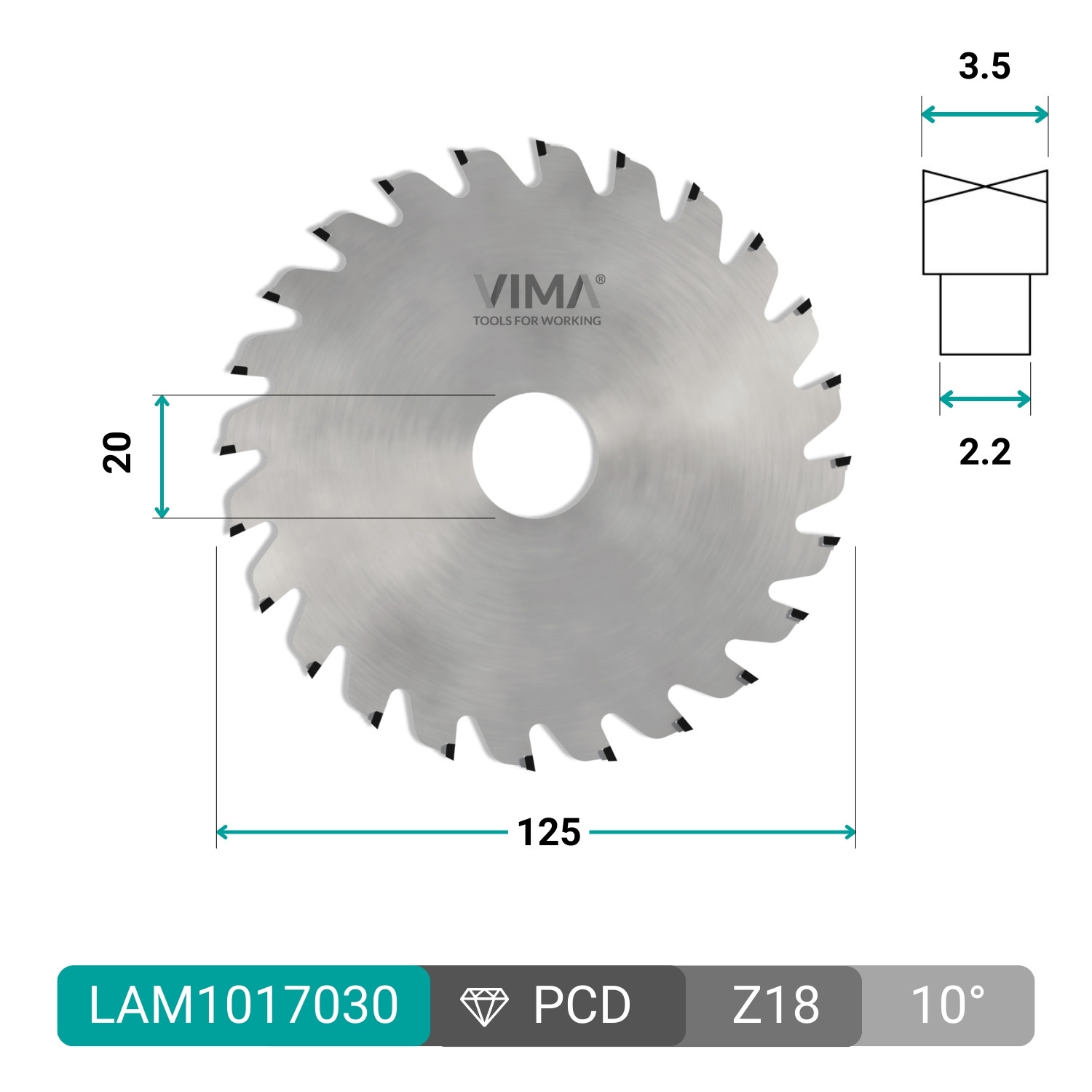

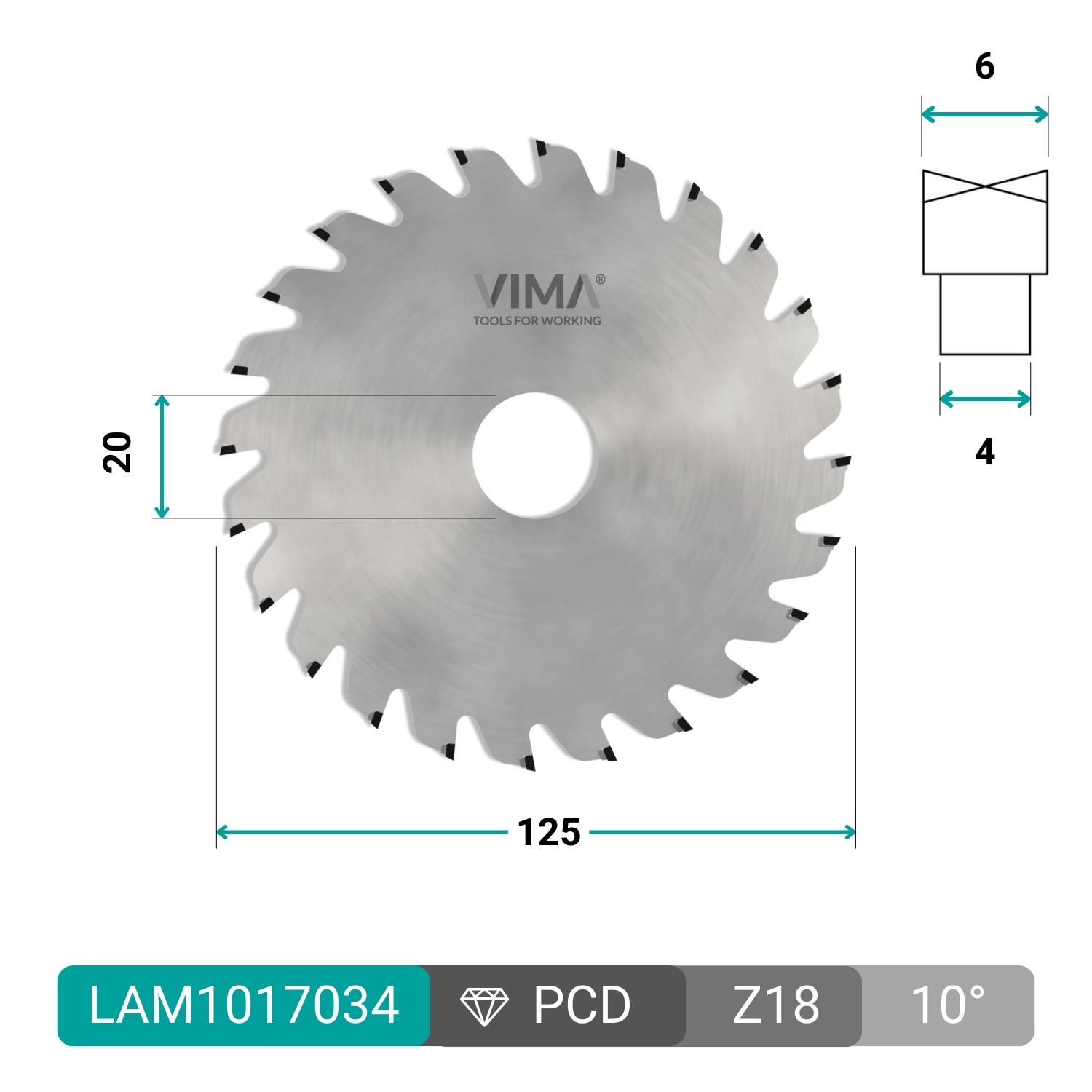

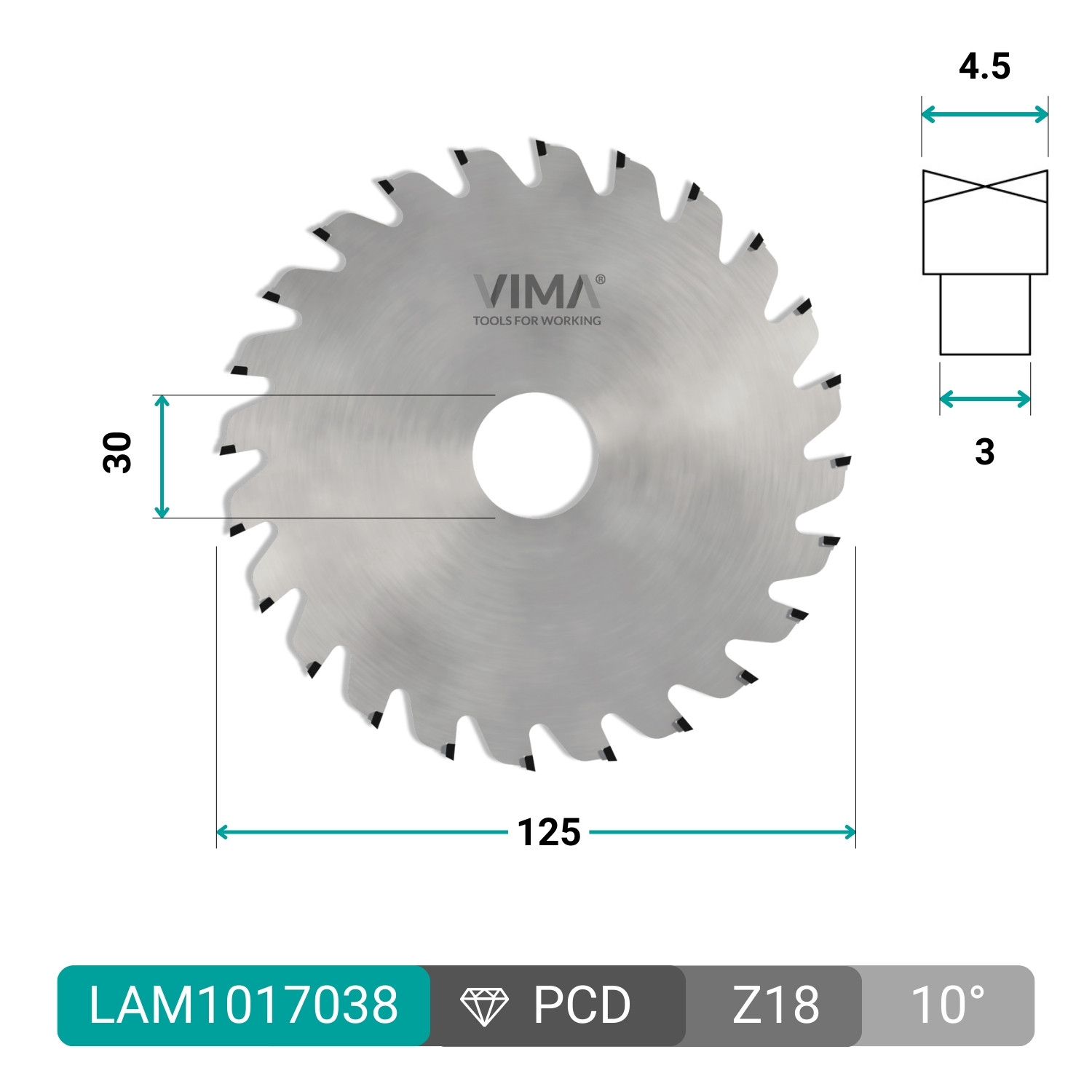

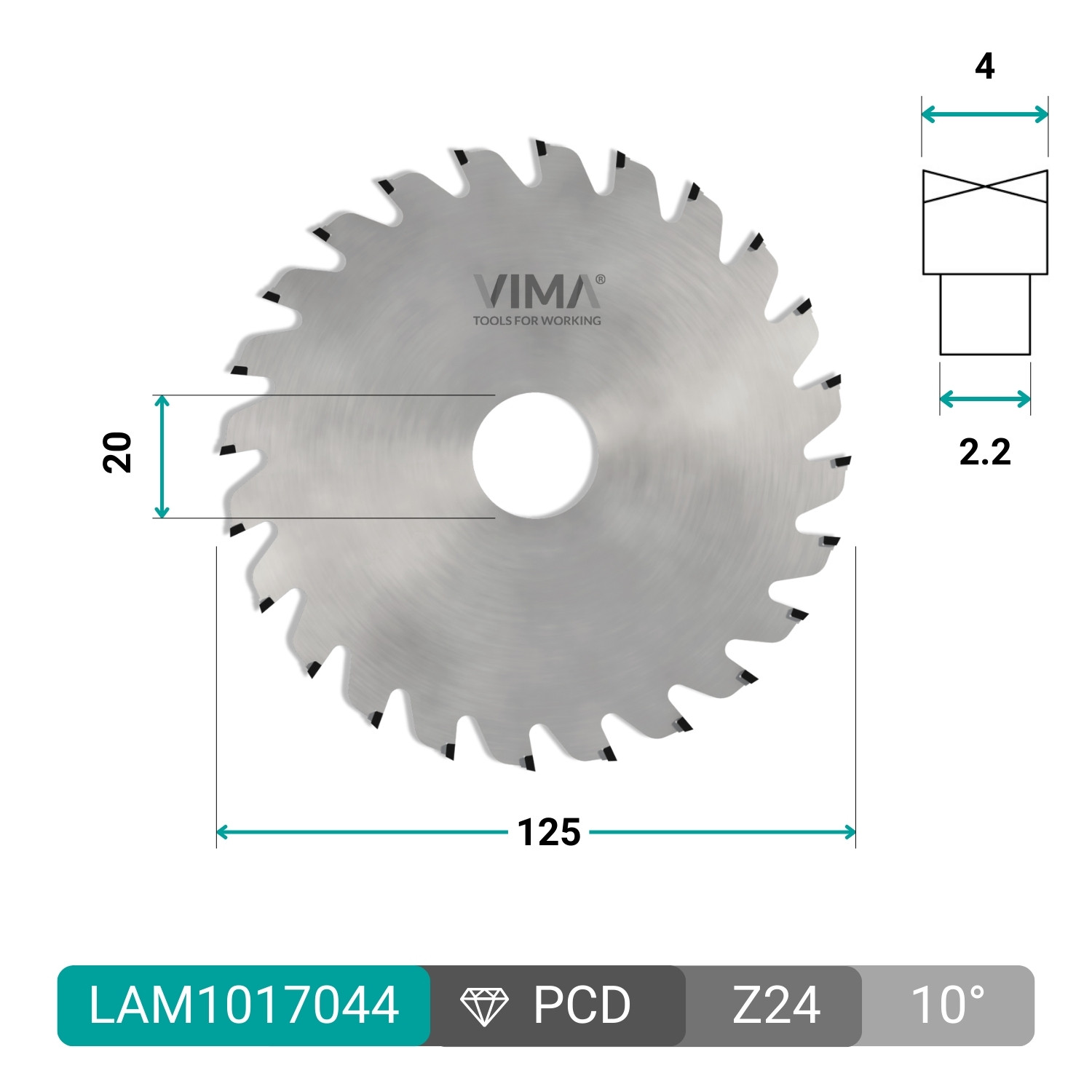

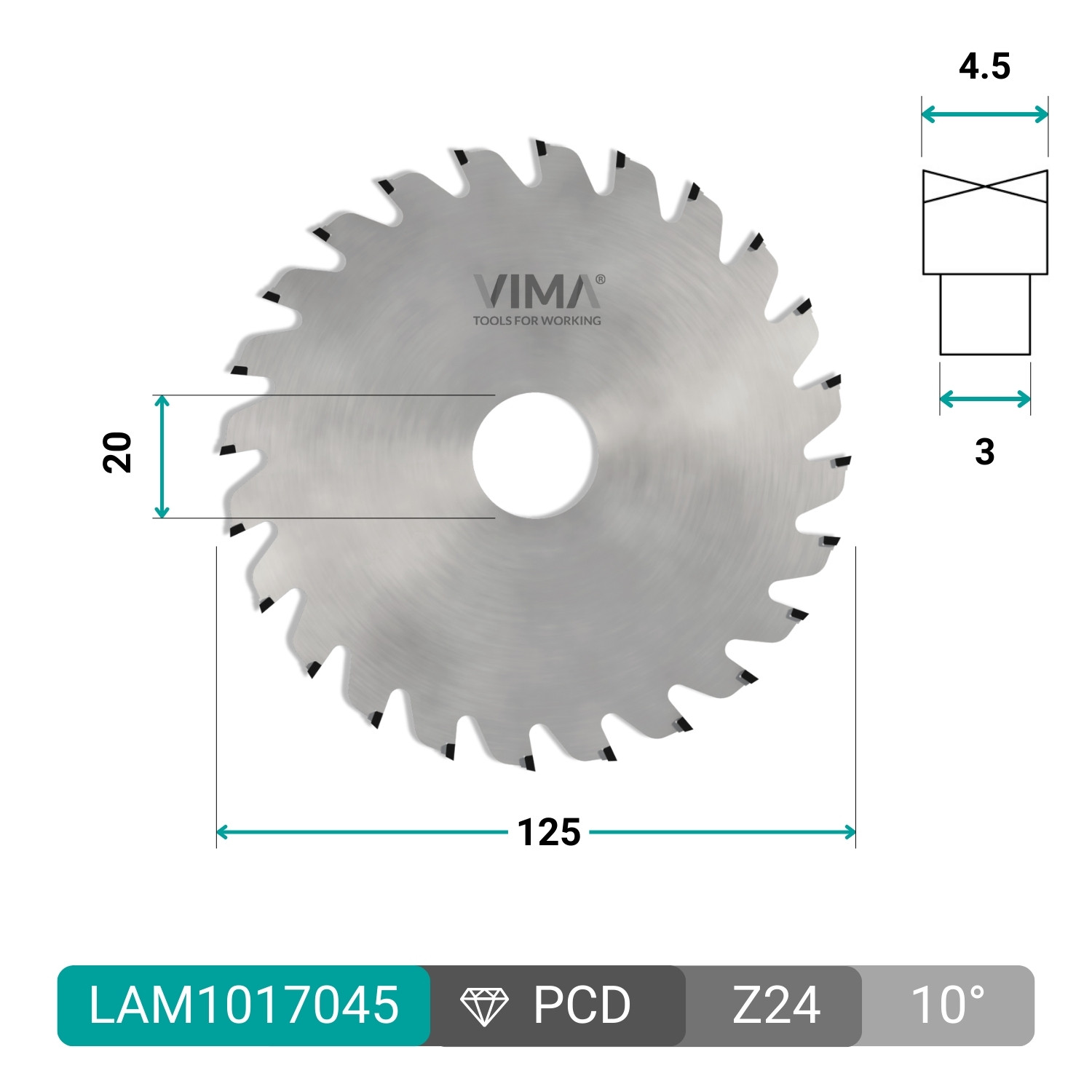

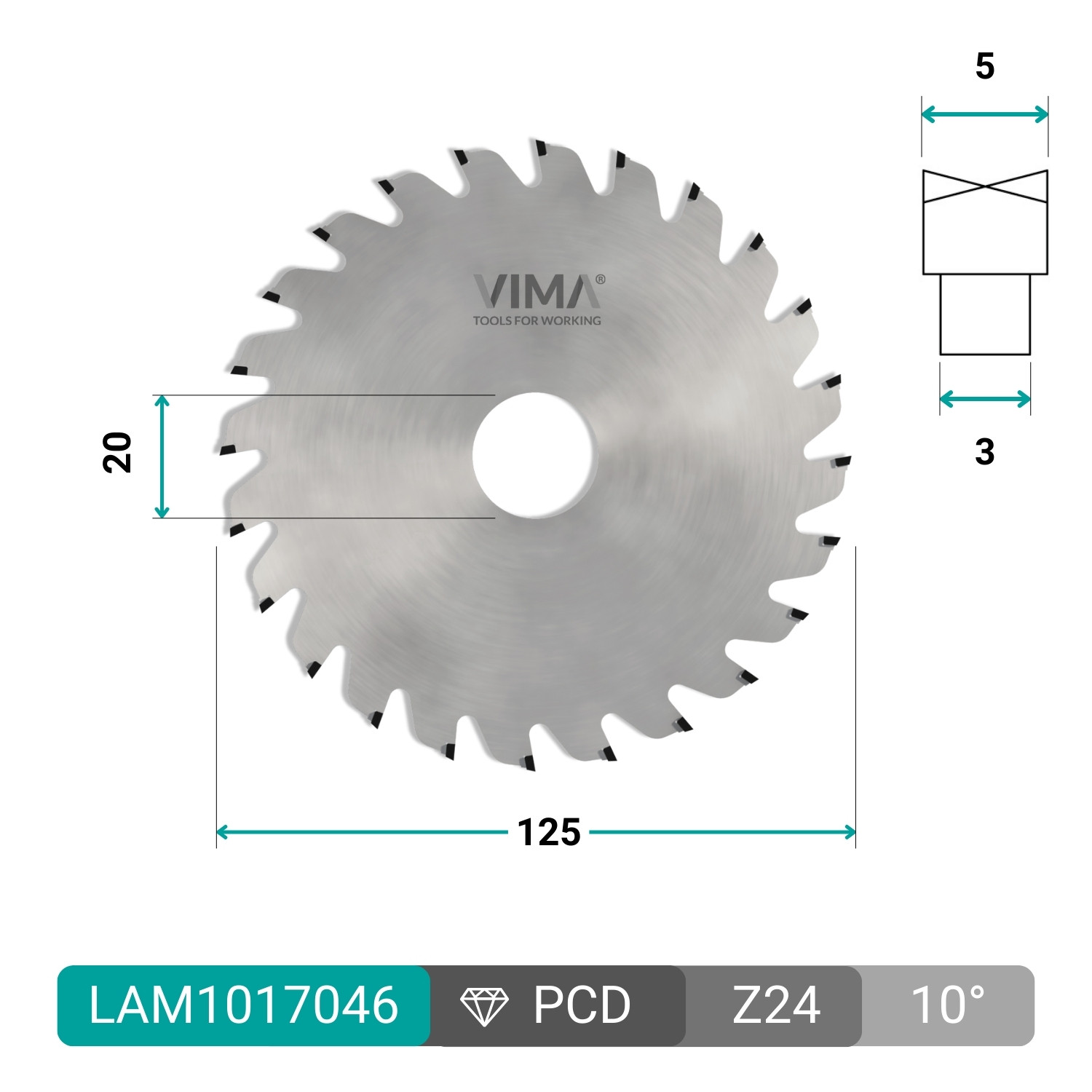

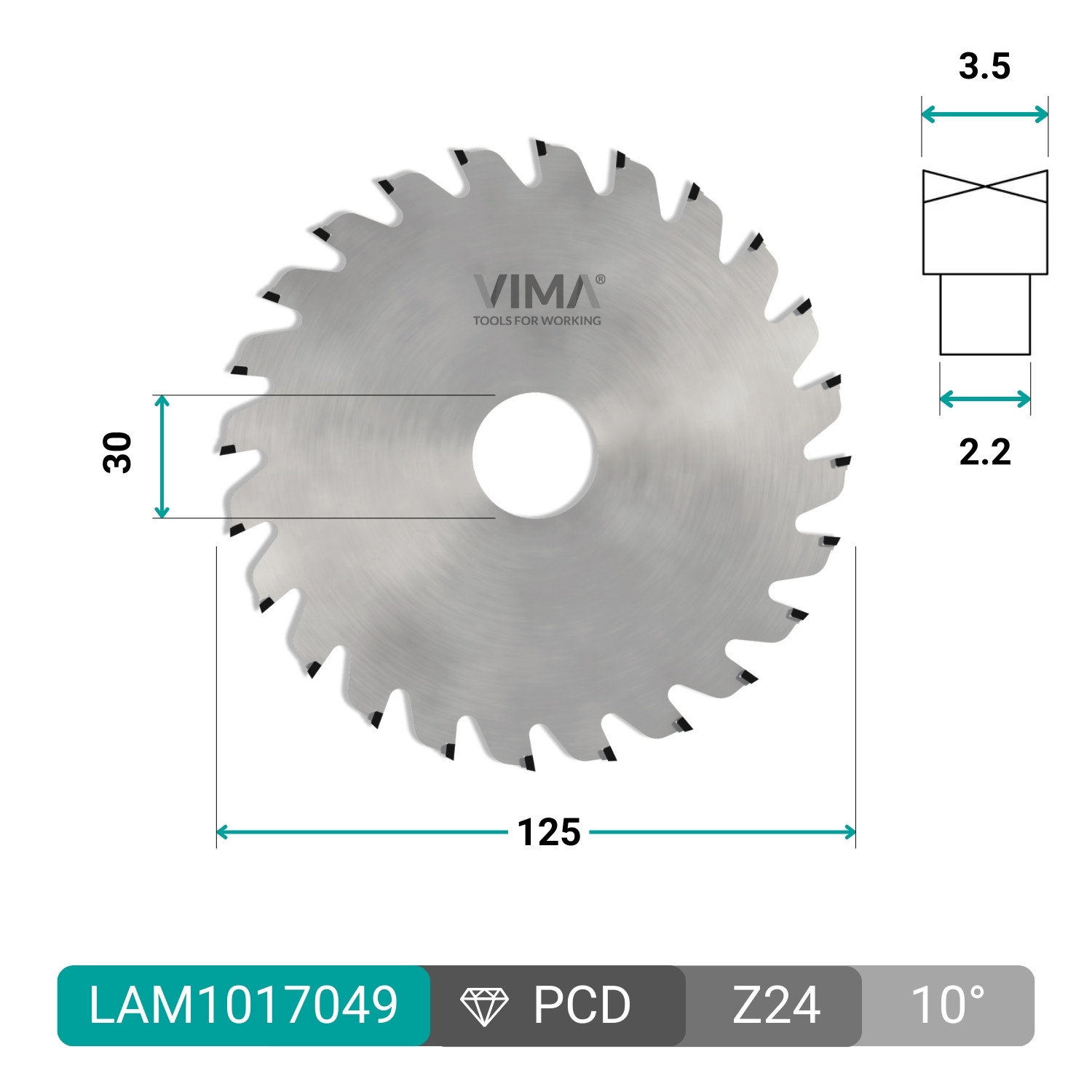

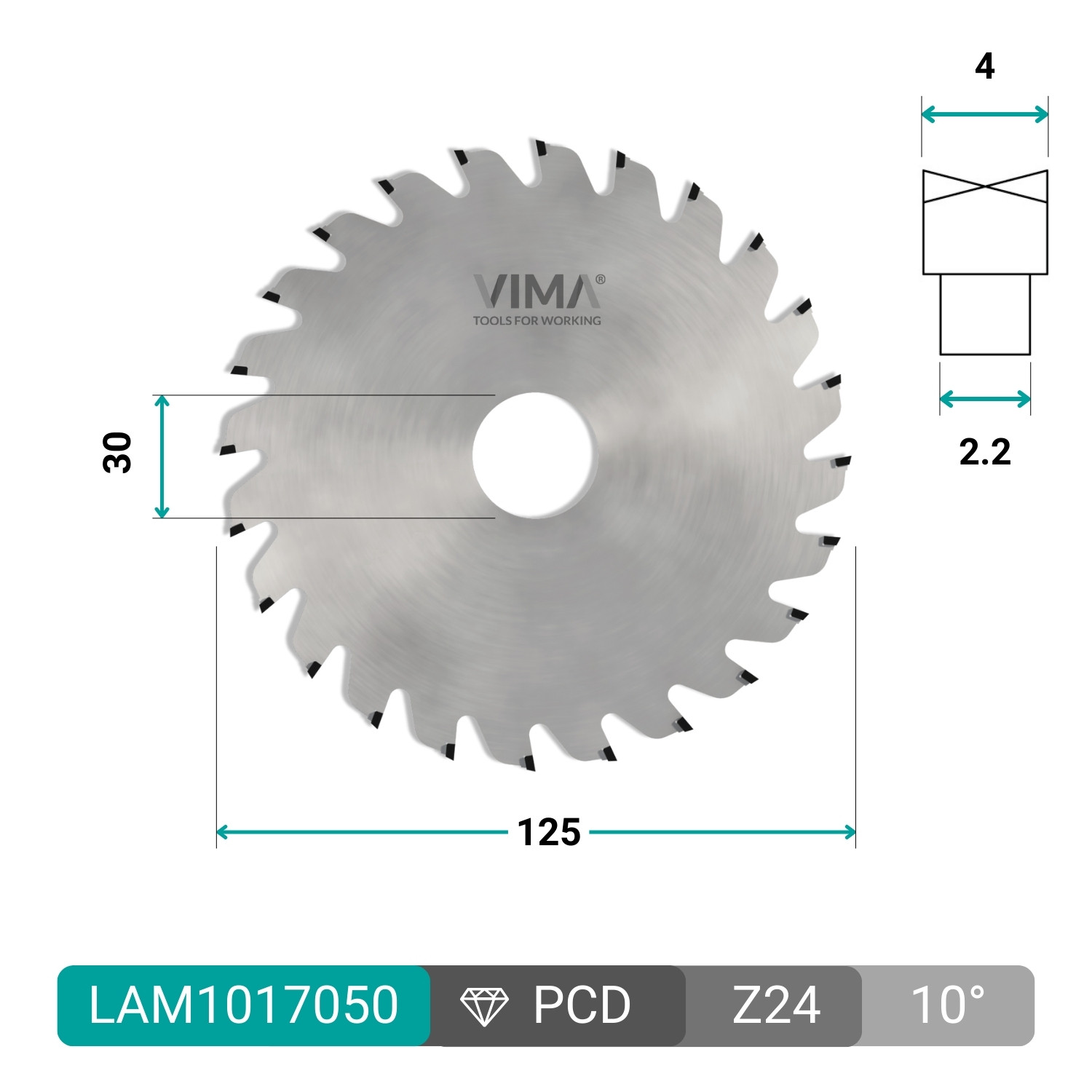

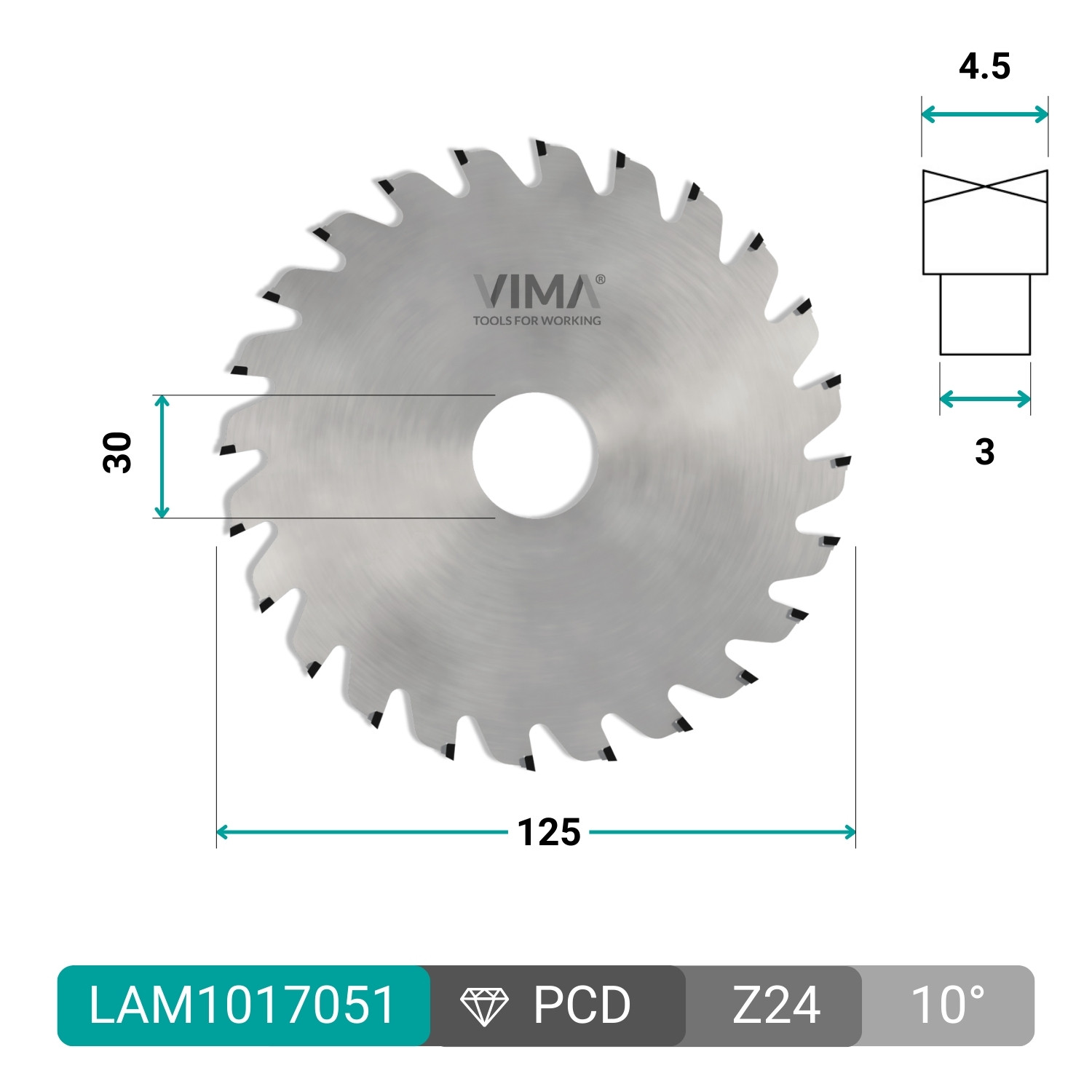

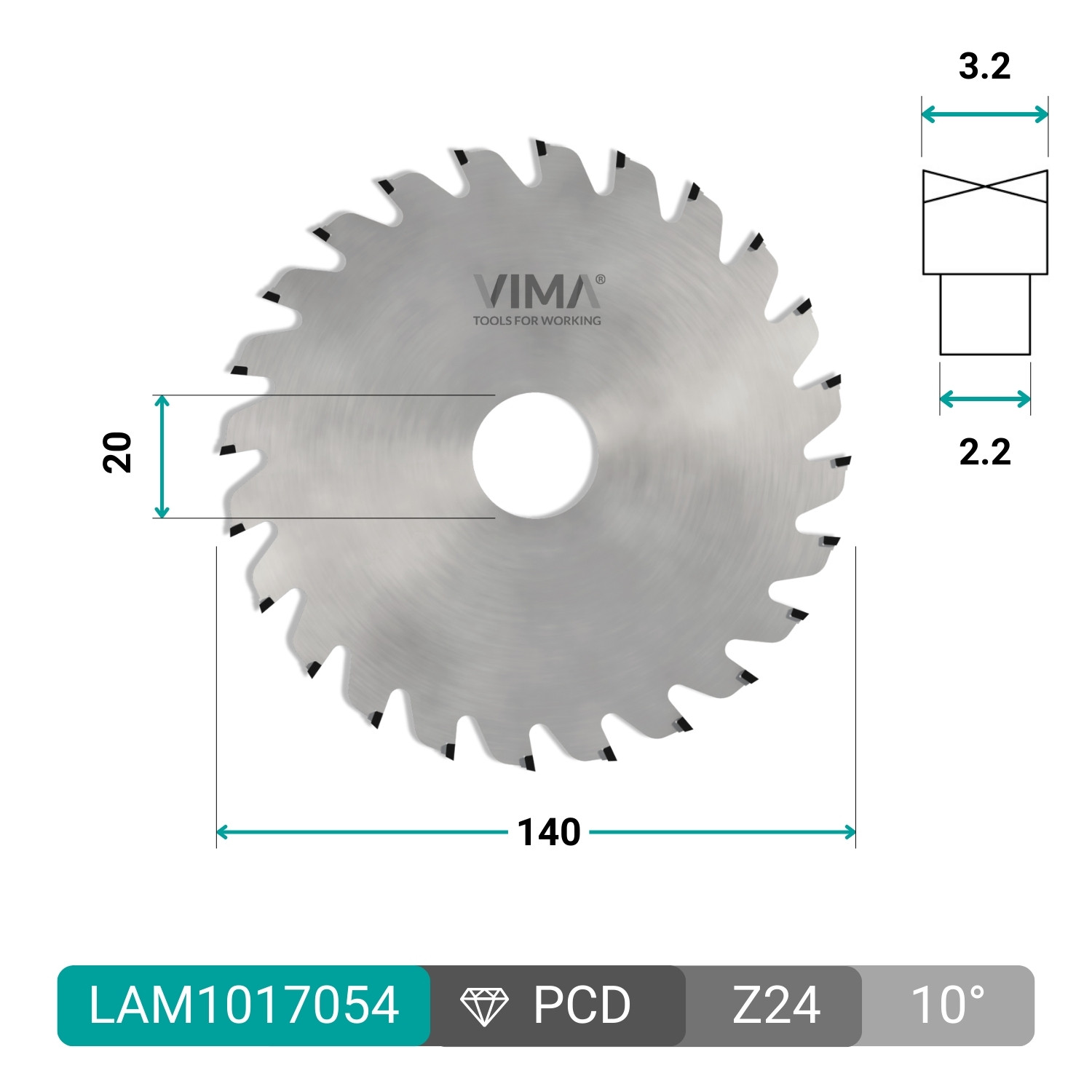

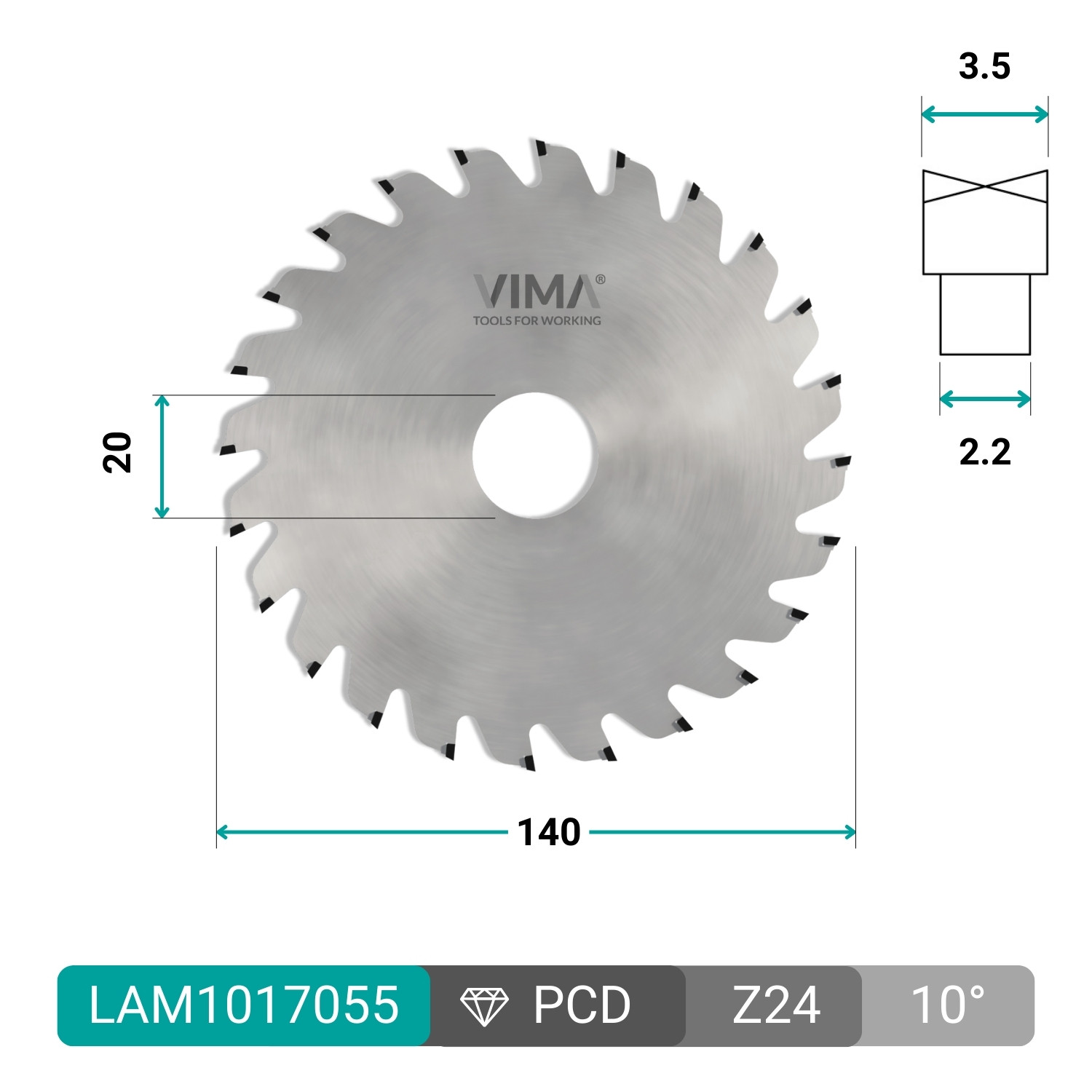

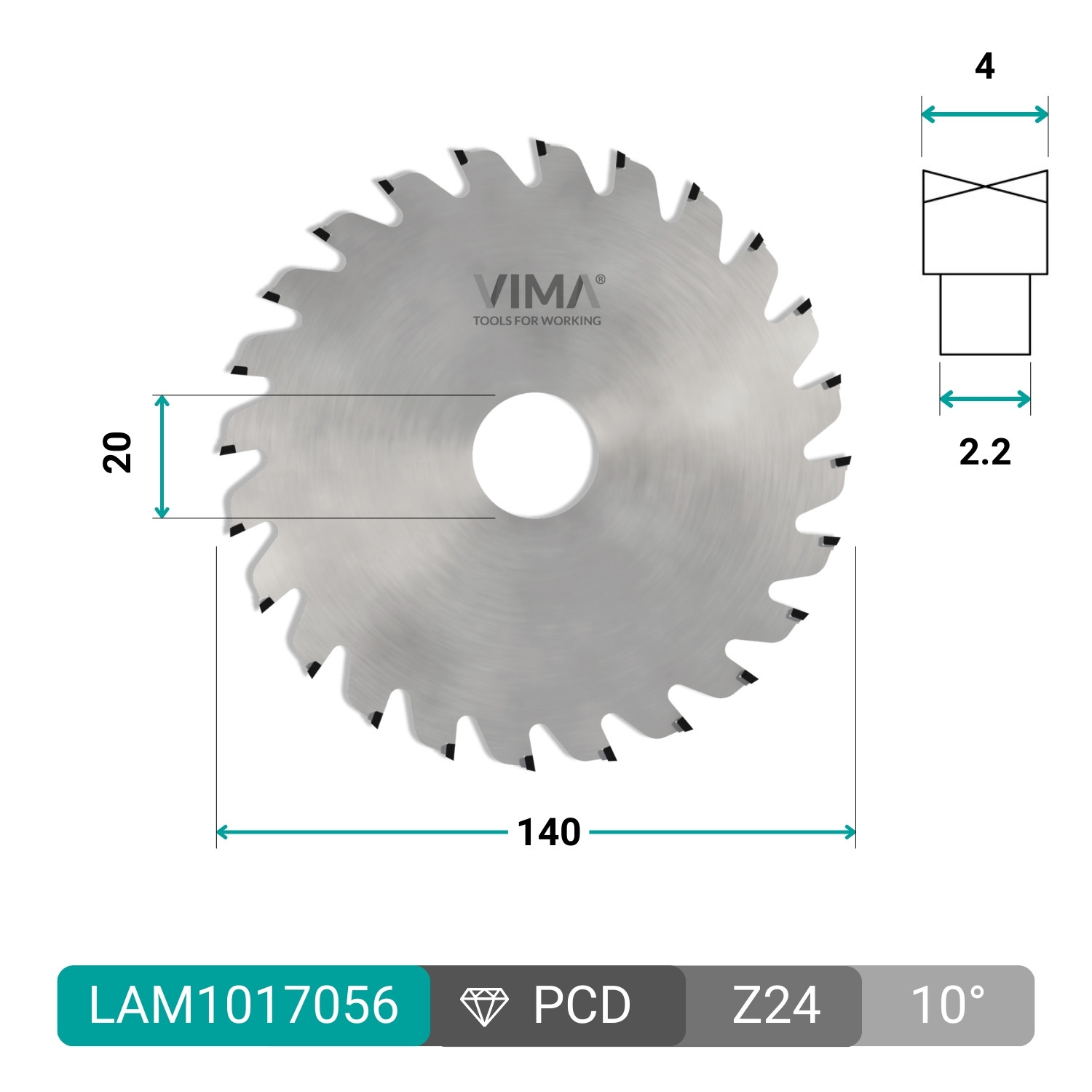

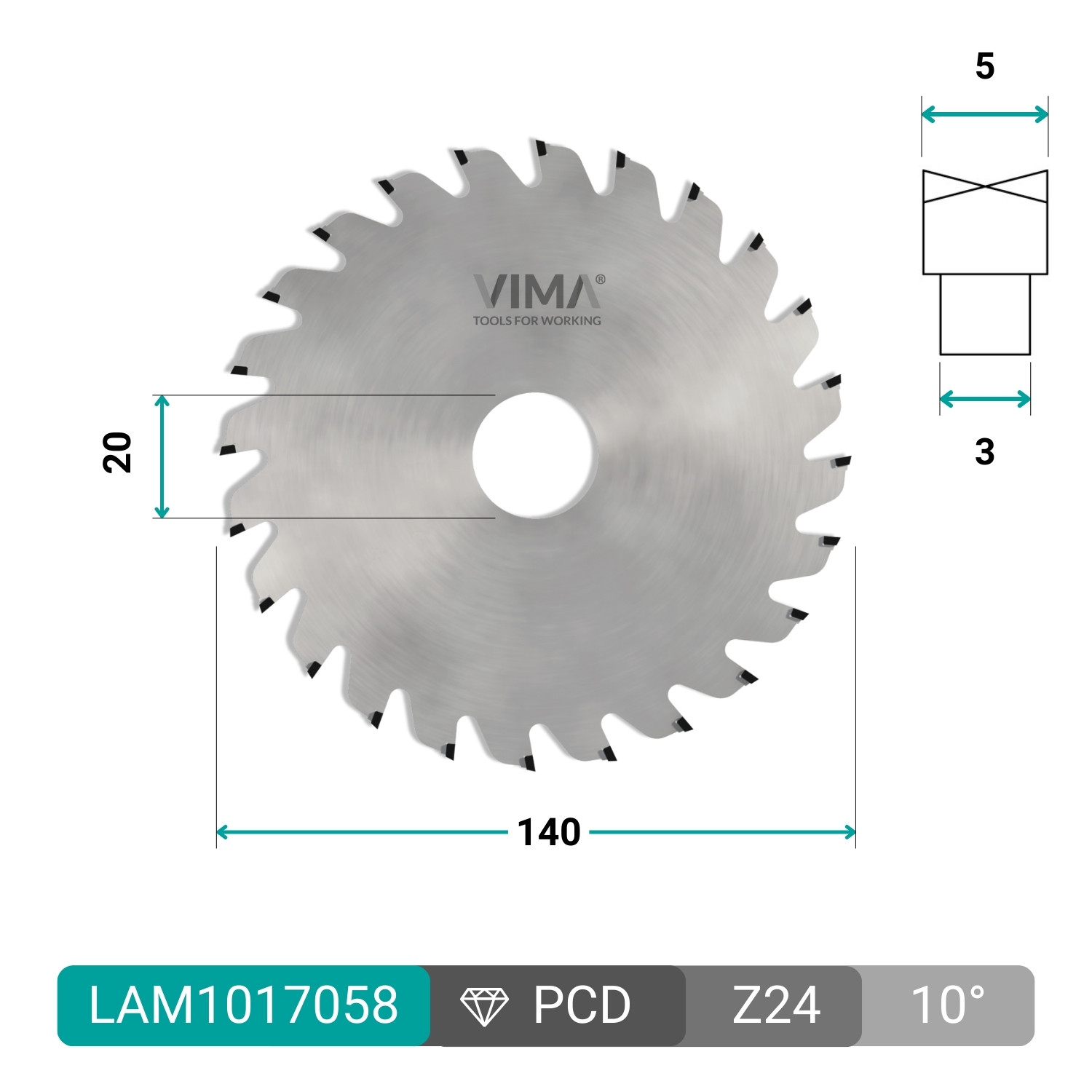

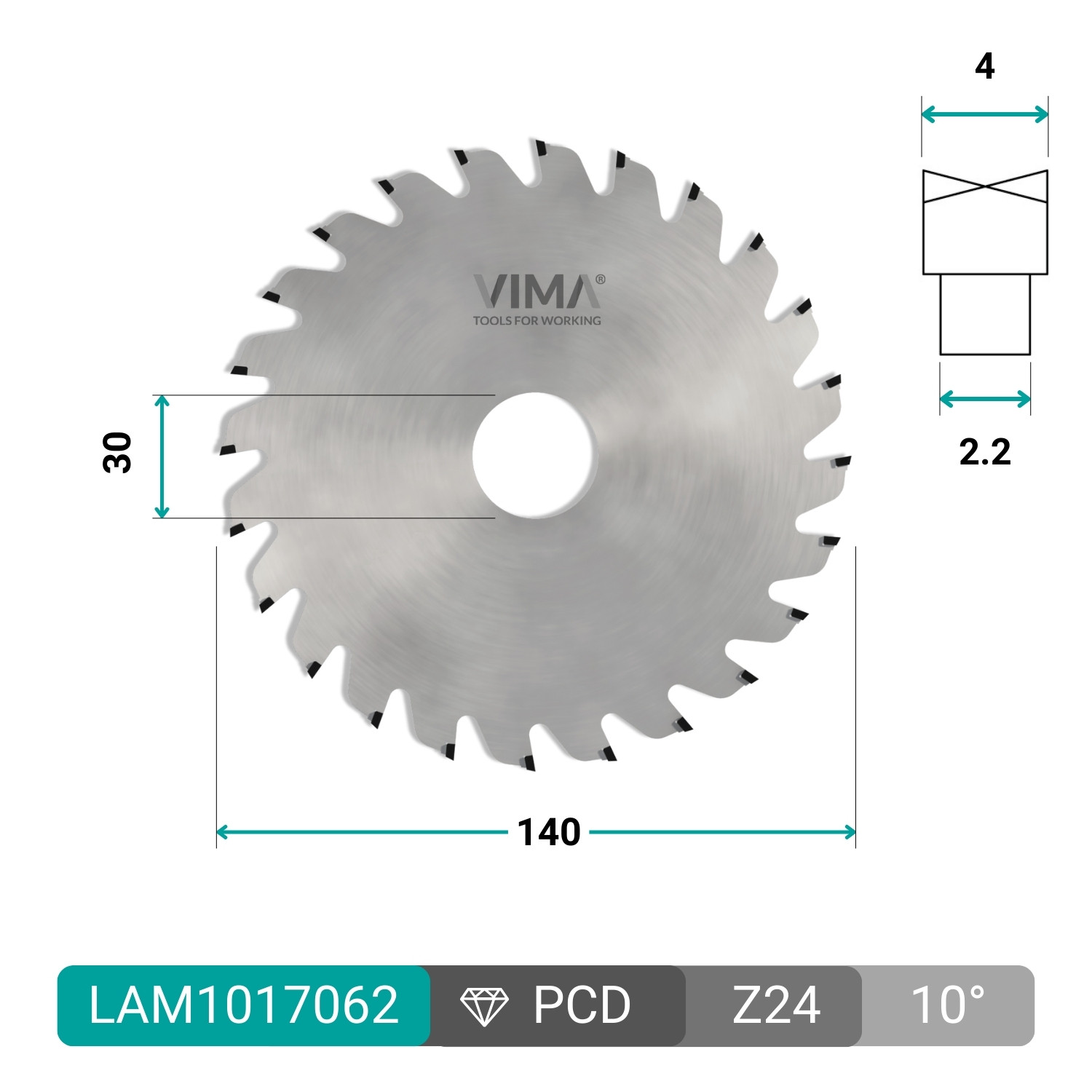

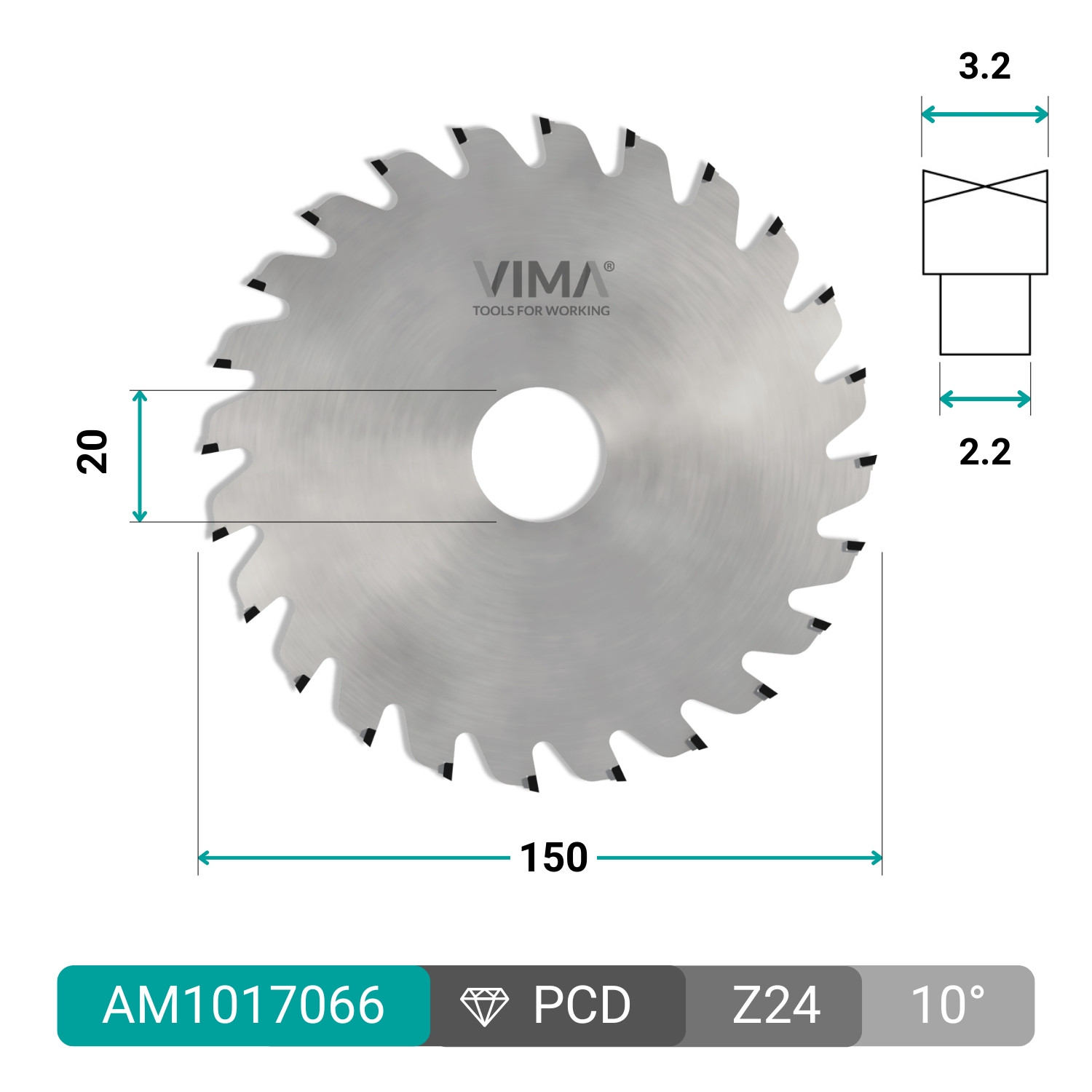

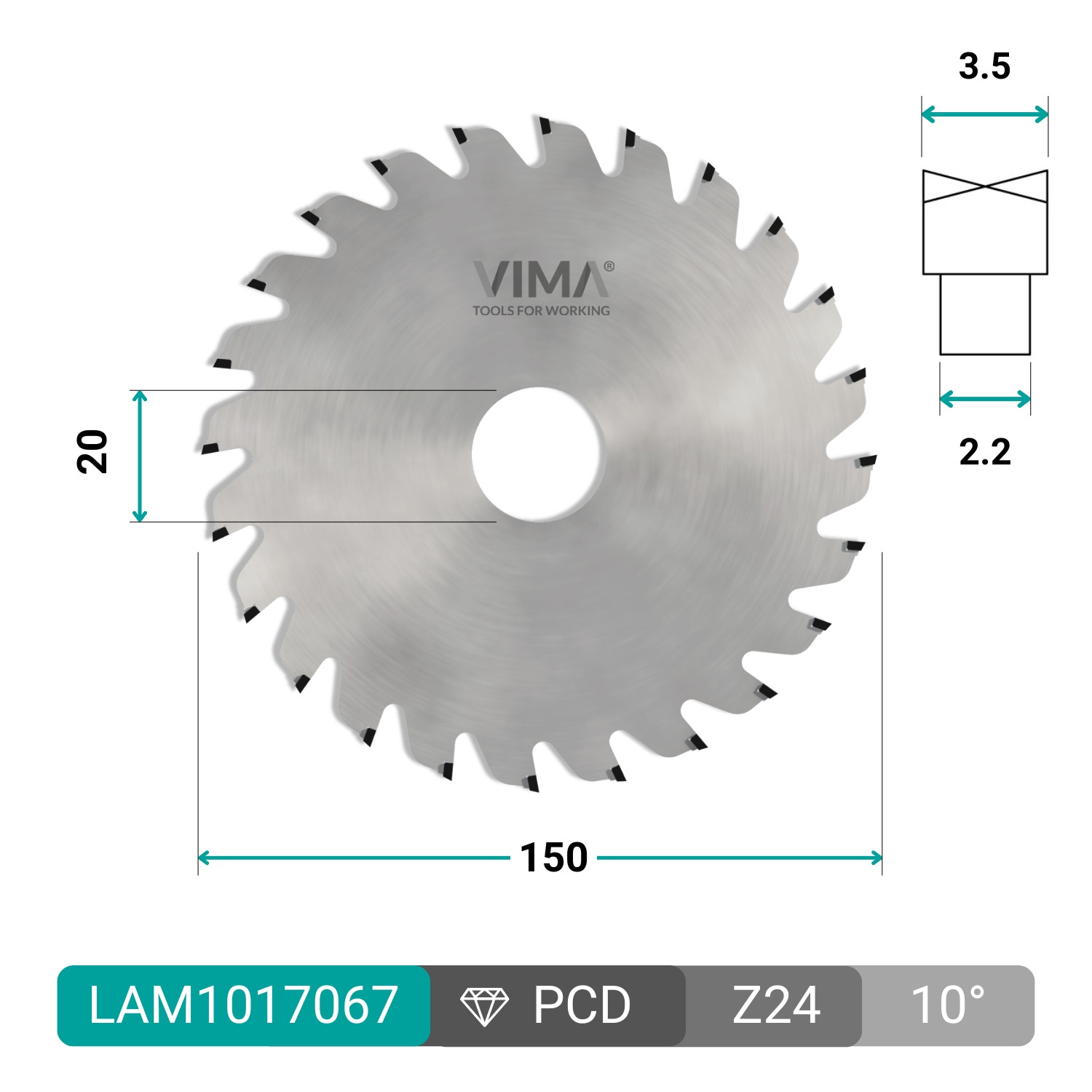

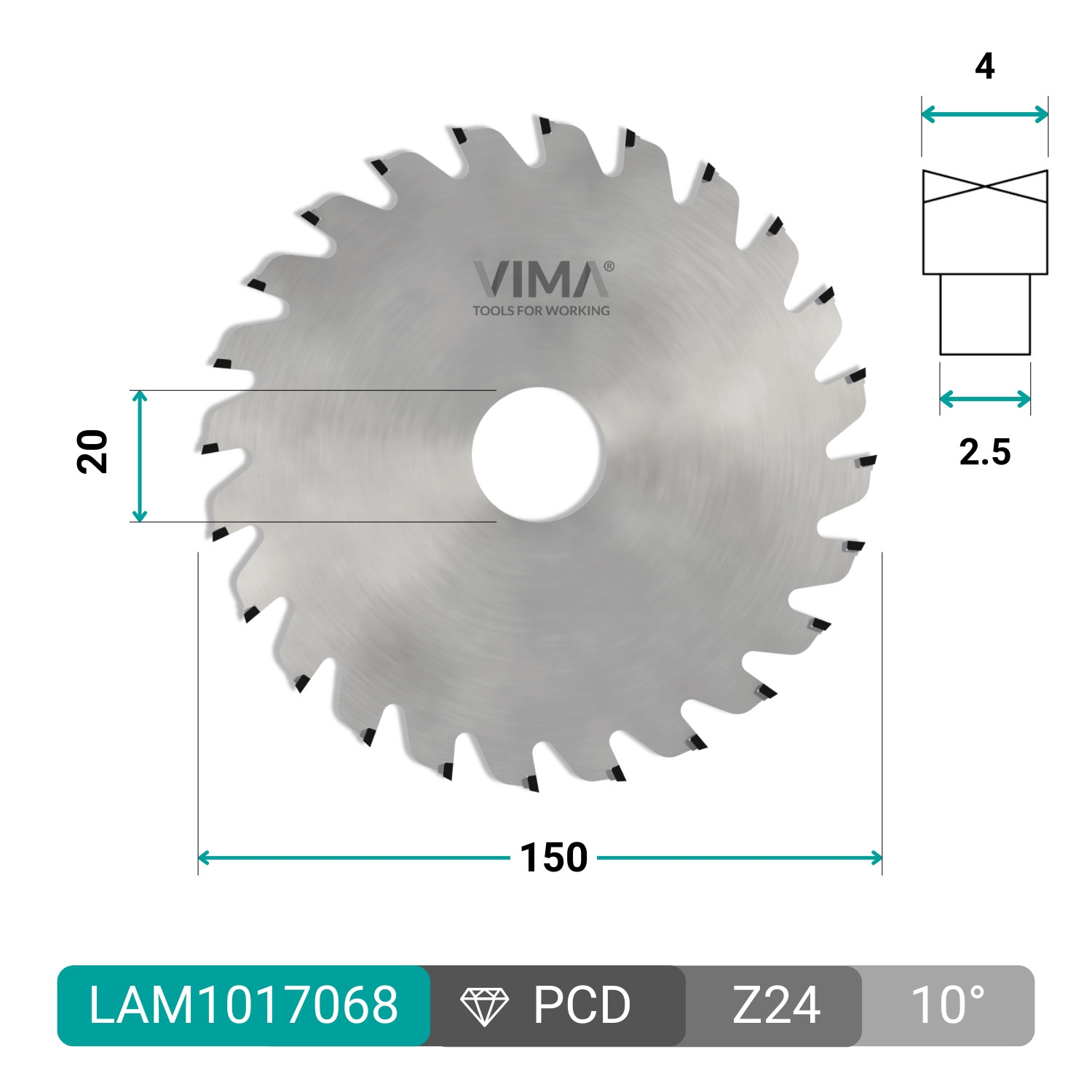

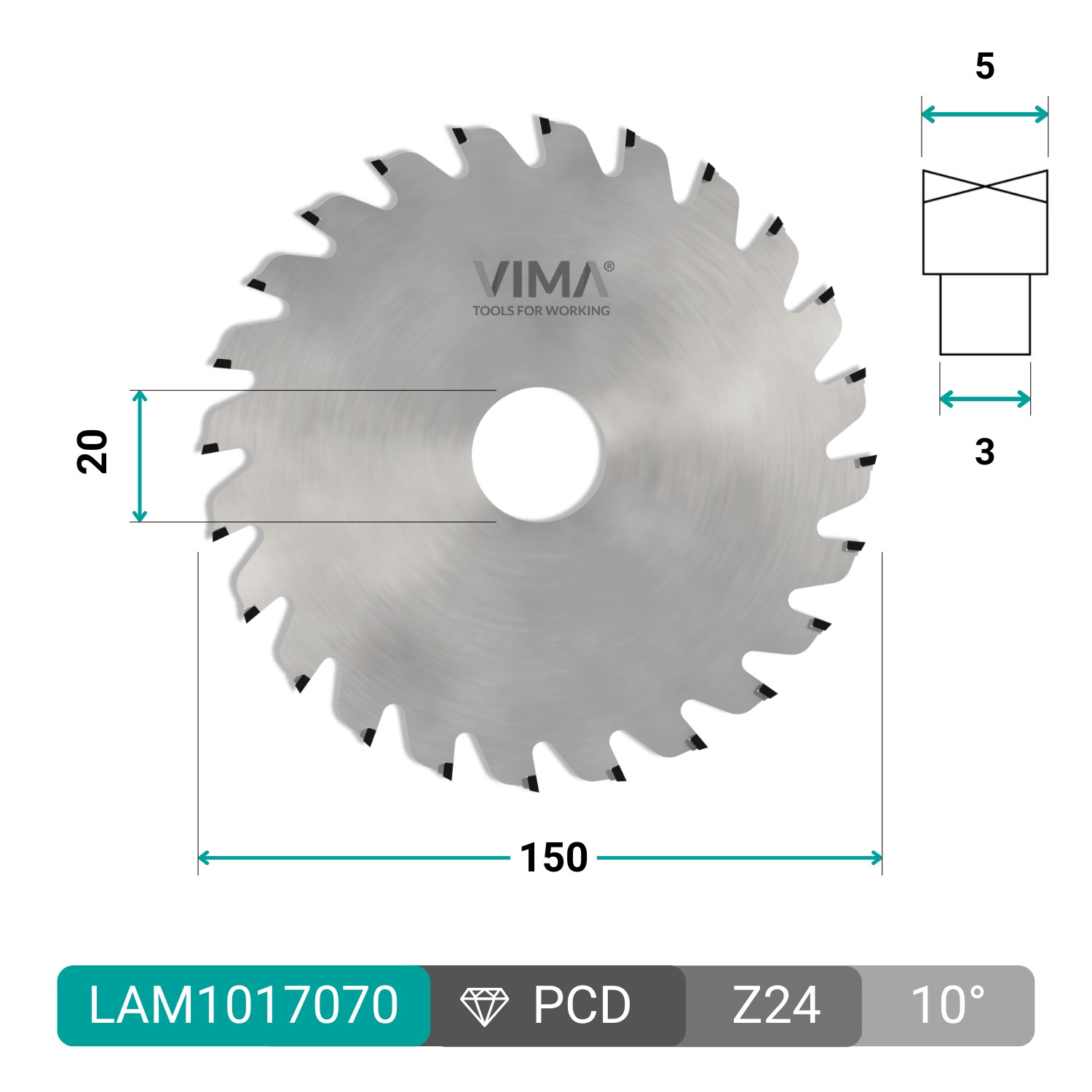

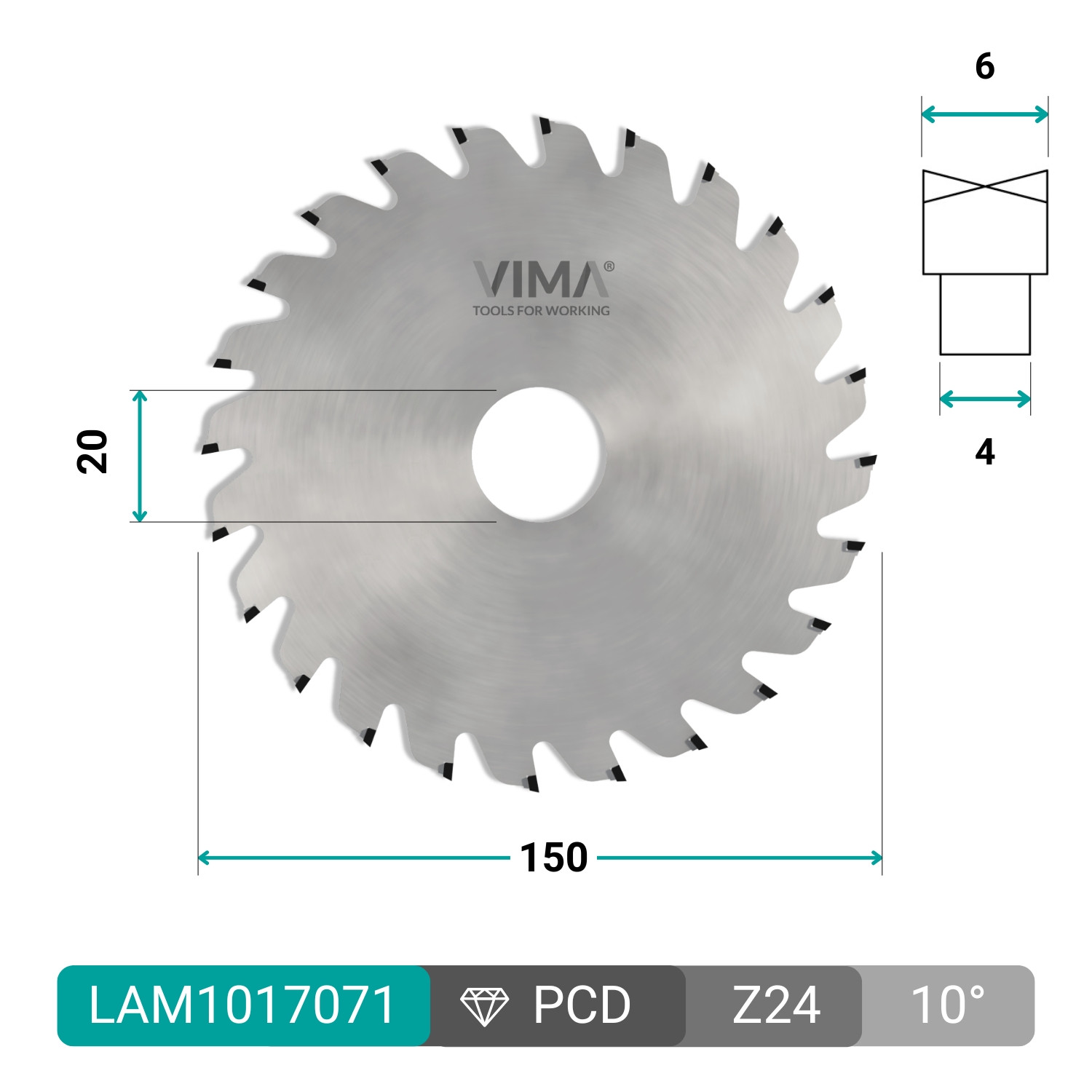

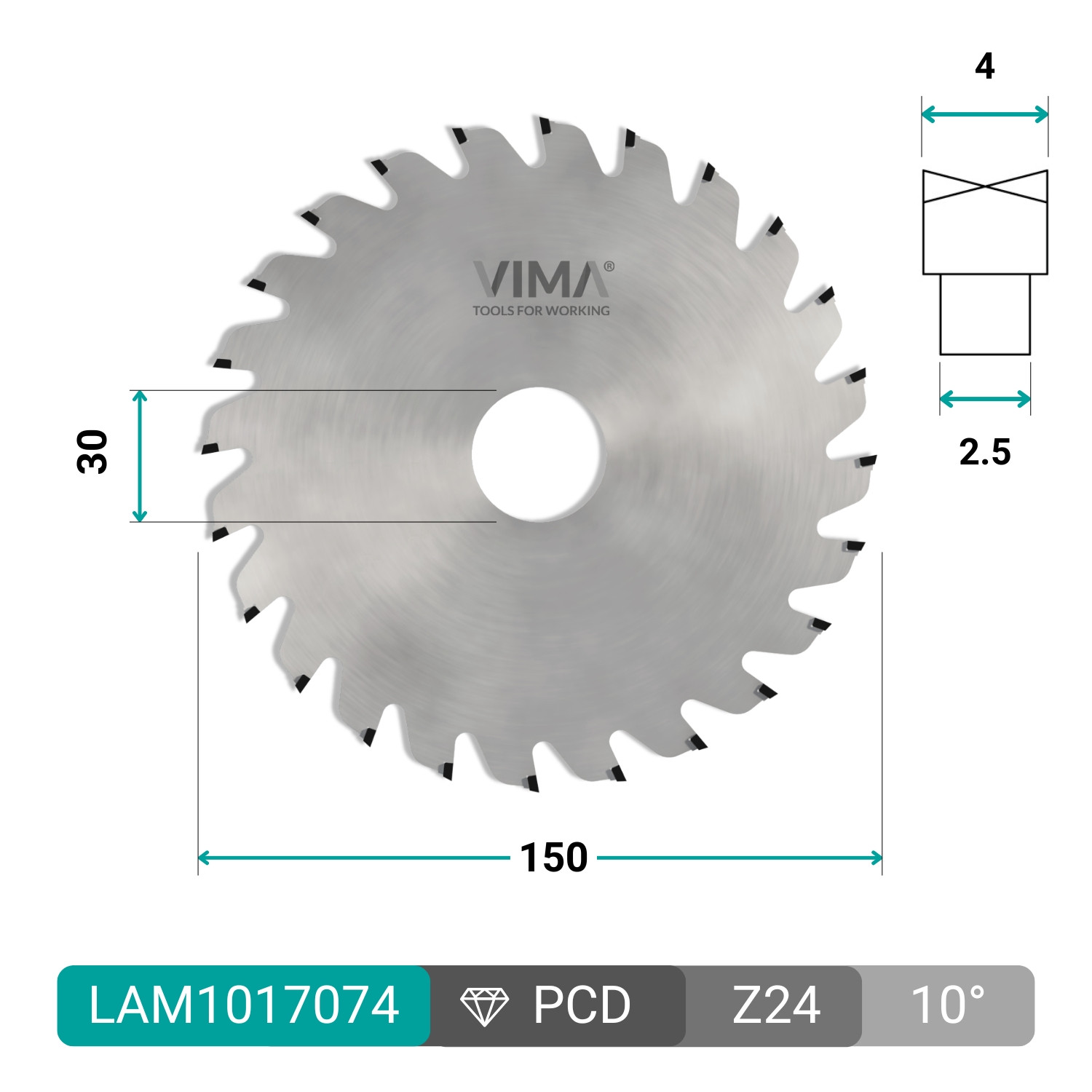

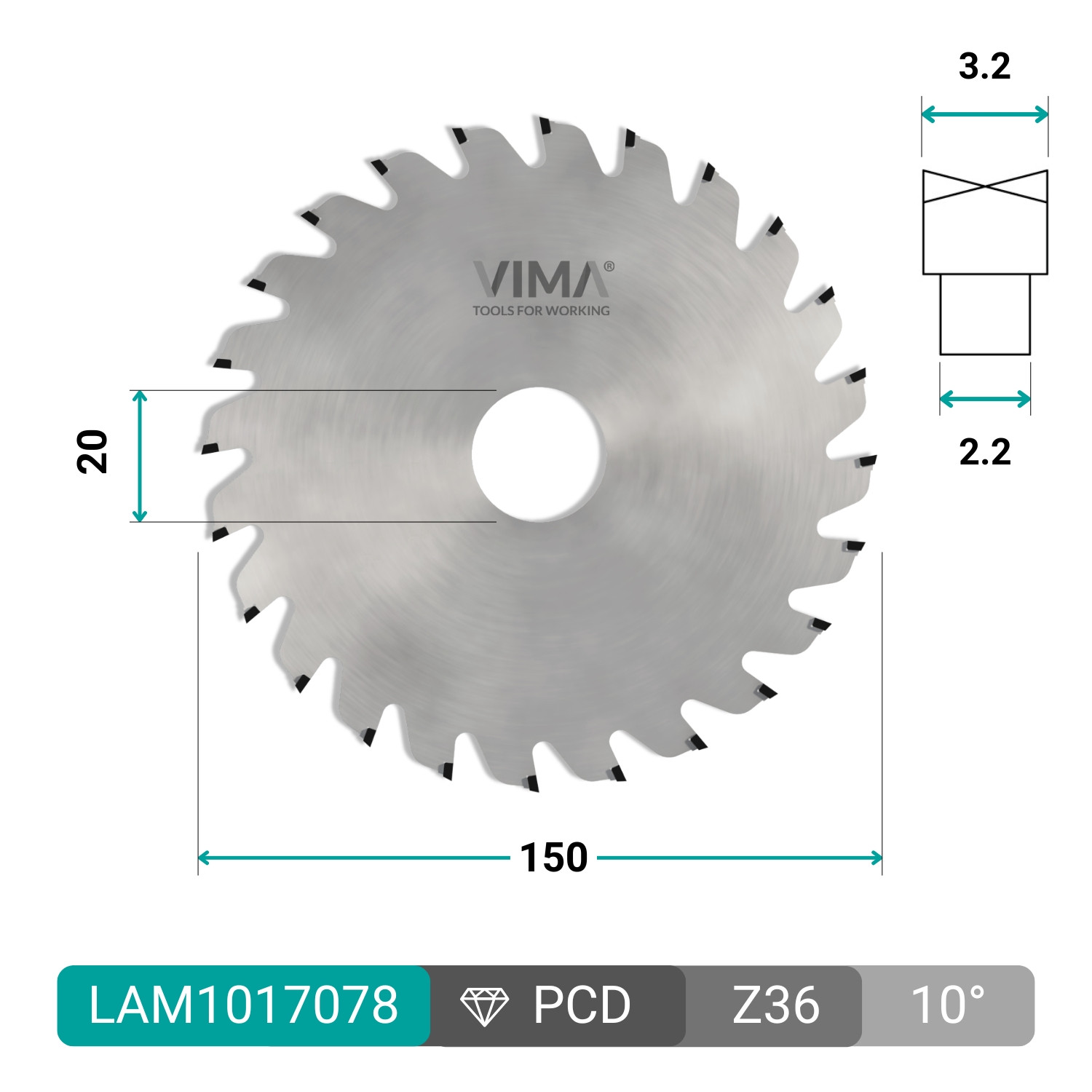

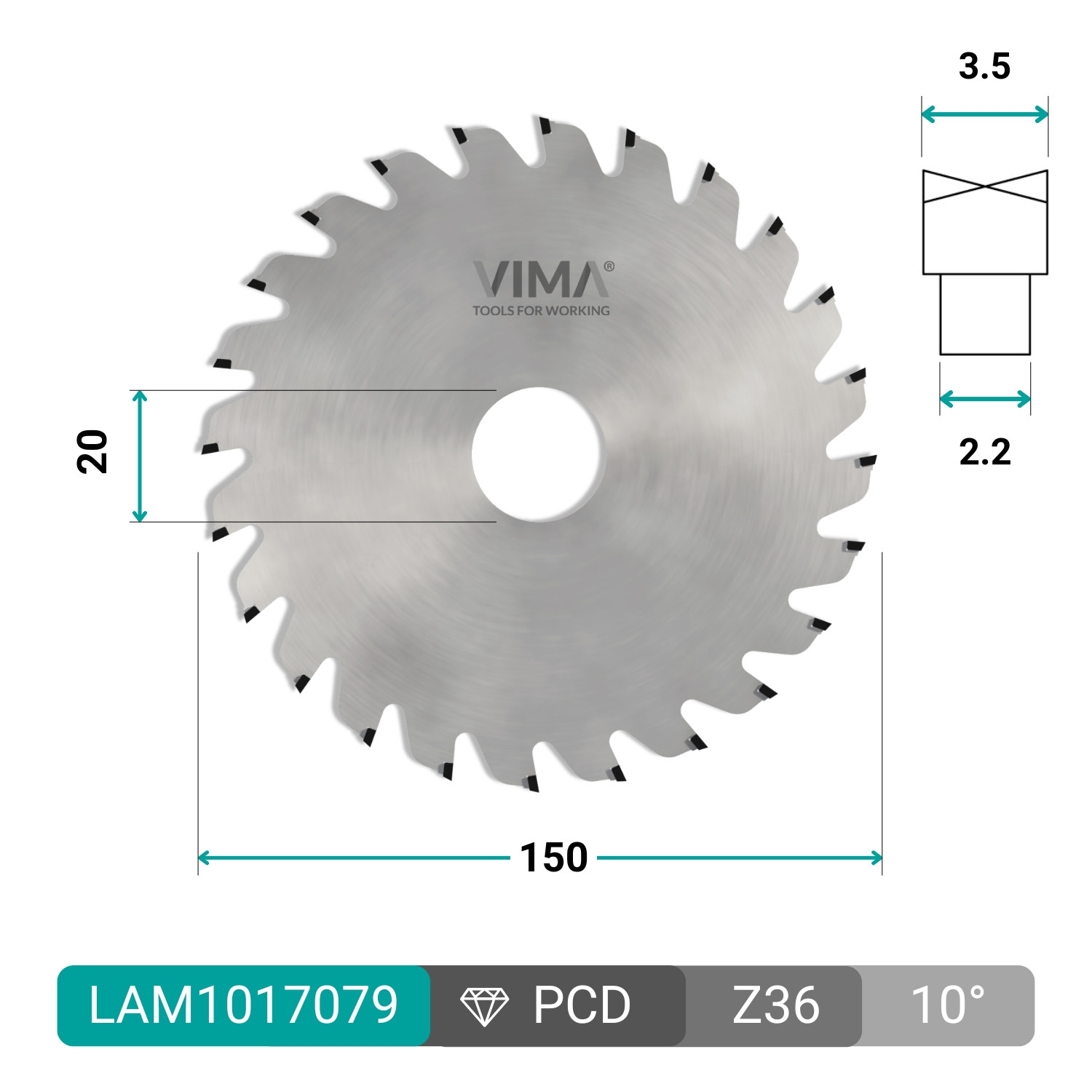

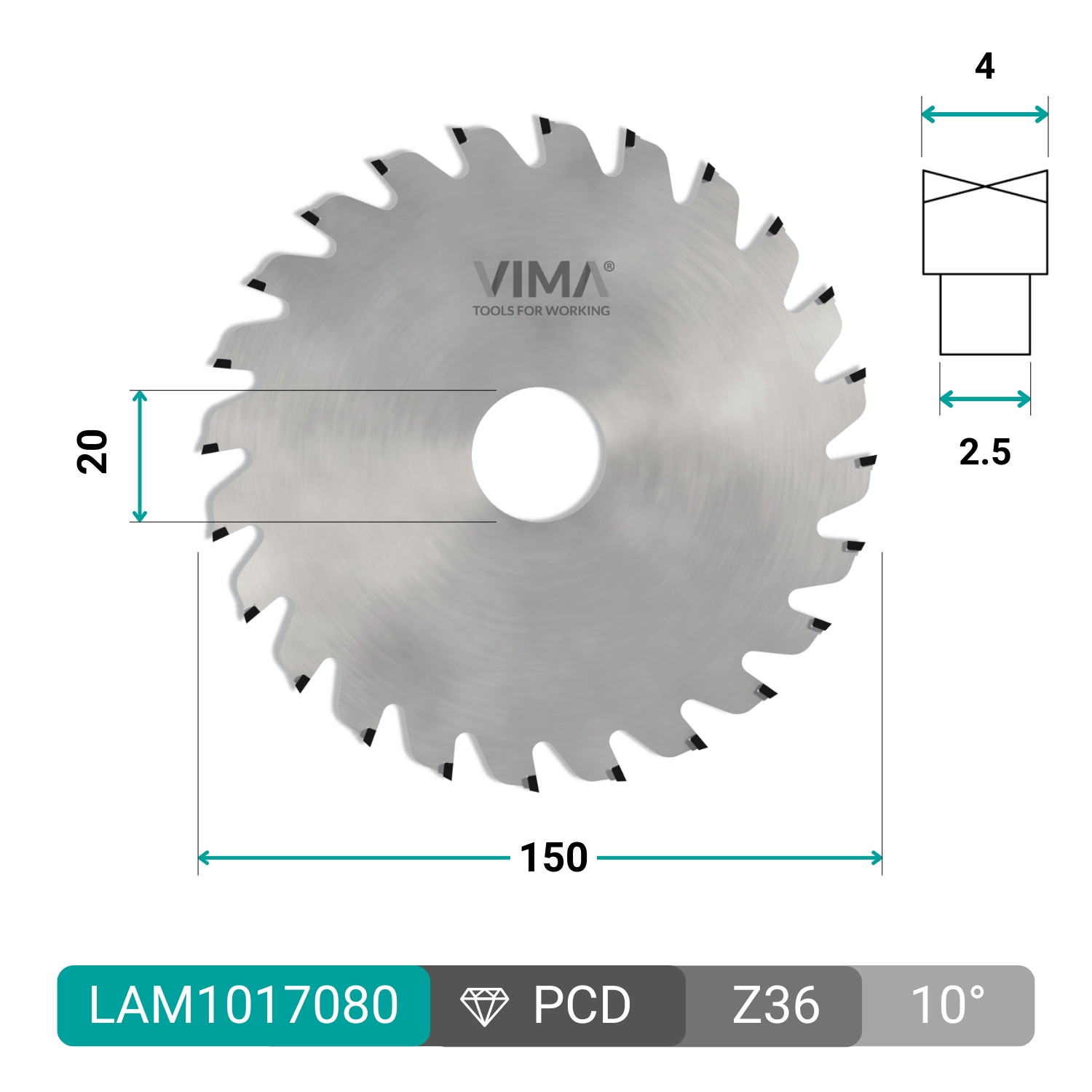

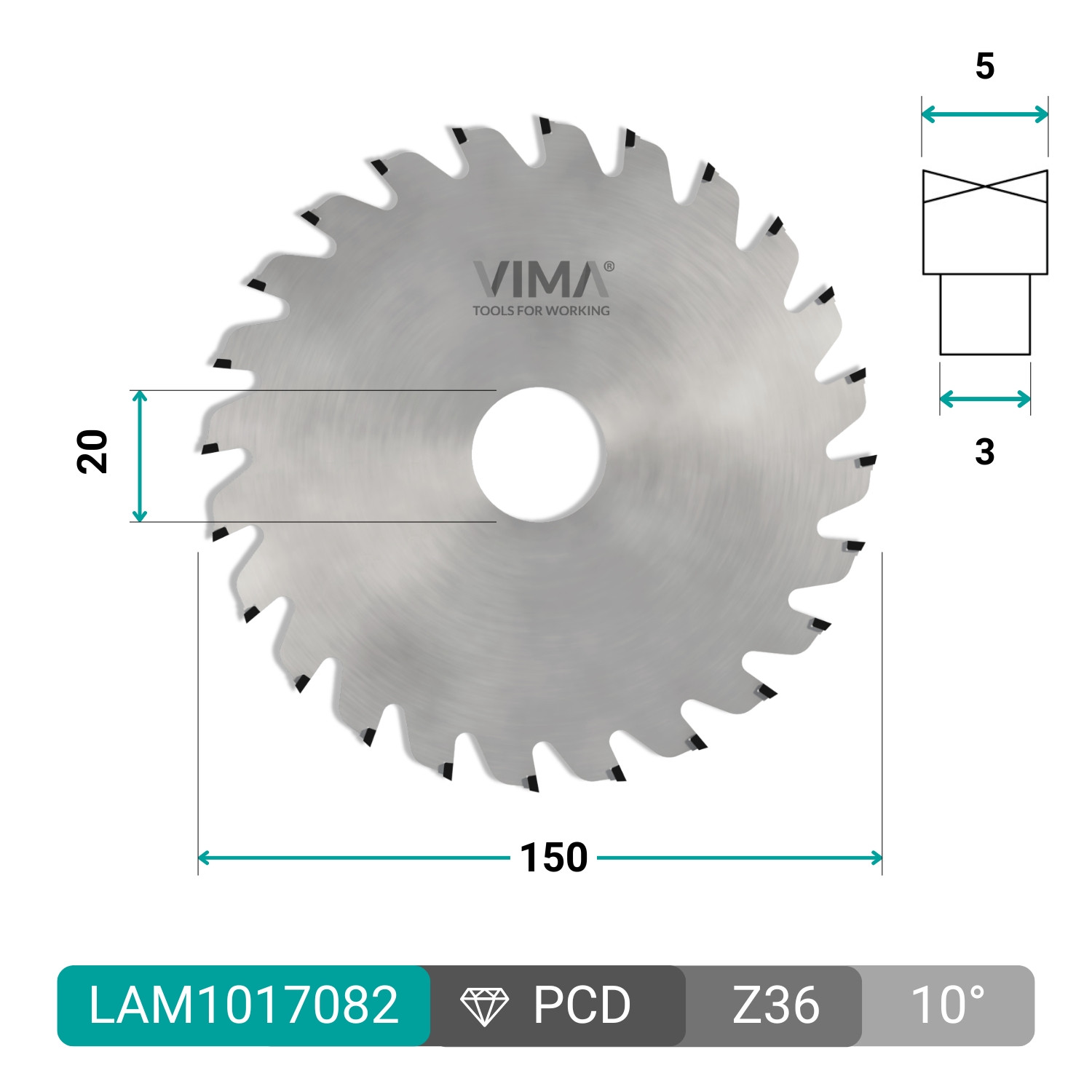

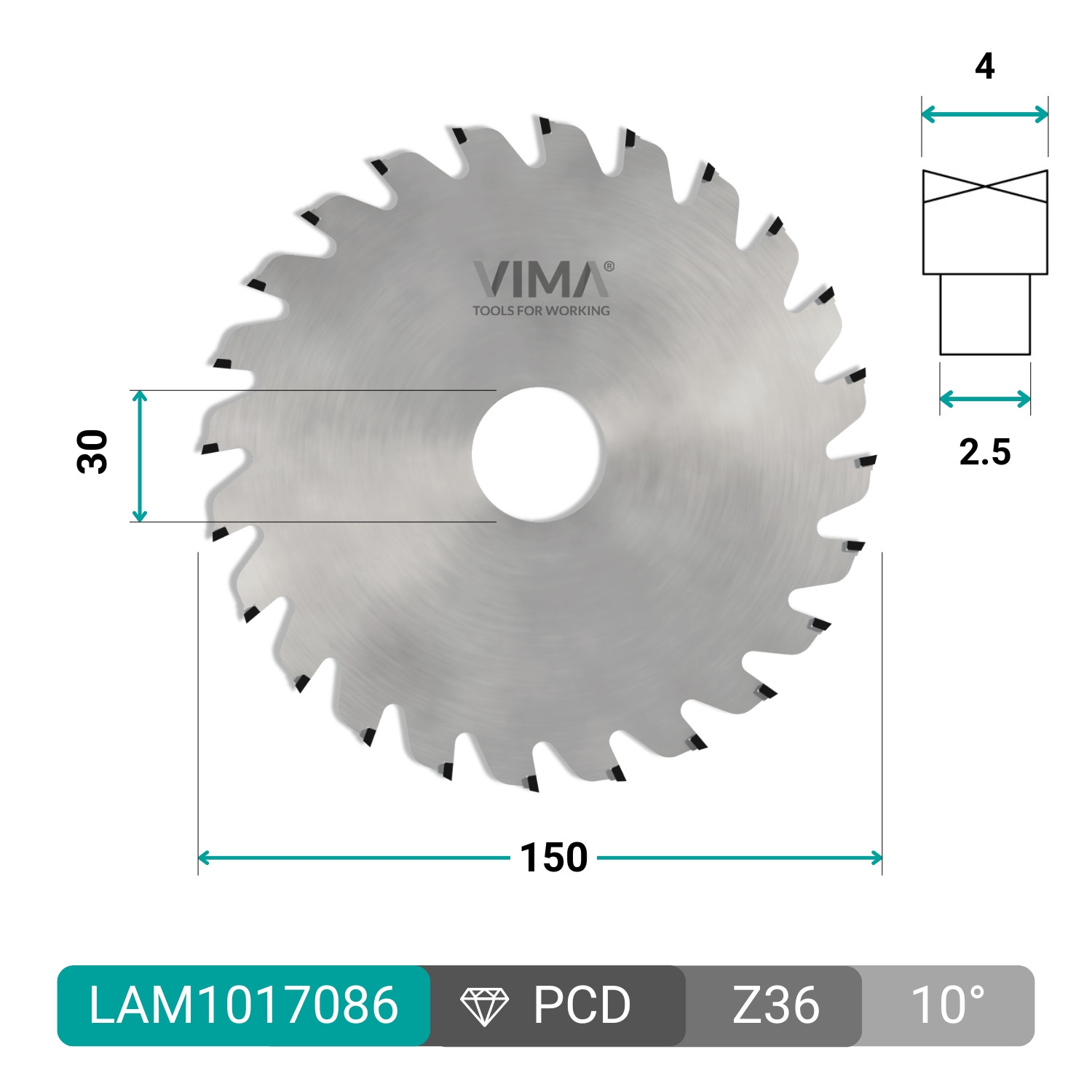

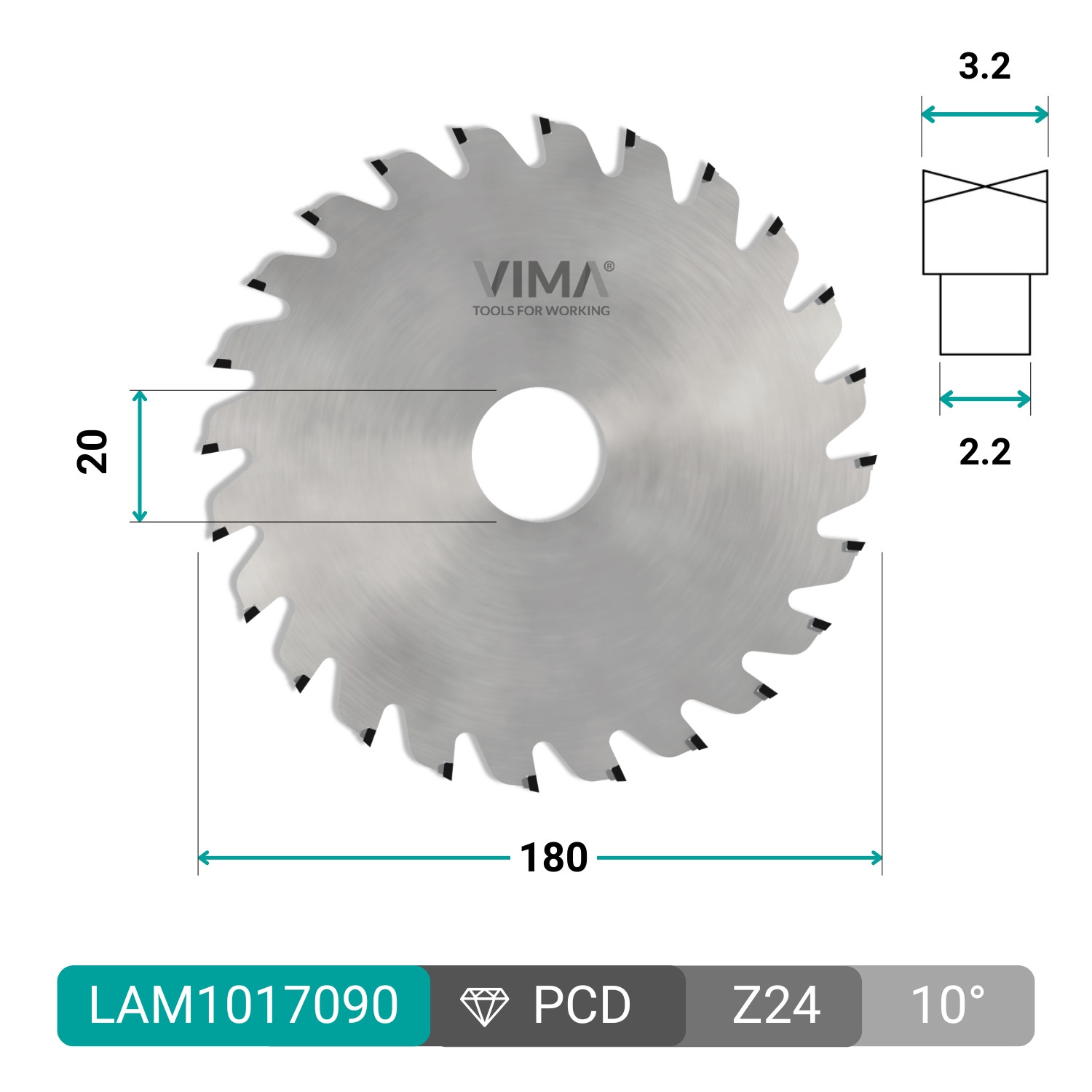

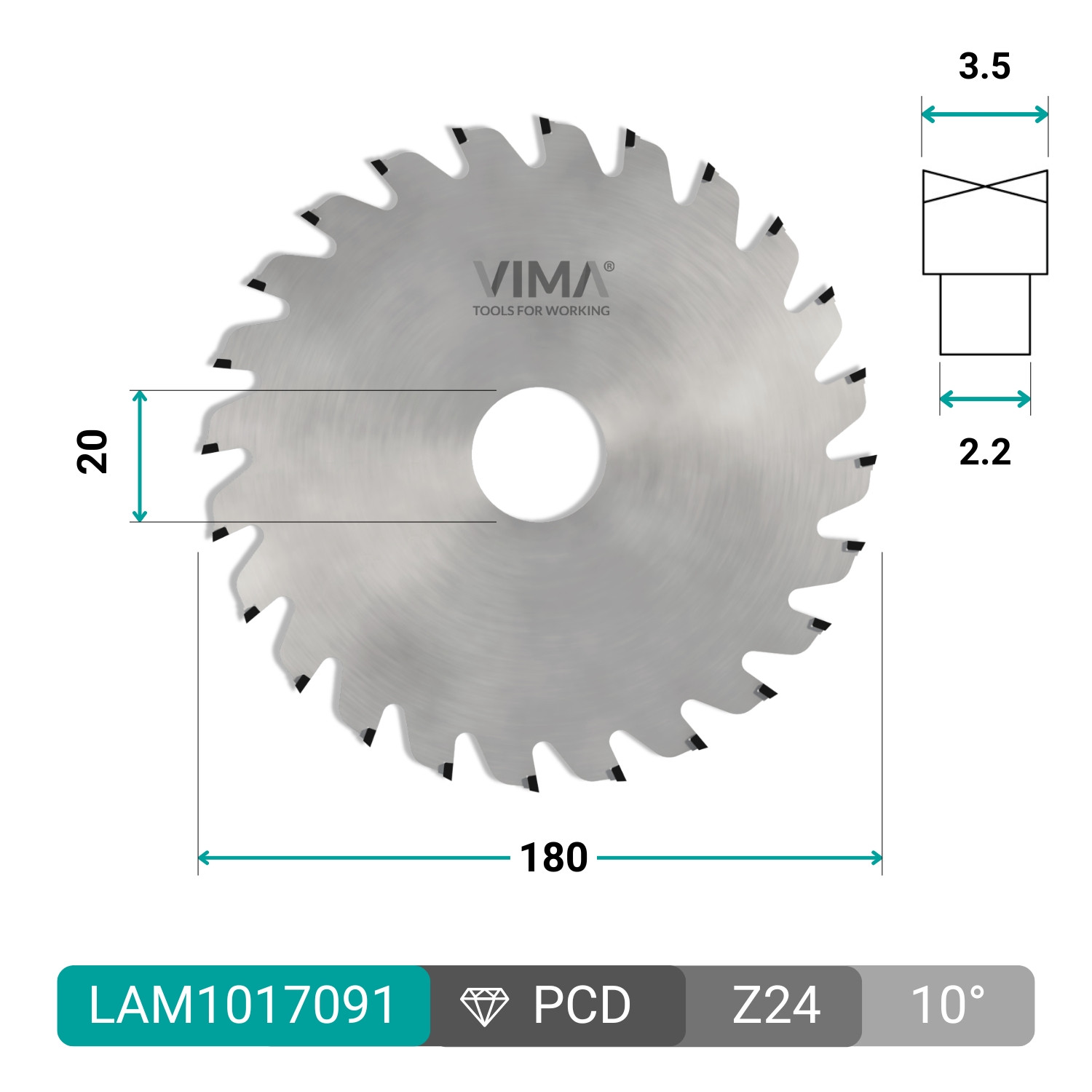

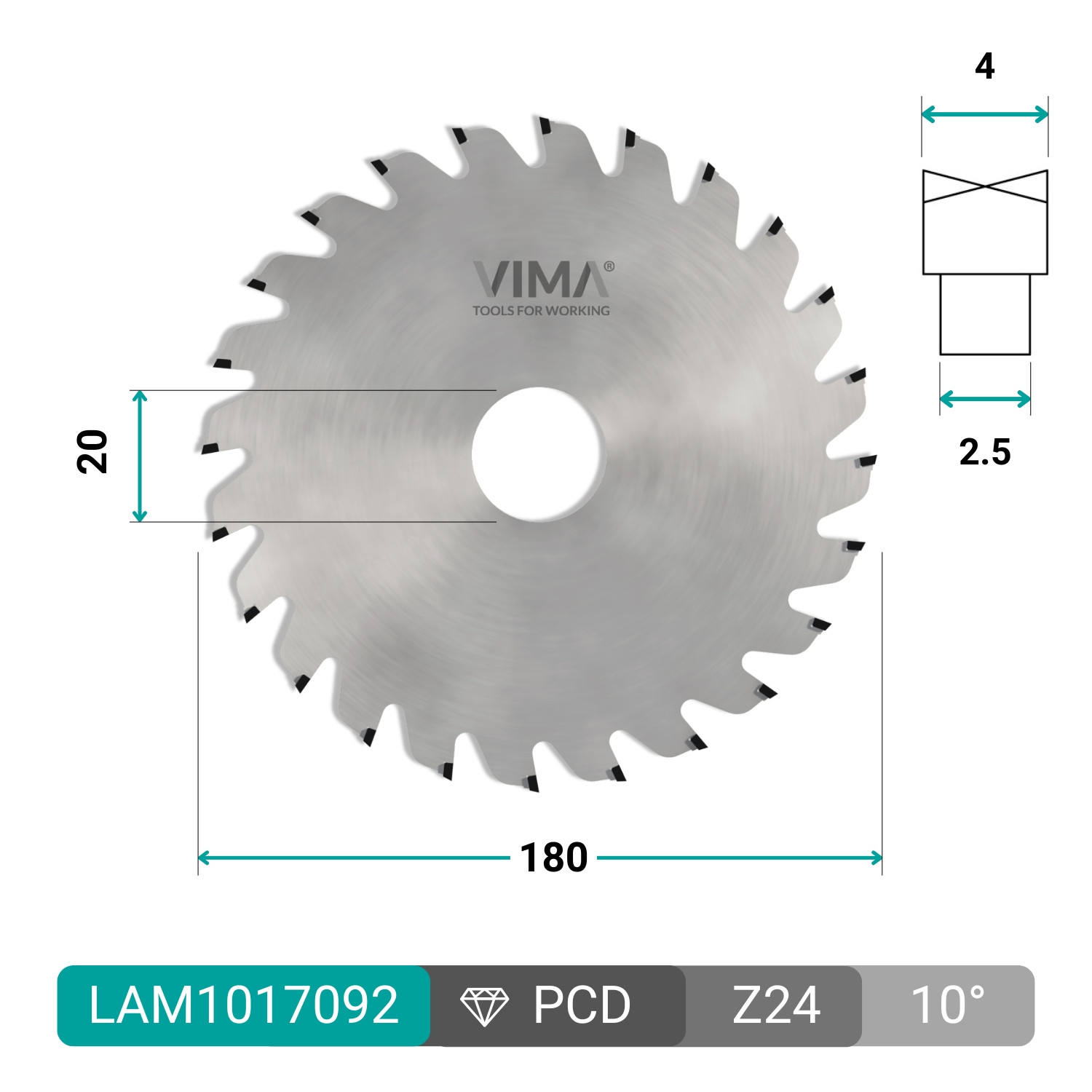

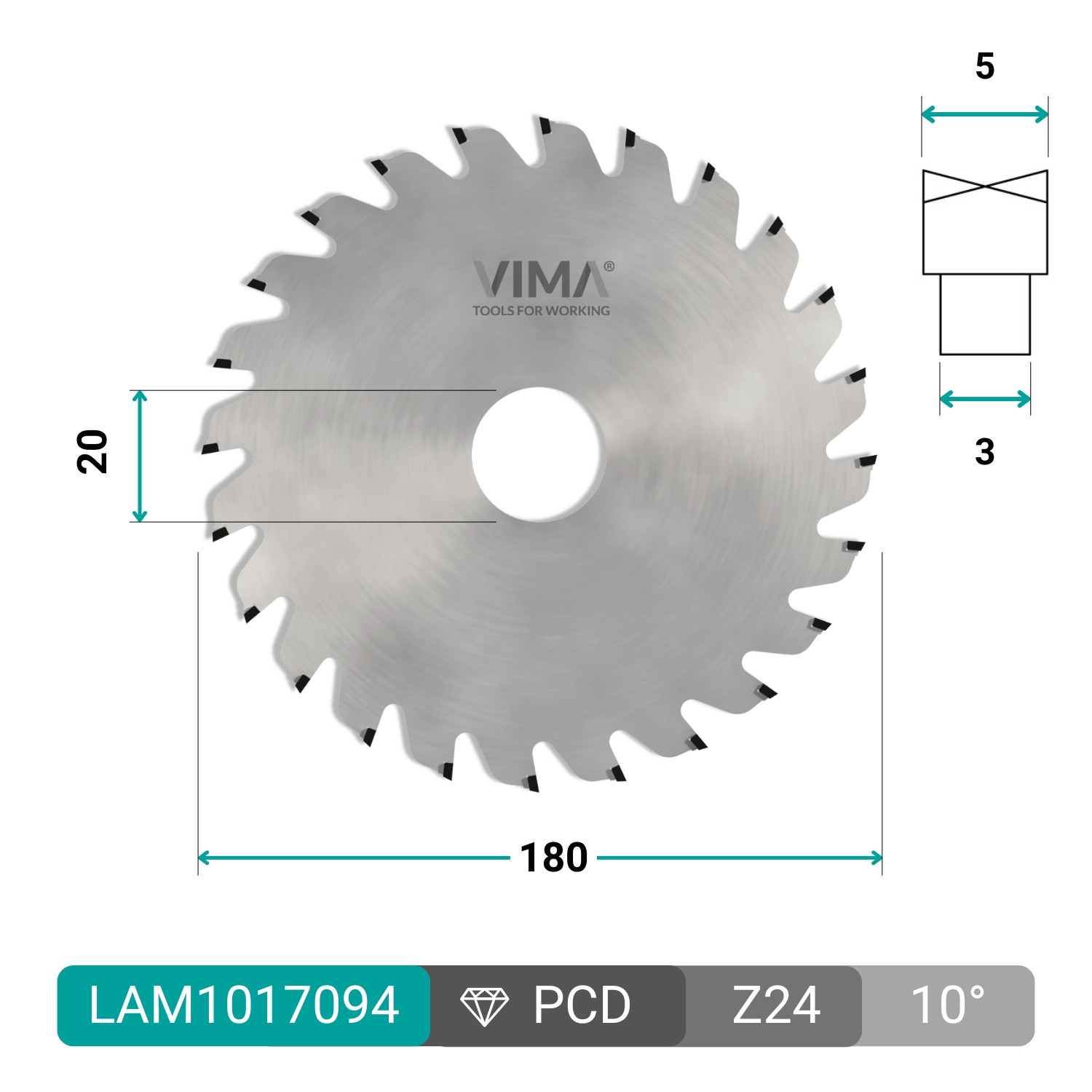

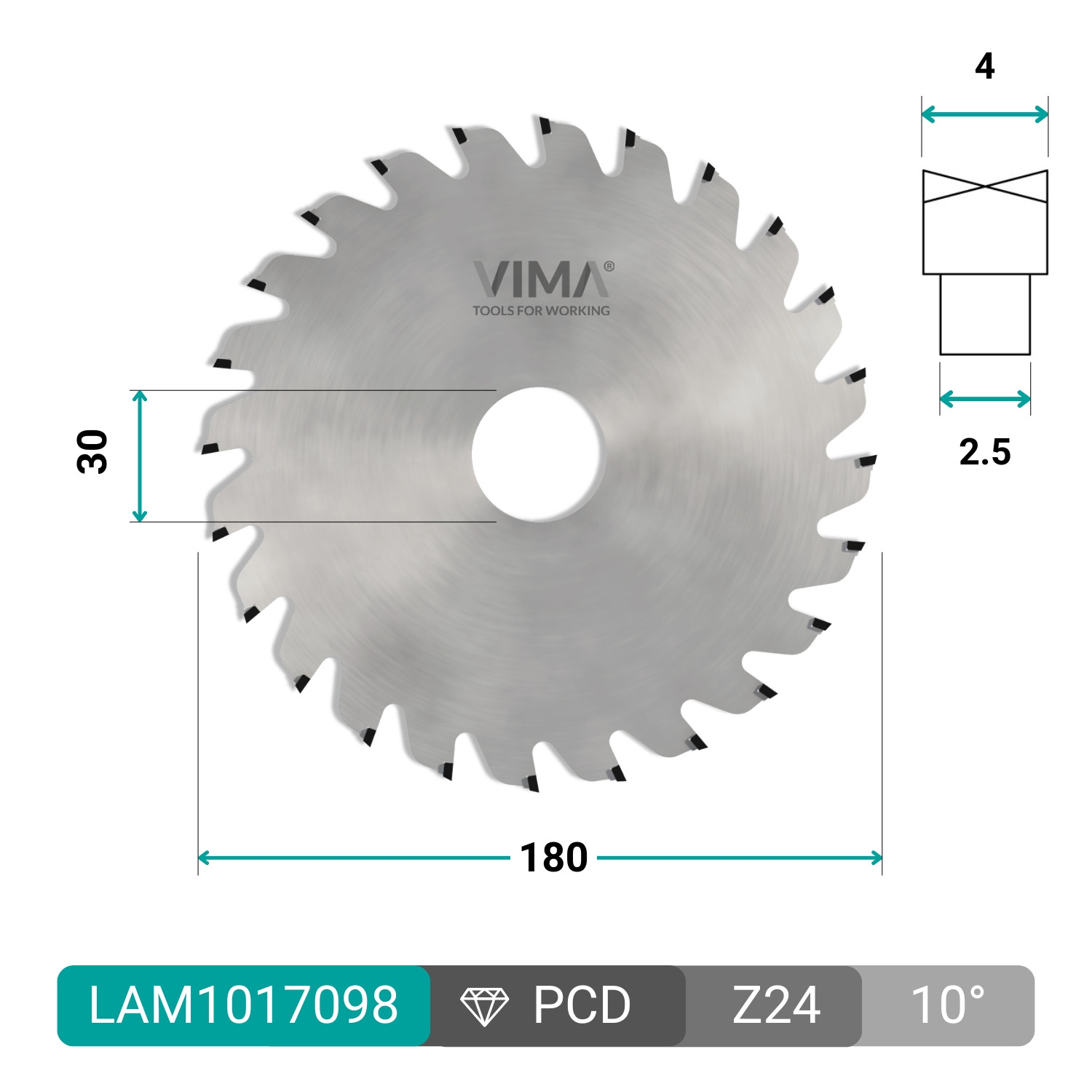

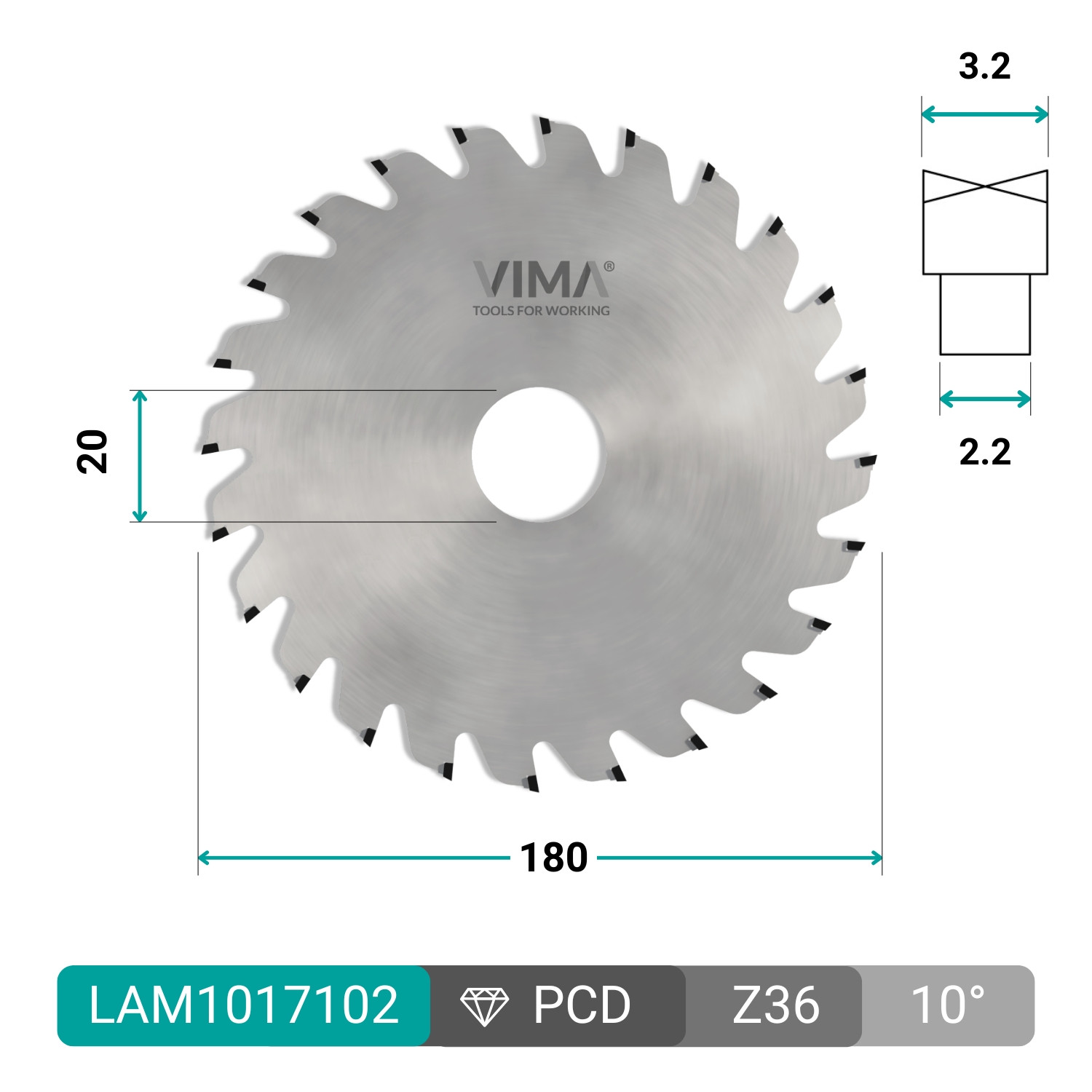

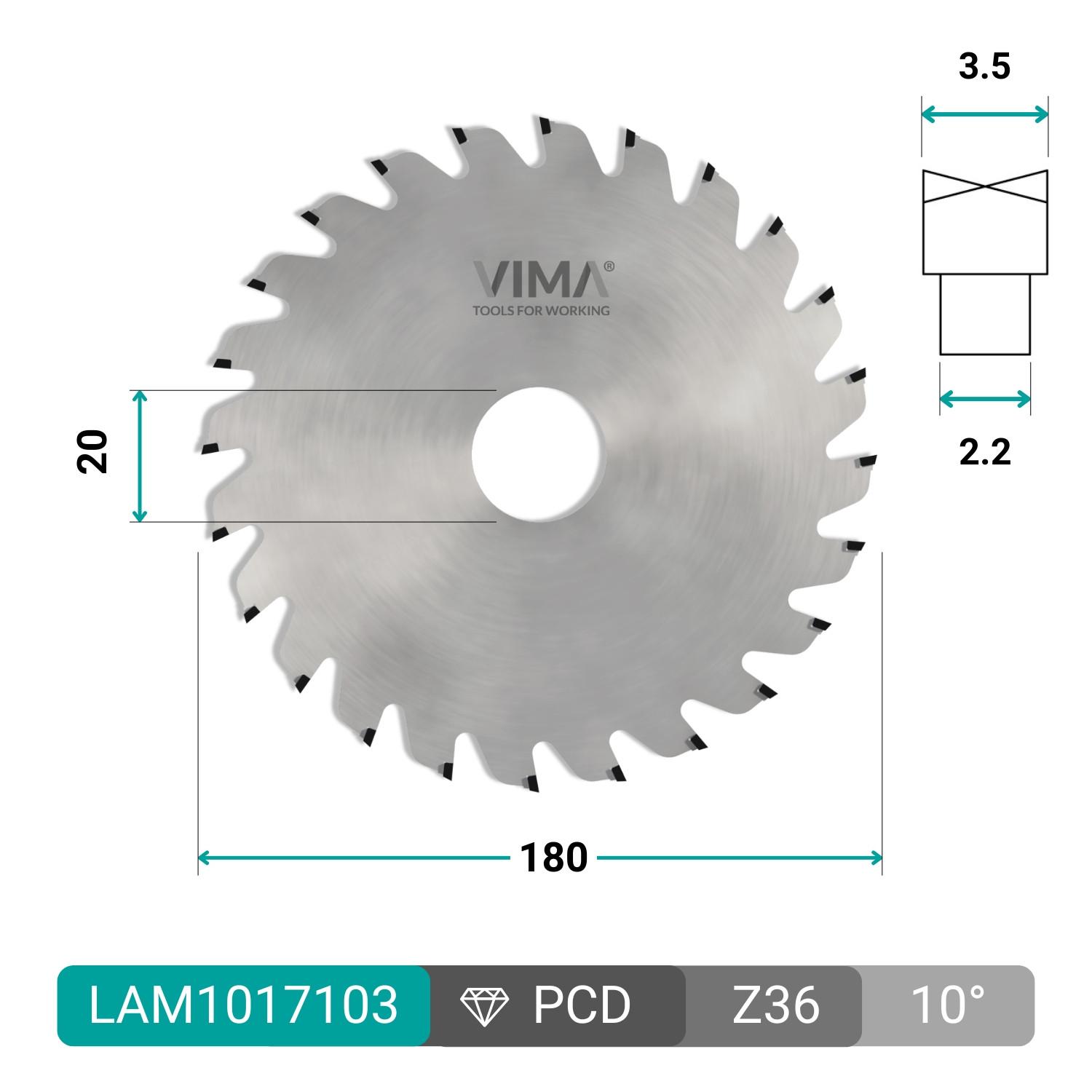

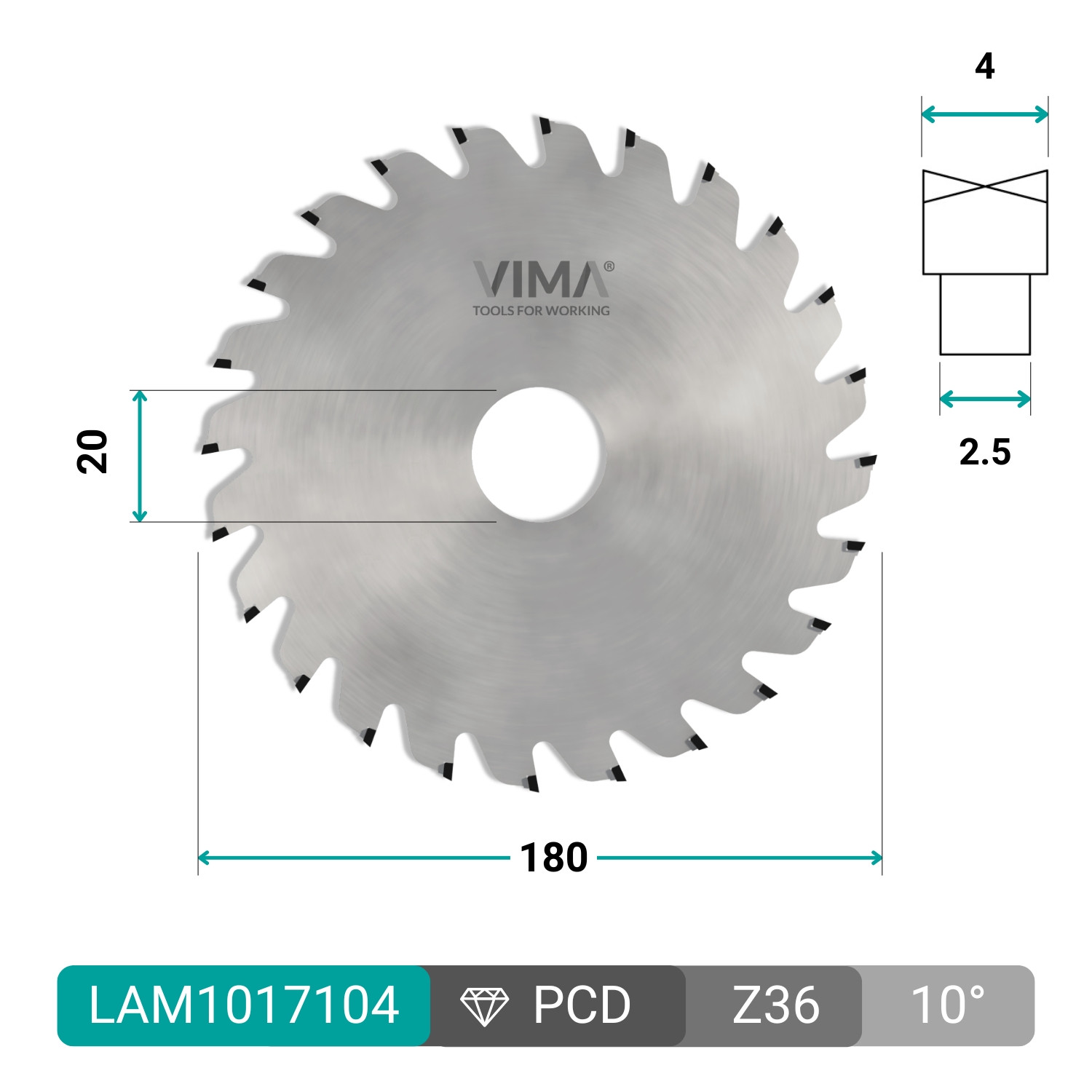

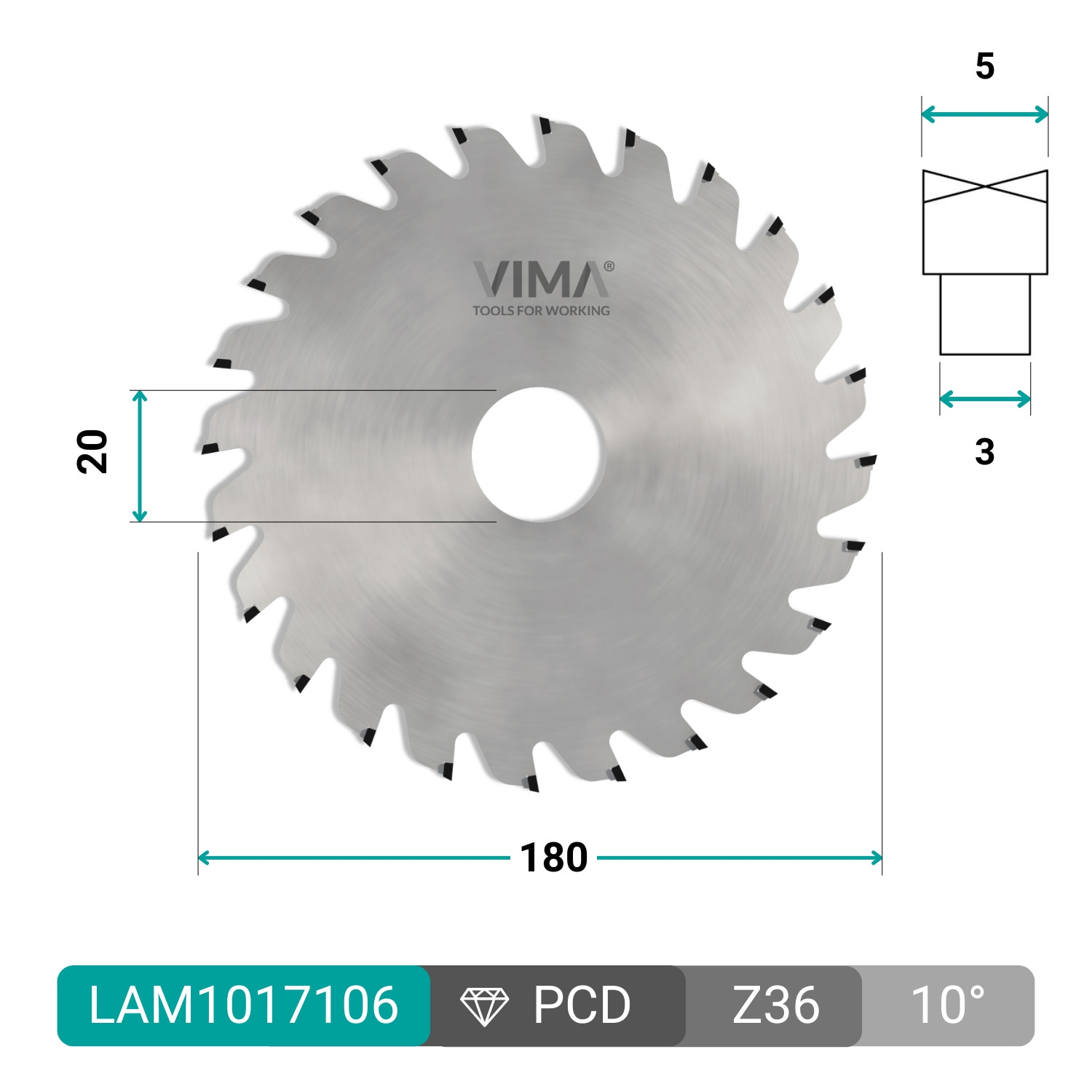

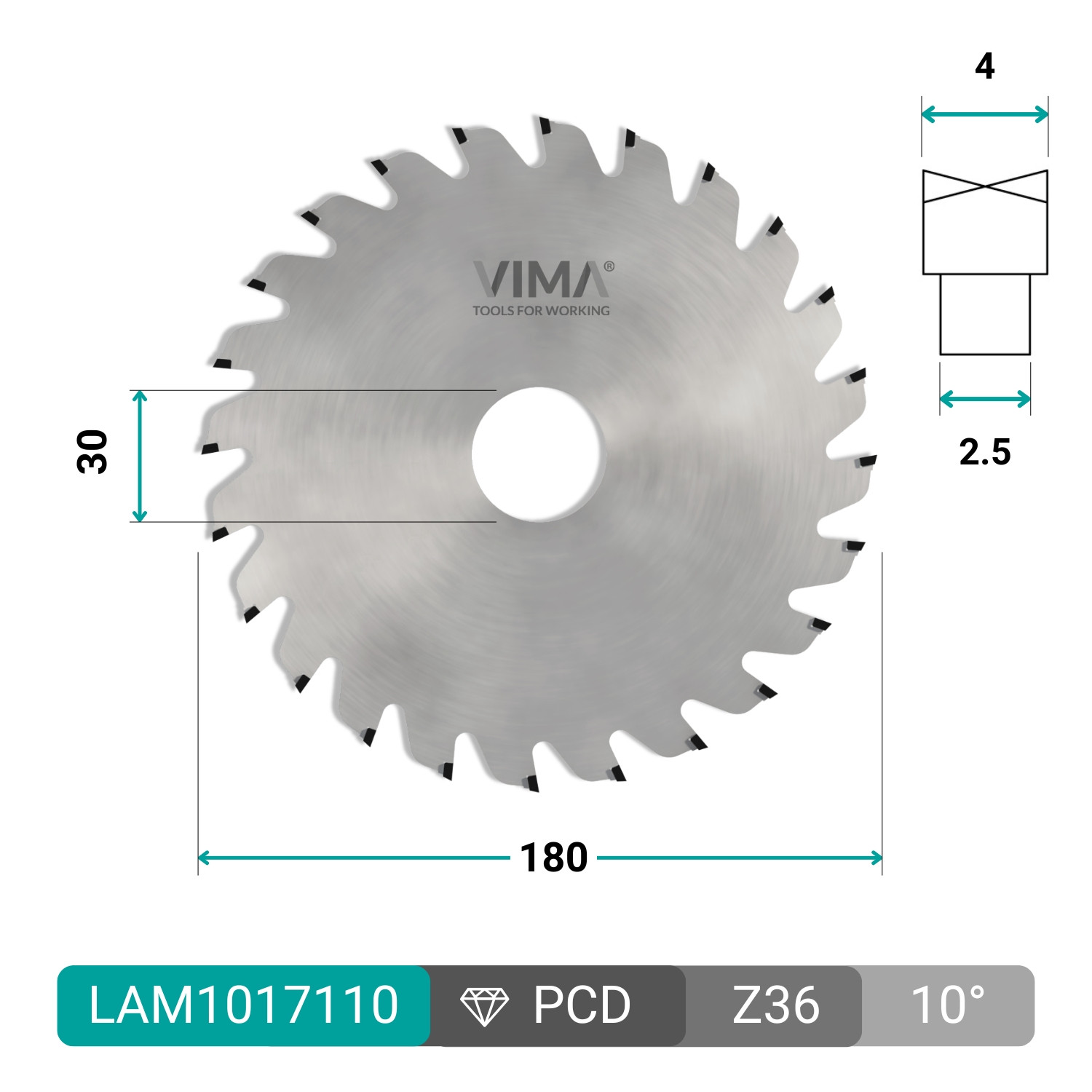

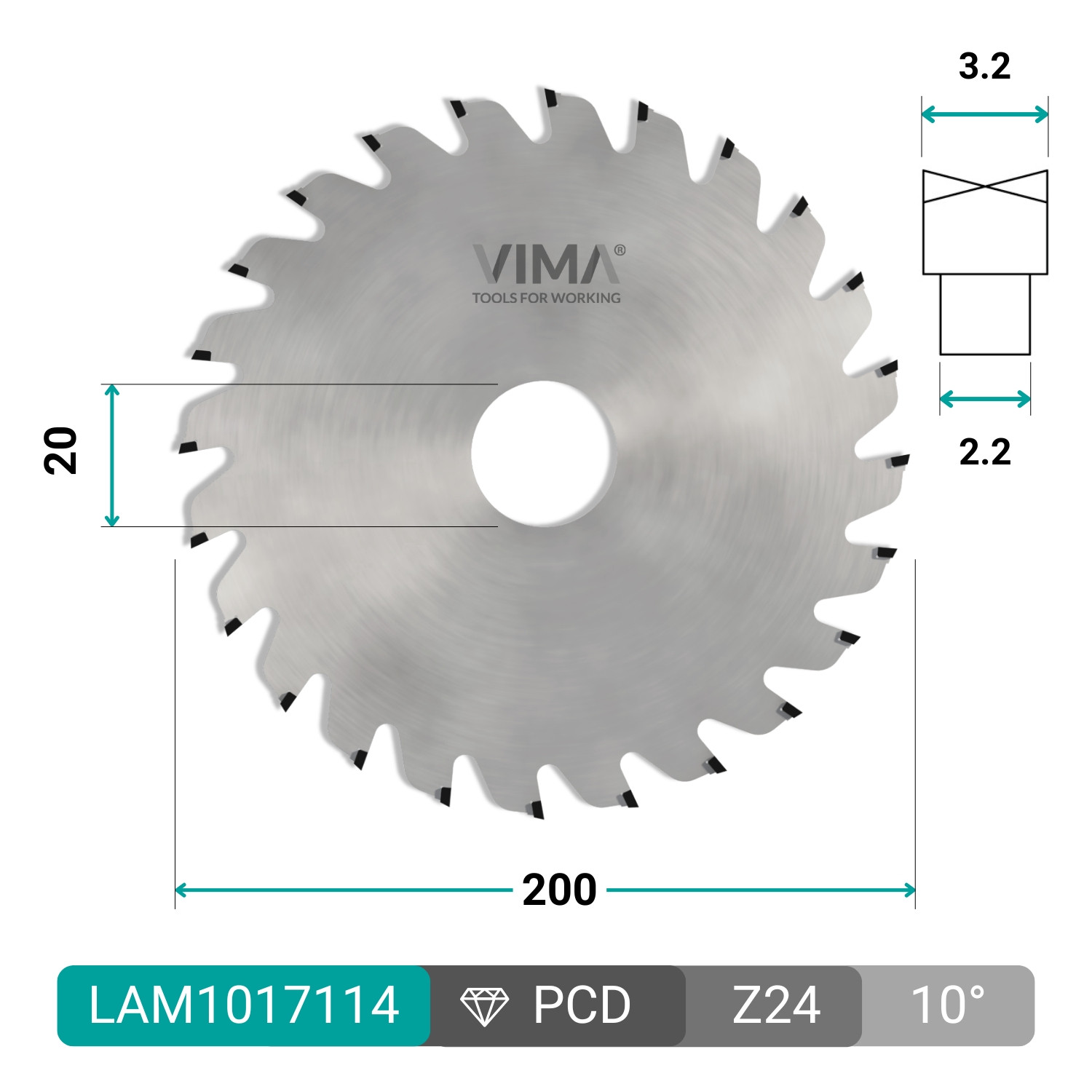

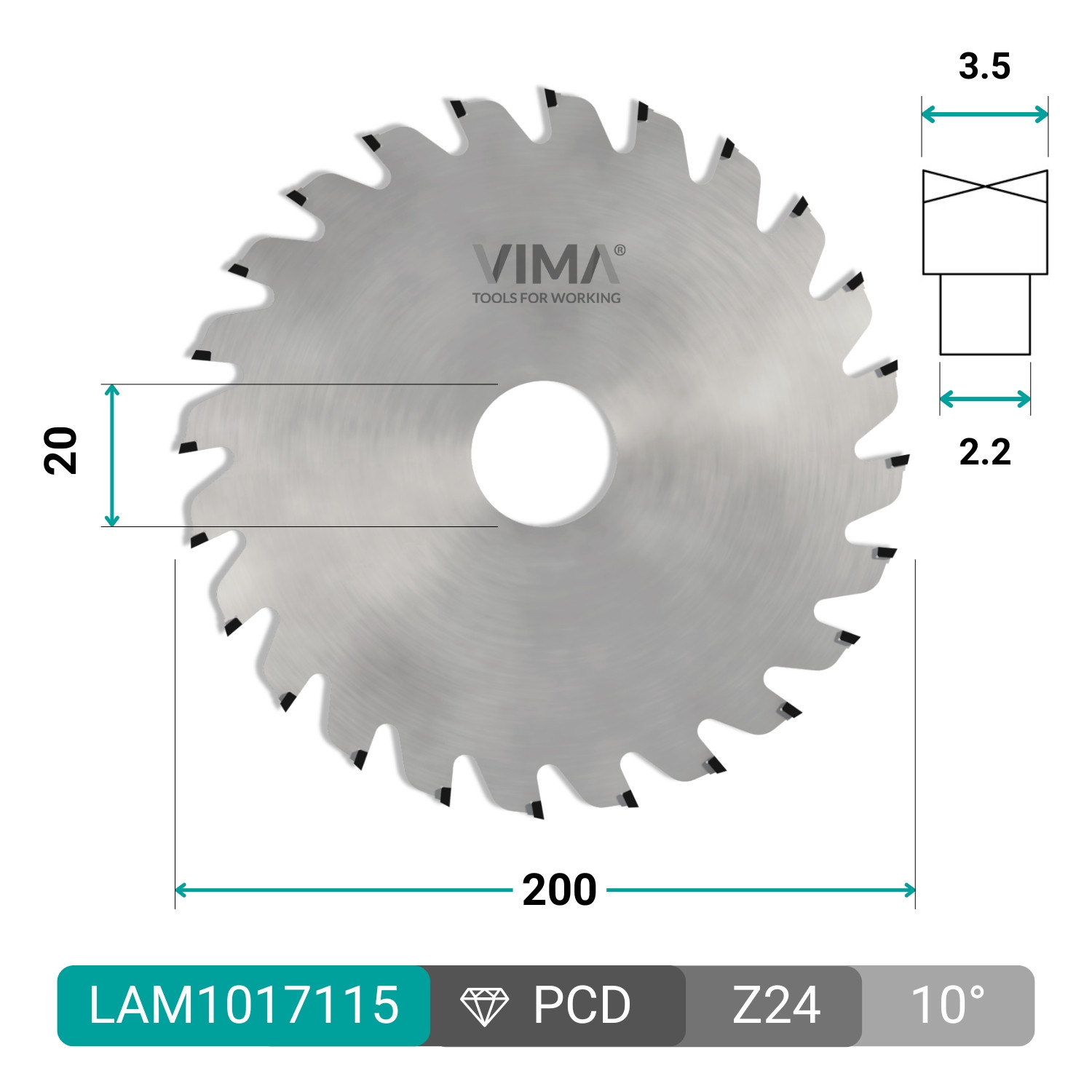

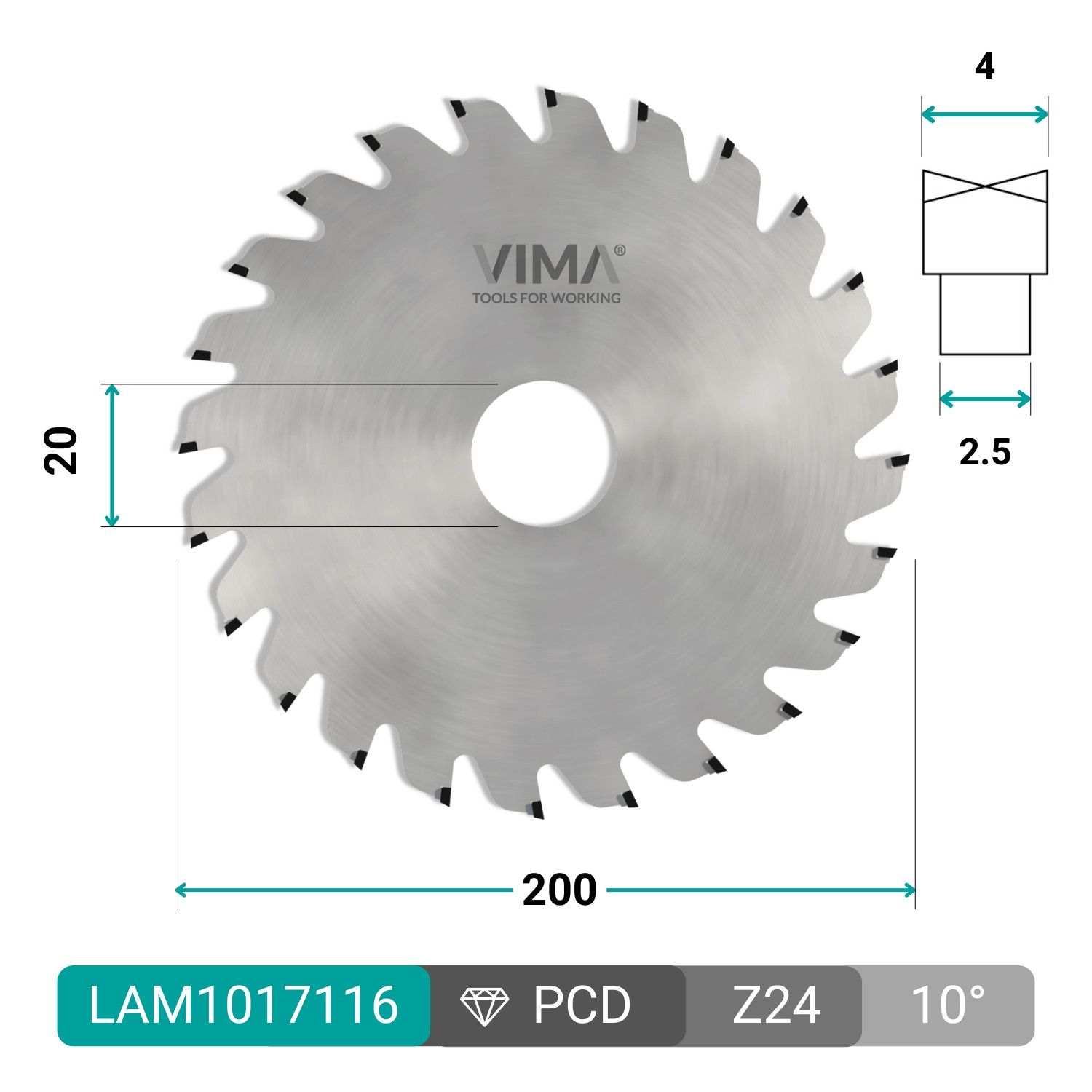

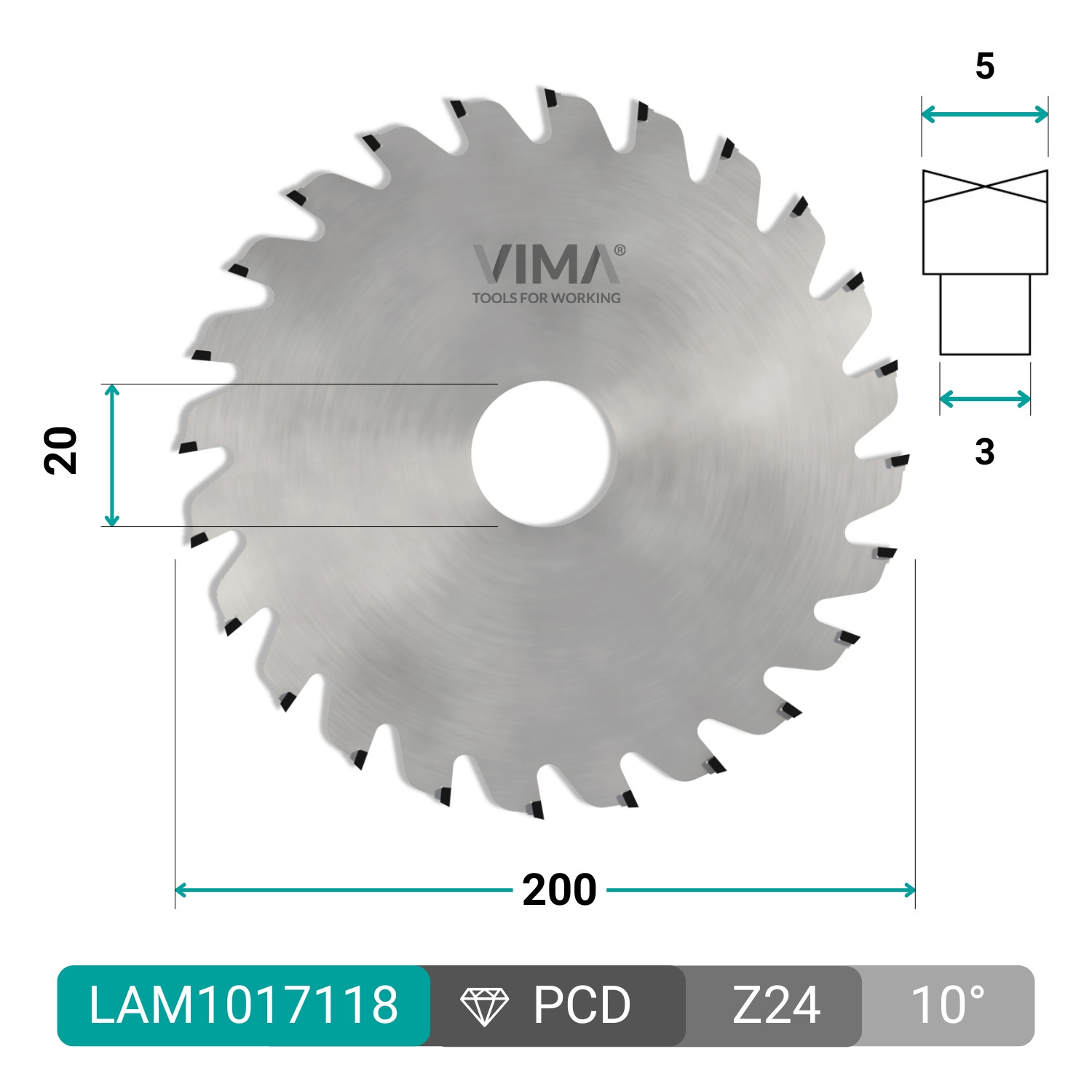

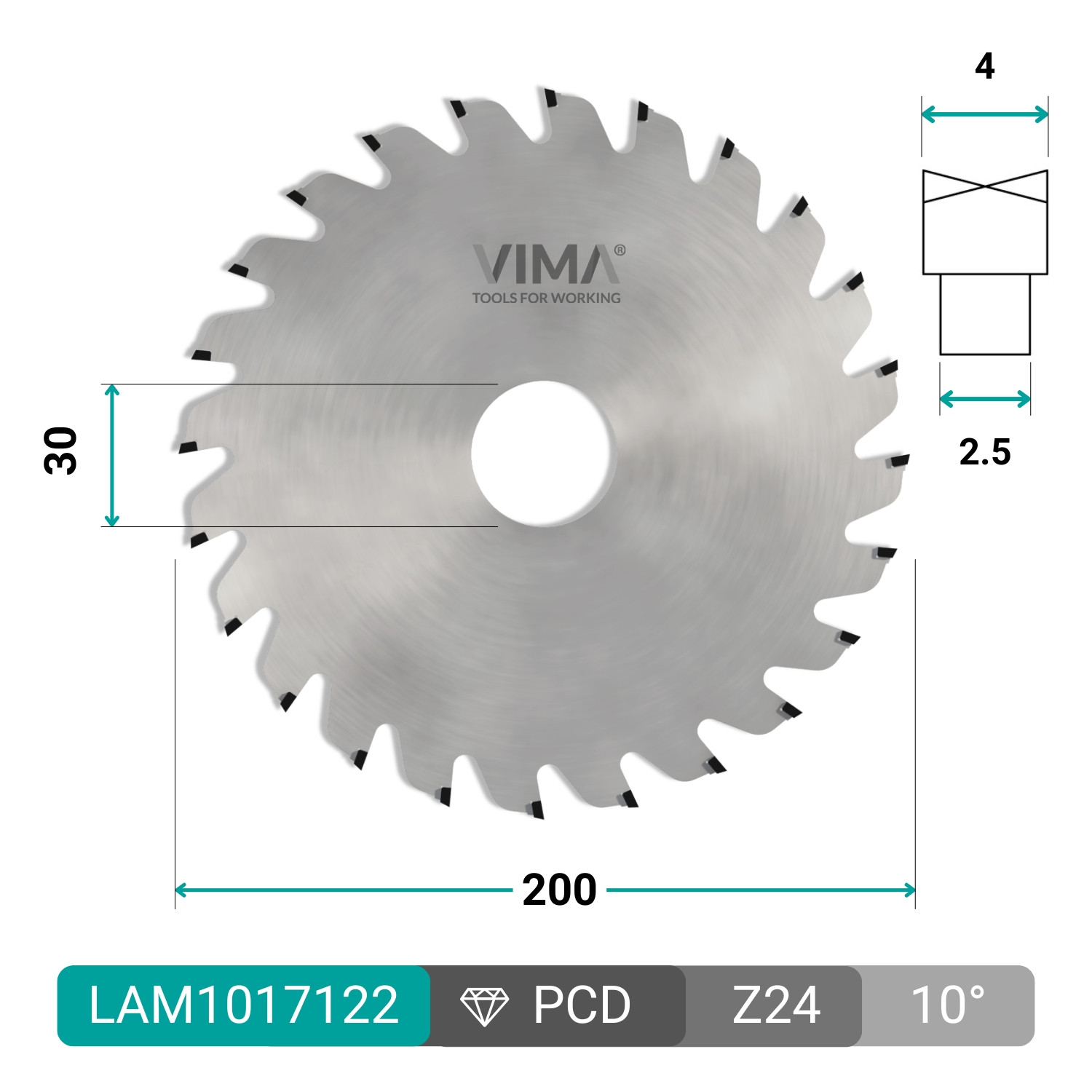

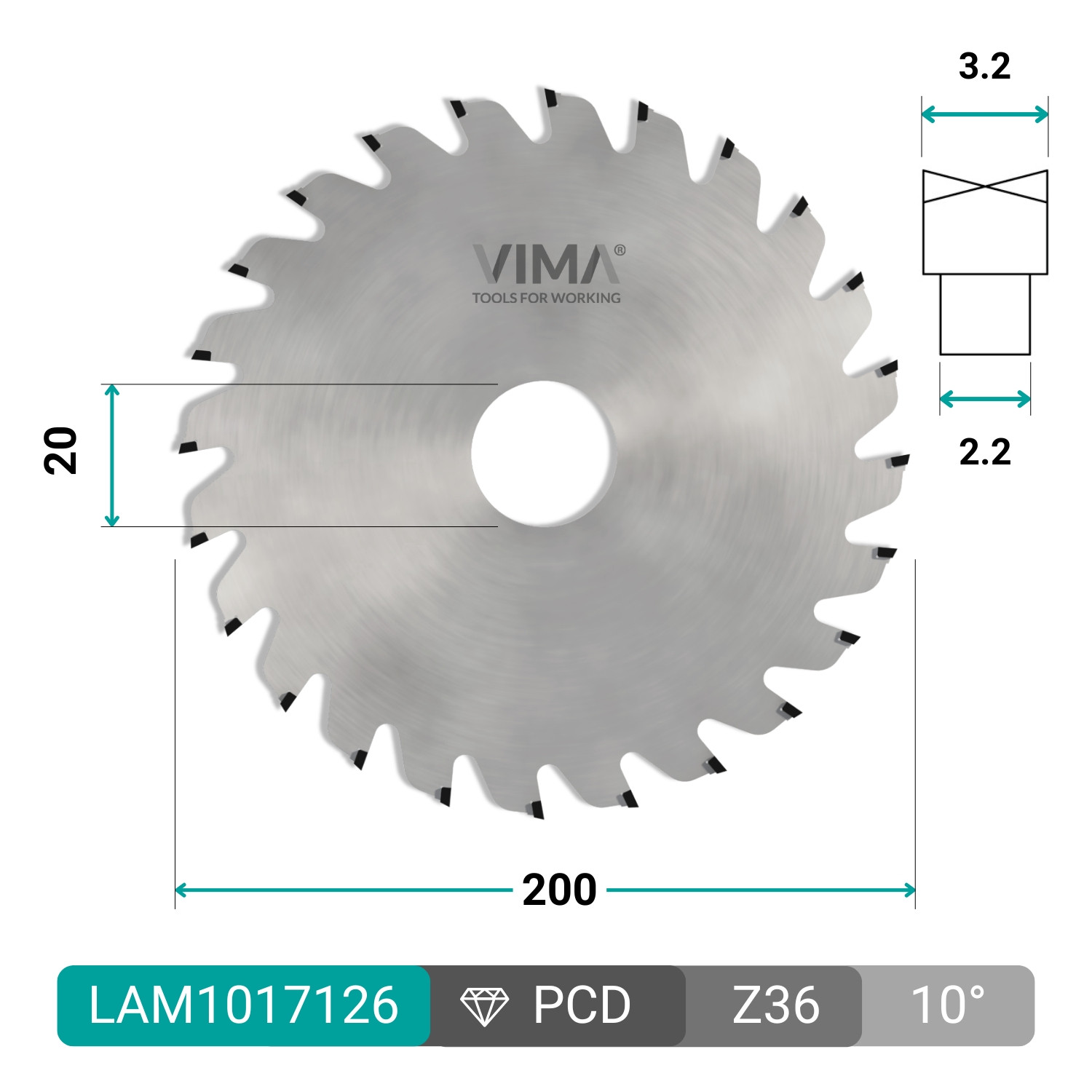

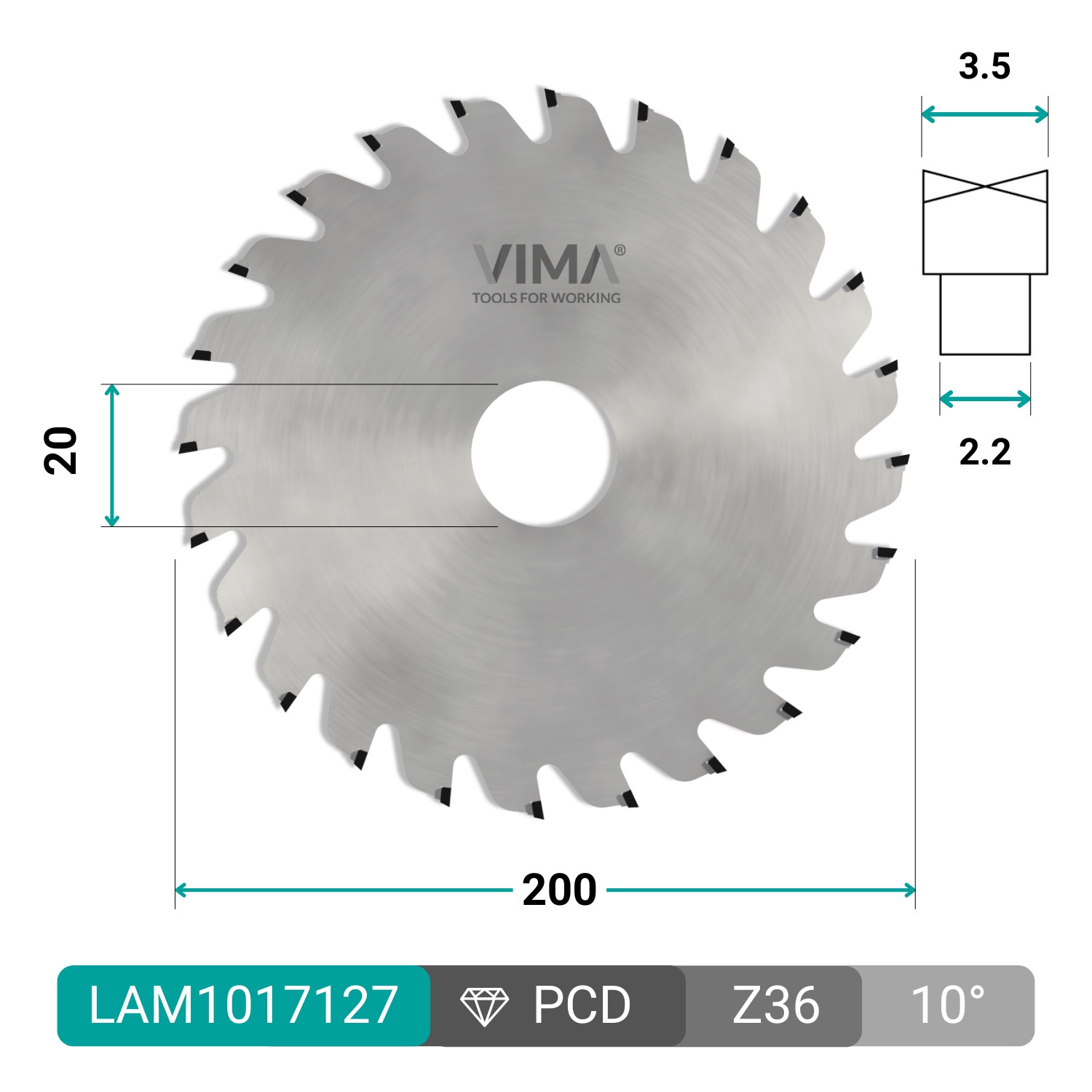

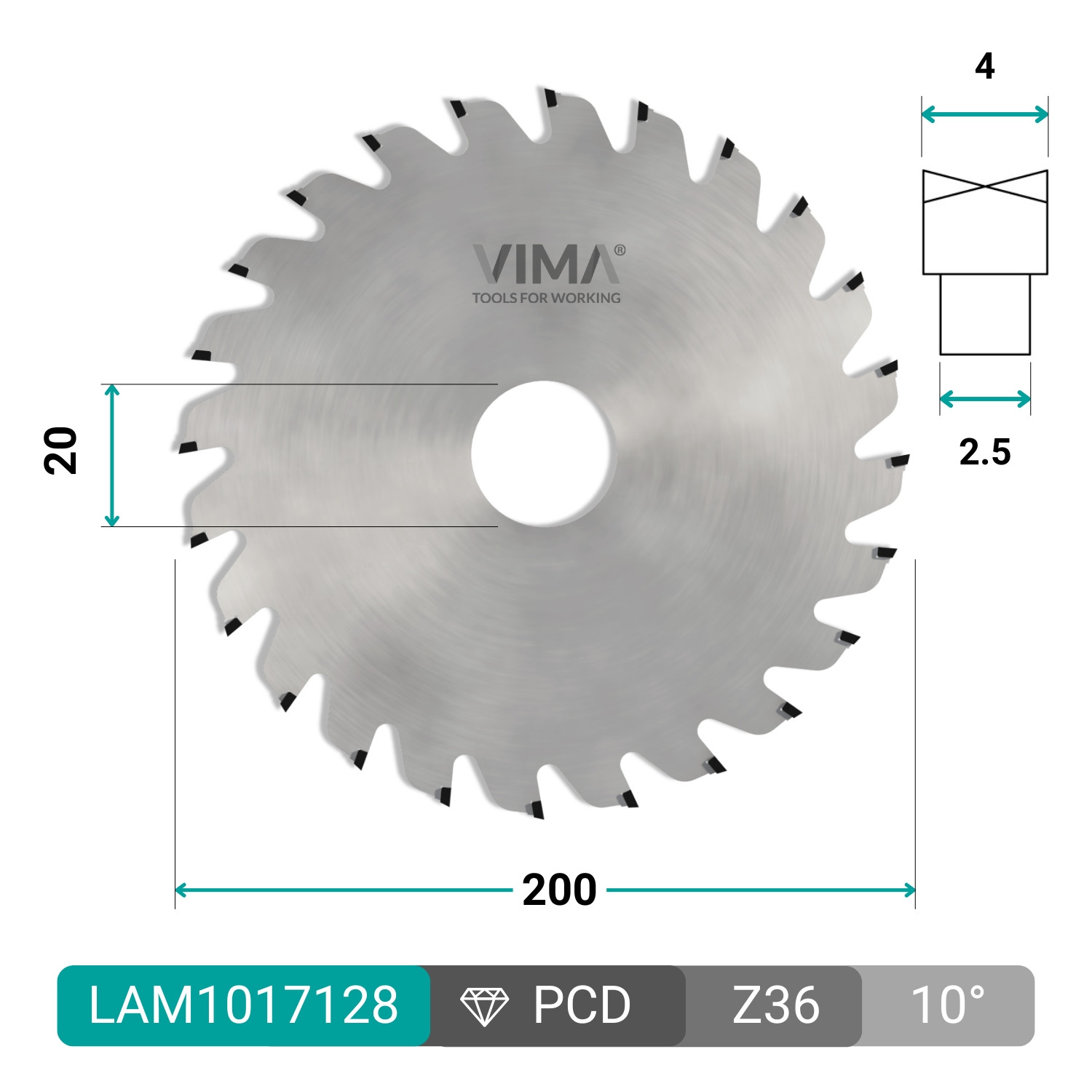

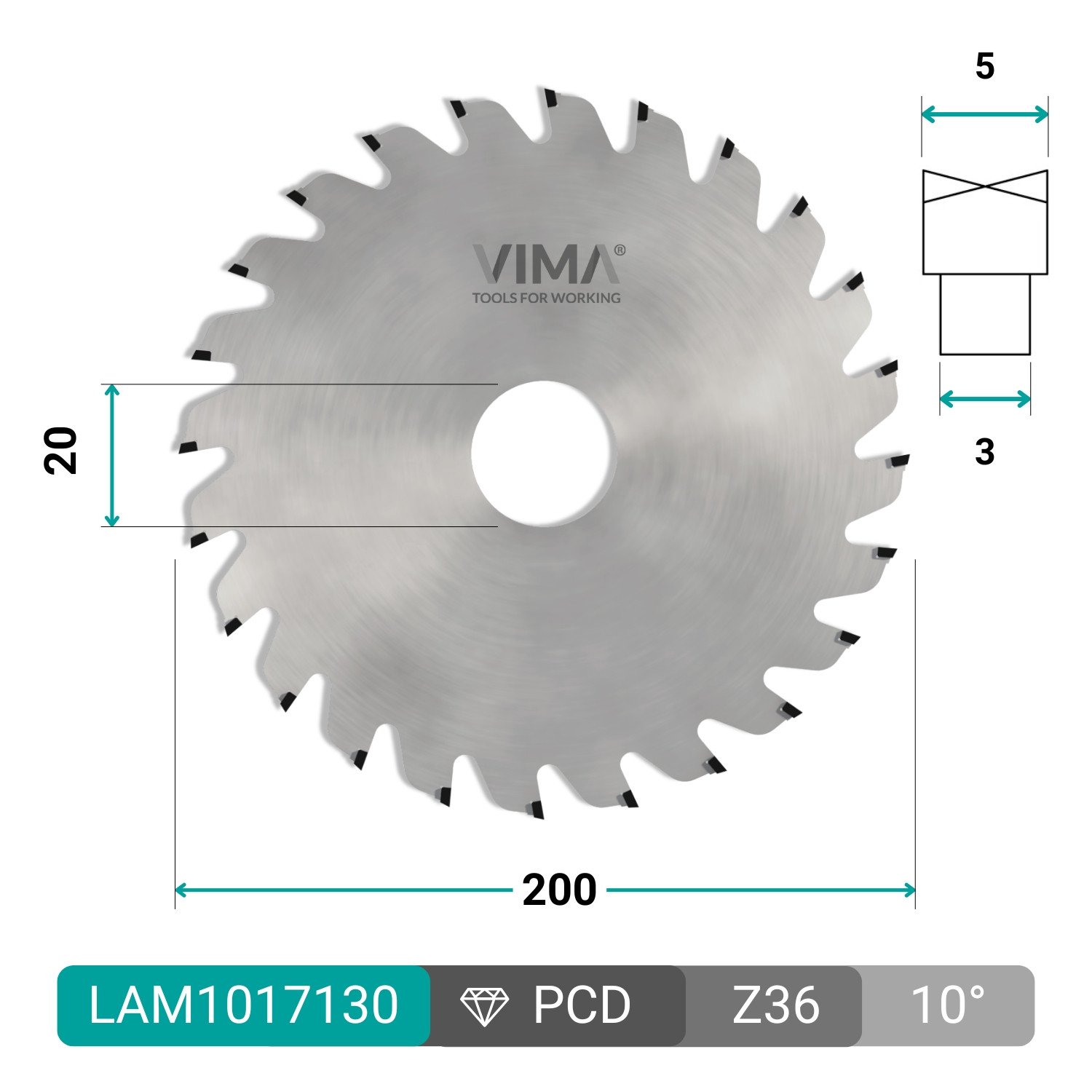

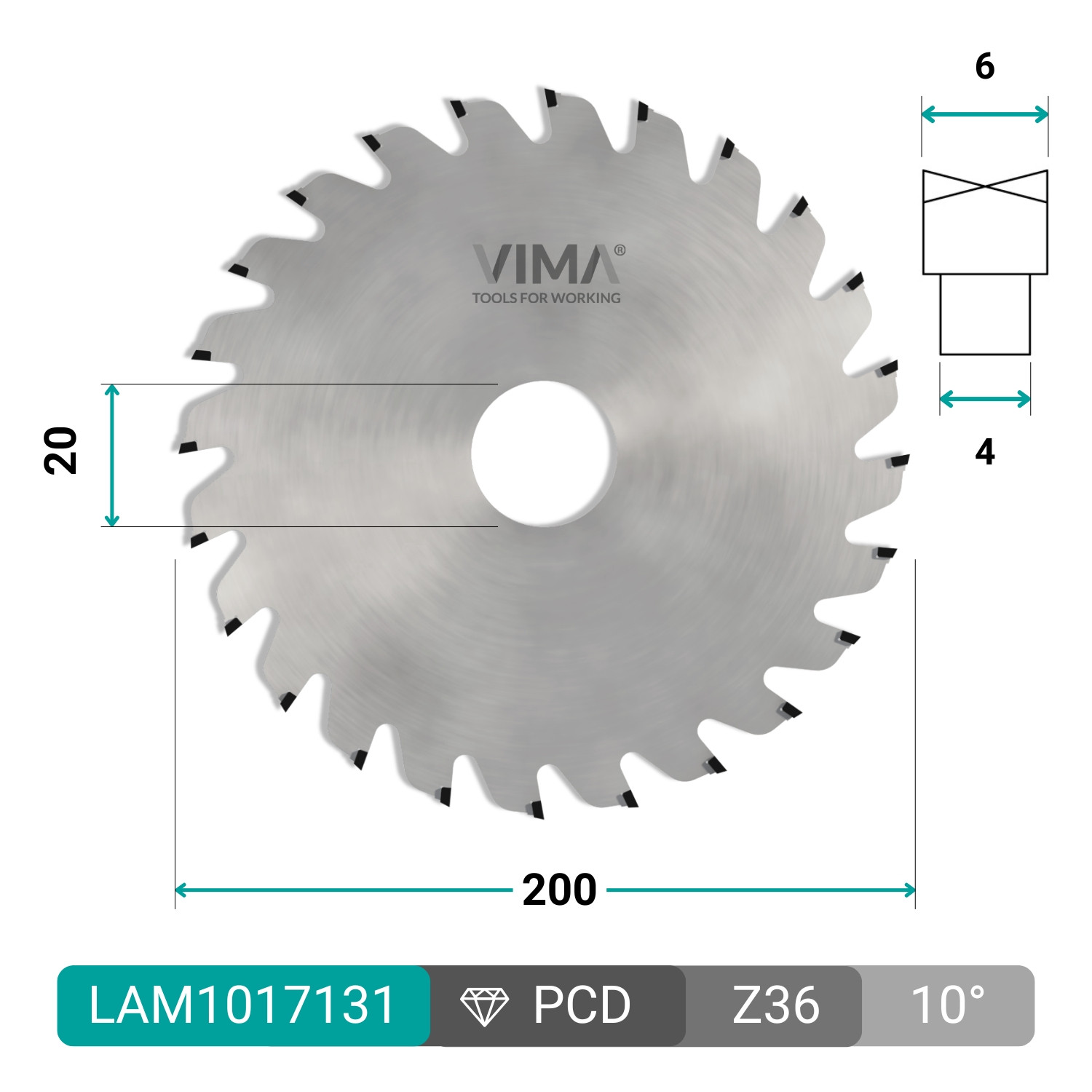

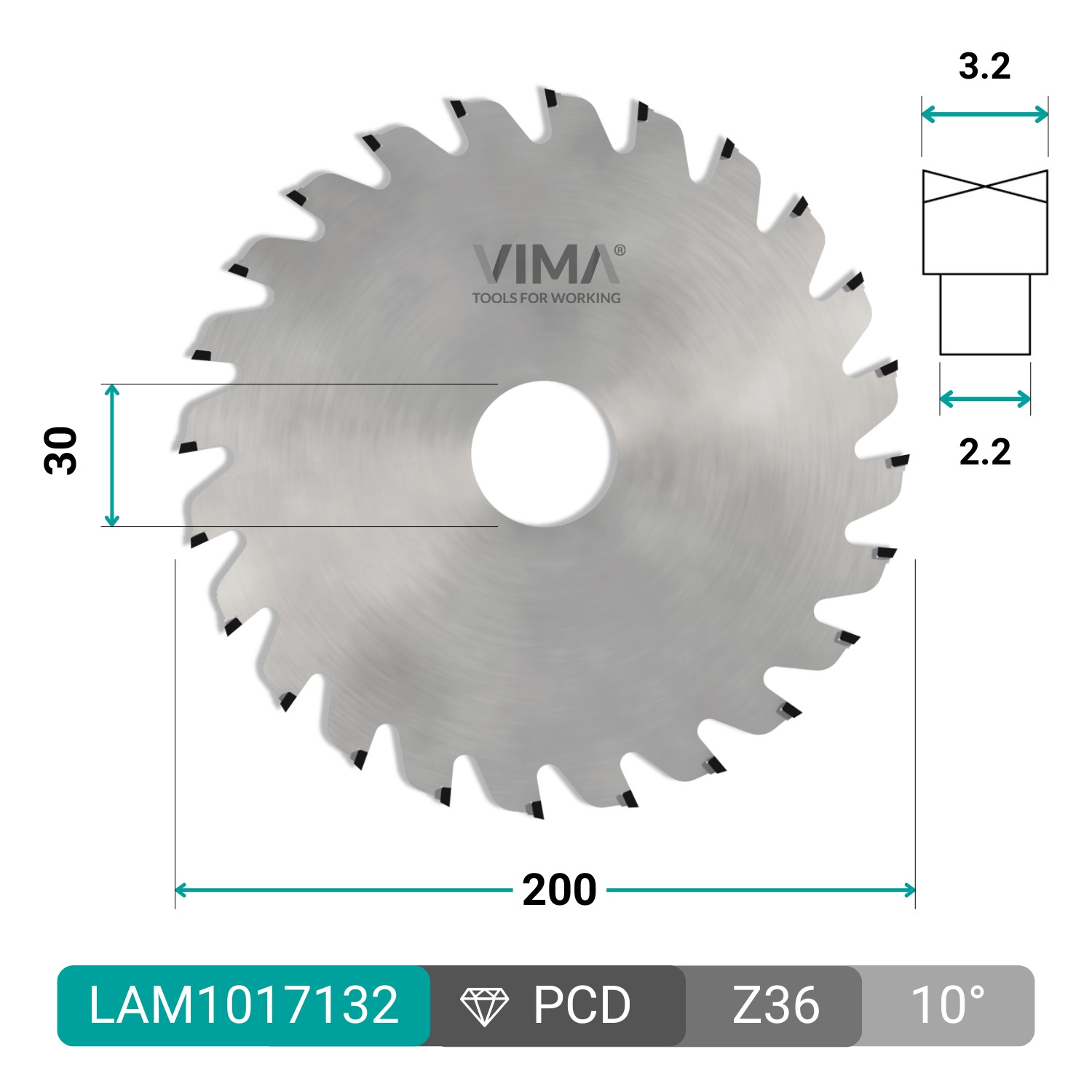

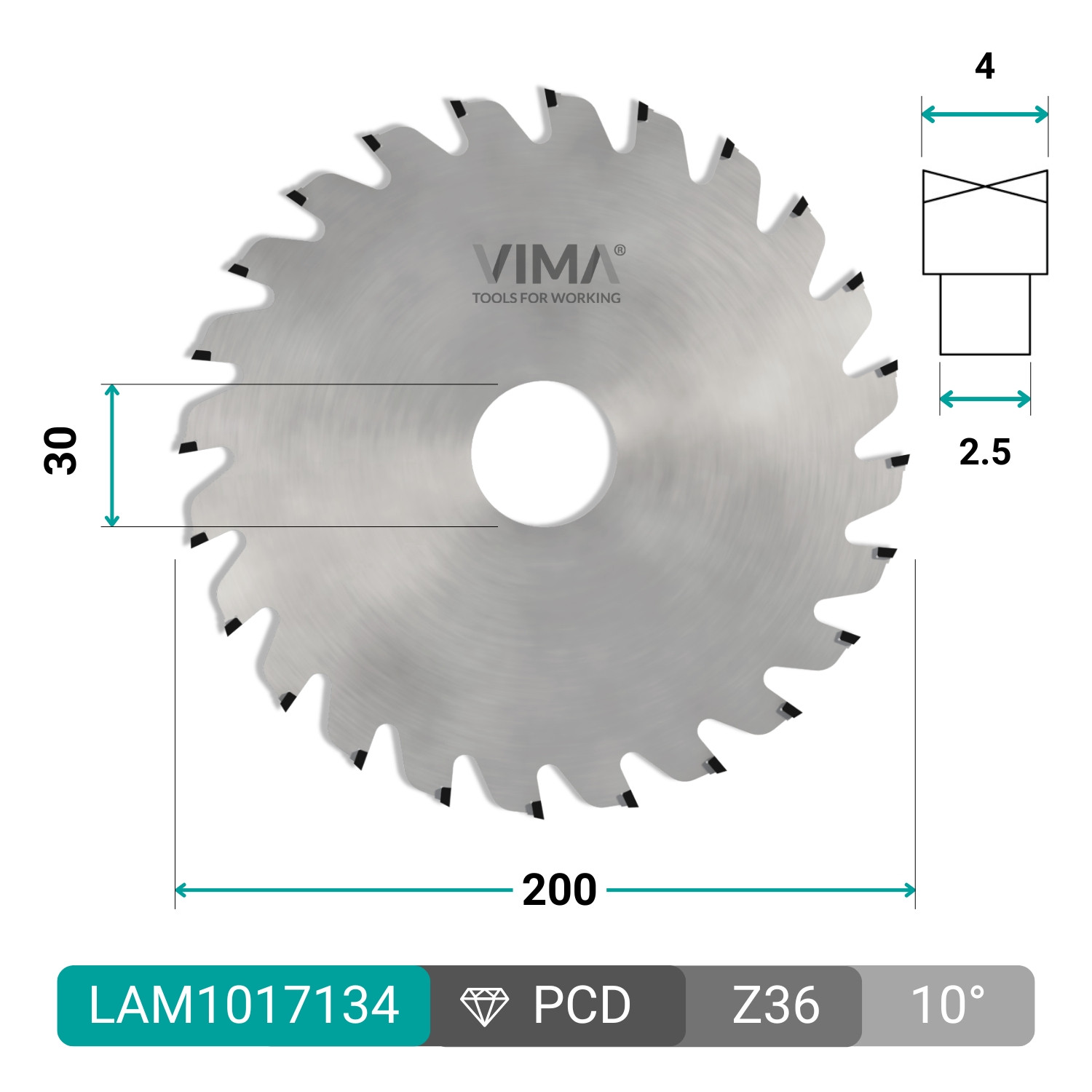

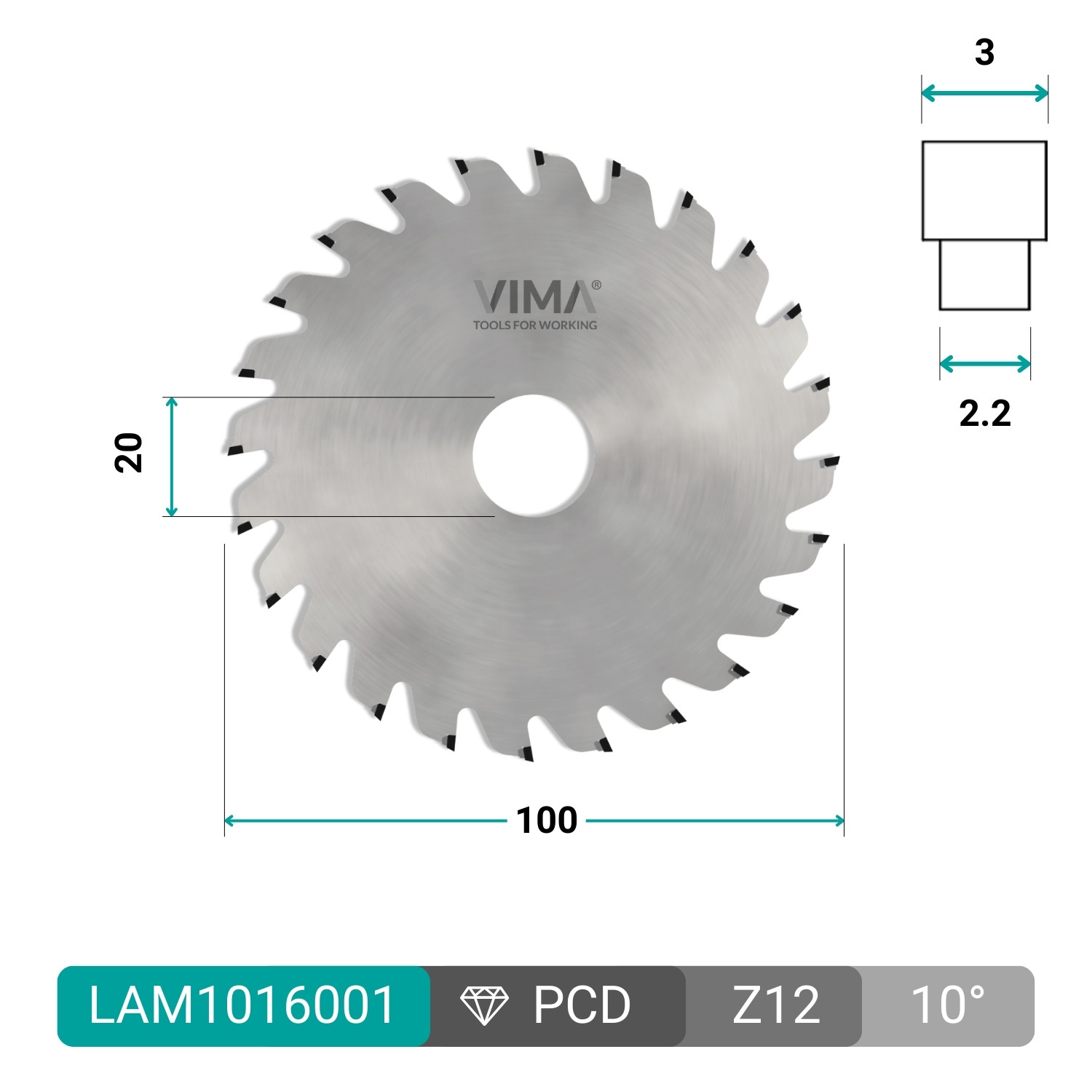

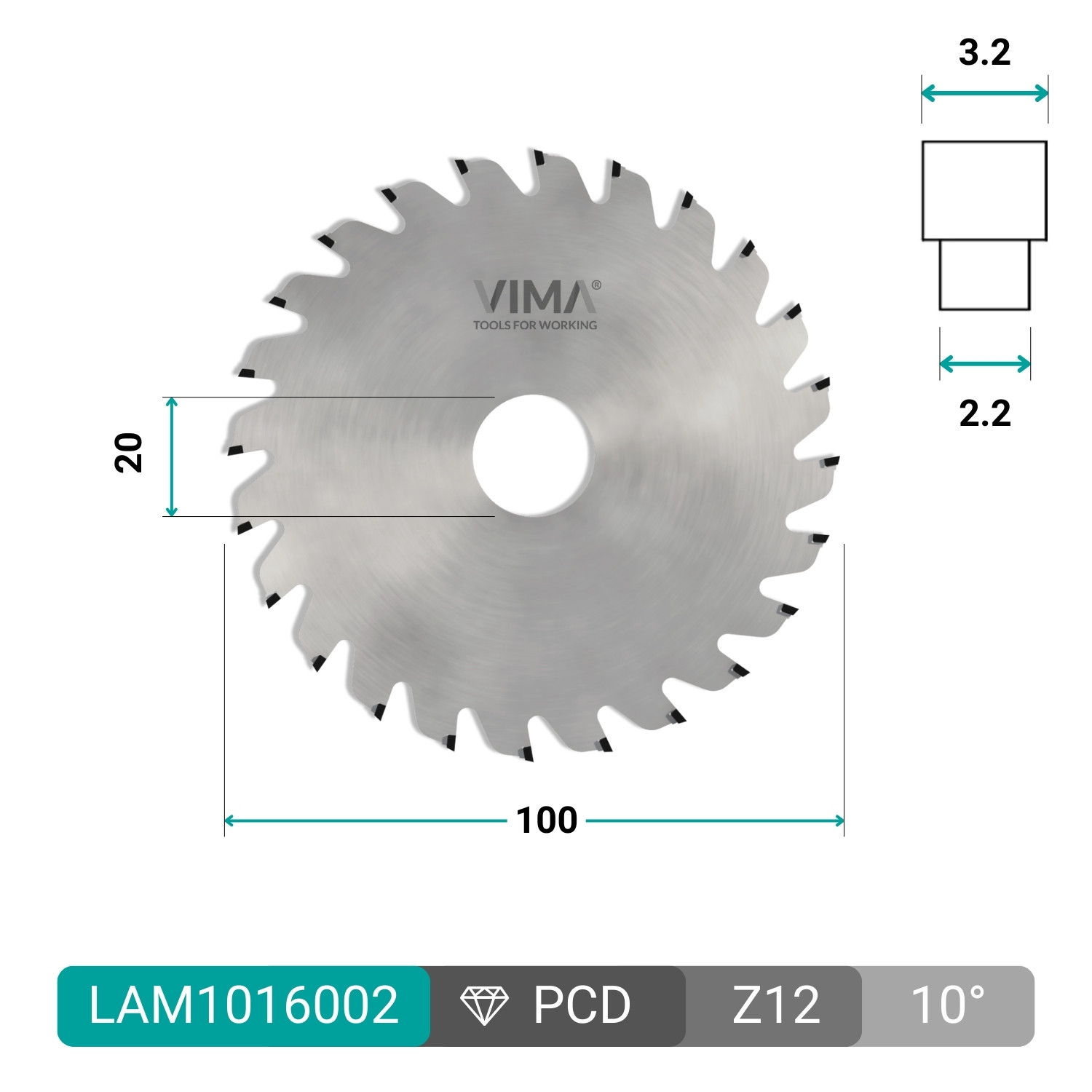

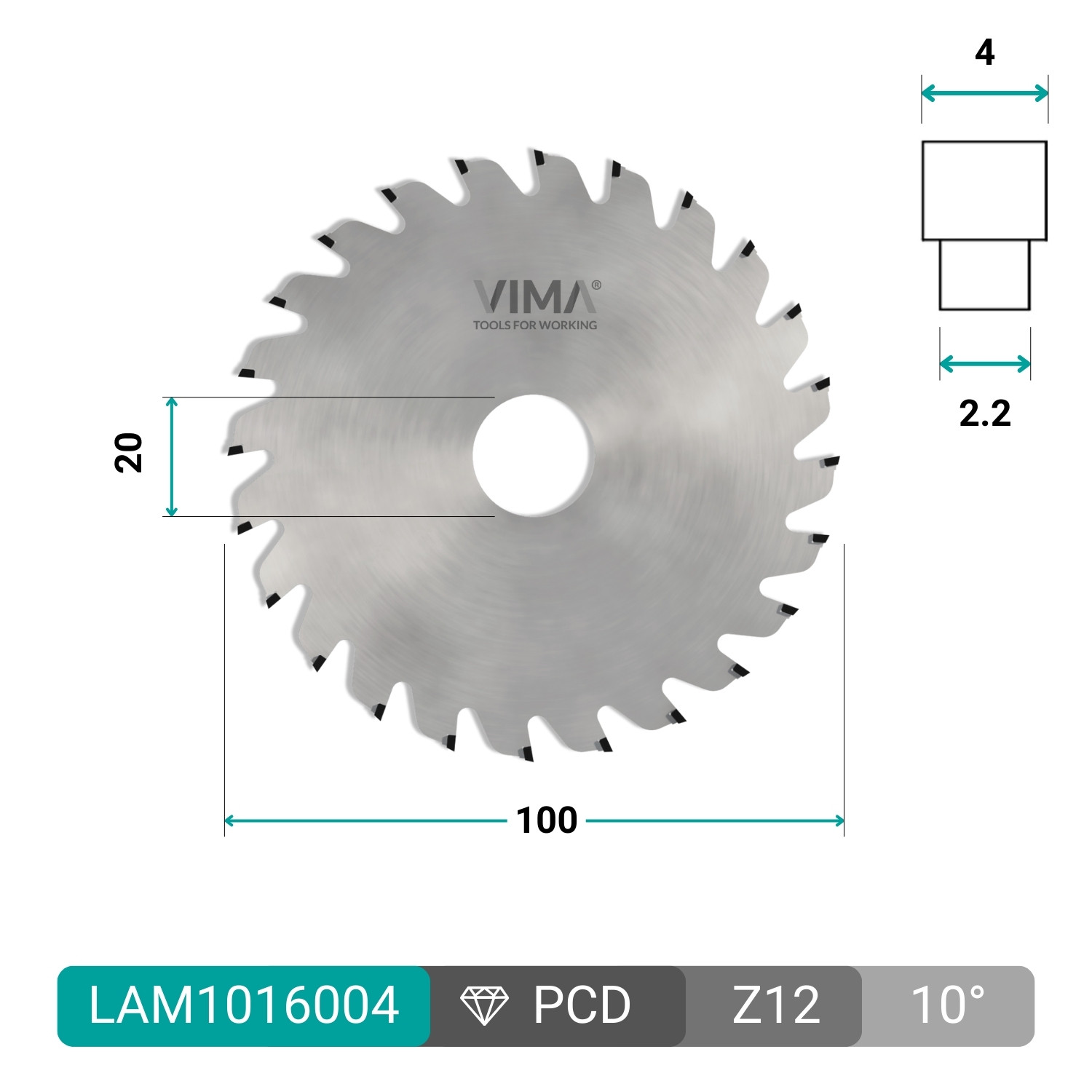

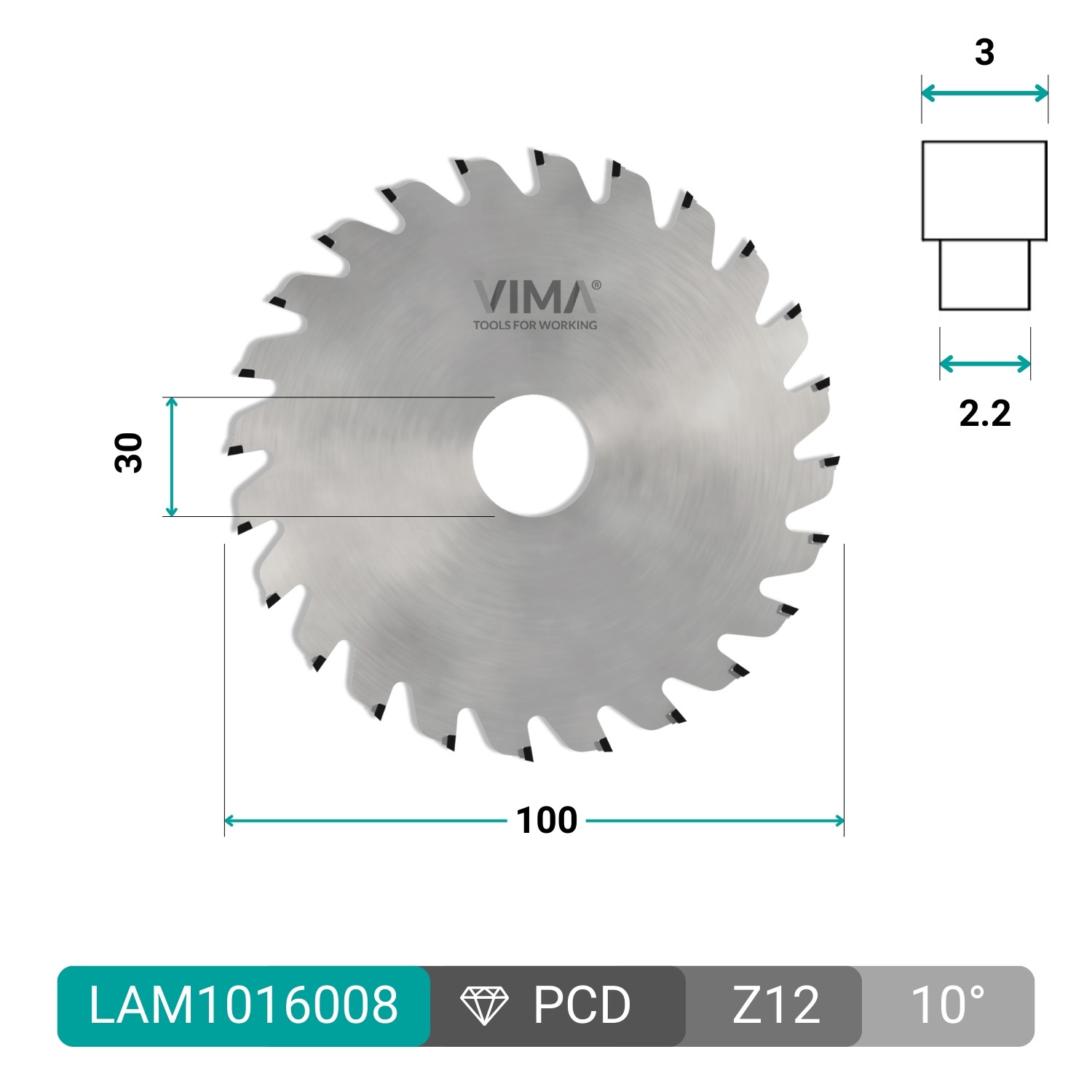

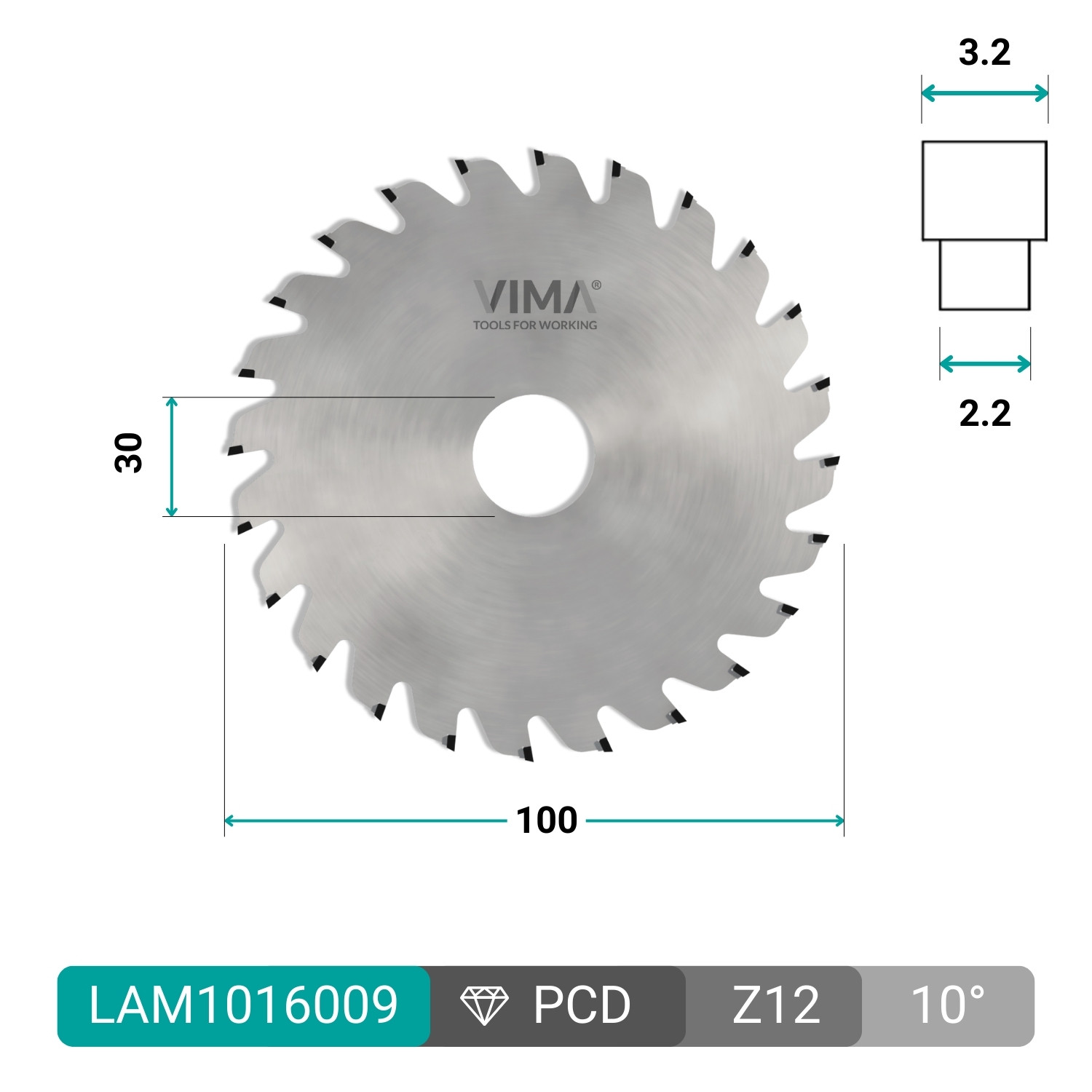

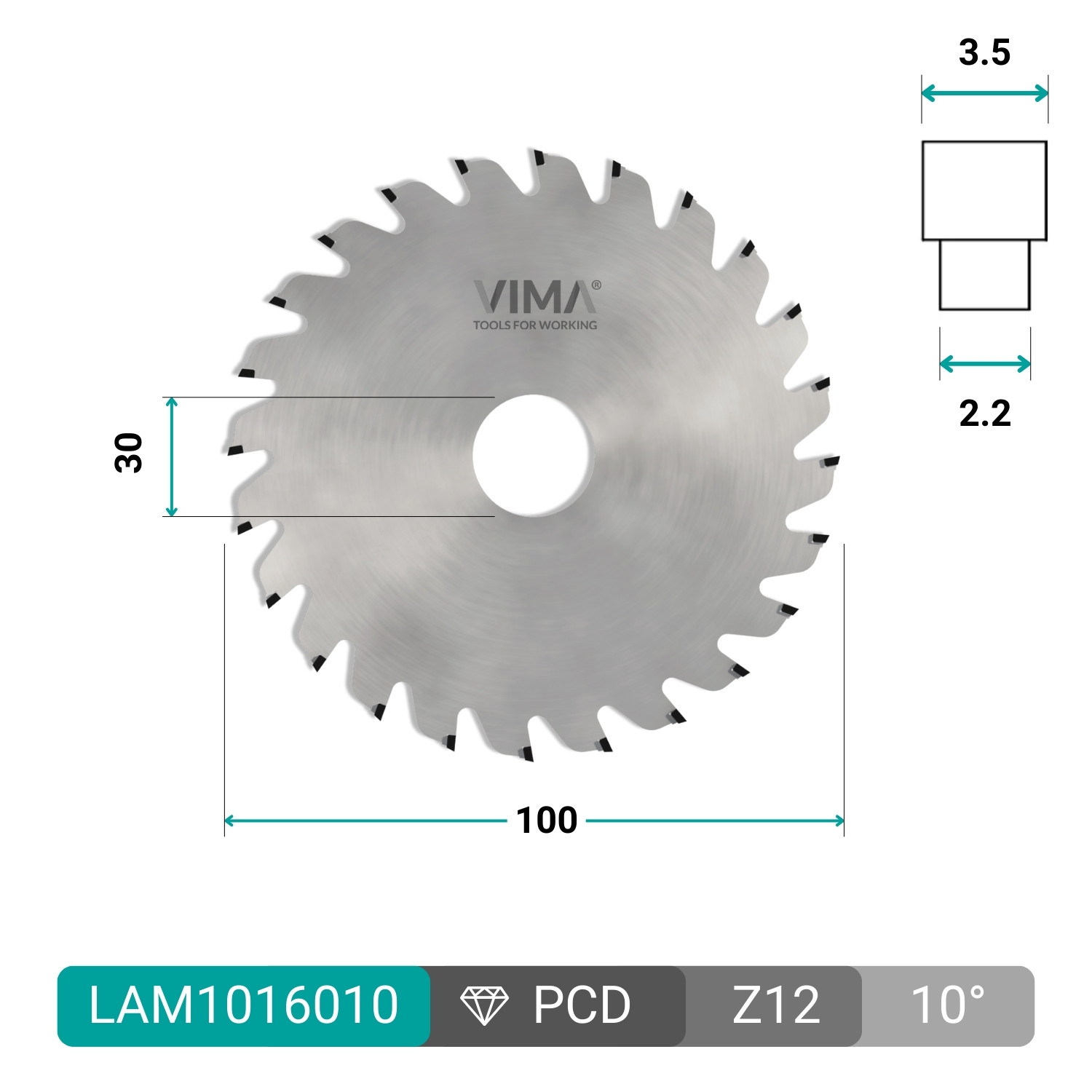

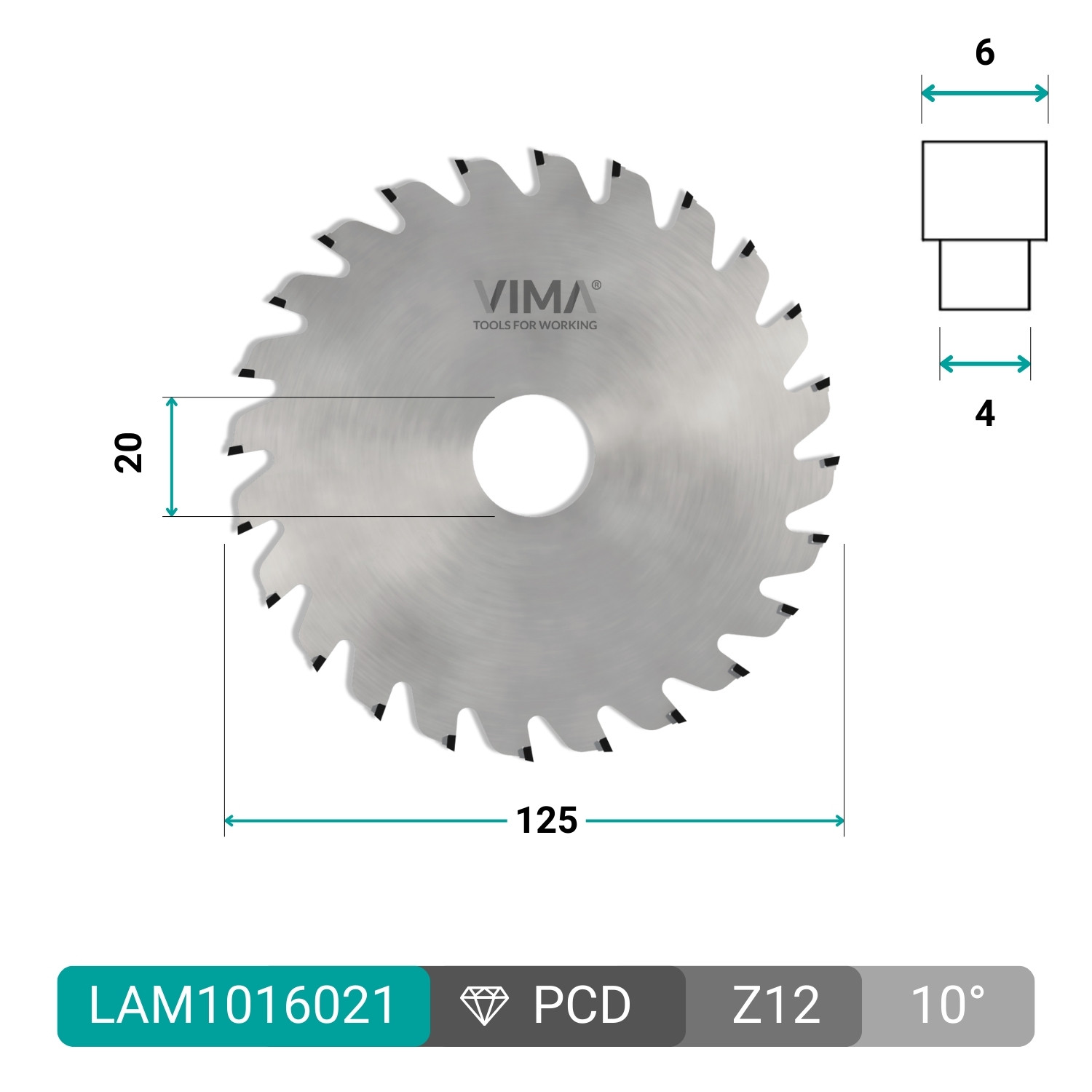

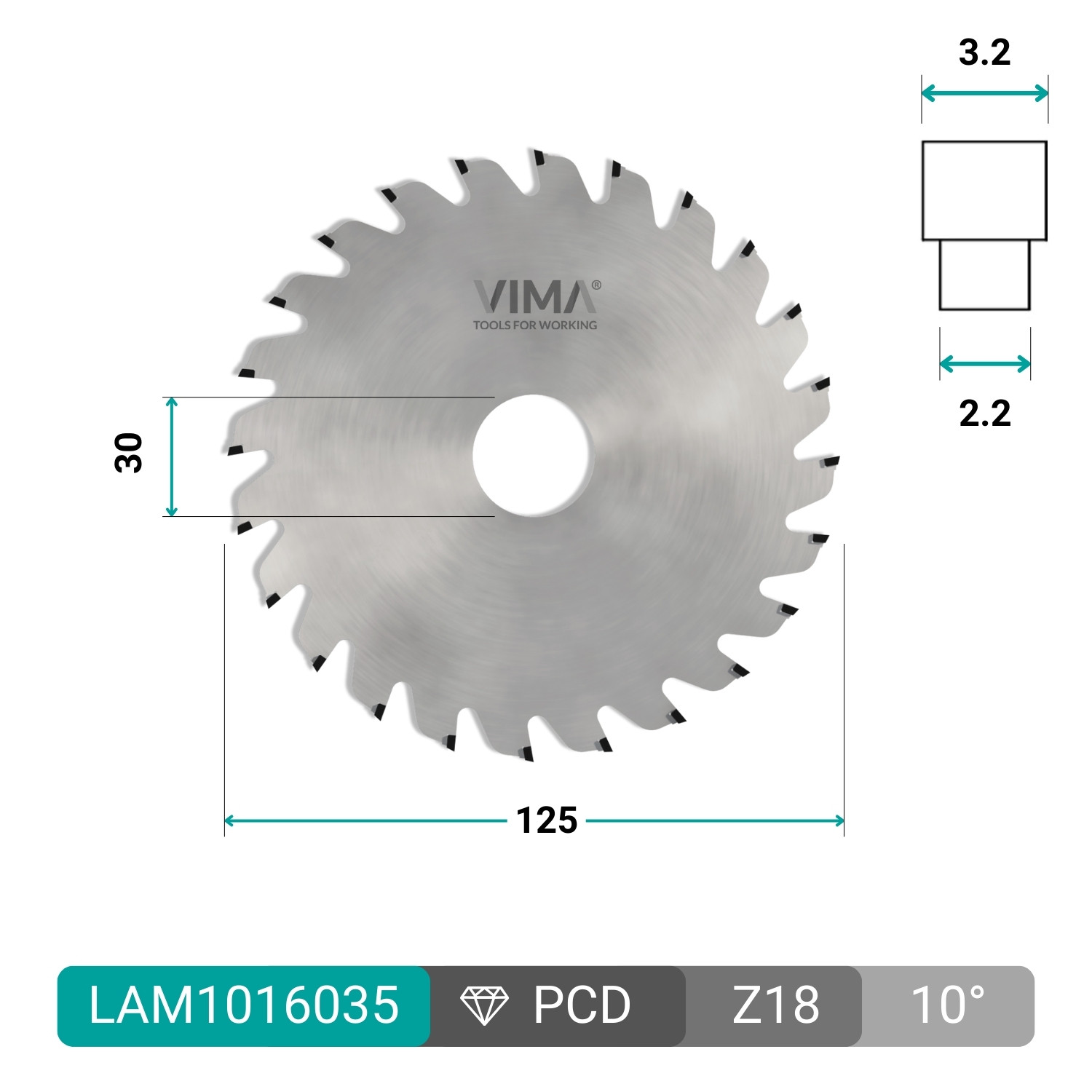

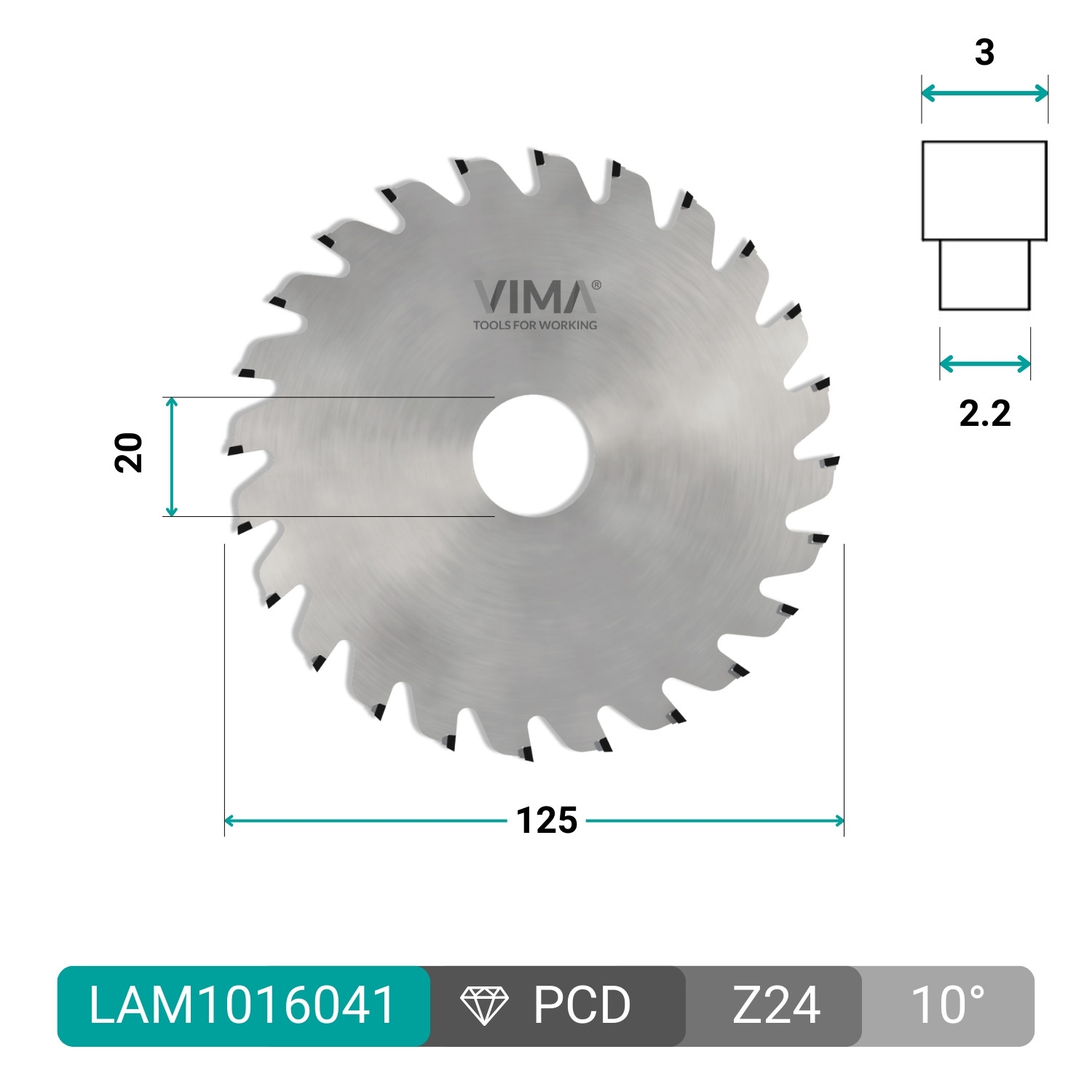

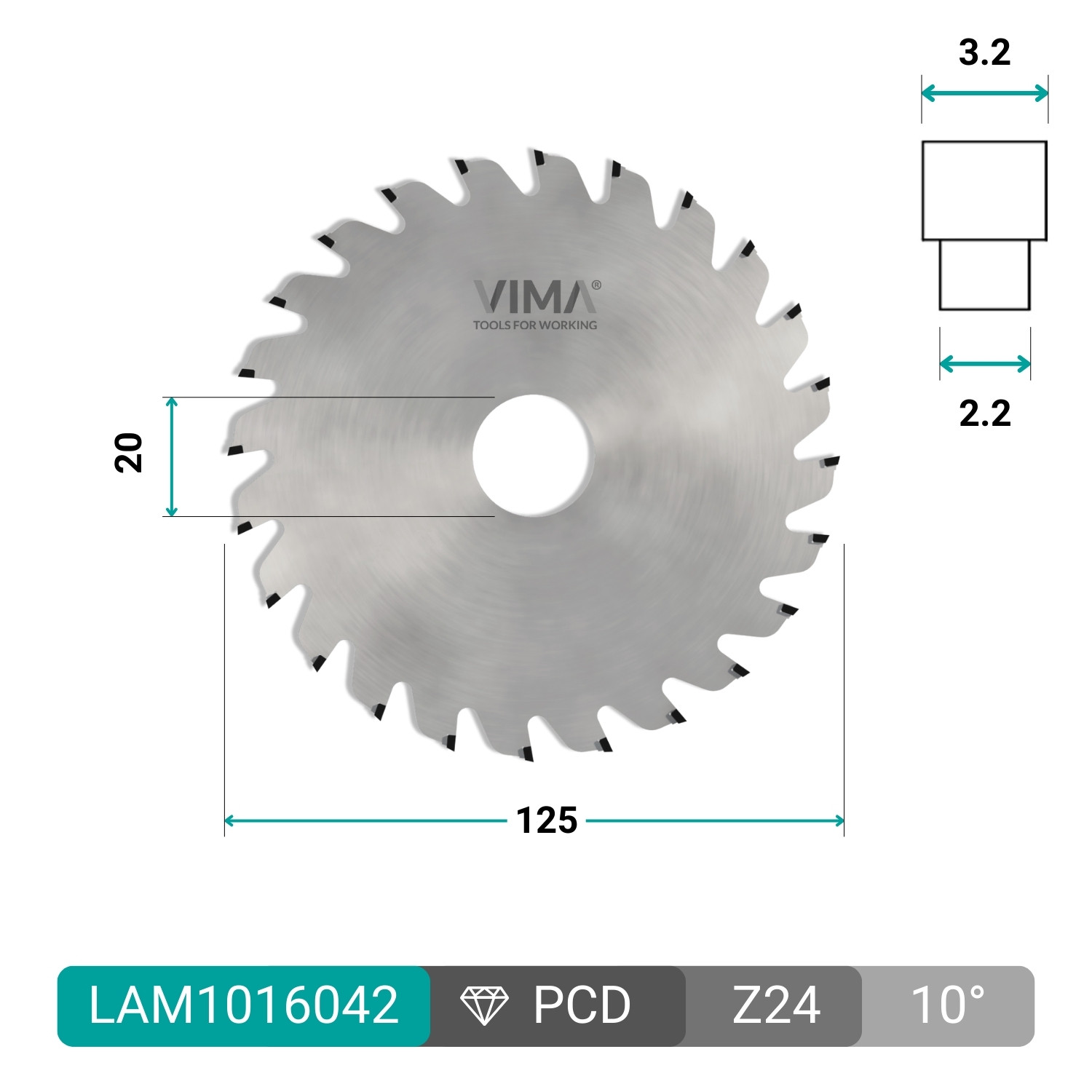

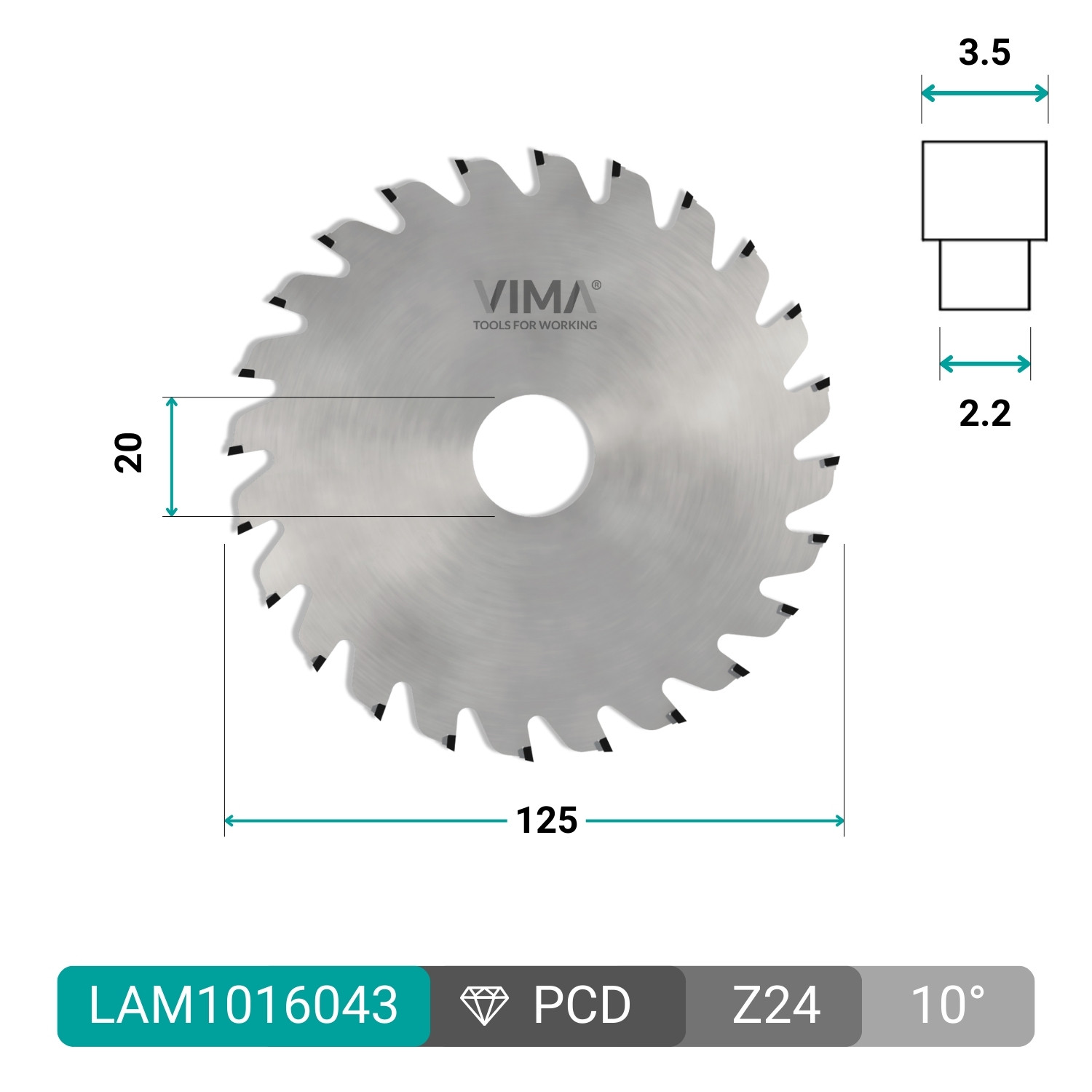

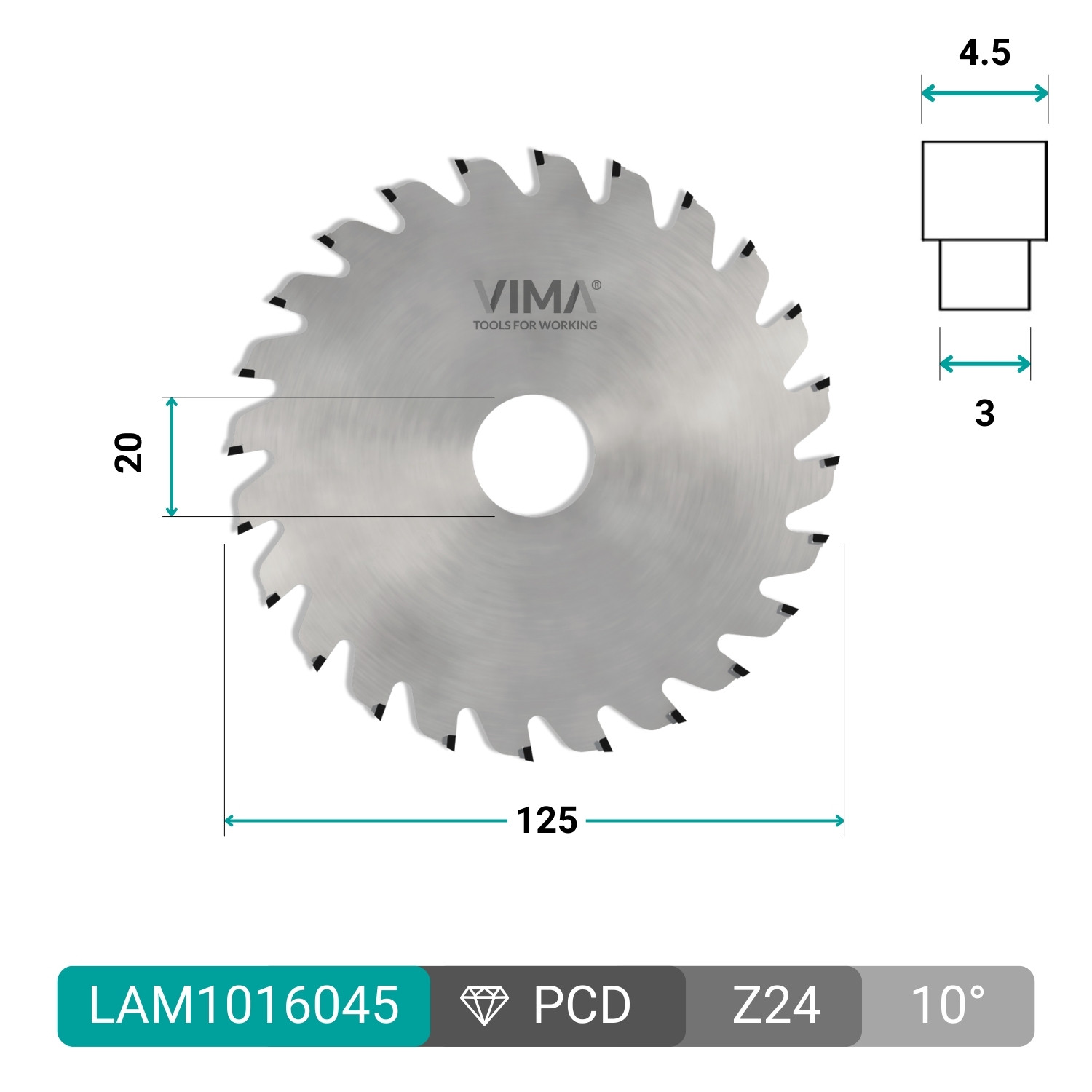

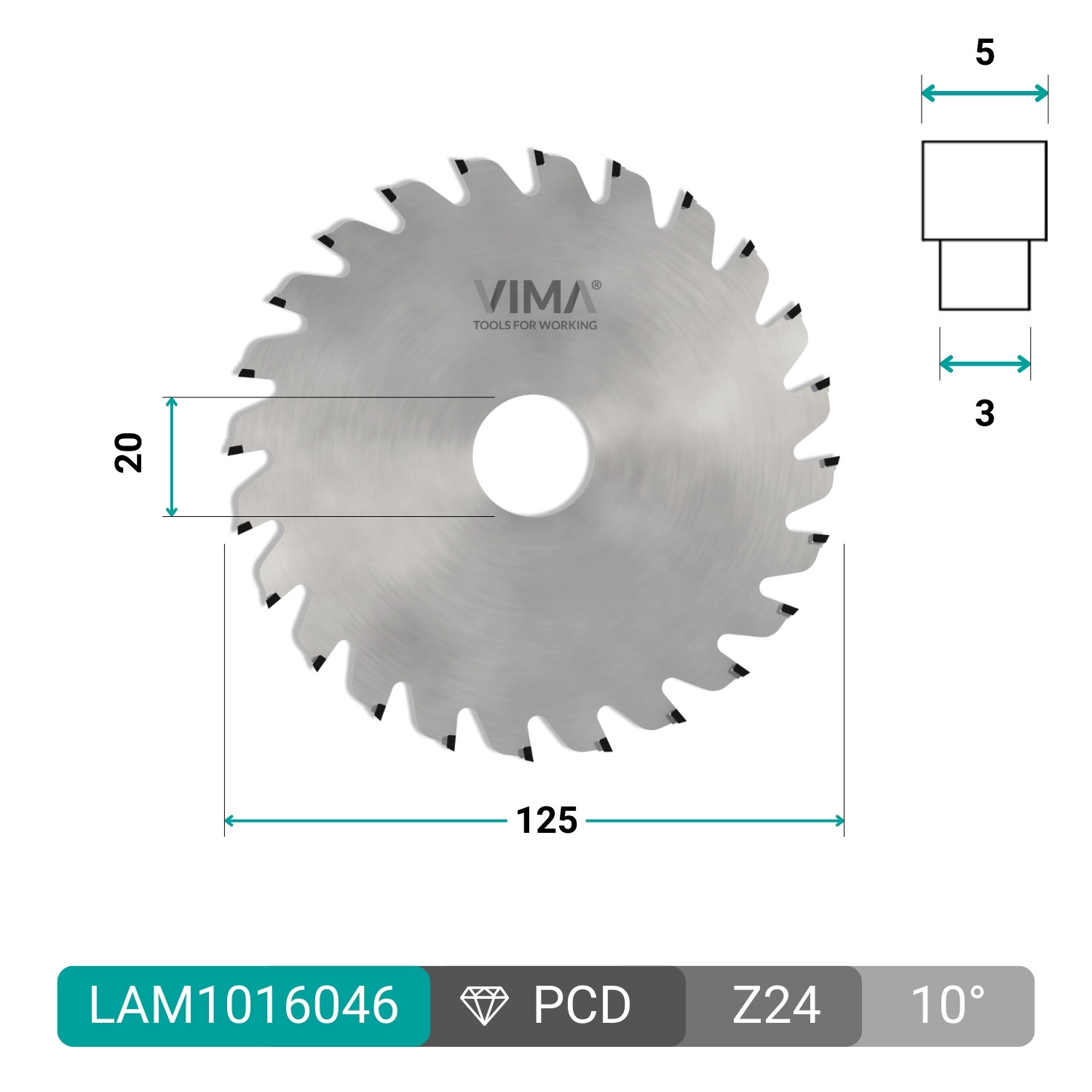

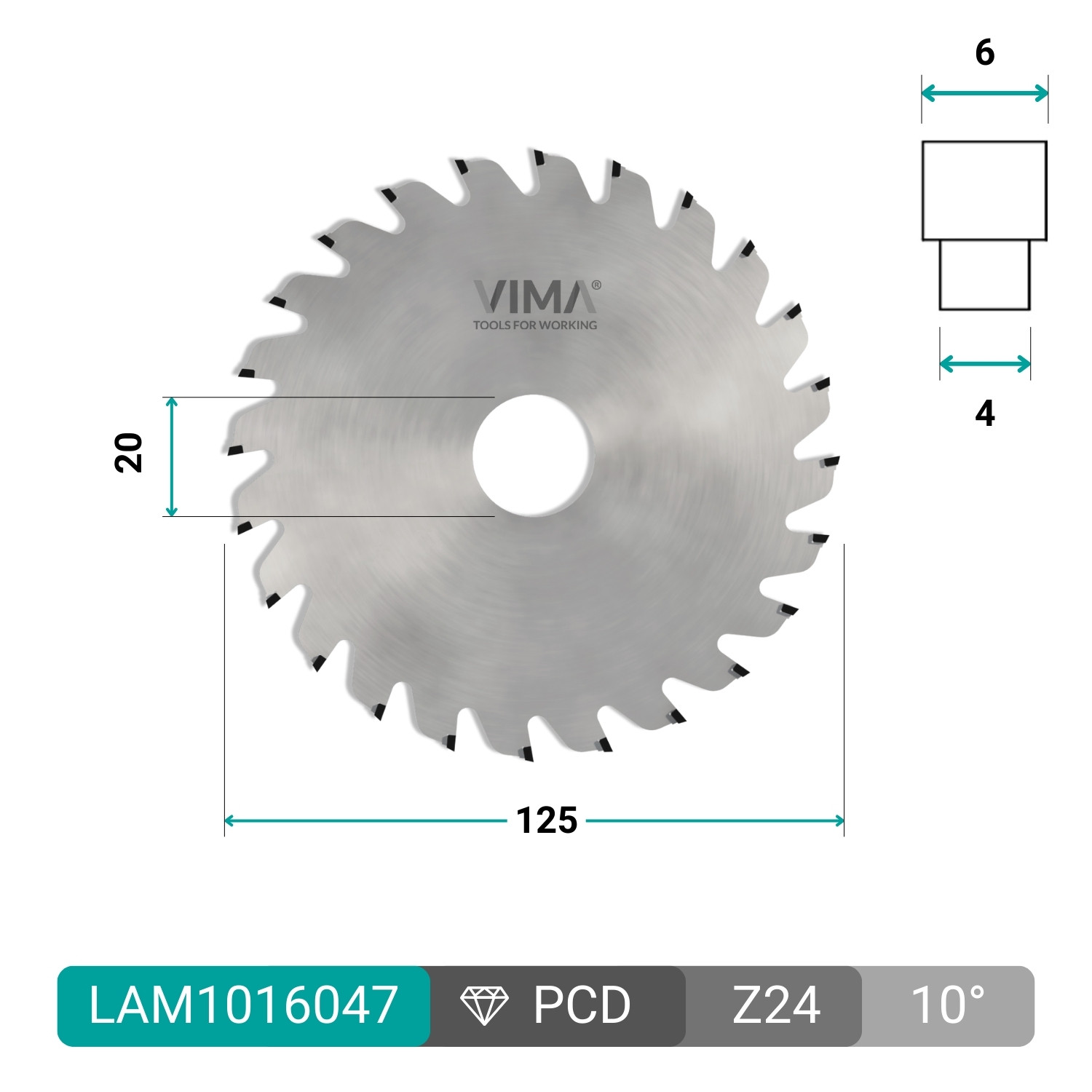

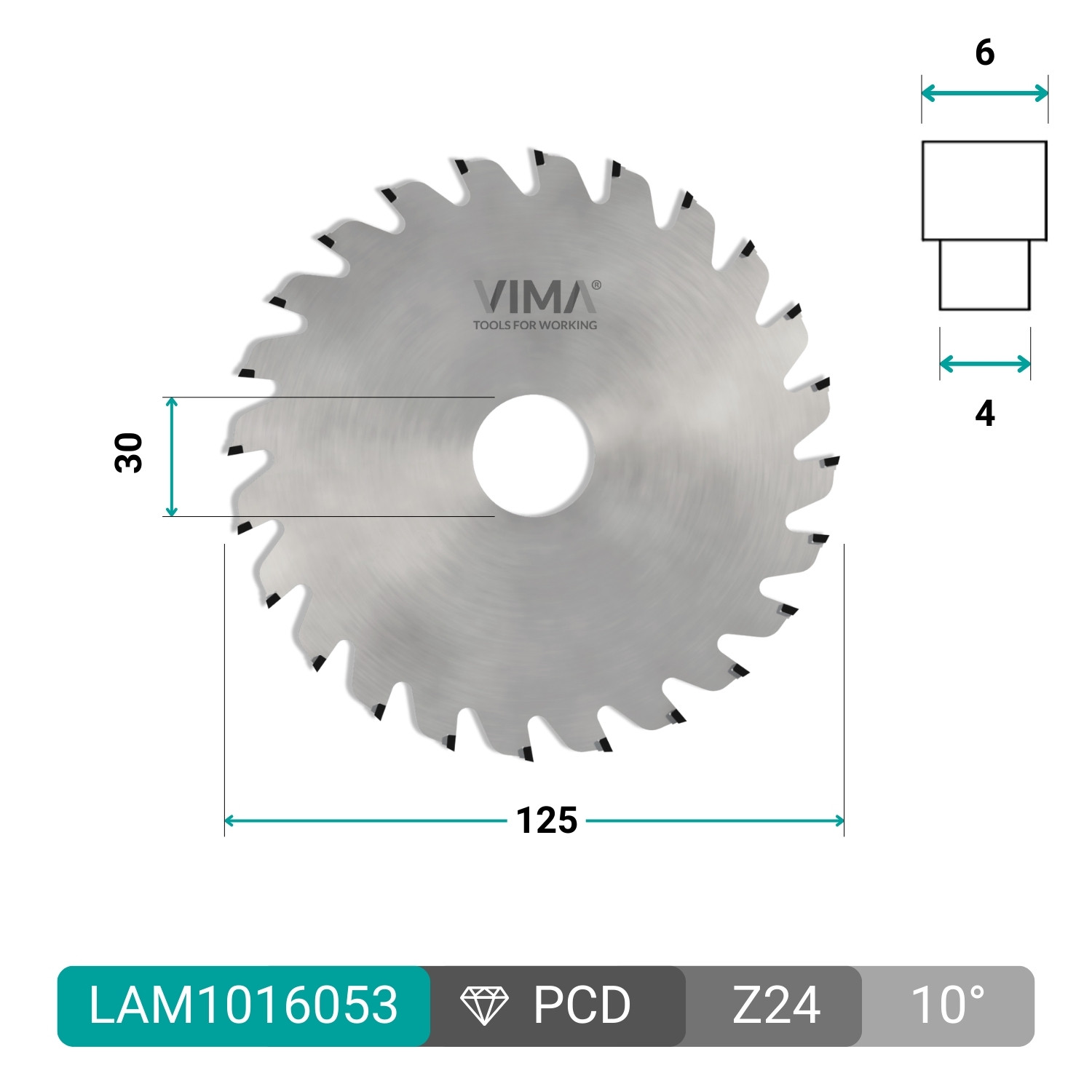

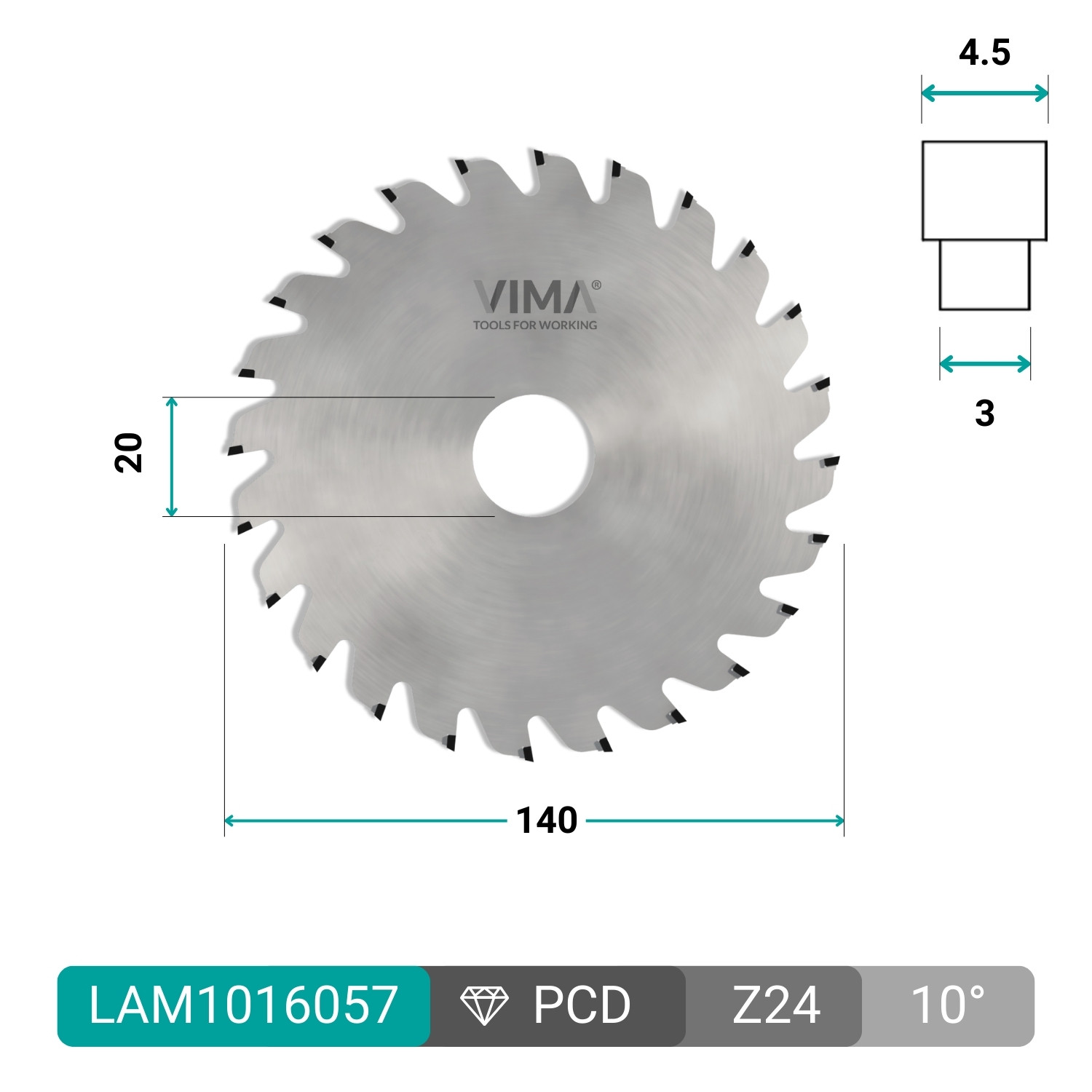

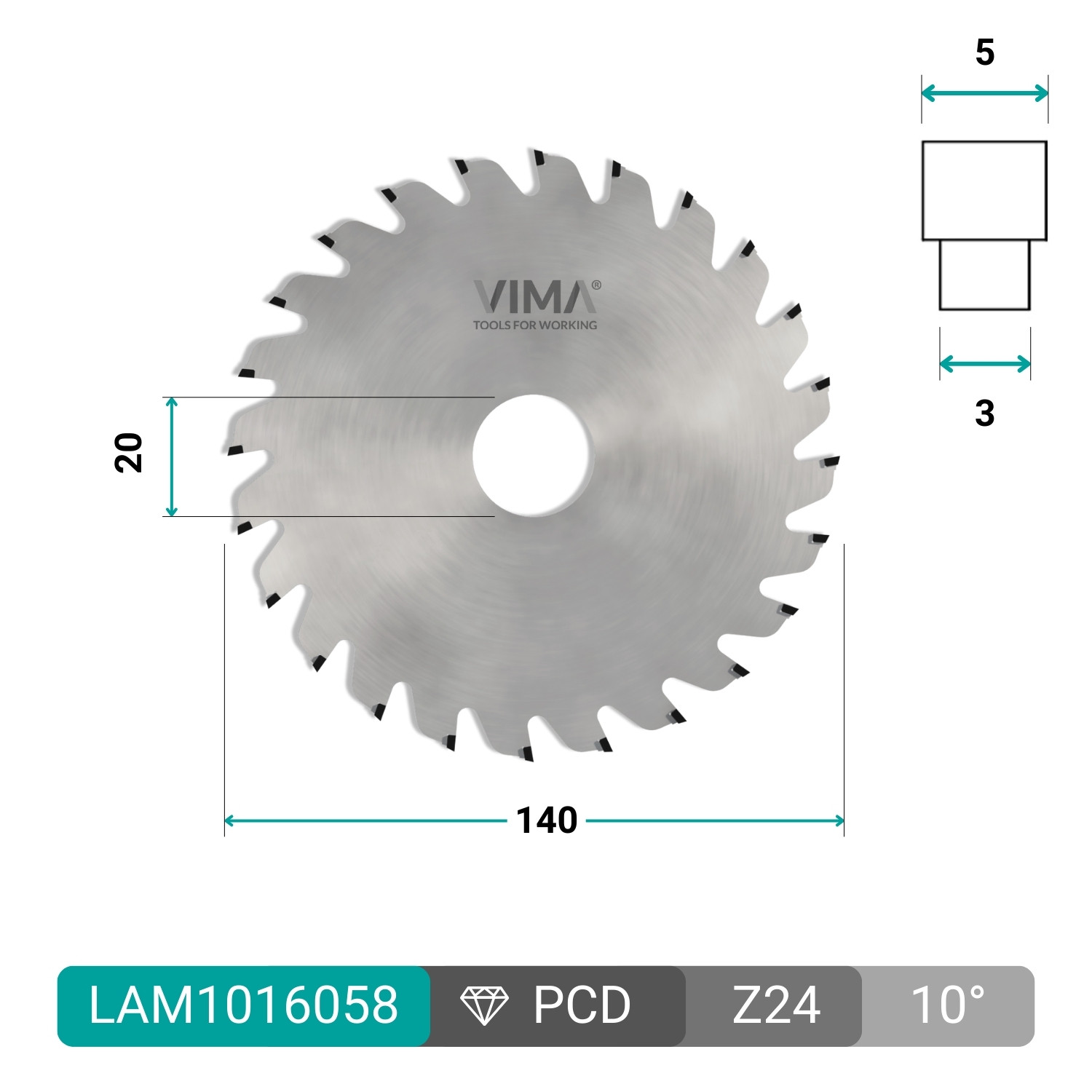

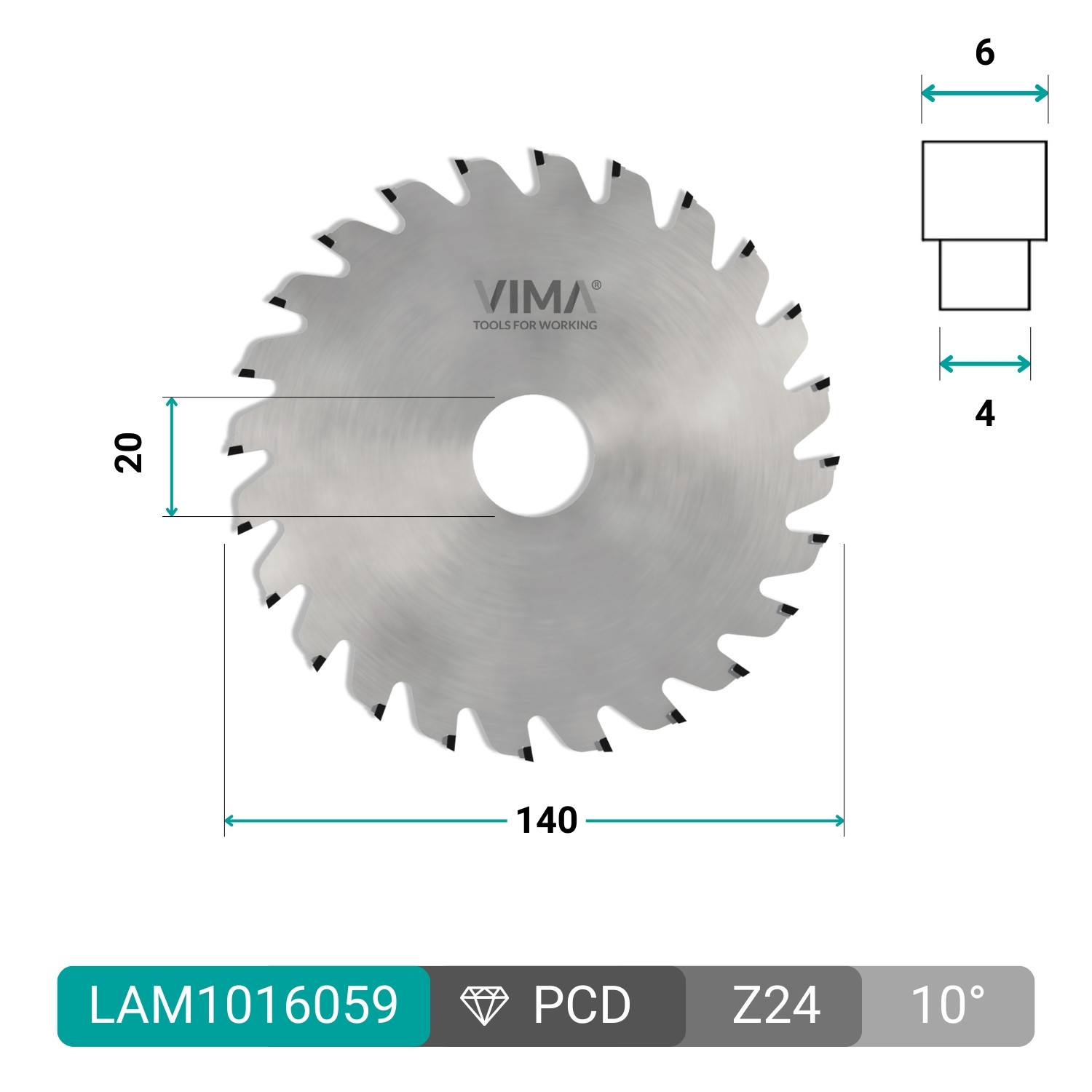

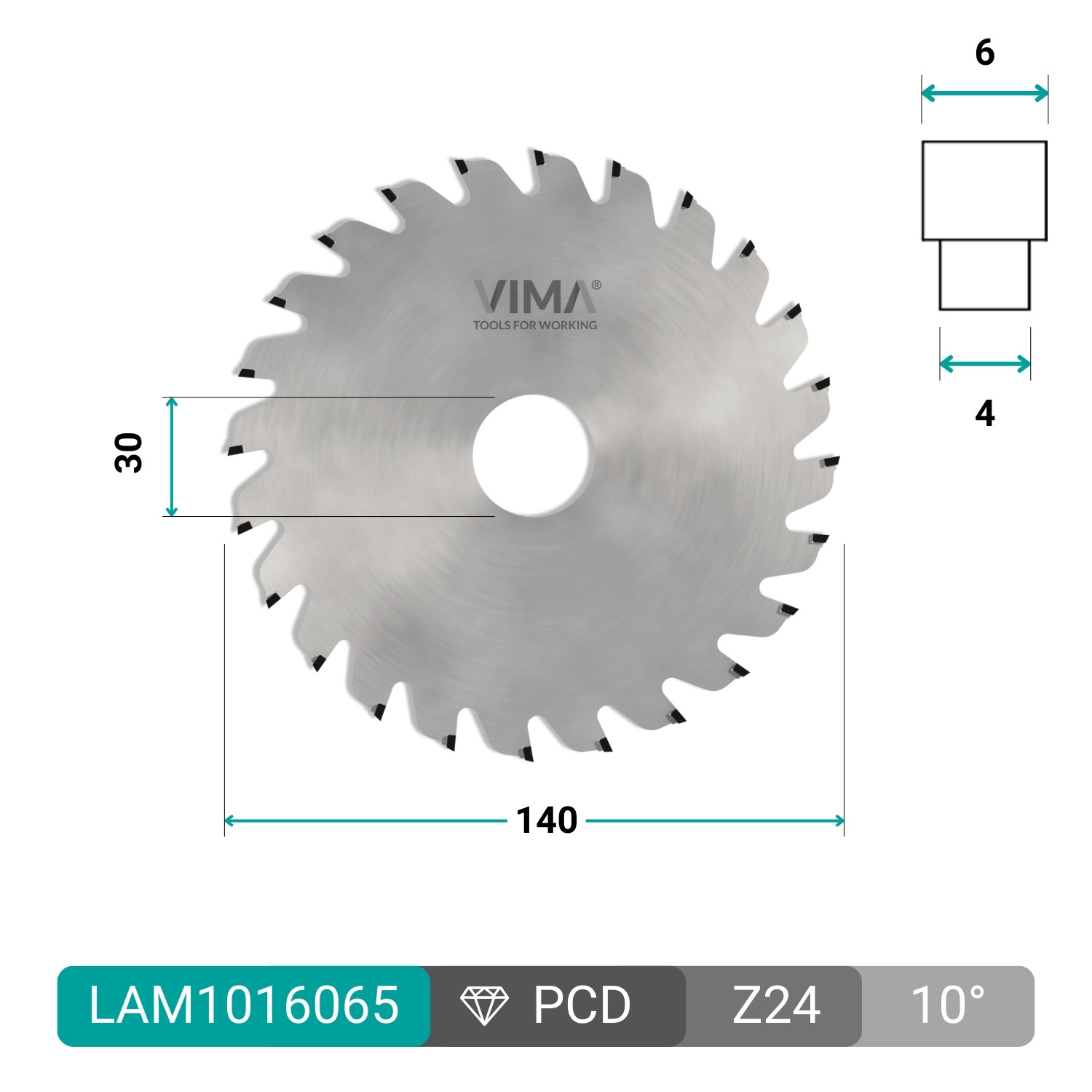

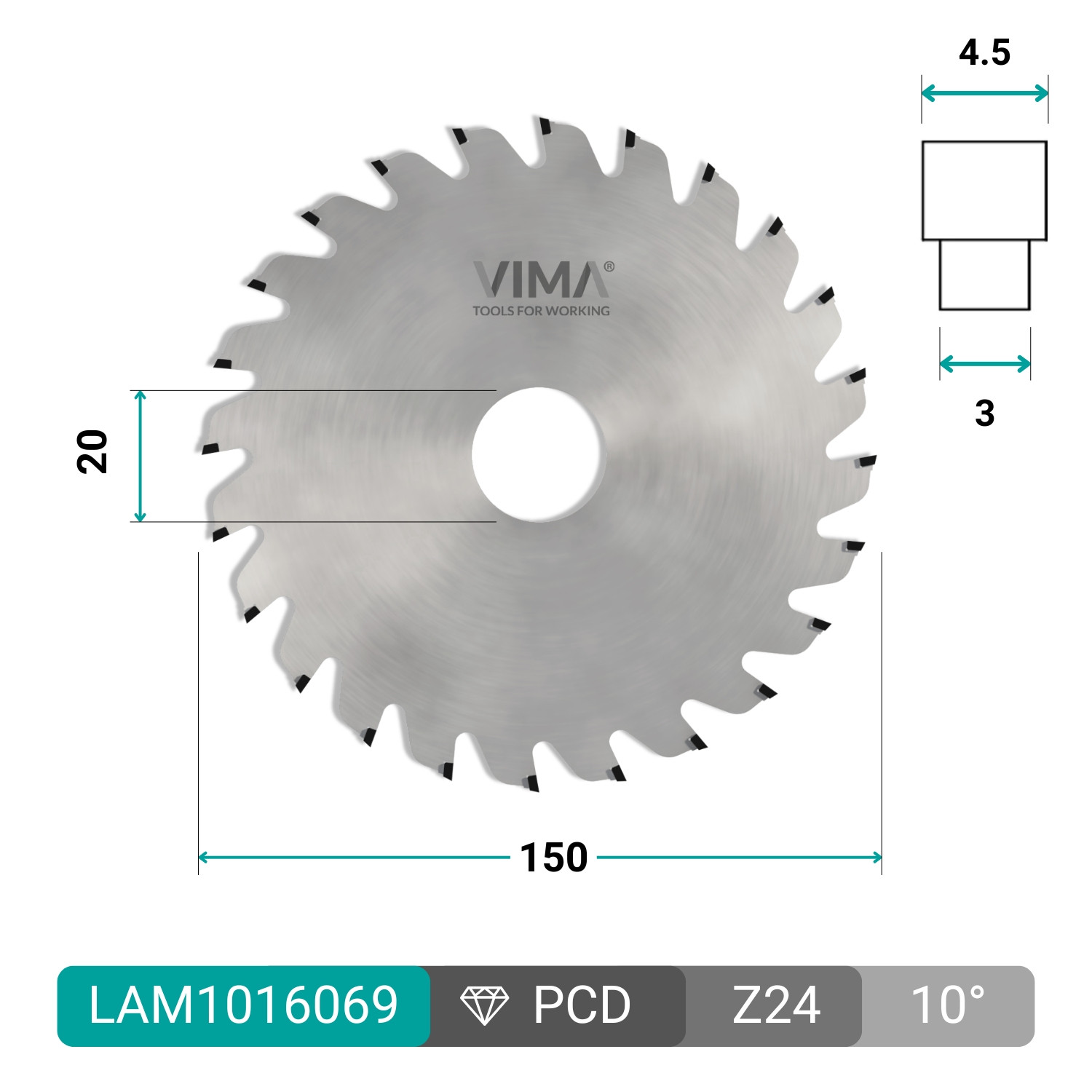

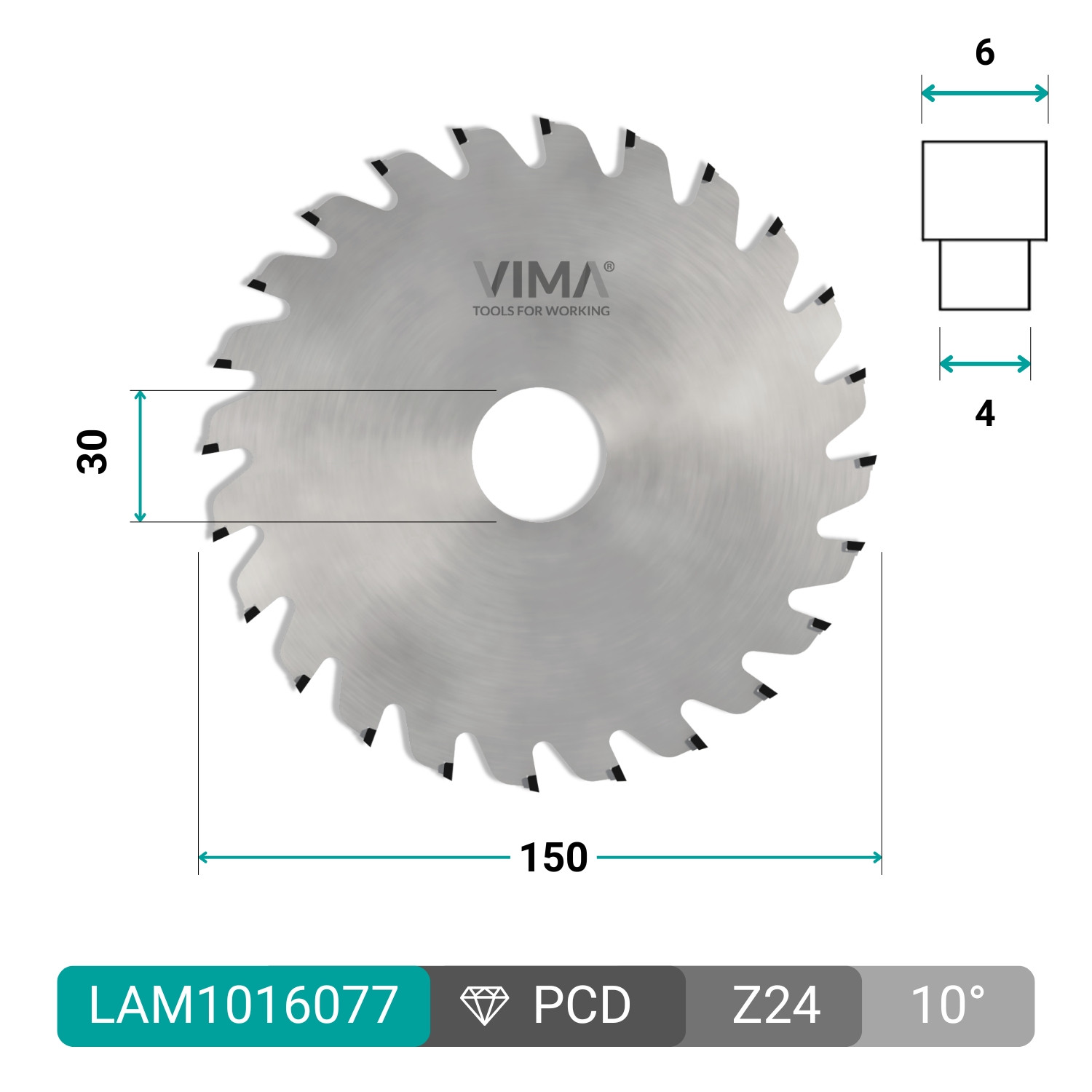

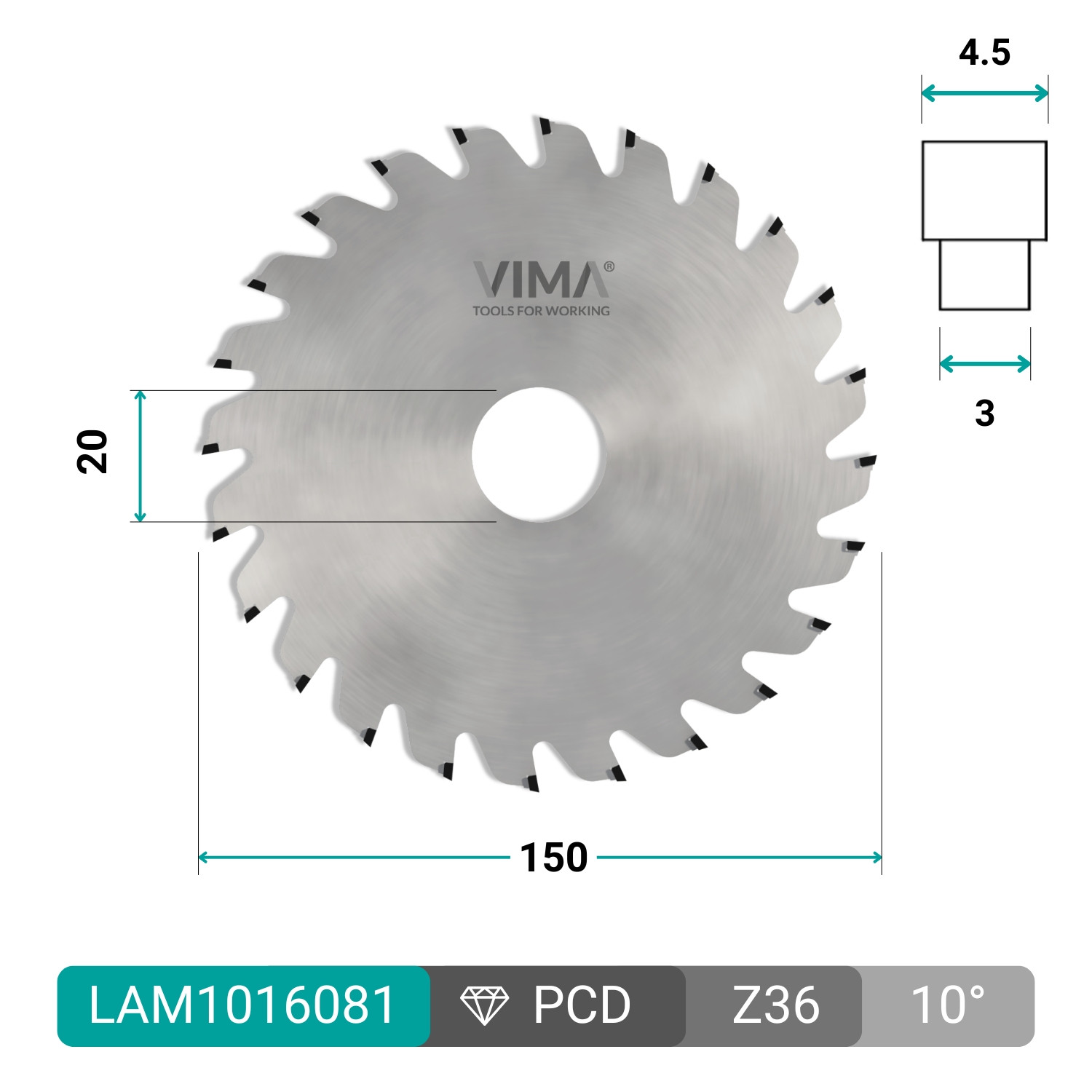

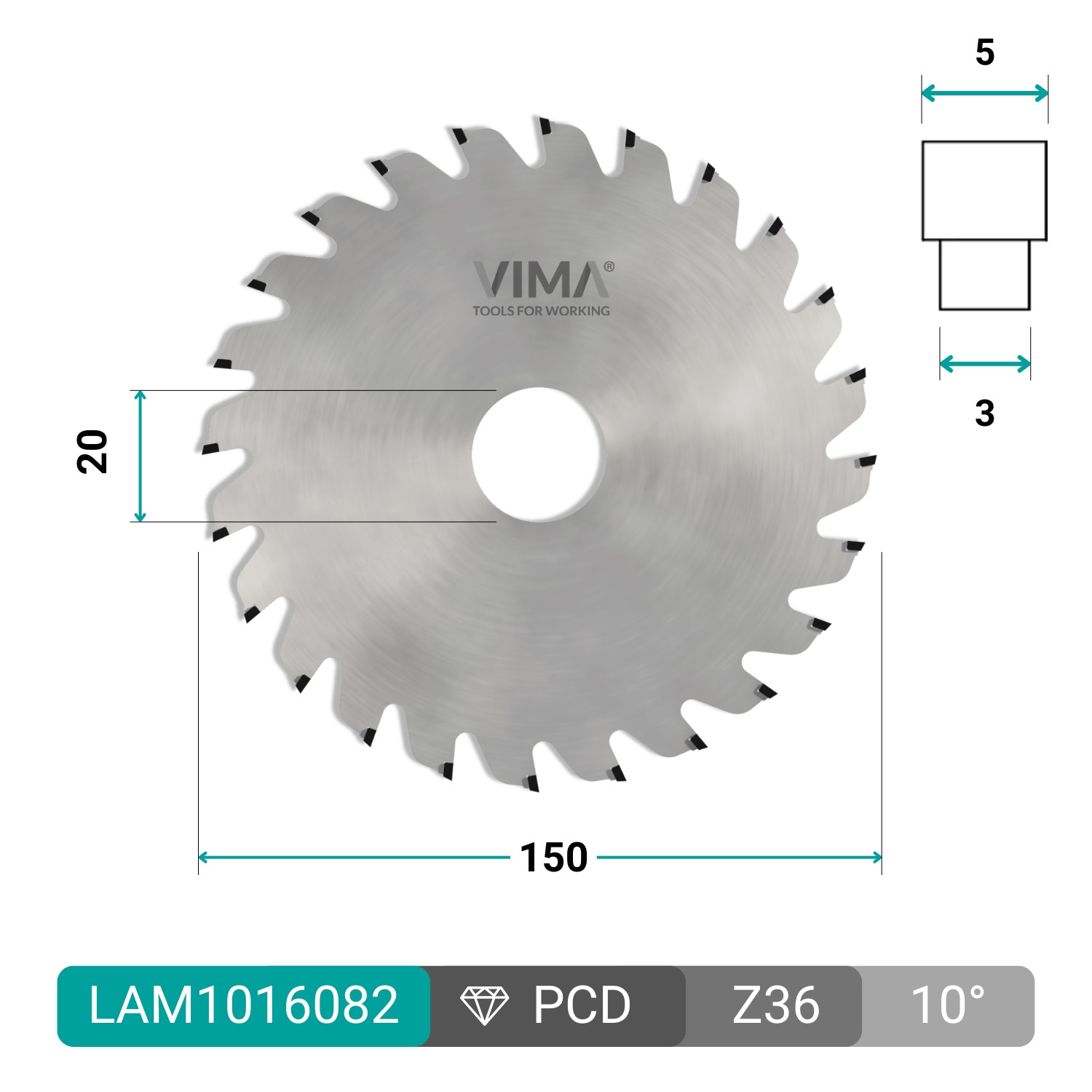

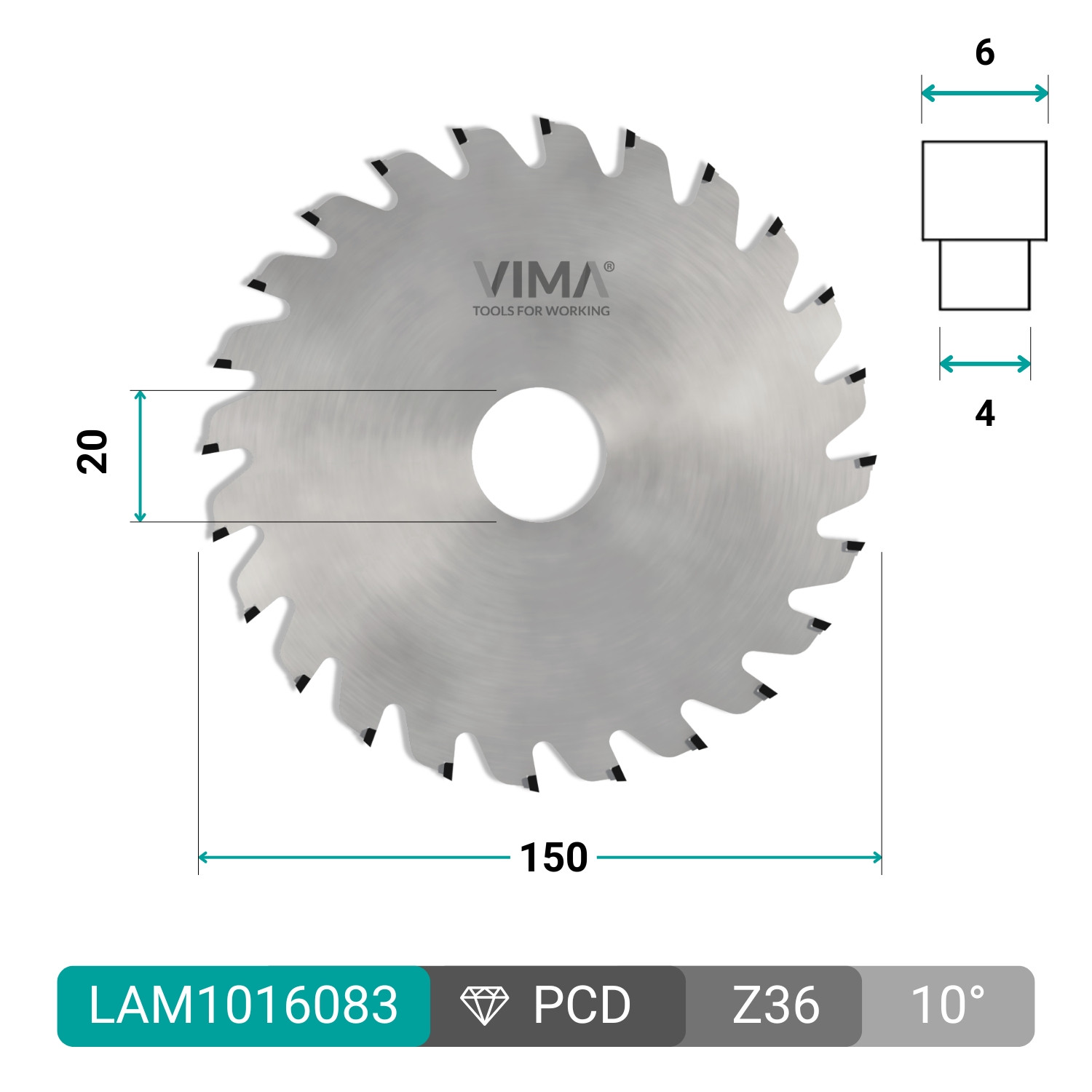

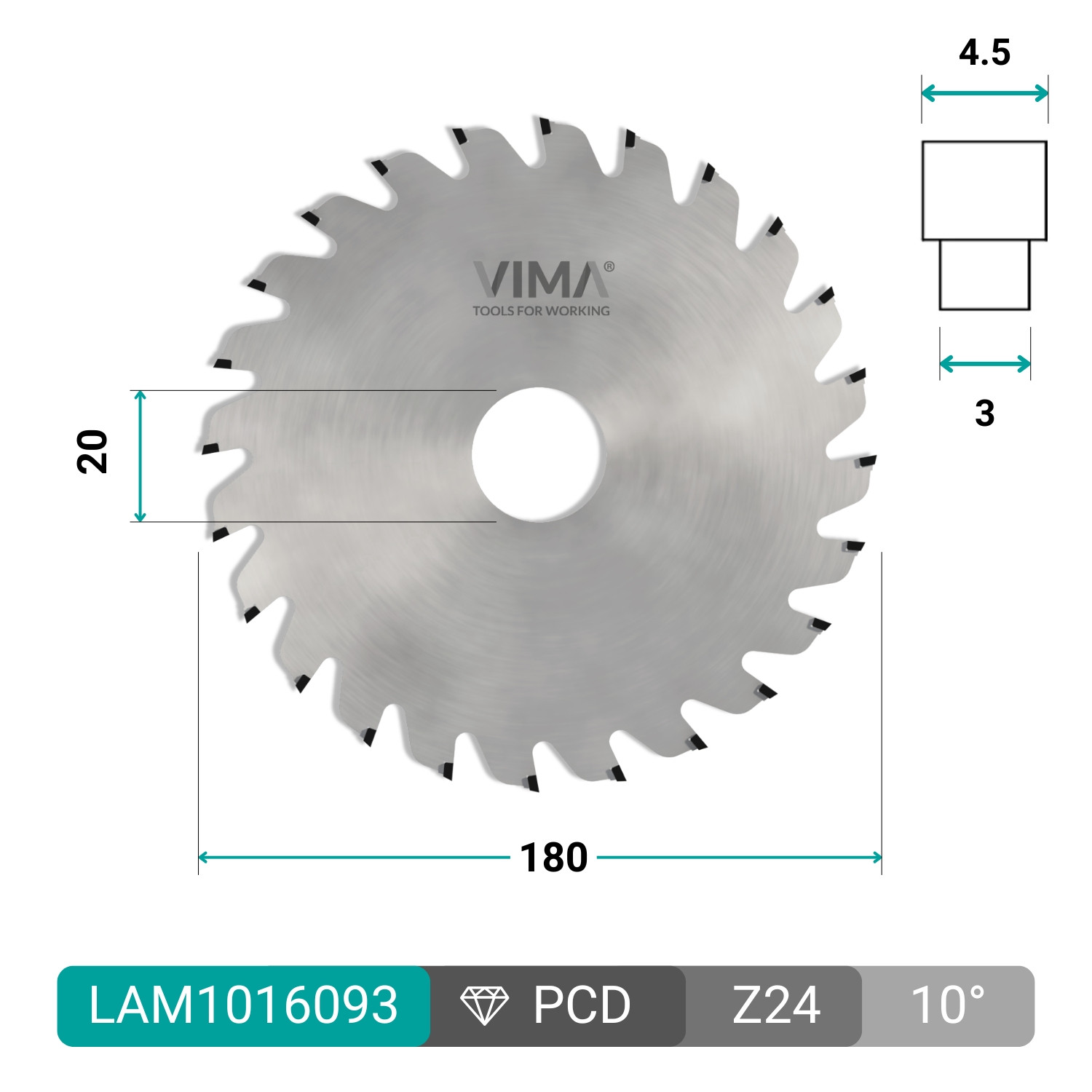

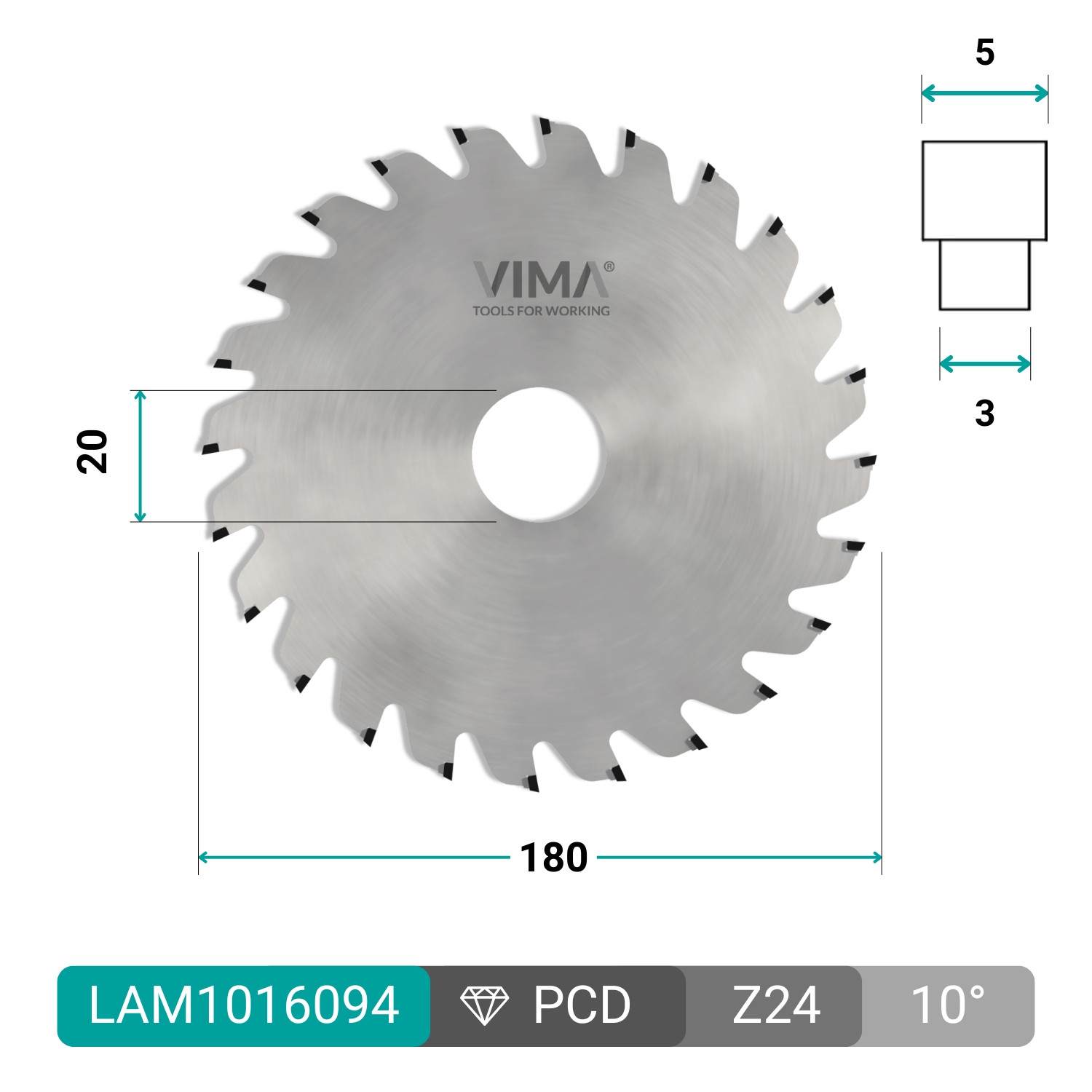

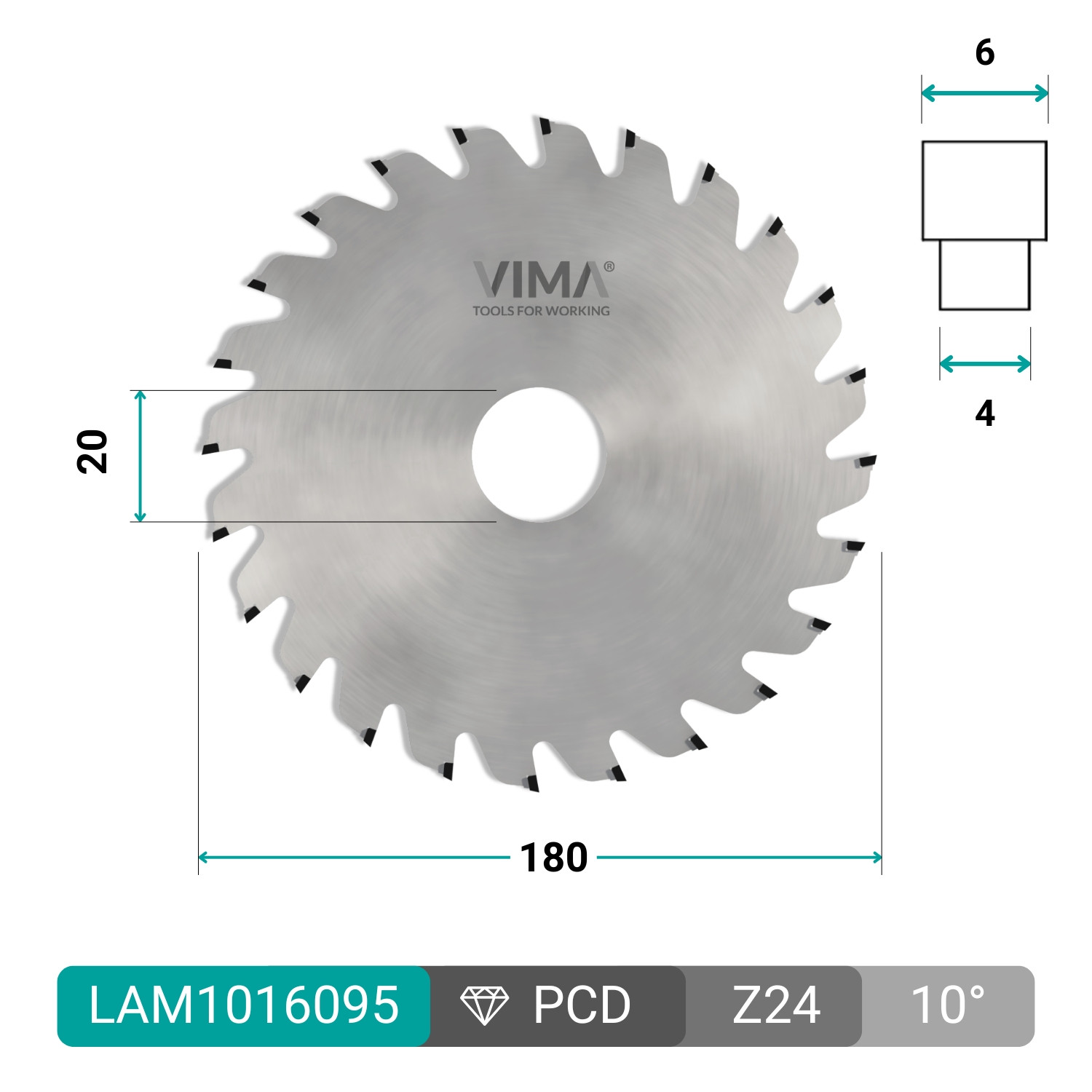

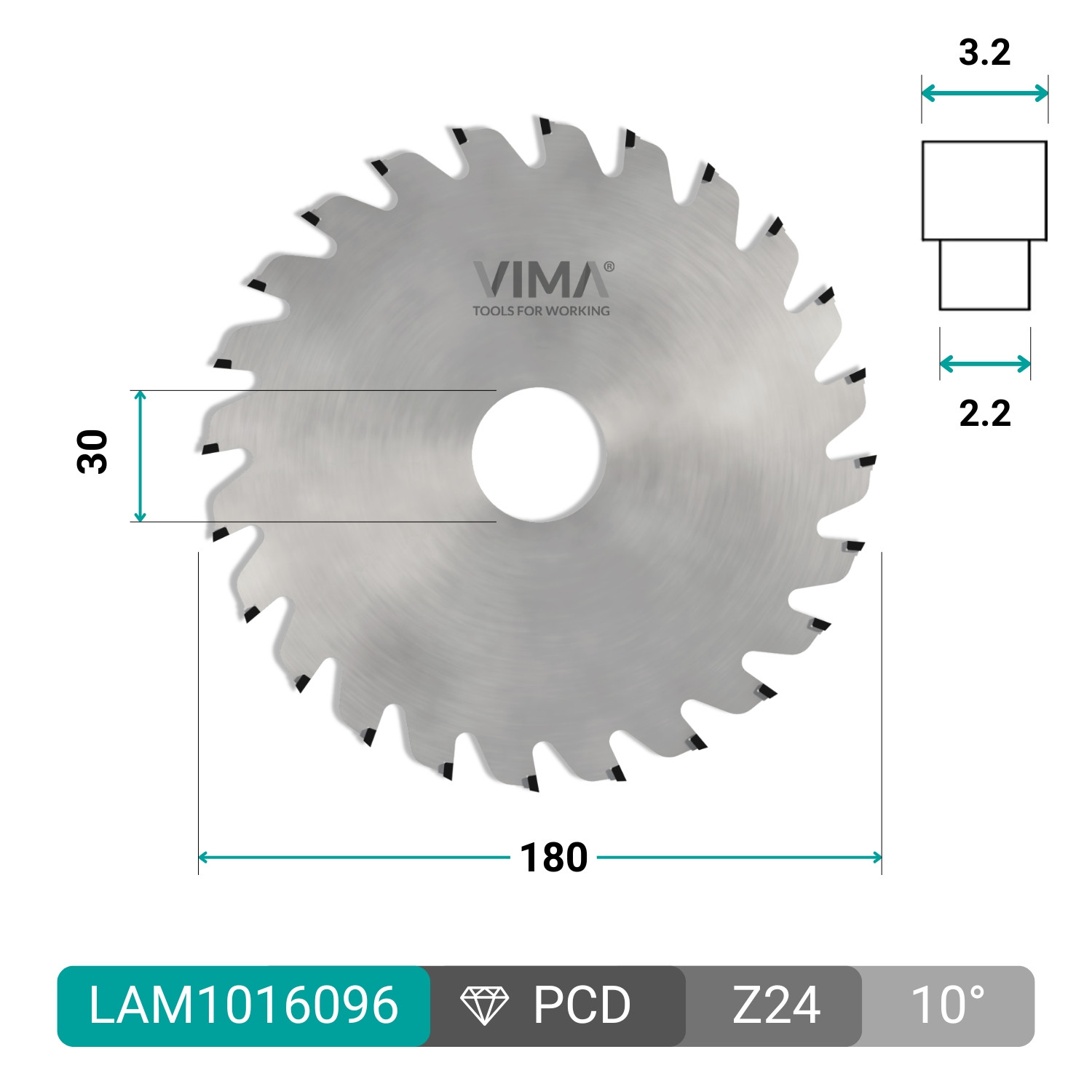

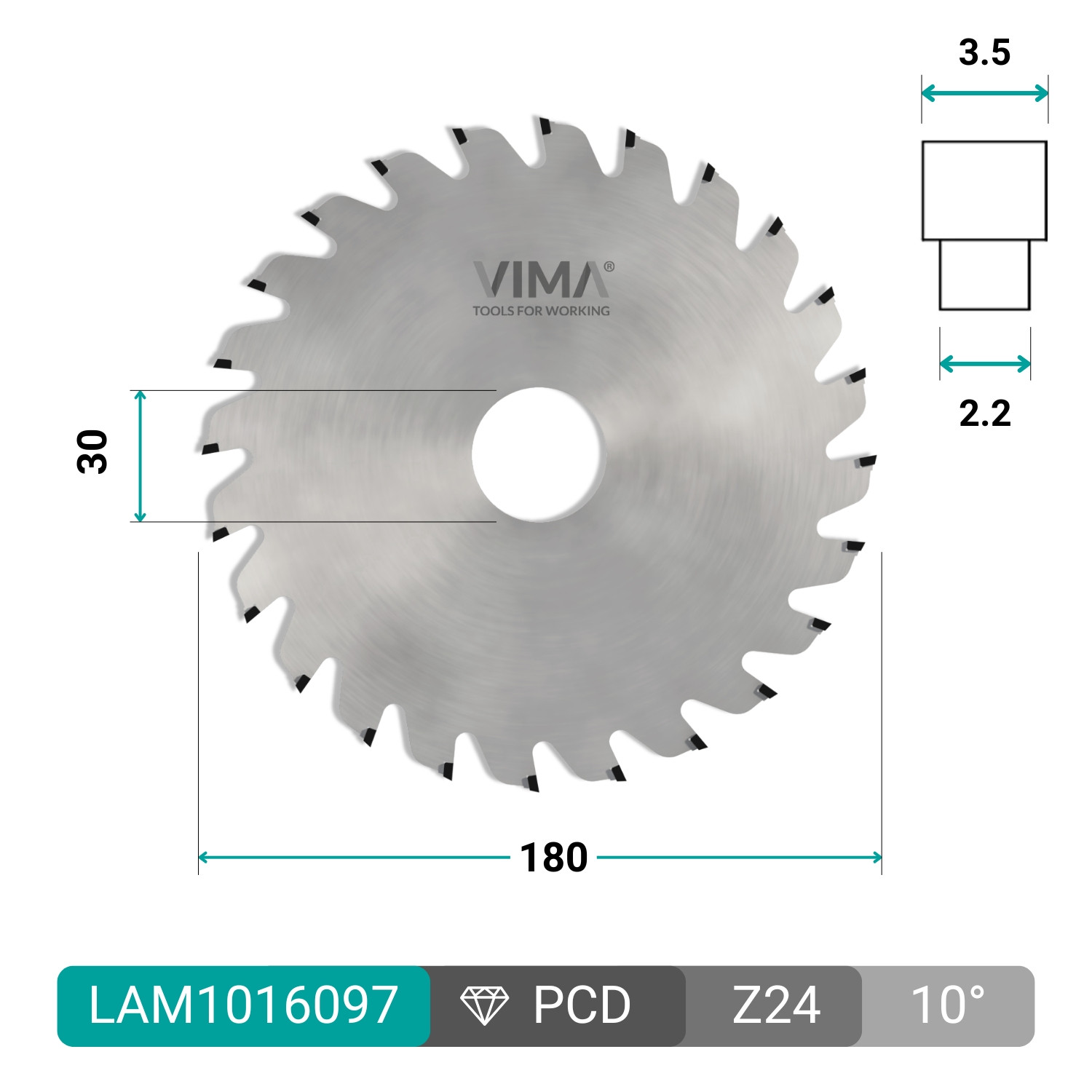

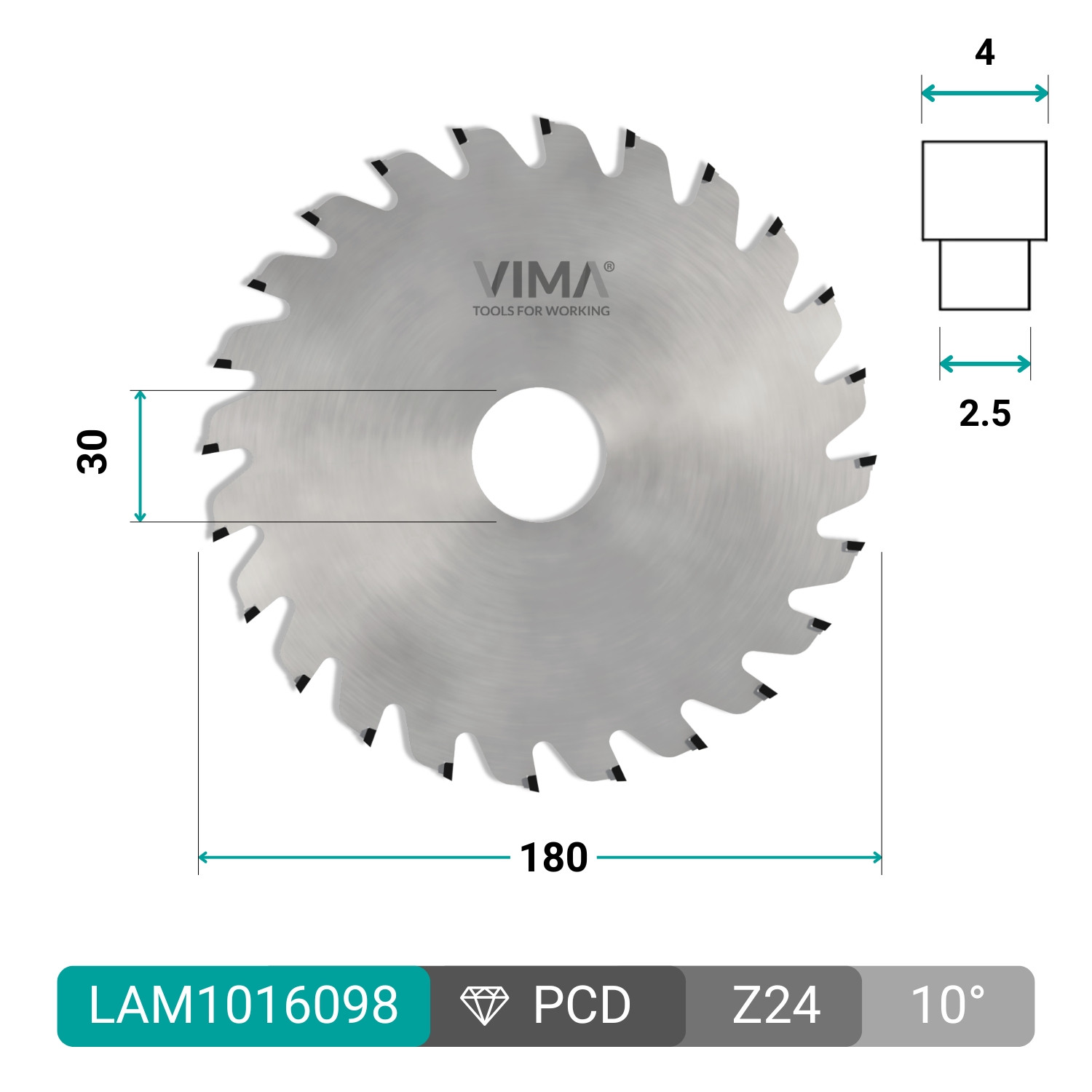

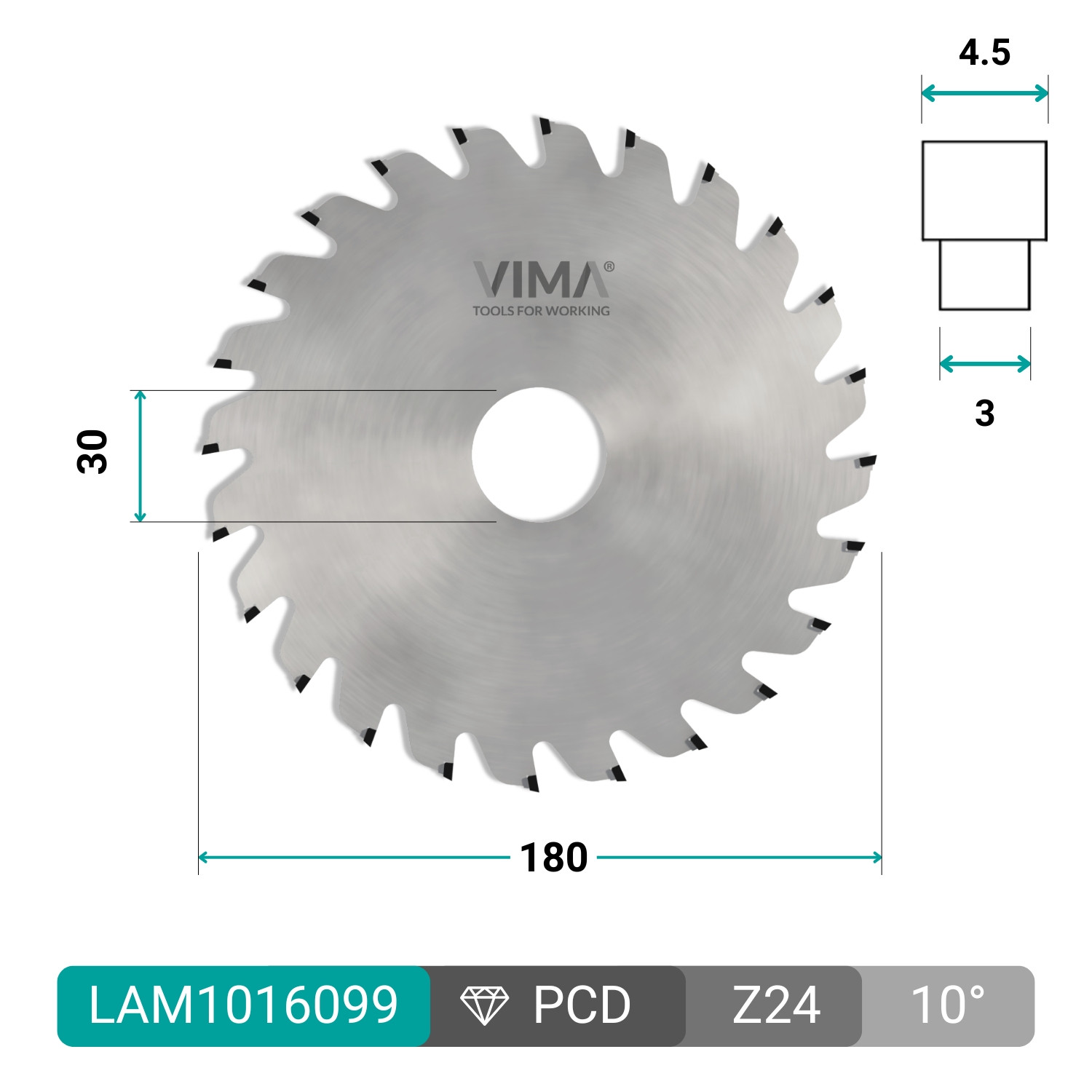

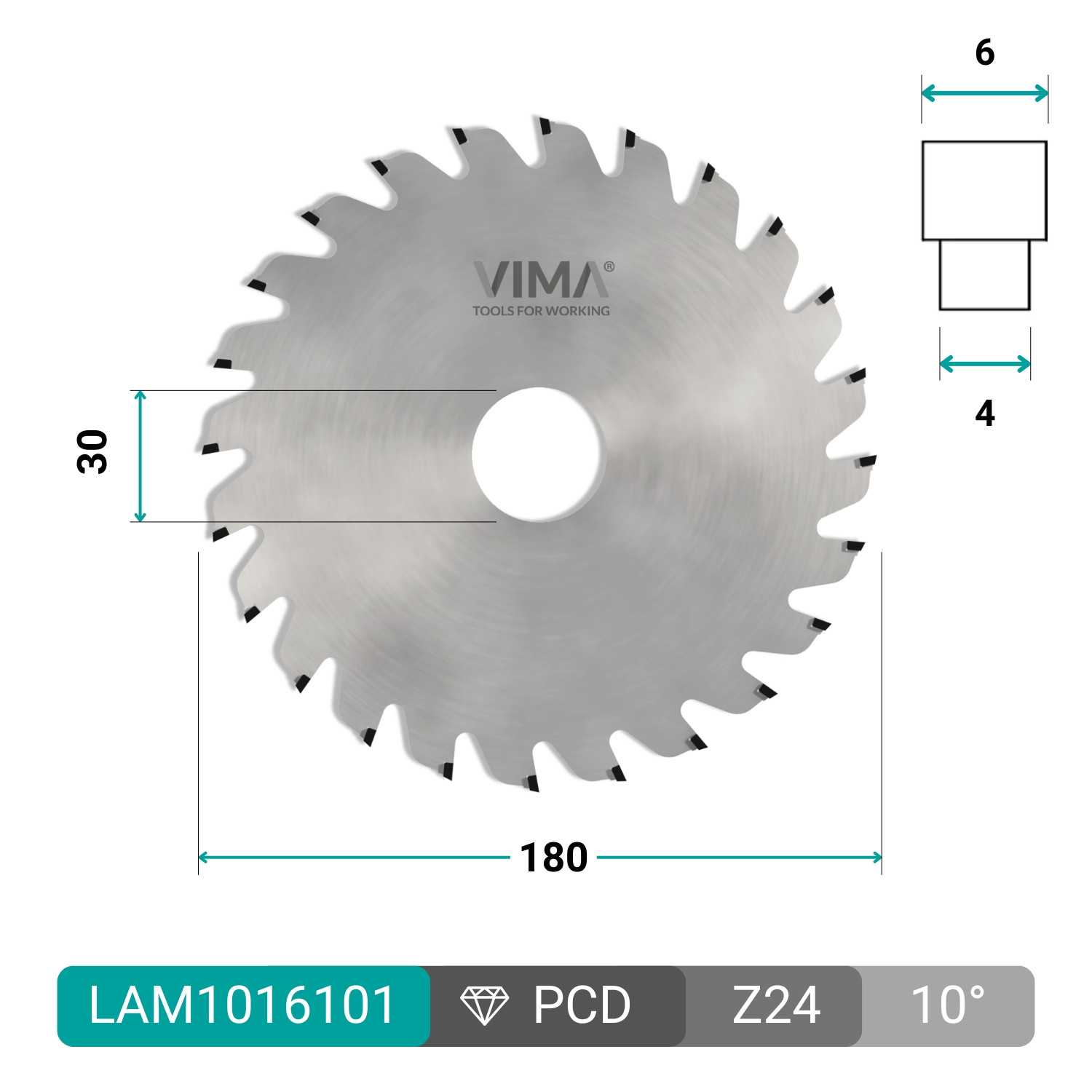

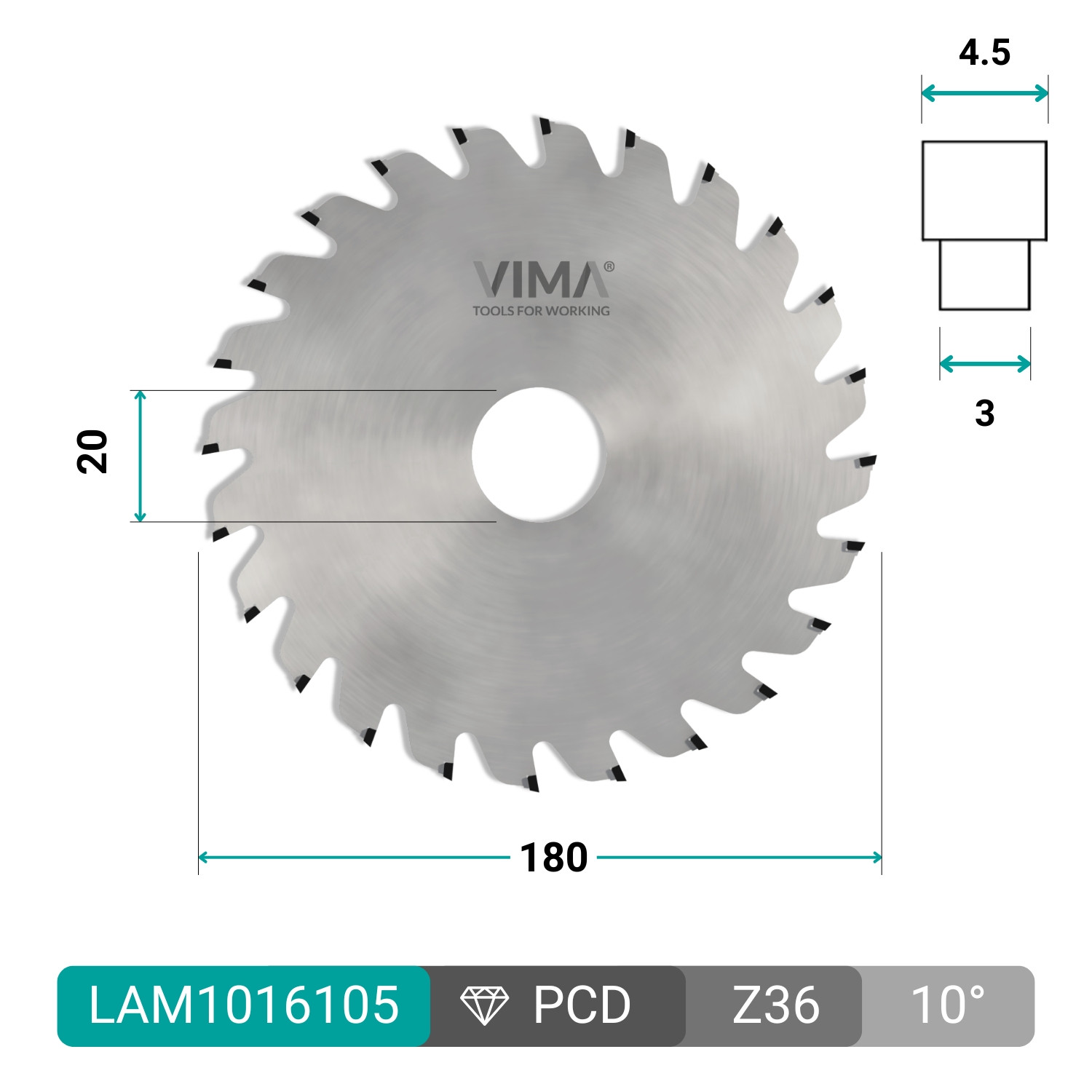

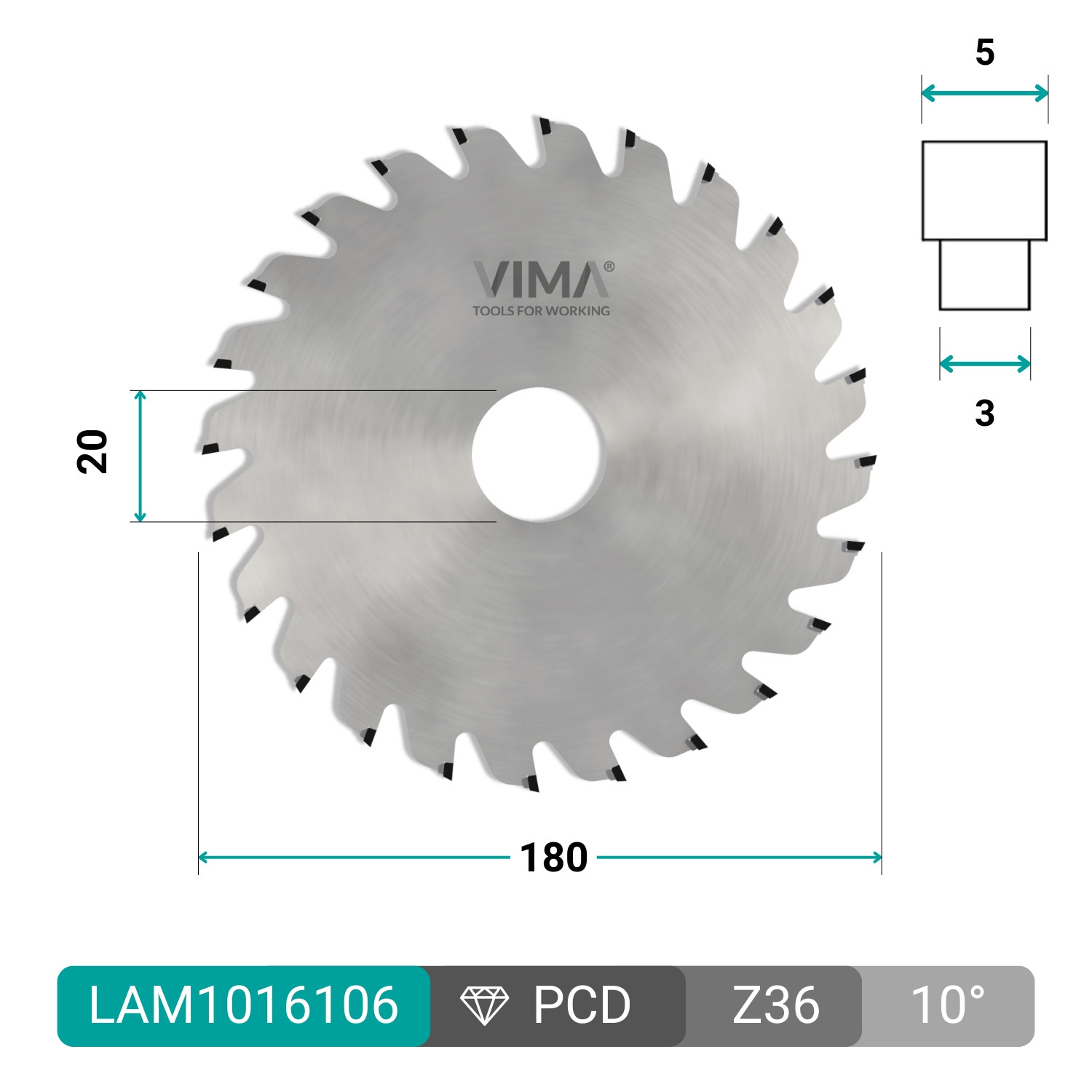

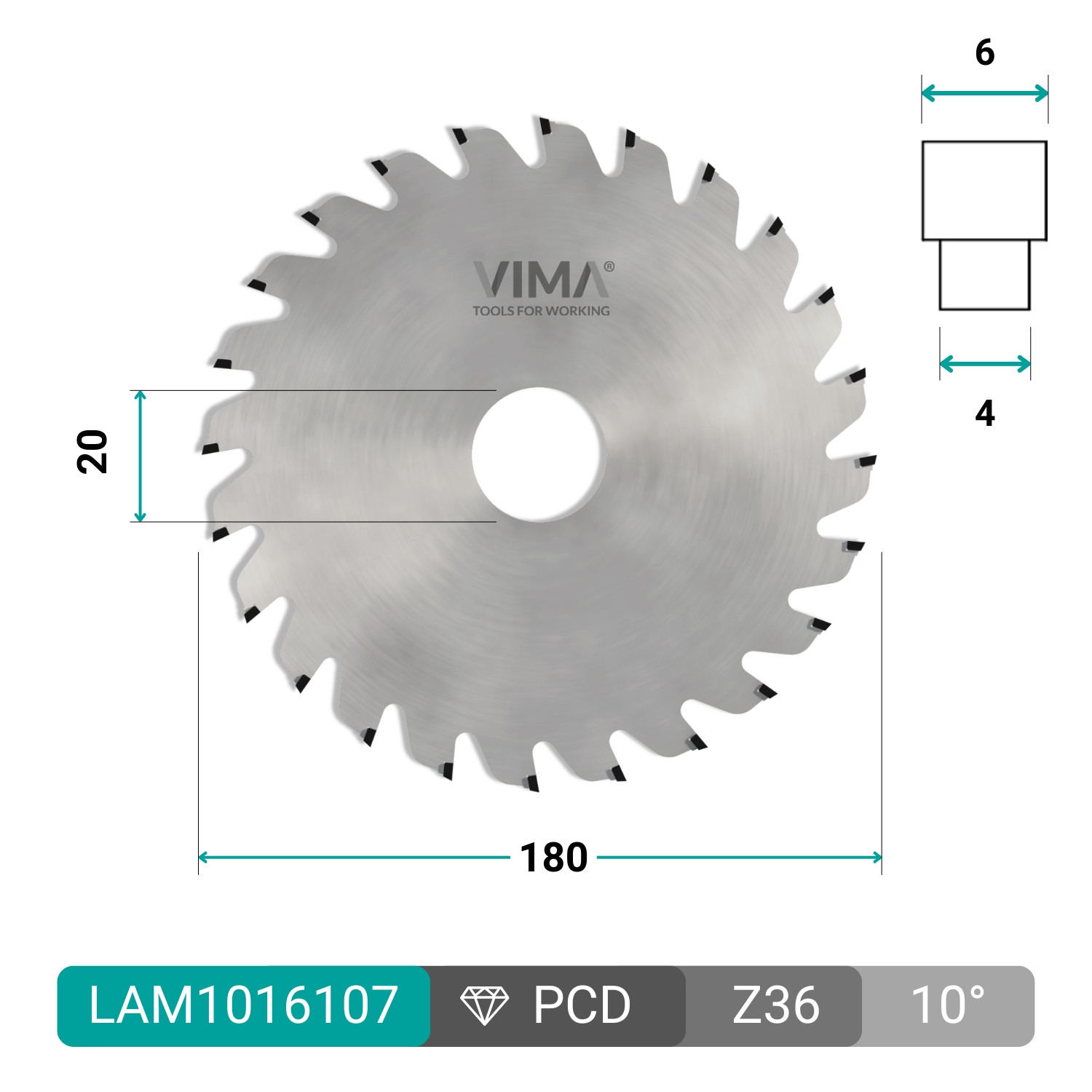

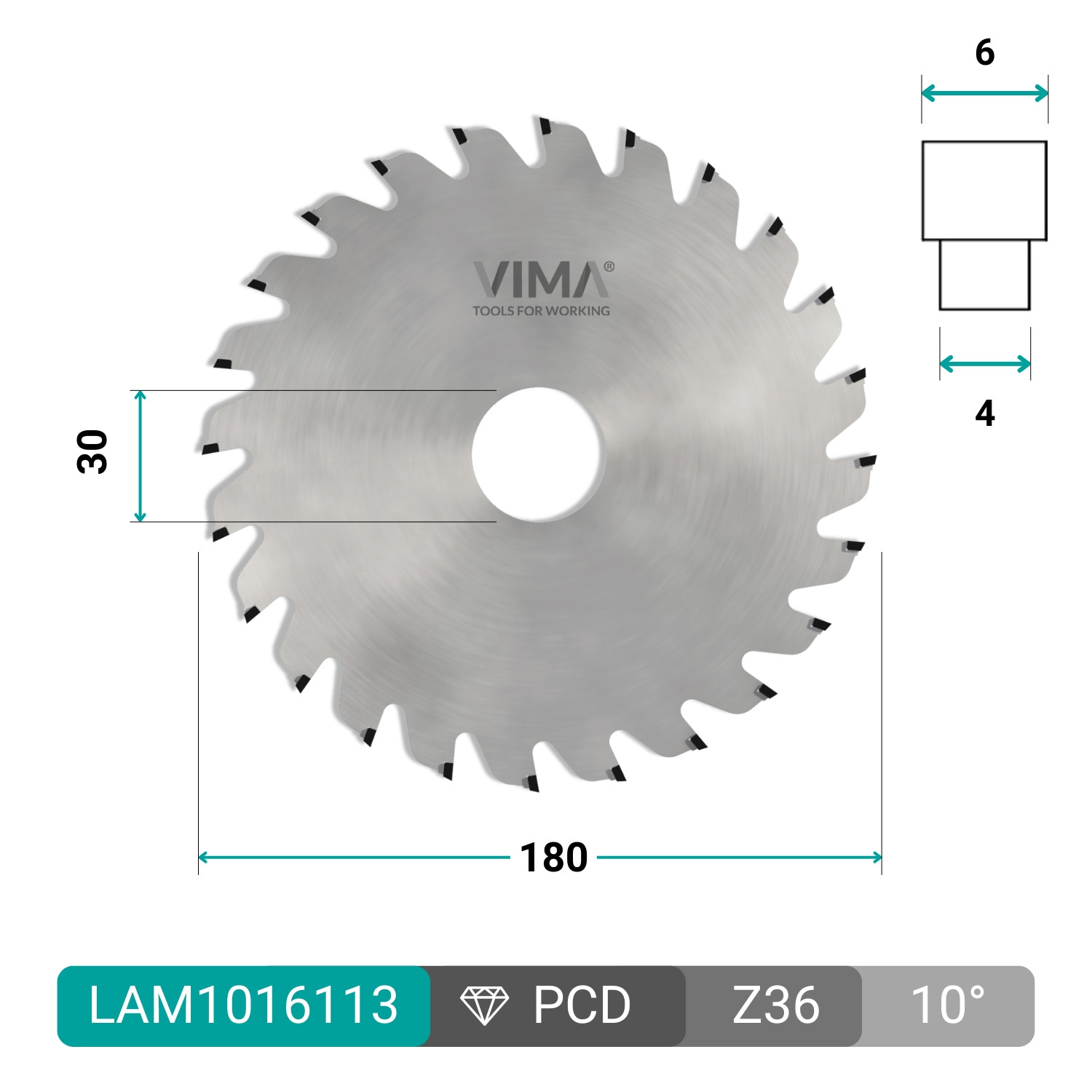

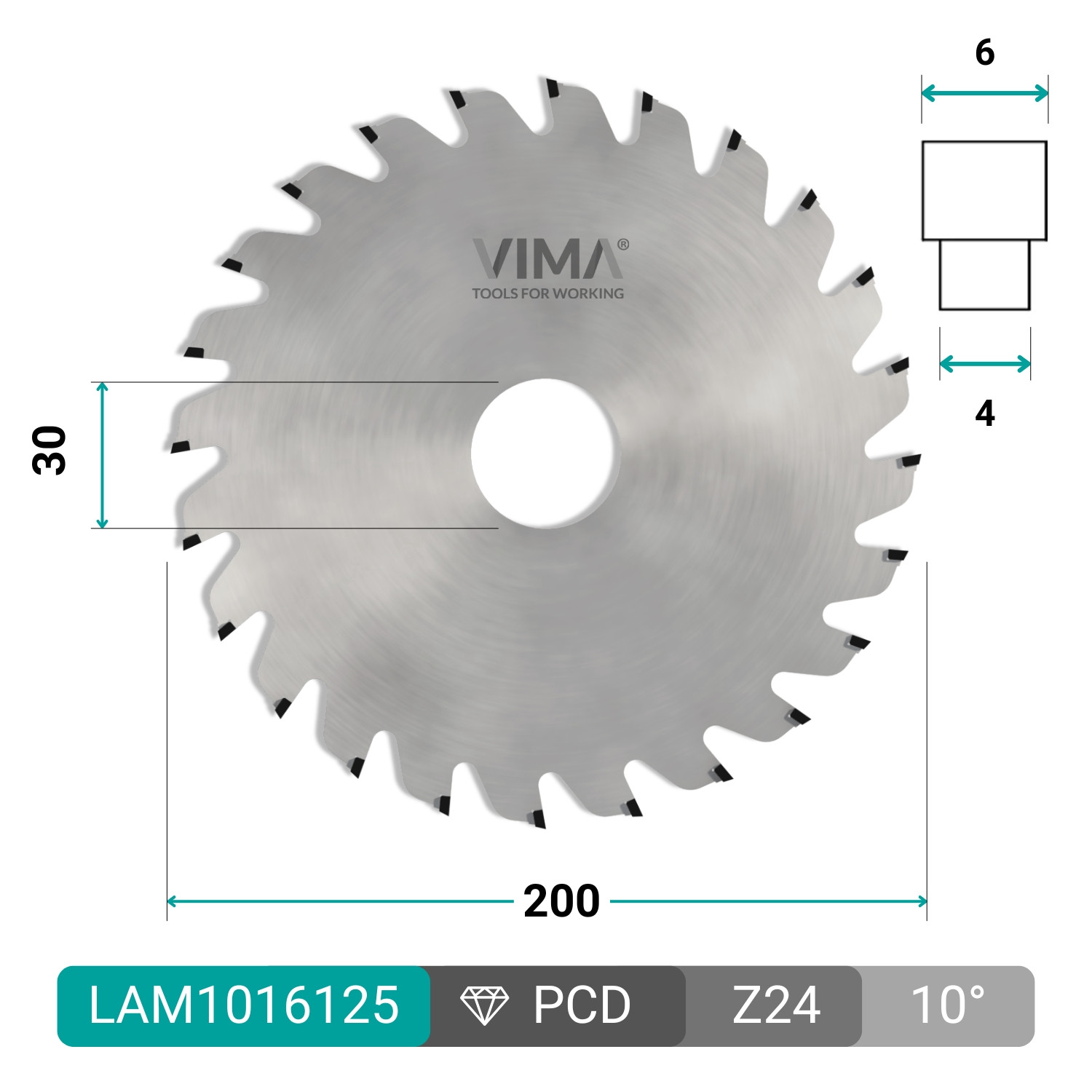

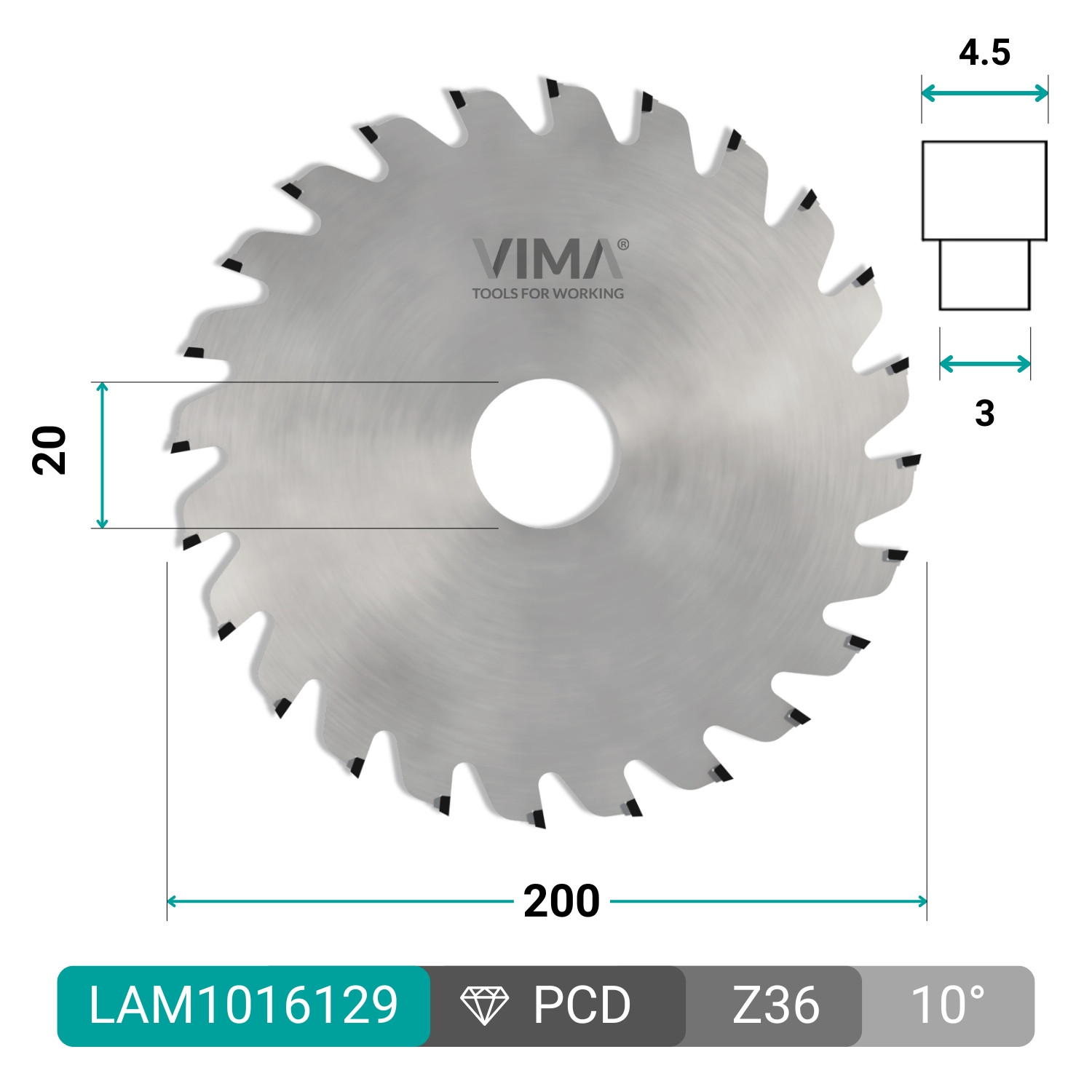

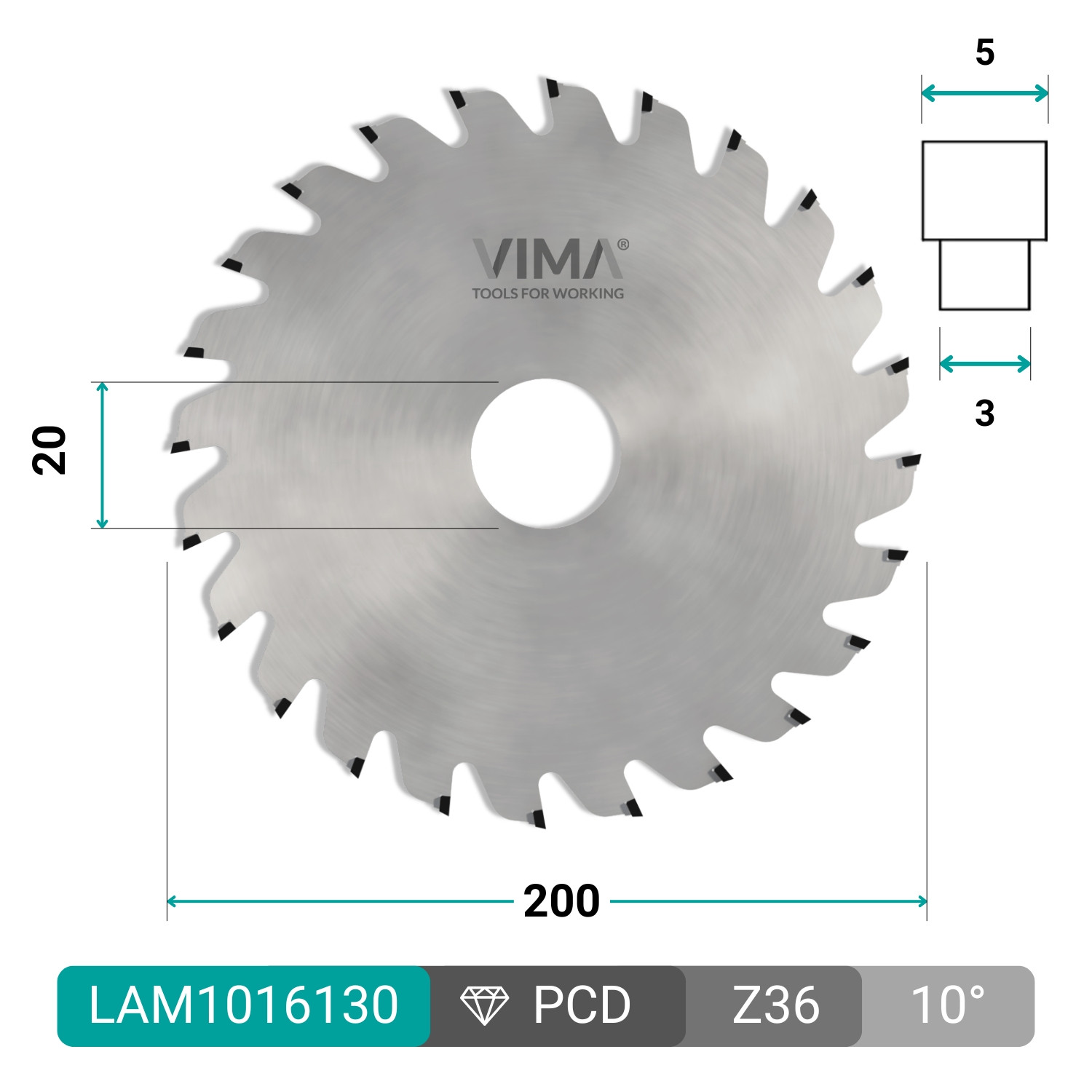

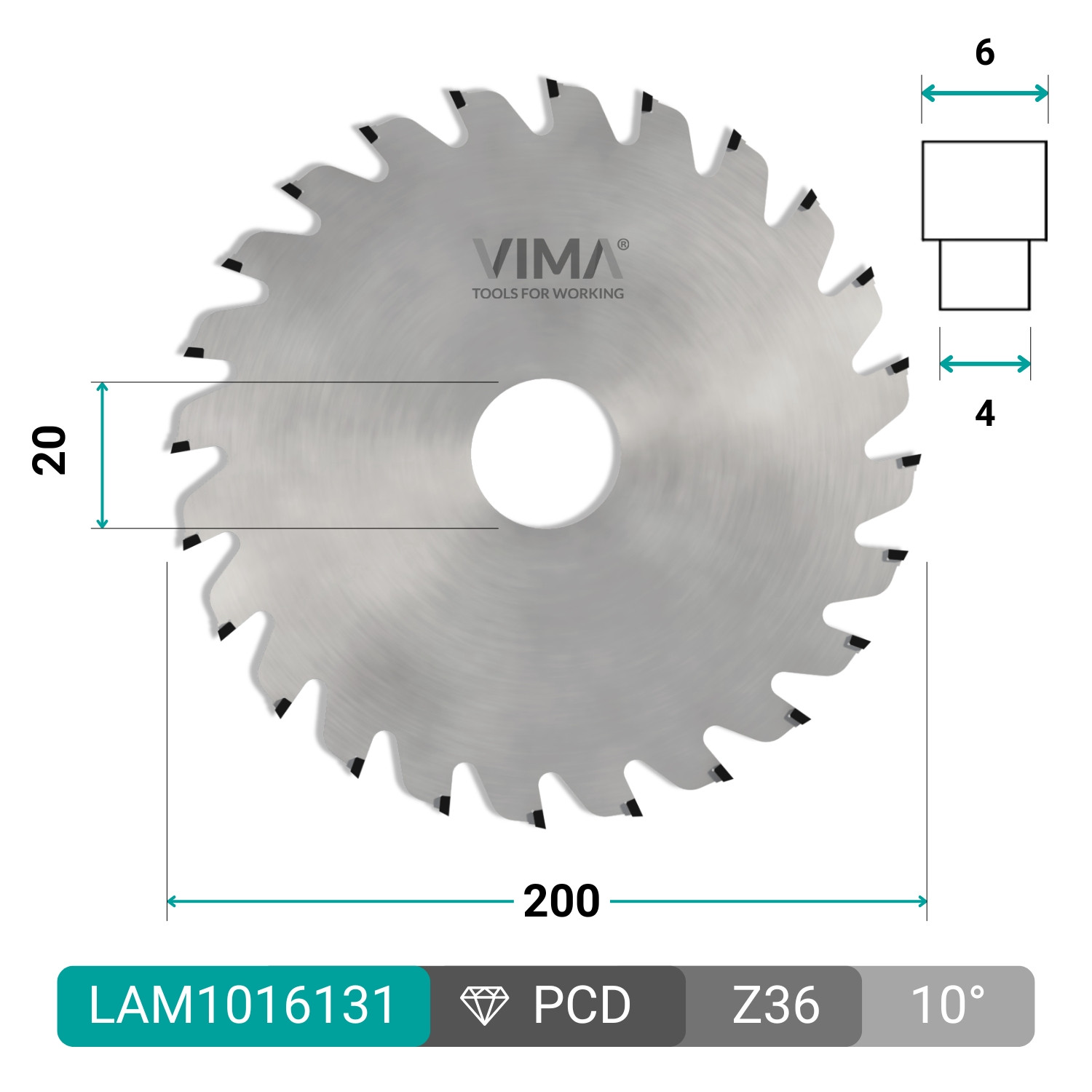

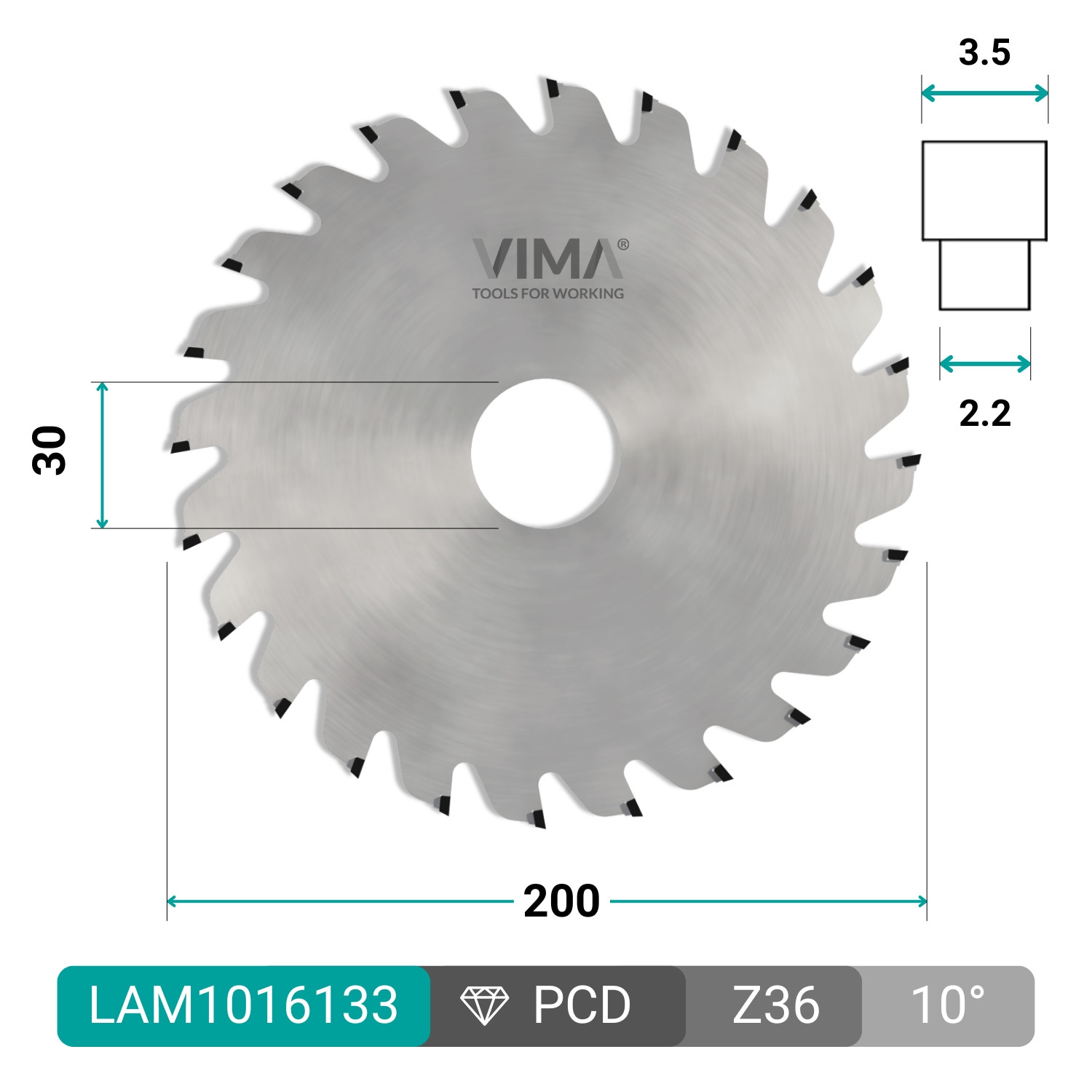

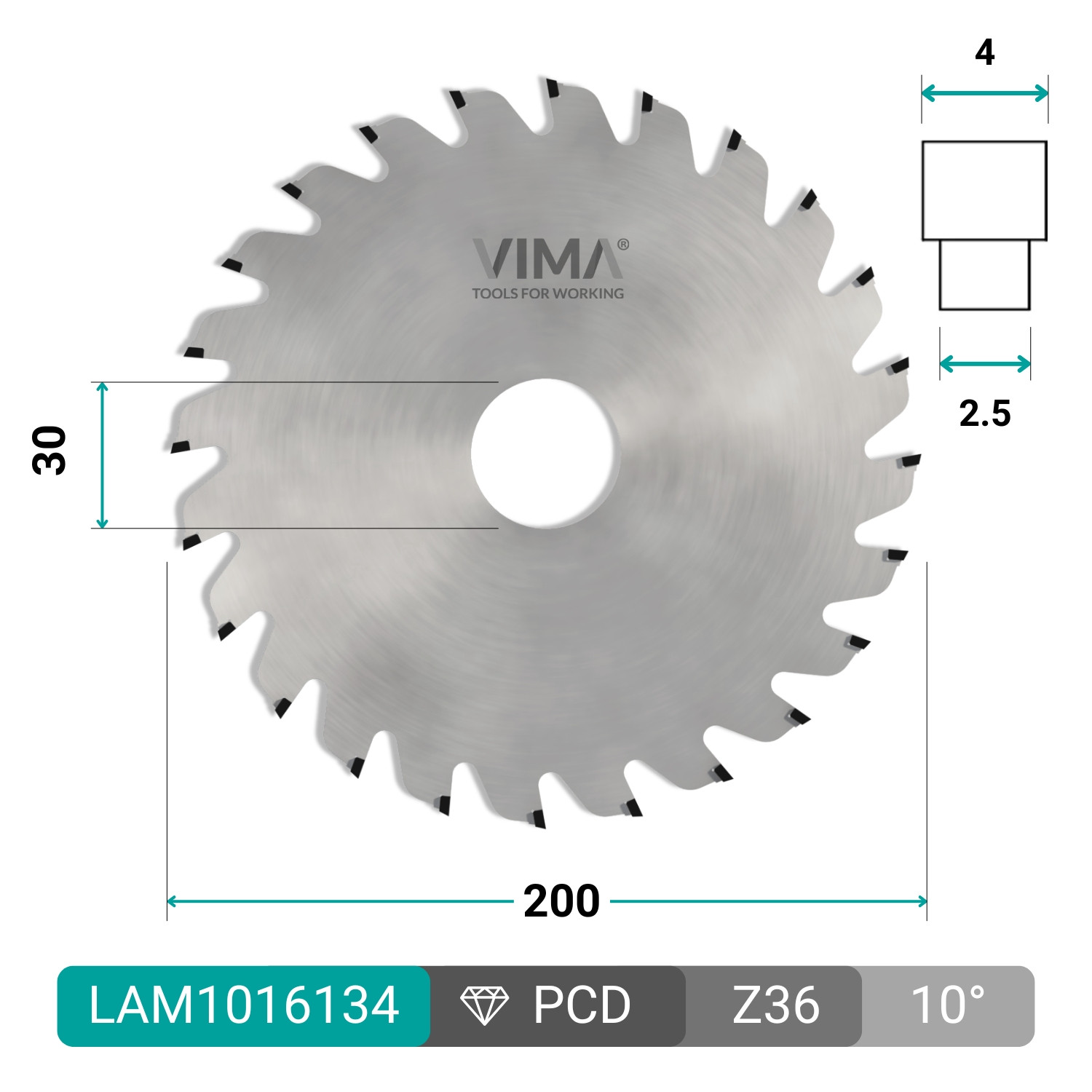

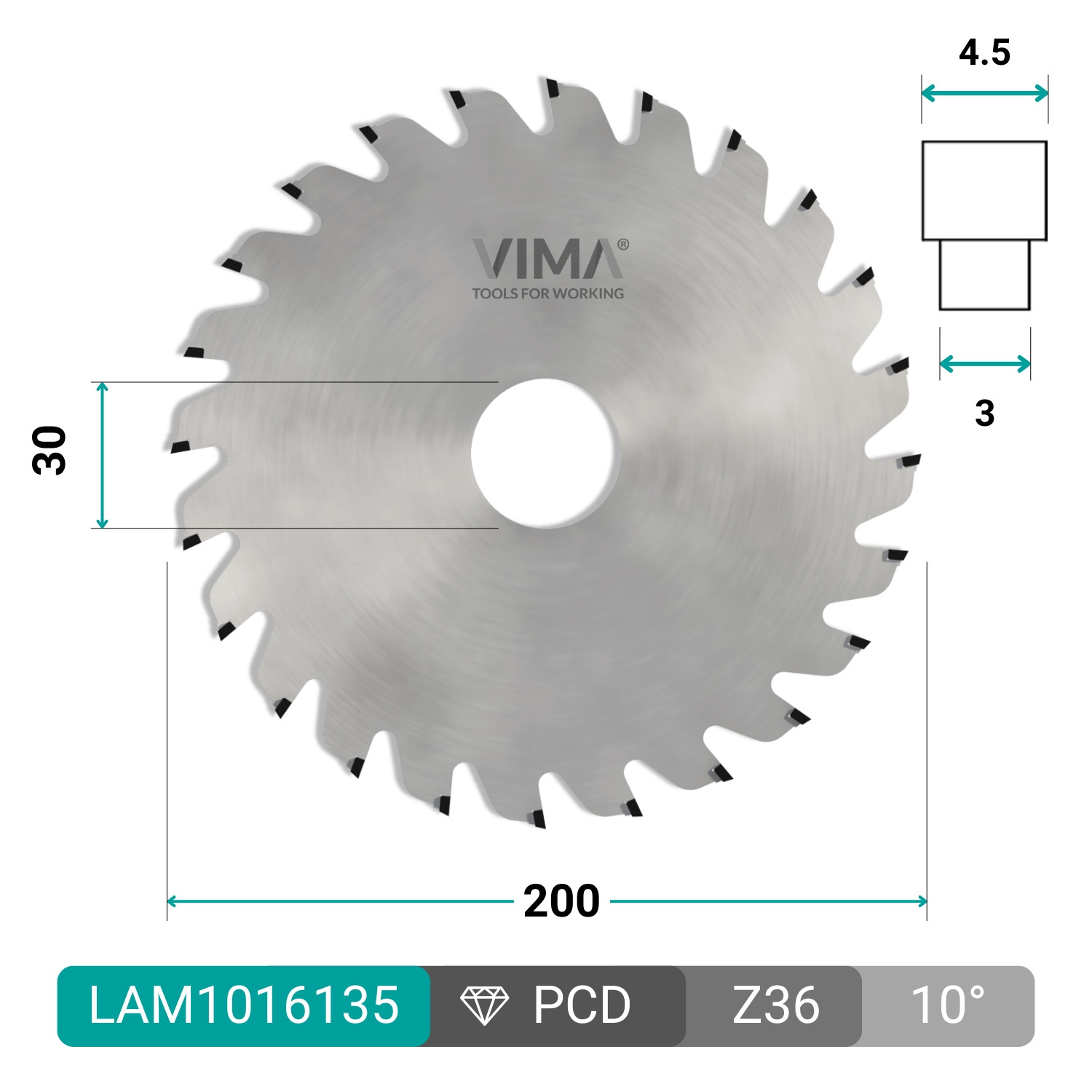

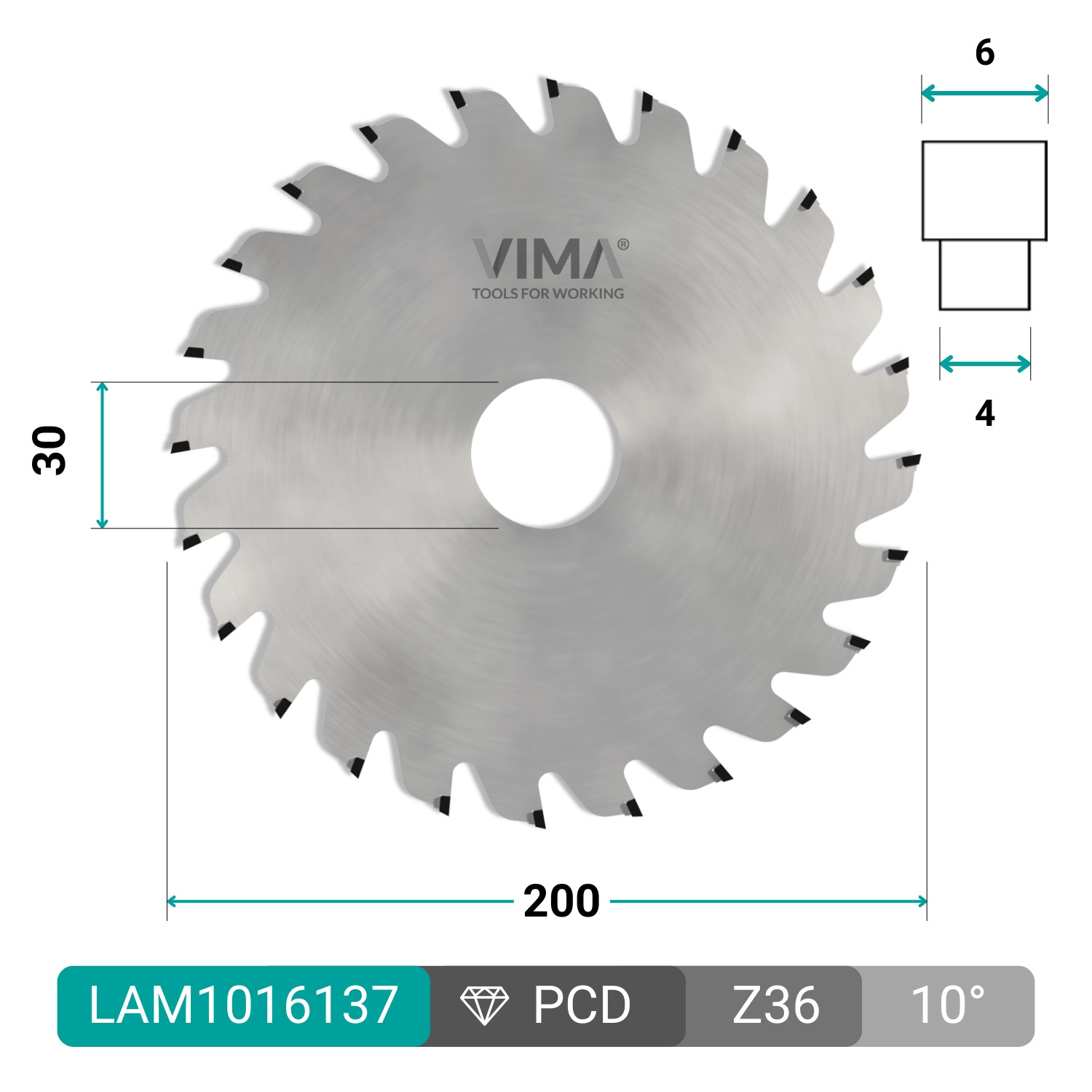

PCD circular blade engineered for accurate flat grooving on CNC machines and panel saws. The H6 PCD tip ensures exceptional durability, clean cutting and reduced vibration on MDF/HDF, chipboard and plywood.

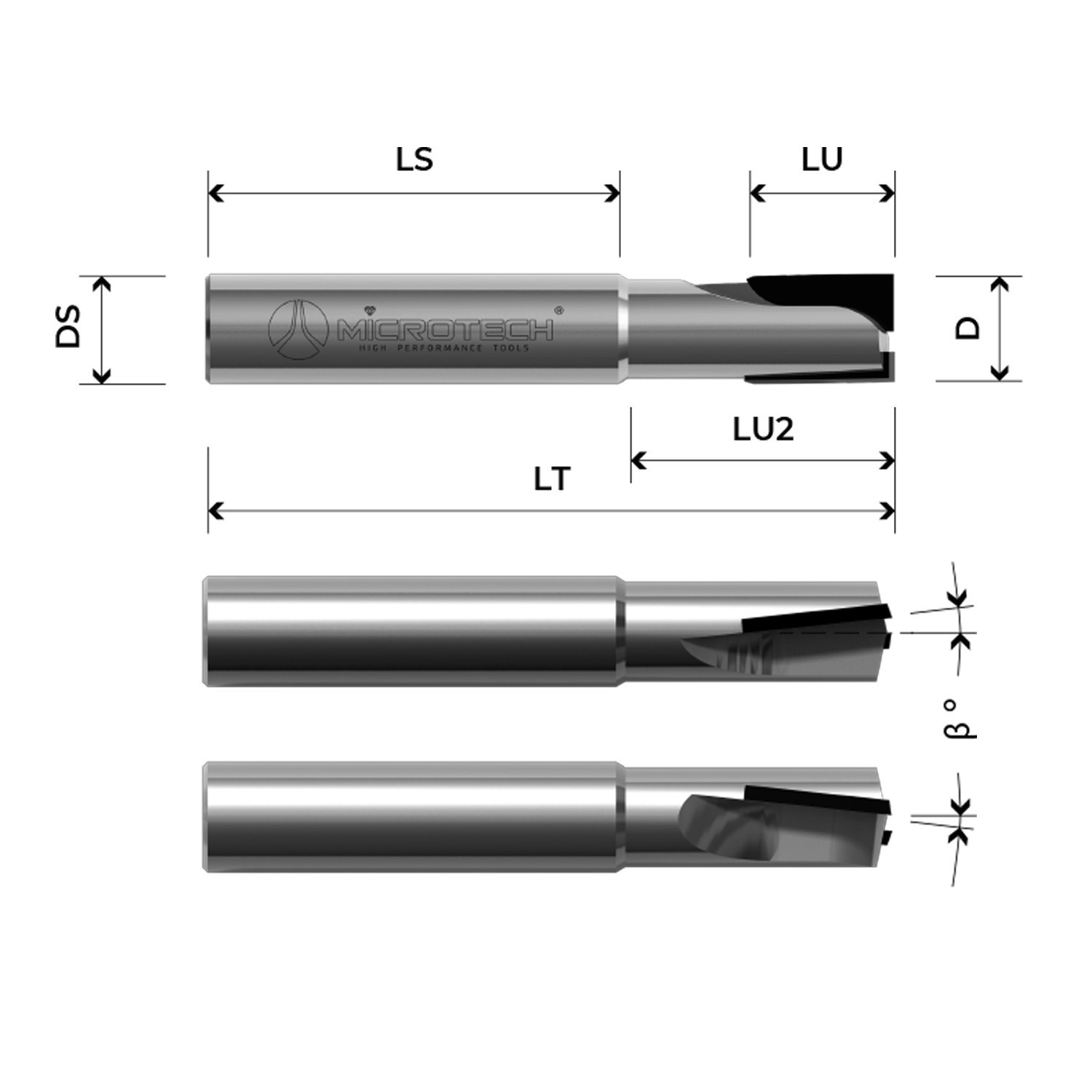

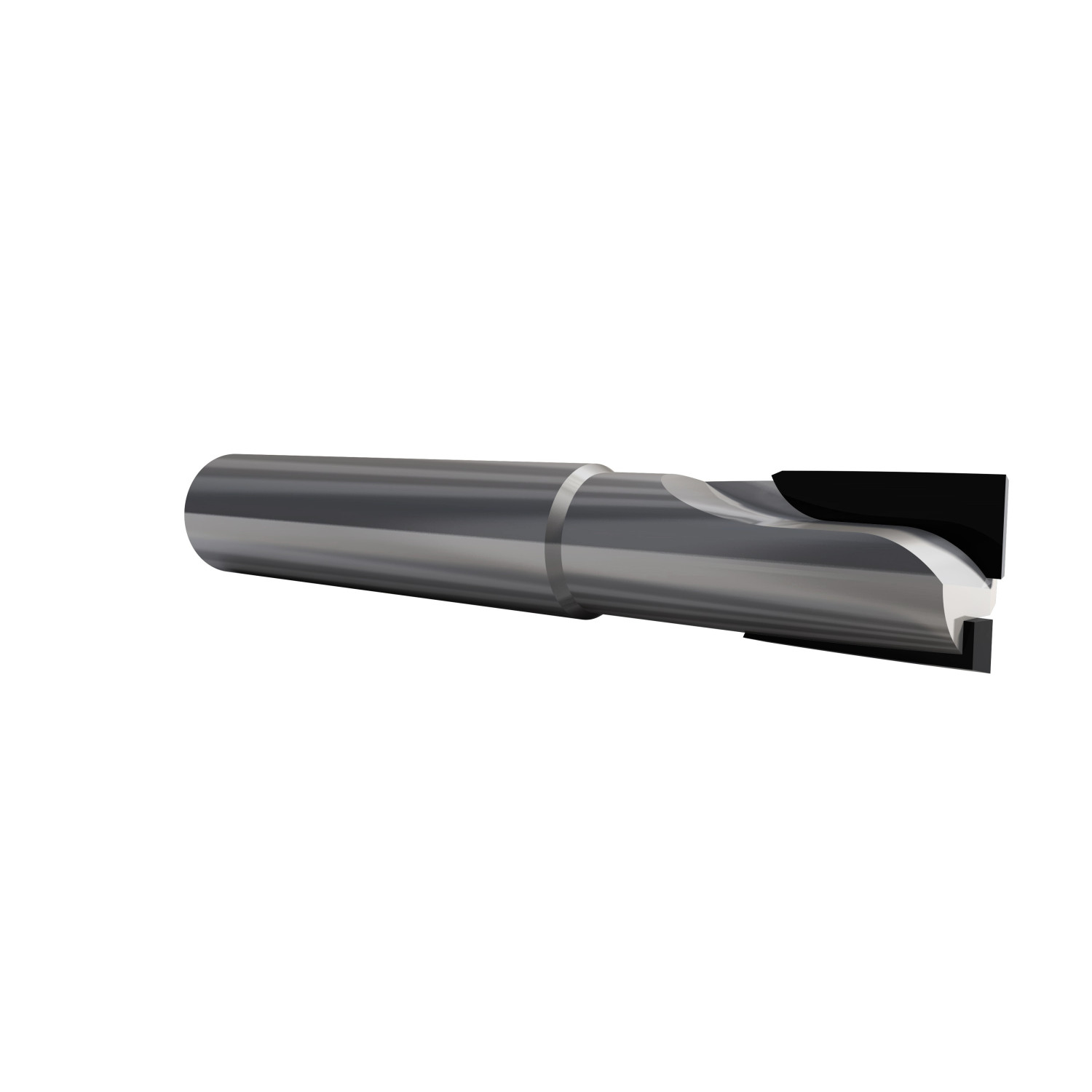

PCD diamond router bit designed for contouring operations on compact and technical materials requiring superior edge quality. The alternating positive and negative cutting geometry ensures balanced cutting action and stable machining.

• PCD cutting edges H 3.5 mm for extended tool life

• Alternating positive/negative Z2 geometry for clean edges

• Solid HW body for rigidity and precision

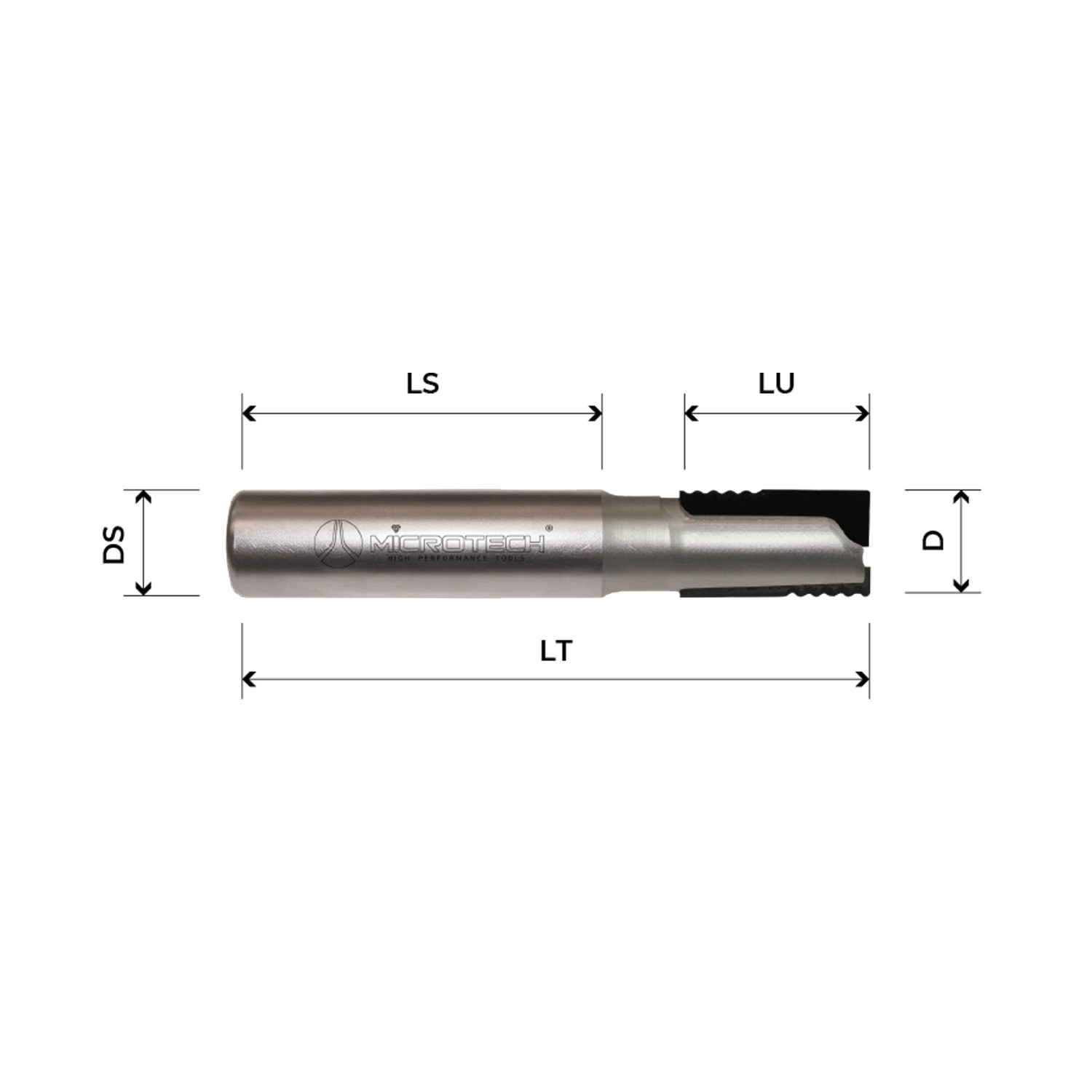

PCD diamond router bit designed for nesting and contouring operations on compact and abrasive materials. The alternating positive and negative cutting edges with chipbreaker provide combined roughing and finishing in a single pass.

• PCD cutting edges H 3.5 mm with alternating Z2 geometry

• Chipbreaker design for roughing and finishing

• Heavy HDM body for maximum stability

PCD diamond router bit designed for grooving operations requiring excellent surface quality on coated panels. The negative Z1 cutting edge and solid HW body ensure cutting stability, controlled material removal and clean surface finishing.

• PCD cutting edge H 3.5 mm for long service life

• Negative Z1 geometry for superior surface finish

• Solid HW body for rigidity and stability

PCD diamond router bit designed for grooving operations requiring excellent surface quality on coated panels. The negative Z2 cutting edges and solid HW body ensure controlled cutting action and clean surface finishing.

• PCD cutting edges H 3.5 mm for long service life

• Negative Z2 geometry for superior surface quality

• Solid HW body for rigidity and stability

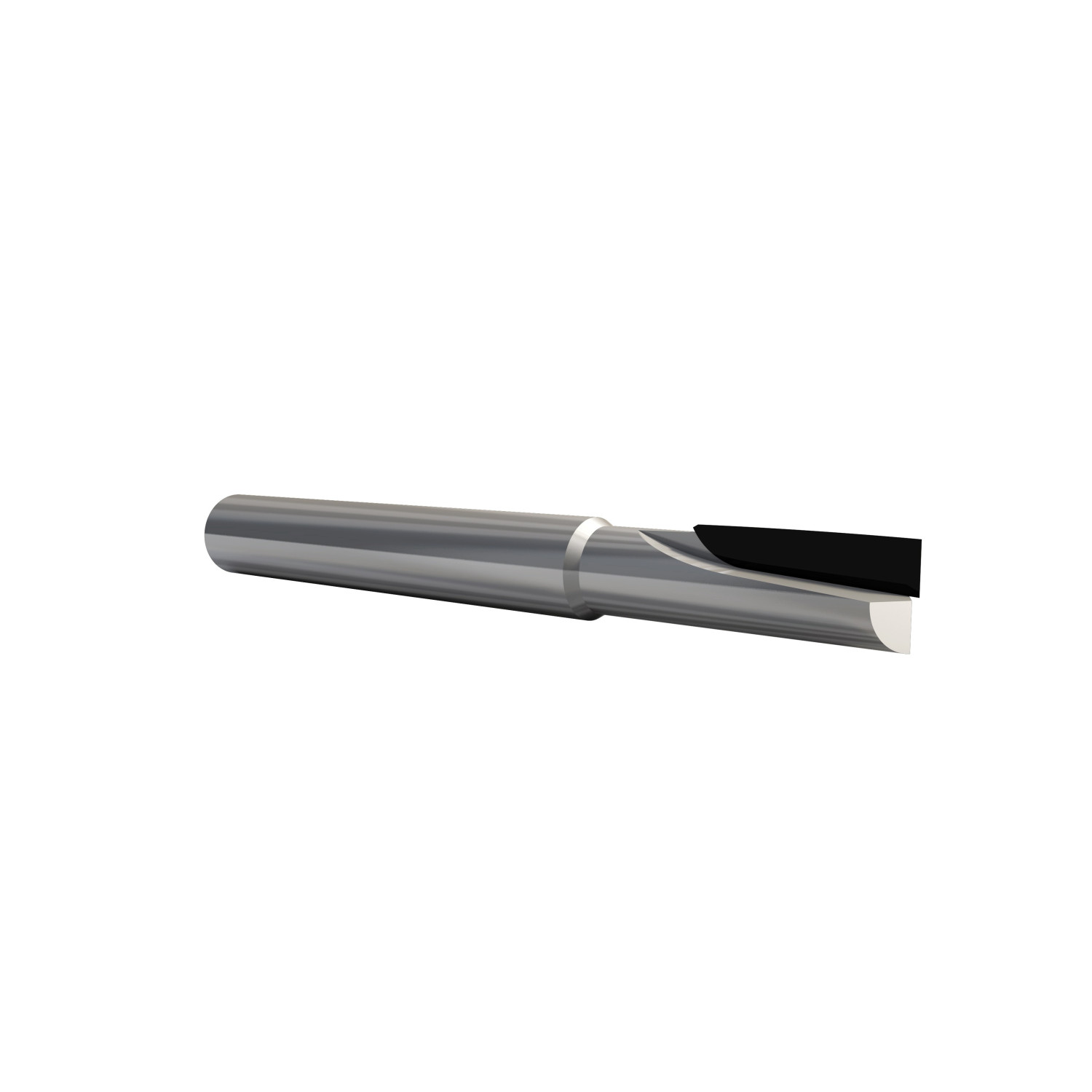

PCD diamond router bit designed for grooving and contouring operations on CNC machines with manual or mechanical feed. The straight Z1 cutting edge and solid HW body ensure cutting stability, clean finishing and extended tool life.

• PCD cutting edge H 3.5 mm for long service life

• Straight Z1 geometry for controlled cutting

• Solid HW body for rigidity and precision

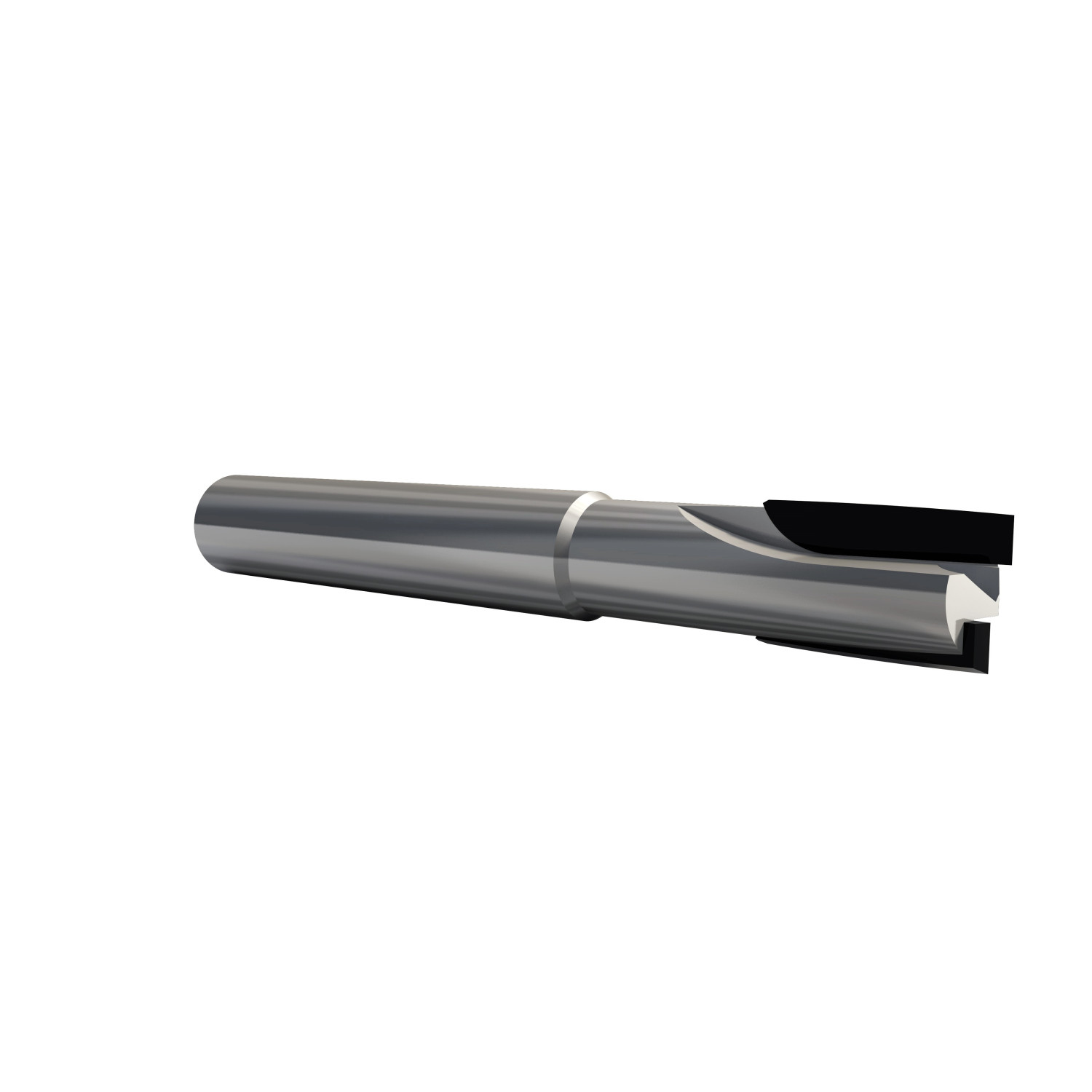

PCD diamond router bit designed for grooving and contouring operations on CNC machines with mechanical feed. The dual straight Z2 cutting edges and solid HW body ensure balanced cutting action and consistent surface quality.

• PCD cutting edges H 3.5 mm for extended durability

• Z2 configuration for higher stability and productivity

• Solid HW body for rigidity and precision

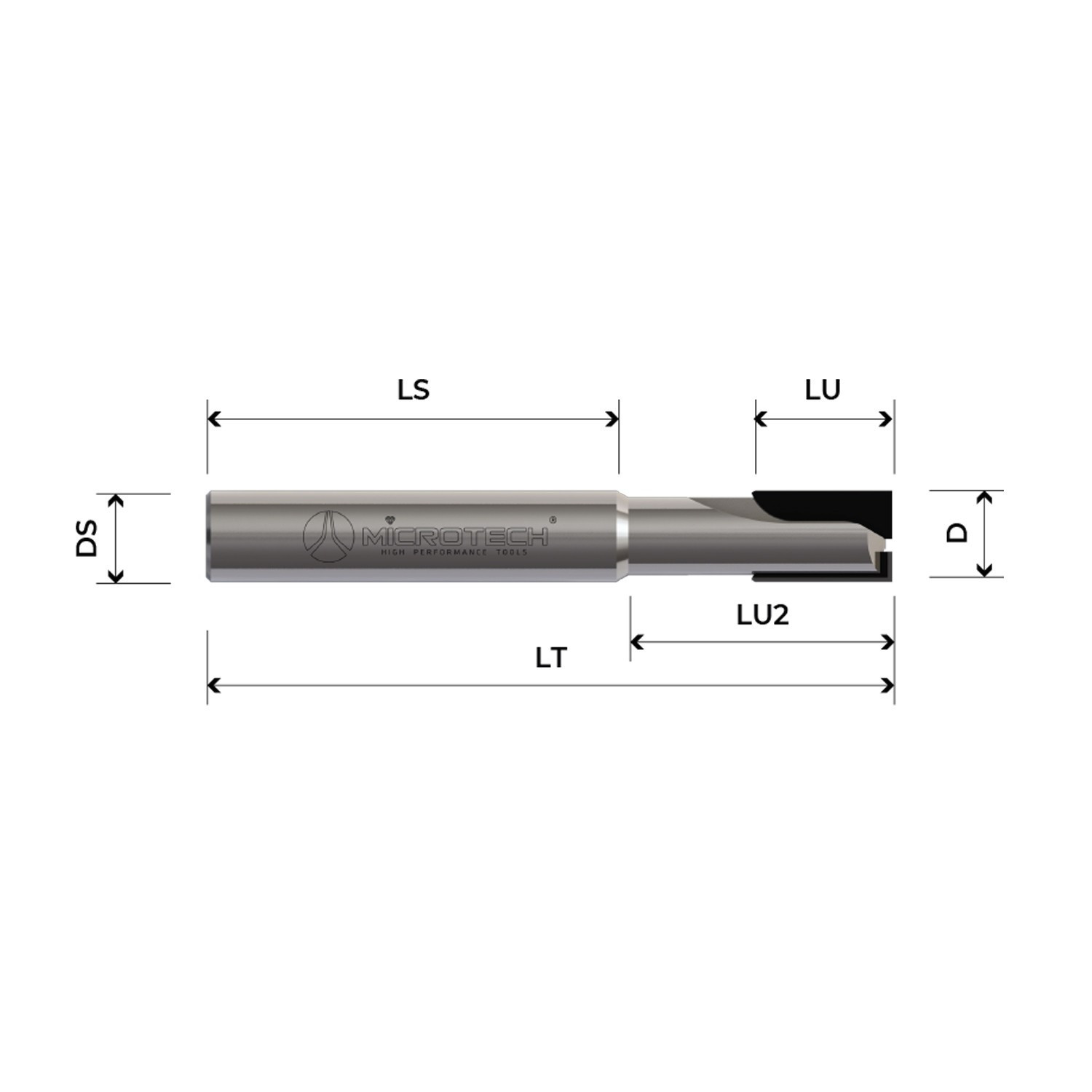

PCD diamond router bit designed for surfacing, drilling and rebate operations on coated panels and technical materials. The negative cutting geometry and center-cutting design ensure excellent side finish and controlled material removal.

• PCD cutting edge H 4.5 mm for long tool life

• Negative geometry for superior side finish

• Center-cutting design for drilling operations

.jpg)